Preparation method of scratch-resistant and wear-resistant color coat steel plate

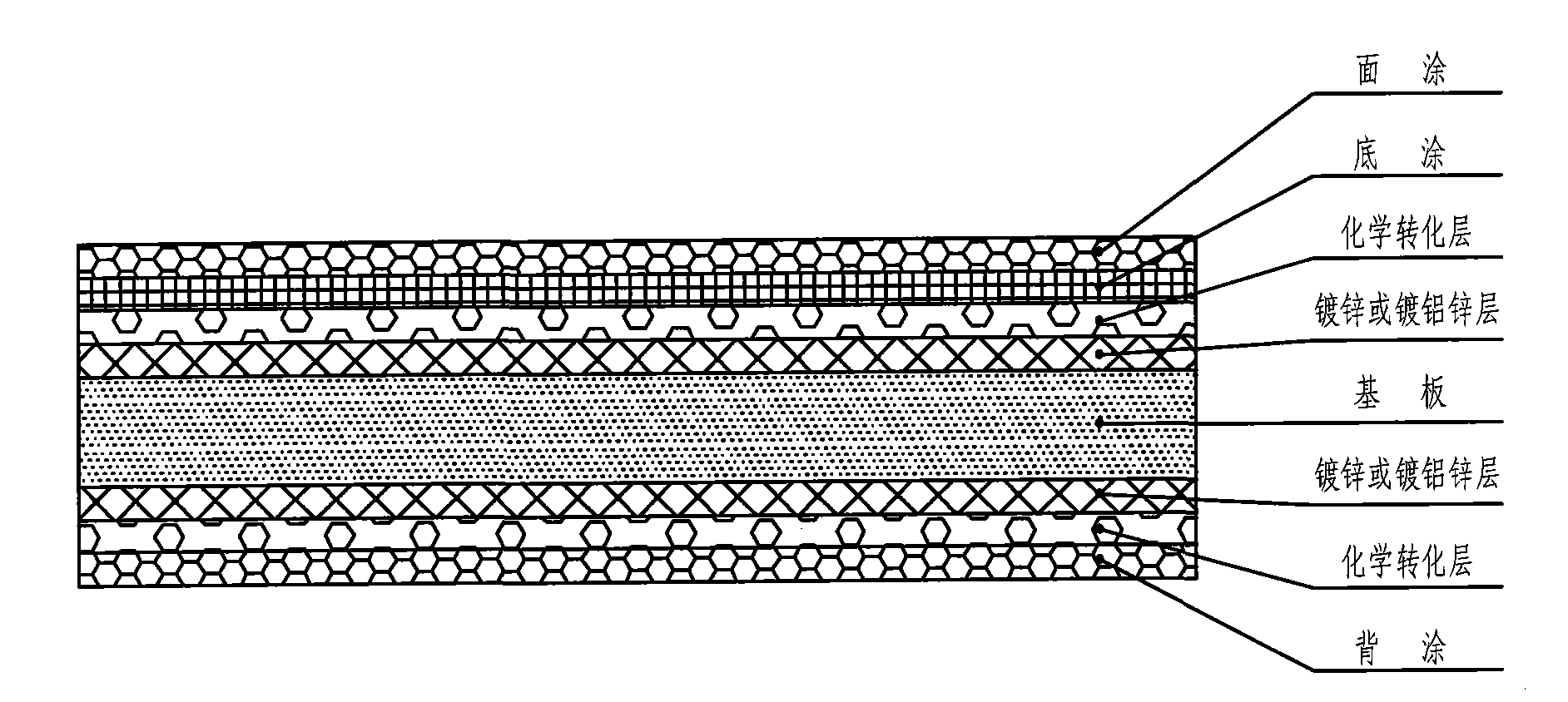

A technology for color-coated steel plates and substrates, applied in coatings, devices for applying liquid to surfaces, pre-treatment surfaces, etc., can solve the problems of cracking and exploding paint films, poor T-bending performance, and easy damage to paint films. , to achieve the effect of improving adhesion, good bending performance and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

