Patents

Literature

98results about How to "Little effect on conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

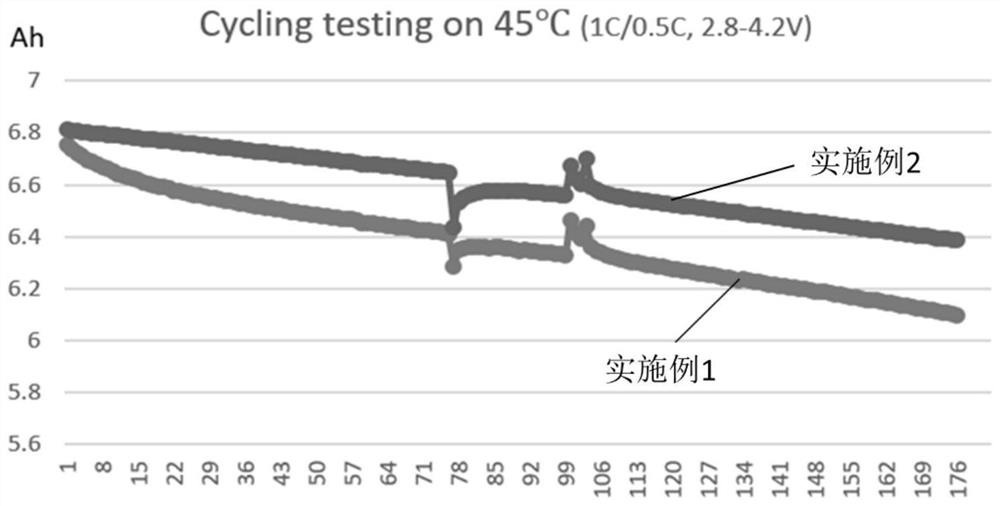

Double-functional lithium battery electrolyte additive and preparation method thereof

InactiveCN102386441AImprove flame retardant performanceGood flame retardancy and even non-combustibilityGroup 5/15 element organic compoundsSecondary cellsOrganic solventPhosphate

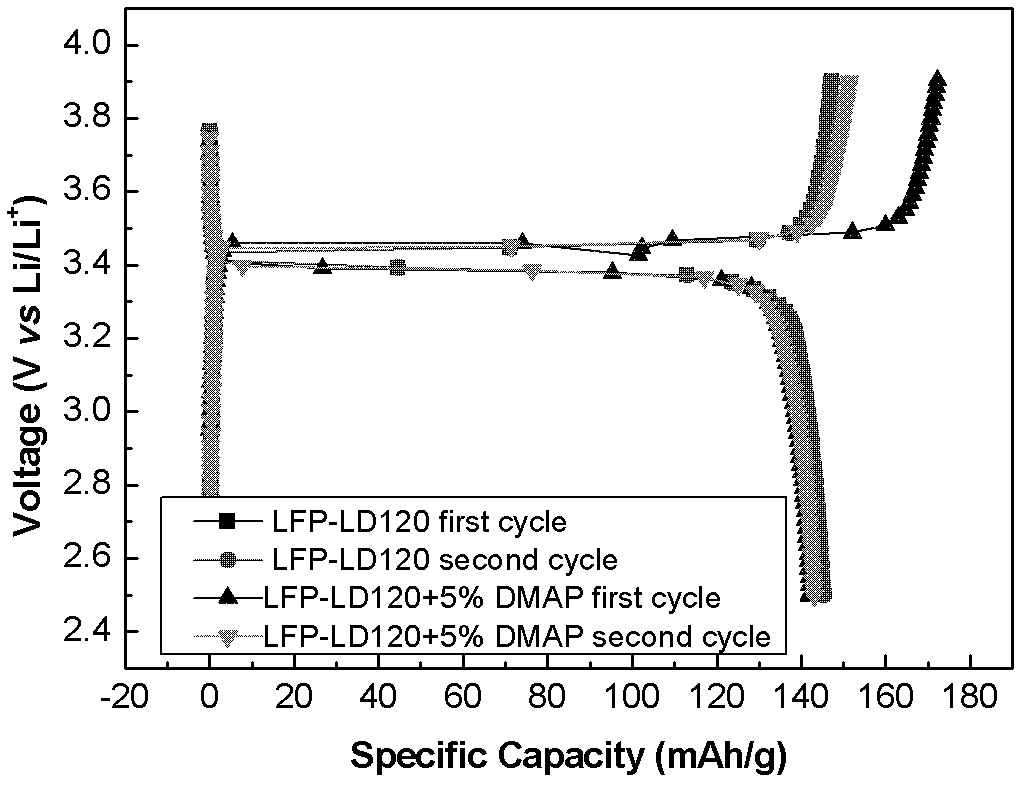

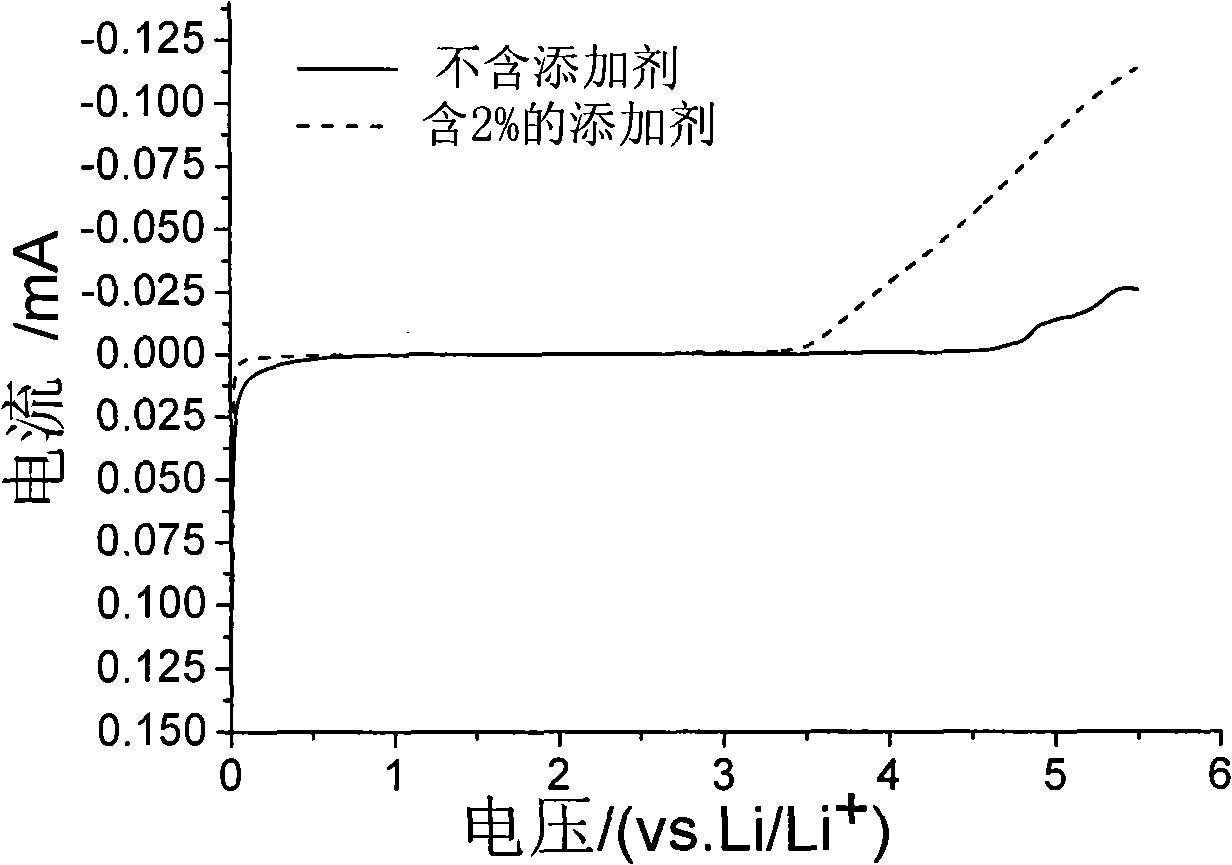

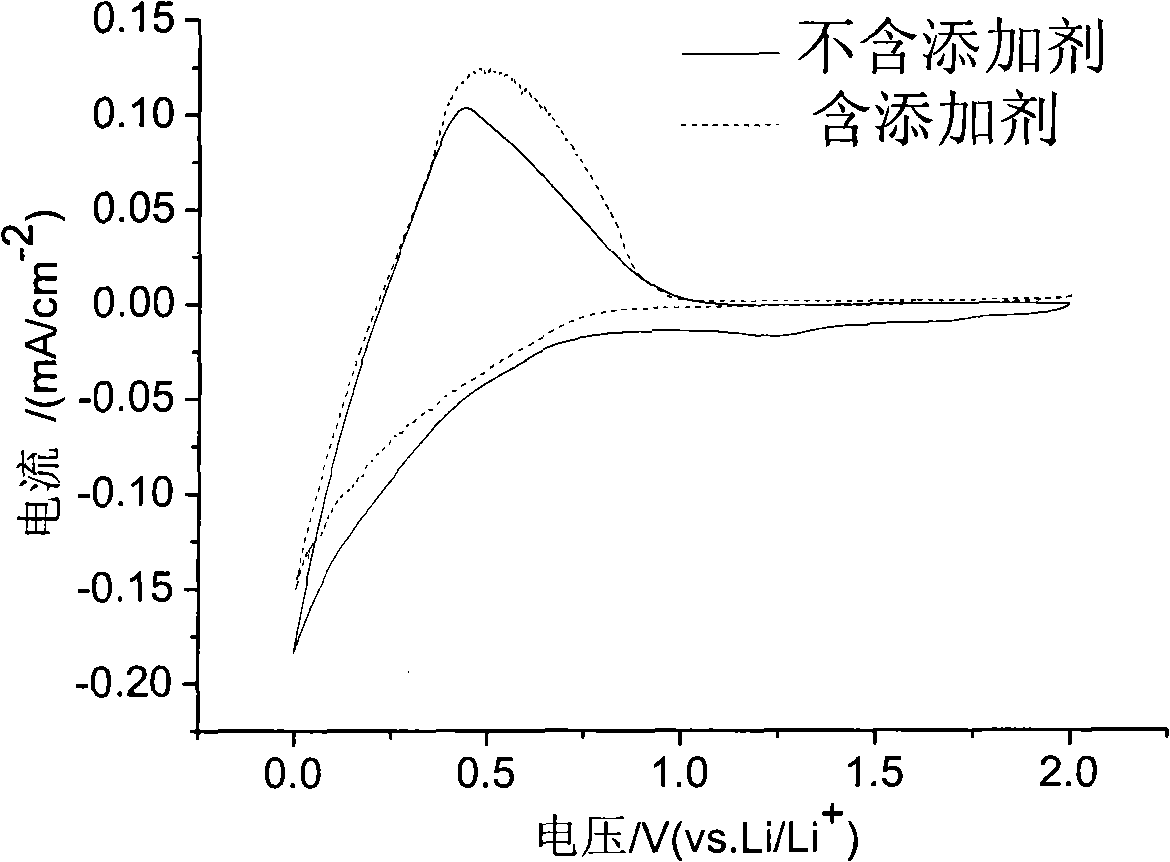

The present invention provides a double-functional lithium battery electrolyte additive and a preparation method thereof, and relates to the lithium battery electrolyte. The present invention provides the double-functional lithium battery electrolyte additive and the preparation method thereof, wherein the double-functional lithium battery electrolyte additive has a flame retardant performance, even a totally non-combustible characteristic. The double-functional lithium battery electrolyte additive is alkenyl phosphate. Phosphite trimester and alkenyl alkylogen are used as raw materials and react in organic solvent for preparing the double-functional lithium battery electrolyte additive. The double-functional lithium battery electrolyte additive and the routine lithium ion battery electrolyte can form the lithium ion battery electrolyte with double functions. The double-functional lithium battery electrolyte additive belongs to a double-functional additive and has the advantages of: higher phosphorus content and better flame retardation effect, wherein the existence of double bonds causes prior film forming of the double-functional lithium battery electrolyte additive in a discharging process. Compatibility between the electrolyte and a cathode is improved, and thermal stability of the cathode SEI layer is obtained.

Owner:XIAMEN UNIV

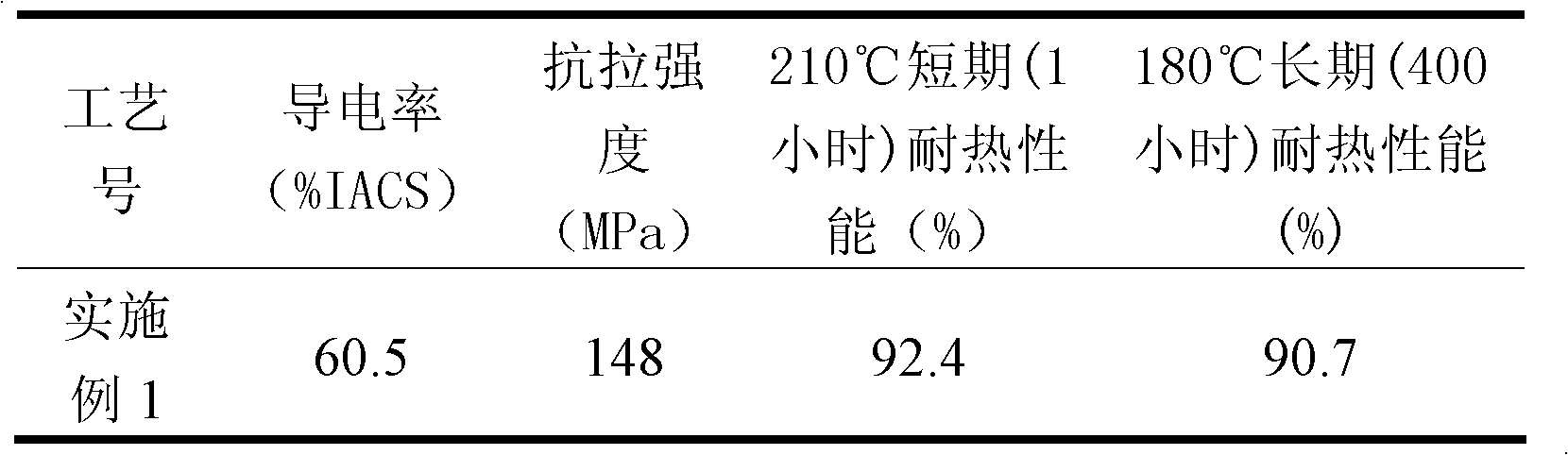

Heat resistant aluminum alloy conductor material and preparation method thereof

ActiveCN102230113AImprove conductivityLow conductivityMetal/alloy conductorsCable/conductor manufactureElectrical conductorManganese

The invention provides a heat resistant aluminum alloy conductor material and a preparation method thereof. The heat resistant aluminum alloy conductor material comprises the following components of 0.06-0.15 % of zirconium, 0.15-0.30 % of erbium, 0.10-0.20 % of iron, less than 0.05 % of silicon, less than 0.01 % of inevitable impurities like titanium, vanadium, chromium, manganese and the like and the balance of aluminum. According to the preparation method, the heat resistant aluminum alloy conductor material is directly rolled after each component is fused and cast. The conductor material can realize that the electric conductivity can reach 59.5-60.5 % IACS (International Association Of Classification Societies), the long-term heat resistance temperature can reach 180 DEG C and the short-term heat resistance temperature can reach 210 DEG C without heat treatment; therefore, the conductor material is an electric wire and cable conductor material with great potential. The conductor material can be widely used for construction and capacity expansion reconstruction of electric power engineering; and by using the conductor material, the transmission line capacity is largely increased, the transmission line loss is reduced, the distance between poles of the transmission line can be increased, the line building cost is reduced, the tense corridor resources are saved and obvious economic benefit and energy-saving and environment-friendly significance are obtained. The heat resistant aluminum alloy conductor material provided by the invention has the advantages of reasonable component mixing ratio, simple preparation process, convenience for realizing continuous production and suitability for industrial application; and the production cost and the energy consumption of the heat resistant aluminum alloy can be effectively reduced.

