Abrasion-resistant steel sheet having excellent processability, and method for production thereof

A technology of excellent workability, wear-resistant steel plate, applied in the field of wear-resistant steel plate and its manufacturing, can solve the problems of not necessarily bending workability, improvement, manufacturing period, manufacturing cost, etc., to reduce heat treatment costs and improve bending processing. performance, shortening the manufacturing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

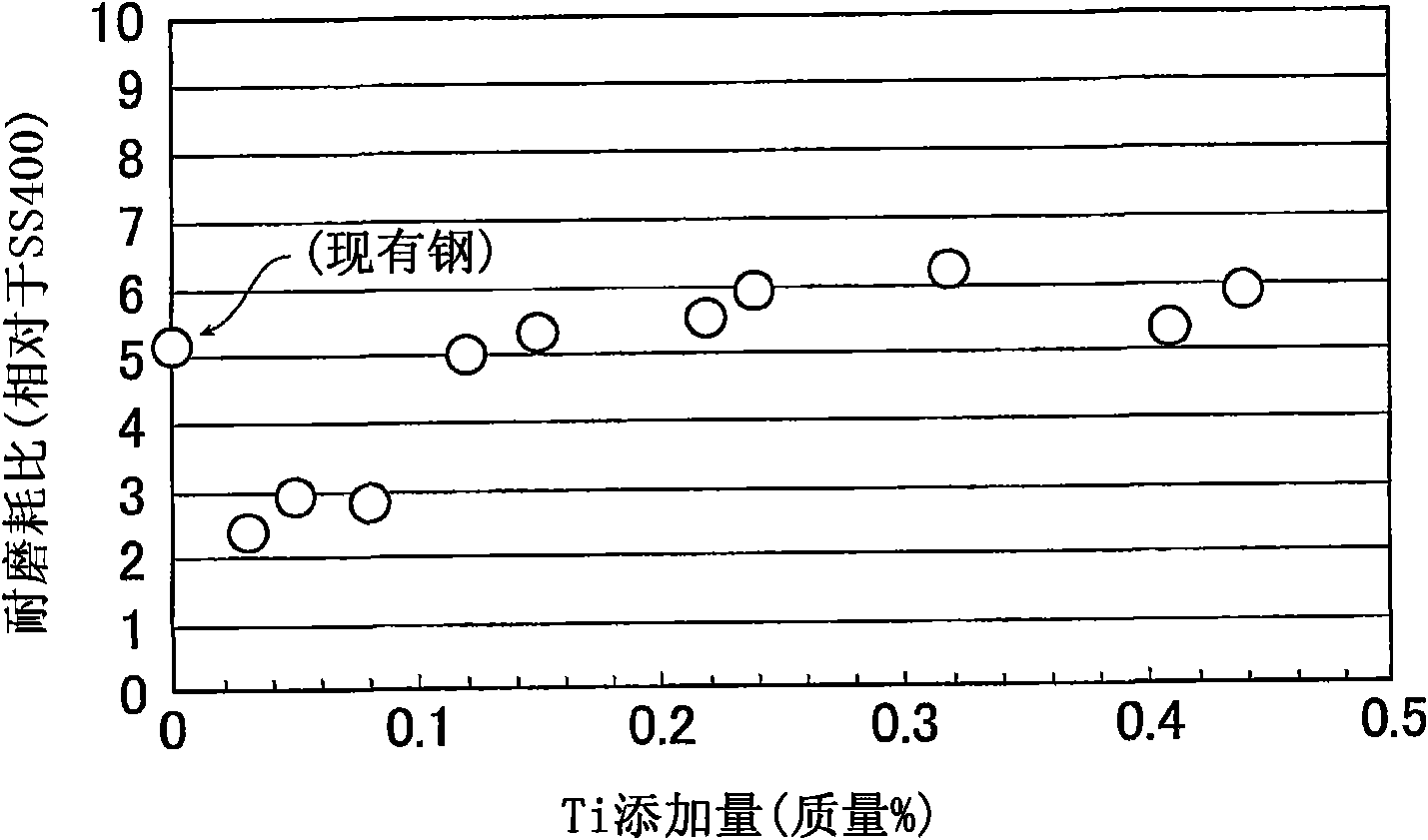

