Patents

Literature

251results about How to "Excellent bending workability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength hot-rolled steel sheet and method for producing same

ActiveCN104053806AExcellent bending workabilityIncrease useHot-dipping/immersion processesFurnace typesSheet steelCarbide

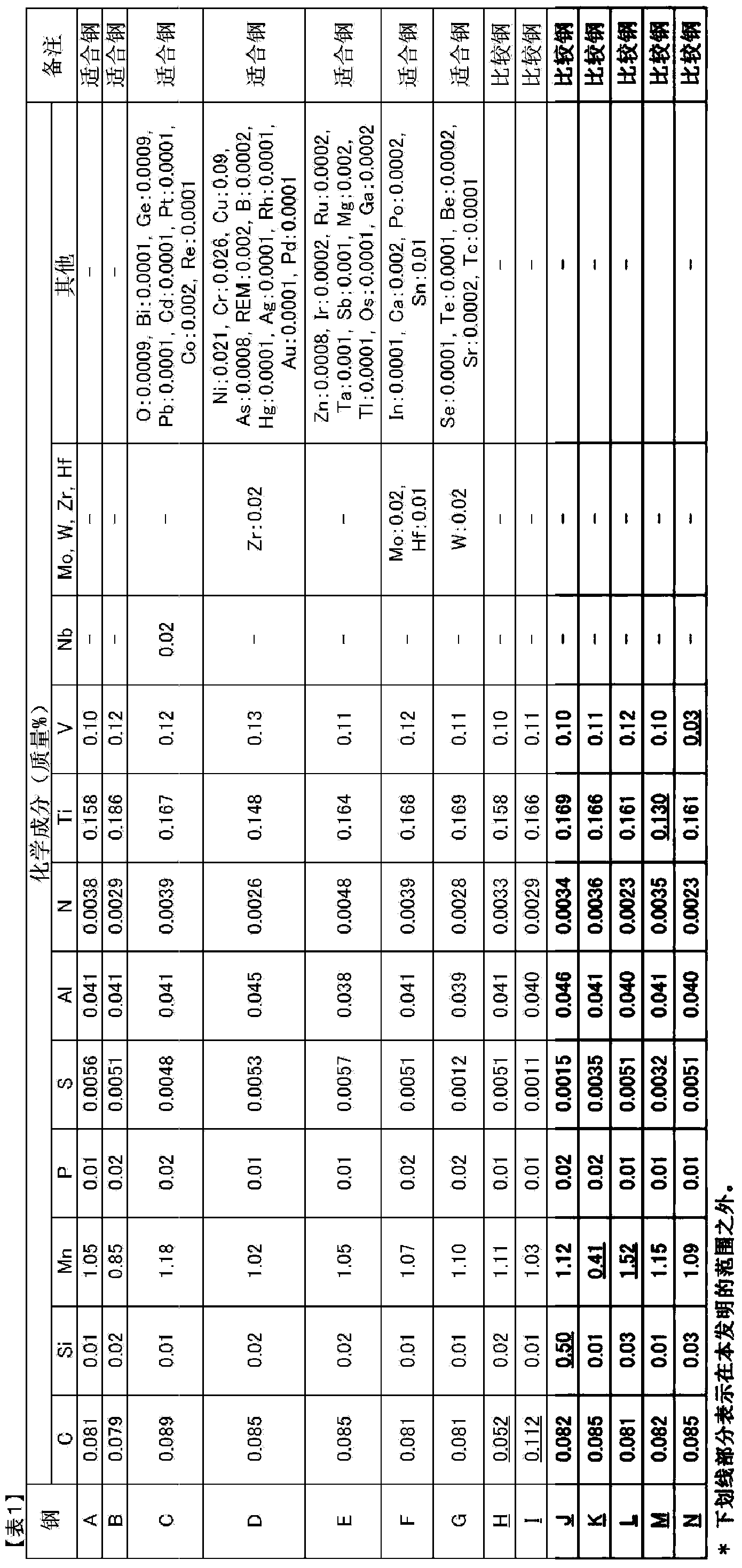

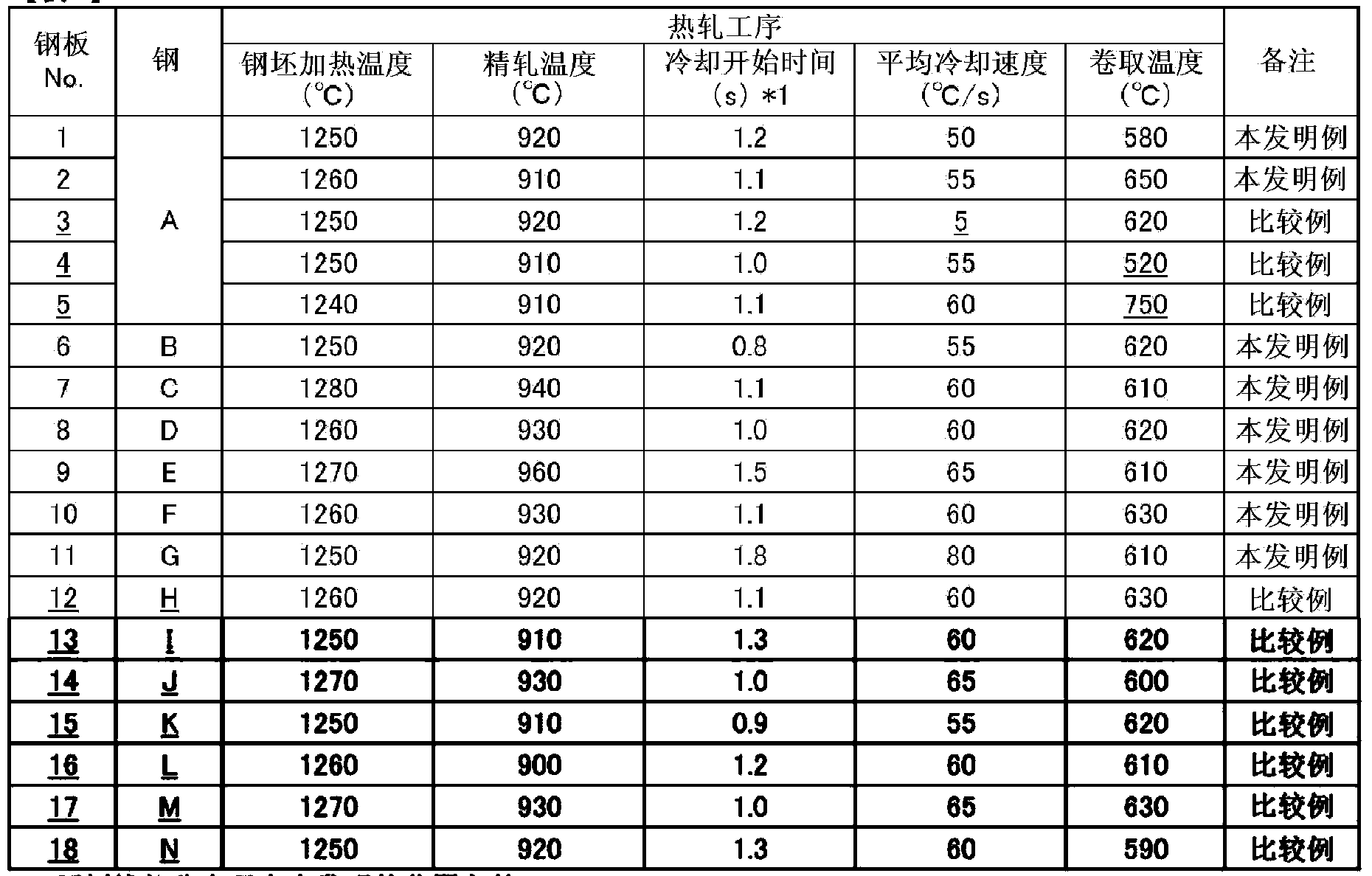

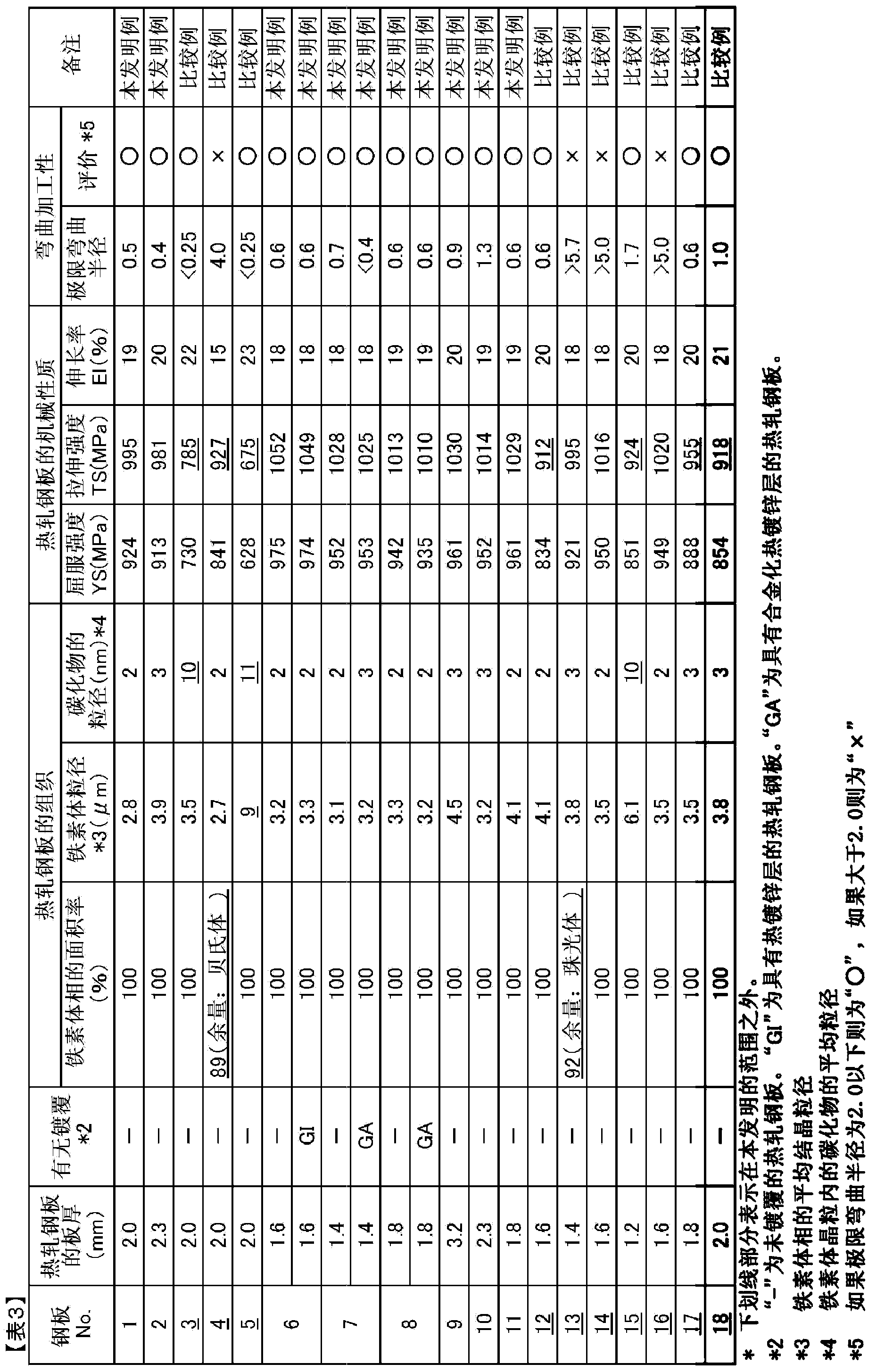

The present invention addresses the problem of providing: a high-strength hot-rolled steel sheet which has excellent strength and excellent processability (in particular, bending processability) at the same time; and a method for producing the high-strength hot-rolled steel sheet. In order to solve the above-mentioned problem, the present invention is characterized by: having a specific composition; having an area ratio of a ferrite phase of 95% or more; having an average crystal grain diameter of the ferrite phase of 8 mum or less; having a structure wherein the average particle diameter of carbides within the crystal grains of the ferrite phase is less than 10 nm; and having a tensile strength of 980 MPa or more.

Owner:JFE STEEL CORP

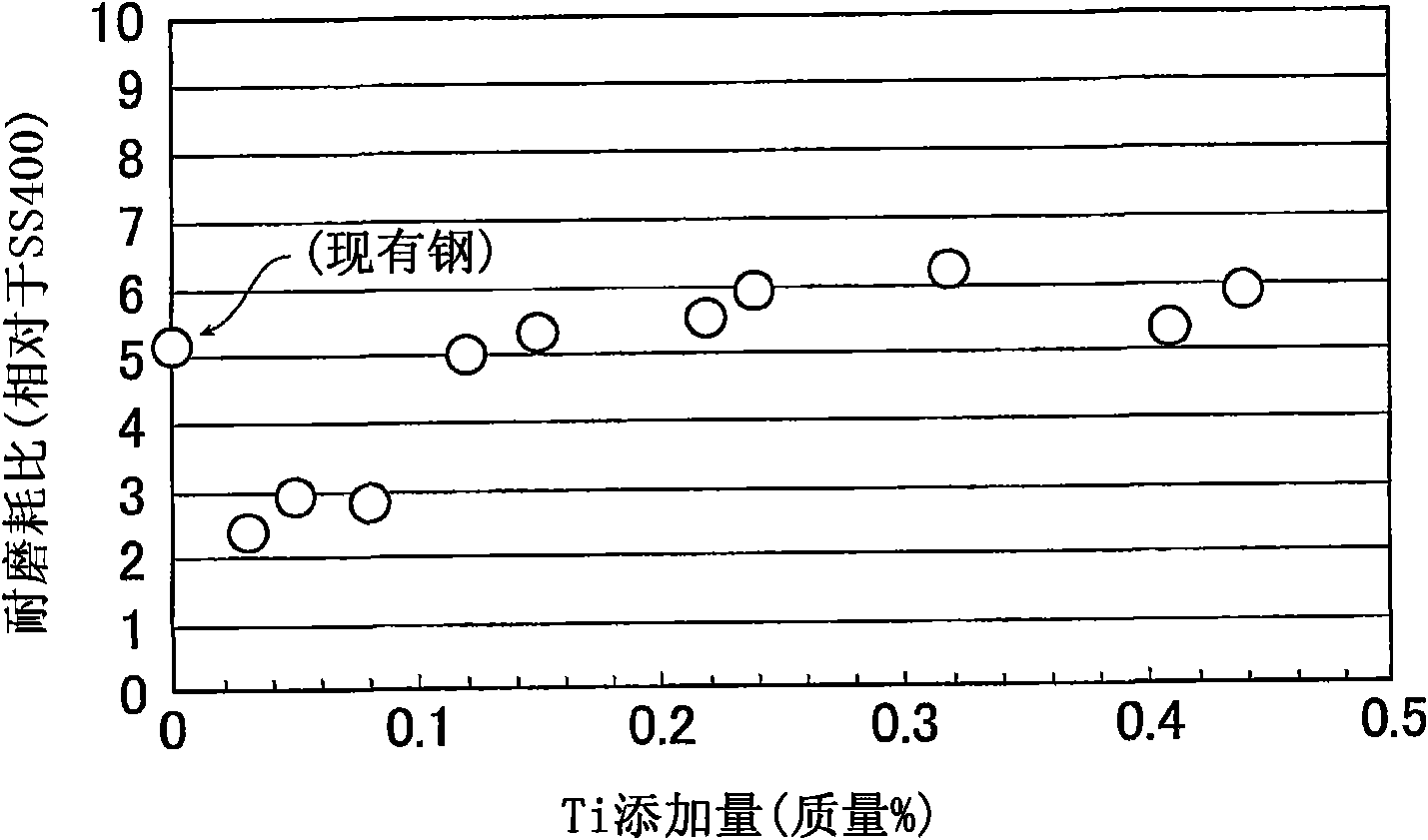

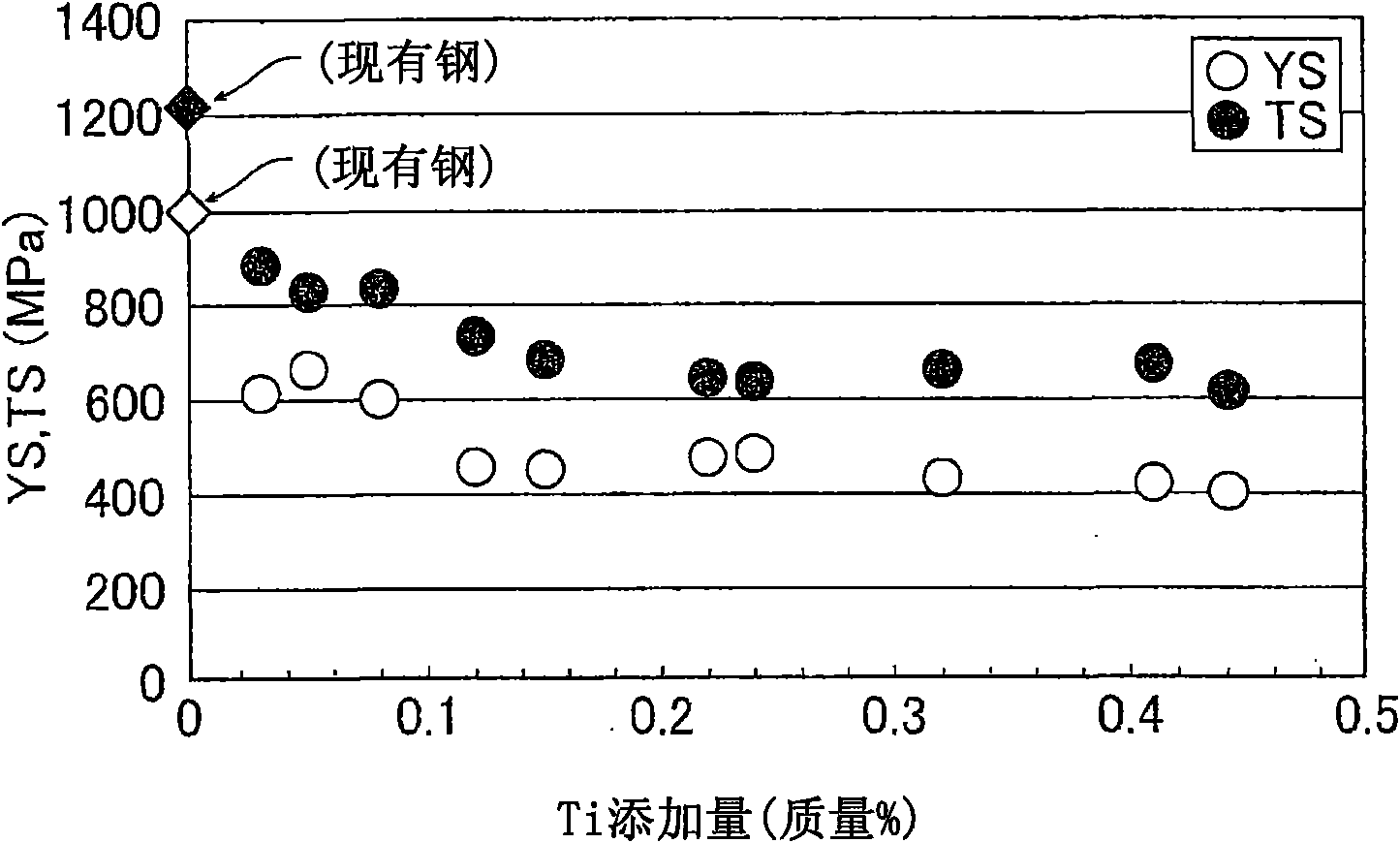

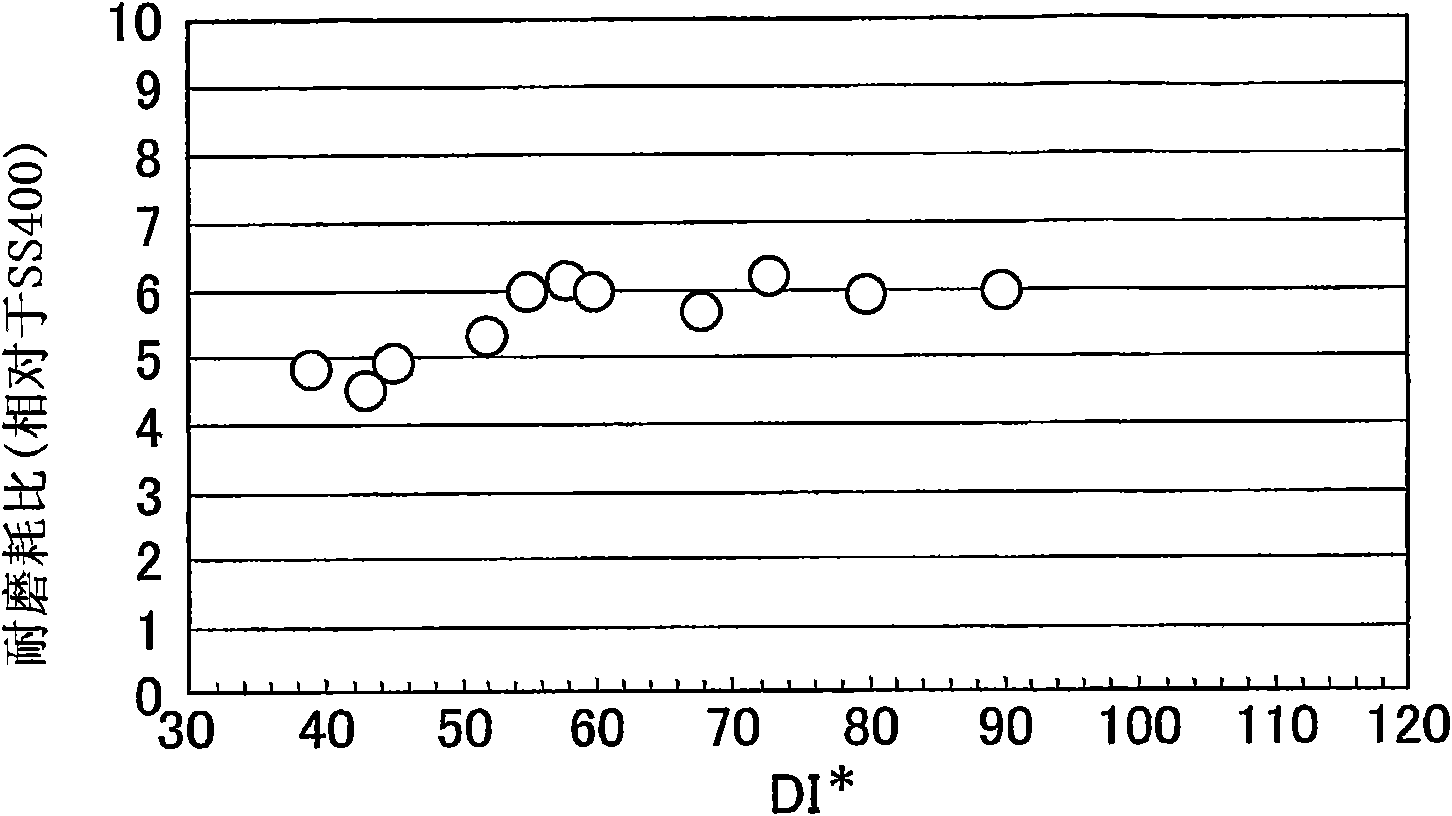

Abrasion-resistant steel sheet having excellent processability, and method for production thereof

An abrasion resistant steel excellent in bending formability and suitable for members, e.g., power shovels, which come into contact with earth and sand, and a production method thereof are provided. Specifically, the steel contains, on a percent by mass basis, 0.05% to 0.35% of C, 0.05% to 1.0% of Si, 0.1% to 2.0% of Mn, 0.1% to 1.2% of Ti, 0.1% or less of Al, at least one element of 0.1% to 1.0%of Cu, 0.1% to 2.0% of Ni, 0.1% to 1.0% of Cr, 0.05% to 1.0% of Mo, 0.05% to 1.0% of W, and 0.0003% to 0.0030% of B, if necessary at least one element of 0.005% to 1.0% of Nb and 0.005% to 1.0% of V,and the remainder including Fe and incidental impurities, where DI* represented by the following formula is less than 60. DI * = 33.85 0.1 C * 0.5 0.7 Si + 1 3.33 Mn + 1 0.35 Cu + 1 0.36 Ni + 1 2.16 Cr + 1 3 Mo * + 1 1.5 W * + 1 where C* = C - 1 / 4 (Ti - 48 / 14N), Mo* =; Mo (1 - 0.5 (Ti - 48 / 14N)), and W* = W (1 - 0.5 (Ti - 48 / 14N)).

