High-strength steel plate and method for producing same

A technology of high-strength steel plate and manufacturing method, applied in the direction of manufacturing tools, metal rolling, furnace type, etc., can solve the problems of economical problems, insufficient meeting of strong needs, low productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

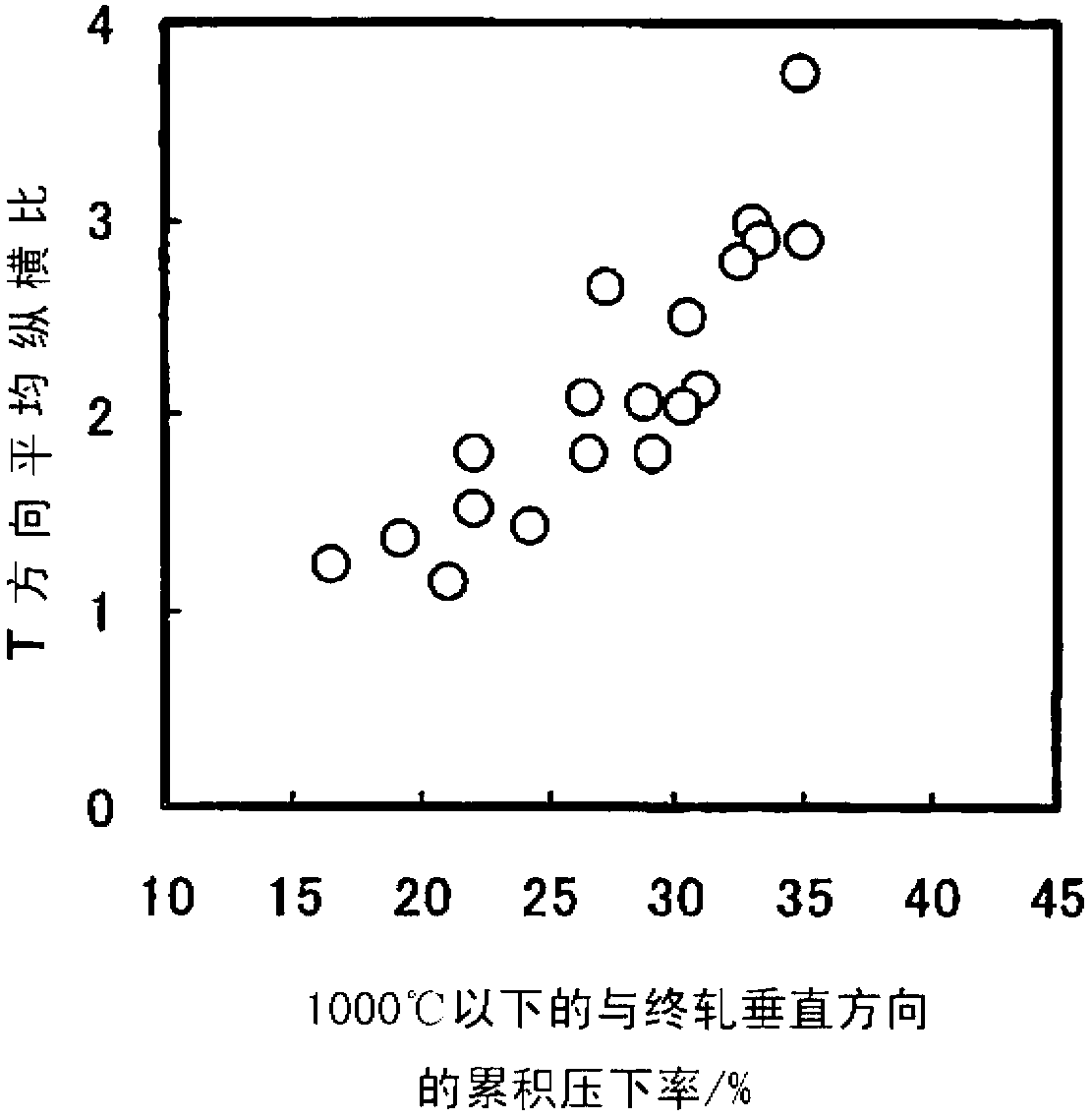

[0084] The steels A to AI having the composition shown in Table 1 were smelted, and the obtained steel slabs were produced under the respective manufacturing conditions of Examples 1 to 18 of the present invention and Comparative Examples 19 to 49 shown in Table 2. 6 ~ 32mm steel plate. In addition, after heating at a temperature of 1250° C. to 1350° C. for 3 hours or more (“decarburization treatment” in Table 2), all were once cooled. Then, reheating by heating to 1100° C. or higher was performed ("hot rolling and accelerated cooling / rolling heating temperature" in Table 2). Ar3 is an actual value measured by detecting thermal expansion when cooling a sample taken from a steel plate to 1100° C. under the condition of 2.5° C. / min.