Owner:CENT SOUTH UNIV

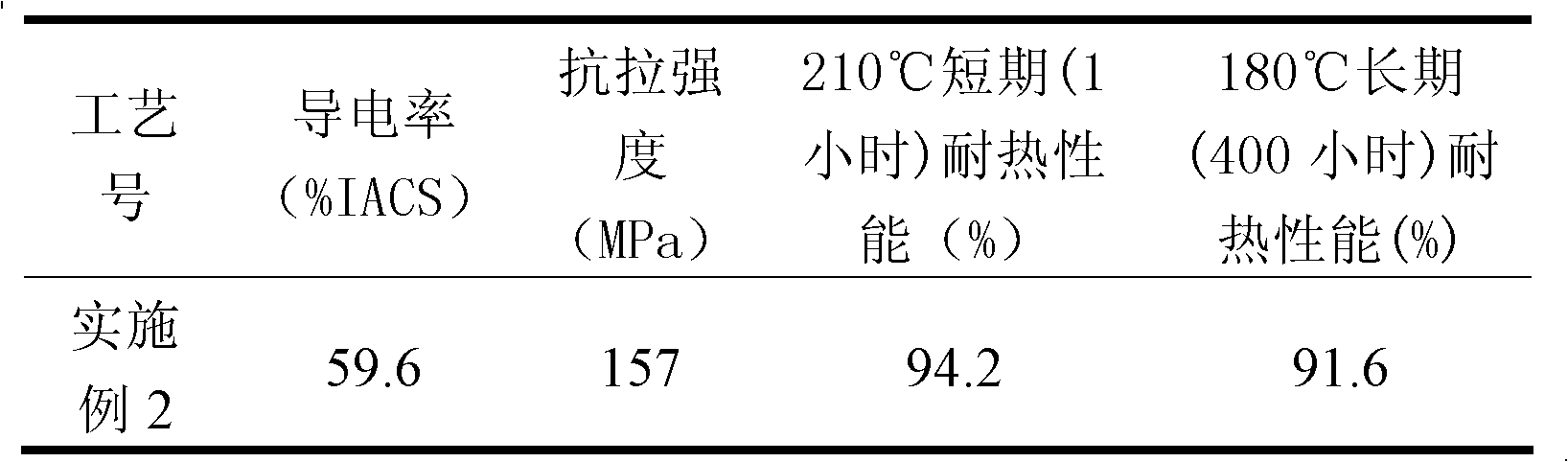

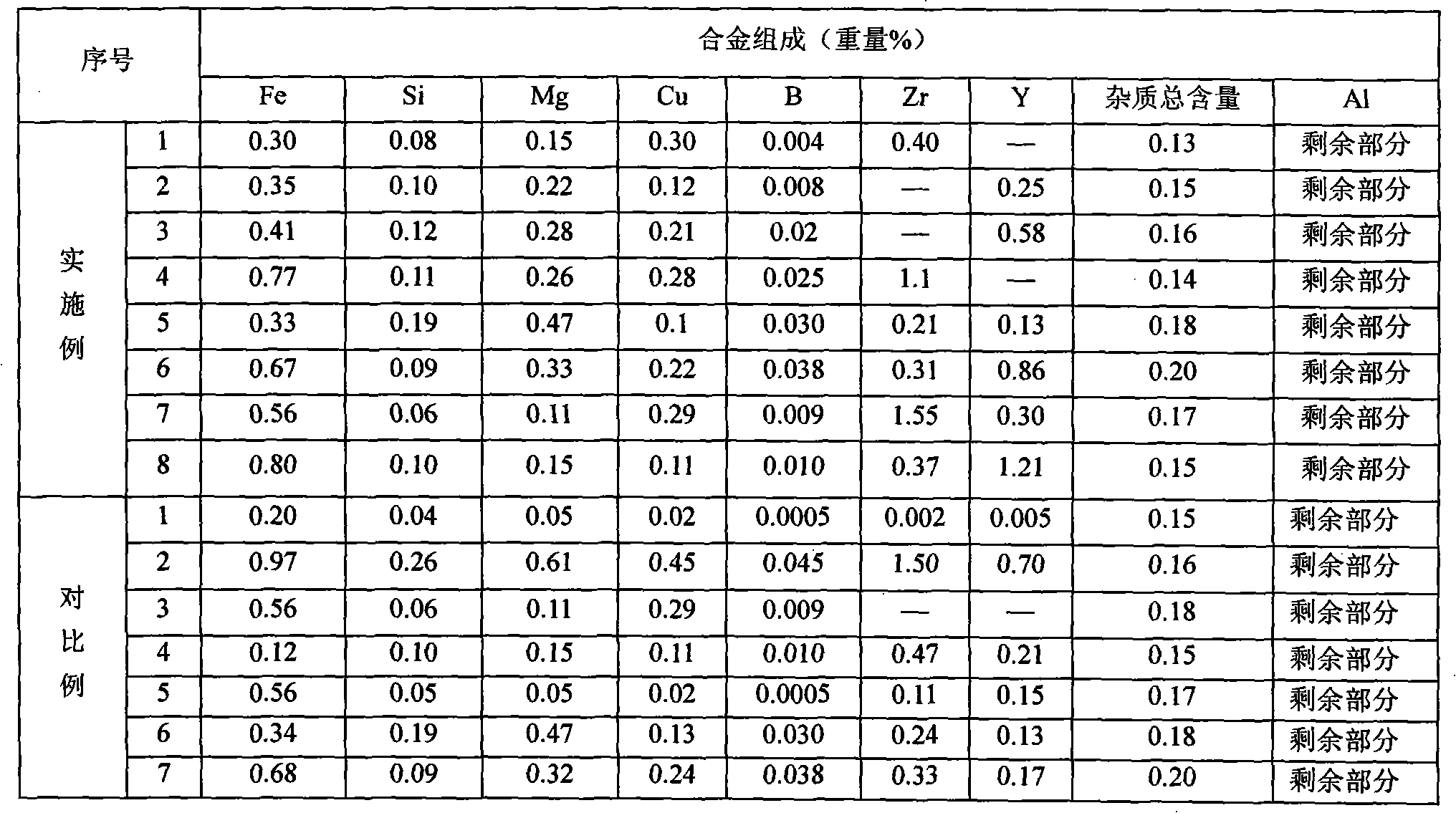

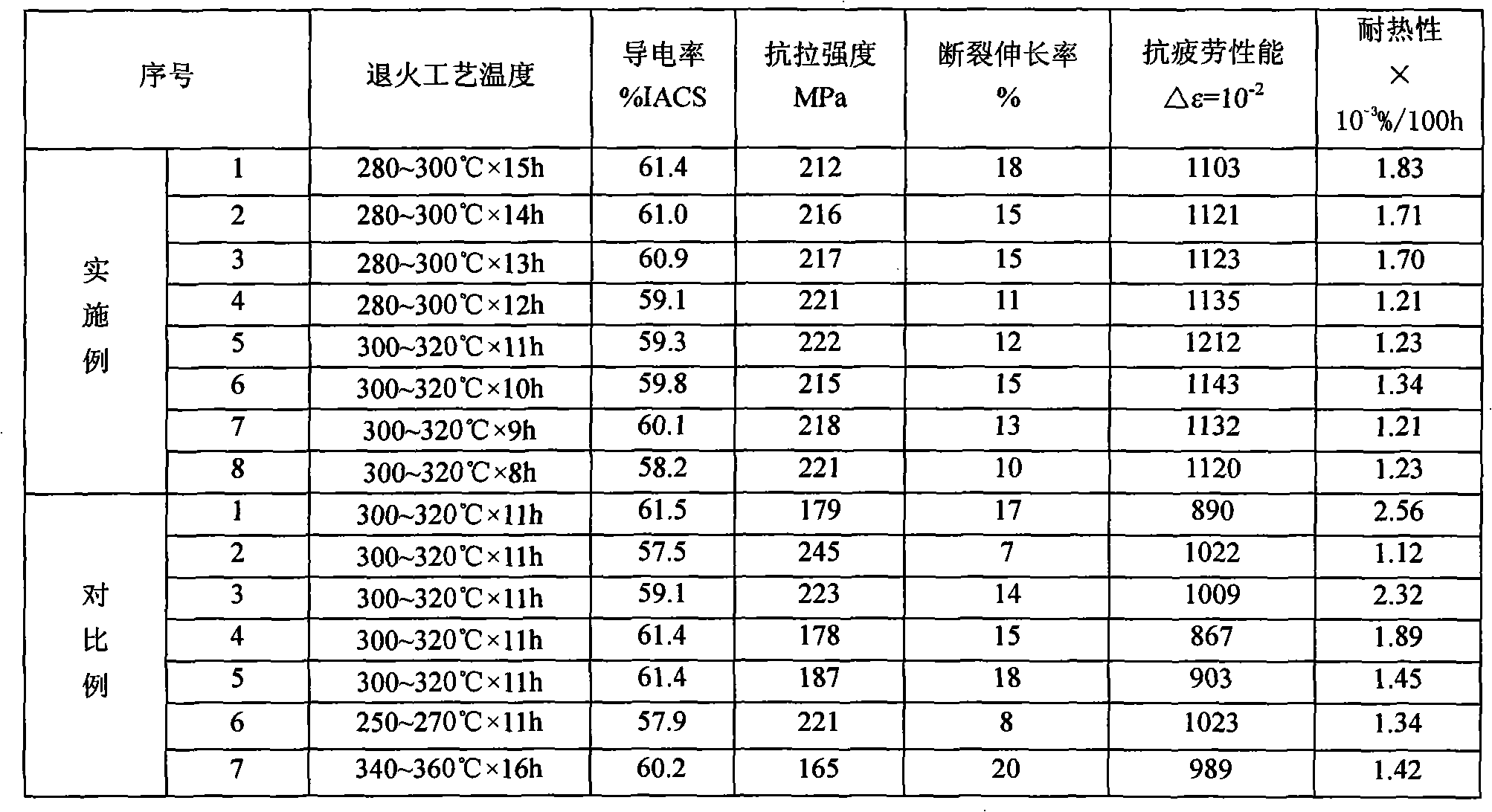

Aluminium alloy conductor for automotive wires and manufacturing method thereof

ActiveCN101923908AHigh tensile strengthImprove corrosion resistanceInsulated cablesMetal/alloy conductorsYttriumMagnesium

The invention discloses an aluminium alloy conductor for automotive wires, which has the advantages of high heat resistance, conductivity, tensile strength, extensibility and fatigue resistance, and a manufacturing method thereof. The alloy contains 0.3 to 0.8 weight percent of iron, 0.05 to 0.20 percent of silicon, 0.1 to 0.5 weight percent of magnesium, 0.1 to 0.3 weight percent of copper, 0.001 to 0.04 weight percent of boron, 0.001 to 0.04 weight percent of zirconium, 0.001 to 0.04 weight percent of yttrium, and the balance of aluminium and inevitable impurities, wherein one or two elements, except the aluminium and the inevitable impurities, account for 0.1 to 2.0 weight percent. The manufacturing method comprises the following steps of: adding the iron, silicon, magnesium, copper, boron, zirconium, yttrium and aluminium into a smelting furnace; smelting, and casting and rolling; performing intermediate annealing treatment; drawing into aluminium alloy filaments with the diameterof 0.5mm; and stranding into wire cores, and performing annealing treatment. The conductor prepared by the method has the tensile strength of 210MPa and above, the elongation at break of over 10 percent, the conductivity of over 58 percent, and excellent heat resistance and flexibility.

Owner:安徽中青欣意铝合金电缆有限公司

Flame-retardant electrolyte for secondary lithium-sulfur battery and preparation method for flame-retardant electrolyte

InactiveCN105977533AReduce flammabilityImprove electrochemical performanceFinal product manufactureSecondary cells servicing/maintenanceOrganic solventLithium–sulfur battery

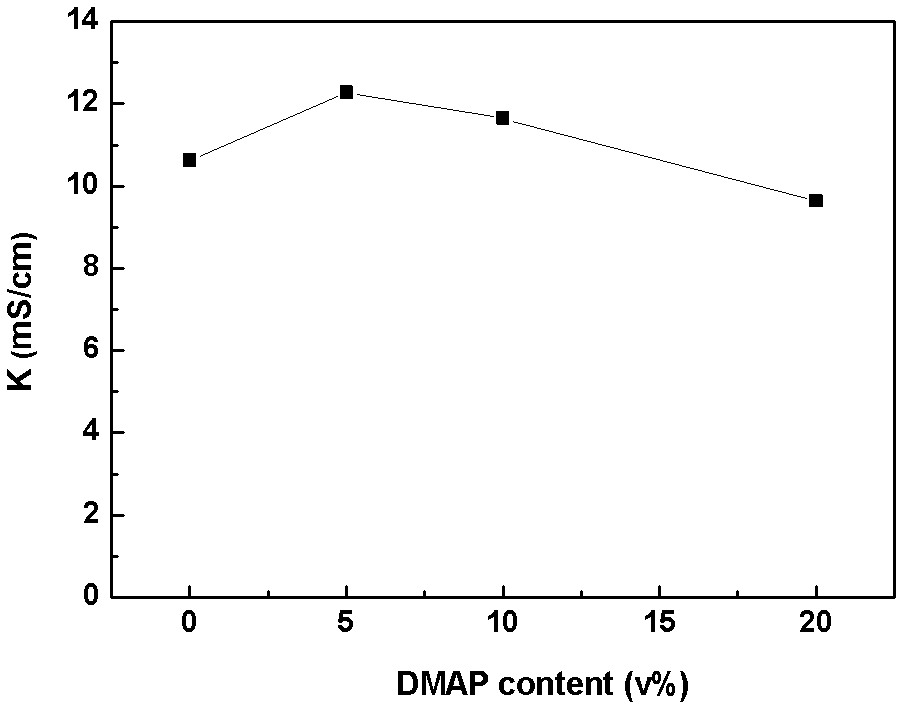

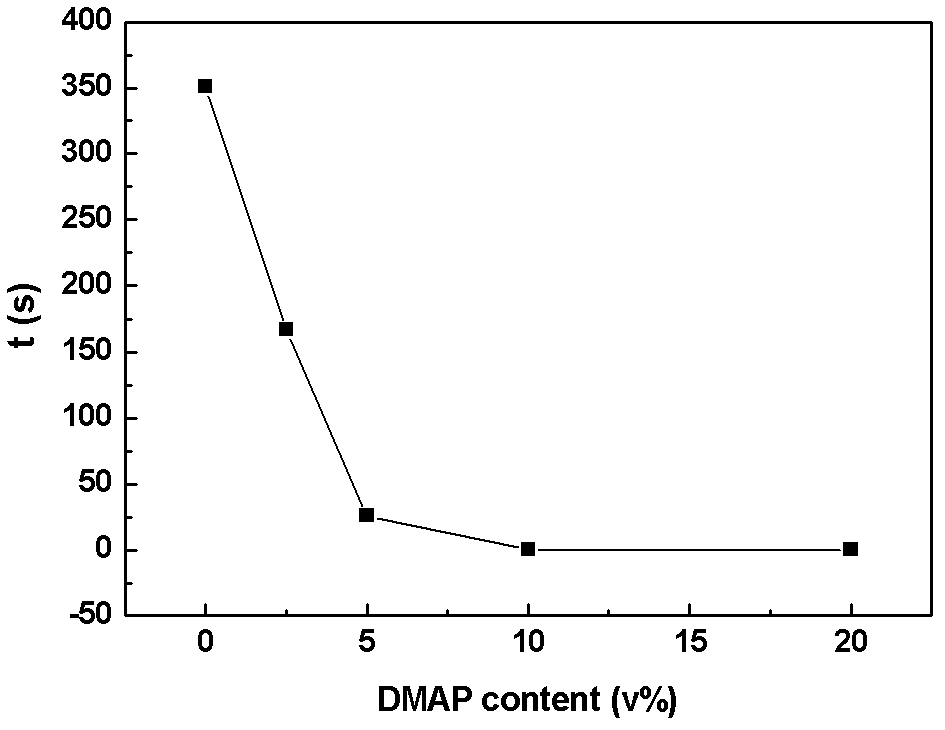

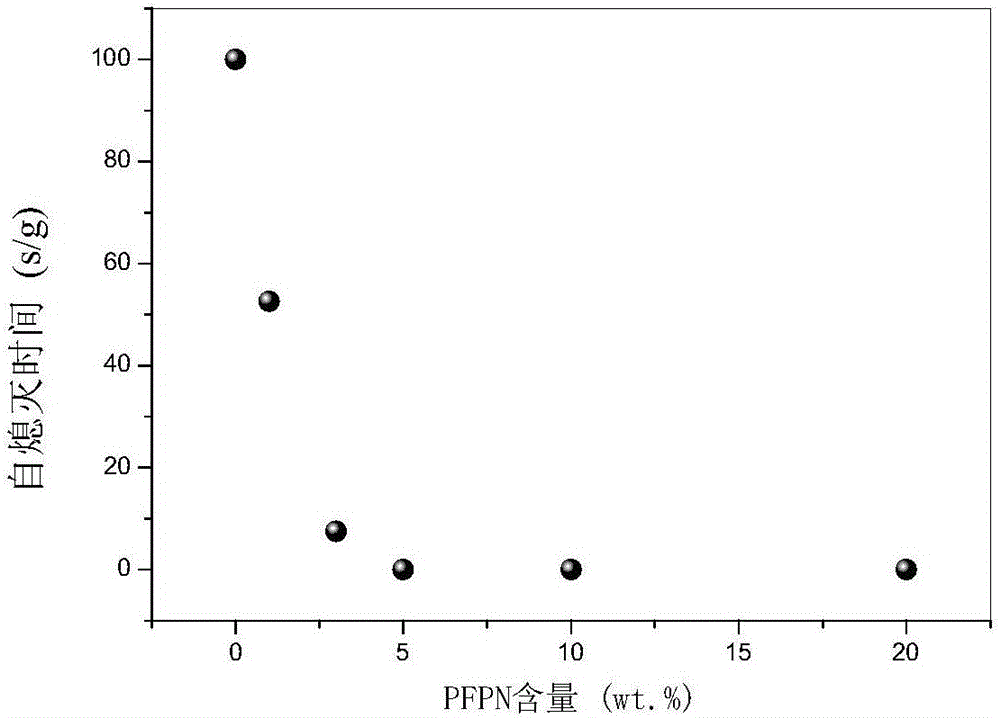

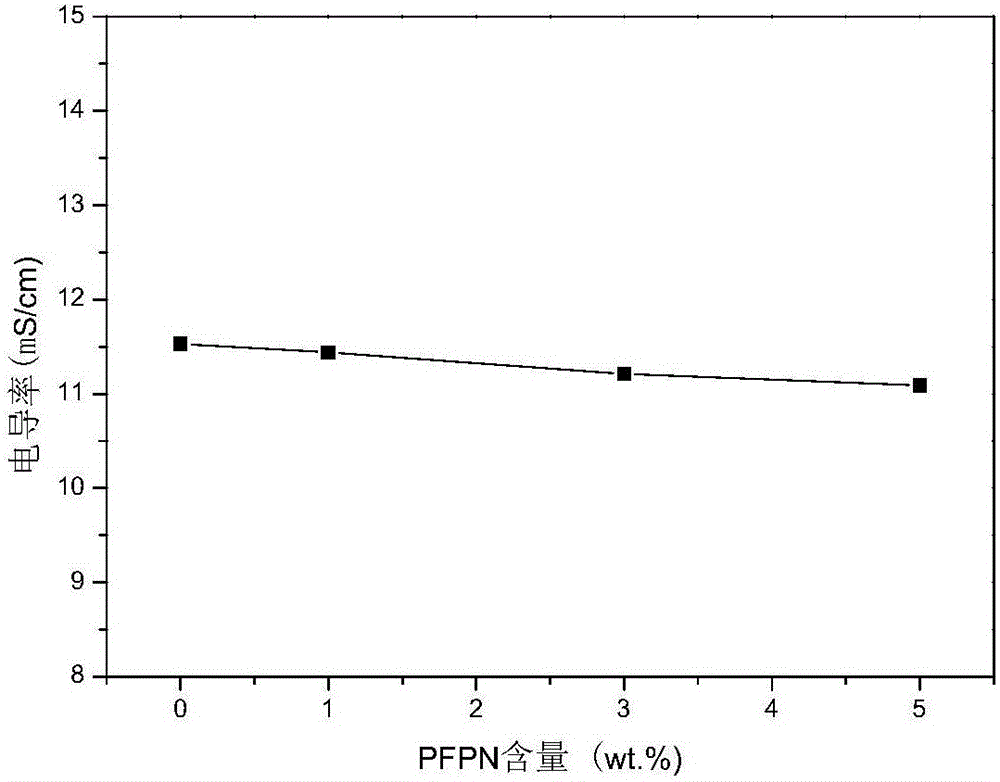

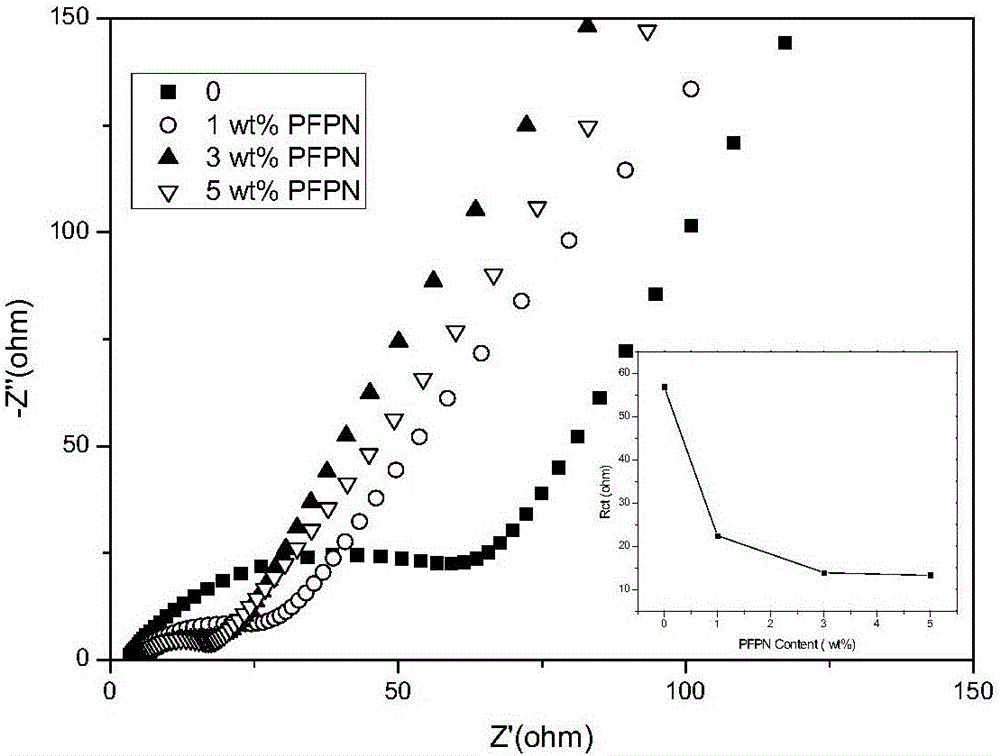

The invention relates to a flame-retardant electrolyte for a secondary lithium-sulfur battery and a preparation method for the flame-retardant electrolyte. The flame-retardant electrolyte comprises a lithium salt, an organic solvent and a fire retardant, wherein the concentration of the lithium salt is 0.5-5mol / L in the electrolyte; the fire retardant is phosphonitrile fluoride fire retardant, which accounts for 0.1-20% of the total flame-retardant electrolyte based on mass percentage; the lithium salt is added to the organic solvent to be uniformly stirred to prepare the electrolyte; and then the fire retardant is added to the electrolyte to be continuously stirred and uniformly mixed to obtain the flame-retardant electrolyte for the secondary lithium-sulfur battery. Compared with the prior art, the flammability of the electrolyte added with the phosphonitrile fluoride additive is greatly lowered, and the influence on the conductivity is relatively low; according to the secondary lithium-sulfur battery assembled by the electrolyte containing the phosphonitrile fluoride fire retardant, the electrochemical performance of the secondary lithium-sulfur battery is obviously improved, and an effect of giving consideration to both of the flame-retardant effect and the electrochemical performance can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