Owner:JFE STEEL CORP

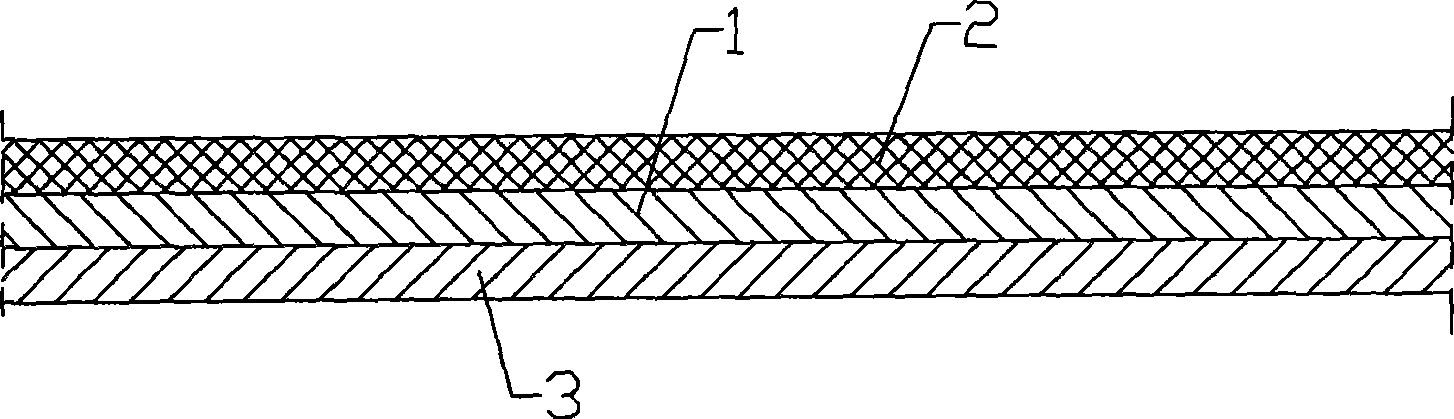

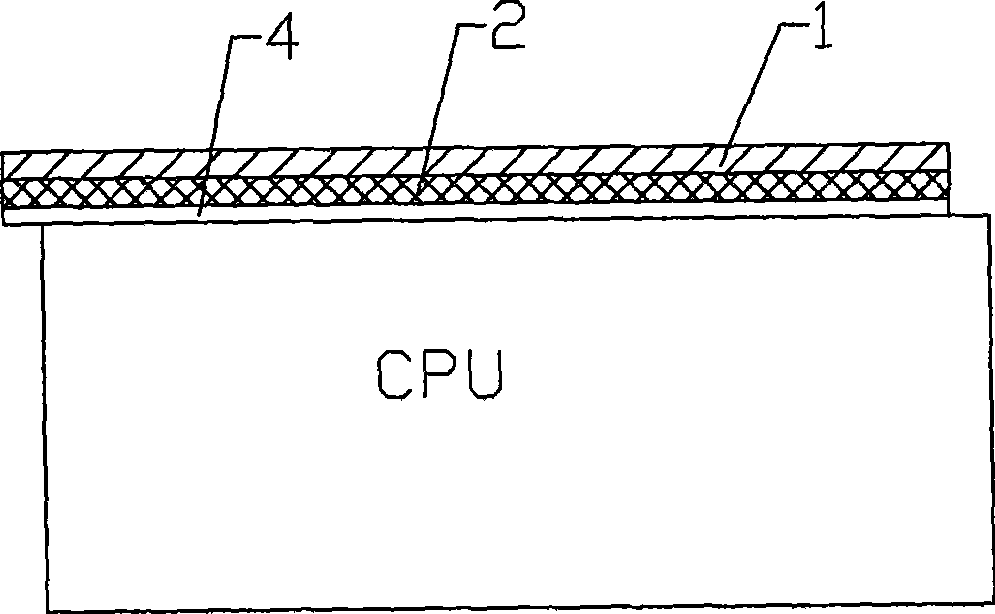

Composite graphite heat conducting radiation fins

InactiveCN101458049AHigh strengthEasy to processSynthetic resin layered productsLaminated elementsHeat sinkRadiation

The invention discloses a combined graphite heat conducting radiating fin which comprises an intermediate layer formed by a pure-graphite heat conducting radiating fin. One surface of the intermediate layer is provided with a gum layer which increases the strength of a soft graphite sheet and prevents the graphite sheet from generating bug dust and influencing the appearance and the use, and the gum layer also betters bending capability; and a three-dimensional assembly can be processed, thereby further facilitating the processing of a graphite heat conducting radiating material with any size, any shape and any structure and enlarging use range of the graphite sheet. By adopting the anisotropic graphite heat conducting radiating fin, the efficiency in heat conduction and radiation is high, small area is occupied, the weight is light, the heat is uniformly conducted and radiated, heat point areas are eliminated, and the performance of an electronic product is improved when a heat source is isolated from components.

Owner:王晓山

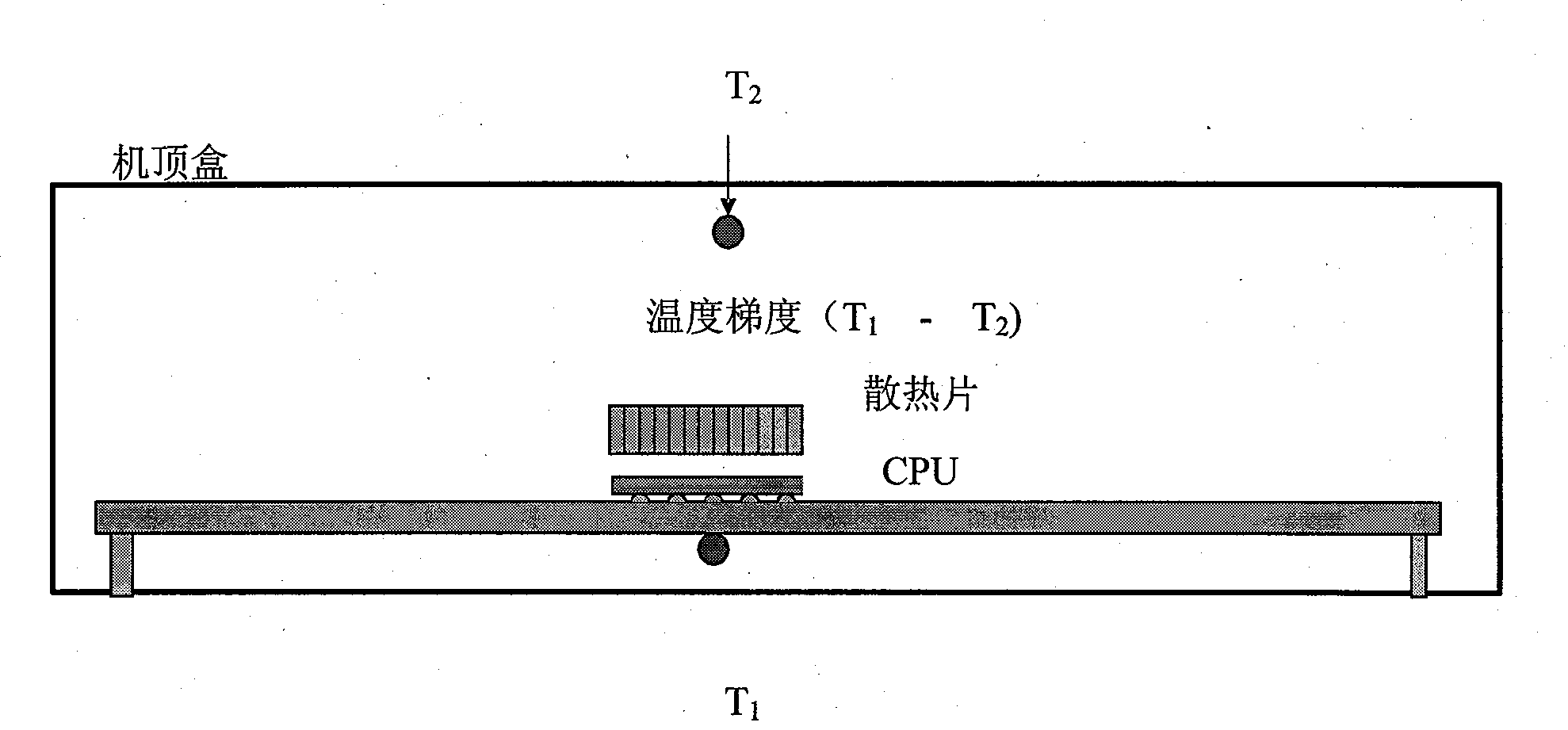

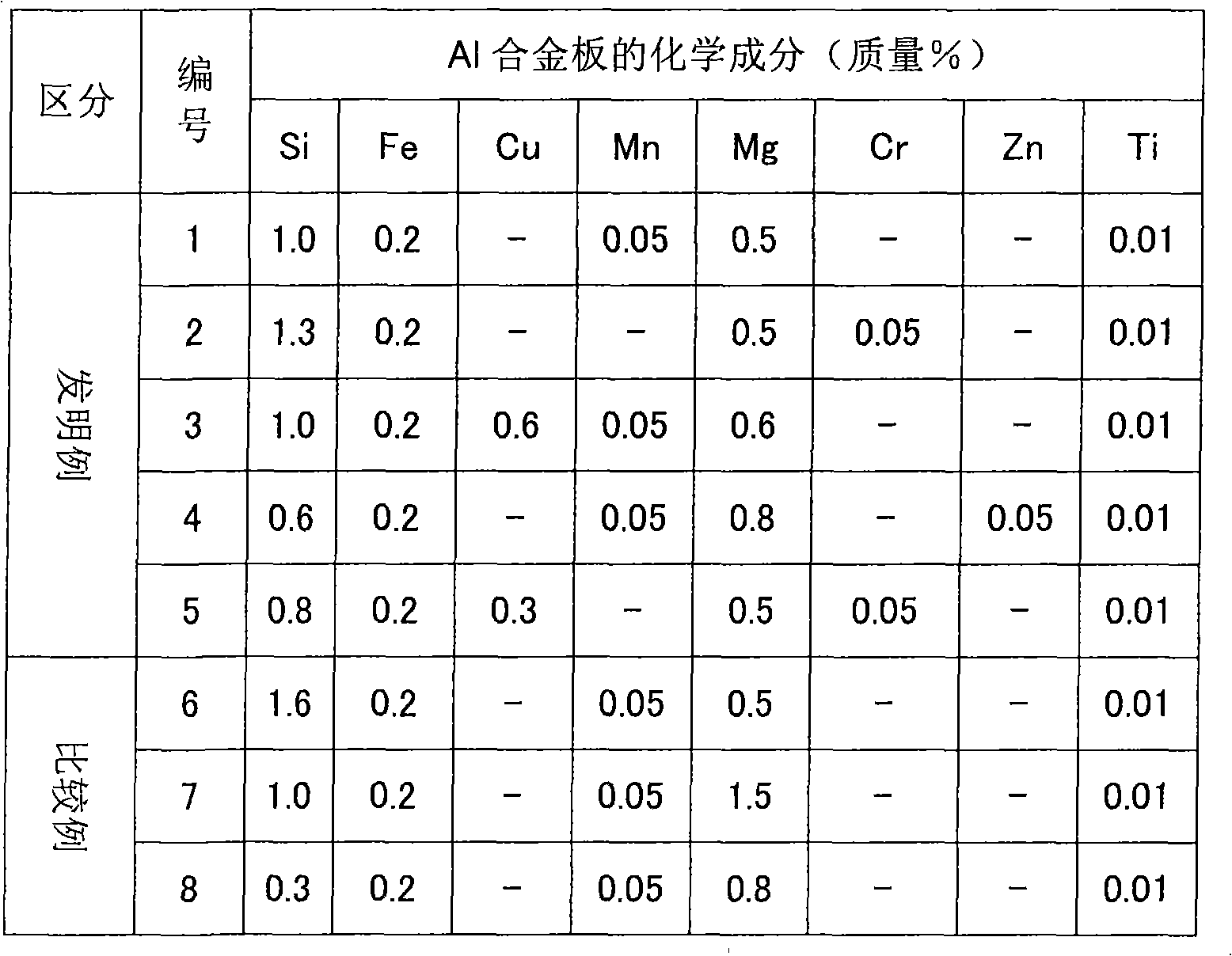

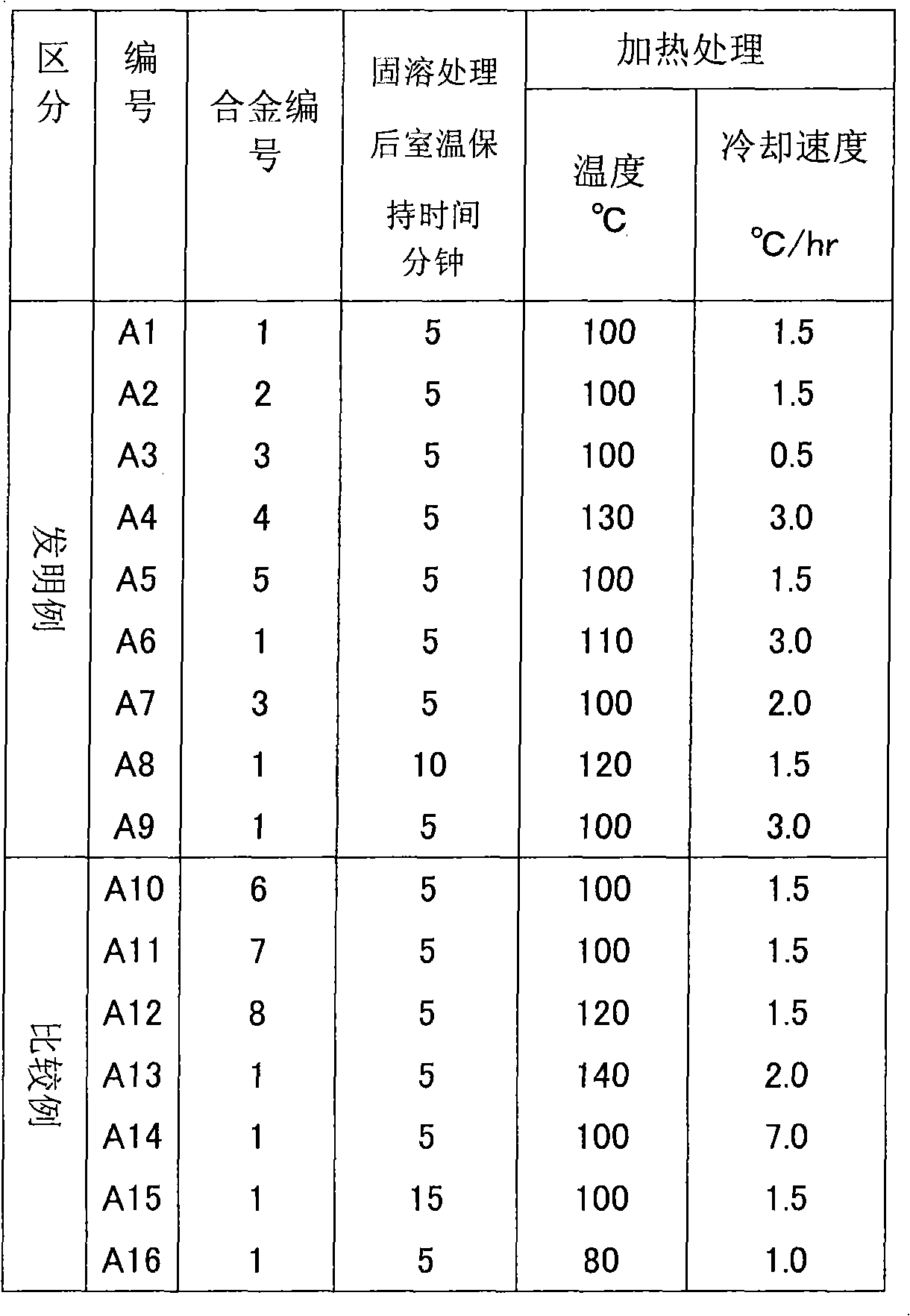

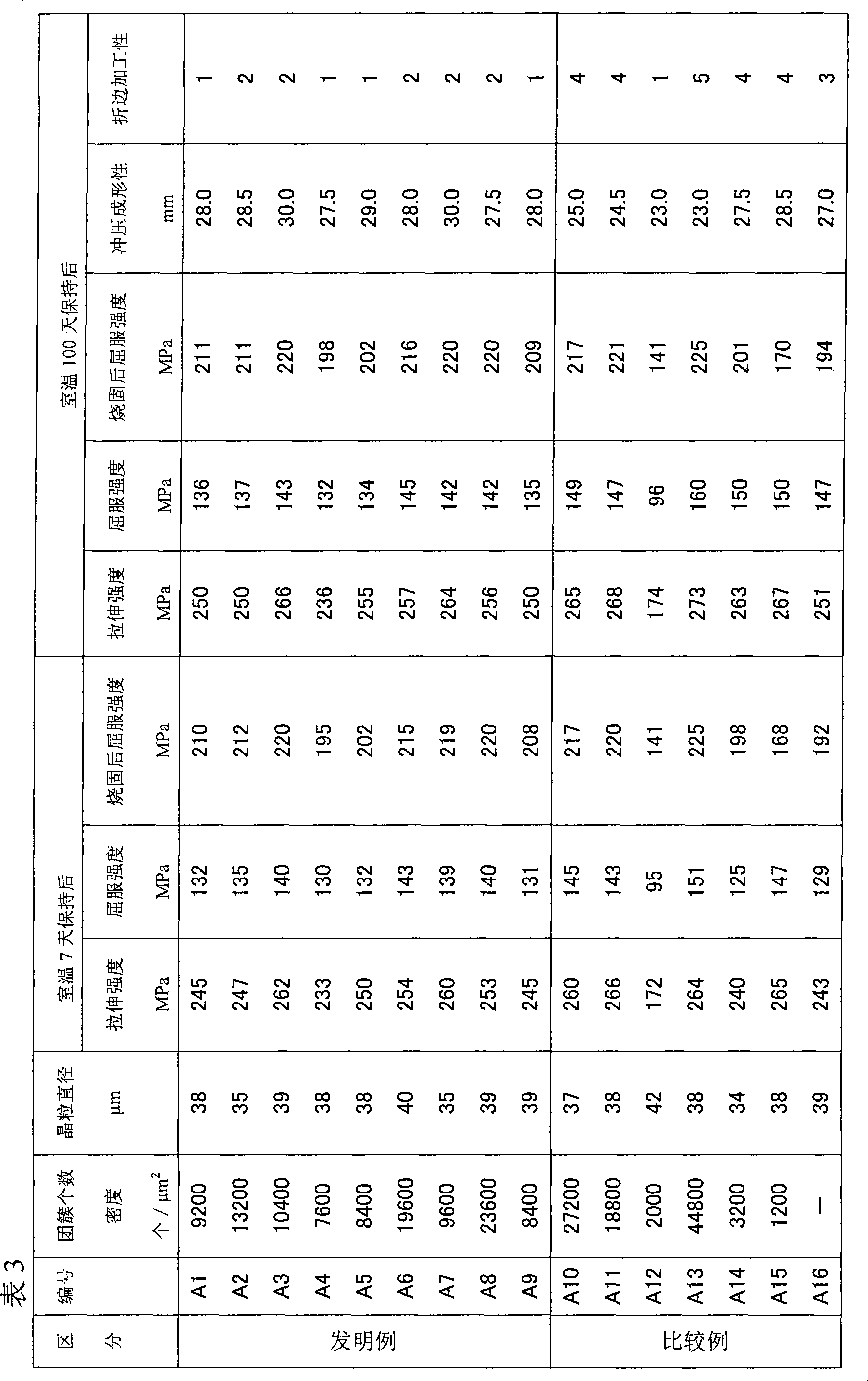

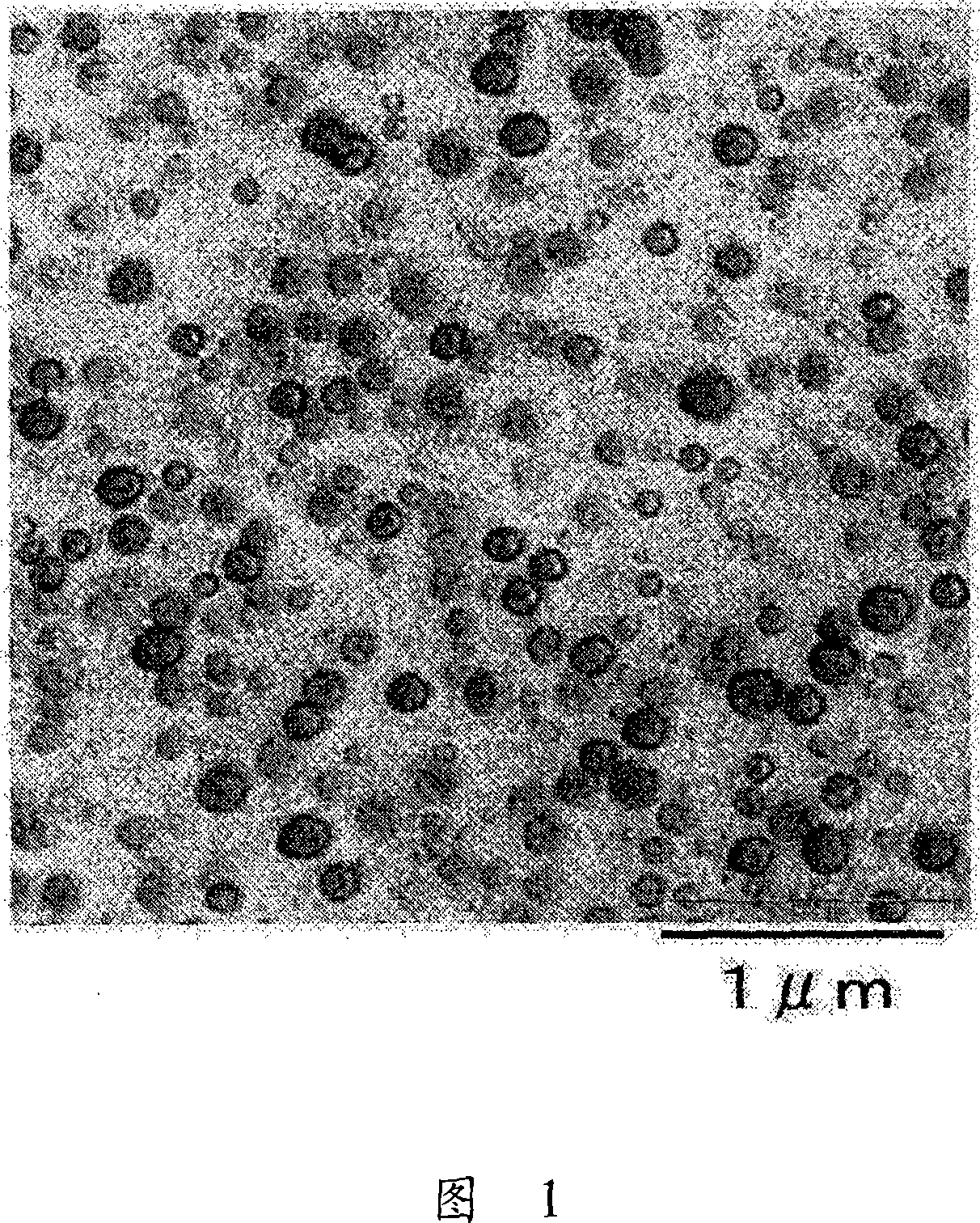

Aluminum alloy sheet superior in paint baking hardenability and invulnerable to room temperature aging, and method for production thereof

An aluminum alloy sheet of specific Al-Mg-Si composition, which, owing to preliminary aging treatment under adequate conditions, has a specific metallographic structure in which there are a large number of clusters of specific size (each being an aggregate of atoms) expressed in terms of number density, which, when observed under a transmission electron microscope of 1,000,000 magnifications, appear as dark contrast in the bright field image. It is superior in paint baking hardenability and is invulnerable to room temperature aging during storage for a comparatively long period of 1 to 4 months.