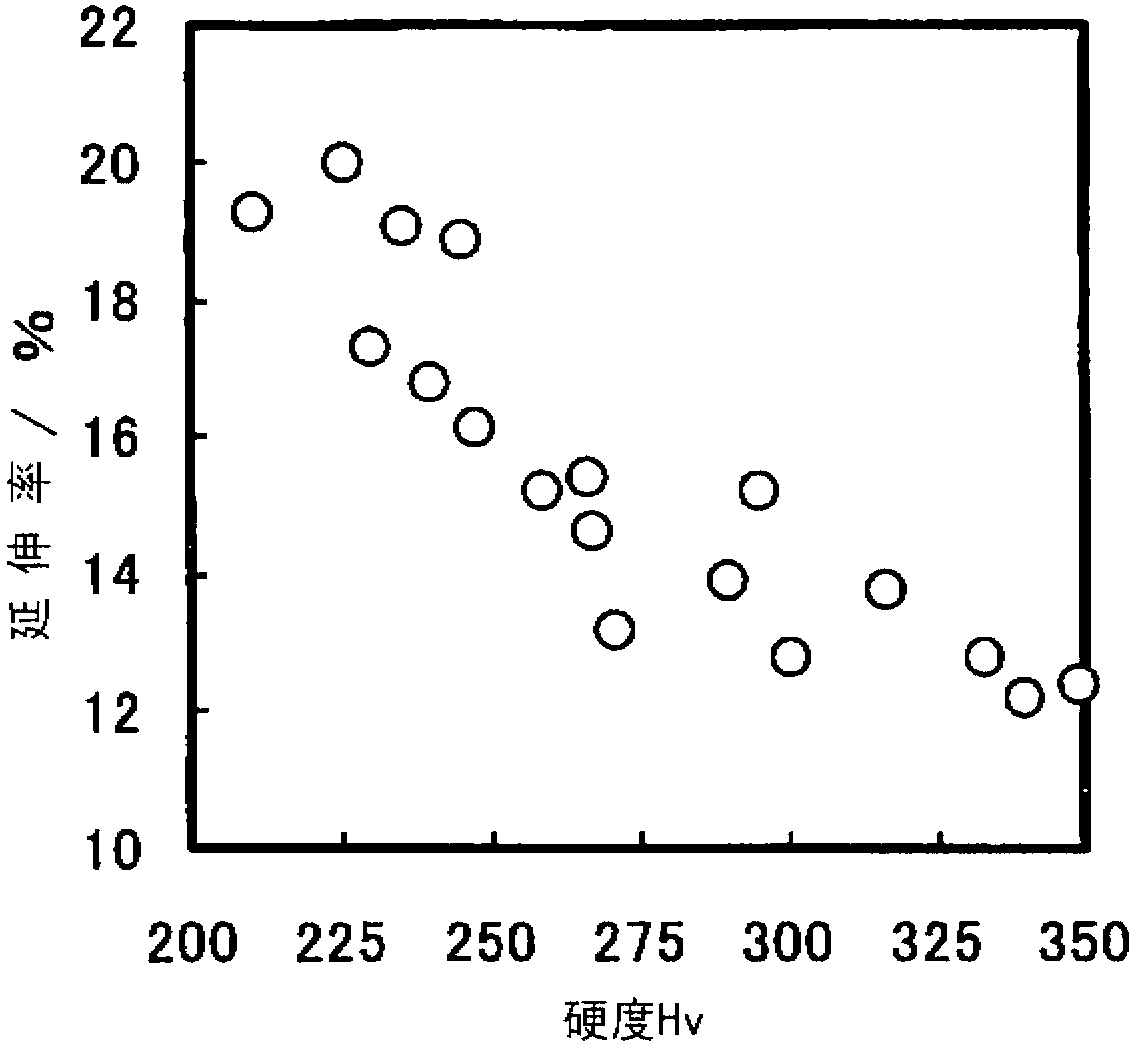

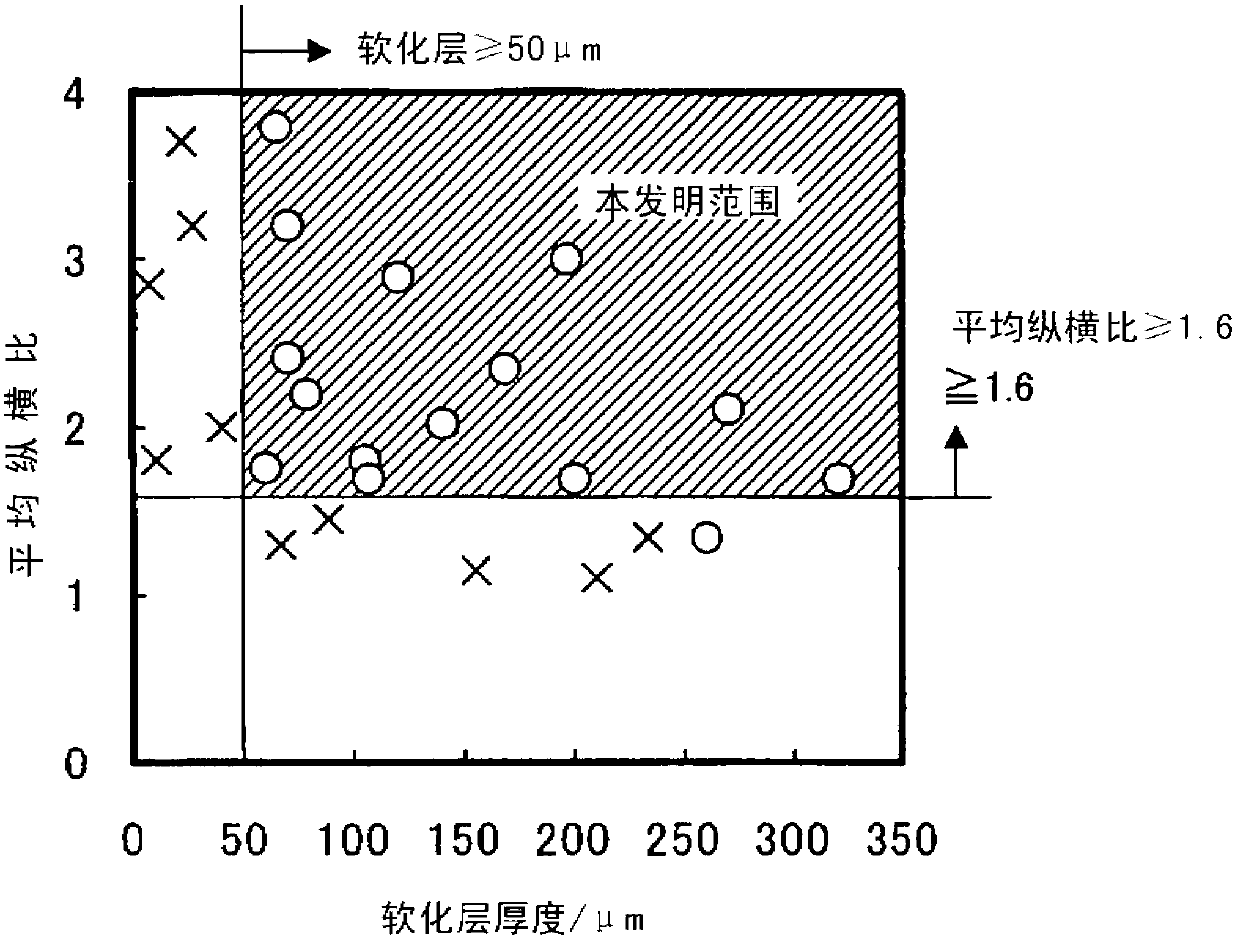

[0085] For these steel sheets, the thickness of the softened layer of Hv250 or less in the surface layer of the steel sheet, and the aspect ratio of the austenite grains in the L direction and T direction were measured, and the yield strength, ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com