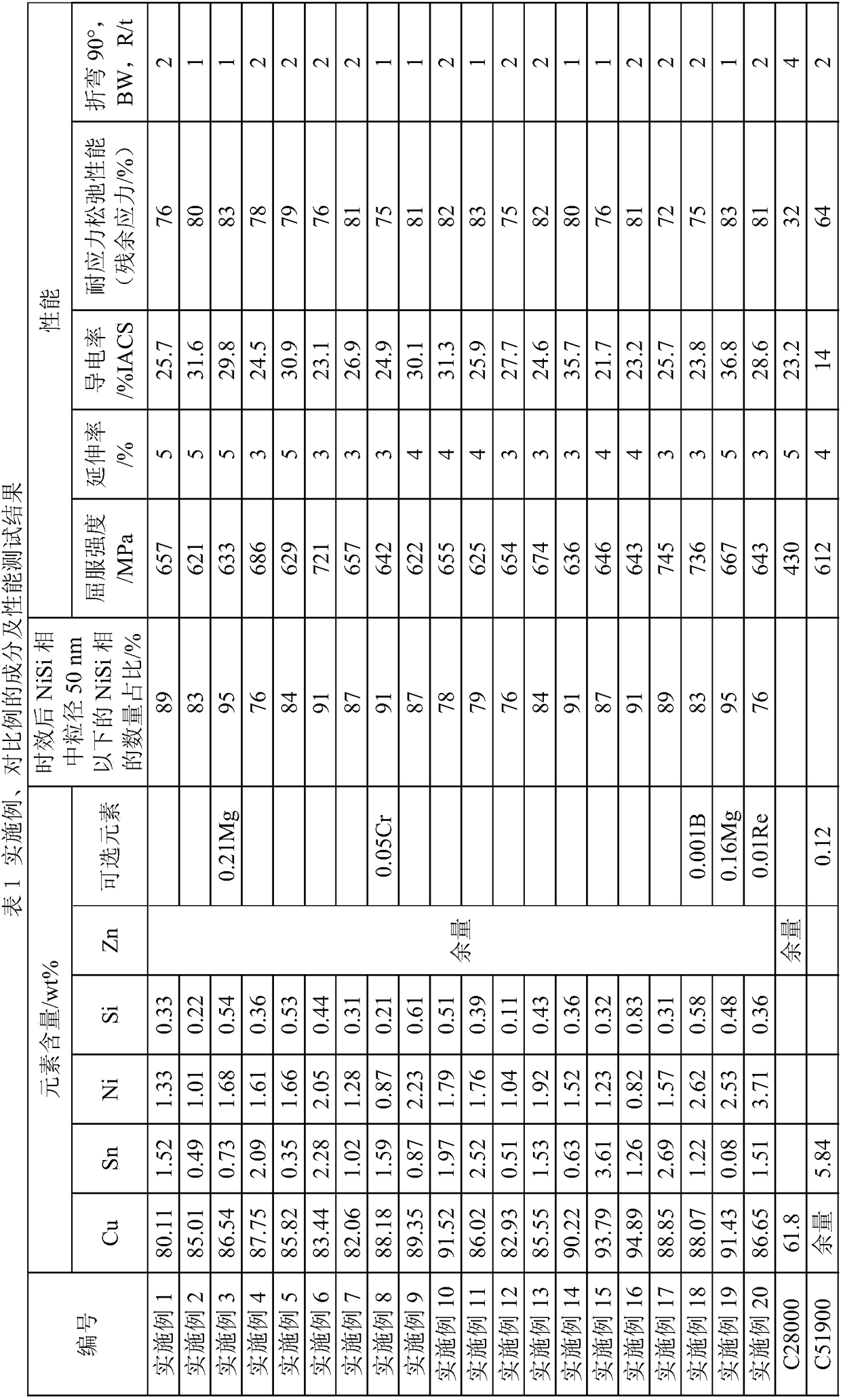

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Copper strip preparation process for high-end frame material

Provided is a copper strip preparation process for a high-end frame material. According to the weight percentage of components in a smelting furnace, the total content of standard electrical cathode copper and Cu in all alloys is 96.5% or above, iron Fe accounts for 2.1-2.6%, phosphor P accounts for 0.015-0.15%, zinc Zn accounts for 0.05-0.20%, stannum Sn accounts for 0.005-0.050%, magnesium Mg accounts for 0.008-0.05%, the sum of impurities does not exceed 0.1%, the sum of alloy elements and impurities is 0.15% or below, and the weight sum of the above components is 100%; then, the followingsteps of smelting, casting, saw cutting, hot rolling, face milling, cold rolling, edge cutting, annealing, rolling of finished products, cleaning, shearing of finished products and package and warehousing are carried out. The problem of high temperature softening and other aspects of an original TFe2.5 and other frame material copper strips is solved, the high-end frame material has the obvious advantages of high strength, excellent electrical conductivity, good subsequent processing performance and the like compared with frame materials prepared by adopting an original process, the chemical composition of the material is stable, and the surface is clean, smooth and free of oxidation and discoloration.

Owner:中铝洛阳铜加工有限公司

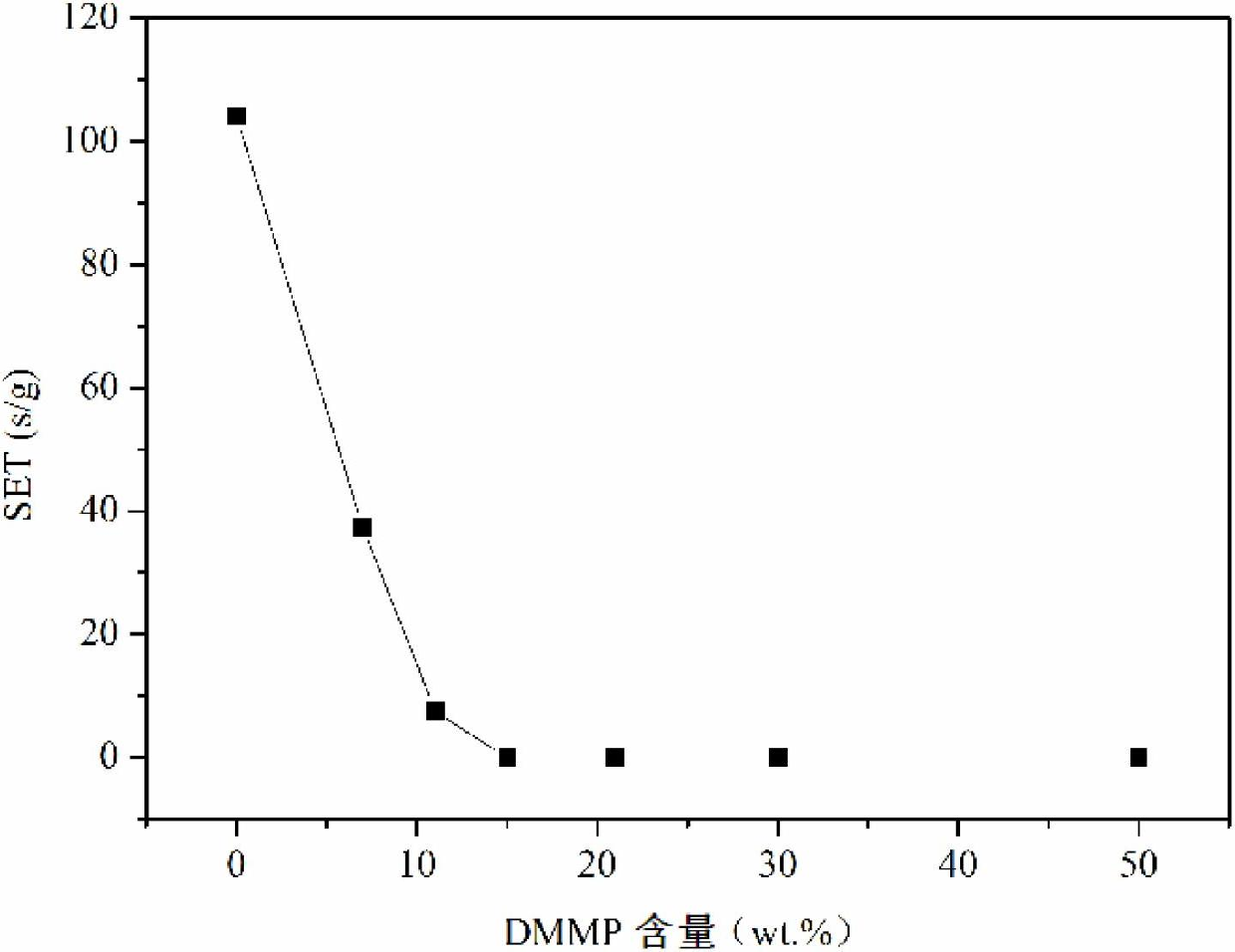

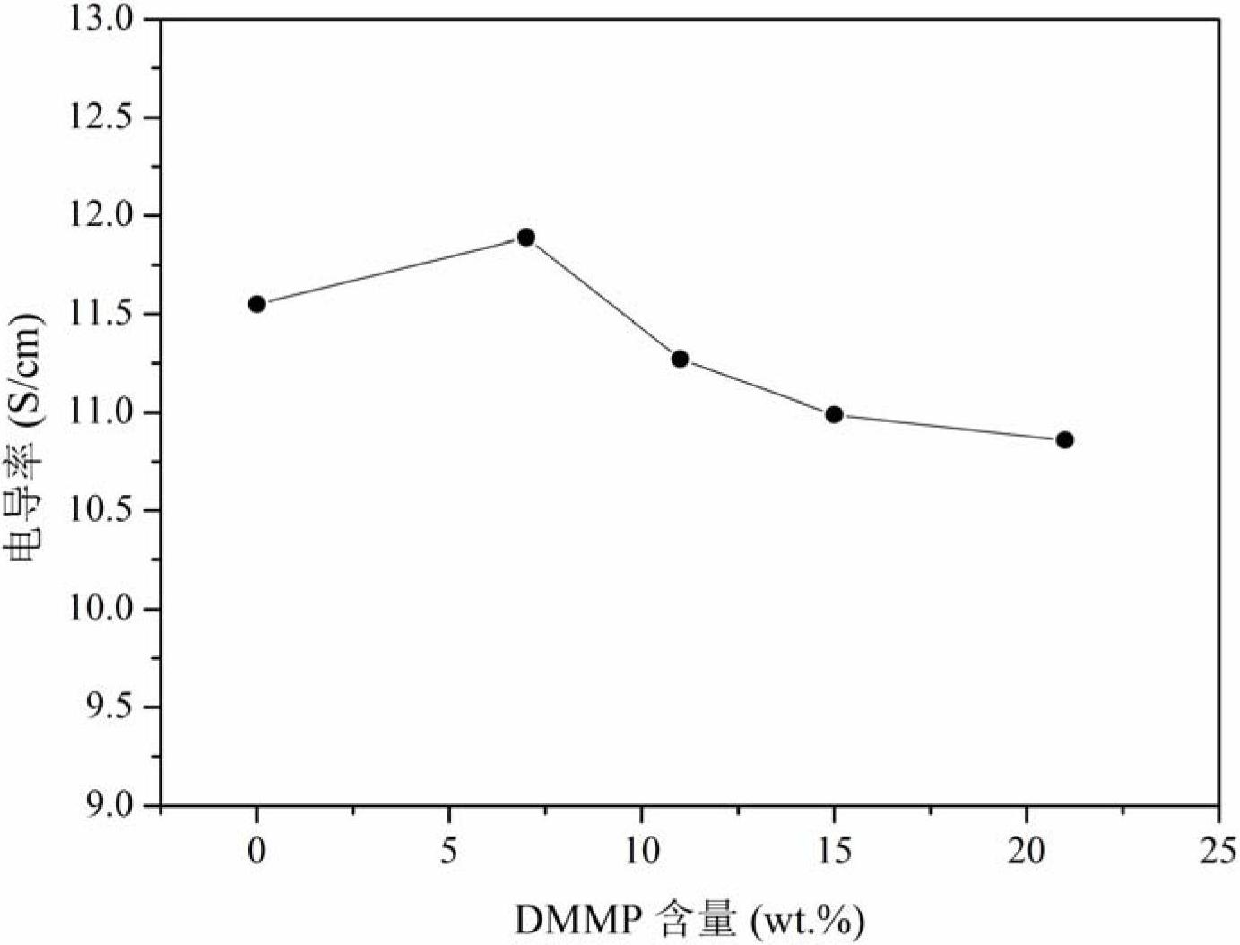

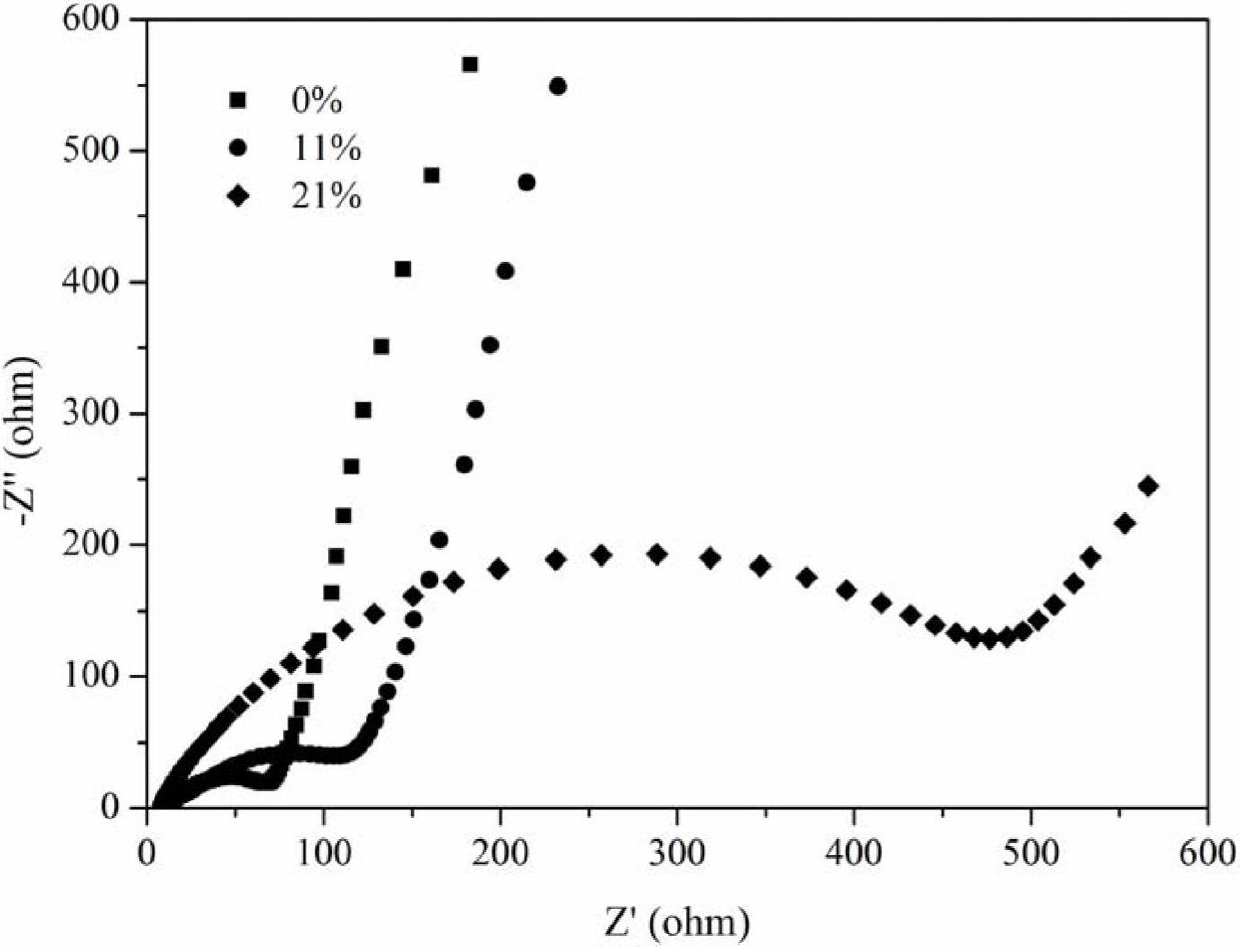

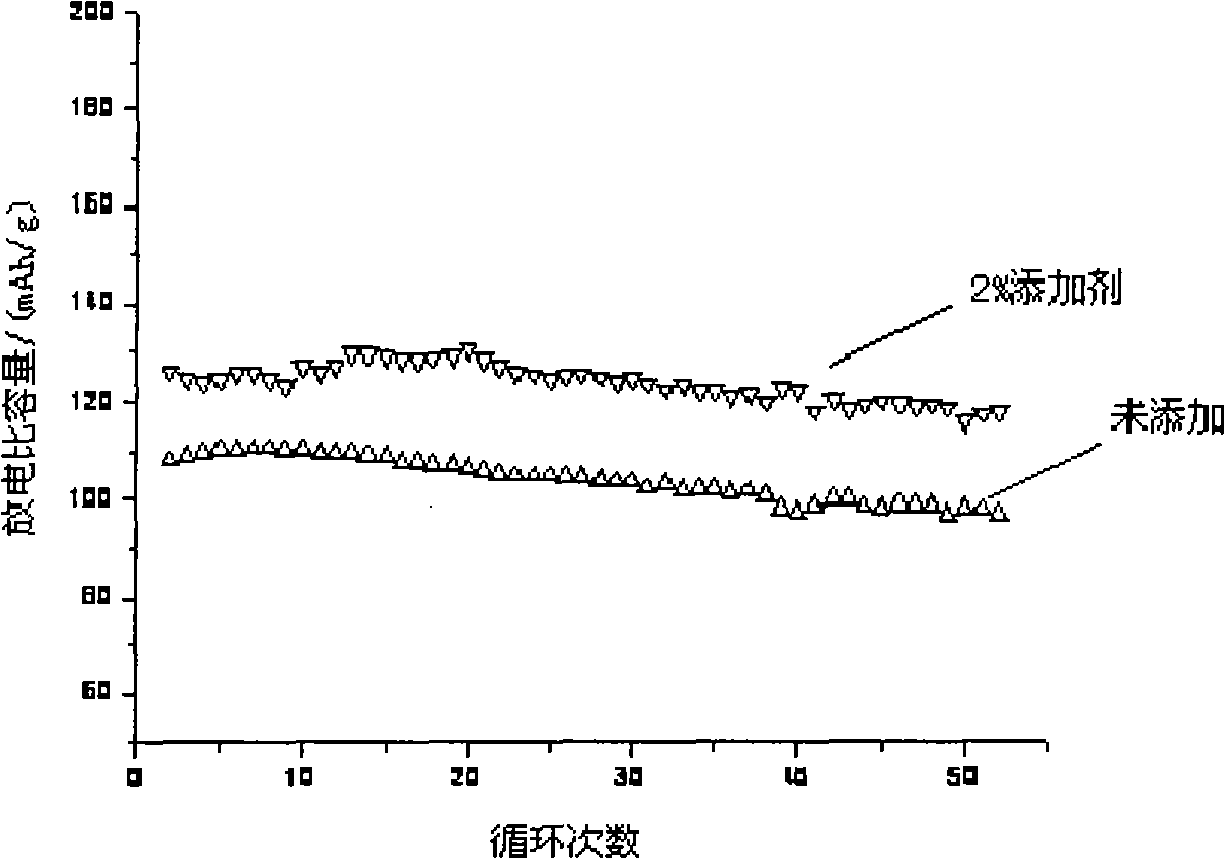

Flame-retardant electrolyte for secondary lithium-sulfur battery and preparation method thereof

InactiveCN102683747AReduce flammabilityLittle effect on conductivityLi-accumulatorsLithium–sulfur batteryPhysical chemistry

The invention discloses a flame-retardant electrolyte for a secondary lithium-sulfur battery and a preparation method thereof. The electrolyte is prepared by adding a phosphorus-containing flame retardant on the basis of the conventional lithium ion electrolyte, and the flame retardant accounts for 1-50 percent by mass of the total weight of the electrolyte. The invention further discloses a secondary lithium-sulfur battery prepared by using an electrolyte which contains an appropriate amount of flame-retardant additive. According to charging and discharging tests at the voltage of 1.0-3.0V, the electrochemical performance is not influenced, and the volume keeping rate is high after 50 cycles; and moreover, the flammability of the electrolyte is lowered greatly, and the safety performance of the lithium-sulfur battery can be enhanced.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing high-strength, high-conductivity and heat-resistant aluminum alloys

The invention discloses a method for preparing high-strength, high-conductivity and heat-resistant aluminum alloys. The method for preparing the high-strength, high-conductivity and heat-resistant aluminum alloys comprises the following steps: putting pure aluminum powder into a ball mill, ball milling, then putting the aluminum powder after ball milling into a cold isostatic pressure encapsulation sleeve and carrying cold isostatic pressure treatment, and putting pressure blanks after carrying out cold isostatic pressure treatment in a protective atmosphere to carry out sintering densification at a sintering temperature of 600-640 DEG C; and carrying out hot squeezing and cold drawing on sintered aluminum bars to obtain the high-strength, high-conductivity and heat-resistant aluminum alloys. The high-strength, high-conductivity and heat-resistant aluminum alloys prepared by the method are free of other alloy metals and just contain a nano-sized tiny oxide substance point which is used as a strengthening phase, and the strengthening phase is tiny and uniform, so that the strength of the material is improved, and the influence on the conductivity of the material is small; the oxide strengthening phase can stably exist at the high temperature, so that the recovery and re-crystallization of the material can be remarkably avoided, and the growth of crystal grains is avoided; therefore, the strength can be retained at the high temperature; the heat resistance of the material is remarkably improved.