Owner:KOBE STEEL LTD

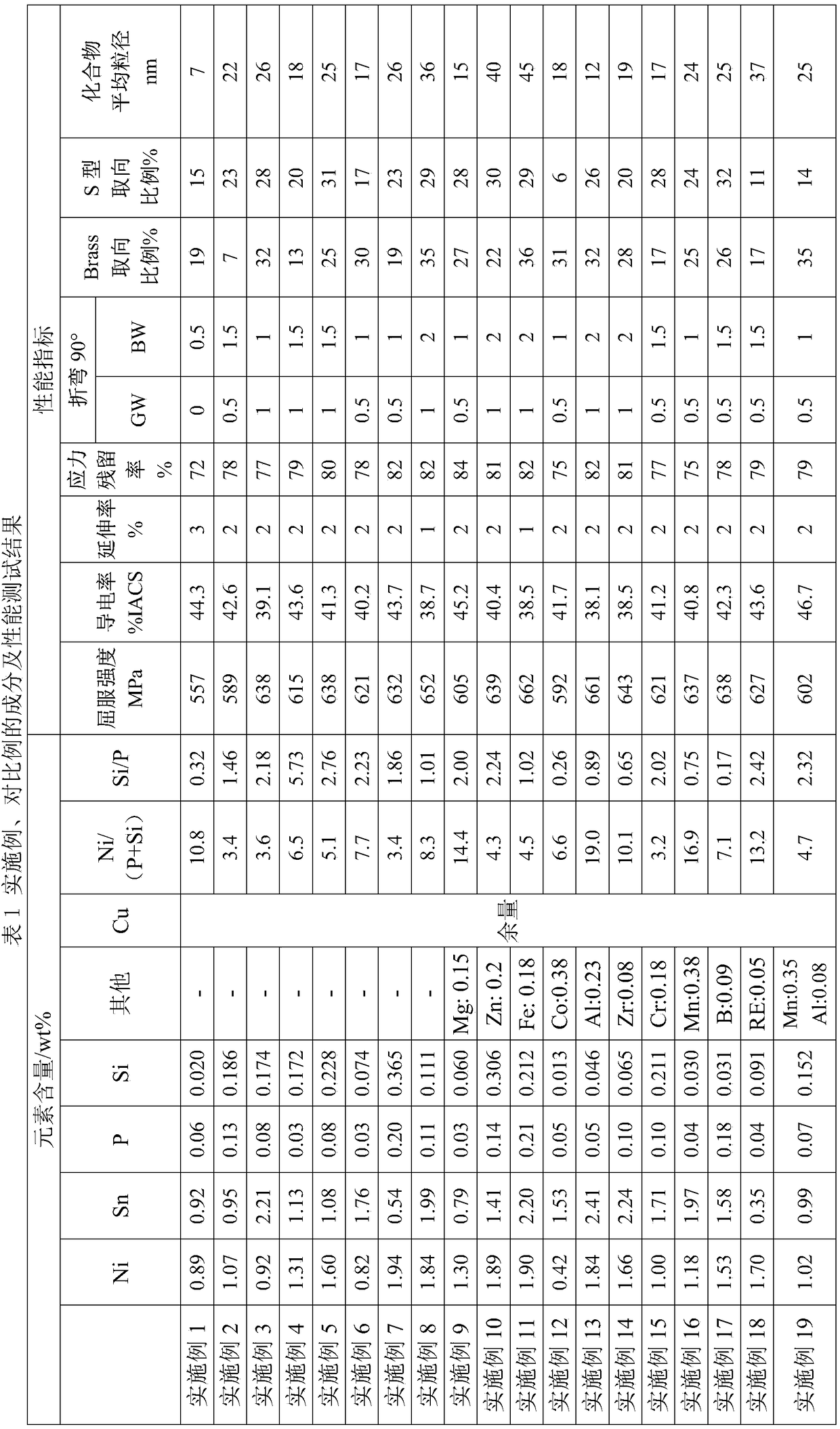

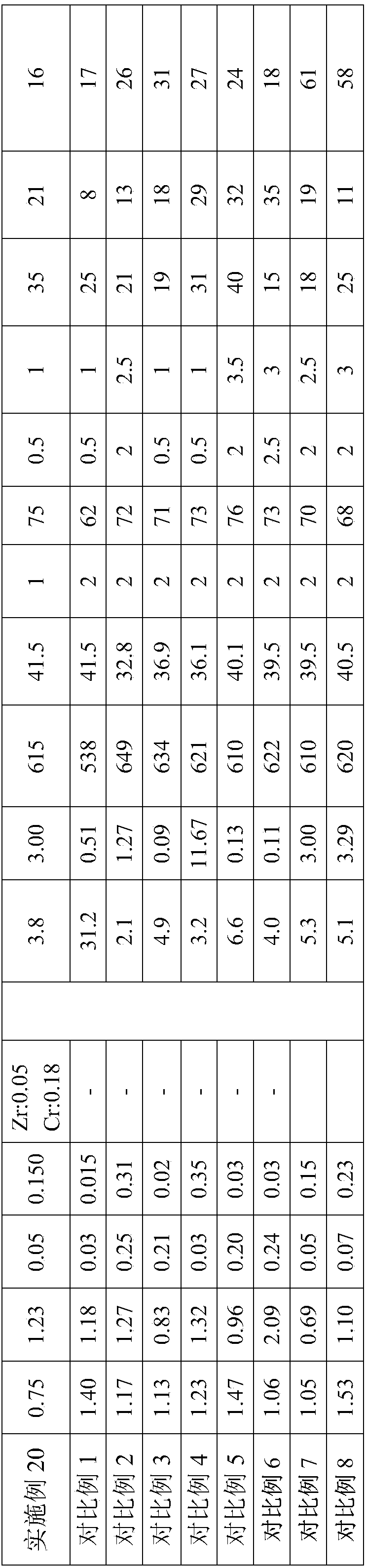

Copper alloy, copper alloy plate, and process for producing the same

This invention provides a copper alloy having excellent stress relaxation resistance, comprising Ni: 0.1 to 3.0% (% by mass; the same shall apply hereinafter), Sn: 0.01 to 3.0%, and P: 0.01 to 0.3% with the balance consisting of copper and unavoidable impurities, characterized in that the content of Ni in an extraction residue after extraction separation on a filter having an opening size of 0.1 [mu]m by an extraction residue method is not more than 40% in terms of the proportion to the content of Ni in the copper alloy. In the extraction residue method, 10 g of the copper alloy is immersed in 300 ml of a methanol solution having an ammonium acetate concentration of 10% by mass. This copper alloy is used as an anode. On the other hand, platinum is used as a cathode. Galvanostatic electrolysis is carried out at a current density of 10 mA / cm<2>. A solution containing this copper alloy dissolved therein is subjected to suction filtration by a polycarbonate membrane filter having an opening size of 0.1 [mu]m, and the insolubles as the residue are separated and extracted on the filter. The content of Ni in the extraction residue is determined by dissolving the insolubles as the residue on the filter in a solution composed of a mixture of aqua regia and water at a ratio of 1 : 1, and then analyzing the solution by ICP emission spectrometry.

