Copper alloy sheet

A copper alloy and plate technology, applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc., can solve the problems of reduced electrical conductivity or bending workability, difficulty in electrical conductivity and bending workability, and reduced processing solidification coefficient, etc. Achieve the effects of improved workability and stress relaxation properties, improved migration resistance, and good bending workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

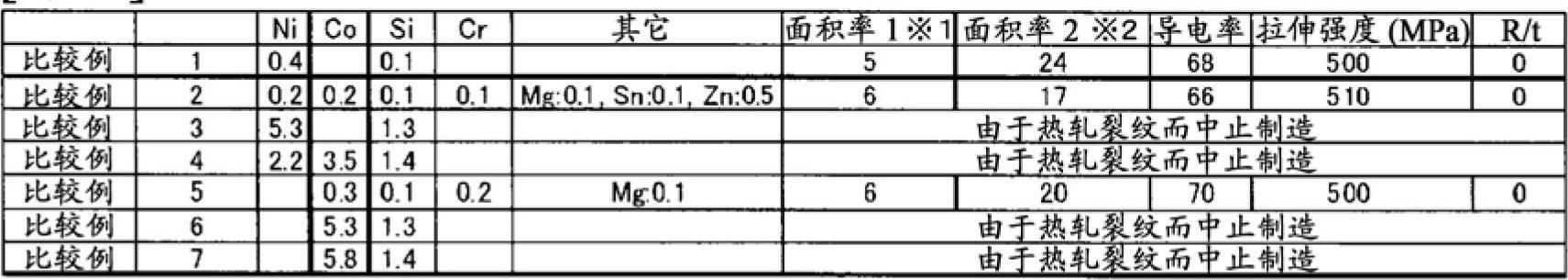

[0075] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

[0076] Next, examples of the present invention will be described. Copper alloys having the respective compositions shown in Table 1 below were cast to produce copper alloy sheets, and their properties such as strength, electrical conductivity, and bendability were evaluated.

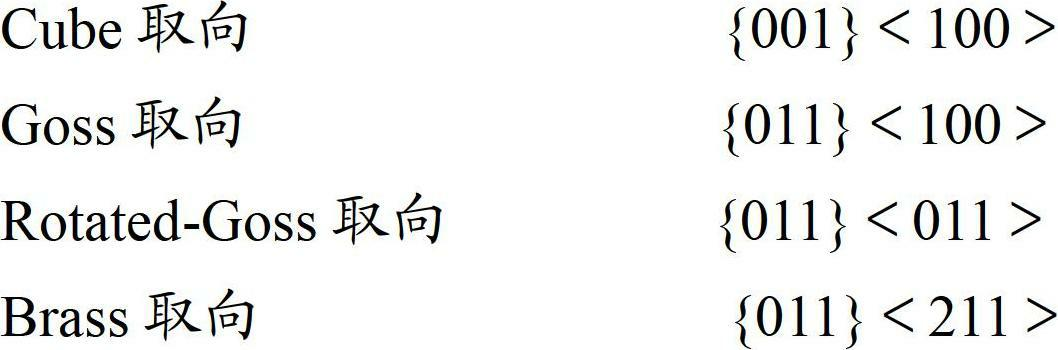

[0077] First, casting was performed by a DC (Direct Chill) method to obtain an ingot having a thickness of 30 mm, a width of 100 mm, and a length of 150 mm. Next, these ingots were heated to 900° C., kept at this temperature for 1 hour, hot-rolled to a thickness of 14 mm, and rapidly cooled. Next, both surfaces were face-cut by 1 mm each to remove the oxide film, and then cold rolling 1 with a rolling ratio of 90 to 98% was performed. Then, heat treatment is performed at 600 to 700° C. for 1 hour, and cold rolling 2 is implemented at a cold rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com