Owner:UNIV OF SCI & TECH BEIJING

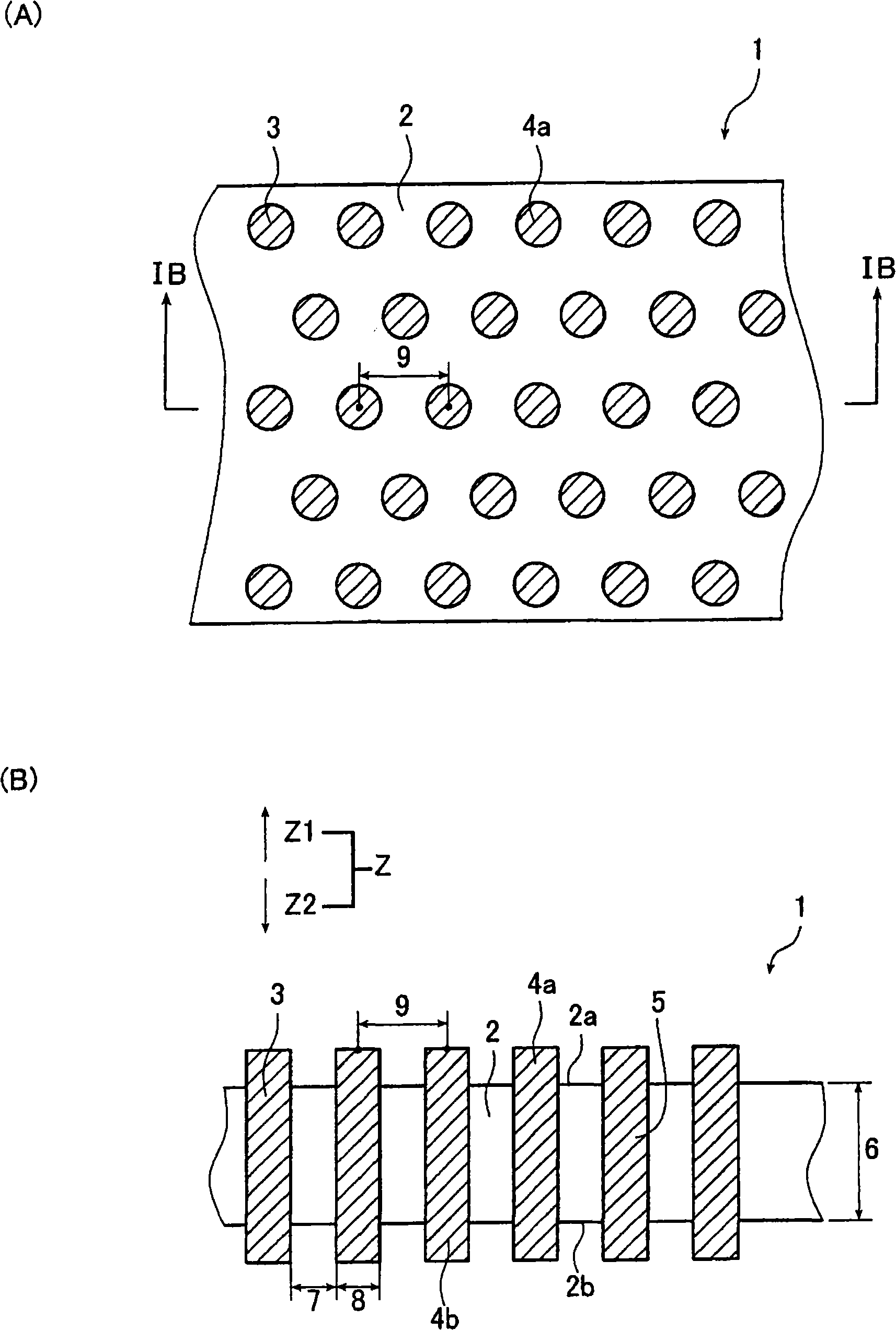

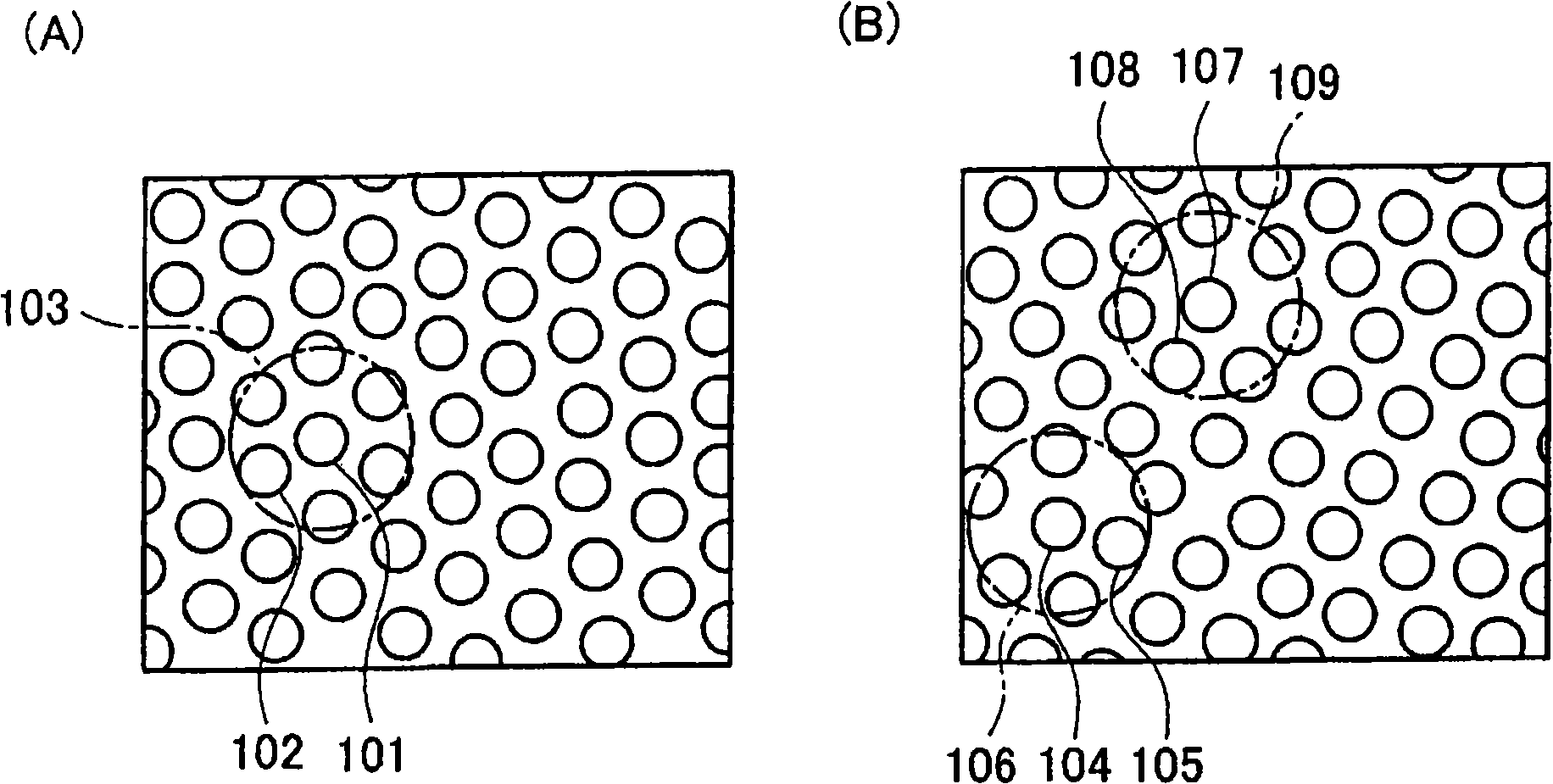

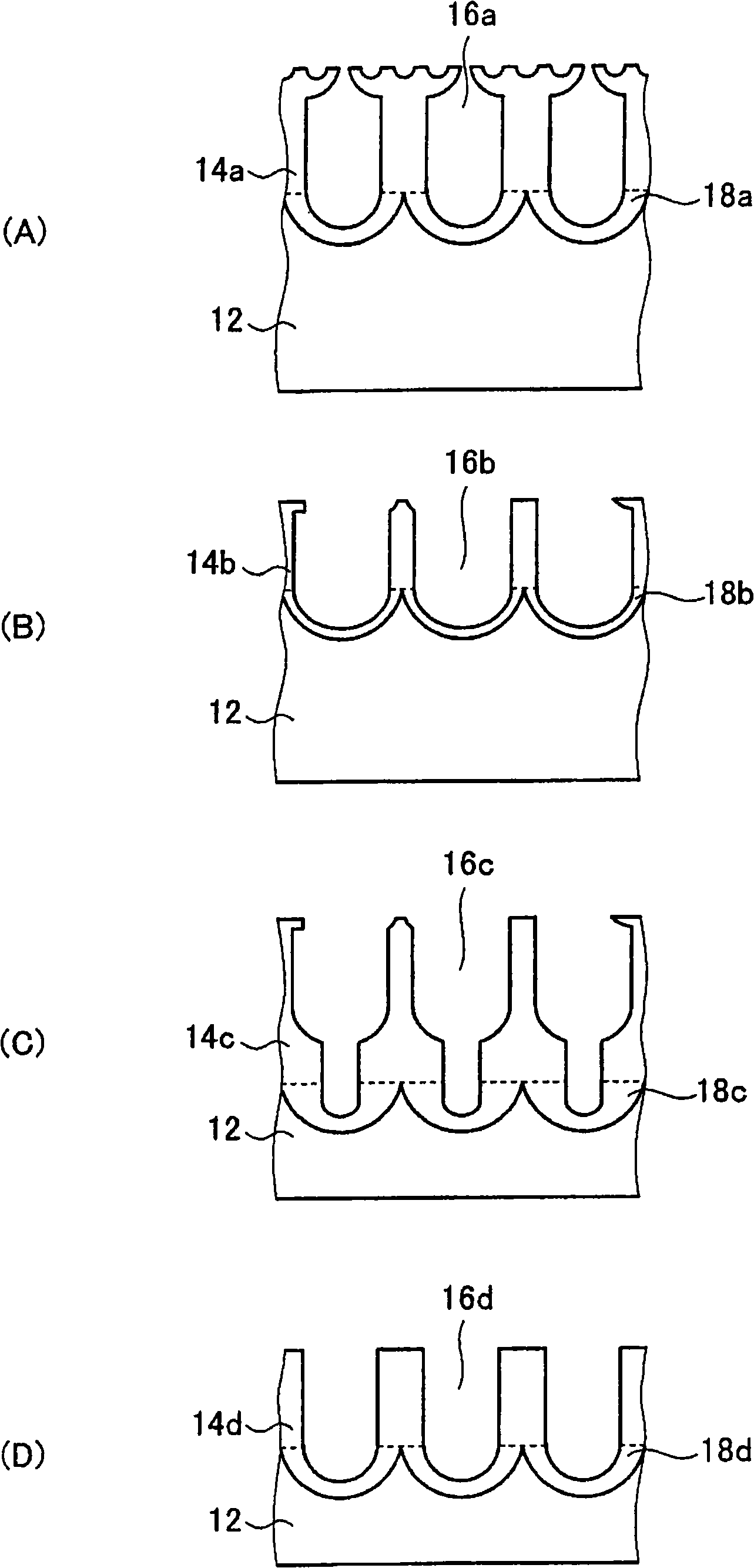

Anisotropically conductive member and method of manufacturing the same

ActiveCN101276661AIncrease setup densityReduce damageCoupling device connectionsNon-insulated conductorsAluminiumEngineering

Owner:FUJIFILM CORP

Machining method for copper alloy for slot wedge

The invention discloses a processing method of a copper alloy for slot wedges, which is prepared by continuous casting → solid solution quenching → continuous extrusion → cold deformation → cryogenic treatment → aging; the copper alloy is composed of copper, nickel, silicon, Composed of elements such as chromium, cobalt, aluminum, magnesium, etc., the material properties obtained by the technical solution provided by the invention are excellent, and fully meet the use requirements of the generator rotor slot wedge.

Owner:徐高杰

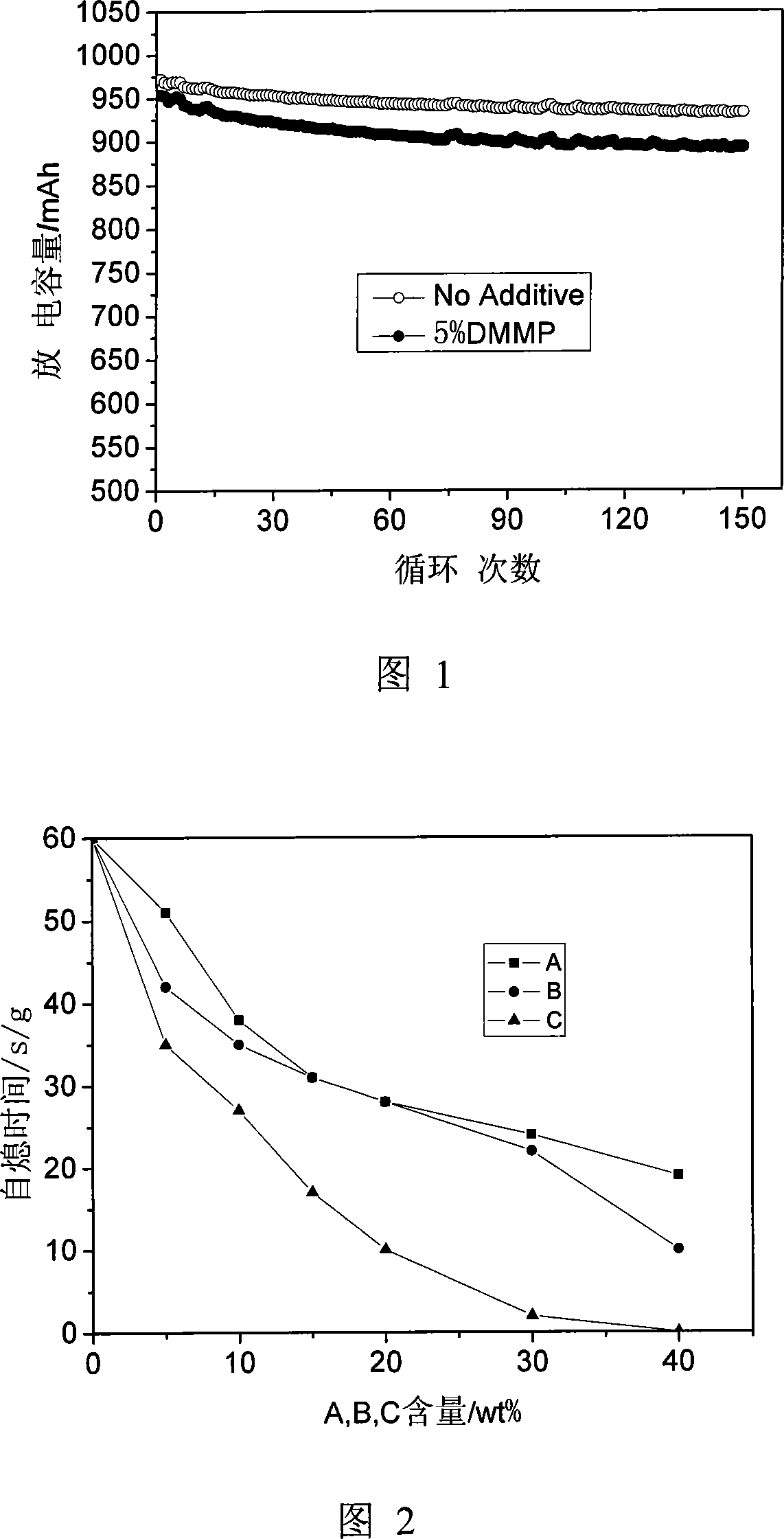

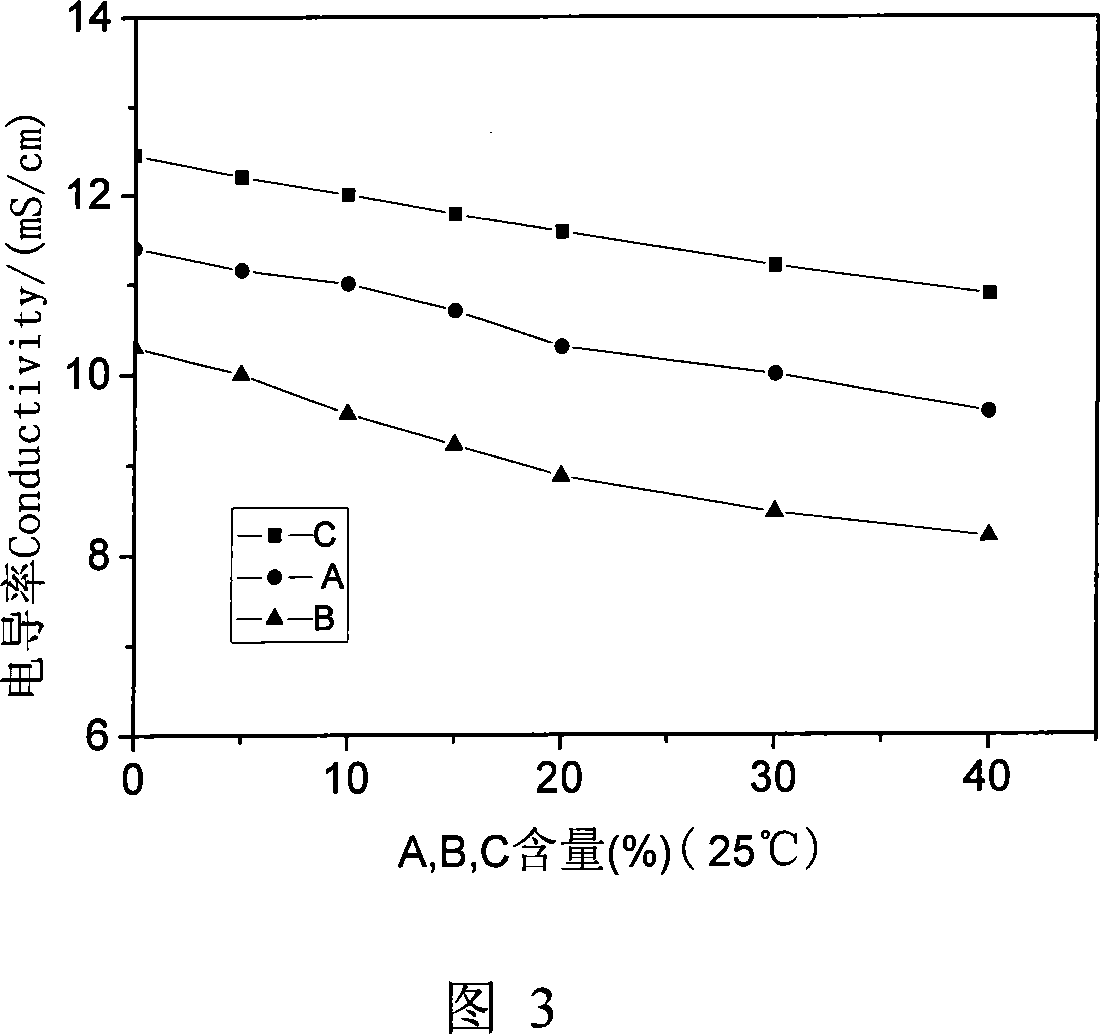

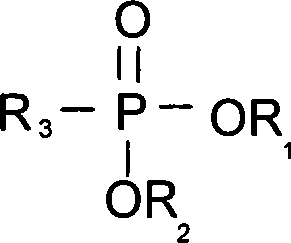

Phosphorus-contained flameproof additive agent for lithium ion cell electrolysing solution and method of use thereof