Owner:KOBE STEEL LTD

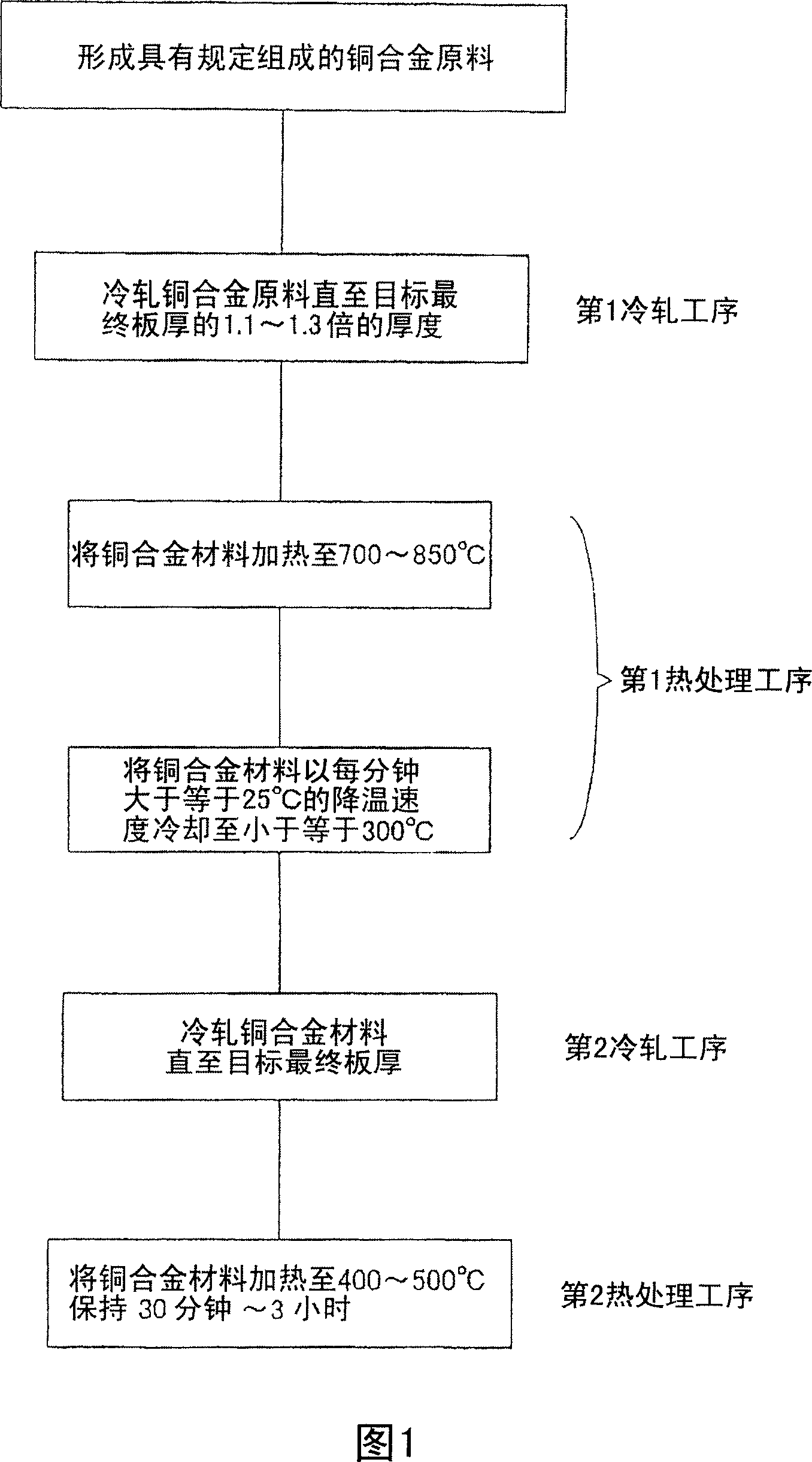

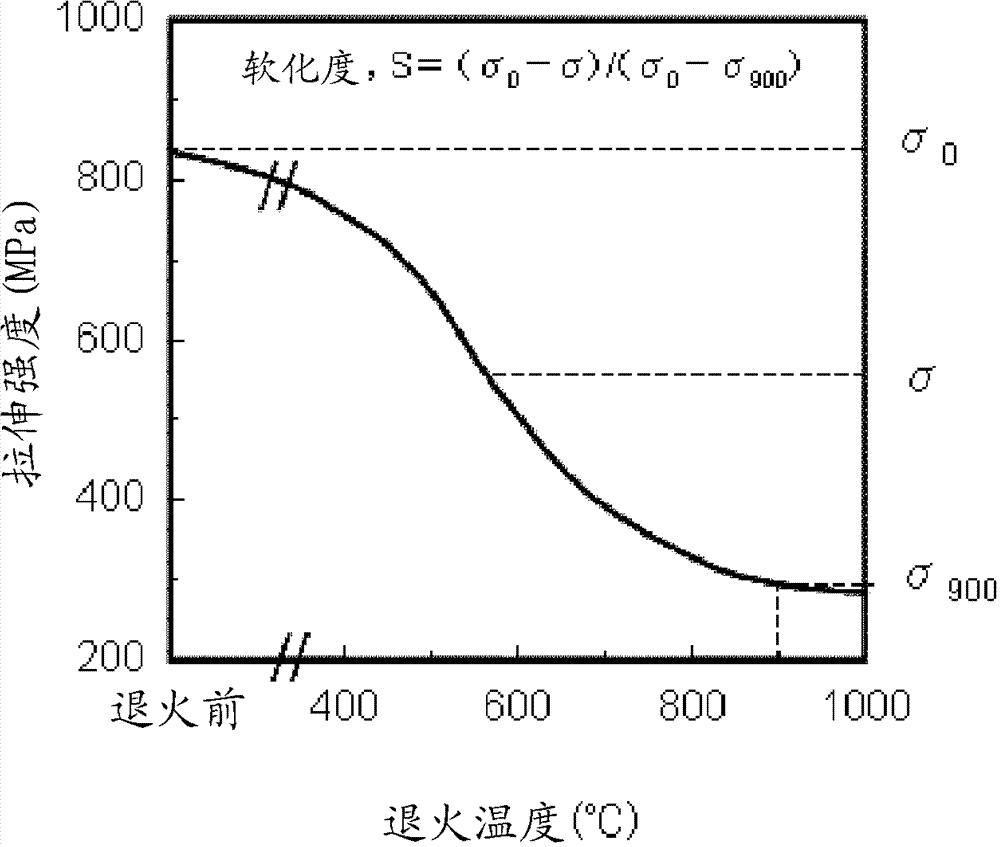

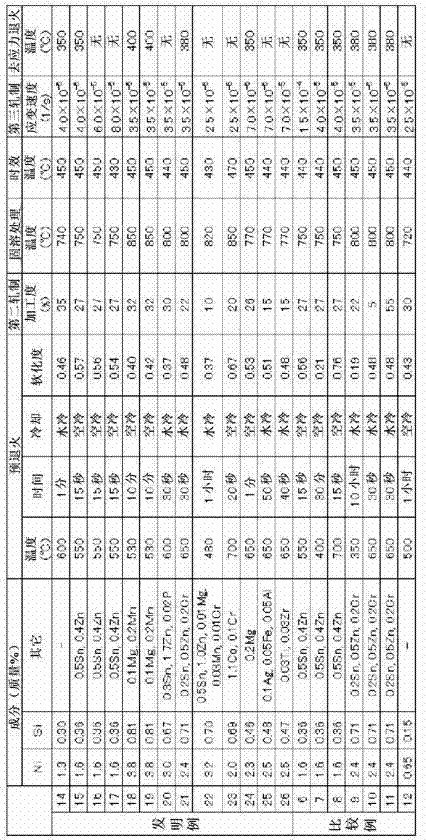

Copper-based alloy and method of manufacturing same

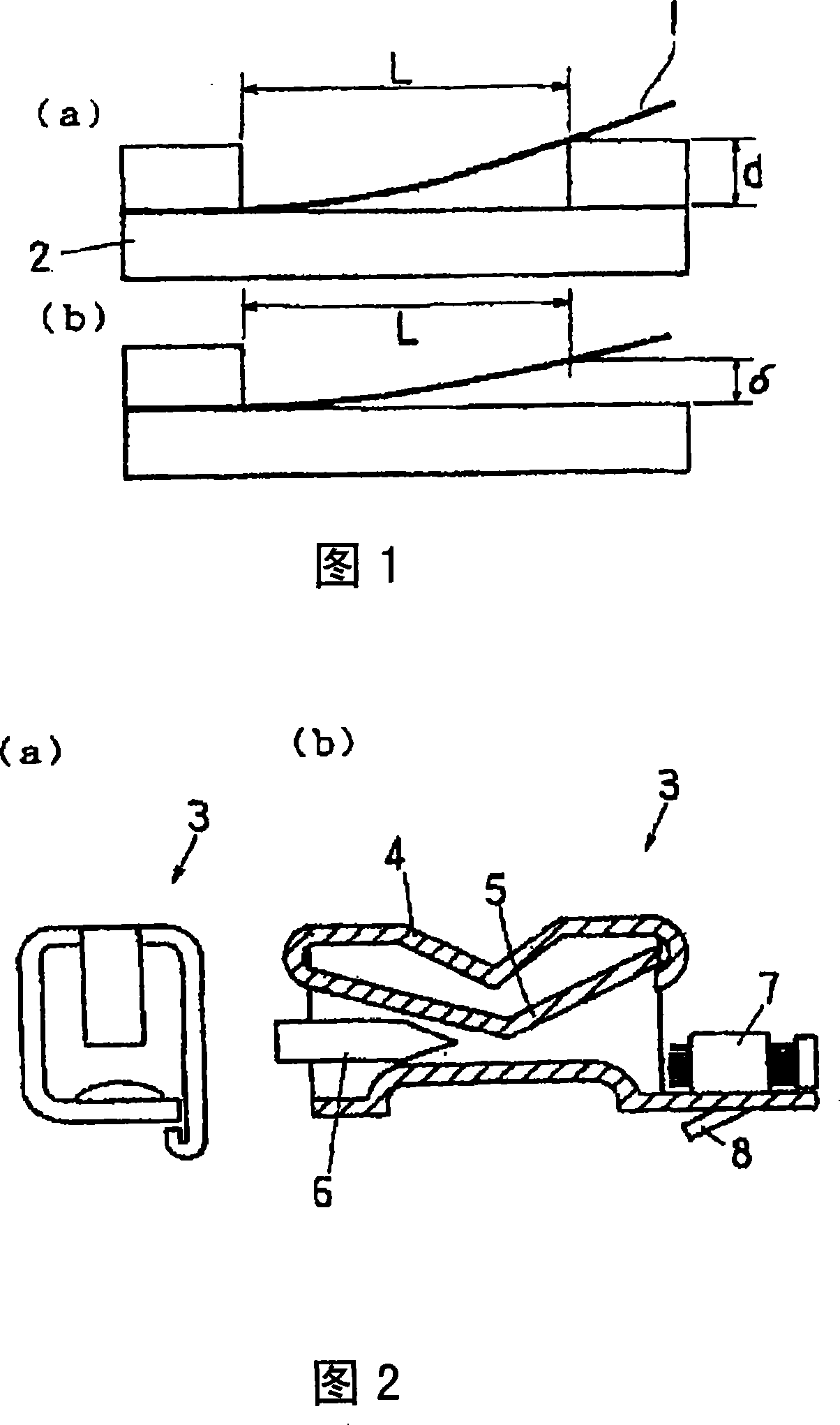

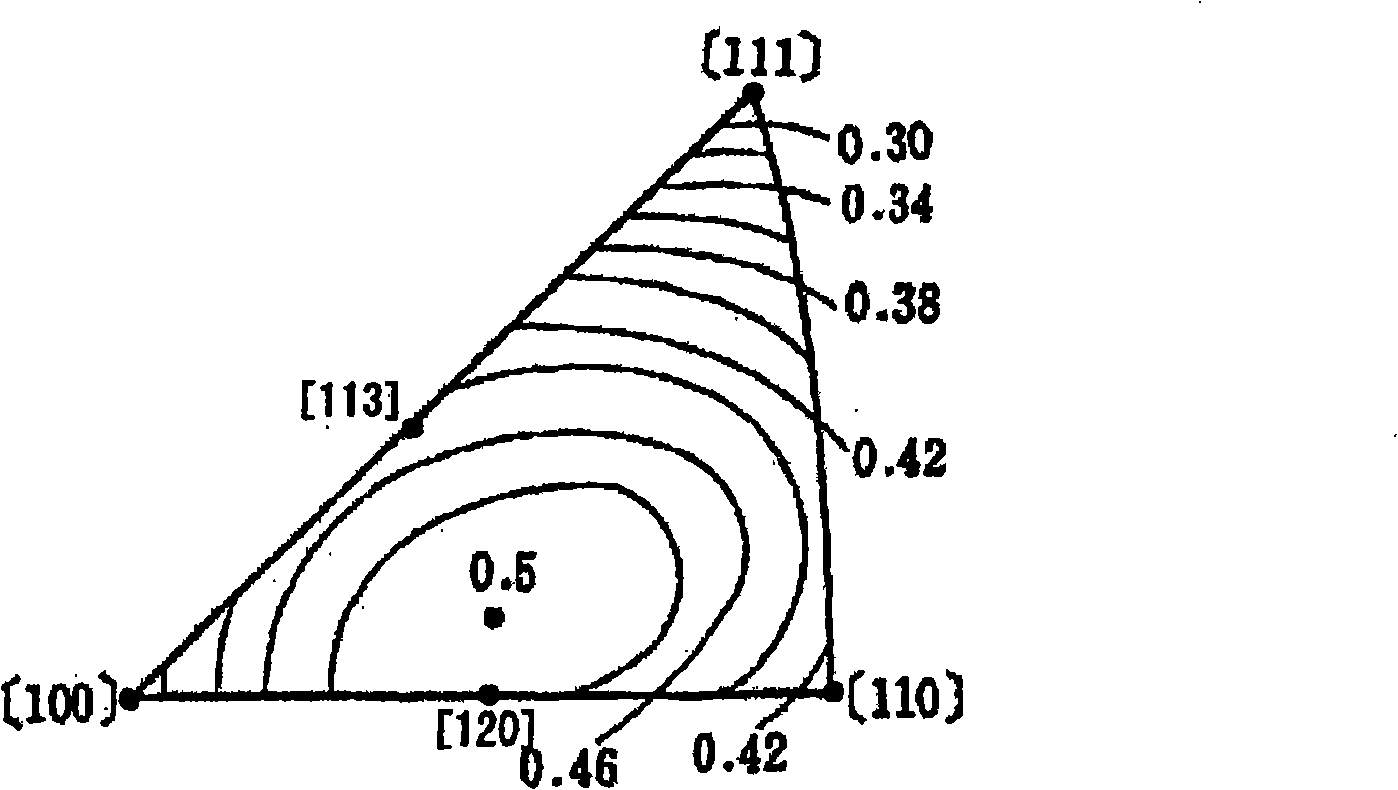

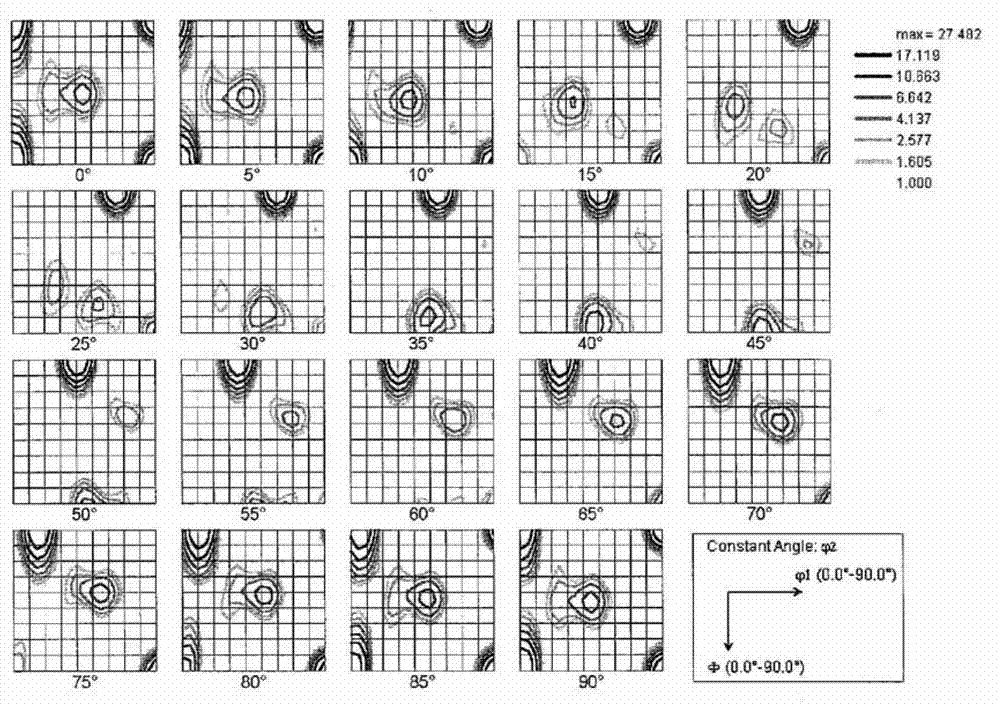

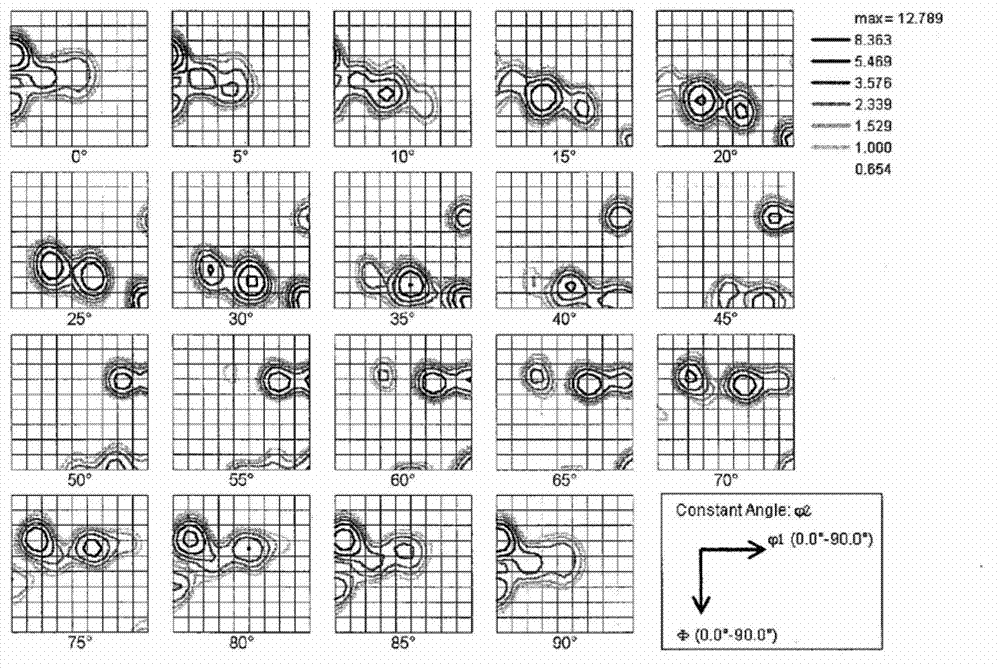

This invention is a copper-based alloy for use in connectors, lead frames, switches and relays and the like that has a superior balance of conductivity, tensile strength and workability in bending and method of manufacturing same. The alloy is manufactured by taking an ingot of a copper-based alloy containing Ni, Sn, P and also at least one or more elements selected from a group consisting of Zn, Si, Fe, Co, Mg, Ti, Cr, Zr and Al in a total amount of 0.01-30 wt. % with the remainder being Cu and unavoidable impurities, performing a combination process of cold rolling followed by annealing at least one time and then performing cold rolling at a percent reduction Z that satisfies the following Formula (1): Z<100−10X−Y (1) [where Z is the percent cold reduction (%), X is the Sn content (wt. %) among the various elements, and Y is the total content (wt. %) of all elements other than Sn and Cu] followed by low-temperature annealing performed at a temperature below the recrystallization temperature. This causes dispersion and precipitation of Ni—P compounds so that a precipitation-strengthened type copper-based alloy with an x-ray diffraction intensity ratio of the surface SND as given by the following formula is 0.05≦SND≦0.15 [provided that SND=I{200}÷[I{111}+I{220}+I{311}], where I{200} is the x-ray diffraction intensity of the {100} plane, {111} is the x-ray diffraction intensity of the {111} plane, I{220} is the x-ray diffraction intensity of the {110} plane, and {311} is the x-ray diffraction intensity of the {311} plane] and a superior balance of conductivity, tensile strength, 0.2% yield strength, springiness, Vickers hardness and bending workability is obtained.

Owner:DOWA METALTECH CO LTD

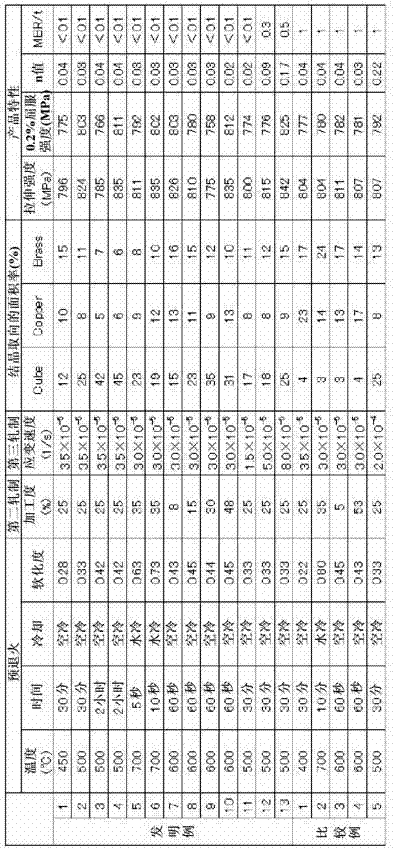

Copper alloy sheet and method for producing same

ActiveUS20100269959A1Excellent bending workabilityExcellent stress relaxation resistanceCoupling contact membersChemical compositionX-ray

A copper alloy sheet has a chemical composition containing 0.7 to 4.0 wt % of Ni, 0.2 to 1.5 wt % of Si, and the balance being copper and unavoidable impurities, the copper alloy sheet having a crystal orientation which satisfies I{200} / I0{200}≧1.0, assuming that the intensity of X-ray diffraction on the {200} crystal plane on the surface of the copper alloy sheet is I{200} and that the intensity of X-ray diffraction on the {200} crystal plane of the standard powder of pure copper is I0{200}, and which satisfies I{200} / I{422}≧15, assuming that the intensity of X-ray diffraction on the {422} crystal plane on the surface of the copper alloy sheet is I{422}.

Owner:DOWA METALTECH CO LTD

Cu-Ni-Si-based copper alloy sheet material and method of manufacturing same

InactiveCN101245422AExcellent stress relaxation resistanceHigh strengthSolid-state devicesSemiconductor devicesX-rayCrystal orientation

Owner:DOWA METALTECH CO LTD

Copper alloy sheet and method for producing same

InactiveCN103080347AExcellent bending workabilityHigh strengthConductive materialProcess efficiency improvementCrystal orientationHardness

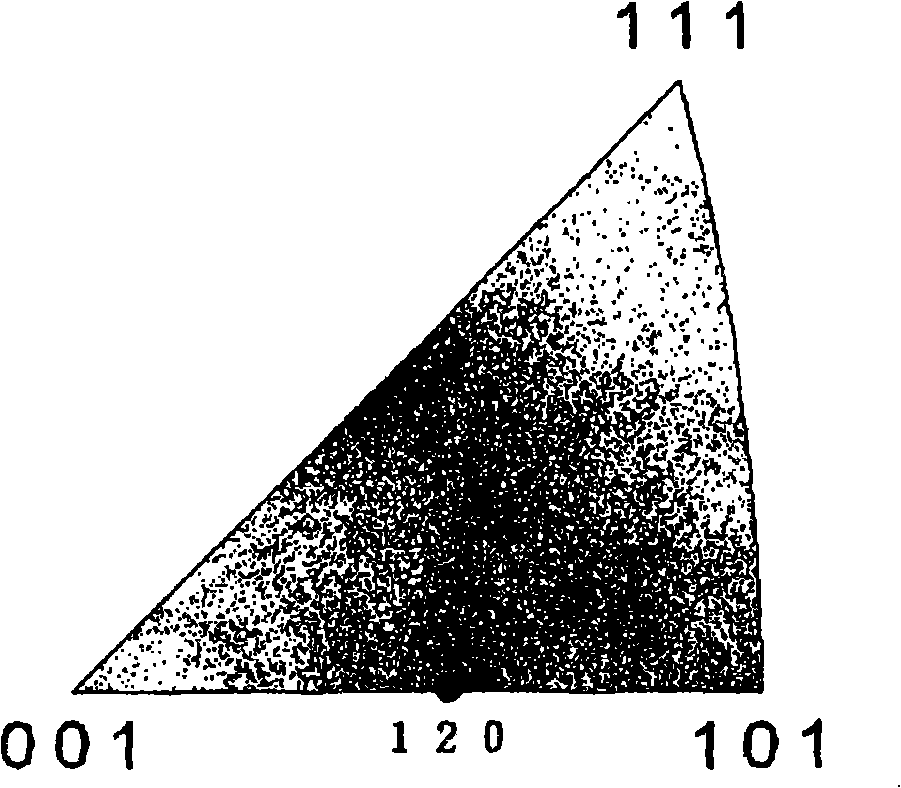

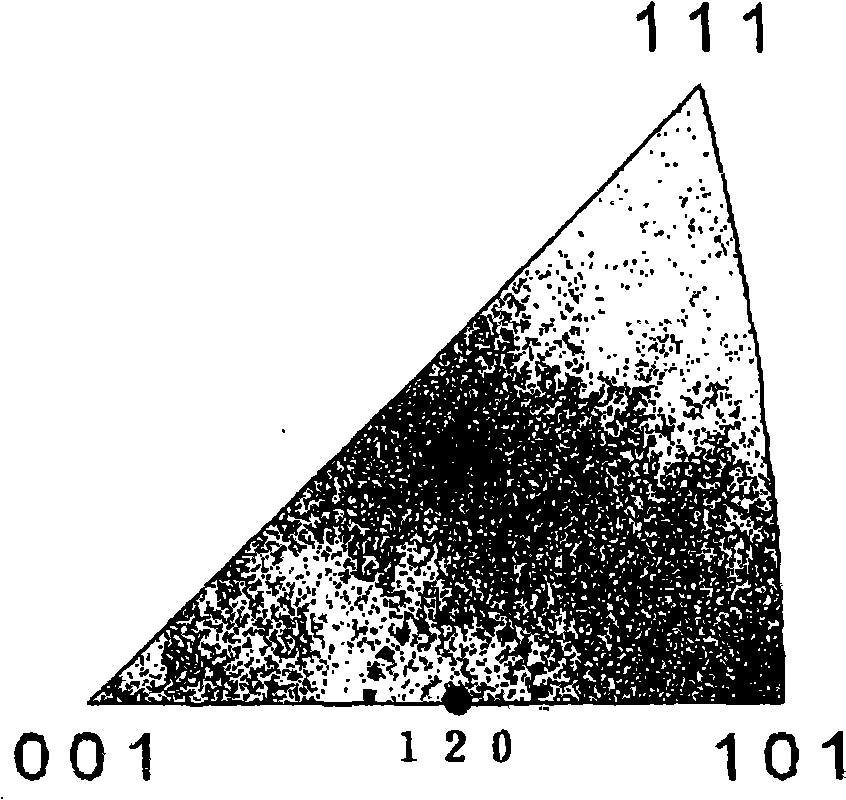

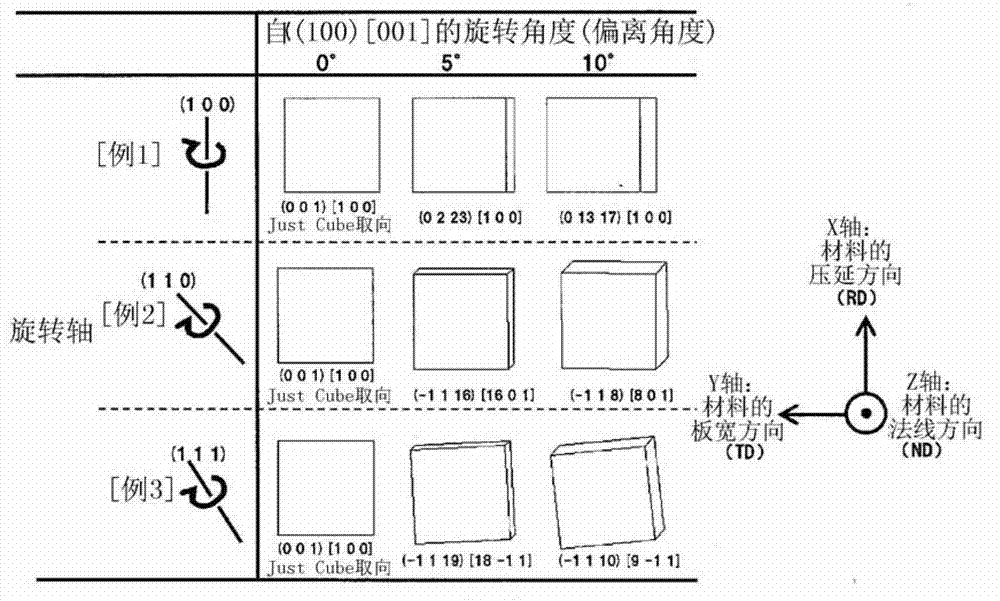

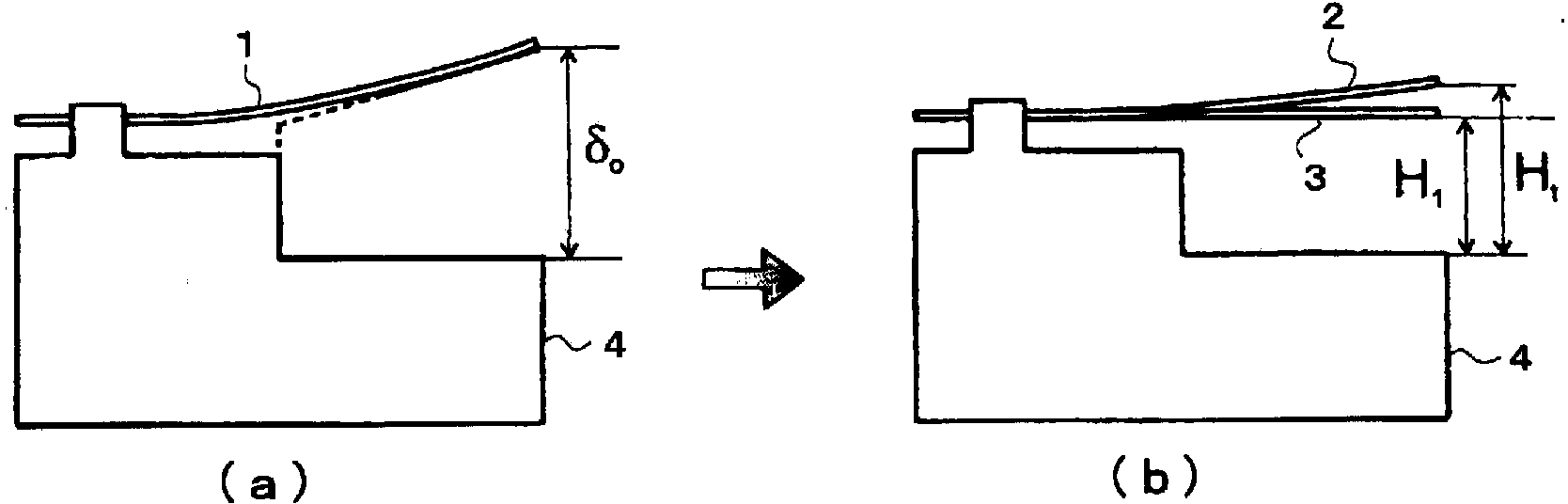

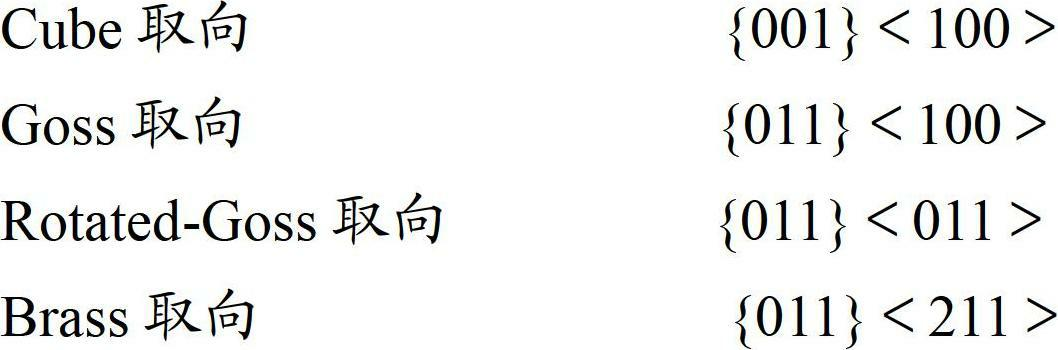

{Problems} To provide a copper alloy sheet material, excellent in bending property and mechanical strength, and suitable for lead frames, connectors, terminal materials, and the like in electrical / electronic equipments, for connectors, for example, to be mounted on automotive vehicles, and for terminal materials, relays, switches, and the like; and to provide a method of producing the same. {Means to solve} A copper alloy sheet material, containing at least one of Cr, Zr, and Ti in an amount of 0.05 to 1.0 mass% in total, with the balance being copper and unavoidable impurities, wherein an area ratio of Cube orientation {0 0 1} <1 0 0> is 5% or more and 70% or less, in crystal orientation analysis by an EBSD analysis, and wherein a Vickers hardness is 120 or more; and a method of producing the same.

Owner:FURUKAWA ELECTRIC CO LTD

Copper alloy material, and method for production thereof

InactiveUS20100170595A1Improve propertiesExcellent bending workabilityStress relaxationUltimate tensile strength

A copper alloy material according to the present invention is characterized in that the copper alloy material includes: an element X between 0.1% and 4% by mass, in which the element X represents one transition element or not less than two elements selected from Ni, Fe, Co and Cr; an element Y between 0.01% and 3% by mass, in which the element Y represents one element or not less than two elements selected from Ti, Si, Zr and Hf; and a remaining portion to be comprised of copper and an unavoidable impurity, wherein the copper alloy material has an electrical conductivity of not less than 50% IACS, an yield strength of not less than 600 MPa, and a stress relaxation rate of not higher than 20% as to be measured after the same is maintained for 1000 hours at a state under applying a stress of 80% of the yield strength.

Owner:FURUKAWA ELECTRIC CO LTD

Copper alloy with high strength and excellent processability in bending and process for producing copper alloy sheet

InactiveUS20090084473A1High strengthDeterioration in bending workabilityMetal rolling arrangementsHigh intensityImpurity

The present invention provides a Cu—Fe—P alloy which has a high strength, high conductivity and superior bending workability. The copper alloy comprises 0.01 to 1.0% Fe, 0.01 to 0.4% P, 0.1 to 1.0% Mg, and the remainder Cu and unavoidable impurities. The size of oxides and precipitates including Mg in the copper alloy is controlled so that the ratio of the amount of Mg measured by a specified measurement method in the extracted residue by a specified extracted residue method to the Mg content in said copper alloy is 60% or less, thus endowing the alloy with a high strength and superior bending workability.

