Water coating composition

A technology of water-based coatings and compositions, which is applied in the direction of epoxy resin coatings, coatings, and devices for coating liquids on the surface, etc., which can solve problems such as bending processability, water whitening resistance, acid resistance, adhesion, odor, etc. No problem, excellent smell, improved bending processability, excellent corrosion resistance of contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

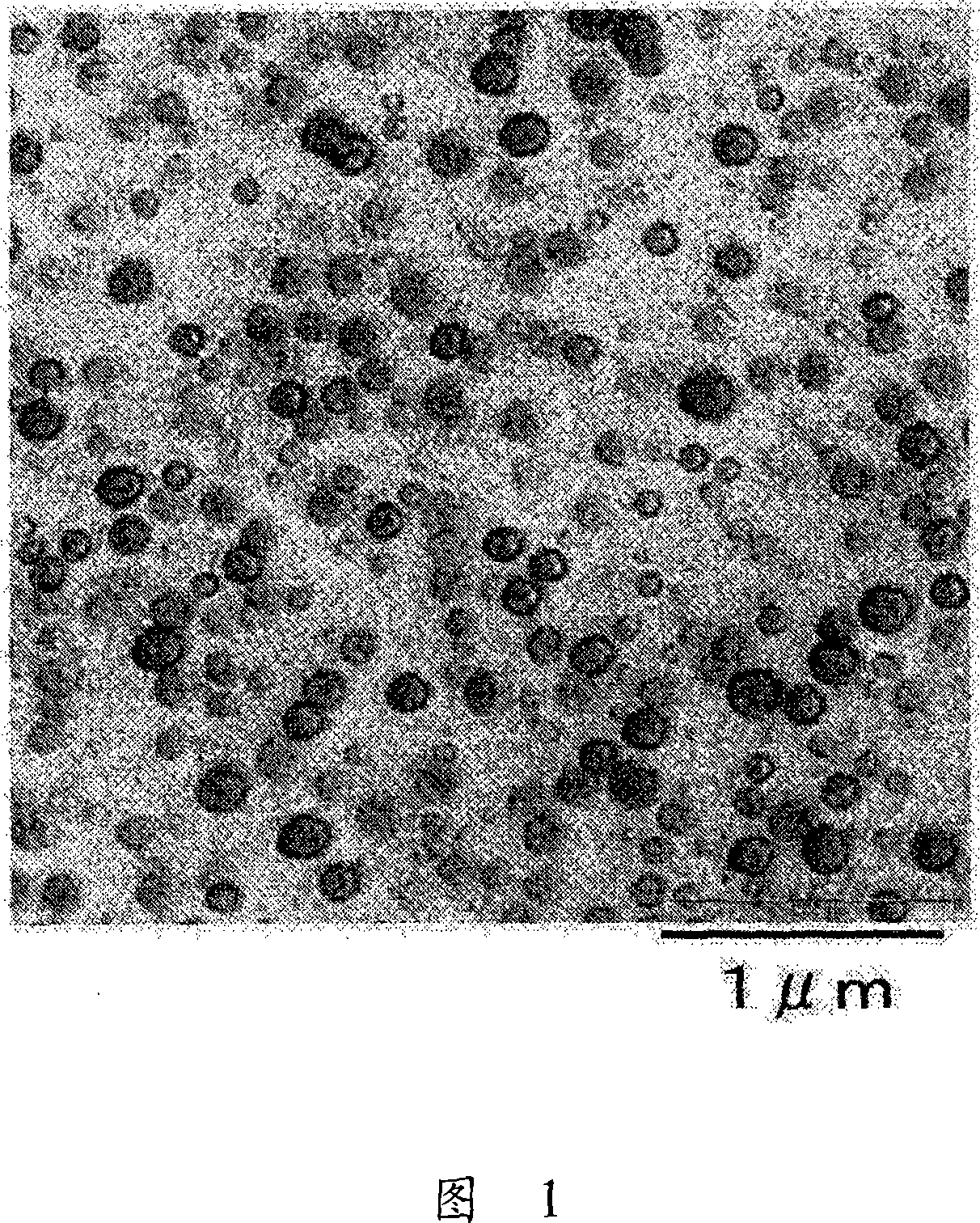

Image

Examples

manufacture example 1

[0151] Production Example 1: Production of Epoxy Resin Solution (a1)

[0152] Add 558 parts of Epikote 828EL (Note 3), 329 parts of bisphenol A, and 0.6 part of tetrabutylammonium bromide into a four-necked flask equipped with a reflux tube, a thermometer, and a stirrer, and react at 160°C under a nitrogen stream. The reaction was followed by an epoxy equivalent, and the reaction was carried out for about 5 hours to obtain a bisphenol A epoxy resin having a number average molecular weight of about 11,000 and an epoxy equivalent of about 8,000.

[0153] (Note 3) Epikote 828EL: manufactured by Japan Epoxy Resins Co., Ltd., bisphenol A type epoxy resin, epoxy equivalent about 190, molecular weight about 350

manufacture example 2

[0154] Production Example 2: Production of carboxyl group-containing acrylic resin solution (a2)

[0155] Add 882 parts of n-butanol to a four-necked flask equipped with a reflux tube, a thermometer, a dropping funnel, and a stirrer, and mix 180 parts of methacrylic acid, 240 parts of styrene, 180 parts of ethyl acrylate, and 18 parts of 2-ethyl peroxide. The mixture of tert-butyl hexanoate was heated to 100°C under a stream of nitrogen gas and added dropwise from the dropping funnel in about 3 hours, then continued to stir at the same temperature for 2 hours after the dropwise addition, and then cooled to obtain a solid component of 40% acrylic resin solution. The resin acid value of the obtained resin (solid content) was 196 mgKOH / g, and the number average molecular weight was about 19000.

manufacture example 3

[0156] Production Example 3: Production of Acrylic Modified Epoxy Resin Dispersion (A)

[0157] Add 80 parts of bisphenol A type epoxy resins (solid content) obtained in manufacture example 1, 40% acrylic resin solution ( 20 parts of solid content), 33 parts of diethylene glycol monobutyl ether, heated to 100°C to dissolve, then added 2 parts of N,N-dimethylaminoethanol, reacted for about 2 hours, then added 3 parts of N, The N-dimethylaminoethanol reaction was continued for 20 minutes. Then, 165 parts of deionized water was dripped over 1 hour for water dispersion to obtain an acrylic modified epoxy resin dispersion having an acid value of 34 mgKOH / g and a solid content of 30%.

[0158] [Manufacture of resole phenolic resin (B)]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com