InactiveCN101083345AHigh in phosphorusImprove flame retardant performanceSecondary cellsHeat-exchange elementsPole pieceStructural formula

The invention publishes a phosphoric flame-resistant additive which is used in the solution of the lithium ion battery, which is a phosphoric organic compound, its basic structural formula likes right, or is the isometry body of the state structure; of which R1, R2, R3 are alkyl CnH2n+1 or alkene base CnH2n-1, and the carbon atom number of R1, R2, R3 is 1<=n<=4. The application method of the phosphoric flame-resistant additive is adding the phosphoric flame-resistant additive in the ordinary lithium ion battery solution; its quantity is the 5 to 40wt% of the lithium ion battery solution weight. The phosphoric flame-resistant additive has high phosphoric quantity, the good flame-resistant effect, and low viscosity, not only enables the electrolyte to have the good flame retardance, simultaneously has little influence of viscosity, conductivity of electrolyte, has good wettability with positive and negative pole piece and the membrane, and has good charging and discharging performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

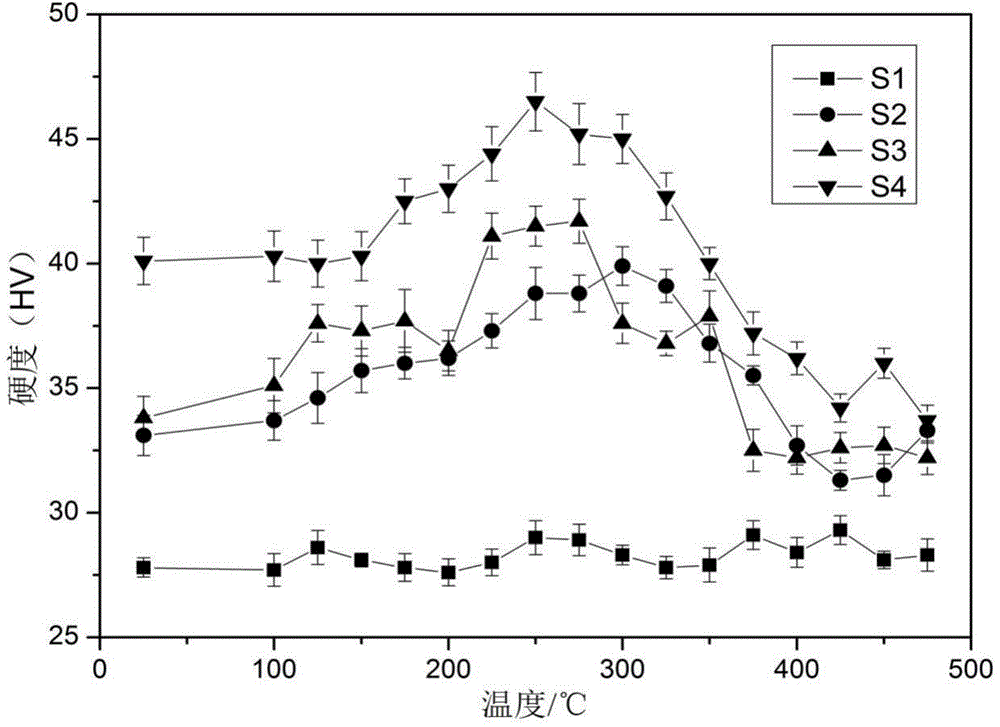

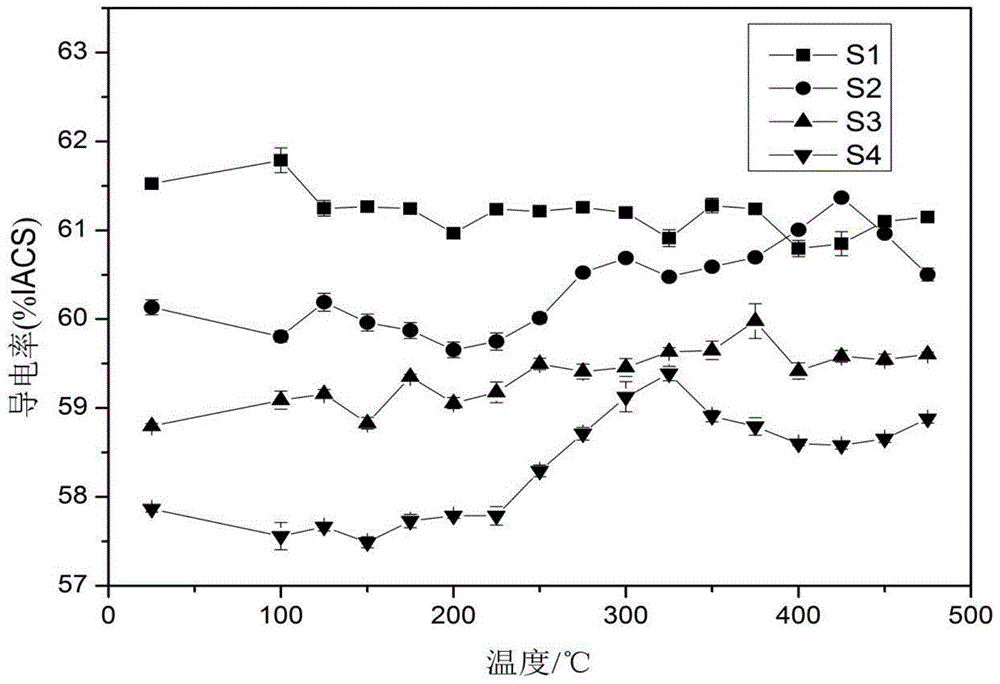

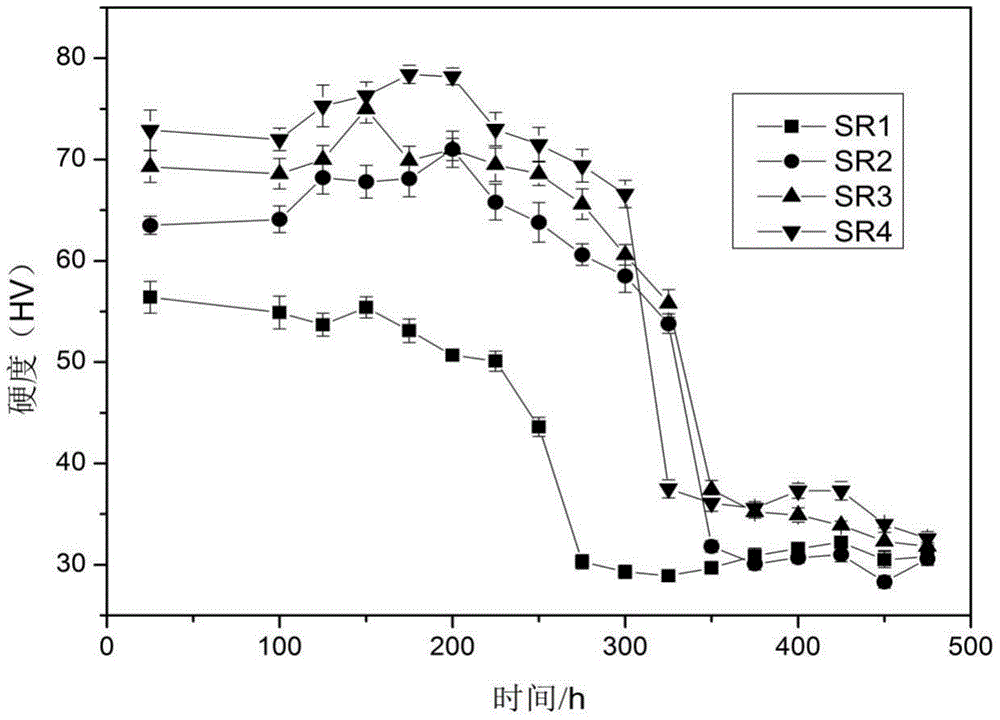

Al-Er-Cu high-strength high-electric conductivity aluminium alloy and thermomechanical treatment technology thereof

InactiveCN104946943ALittle effect on conductivityImprove conductivitySolution treatmentRoom temperature

An Al-Er-Cu high-strength high-electric conductivity aluminium alloy and a thermomechanical treatment technology thereof belong to the technical field of alloy. The alloy is formed by adding 0.22-0.27% of Er and 0.55-1.09% of Cu into an aluminium matrix. Al-Er-Cu alloy is smelted under the temperature of 770+ / -10 DEG C, is fully stirred and then is cast to obtain as-cast alloy. The solid solution aging thermal treatment technology comprises the following steps: the alloy is firstly subjected to solution treatment for 24 hours under 640+ / -10 DEG C, and is subjected to water quenching to a room temperature; and then the alloy is subjected to isochronal aging for 3 hours at intervals of 25 DEG C between 100 DEG C and 475 DEG C. The thermomechanical treatment technology comprises the following steps: after the alloy subjected to solution treatment is cold-rolled, the alloy is subjected to isochronal aging for 3 hours at intervals of 25 DEG C between 100 DEG C and 475 DEG C, or after the alloy is subjected to solution treatment and cold rolling as well as peak aging and cold rolling, the alloy is subjected to isothermal annealing under the temperature of 200 DEG C. According to the invention, the solution strengthening, the precipitated phase strengthening and the work hardening of Cu are adopted, and a mass of nanoscale strengthening phase particles are precipitated in the annealing process, so that the alloy is strengthened in the annealing process, and the electric conductivity of the alloy is further improved.

Owner:BEIJING UNIV OF TECH

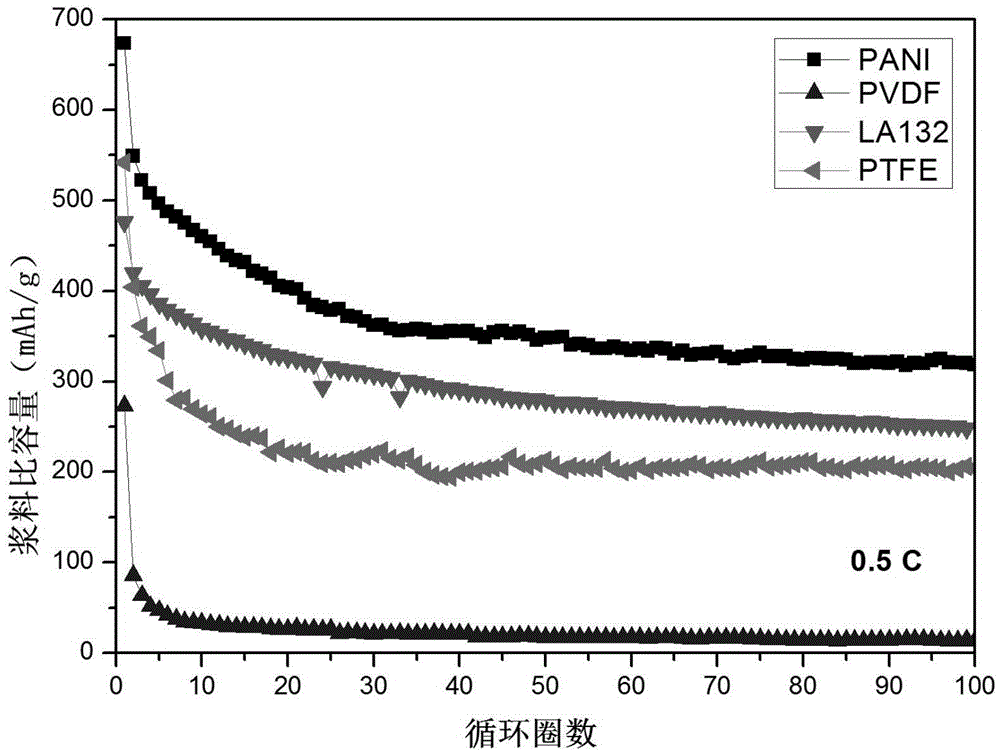

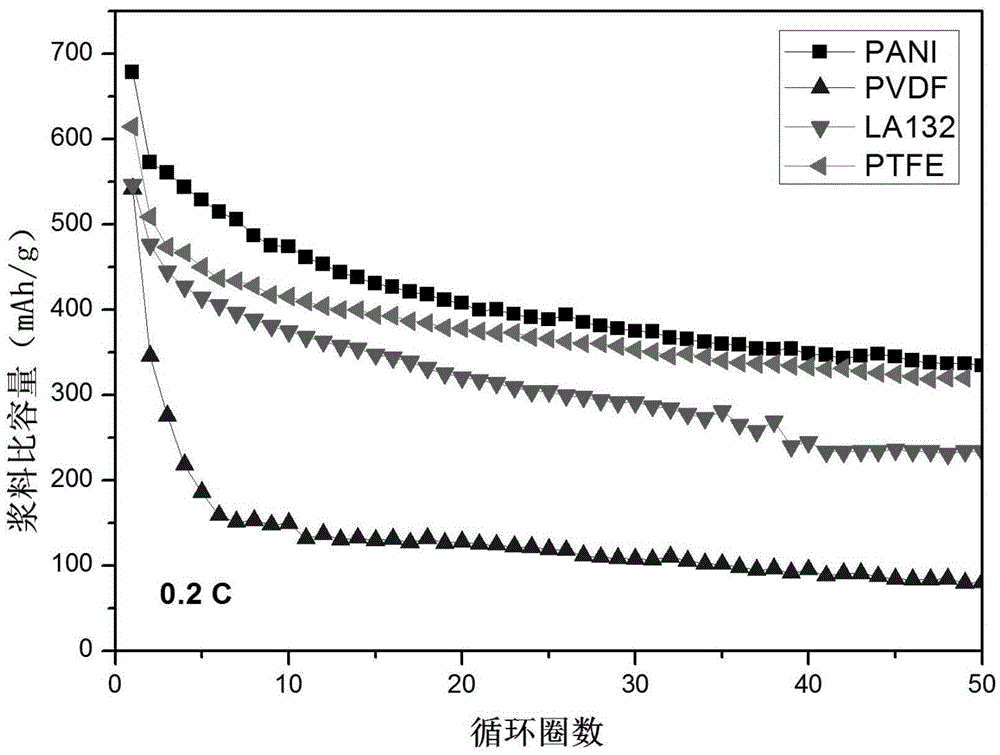

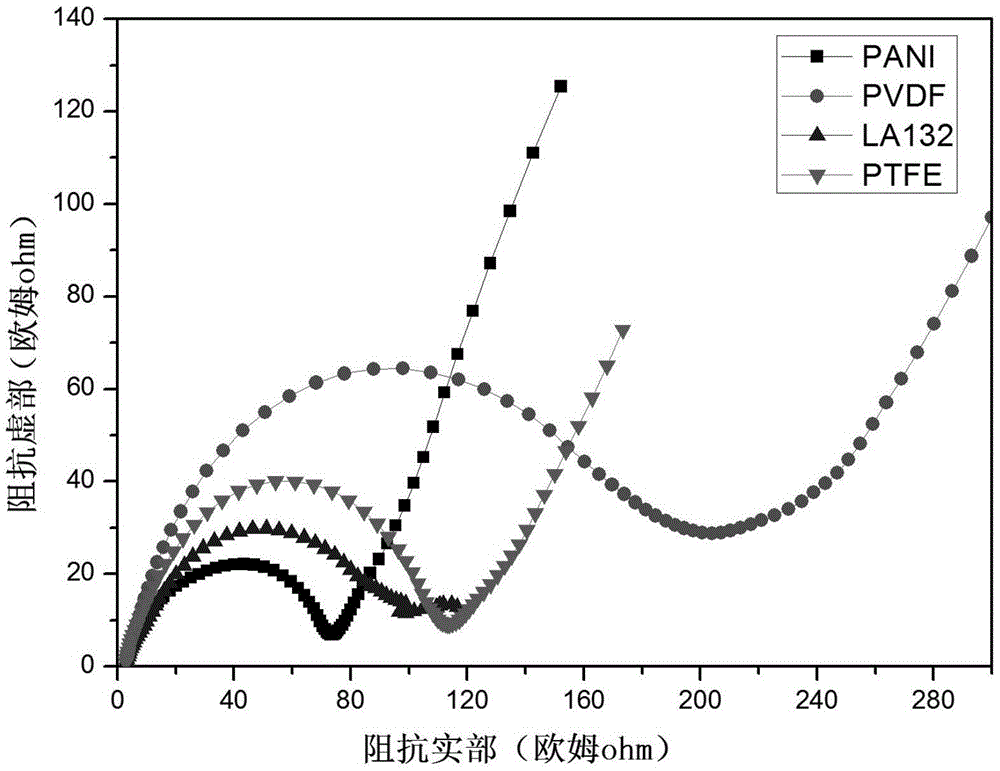

Conductive adhesive for positive electrode of lithium-sulfur battery and preparation method of conductive adhesive

InactiveCN105655593AReduce Shuttle EffectImprove cycle lifeCell electrodesLi-accumulatorsPolymer scienceAdhesive

The invention provides a conductive adhesive for a positive electrode of a lithium-sulfur battery and a preparation method of the conductive adhesive, and belongs to the technical field of lithium-sulfur battery materials. The problems that the existing conductive adhesive consists of a conductive component and a non-conductive component, and the use amount of the adhesive is large are solved. The adhesive consists of a doped conductive polymer material and a good solvent, wherein the mass fraction of the doped conductive polymer material is more than or equal to 0.25%. The invention also provides a preparation method of the conductive adhesive for the positive electrode of the lithium-sulfur battery. The doped conductive polymer material is dissolved in the good solvent until the doped conductive polymer material is completely dispersed to obtain the conductive adhesive for the positive electrode of the lithium-sulfur battery. The adhesive is not added with other non-conductive components, so that the cycle life of the battery is prolonged; during film formation, the density of conductive polymer is relatively low, and therefore the use amount of the adhesive is very small, and the proportion of sulfur in the positive electrode material is improved, thereby the specific capacity of the battery is increased.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Aluminium alloy conductor and preparation method thereof

InactiveCN103014461AHigh strengthImprove toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthTitanium

The invention relates to an aluminium alloy conductor and a preparation method thereof. The aluminium alloy conductor comprises the following components in percentage by weight: 1.0-1.1% of Cu, 0.03-0.05% of Fe, 0.001-0.0015% of C, 0.003-0.005% of Ti, 0.003-0.005% of V, 0.1-0.3% of Ni, 0.01-0.03% of W, 0.003-0.005% of La-containing rare earth and the balance of Al and inevitable impurities. By adopting the technical scheme provided by the invention, the strength of the aluminium alloy conductor is improved while the influence on the conductivity of the conductor is less, and the toughness of the aluminium alloy conductor is improved.

