Uniform cooling fin and production method thereof

A technology for uniform heat dissipation and heat dissipation components, which is used in cooling/ventilation/heating transformation, film/flaky adhesives, adhesives, etc. problems, to achieve the effect of fewer manufacturing processes, shortened production cycle, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

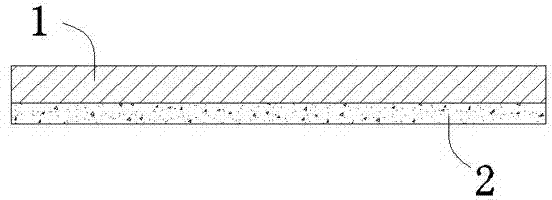

[0019] Example: see figure 1 , the embodiment of the present invention provides a uniform heat sink, which includes a high thermal conductivity metal sheet 1 with a thermal conductivity value greater than 100W / mK and a low thermal conductivity adhesive layer 2 with a thermal conductivity value less than 0.2W / mK, the low thermal conductivity adhesive layer 2 and The high thermal conductivity metal sheets 1 are bonded together. The thickness of the high thermal conductivity metal sheet 1 is 0.001-0.2mm, and the thickness of the low thermal conductivity adhesive layer 2 is 0.003-0.15mm. The high thermal conductivity metal sheet 1 is a sheet body made of one of copper, aluminum, gold, silver or their alloy materials. The composition mass percentage of the low thermal conductivity adhesive layer 2 is: 1%-99% of acrylic glue and / or viscous silica gel, and 1%-99% of foaming resin.

[0020] The structure design of the present invention is ingenious and reasonable, innovatively combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com