Titan copper excellent in strength, electric conductivity, bending workability and manufacturing method thereof

A manufacturing method and technology of titanium-copper, applied in conductive materials, conductive materials, conductors, etc., can solve problems such as poor conductivity of titanium-copper, and achieve the effect of excellent bending workability and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

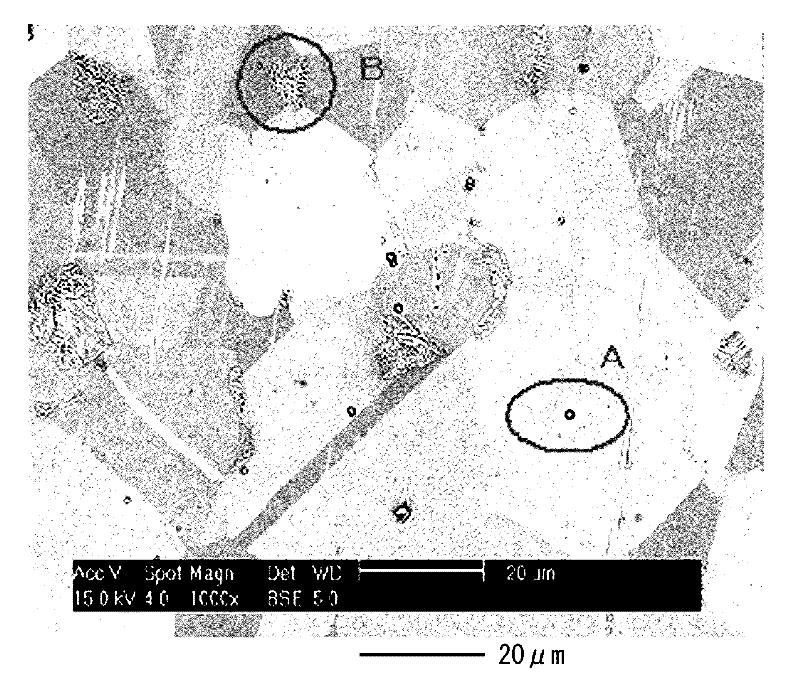

Image

Examples

Embodiment

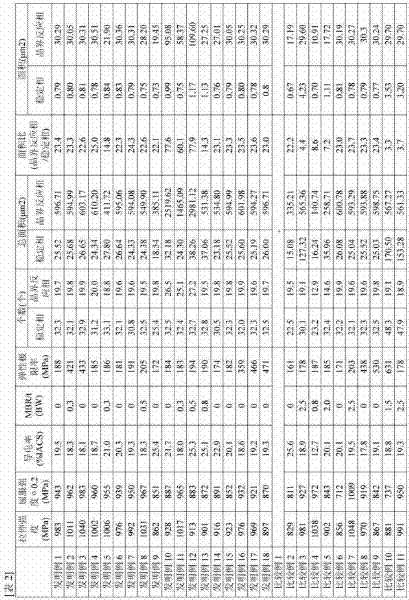

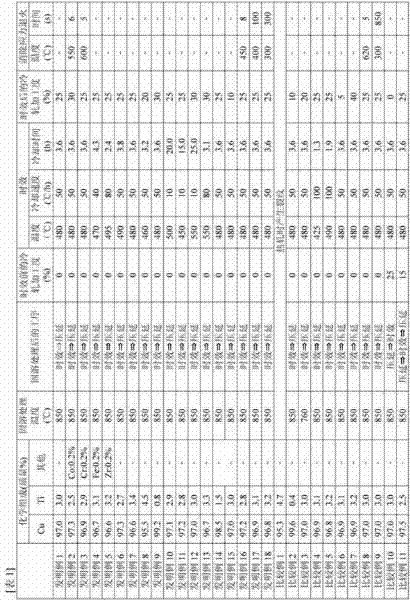

[0056] Using electrolytic copper as raw material, cast various ingots (width 60mm×thickness 30mm) shown in Table 1 with a high-frequency vacuum melting furnace, hot-roll at 850°C until the thickness is 8mm, and scrape the oxide scale on the surface After that, cold rolling is performed. After that, solution treatment was performed at the temperature shown in Table 1. Furthermore, the cooling rate and time from the aging temperature (maximum attained temperature) to 300°C were set as shown in Table 1. After aging treatment, cold rolling after aging was carried out at the working degree shown in Table 1, so that the final plate thickness 0.1mm.

[0057] Evaluation of various characteristics was performed on each titanium-copper sample obtained as above. Yield strength σ0.2 was measured using a tensile tester according to JIS Z2241. The electrical conductivity was measured in accordance with JIS H0505. Elasticity (elastic limit value) was measured in accordance with JIS H3130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com