Owner:张桂芬

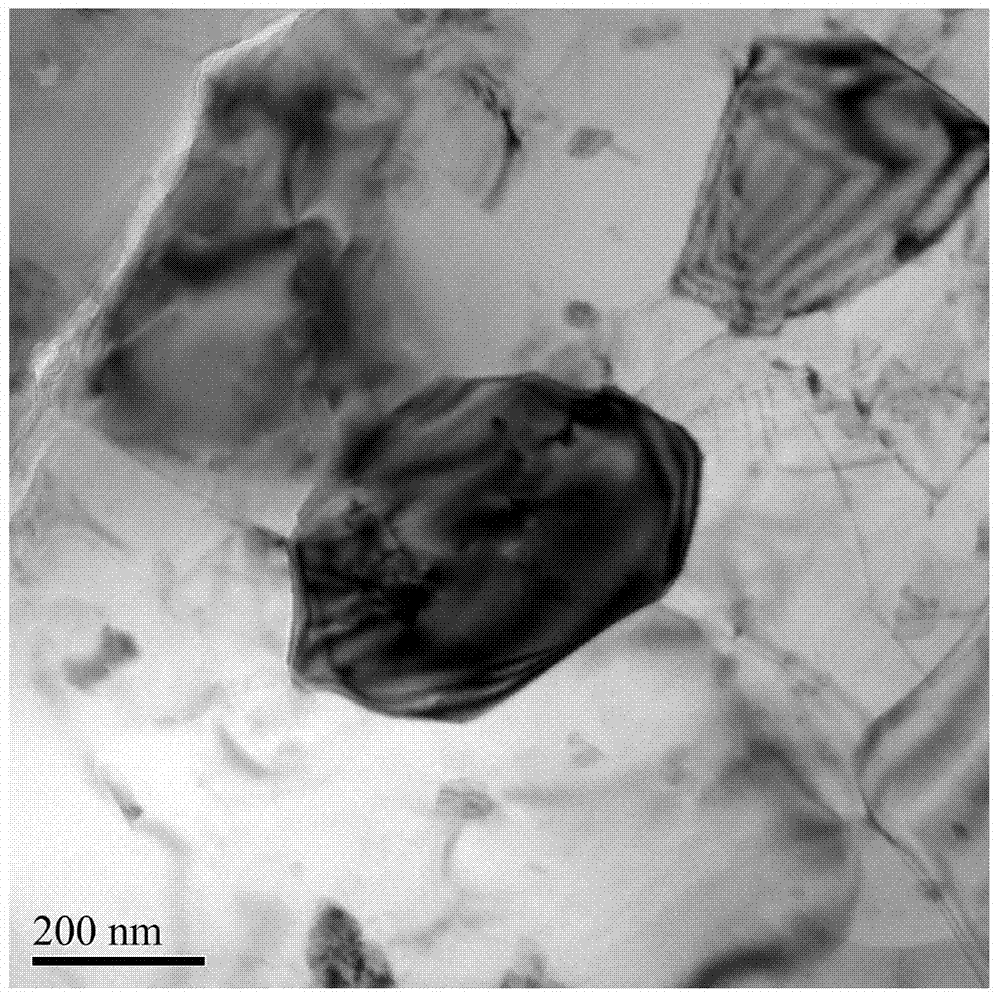

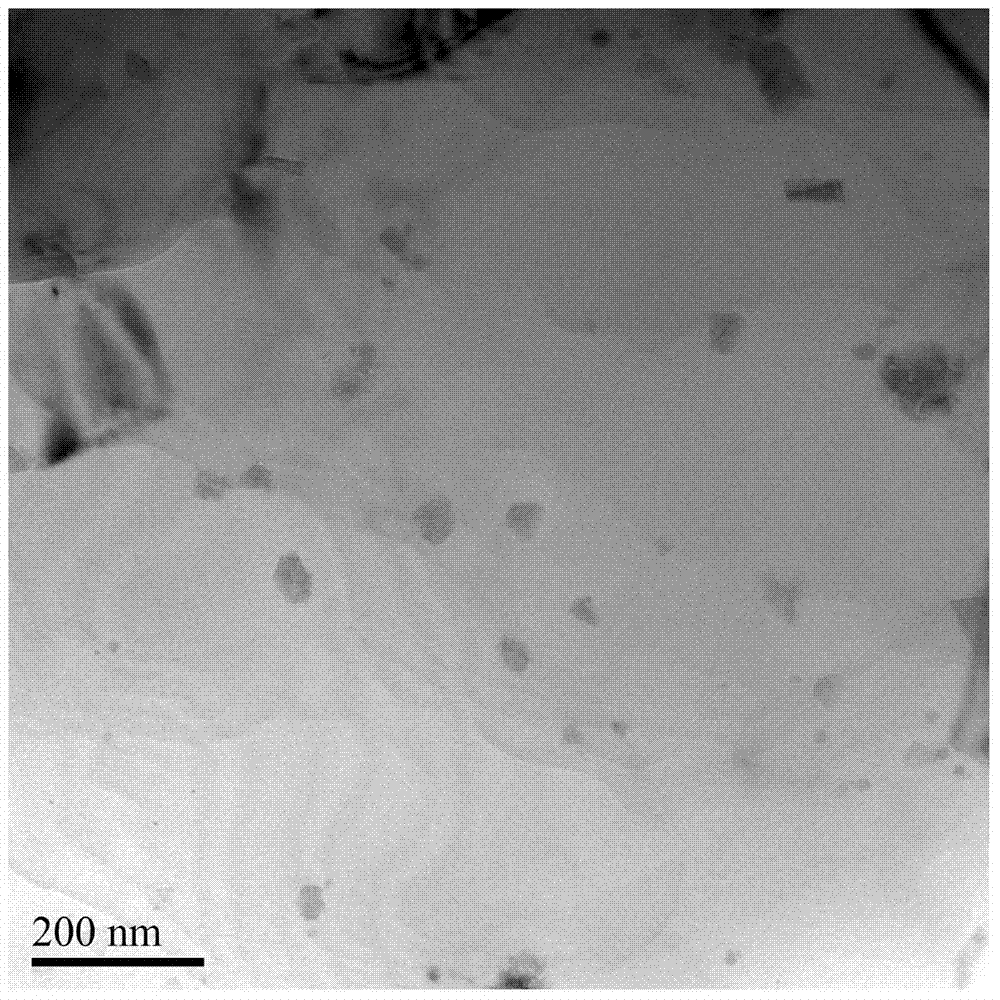

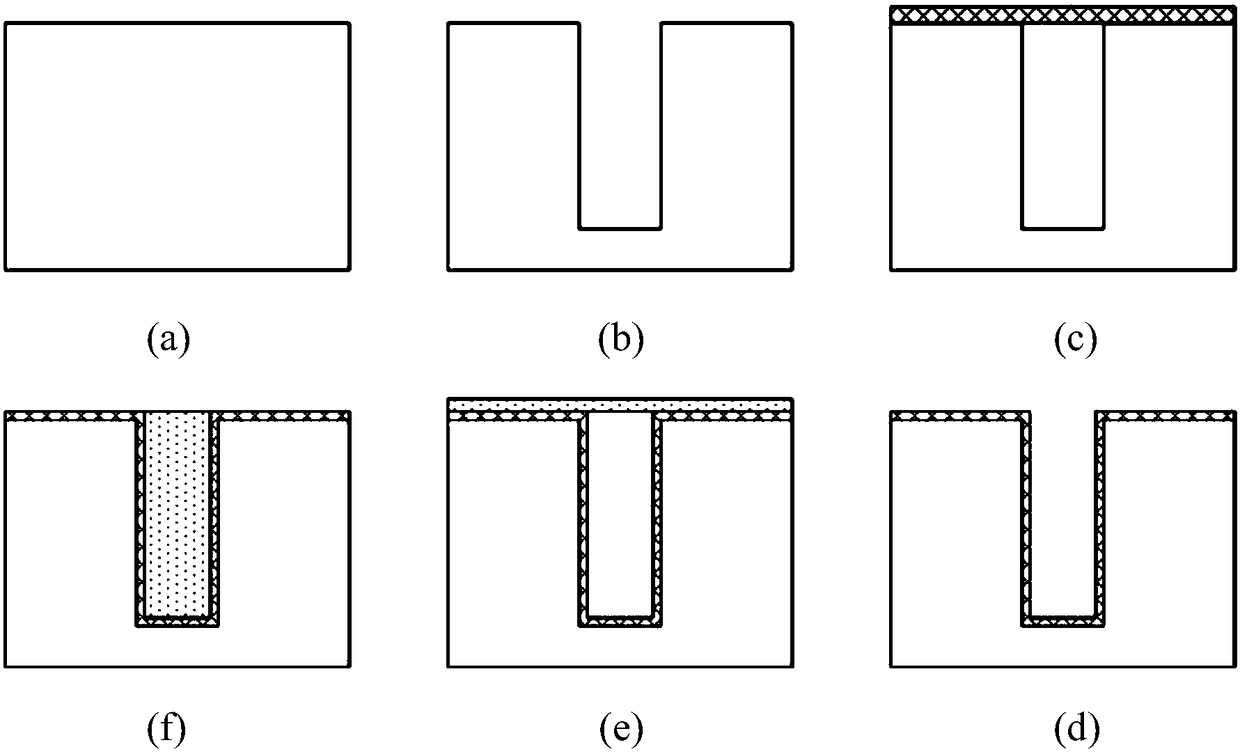

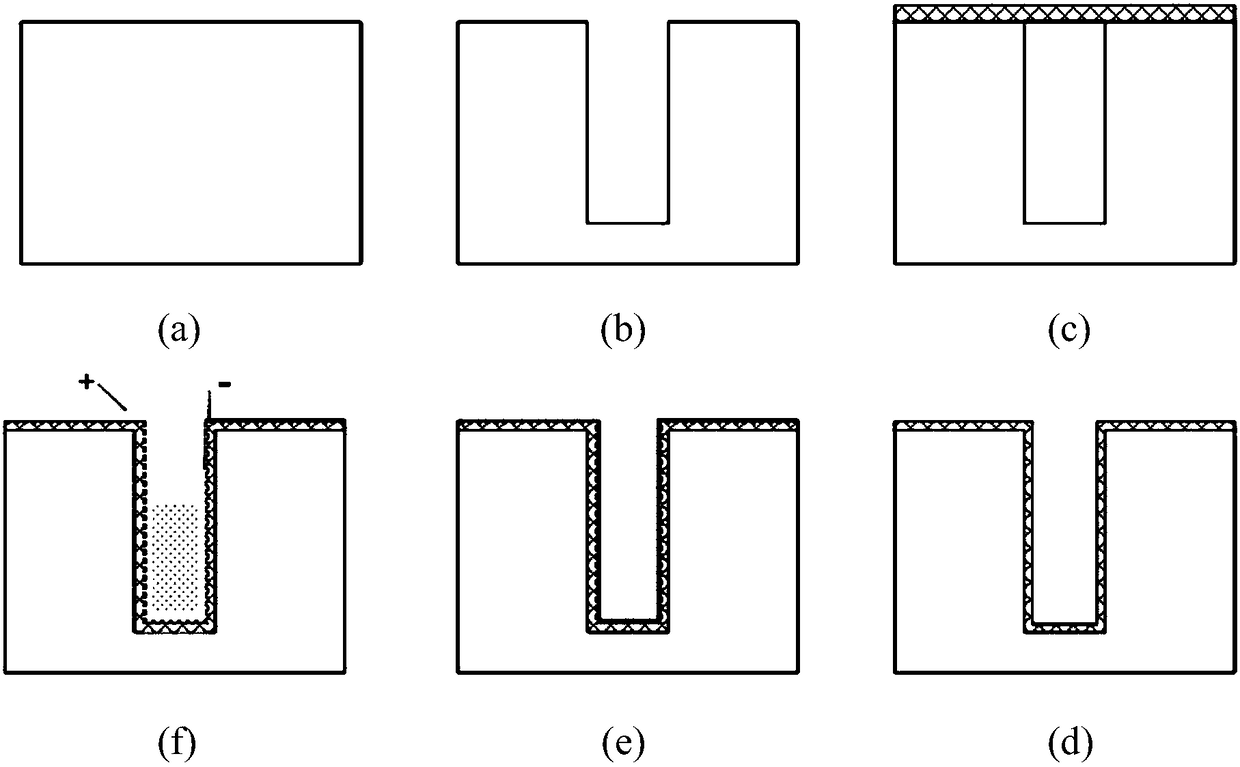

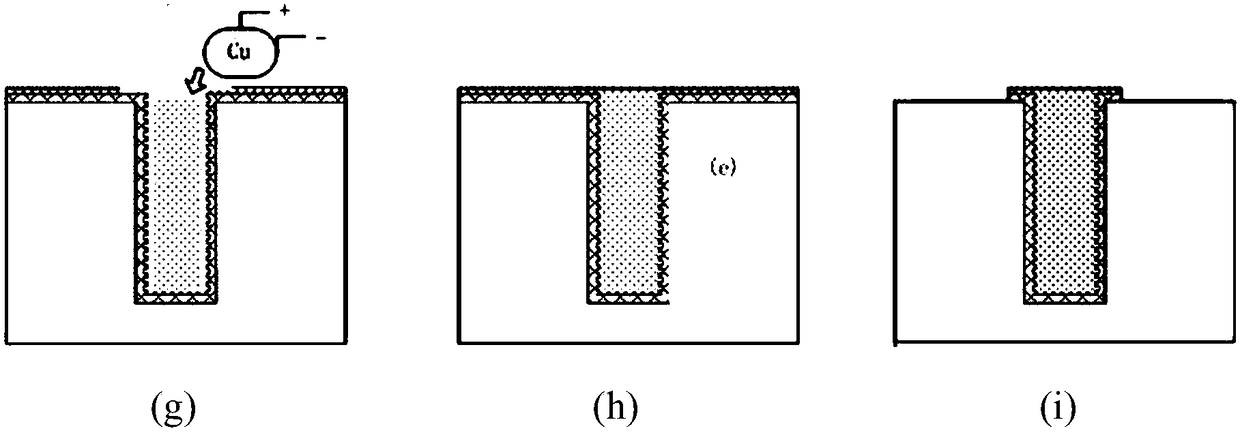

Composite material for filling vertical through silicon via (TSV) and filling method thereof

InactiveCN108109955AImprove reliabilityReduces the possibility of fracture failureSemiconductor/solid-state device manufacturingCopper atomFailure rate

The invention discloses a composite material for filling a vertical through silicon via (TSV) and a filling method thereof, wherein the composite material is mainly composed of diamond and copper, thediameter of the diamond is less than 1 [mu]m, and the diamond is monocrystal diamond or boron-doped diamond. The filling method comprises sputtering an adhesion layer, a barrier layer, and a seed layer in the TSV in advance, depositing the composite material by a composite electrodeposition method, and then attaching and depositing the copper atoms along a current direction to fully fill the TSVby energization so as to form a completely filled composite layer on a silicon wafer. By the key internal composition and structure of the composite material, the overall process flow design of the corresponding filling method, and the improvements in conditions and parameters of each step, and using a specific composite material as a TSV filling material and using a specific filling method, the reliability of the TSV can be improved and the failure rate of the TSV can be reduced to avoid filling defects.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength and high-conductivity copper alloy material

InactiveCN105936983APrevent aggregation to form segregationPrevents the formation of large diameter copper alloy phasesAlloy elementHigh conductivity

The invention discloses a high-strength and high-conductivity copper alloy material. A high-strength and high-conductivity copper alloy comprises 0.6 wt%-0.8 wt% of Cr, 0.06 wt%-0.08 wt% of Be, 0.18 wt%-0.2 wt% of Ni, 0.03 wt%-0.04 wt% of Si, 0.08%-0.1 wt% of Zn, 1.3 wt%-1.5 wt% of Ag and the balance Cu. On component design, an alloy element is selected to be added in the copper alloy material, wherein the influence on the electric conduction capability of the copper alloy is very small when the content of the alloy element is small; on the premise that the electric conduction performance of a copper alloy base body is guaranteed, solution strengthening, age hardening and other factors of the copper alloy are comprehensively considered, and grain refinement of an alloy phase is facilitated; under the condition that it is guaranteed that the electric conduction performance of the copper alloy material is not reduced, the mechanical performance of the copper alloy is greatly improved, and the problem of the contradiction between the strength and electric conductivity of a high-strength and high-conductivity copper alloy base body is effectively solved; and meanwhile good high-temperature resisting performance is achieved, and heat stability is good.

Owner:河南江河机械有限责任公司 +1

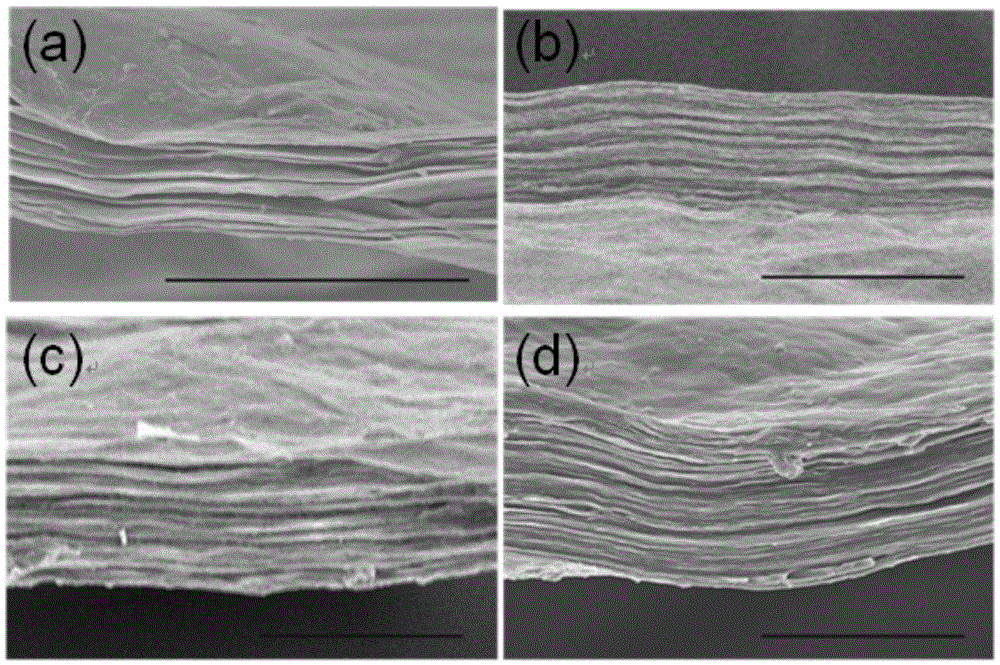

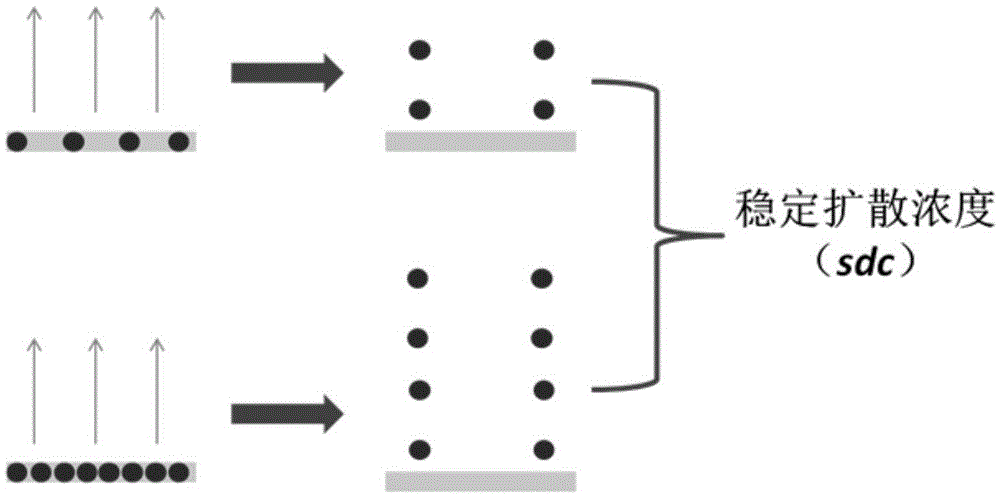

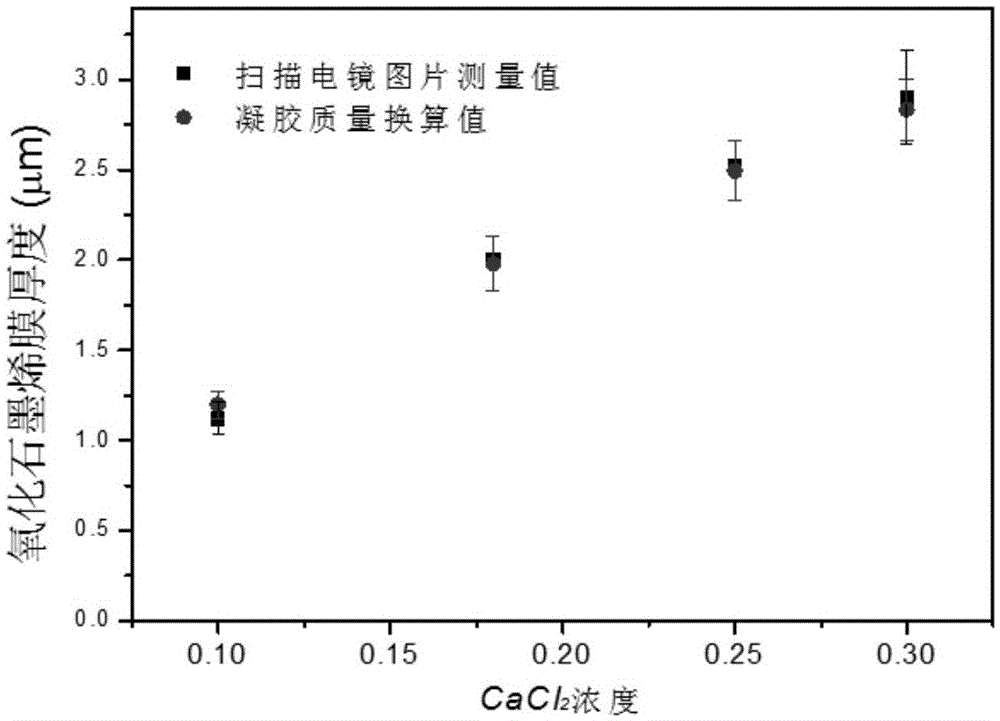

Graphene self-supporting material subjected to ion-induced assembly and preparation method thereof

