Cu-Ni-Si alloy and method for manufacturing same

A cu-ni-si, manufacturing method technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of local punching and processing deepening, and achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

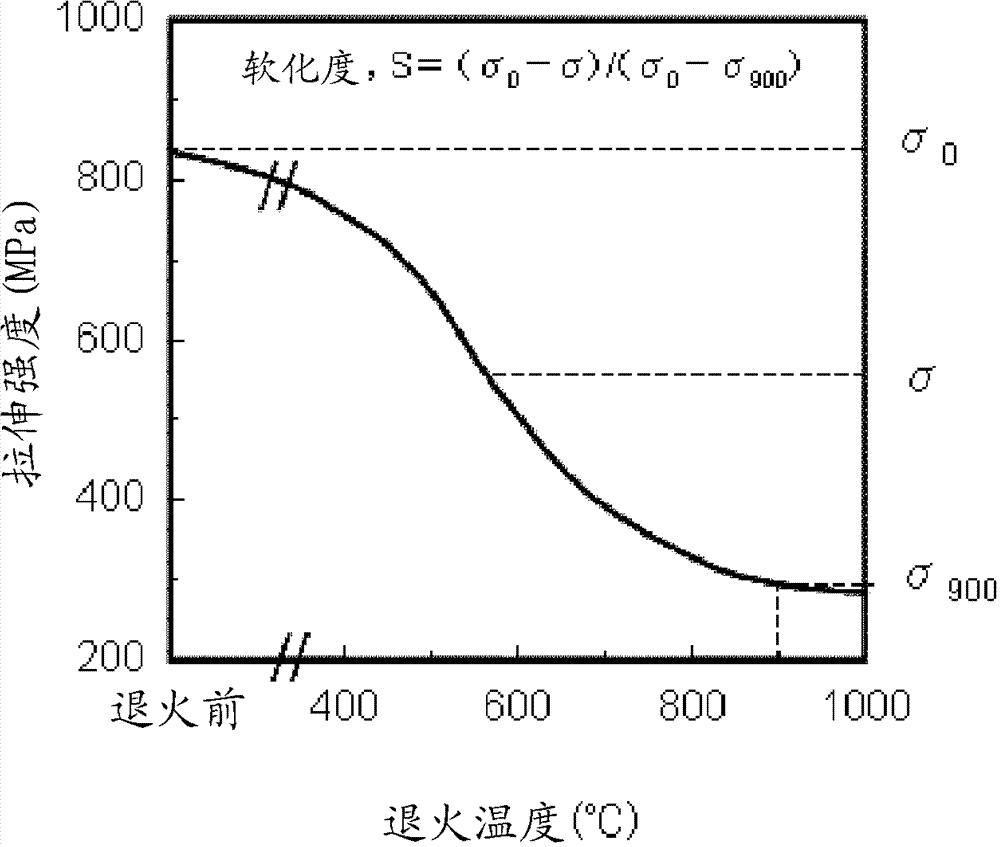

[0084] An alloy containing Ni: 2.6% by mass, Si: 0.58% by mass, Sn: 0.5% by mass, and Zn: 0.4% by mass, and the remainder consisting of copper and unavoidable impurities was used as an experimental material. The relationship between the processing degree of cold rolling and the strain rate of the third cold rolling, crystal orientation and n value, and the influence of crystal orientation and n value on product bendability were studied.

[0085]2.5 kg of electrolytic copper was melted in a high-frequency melting furnace in an argon atmosphere using a graphite crucible with an inner diameter of 60 mm and a depth of 200 mm. Alloying elements were added to obtain the above-mentioned alloy composition, and the temperature of the melt was adjusted to 1300° C., followed by casting in a cast iron mold to form an ingot with a thickness of 30 mm, a width of 60 mm, and a length of 120 mm. This ingot was heated at 950° C. for 3 hours, and hot rolled to a thickness of 10 mm. Use a grinde...

Embodiment 2)

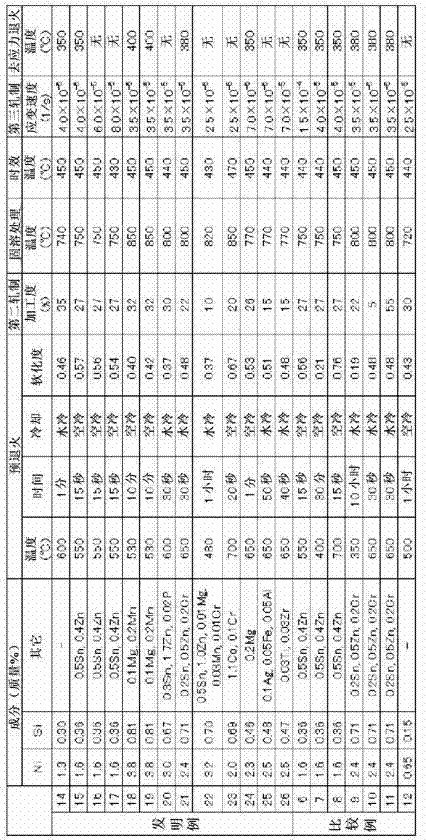

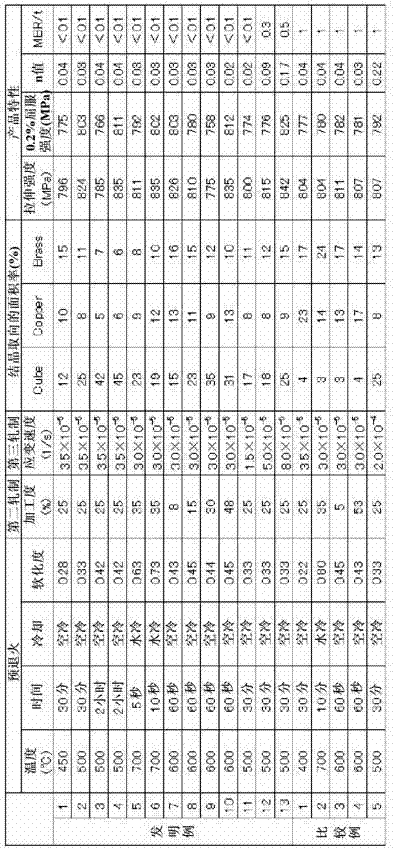

[0110] Whether or not the improvement effect of bendability shown in Example 1 can be obtained by Cu—Ni—Si alloys having different compositions and manufacturing conditions was examined.

[0111] Casting, hot rolling, and surface grinding were carried out in the same manner as in Example 1 to obtain a plate having a thickness of 9 mm having the composition shown in Table 2. This plate was rolled and heat-treated in the following order of steps to produce a product sample with a plate thickness of 0.15 mm.

[0112] (1) First cold rolling: cold rolling to a predetermined thickness corresponding to the rolling degree of the second cold rolling.

[0113] (2) Pre-annealing: Insert the sample into an electric furnace adjusted to a specified temperature, and after keeping it for a specified time, cool it under the following two conditions: put the sample in a water tank for cooling (water cooling), or place the sample in a Cooling in the atmosphere (air cooling).

[0114] (3) Secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com