Aluminum alloy conductor and preparation method thereof

A technology for aluminum alloy conductors and aluminum intermediate alloys, which is applied in the direction of metal/alloy conductors, etc., can solve the problems of reducing the conductivity of aluminum alloys, and achieve the effect of reducing the conductivity and improving the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

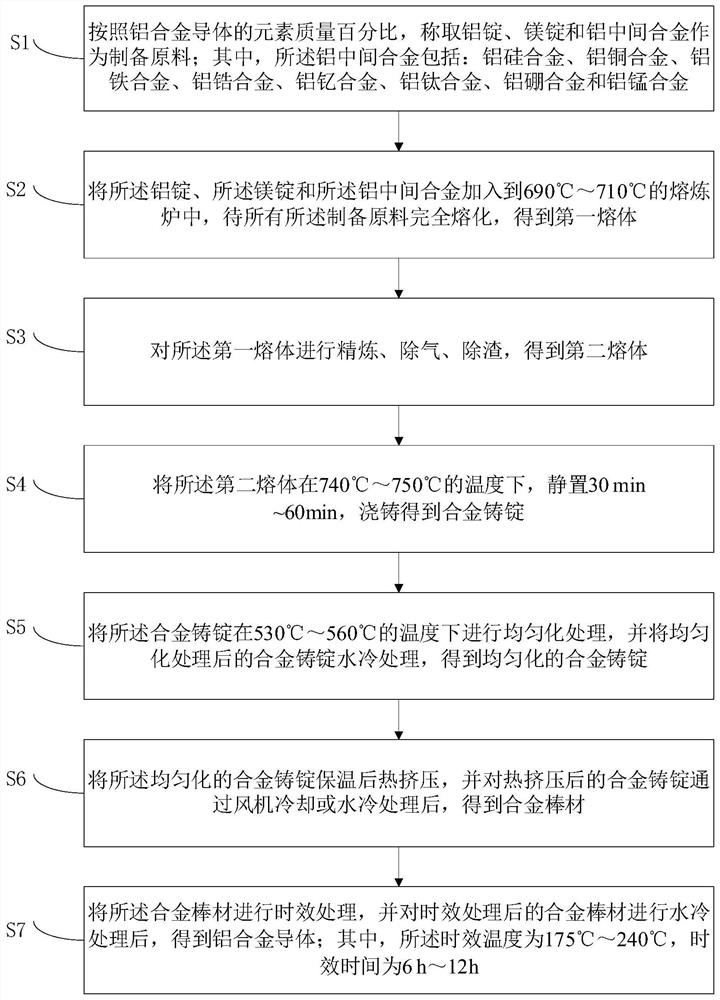

[0039] Such as figure 1 As shown, the preparation method of the aluminum alloy conductor provided by the present invention comprises the following steps:

[0040] S1. According to the element mass percentage of the aluminum alloy conductor, aluminum ingots, magnesium ingots and aluminum master alloys are weighed as raw materials for preparation; wherein, the aluminum master alloys include: aluminum-silicon alloys, aluminum-copper alloys, aluminum-iron alloys, aluminum-zirconium alloys, Al-yttrium alloys, aluminum-titanium alloys, aluminum-boron alloys, and aluminum-manganese alloys.

[0041] Among them, the aluminum alloy conductor includes the following elements by mass percentage:

[0042] Magnesium: 0.50% to 0.70%, silicon: 0.35% to 0.60%, copper: 0.05% to 0.15%, iron: 0.05% to 0.20%, zirconium: 0.01% to 0.15%, yttrium: 0.03% to 0.15%, titanium: 0.003% to 0.015%, boron: 0.03% to 0.05%, manganese: 0.001% to 0.015%, unavoidable impurities: total content <0.15%, and the bala...

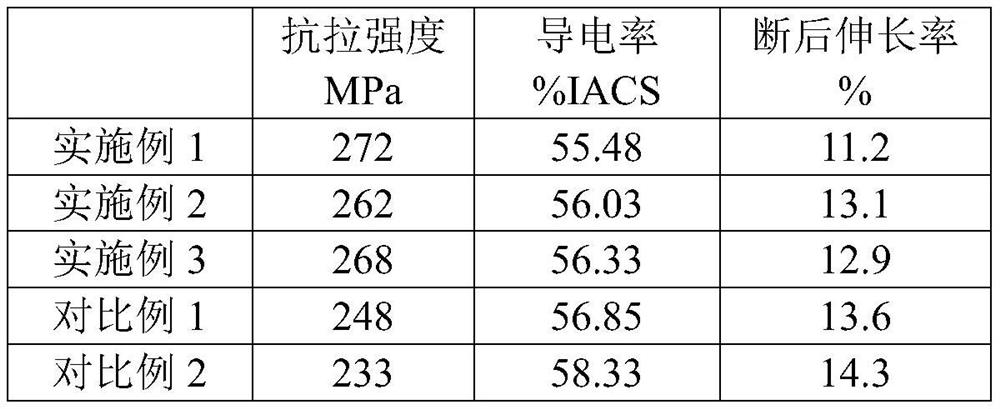

Embodiment 1

[0066] The mass percentage of elements in the aluminum alloy conductor is as follows:

[0067] Magnesium: 0.60%, Silicon: 0.45%, Copper: 0.15%, Iron: 0.05%, Zirconium: 0.03%, Yttrium: 0.13%, Titanium: 0.015%, Boron: 0.03%, Manganese: 0.005%, and the balance is Al and Unavoidable impurities.

[0068] S1. According to the above-mentioned element mass percentages of aluminum alloy conductors, aluminum ingots with a purity of 99.99%, magnesium ingots with a purity of 99.99%, and an aluminum master alloy are taken as raw materials for preparation; wherein, the aluminum master alloy includes: aluminum-silicon alloy, aluminum-copper alloy alloys, aluminum-iron alloys, aluminum-zirconium alloys, aluminum-yttrium alloys, aluminum-titanium alloys, aluminum-boron alloys and aluminum-manganese alloys;

[0069] S2. Adding aluminum ingots with a purity of 99.99%, magnesium ingots with a purity of 99.99%, and an aluminum master alloy into a melting furnace at 700° C., until all the preparat...

Embodiment 2

[0076] The mass percentage of elements in the aluminum alloy conductor is as follows:

[0077] Magnesium: 0.50%, Silicon: 0.35%, Copper: 0.10%, Iron: 0.15%, Zirconium: 0.08%, Yttrium: 0.1%, Titanium: 0.005%, Boron: 0.03%, Manganese: 0.001%, and the balance is Al and Unavoidable impurities.

[0078] S1. According to the above-mentioned element mass percentages of aluminum alloy conductors, aluminum ingots with a purity of 99.99%, magnesium ingots with a purity of 99.99%, and an aluminum master alloy are taken as raw materials for preparation; wherein, the aluminum master alloy includes: aluminum-silicon alloy, aluminum-copper alloy alloys, aluminum-iron alloys, aluminum-zirconium alloys, aluminum-yttrium alloys, aluminum-titanium alloys, aluminum-boron alloys and aluminum-manganese alloys;

[0079] S2. Adding aluminum ingots with a purity of 99.99%, magnesium ingots with a purity of 99.99%, and an aluminum master alloy into a melting furnace at 700° C., until all the preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com