Owner:KOBE STEEL LTD

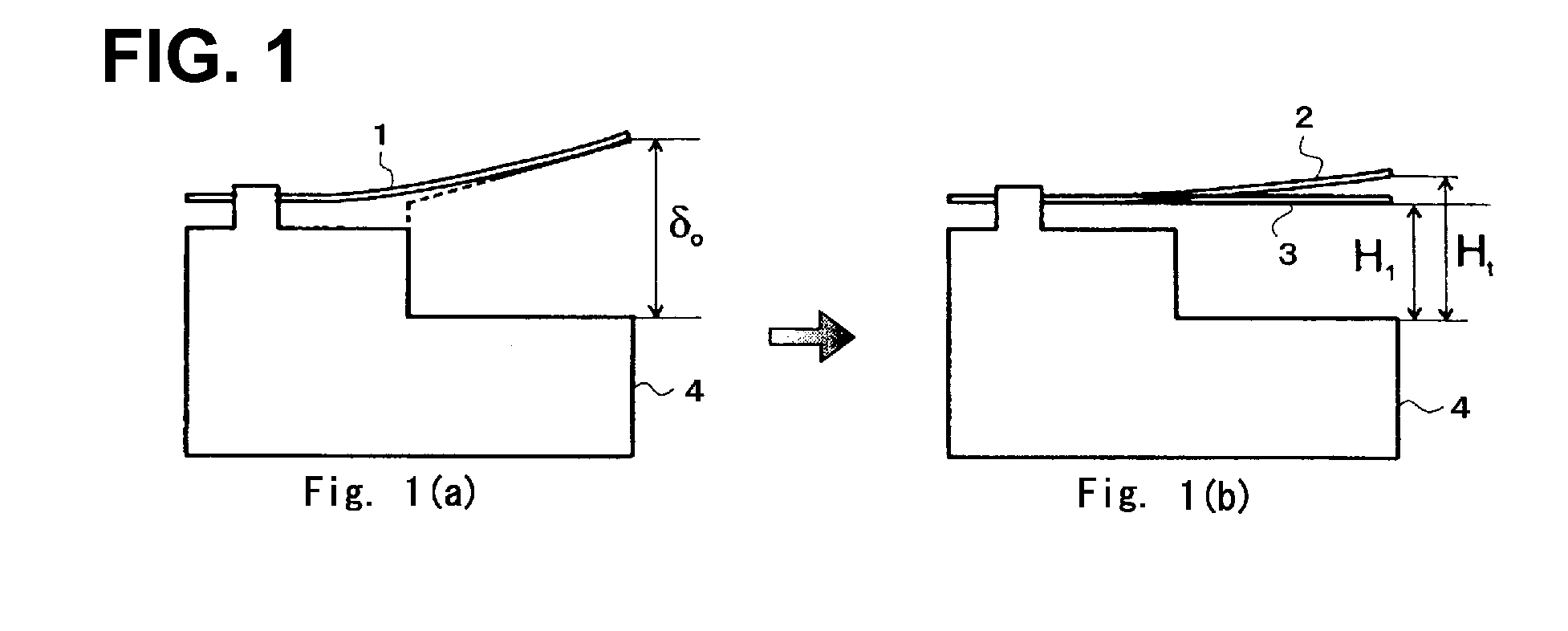

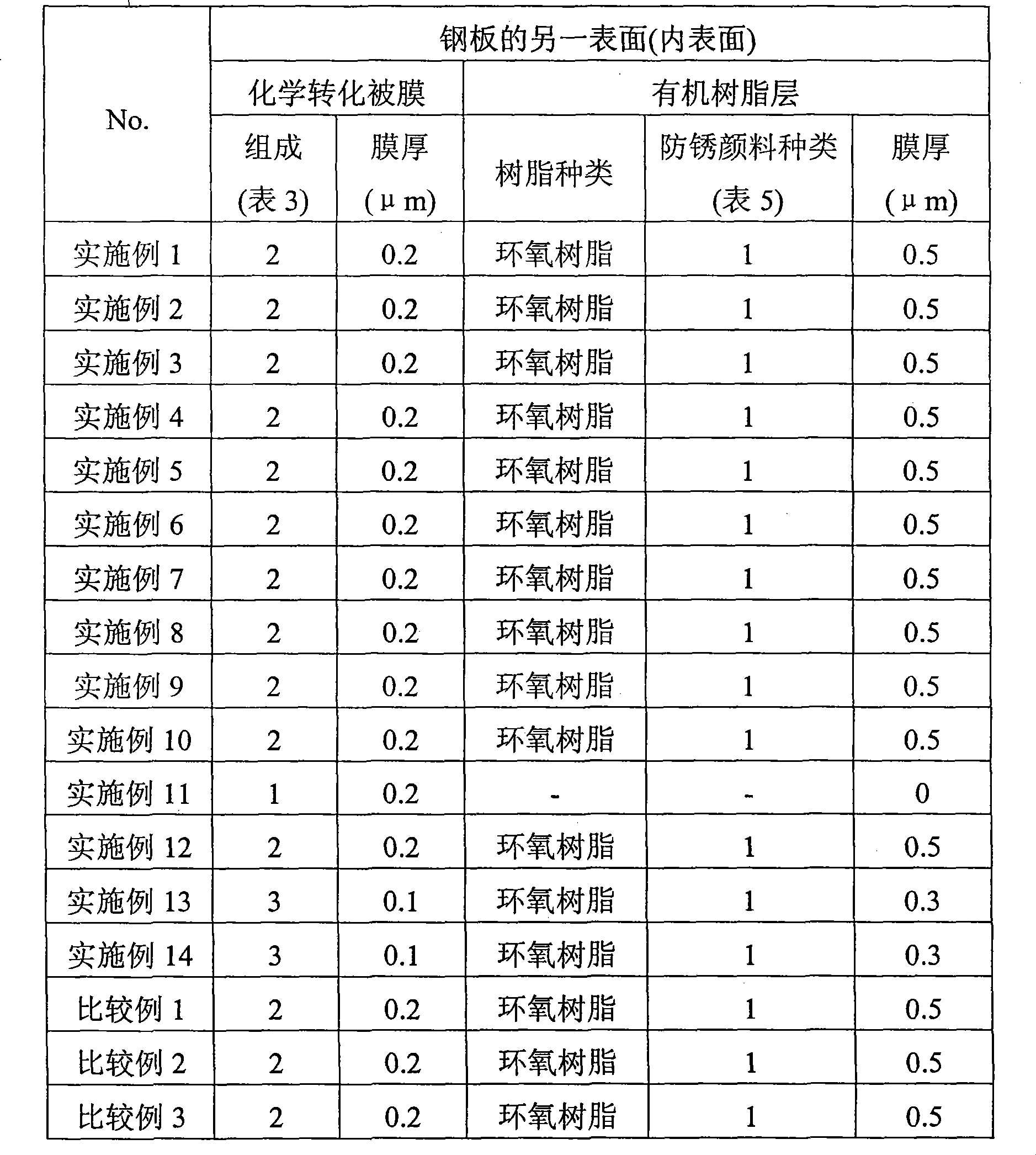

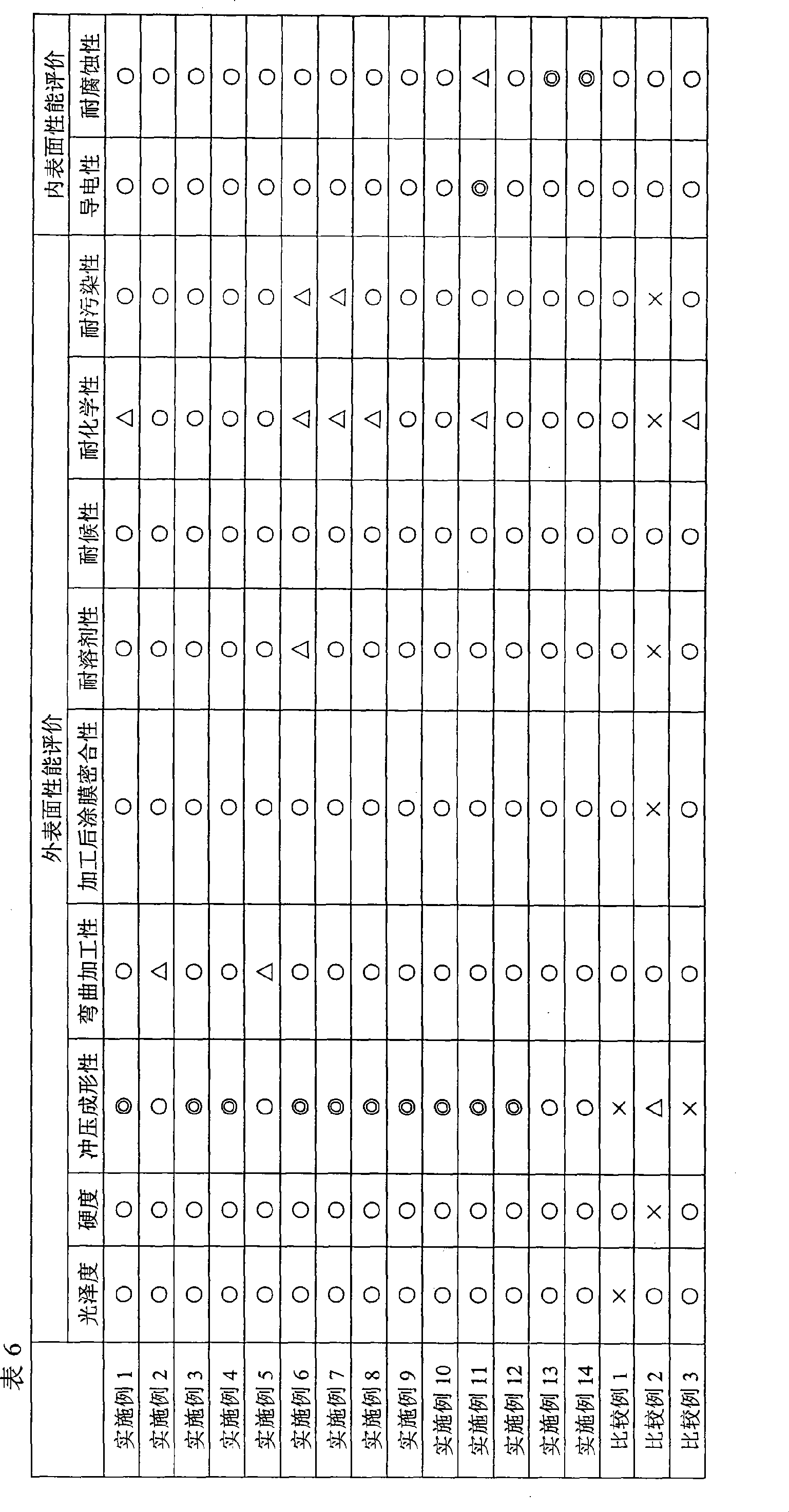

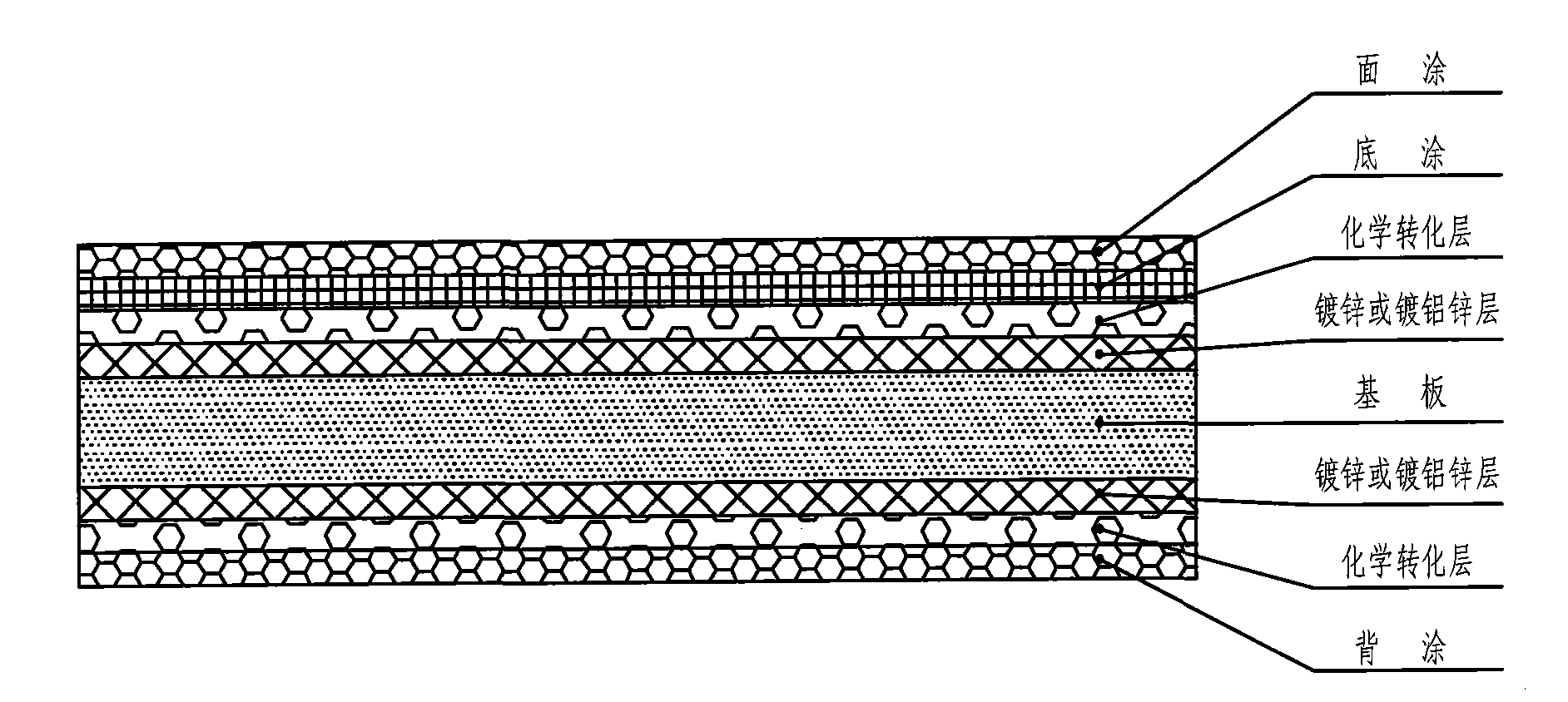

Coated steel sheet, works, panels for thin televisions and process for production of coated steel sheet

ActiveCN101394998AExcellent adhesionGood solvent resistanceHot-dipping/immersion processesPretreated surfacesPolymer scienceWeather resistance

Owner:JFE STEEL CORP

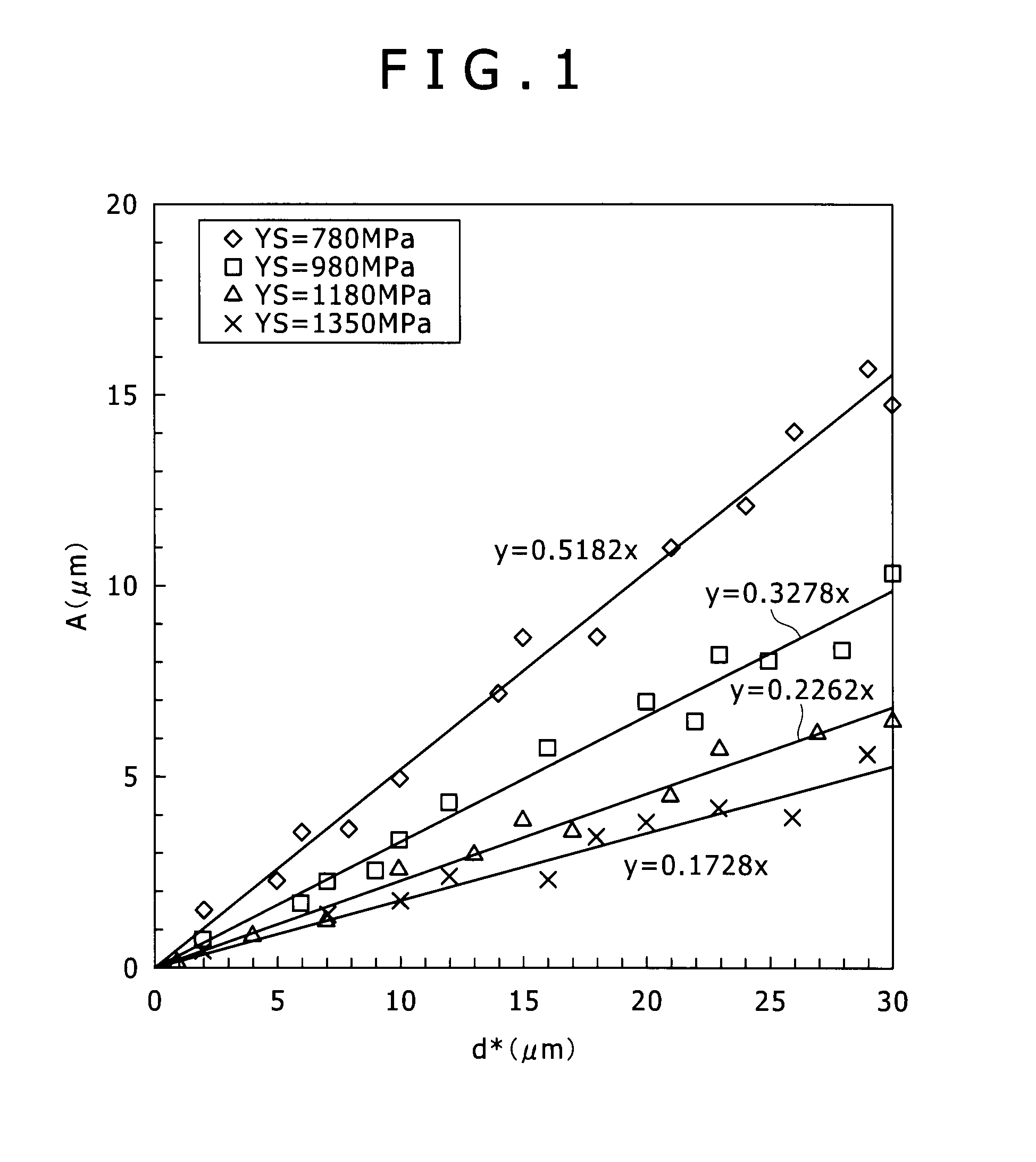

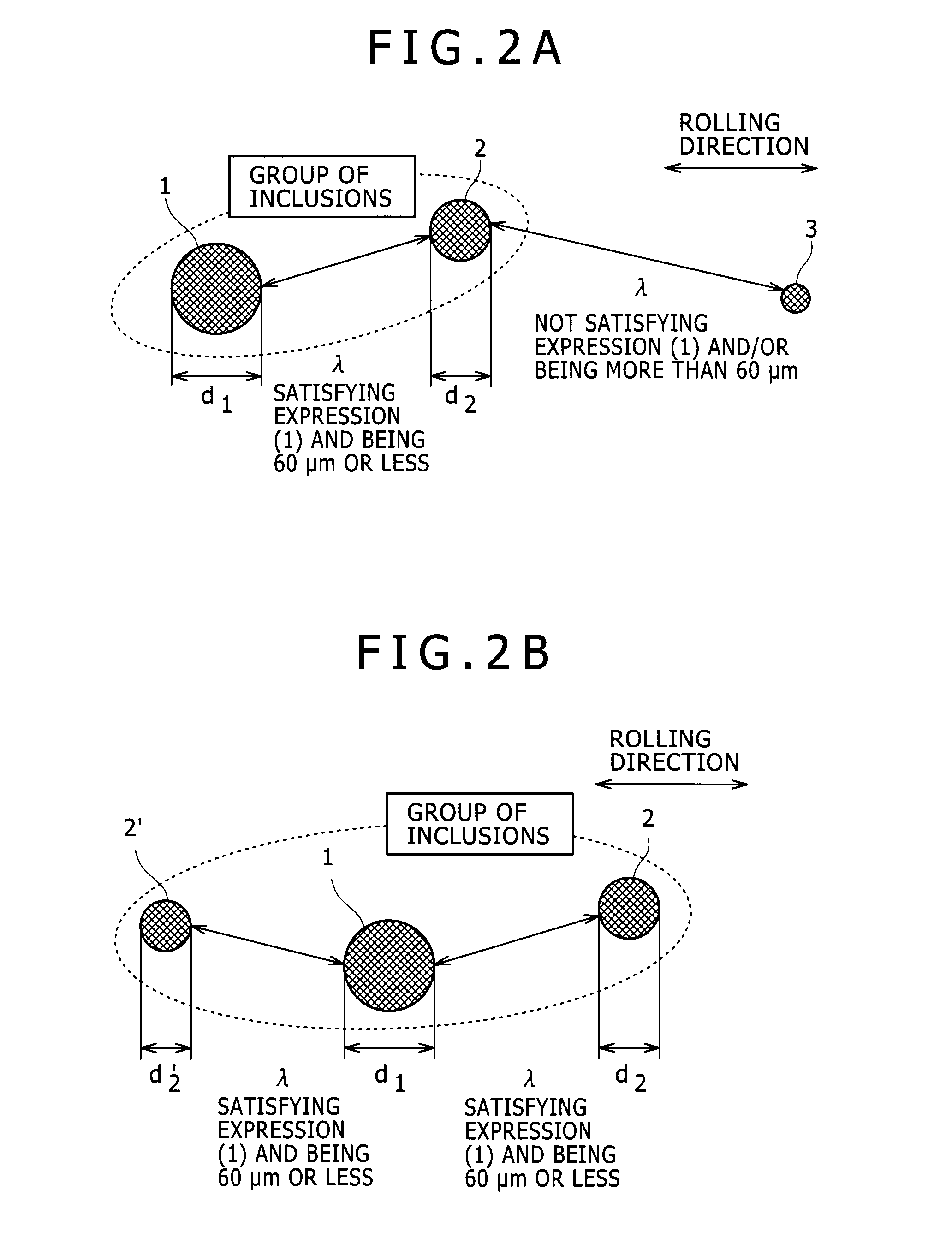

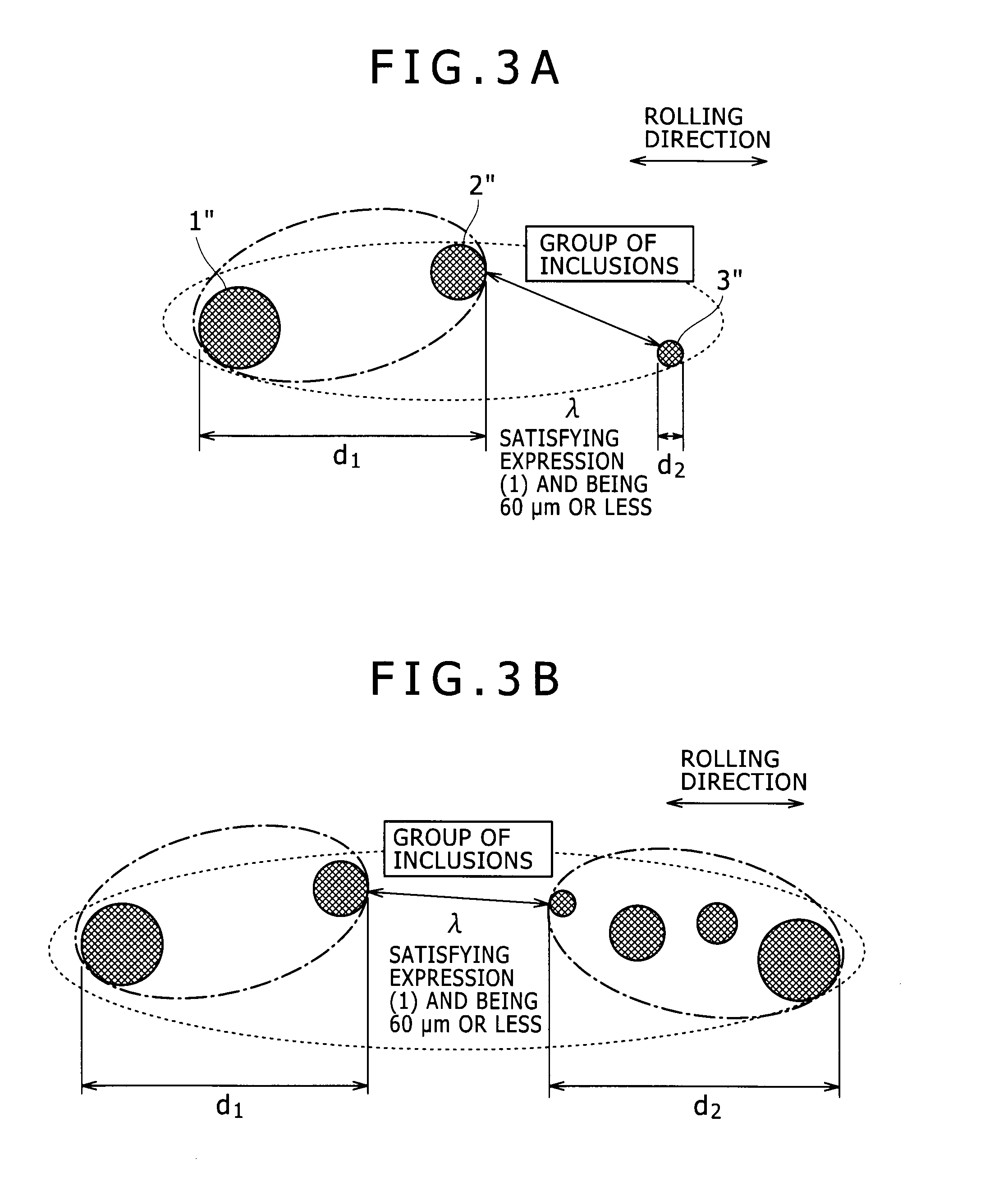

High-strength cold-rolled steel sheet excellent in bending workability

ActiveUS20110287280A1Excellent bending workabilitySuitable for manufactureThin material handlingMetal layered productsChemical compositionNumber density

A cold-rolled steel sheet has a chemical composition of C: 0.12% to 0.3%, Si: 0.5% or less, Mn: less than 1.5%, Al: 0.15% or less, N: 0.01% or less, P: 0.02% or less, and S: 0.01% or less, with the remainder including iron and inevitable impurities and has a martensite single-phase structure as its steel microstructure. In a surface region of the steel sheet from the surface to a depth one-tenth the gauge, the number density of n-ary groups of inclusions determined by specific n-th determinations is 120 or less per 100 cm2 of a rolling plane, where the distance in steel sheet rolling direction between outermost surfaces of two outermost particles of the group of inclusions is 100 μm or more. The steel sheet is a high-strength cold-rolled steel sheet which has a sufficiently minimized rate of bending fracture starting from inclusions and thereby has excellent bending workability.

Owner:KOBE STEEL LTD

Copper-based alloy and method of manufacturing same

This invention is a copper-based alloy for use in connectors, lead frames, switches and relays and the like that has a superior balance of conductivity, tensile strength and workability in bending and method of manufacturing same. The alloy is manufactured by taking an ingot of a copper-based alloy containing Ni, Sn, P and also at least one or more elements selected from a group consisting of Zn, Si, Fe, Co, Mg, Ti, Cr, Zr and Al in a total amount of 0.01-30 wt. % with the remainder being Cu and unavoidable impurities, performing a combination process of cold rolling followed by annealing at least one time and then performing cold rolling at a percent reduction Z that satisfies the following Formula (1):Z<100−10X−Y (1)[where Z is the percent cold reduction (%), X is the Sn content (wt. %) among the various elements, and Y is the total content (wt. %) of all elements other than Sn and Cu] followed by low-temperature annealing performed at a temperature below the recrystallization temperature. This causes dispersion and precipitation of Ni—P compounds so that a precipitation-strengthened type copper-based alloy with an x-ray diffraction intensity ratio of the surface SND as given by the following formula is 0.05≦SND≦0.15 [provided that SND=I{200}÷[I{111}+I{220}+I{311}], where I{200} is the x-ray diffraction intensity of the {100} plane, I{111} is the x-ray diffraction intensity of the {111} plane, I{220} is the x-ray diffraction intensity of the {110} plane, and I{311} is the x-ray diffraction intensity of the {311} plane] and a superior balance of conductivity, tensile strength, 0.2% yield strength, springiness, Vickers hardness and bending workability is obtained.