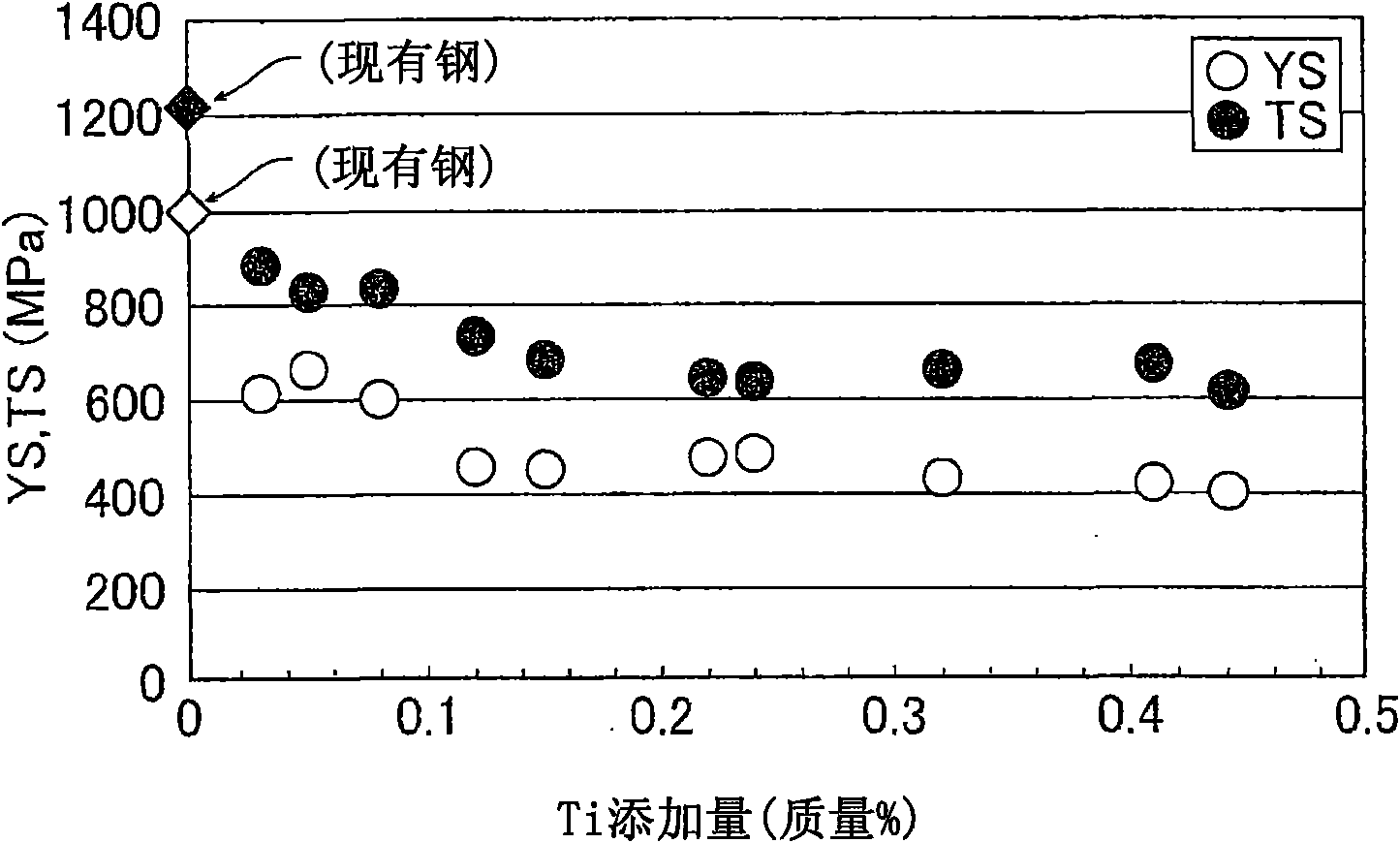

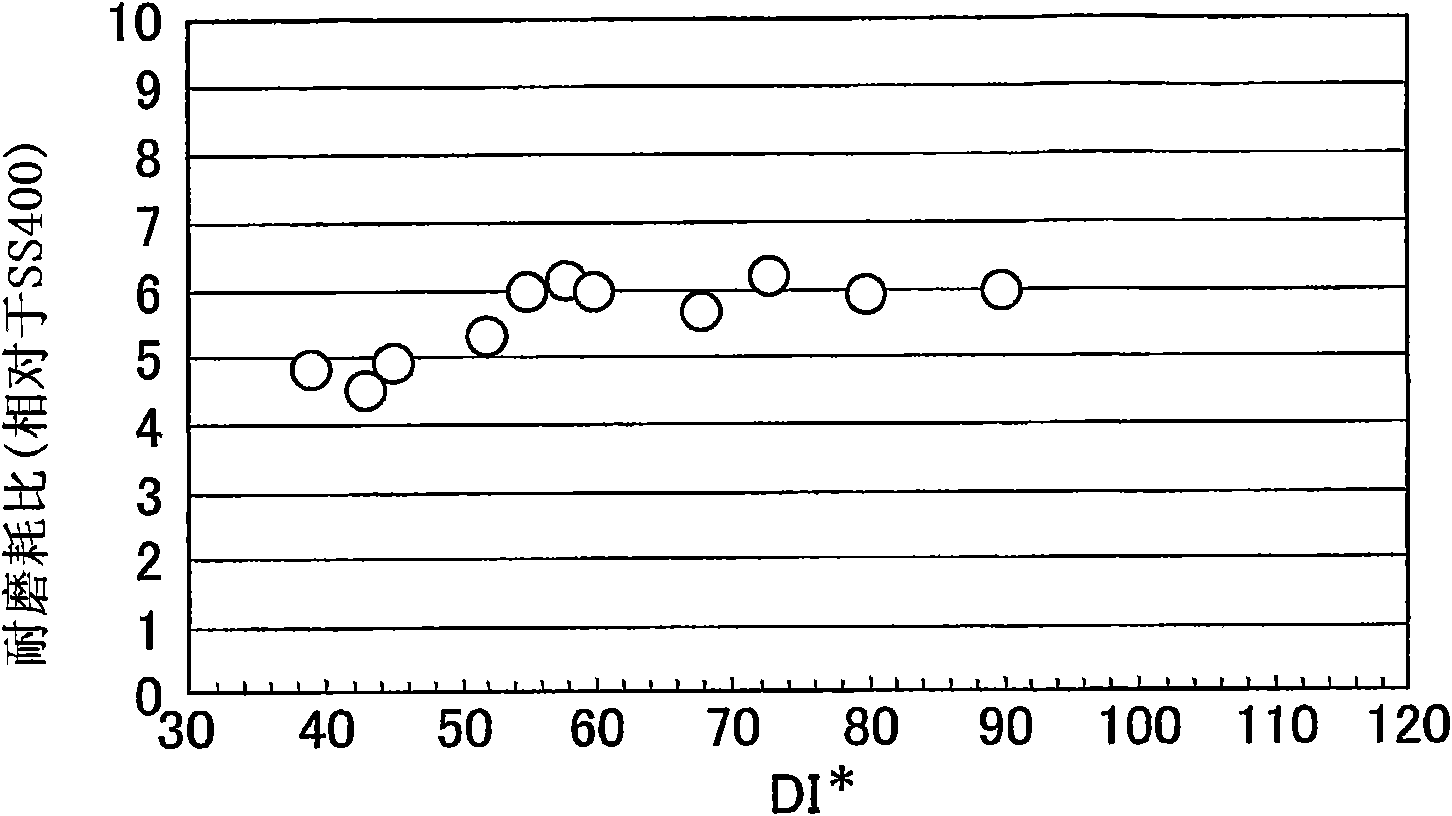

[0095] The molten steel with the composition shown in Table 1 is melted in a vacuum melting furnace to form a small steel ingot (50kg) (steel raw material), and then heated to 1050-1250°C for hot rolling to make it into a steel plate with a thickness of 6-100mm. Test plate. Microstructure observation, tensile test (tensile test), abrasion test, Charpy impact test (Charpy impact test), and bending test (bend test) were performed on each test steel plate.

[0096] (organization observation)

[0097] After grinding the test piece for tissue observation, it was etched with nital, and the structure was identified using an optical microscope (magnification ratio: 400 times) at a position 1 mm below the surface layer, and ferrite grains were measured. diameter (ferrite grain diameter) and the size and number of hard phases. In addition, in the observation field of view, the structure accounting for more than 90% is used as the matrix phase, and the size of the hard phase is the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com