Copper alloy, copper alloy plate, and process for producing the same

A technology of copper alloy plates and copper alloys, applied in the field of copper alloy poles and its manufacture, and copper alloys, can solve the problems of insufficient bending workability and punching and shearing properties, and achieve excellent bending workability, excellent punching and shearing properties, Excellent bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

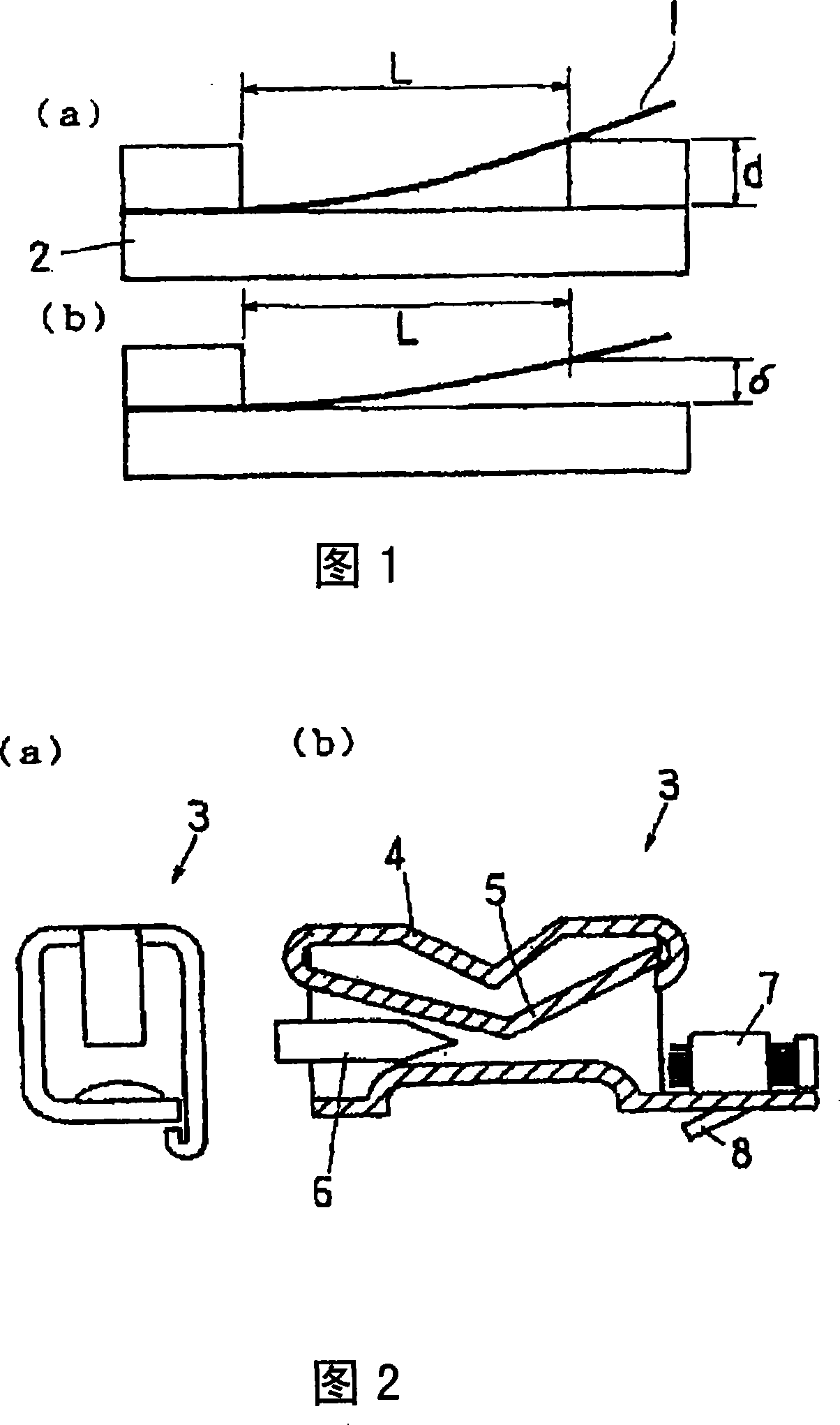

Image

Examples

Embodiment approach 1

[0046] (composition of copper alloy)

[0047] First, the component composition of the copper alloy of the present invention will be described below. In the present invention, the composition of the copper alloy is a Cu-Ni-Sn-P alloy, and as a premise, as mentioned above, it is possible to cast an ingot in a shaft furnace, and because of its high productivity, it is possible to realize a substantial cost reduction. Chemicalized Cu-Ni-Sn-P alloys.

[0048] Then, in order to be excellent in the high stress relaxation resistance characteristic in the direction perpendicular to the rolling direction required as a connecting element such as an automotive terminal / connector, and also to be excellent in bending characteristics, electrical conductivity, and strength, copper alloys Basically, Ni: 0.1 to 3.0%, Sn: 0.01 to 3.0%, and P: 0.01 to 0.3% are respectively contained, and the balance is composed of copper and unavoidable impurities. In addition, the % indication of content of ea...

Embodiment approach 2

[0095] Hereinafter, the copper alloy sheet according to Embodiment 2 of the present invention will be described. First, the composition of the copper alloy according to Embodiment 2 of the present invention will be described.

[0096] Ni is an element that is dissolved in a copper alloy to strengthen the stress relaxation resistance, and is an element that improves the strength. However, when the content is less than 0.4%, there is no such effect, and if it exceeds 1.6%, intermetallic compounds are easily precipitated with P added at the same time, so that solid-solution Ni decreases, and the stress relaxation resistance characteristic decreases. Therefore, the content is 0.4 to 1.6%. More preferably, it is the range of 0.7-0.9%.

[0097]Sn is a solid solution in the copper alloy, and is an element that improves the strength by work hardening. Also in this alloy system is an element that contributes to heat resistance. In the copper alloy sheet of the present invention, in...

Embodiment 1

[0121] Examples of the present invention are described below. Various copper alloy sheets of Cu-Ni-Sn-P alloys with different states of Ni compounds in the structure were produced, and properties such as strength, electrical conductivity, and stress relaxation resistance were evaluated.

[0122] Specifically, copper alloys with chemical compositions shown in Table 1 were melted in a centerless induction furnace, and then ingots were cast by semi-continuous casting to obtain ingots with a thickness of 70 mm x width 200 mm x length 500 mm. The respective ingots were collectively rolled under the following conditions to produce copper alloy thin plates. The surface of each ingot was end-cut and heated, then hot-rolled to form a 16-mm-thick plate, and rapidly cooled in water from a temperature of 650° C. or higher.

[0123] [Table 1]

[0124] Area

Minute

combine

gold

make up

No

Chemical composition of copper alloy plate (remainder C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com