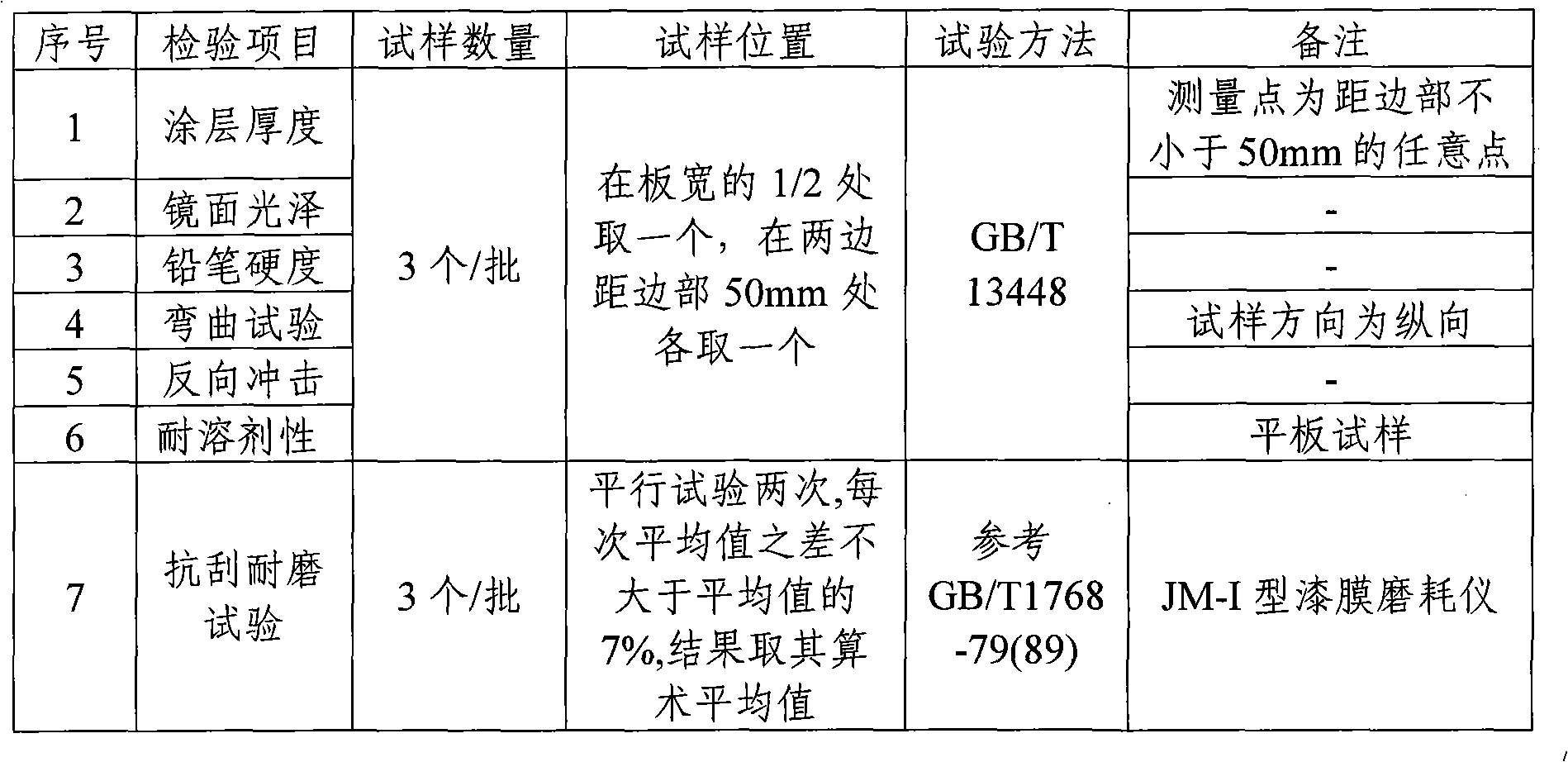

Examples

Embodiment 1

[0039] Using galvanized substrate as the base material, the continuous automatic production process of scratch-resistant and wear-resistant color-coated steel sheets is as follows:

[0040] Unbooking→Spray degreasing I→Brush roller grinding→Degreasing II→Three washings→Chemical conversion coating→Drying→Primer coating / back coating→Baking→Cooling I→Top coating→Baking→Cooling II→Inspection→Collection roll.