The invention discloses a graphene self-supporting material subjected to ion-induced assembly and a preparation method thereof. The preparation method of the graphene self-supporting material subjected to the ion-induced assembly comprises the following steps of (1), uniformly mixing graphene oxide, a solvent and ammonia water to obtain graphene oxide dispersion liquid; (2), taking a substrate, and adsorbing an ionic cross-linking agent solution with certain concentration on the substrate; (3), immersing the substrate in the graphene oxide dispersion liquid, and enabling the substrate to stay for a certain time; (4), taking out the substrate to which graphene oxide gel is adhered; (5), oven-drying or freeze-drying the gel, and removing the substrate, so as to obtain a graphene oxide self-supporting material; (6), carrying out chemical reduction and heat treatment on the material, so as to obtain the graphene self-supporting material. According to the graphene self-supporting material subjected to the ion-induced assembly and the preparation method thereof, the quick preparation, the thickness control and the microstructure control of a graphene material are realized simply and conveniently; the preparation of graphene materials in multiple forms and functions by using substrates in complicated shapes and made from multiple materials as templates is realized.

Owner:杭州德烯科技集团有限公司

Preparation technology of copper alloy for short process slot wedge

The invention discloses a preparation process of a copper alloy for short-flow slot wedges, which adopts the preparation processes of upward continuous casting→continuous extrusion→solution quenching→cold deformation→cryogenic treatment→aging; the copper alloy is composed of copper, nickel, silicon , chromium, silver, magnesium and other components, the technical solution provided by the invention, the obtained material performance is excellent, fully meet the use requirements of the turbine generator rotor slot wedge.

Owner:徐高杰

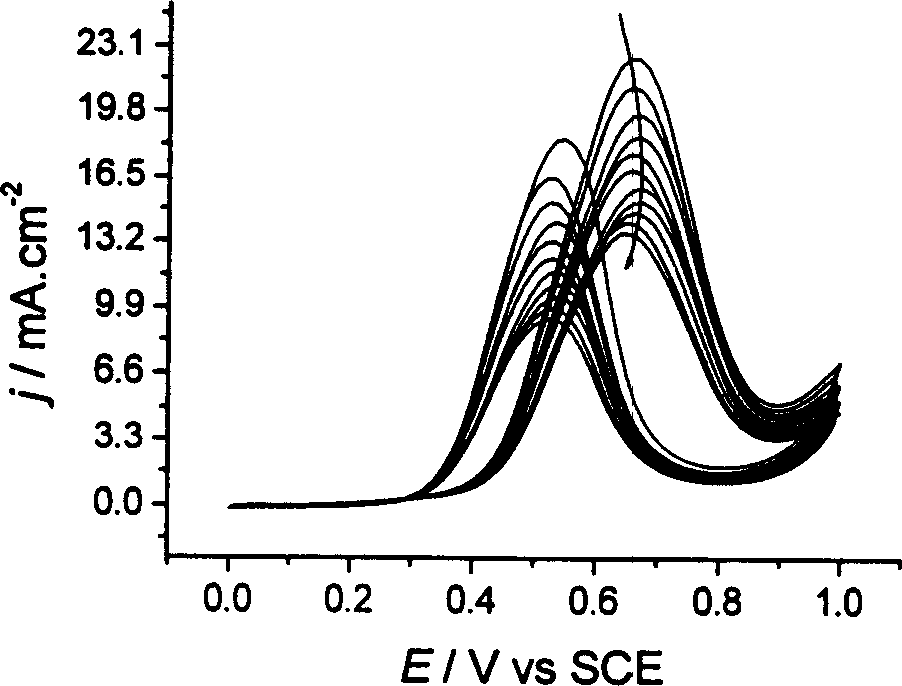

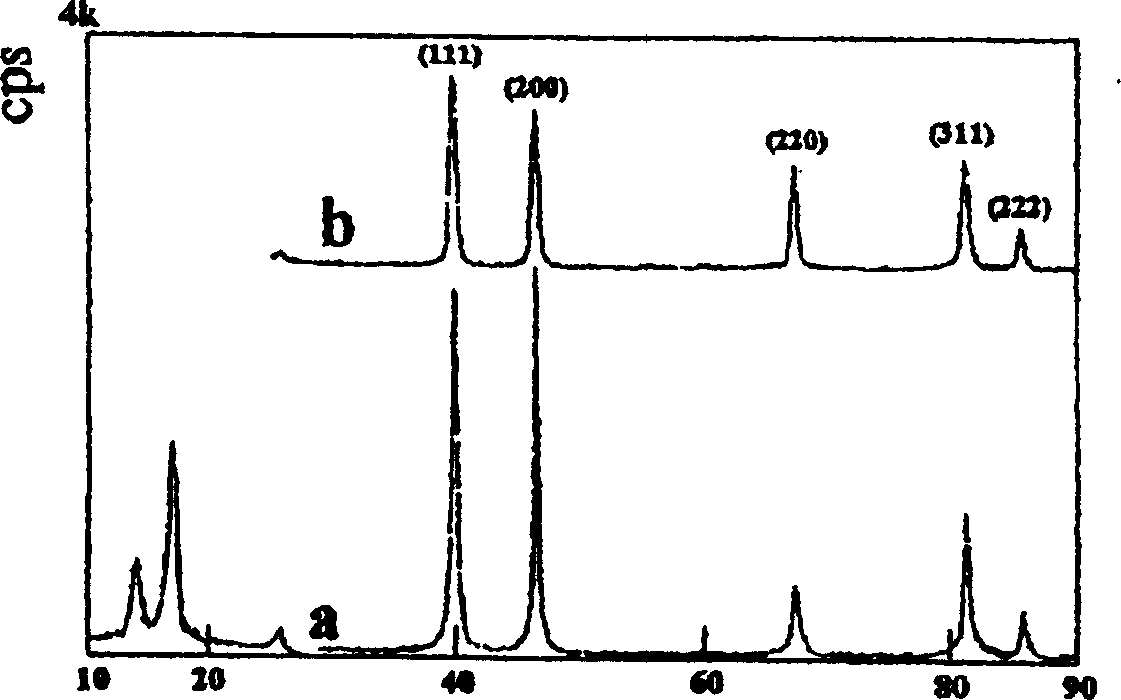

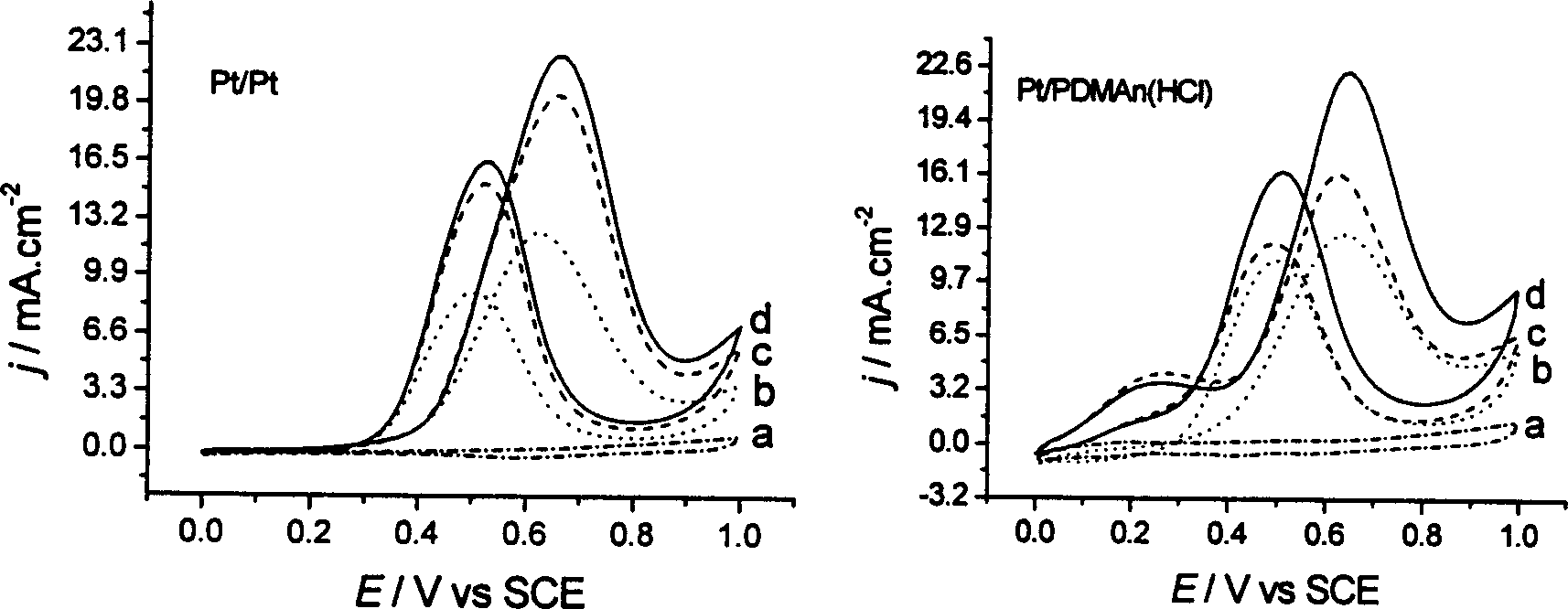

Methanol electro-oxidizing-catalyzing electrode, preparing process and application thereof

InactiveCN1667405AImprove solution processabilityLittle effect on conductivityMaterial electrochemical variablesPolyaniline derivativesElectricity

The invention discloses a menthol electro oxidation catalyst electrode, its process method and application, wherein the electrode relates to a metallization membrane modification electrode and is used as an electrochemical sensor for catalyzing menthol electro oxidation.A charged strong electron donating group polyaniline derivant poly-2,5-dimethoxybenzamine metallization membrane modification electrode comprises inert electrode base, conductive polymer membrane and catalyzer, wherein, polymer adhesion amount on the surface of base electrode is 0.3-1.0mgíñcm-2.The method comprises following steps: mixing PDMAn mixed with alcaine in N,N-dimethyl formamide or tetrahydrofuran to get 1.0í½10.0mg / mL liquor; coating liquor on electrode surface and drying it; changing coating times to adjust polymer adhesive materials; placing electrode in HCI liquor; conducting periodic scan or directional scan and changing times to get modification electrode with different platinum deposit rate.

Owner:XIAMEN UNIV

Lithium ionic cell electrolyte, preparation thereof and lithium ionic cell comprising the electrolyte

ActiveCN101359751AImprove securityGood charge and discharge performanceSecondary cellsElectrolytic agentElectrical battery

The invention discloses a lithium-ion battery electrolyte as well as a preparation method thereof and a lithium-ion battery containing the electrolyte. The electrolyte contains organic fluorine phosphorus compounds as general formula I shows, wherein Ph represents phenyl, P represents phosphorus atom, F represents fluorine atoms, and x is the number of replaced fluorine atoms on the benzene ring, 0 H01M 10 / 40 2 5 2 2008 / 9 / 27 101359751 2009 / 2 / 4 000000000 South China Normal University Guangzhou 510630 Liang Ying Li Weishan Rao Mumin Zhao Lingzhi Cai Zongping yang xiaosong 44245

Owner:SOUTH CHINA NORMAL UNIVERSITY

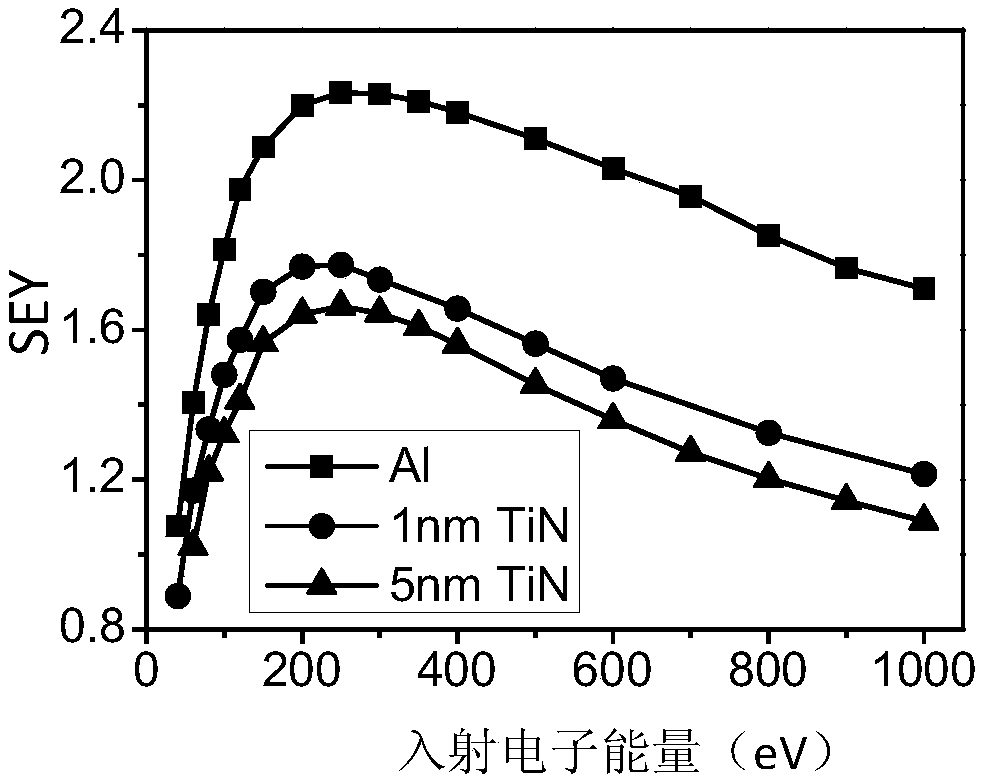

Method for preparing titanium nitride nano film on substrate surface, substrate with film and application thereof

ActiveCN108546929AHigh response controllabilityLower secondary electron emission coefficientChemical vapor deposition coatingNanometreSecondary electrons

The invention provides a method for preparing a titanium nitride nano film on a substrate surface, a substrate with the film and application thereof, and belongs to the technical field of secondary electron emission suppression. The method comprises the following steps: transferring a substrate to a reaction chamber through a pre-vacuum chamber, and vacuuming the reaction chamber; introducing an inert gas into the reaction chamber, annealing the substrate; returning the annealed substrate to the pre-vacuum chamber, and using an ammonia gas plasma and a gaseous titanium source for a plurality of gas washing cycles of the reaction chamber; sending the substrate back to the reaction chamber, maintaining the temperature of the reaction chamber at 150 to 220 DEG C, and using the ammonia gas plasma and the gaseous titanium source for plasma enhanced titanium nitride atomic layer deposition reaction to obtain the substrate with the titanium nitride nano film. The ultrathin film prepared by the method has strong controllability, bonding strength between the film and the substrate is high, surface conformality is good, and surface uniformity in complex structures such as plane and porous structures is high.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

High-strength and high-conductivity copper alloy wire material and preparation method thereof

ActiveCN111809079AReasonable ingredientsHigh strengthConductive materialMetal/alloy conductorsCorrosionSolid solution strengthening

The invention discloses a high-strength and high-conductivity copper alloy wire material and a preparation method thereof. The high-strength and high-conductivity copper alloy wire material comprises,by mass percent, 0.2-0.6% of Ni, 0.1-0.4% of Fe, 0.07-0.17% of Mg, 0.10-0.15% of Ca, 0.01-0.09% of Ag, 0.1-0.3% of La, 0.01-0.03% of P, 0.01-0.03% of Sn, 0.1-0.5% of Ti and the balance Cu. By means of Ni solution strengthening, a microalloying refine structure and a second phase, the high-strength and corrosion-resistant Cu-Ni alloy wire material with excellent comprehensive performance is obtained.