Owner:DOWA METALTECH CO LTD

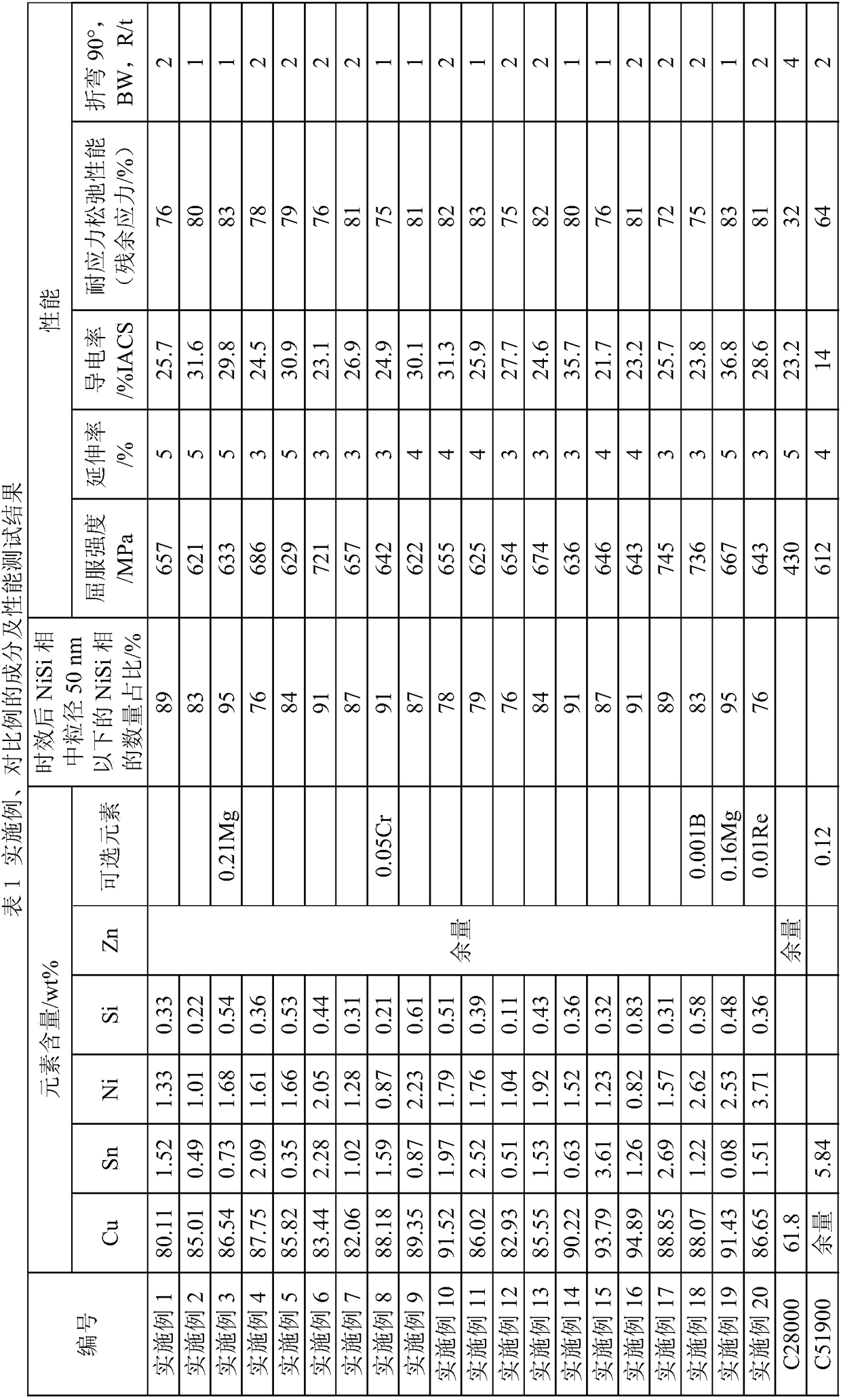

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

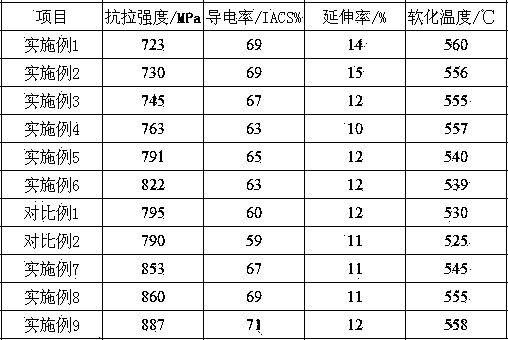

High-strength Cu-Ni-Si alloy and preparation method thereof

The invention relates to a high-strength Cu-Ni-Si alloy and preparation method thereof. The alloy comprises 2.0-6.0% of Ni, 0.5-1.5% Si, 0.5-1.0% of Ti, 0.5-1.0% of Mn, 0.5-1.0% of Ag and the balance of copper and unavoidable impurity elements. The preparation method sequentially comprises the following steps of smelting; casting; homogenization treatment; hot rolling and solution treatment; pre-cold rolling and aging treatment; and cold-rolling deformation. A Ni2Si non-oxide reinforcing phase is generated in the alloy disclosed by the invention; after the rolling is carried out repeatedly, the nucleation positions of precipitated phases can be increased, the more the broken grains, the more grain boundaries, the more nucleation positions of the precipitated phases and the more the precipitated phases; and under the condition that aging treatment is carried out repeatedly, the more precipitated phases are precipitated and thus the comprehensive performance of the alloy is dramatically increased, the strength, the elongation property at a high temperature and the electric conductivity are improved and the bending workability of the alloy is also improved.

Owner:HENAN UNIV OF SCI & TECH

Copper alloy material for electric element and method of making same

ActiveCN1925065AReduce anisotropyExcellent bending workabilityLine/current collector detailsMetal/alloy conductorsUltimate tensile strengthCopper alloy

Owner:株式会社日立金属新材料

Cu-Ni-Si alloy and method for manufacturing same

InactiveCN103781925AHigh strengthExcellent bending workabilityConductive materialMetal/alloy conductorsCrystal orientationAlloy

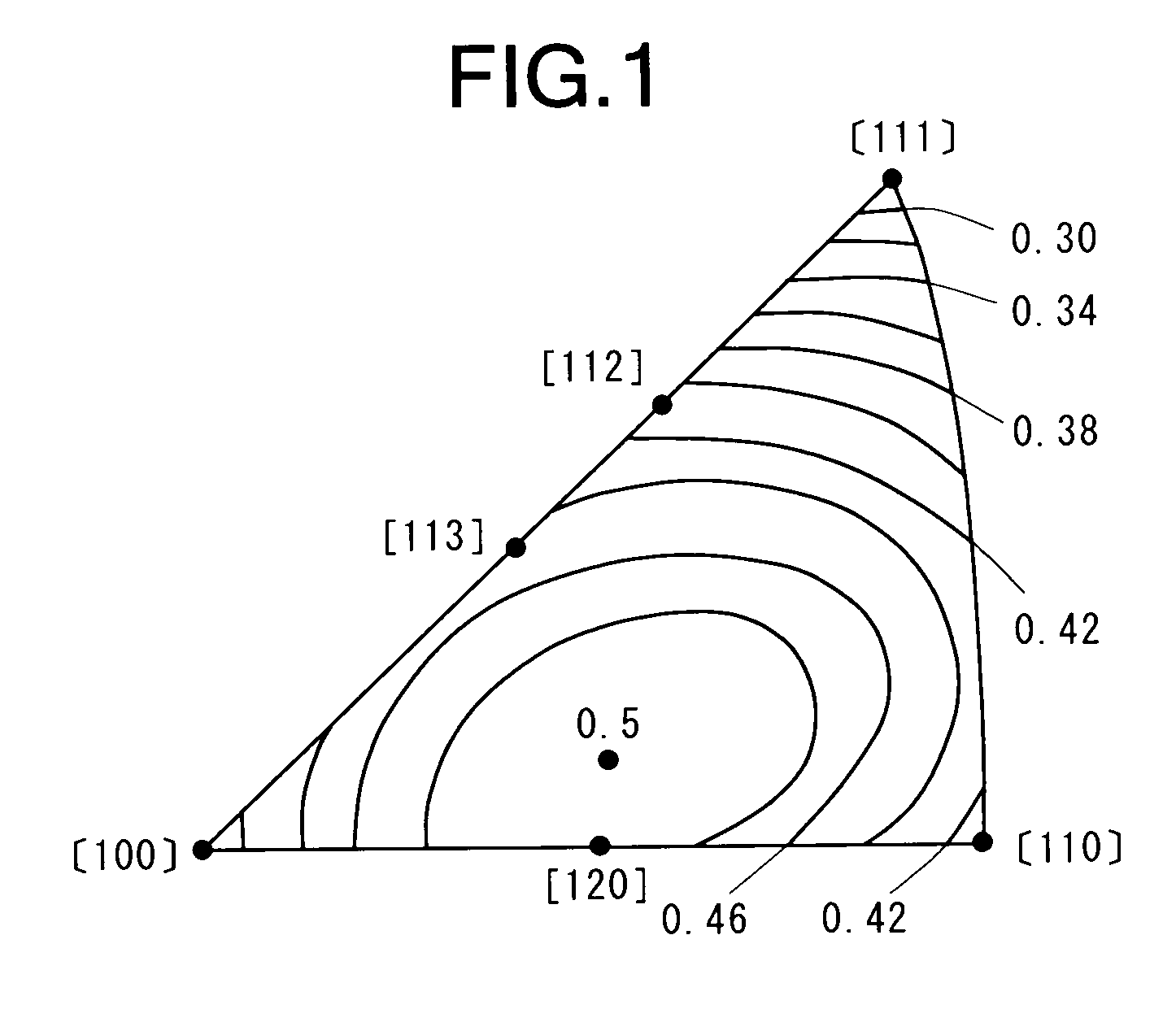

Provided is a Cu-Ni-Si alloy and a method for manufacturing the Cu-Ni-Si alloy, the Cu-Ni-Si alloy being provided with exceptional strength and bendability, and being suitable as an electro-conductive spring material for a connector, terminal, relay, switch or other component. The Cu-Ni-Si alloy contains 1.0 to 4.5 wt% of Ni, 0.2 to 1.0 wt% of Si, and copper and inevitable impurities constituting the balance. Electron back-scatter diffraction (EBSD) measuring is performed. When the crystal orientation is analyzed the area of cube orientation {001} <100>; constitutes 5% or more, the area of brass orientation {110} <112>; constitutes 20% or less, and the area of copper orientation {112} <111>; constitutes 20% or less. The work-hardening coefficient is 0.2 or less.

Owner:JX NIPPON MINING & METALS CO LTD

Copper alloy material and manufacturing method thereof

ActiveCN103534370AIncrease stressImprove featuresSingle bars/rods/wires/strips conductorsConductive materialCrystal orientationStress relaxation

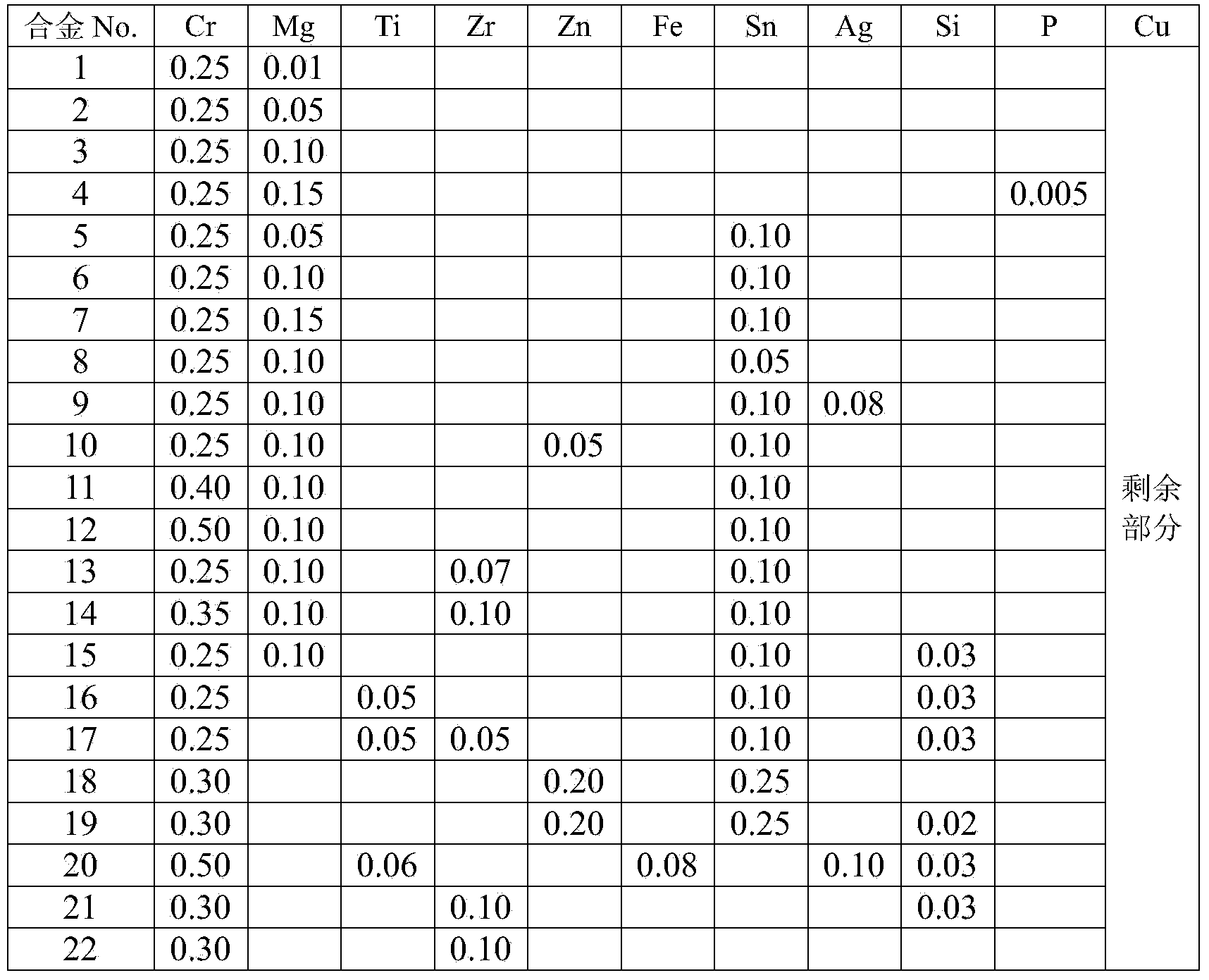

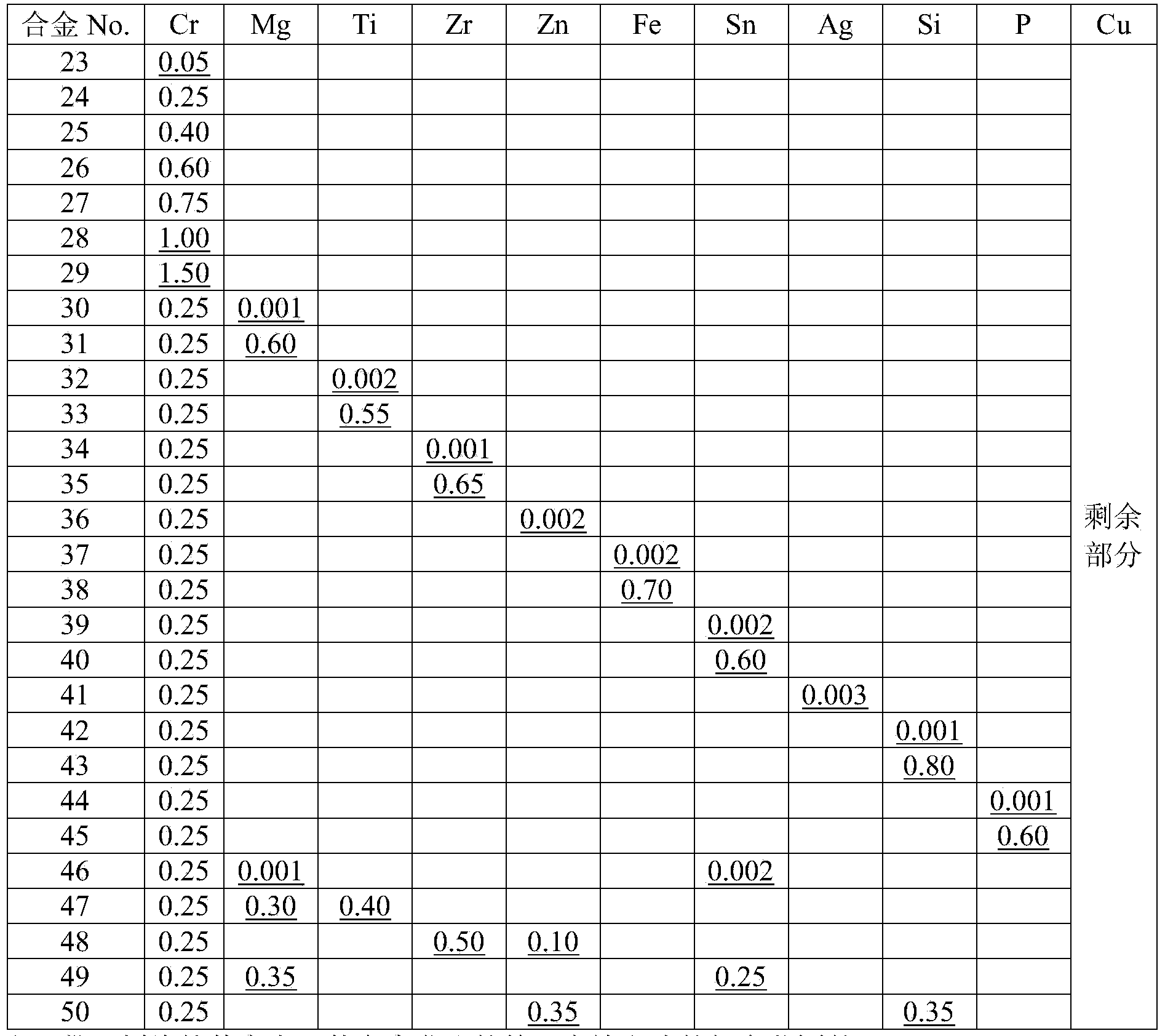

Provided is a copper alloy material having excellent bendability, proof strength, conductivity, and stress relaxation resistance, and that is suitable for automotive components and the surrounding infrastructure, particularly in electric vehicles and hybrid electric vehicles, as well as for the lead frames, connectors, terminals, etc. of solar power generation systems and the like. The copper alloy material contains 0.1-0.8 mass% of Cr and 0.01-0.5 mass% in total of at least one type selected from the group consisting of additive element group 1 and additive element group 2, and the remainder comprises copper and inevitable impurities. In the crystal orientation analysis of a rolled surface carried out using electron backscatter diffraction measurement, the area proportion of crystal grains having an orientation that is offset at 15 DEG or less from the cube orientation {001}<100>; is 3% or above, and the proportion of S3 coincidence grain boundaries in the crystal grain boundaries is 20% or above.The additive element group 1 is 0.01-0.5 mass% in total of at least one type selected from the group consisting of Mg, Ti, and Zr; and additive element group 2 is 0.005-0.5 mass% in total of at least one type selected from the group consisting of Zn, Fe, Sn, Ag, Si, and P.

Owner:FURUKAWA ELECTRIC CO LTD

Copper alloy

InactiveUS20140193293A1Reduce intensityHigh yield strengthConductive materialMetal/alloy conductorsUltimate tensile strengthImpurity

Disclosed is a copper alloy containing 1.0% to 3.6% of Ni, 0.2% to 1.0% of Si, 0.05% to 3.0% of Sn, 0.05% to 3.0% of Zn, with the remainder including copper and inevitable impurities. The copper alloy has an average grain size of 25 pm or less and has a texture having an average area percentage of cube orientation of 20% to 60% and an average total area percentage of brass orientation, S orientation and copper orientation of 20% to 50%. The copper alloy has a KAM value of 0.8 to 3.0 and does not suffer from cracking even when subjected to U-bending. The copper alloy has excellent balance between strengths (particularly yield strength in a direction perpendicular to the rolling direction) and bending workability.

Owner:KOBE STEEL LTD

Copper alloy sheet

ActiveCN102639732AHigh strengthExcellent bending workabilitySingle bars/rods/wires/strips conductorsConductive materialElectronic componentImpurity

Provided is a Corson copper alloy sheet which satisfies property requirements for terminals or connectors, such as strength and bendability. The copper alloy sheet is a copper alloy sheet for electric / electronic components which has a copper alloy composition containing, in terms of mass%, 0.8-5% Ni and / or Co and 0.2-1.5% Si, with the remainder comprising Cu and incidental impurities, wherein the areal proportion of crystal grains deflected at an angle less than 15 from the cube orientation has been regulated so as to be less than 10% and the areal proportion of crystal grains deflected at an angle of 15-30 from the cube orientation has been regulated to 15% or higher. The copper alloy sheet has excellent strength and bendability.