[0041] Spray degreasing I adopts alkaline degreasing method, the main components are sodium hydroxide, sodium carbonate, trisodium phosphate, sodium silicate, etc. and surfactants, the temperature of the bath is controlled at 55±5°C; cm 2 ;The effective spraying time is 10 seconds;

[0042] Among the three washings, softened water is used for the first and second washings, and deionized water is used for the third washing to ensure the cleanliness of the substrate surface;

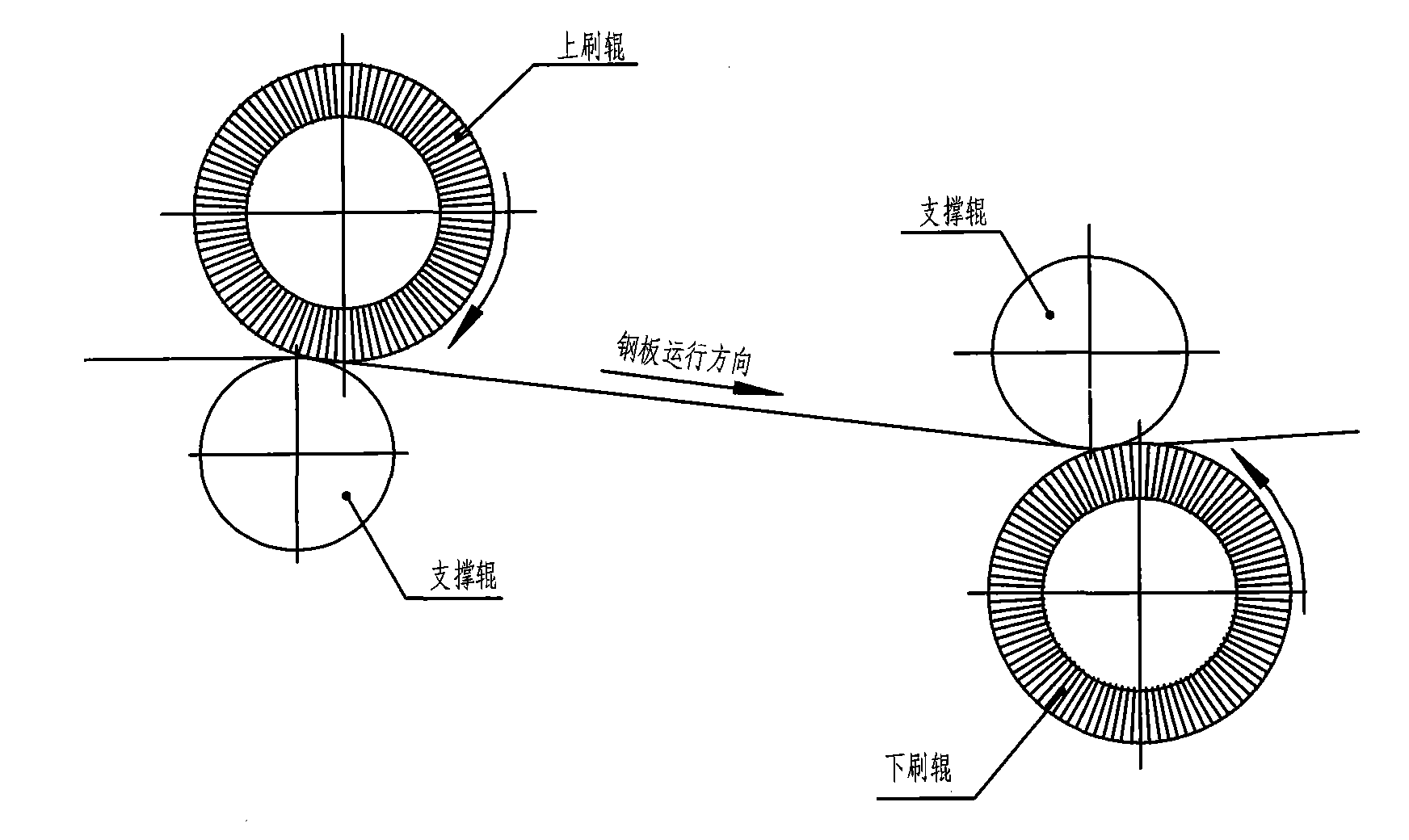

[0043] Brush roller grinding is to place the brush roller on the surface of the galvanized or galv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com