Owner:郑州恒天铜业有限公司

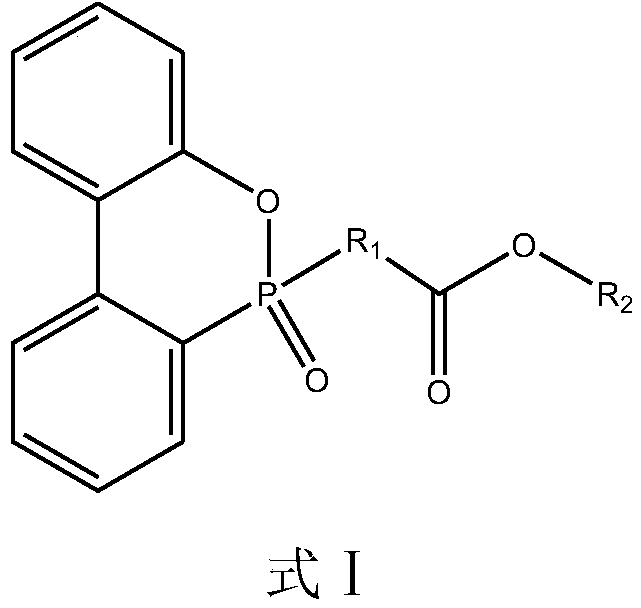

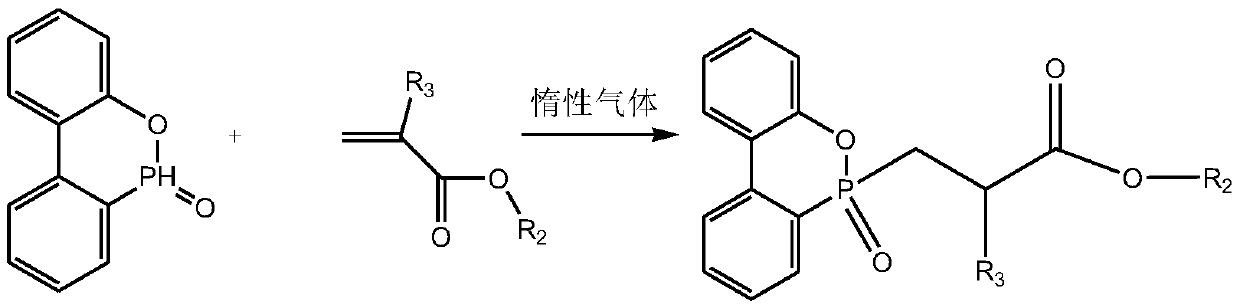

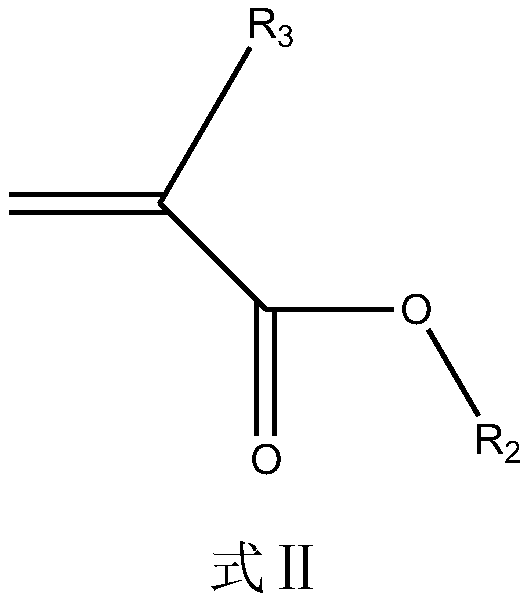

Flame retardant, preparation method and application thereof

InactiveCN109734746AImprove flame retardant performanceImprove electrochemical performanceGroup 5/15 element organic compoundsLi-accumulatorsFire retardantElectrolyte

The invention provides a flame retardant, which has a more obvious flame retardant effect compared with the conventional flame retardant. The invention further provides a preparation method of the flame retardant, the method has the characteristics of simple preparation process and low cost. The invention further provides a lithium battery electrolyte which is added with the flame retardant, can maintain good conductivity and has better compatibility with the negative electrode of the lithium battery, and can ensure that the lithium battery has better electrochemical performance and a better flame retardant effect at the same time. The invention further provides a lithium battery, which comprises the lithium battery electrolyte. The lithium battery not only has good electrochemical performance, but also has a good flame retardant effect and is safer in use.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

Preparation method of polyaniline/P (MMA-BA-HEA) conductive composite material

The invention relates to a preparation method of a polyaniline / P(MMA-BA-HEA) conductive composite material, which takes butyl acrylate, methyl methacrylate, hydroxyethyl acrylate and aniline as raw materials, and comprises the following steps: first, preparing a P(MMA-BA-HEA) emulsion by taking fatty alcohol-polyoxyethylene ether, sodium dodecyl benzene sulfonate and n-amyl alcohol as emulsifying agents and taking azo-diisopropyl-imidazoline as an initiator; and then obtaining the polyaniline (PANI) / P (MMA-BA-HEA) conductive composite material by the in situ polymerization of the aniline in the copolymer emulsion. The polyaniline conductive composite material of the invention has good conductivity and processability, the highest conductivity of the composite material is 1.472S. cm<-1>, the composite material PANI / P (MMA-BA-HEA) has good solubility in organic solvents, such as cyclohexanone, N-methylpyrrolidone and dimethyl sulfoxide, and the problems of processing difficulty and application of the polyaniline conductive material are solved.

Owner:SHAANXI UNIV OF SCI & TECH

Copper alloy for power generator rotor slot wedge and machining process of copper alloy

The invention discloses a copper alloy for generator rotor slot wedges and its processing technology. The copper alloy is composed of copper, nickel, silicon, chromium, cobalt, aluminum, magnesium, titanium, etc., and is smelted→extruded→cold deformed→aging → second cold deformation → second aging and other processing techniques; the technical solution provided by the present invention has excellent material properties and fully meets the requirements for the use of generator rotor slot wedges.

Owner:徐高杰

Manufacturing method of highly-conductive and heat-resisting electrode cross beam component

The invention provides a casting method of a highly-conductive and heat-resisting electrode cross beam component. The method comprises the following steps of: 1. selecting alloy materials; 2. manufacturing a metal mold according with sizes of the component; 3. founding and forming casting alloy materials; 4. and performing thermal process to cast formed pieces; wherein the composition ingredients of the adopted alloy materials include elements of Al, Mg, Si, Zr, Ce and B; the mass percent content of each composition ingredient contains 0.5-1.0% of Mg, 0.4-0.8% of Si, 0.6-0.8% of Zr, 0.05-0.1% of Ce, and 0.03-0.06% of B; the allowance is Al and inevitable impurities; the mass percent ratio of the impurity elements contained in the alloy materials is that: Fe is less than or equal to 0.2%, Cu is less than or equal to 0.05%, Mn is less than or equal to 0.02%, Cr is less than or equal to 0.02%, Zn is less than or equal to 0.05% and Ti is less than or equal to 0.05%. With the casting method, the aluminum alloy electrode cross beam component with good thermal resistance, mechanical property and high electrical conductivity performance can be cast, the electric conductivity can be up to 45% IACS (International Annealed Copper Standard), the temperature can be up to 250 DEG C in long-term application, and the casting method can be used for manufacturing the electrode cross beam components needed by the industrial field of electrolytic zinc.

Owner:沈阳铸研科技有限公司

Tungsten-copper alloy prepared from copper-cerium alloy and preparation method thereof

The invention discloses a tungsten-copper alloy prepared from a copper-cerium alloy by infiltration. The tungsten-copper alloy is prepared from the copper-cerium alloy of which cerium accounts for 0.6 to 2.4 percent of the mass of copper. The invention also discloses a method for preparing the tungsten-copper alloy, which comprises the following steps of: a, placing a corundum crucible in a vacuum furnace for heat preservation and pre-heating; b, weighing the cerium and the copper in a mass ratio of 0.6-2.4 percent:1, polishing the surface of strip-shaped rare earth, placing the polished rare earth into a copper bar, sealing the copper bar with copper powder, placing the sealed copper bar into the pre-heated corundum crucible, placing the corundum crucible in the vacuum furnace for smelting and finally cooling the smelted product along with the furnace to room temperature to obtain the copper-cerium alloy; and c, laminating the copper-cerium alloy prepared by the step b with a tungsten frame, placing the laminated product in a graphite crucible and then placing the graphite crucible in a high-temperature hydrogen atmosphere sintering furnace for sintering and infiltration to obtain the tungsten-copper alloy. The rigidity and the compression strength of the tungsten-copper alloy prepared by the method are obviously improved.

Owner:XIAN UNIV OF TECH

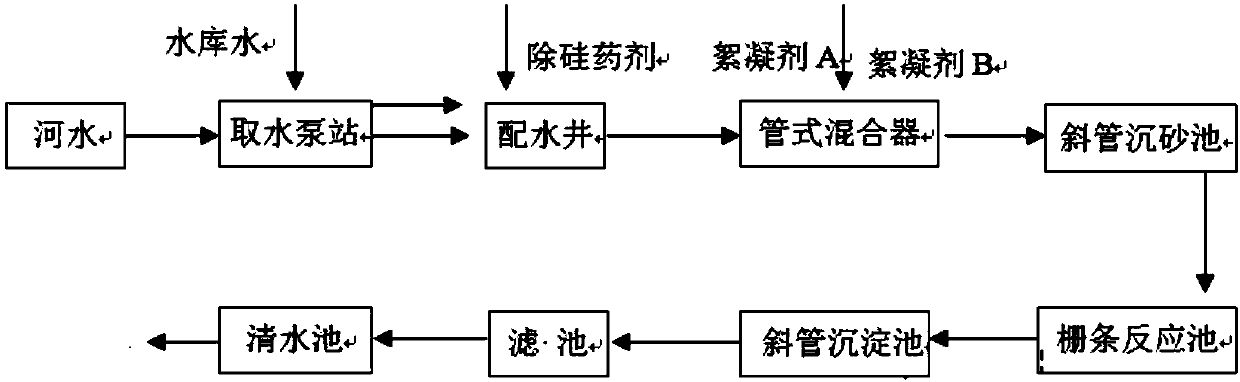

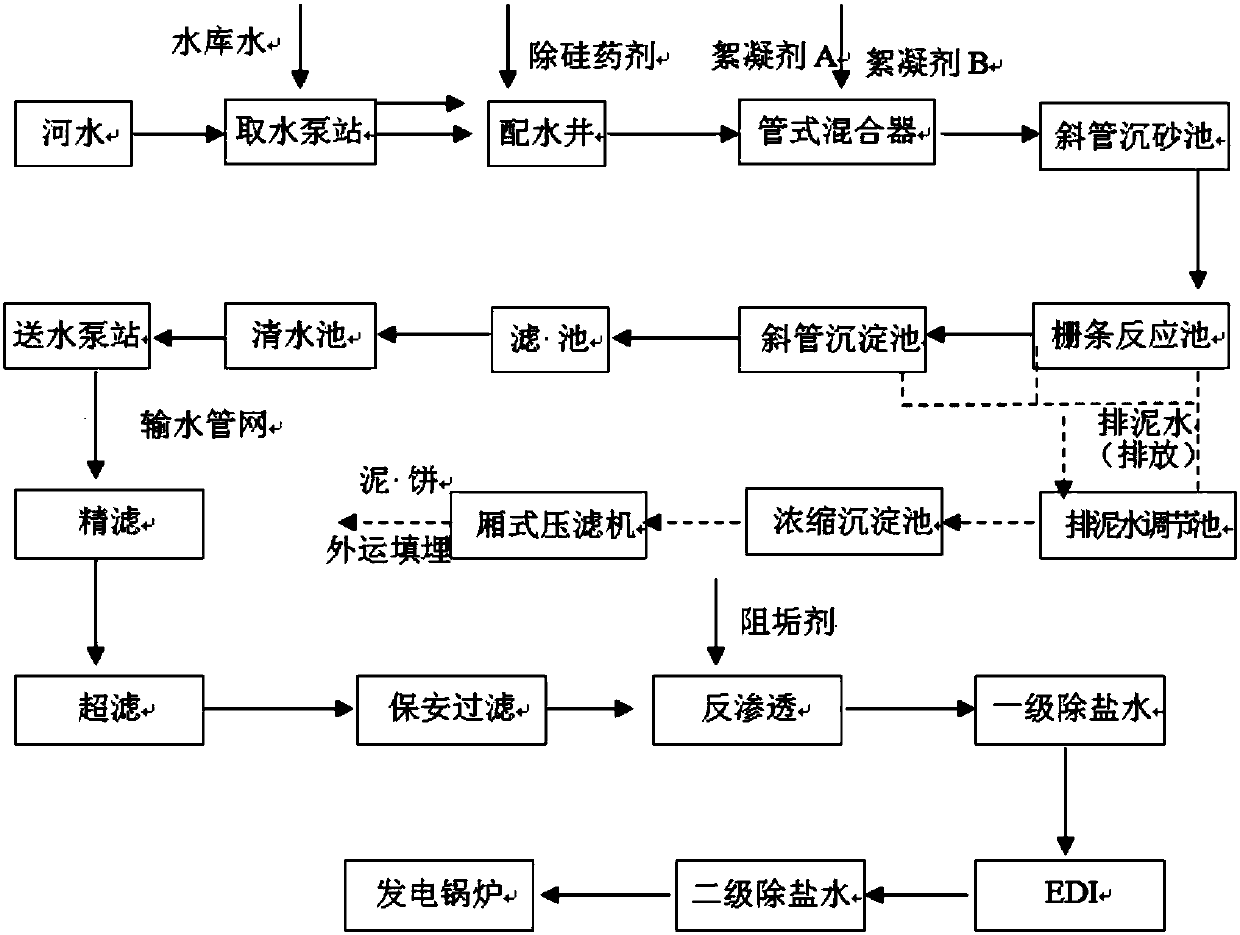

Method and treatment system for reducing silicon content in industrial water

InactiveCN108017199AReduce silicon contentHigh removal rateGeneral water supply conservationMultistage water/sewage treatmentAlkaline earth metalFiltration

The invention belongs to the technical field of industrial water treatment and relates to a method and treatment system for reducing the silicon content in industrial water. The method for reducing the silicon content in industrial water utilizes compounding and adding of several agents for treatment and comprises adding a silicon removing agent into raw water to be treated, carrying out uniform mixing, adding a flocculant A into the mixture, carrying out uniform mixing, optionally adding a flocculant B into the mixture, and carrying out precipitation and filtration to reduce the silicon content of the water. The silicon removing agent comprises an alkali metal compound and / or an alkaline earth metal compound. The flocculant A includes an inorganic high-molecular flocculant. The flocculantB includes an organic polymer flocculant. The method and system can effectively reduce the silicon content in the raw water and effectively relieve the silicon removal load in the primary desalination water station system. The method has simple processes, is easy to operate and has good treatment effects.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

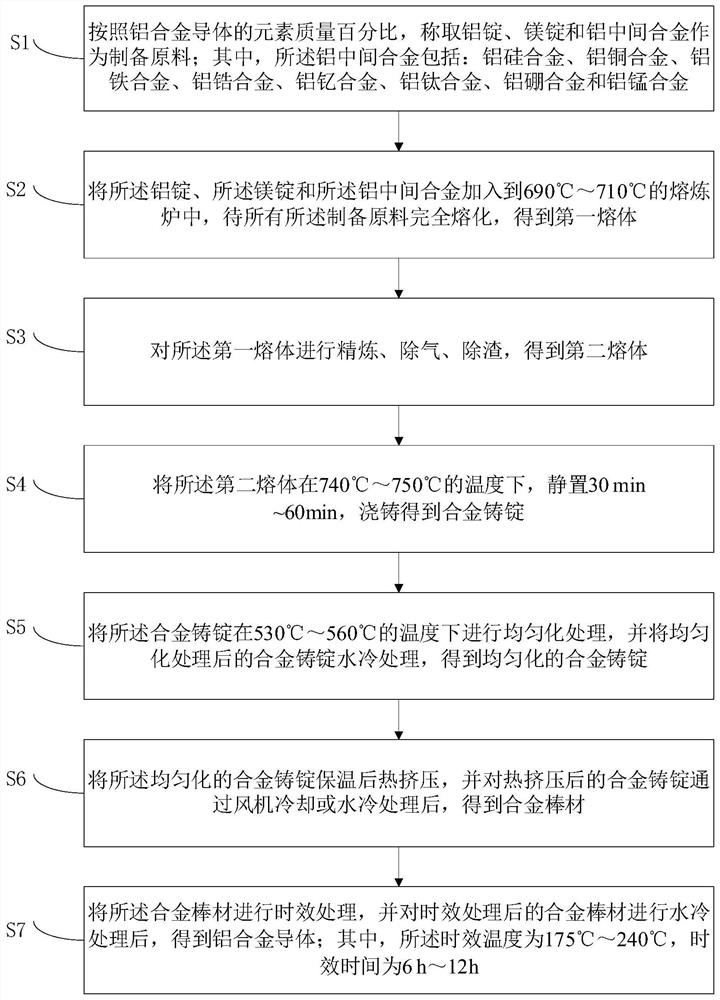

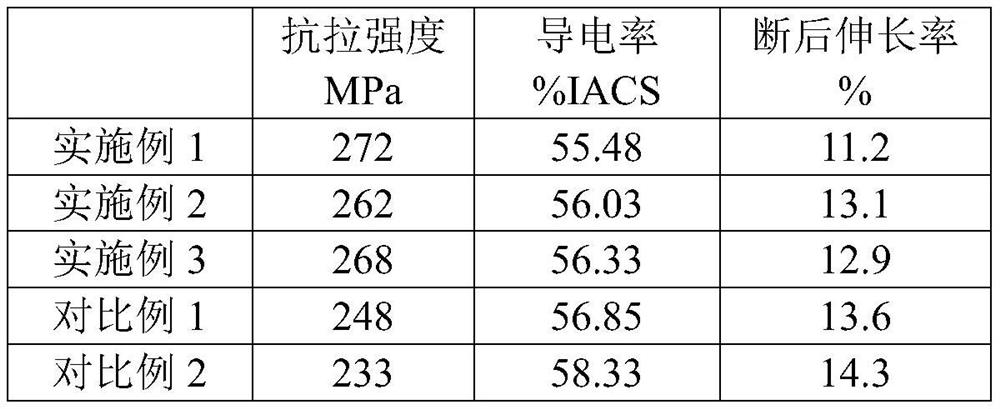

Aluminum alloy conductor and preparation method thereof

ActiveCN112662923ALow conductivityImprove mechanical propertiesMetal/alloy conductorsElectrical conductorManganese

The invention provides an aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises following elements in percentage by mass: 0.50%-0.70% of magnesium, 0.35%-0.60% of silicon, 0.05%-0.15% of copper, 0.05%-0.20% of iron, 0.01%-0.15% of zirconium, 0.03%-0.15% of yttrium, 0.003%-0.015% of titanium, 0.03%-0.05% of boron, 0.001%-0.015% of manganese, smaller than 0.15% of inevitable impurities and the balance of aluminum. By means of the aluminum alloy conductor and the preparation method thereof, the problems that the conductivity of the aluminum alloy is greatly reduced and the like due to the fact that alloy elements for improving the strength are added into existing conductive aluminum alloy in the prior art can be solved.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

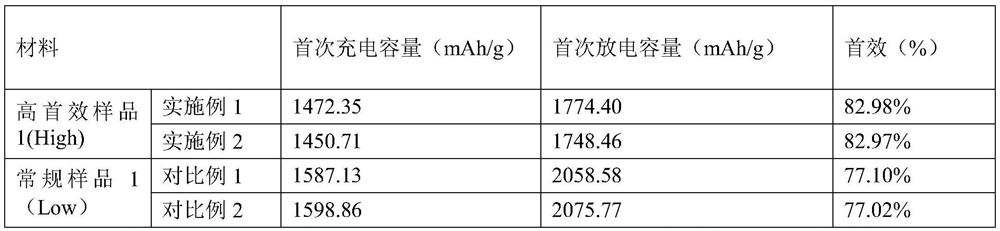

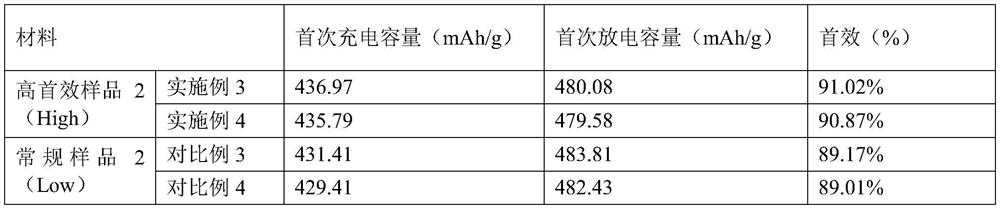

Negative electrode plate containing silicon-based negative electrode material with high initial Coulombic efficiency and lithium ion battery

InactiveCN113363432AImprove the first charge and discharge efficiencyLow costNegative electrodesSecondary cellsCarbon coatingElectrical battery

The invention relates to the technical field of lithium batteries, and discloses a silicon-based negative electrode material with high initial Coulombic efficiency. The preparation process comprises the steps of 1, carbon coating; 2, mixing with LiAlH4; and 3, pyrolyzing, washing and drying to obtain a composite SiOy / C material, namely, the silicon-based negative electrode material with high initial Coulombic efficiency, wherein y is greater than 0 and less than 1. The invention also discloses a negative electrode plate containing the silicon-based negative electrode material with high initial Coulombic efficiency, the negative electrode plate comprises a copper foil, the surface of the copper foil is coated with negative electrode slurry, the negative electrode slurry comprises a negative electrode active substance, a conductive agent and a binder, and the negative electrode active substance is a composite SiOy / C material or a material mixed with graphite. The ratio of Si to O in the SiOx material can be controllably adjusted through the strong reducing agent LiAlH4, the first charge and discharge efficiency of the SiOx material is improved, the raw material cost is low, industrialization is easy to achieve, few electrochemical inert impurities are introduced, and the influence on the conductivity of the silicon-based material is small.

Owner:WANXIANG 123 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com