Owner:FURUKAWA ELECTRIC CO LTD

Copper alloy with outstanding comprehensive performance and application thereof

ActiveCN109022900AGuaranteed electrical conductivityHigh strengthConductive materialMetal/alloy conductorsWire rodUltimate tensile strength

Owner:NINGBO POWERWAY ALLOY MATERIAL

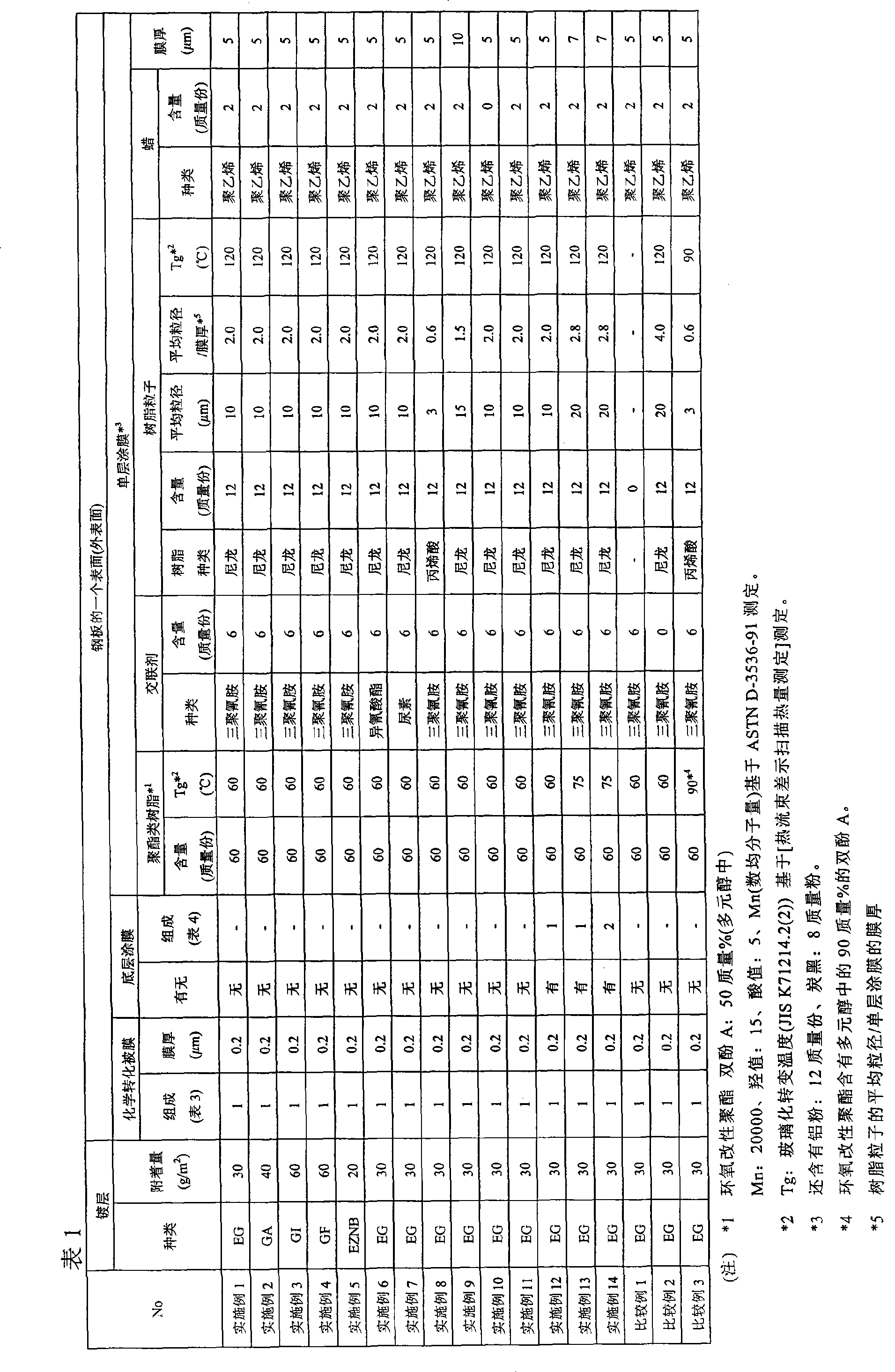

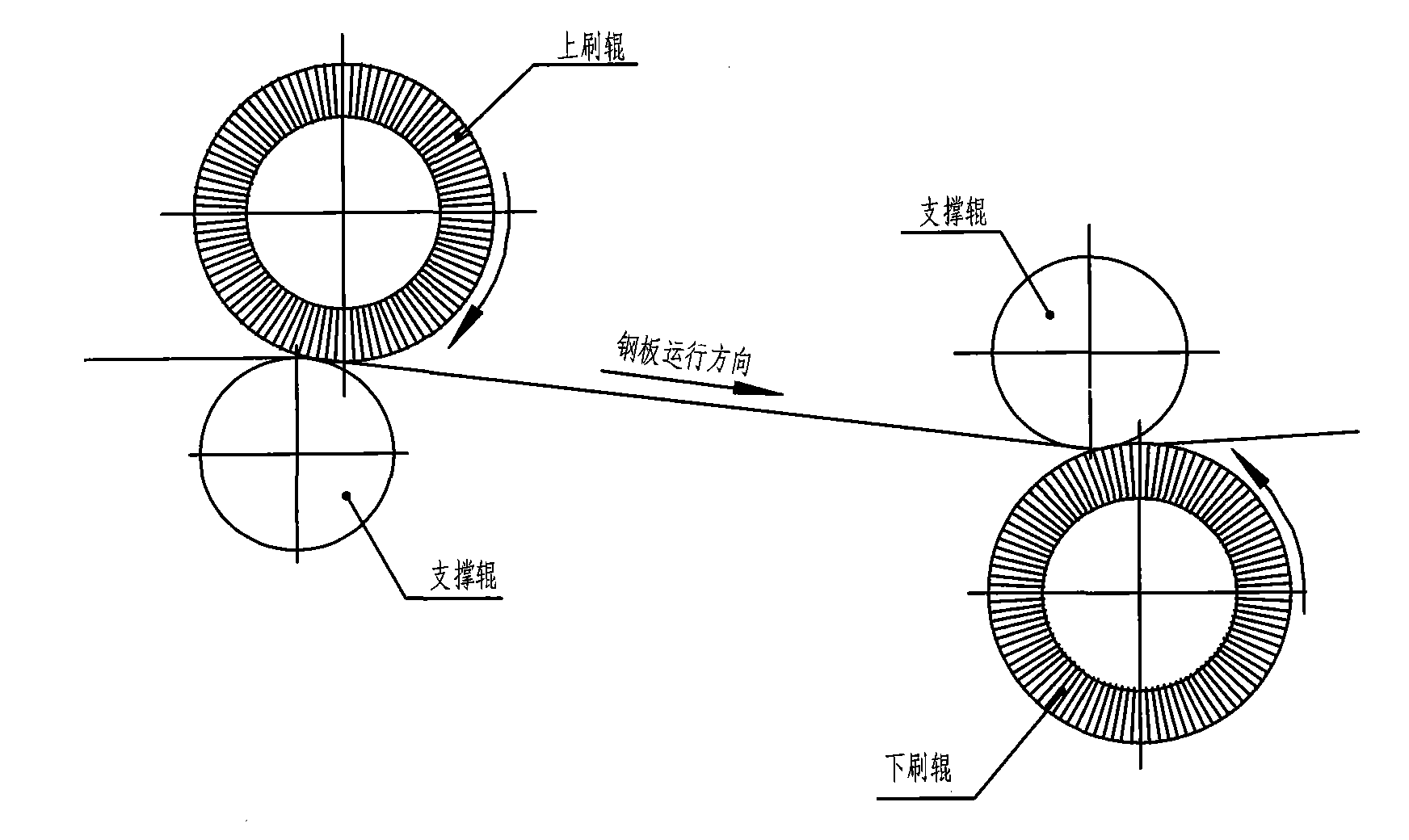

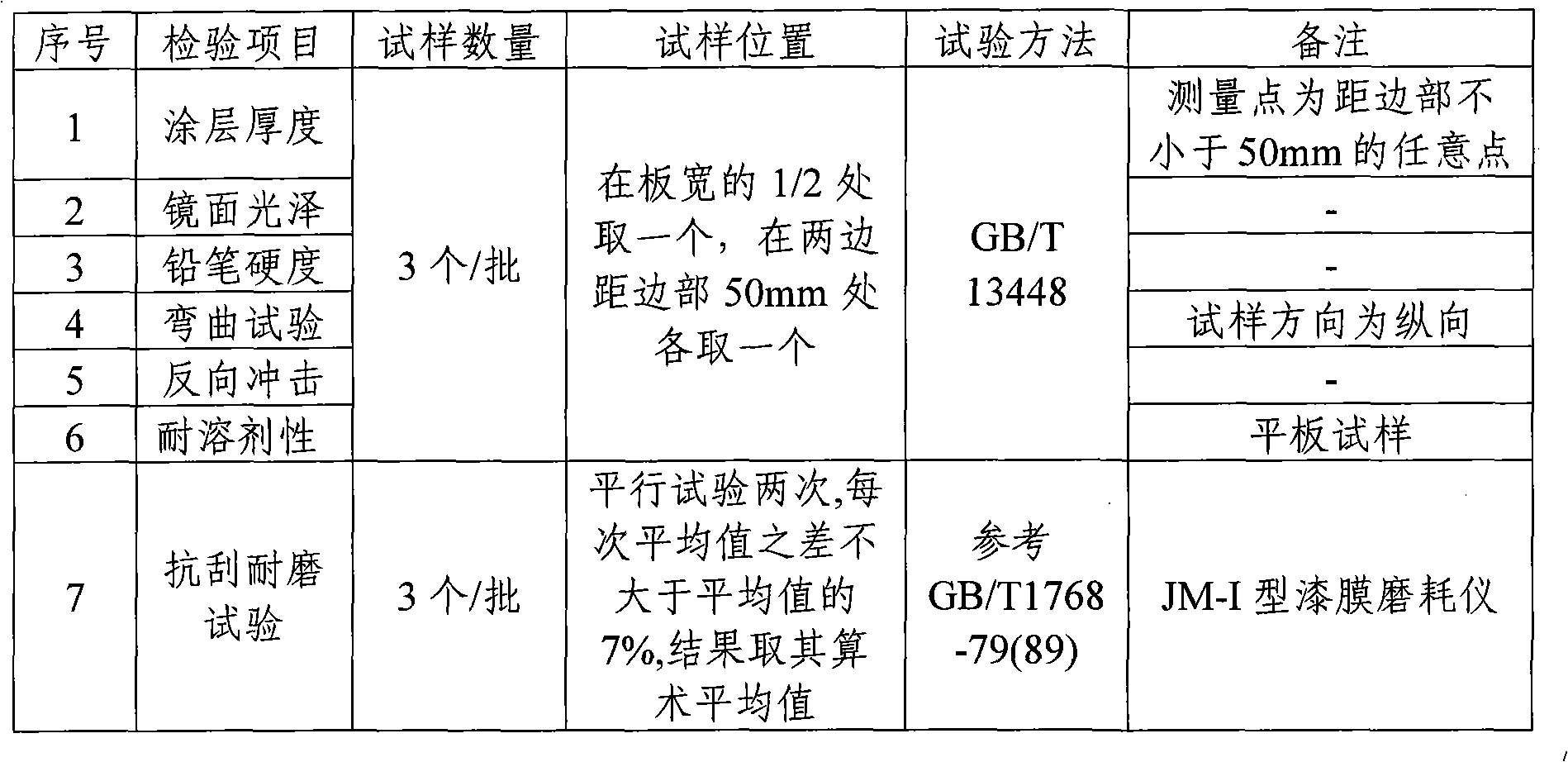

Preparation method of scratch-resistant and wear-resistant color coat steel plate

InactiveCN101664734AImprove adhesionExcellent anti-scratch and wear-resistant propertiesPretreated surfacesCoatingsSheet steelWear resistant

The invention relates to a preparation method of scratch-resistant and wear-resistant color coat steel plate, using a galvanized or aluminized substrate as a base material. The steel plate is preparedby the following steps: firstly, spraying and degreasing; secondly, grinding with a brush roller; thirdly, coating a chemical conversion film and drying; fourthly, coating primer and back coat by roller painting, and baking; and fifthly, coating finish coat by roller painting, baking, and finishing. The preparation method is simple and effective, has less equipment investment and low cost, and isespecially suitable for continuous roller painting production. The prepared scratch-resistant and wear-resistant color coat steel plate has excellent scratch and wear resistance, good bending processability and longer service life than a common color coat steel in a use environment with repeated folding and mutual friction; and the coating is not cracked or peel off under various complicated processing conditions.

Owner:SUZHOU YANGTZE NEW MATERIALS CO LTD

Water coating composition

InactiveCN101054495AHighly corrosiveImprove odorLiquid surface applicatorsEmulsion paintsCarboxyl radicalAcrylic resin

The invention provides a coating composition for pots capable of forming a coating with good bending machinability, water resistance prewhitening property and good smell. A water coating composition is characterized by containing 0.1-20 phr resol (B) and 0.1-20 phr acrylic resin (C) with acid number 100-500mgKOH / g relative to 100 phr acrylic resin modified epoxy resin (A). The resin (A) and the resin (C) are dispersed in the water medium. The acrylic resin (C) has the following necessary components: ethylene copolymer chain (1) taking acid radical polymerized monomer as monomer component and ethylene copolymer chain (2) taking carboxyl radical polymerized monomer as monomer component.

Owner:KANSAI PAINT CO LTD

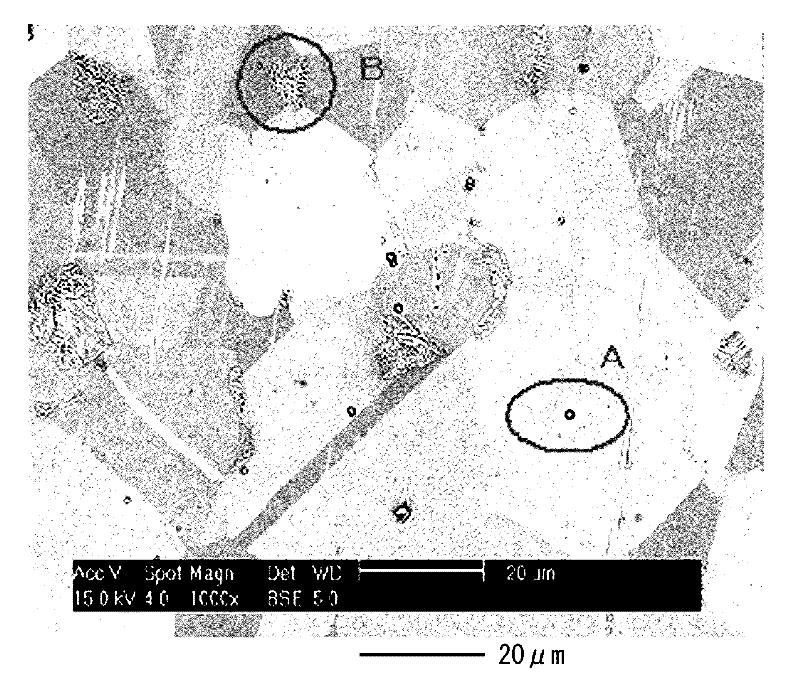

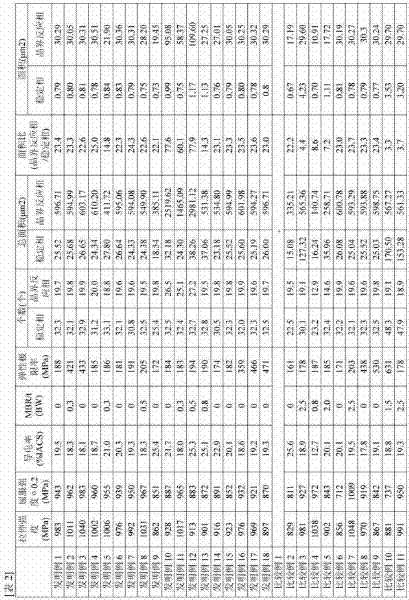

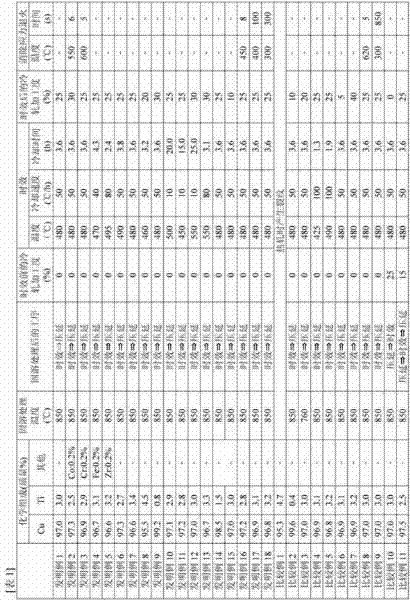

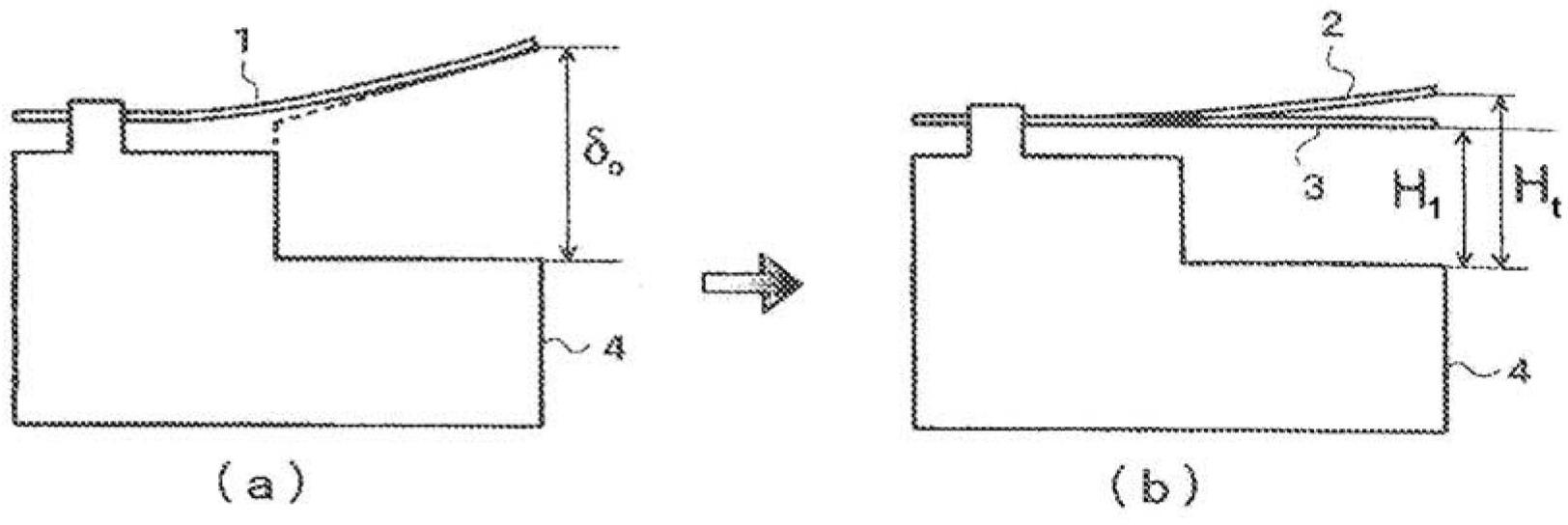

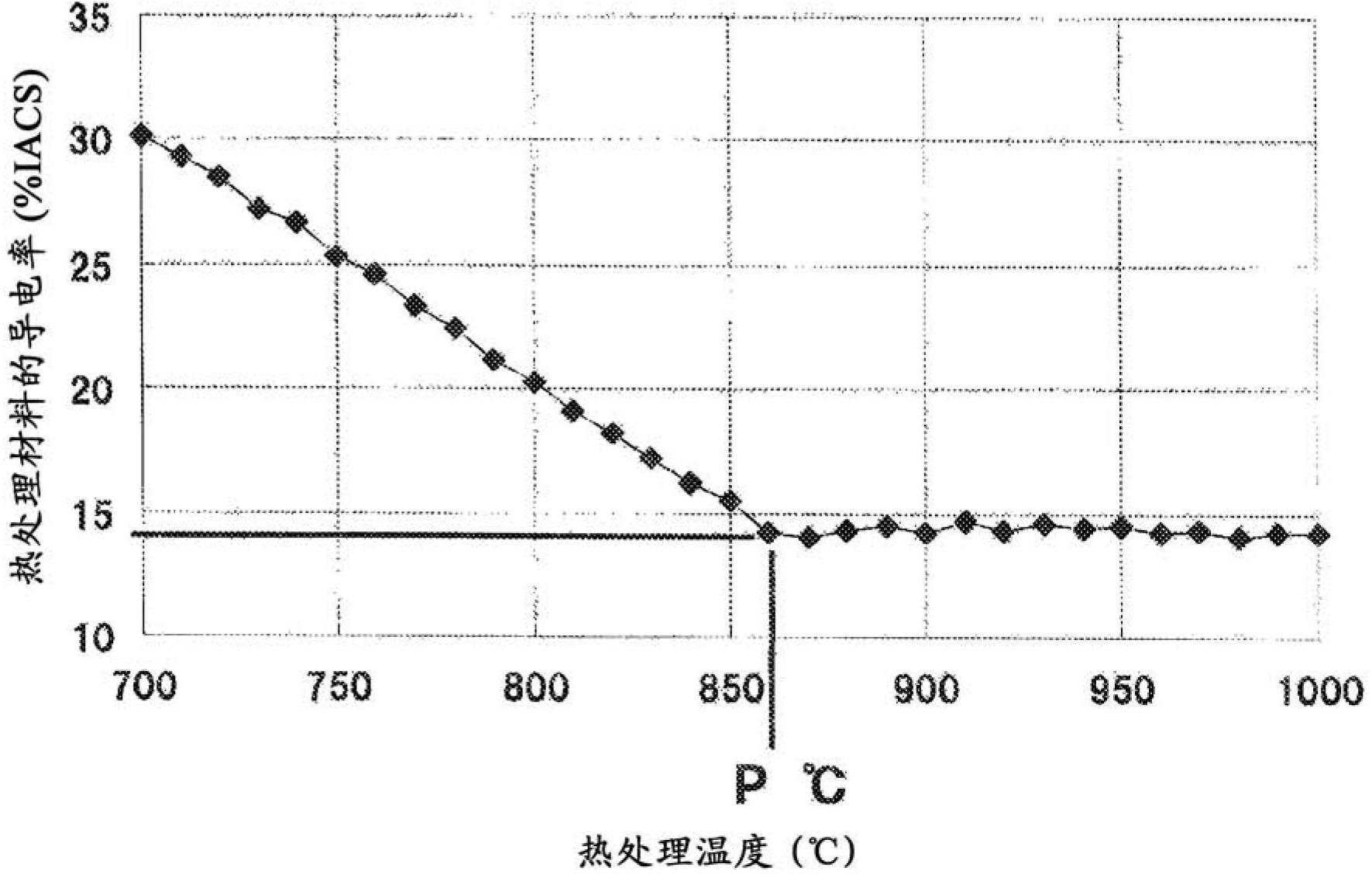

Titan copper excellent in strength, electric conductivity, bending workability and manufacturing method thereof

InactiveCN102453810AGood electrical conductivityExcellent bending workabilityConductive materialMetal rolling arrangementsTitaniumGrain boundary

The invention provides a titanium copper and its producing method. The titanium copper is excellent in strength, conductivity and bending resistance and contains 0.5-4.5 % of Ti by mass, Cu and unavoidable impurities. The area ratio of a grain boundary reaction phase with the Ti concentration thereof smaller than 8.5 % by mass to a stable phase with the Ti concentration greater than 15 % by mass, namely the area ratio of the grain boundary reaction phase to the stable phase, is more than 14. The yield strength sigma 0.2 is more than 850MPa and the conductive rate is more than 18% IACS. During the W bending test specified in JISH3130 in a direction at a right angle with respect to the rolling direction, the ratio of the minimum bending radius ( MBR, unit: mm ) without generating cracks to the plate thickness ( T, unit: mm ) is below 1.

Owner:JX NIPPON MINING & METALS CO LTD

Copper alloy sheet and process for producing same

ActiveCN102695811AExcellent bending workabilityHigh strengthSingle bars/rods/wires/strips conductorsConductive materialCrystal orientationLead frame

Provided is a copper alloy sheet which has excellent bendability and excellent strength and is suitable for use in lead frames, connectors, and terminal materials for electric / electronic appliances, connectors or terminal materials for vehicular mounting, relays, switches, and the like. Also provided is a process for producing the copper alloy sheet. The copper alloy sheet, when analyzed for crystal orientation by EBSD (electron back scatter diffraction), has a value of R defined by the equation of 1 or greater: R=([BR]+[RDW]+[W]) / ([C]+[S]+[B]) where [BR], [RDW], [W], [C], [S], and [B] respectively are the areal proportions of texture components respectively having BR orientation {362}<853>, RD-rotated-cube orientation {012}<100>, cube orientation {100}<001>, copper orientation {121}<111>, S orientation {231}<346>, and brass orientation {110}<112>. The sheet has a proof strength of 500 MPa or greater and a conductivity of 30% IACS or higher.

Owner:FURUKAWA ELECTRIC CO LTD

High-strength steel plate and method for producing same

ActiveCN102712972AExcellent bending workabilityGood welding performanceFurnace typesMetal rolling arrangementsSteel platesImpact test

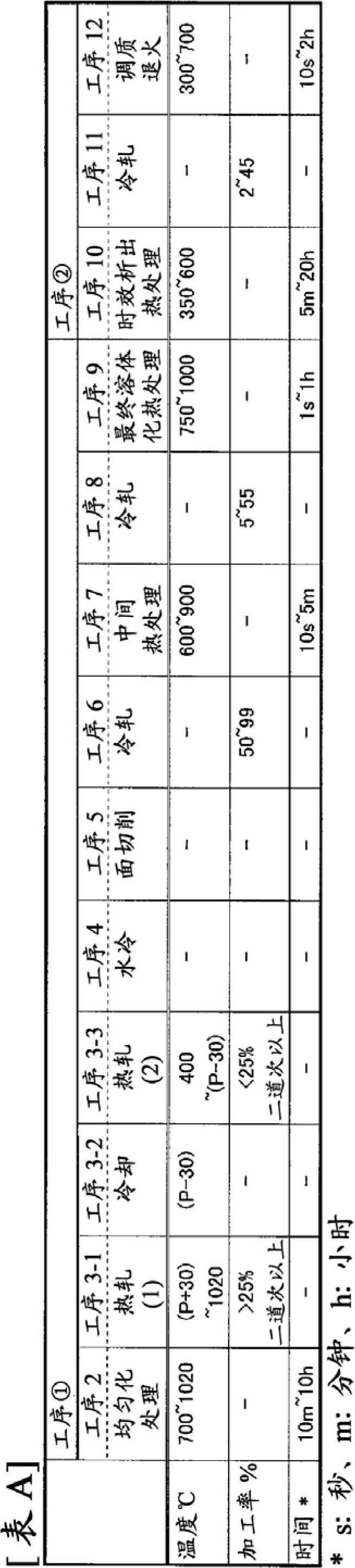

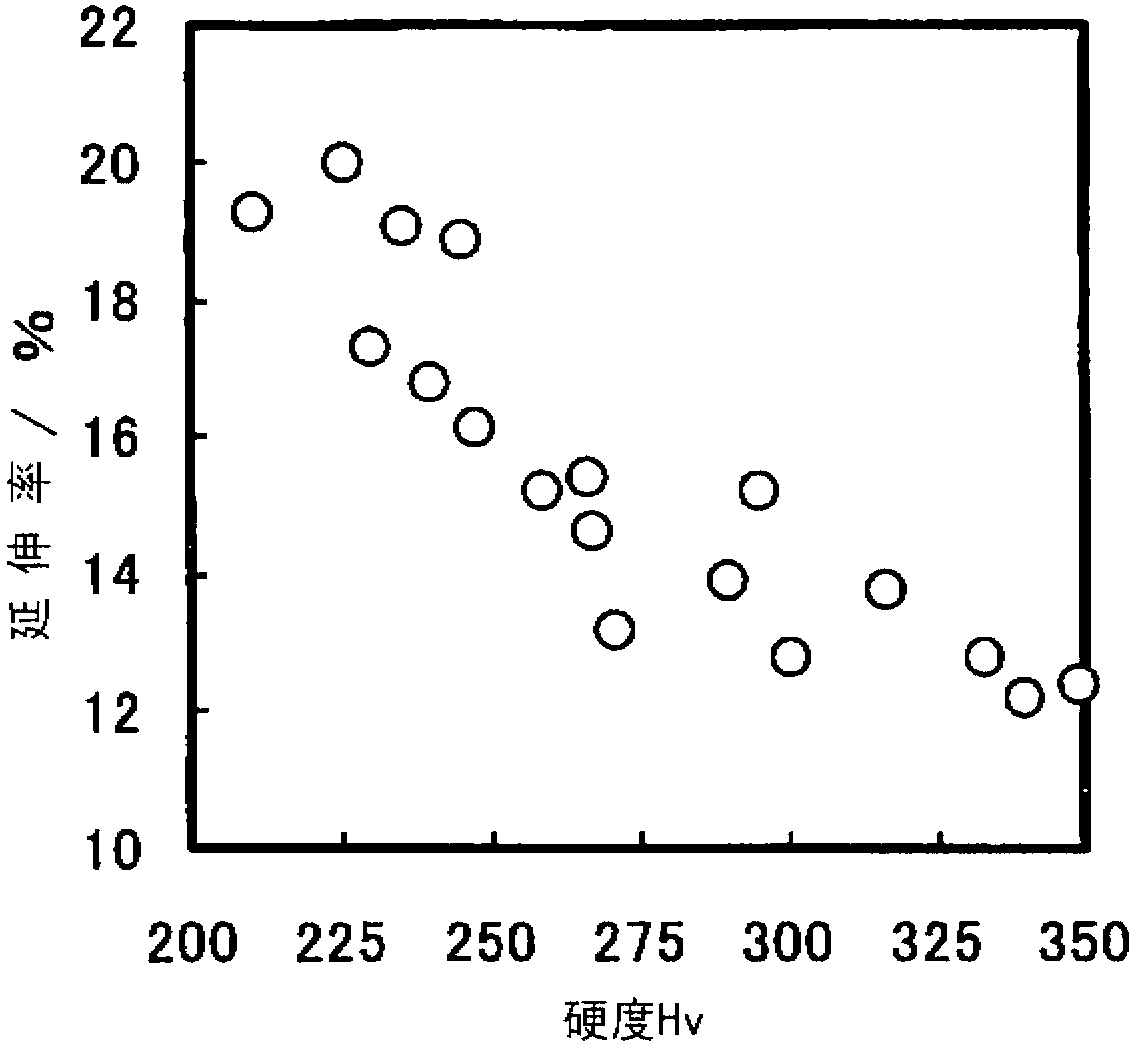

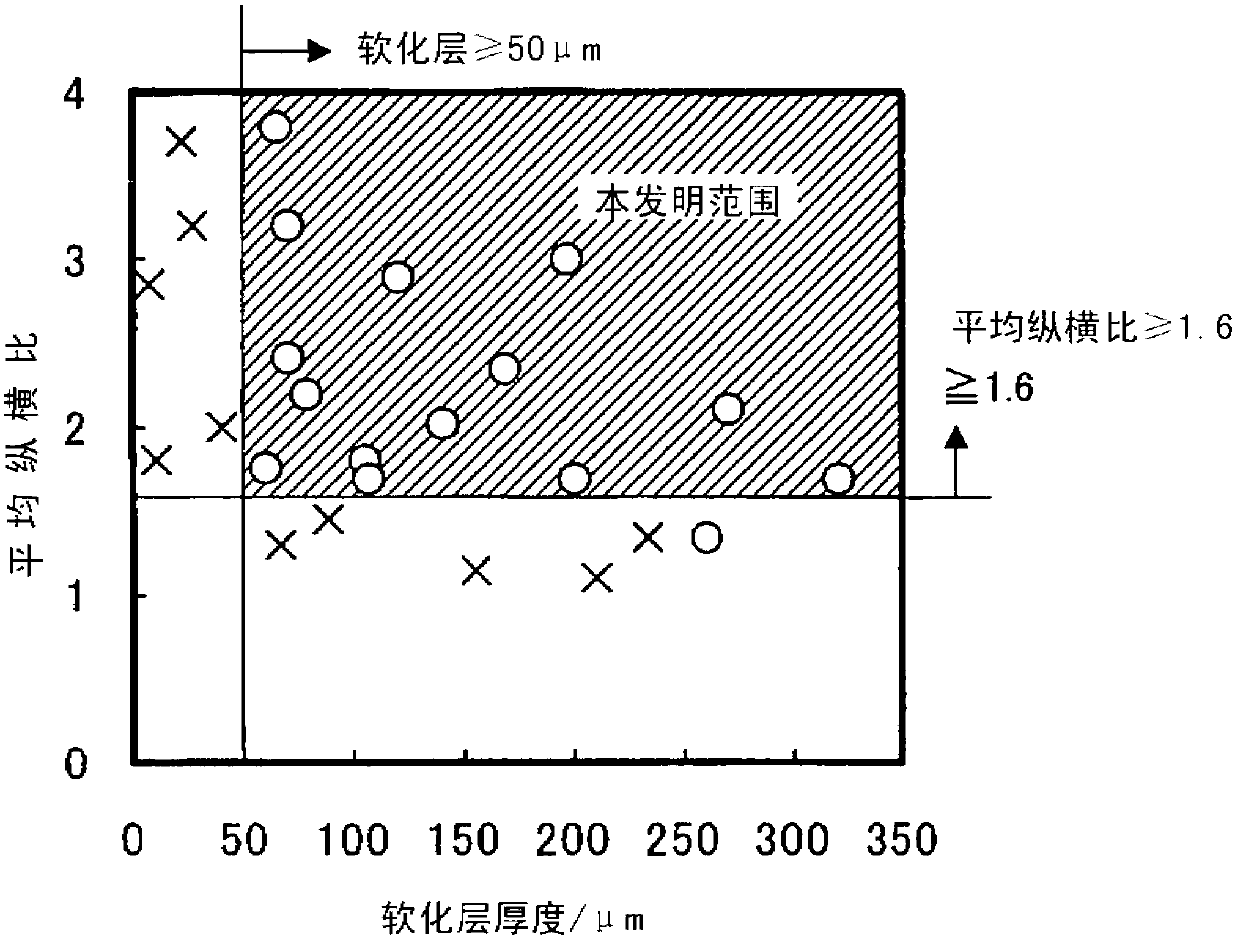

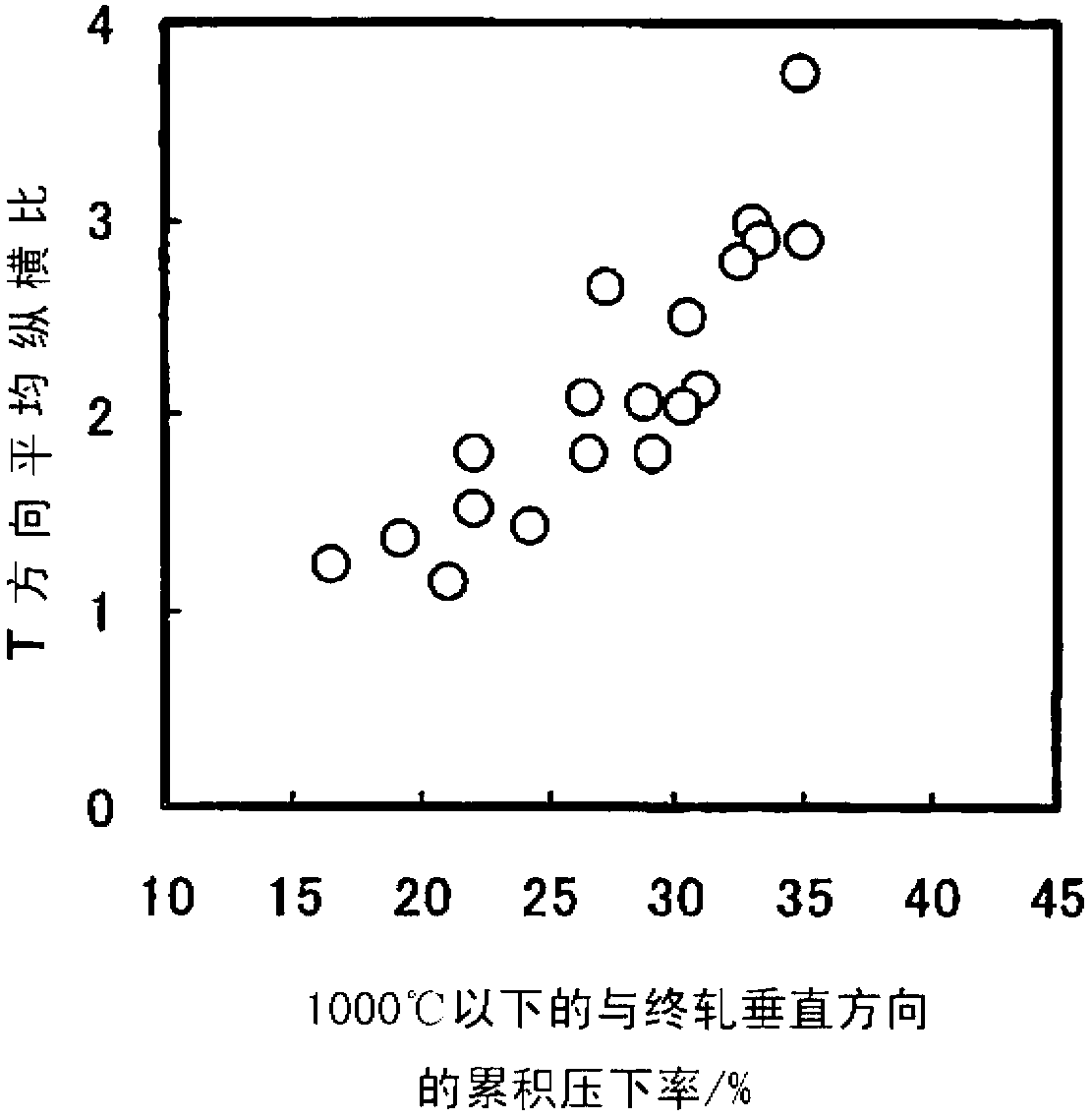

Disclosed is a high-strength steel plate having superior bendability, weldability, and toughness, with yield strength of 885 MPa or greater and average absorbed energy value of 33 J / cm2 in impact tests at -40 DEG C, and a method for producing the same. The high-strength steel plate has a composition of 0.10 - 0.18% C, greater than 0.20% to 0.80% Si, 0.20 - 1.60% Mn, 0.10 - 0.60% Mo, 0.010% - 0.050% Nb, 0.005 - 0.030% Ti, 0.01 - 0.10% Al, 0.0003 - 0.0030% B, 0.012% or less P, 0.005% or less S, 0.0060% or less N, and 0.29% or less Pcm. The high-strength steel plate also has, on the steel plate surface, a Hv 250 or less softened layer with a thickness of 50 [mu]m or greater and exceeding 3% of the steel plate thickness. Furthermore, at a position 1 / 4 of the plate thickness from the surface, the average aspect ratios of former austenite particles in the L cross-section and T cross-section are both 1.6 or greater.

Owner:NIPPON STEEL CORP

High-strength hot-rolled steel sheet and method for producing same

InactiveUS20150030880A1Excellent bending workabilityImprove solubilityHot-dipping/immersion processesFurnace typesSheet steelCarbide

The present invention provides a high-strength hot-rolled steel sheet having both excellent strength and excellent workability (particularly, bending workability), and a method of producing the same.The steel sheet of the present invention has a certain composition as well as microstructures such that an area ratio of ferrite phase is 95% or more, an average grain size of the ferrite phase is 8 μm or less, and carbides in grains of the ferrite phase have an average particle size of less than 10 nm. The steel sheet of the present invention also has a tensile strength of 980 MPa or more.

Owner:JFE STEEL CORP

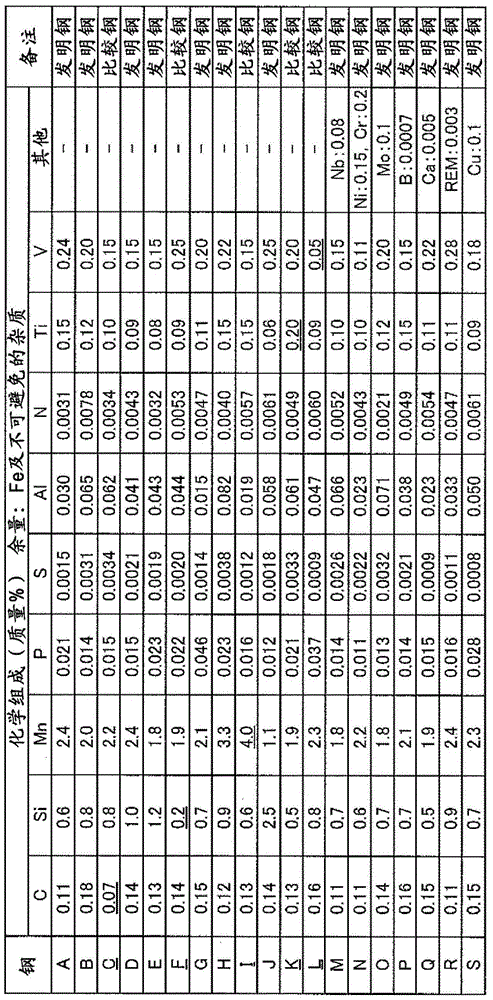

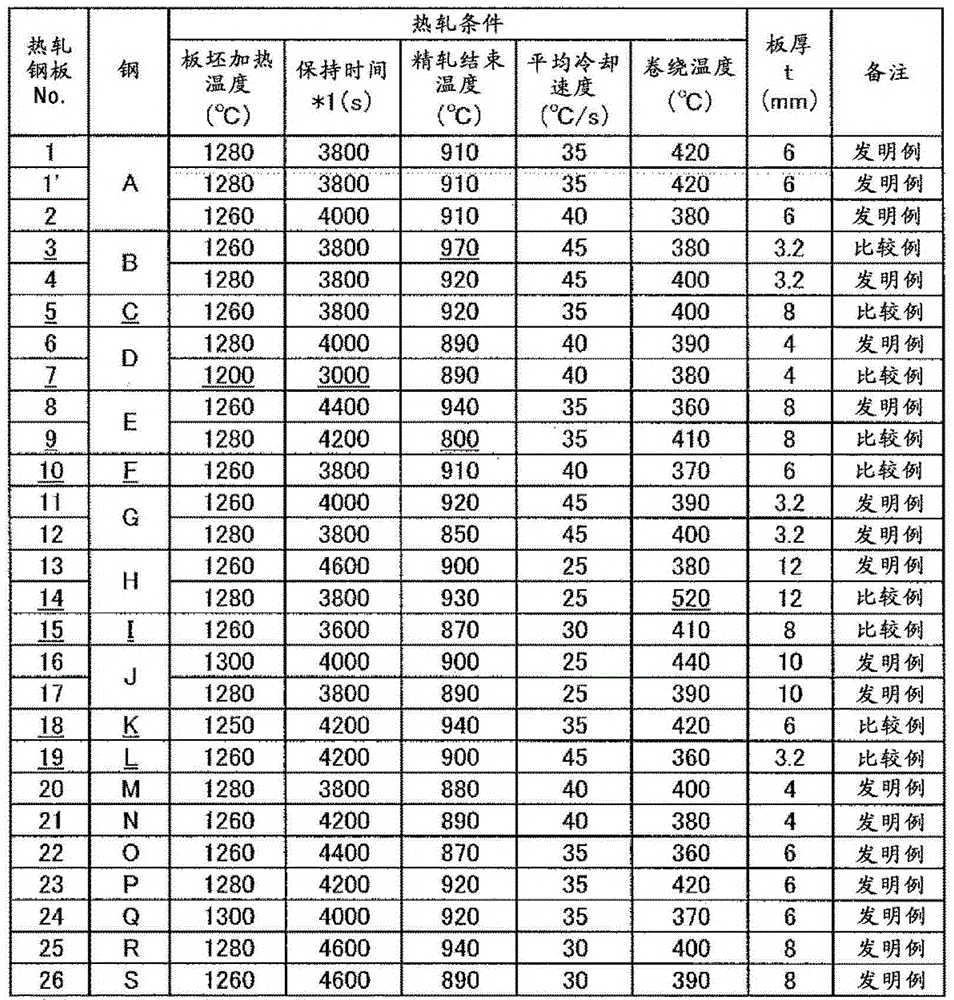

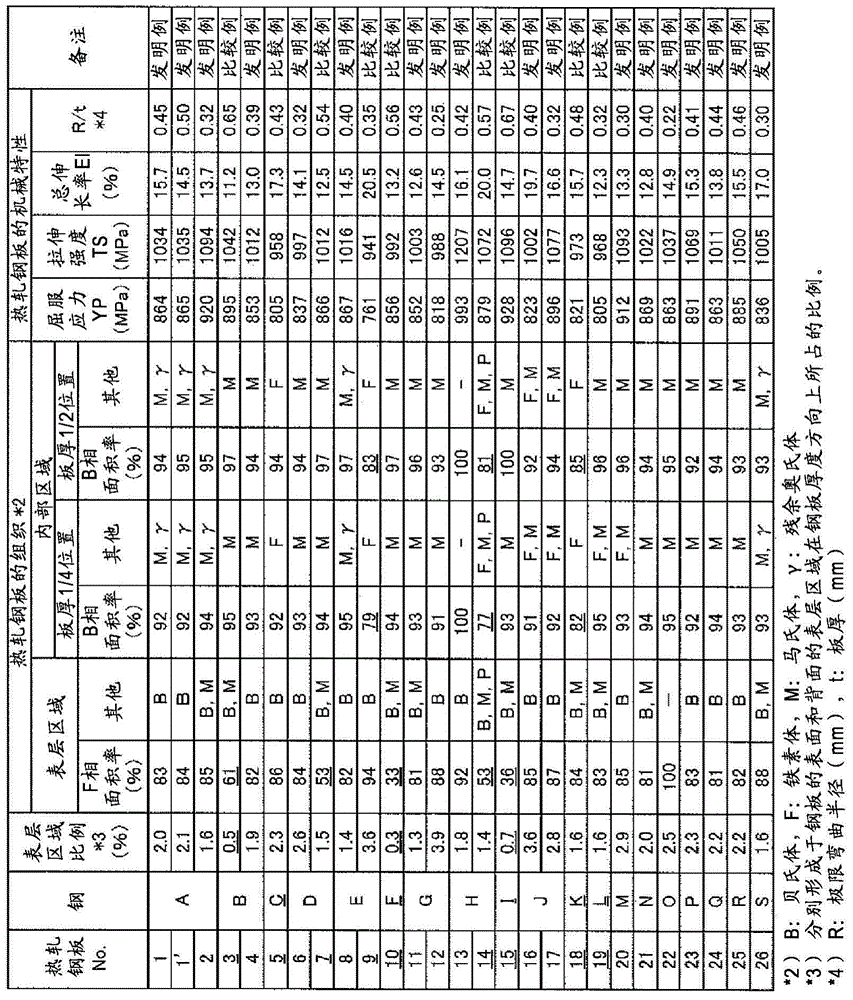

High strength hot rolled steel sheet and method for producing same

ActiveCN105143486AHigh tensile strengthExcellent bending workabilityFurnace typesMetal rolling arrangementsSurface layerUltimate tensile strength

Provided are: a high strength hot rolled steel sheet having a tensile strength of 980 MPa or more and excellent bending workability; and a method for producing the high strength hot rolled steel sheet. This high strength hot rolled steel sheet has a composition that contains more than 0.1% but 0.2% or less of C, from 0.5% to 3.0% (inclusive) of Si, from 1.0% to 3.5% (inclusive) of Mn, 0.05% or less of P, 0.004% or less of S, 0.10% or less of Al, 0.008% or less of N, from 0.05% to 0.15% (inclusive) of Ti and more than 0.10% but 0.30% or less of V with the balance made up of Fe and unavoidable impurities. This high strength hot rolled steel sheet is composed of surface layer regions having a structure wherein a ferrite phase forms the main phase and an inner region having a structure wherein a bainite phase forms the main phase. By setting the ratios of the surface layer regions in the thickness direction of the steel sheet to 1.0-5.0% (inclusive) of the total sheet thickness respectively from the front and back surfaces of the steel sheet, this high strength hot rolled steel sheet achieves a tensile strength (TS) of 980 MPa or more.

Owner:JFE STEEL CORP

Uniform cooling fin and production method thereof

ActiveCN103118521AImprove performanceIngenious structural designFilm/foil adhesivesCooling/ventilation/heating modificationsMetal sheetGraphite

The invention discloses a uniform cooling fin, and further discloses a production method of the uniform cooling fin. The production method includes preparing a high thermal-conducting metal sheet and low thermal-conducting viscose; evenly coating a surface of the high thermal-conducting metal sheet with the low thermal-conducting viscose; and then roasting and foaming to form a uniform cooling fin. The uniform cooling fin is clever and reasonable in structure design with creative combination of the high thermal-conducting metal sheet and the low thermal-conducting viscose. On the basis of guaranteeing quick heat dissipation, the hotpoint areas are eliminated to guarantee comfort in use. The uniform cooling fin is also better in bending work property, convenient to process into optional sizes, shapes and structure, and wide in application range. Affection on appearance and use caused by cracking and breaking conventional graphite fins is avoided effectively and product quality is guaranteed. By the production method, the uniform cooling fin can be produced quickly, producing period is reduced greatly, and producing efficiency is improved. The whole procedure is compact, easy to realize and low in cost; and quality of products is guaranteed efficiently.

Owner:HENGSHAN JIACHENG NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com