Negative electrode plate containing silicon-based negative electrode material with high initial Coulombic efficiency and lithium ion battery

A technology of silicon-based negative electrode material and Coulomb efficiency, applied in secondary batteries, negative electrodes, battery electrodes, etc., can solve the problems of reducing Si gram capacity, difficult to remove by-products, reducing negative electrode conductivity, etc., to achieve low raw material cost, Easy industrial application, low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

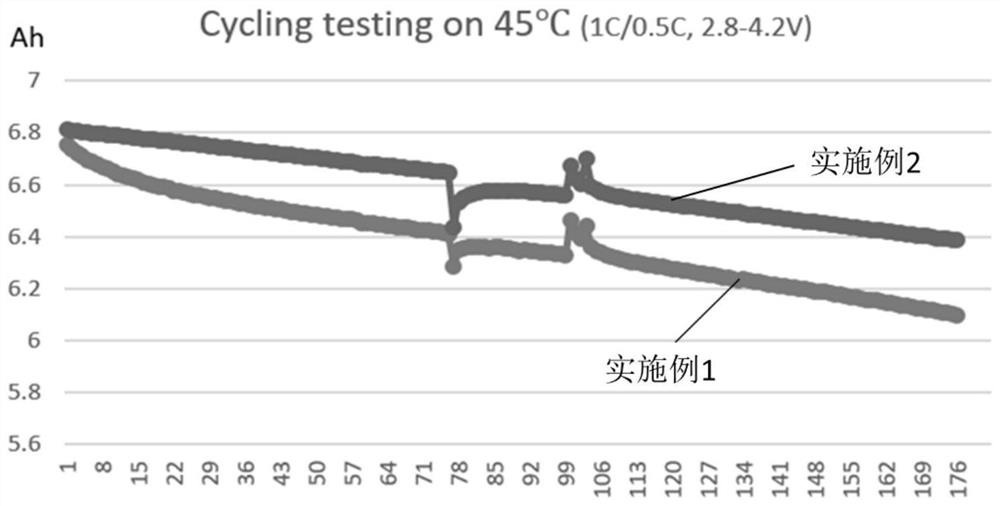

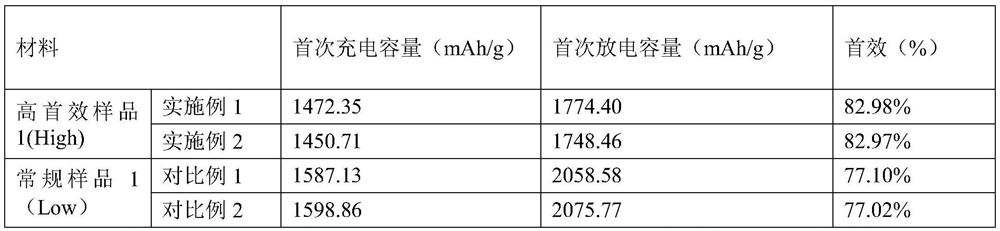

Embodiment 1

[0030] 1) Carbon coating: SiO x Mix evenly with the carbon source, pass into the protective gas, carry out the vapor phase deposition reaction in the tube furnace, cool to room temperature after the reaction is completed, and obtain SiO with a carbon coating mass percentage of 5wt%. x / C material, coated with SiO x The reversible gram capacity of / C material is 1620mAh / g, where 0<x<2;

[0031] 2) Mixing: Take 200g of carbon-coated SiO x / C material, add 40g reducing agent LiAlH 4 , fully mixed evenly in the ball mill equipment;

[0032] 3) Pyrolysis: Put the uniformly mixed material into a tube furnace, feed nitrogen gas, the gas flow rate is 120mL / min, raise the temperature to 500°C at a rate of 5°C / min and keep it warm for 1 hour, continue feeding nitrogen gas, and calcining Naturally cool after reduction to obtain SiO y / C material, where 0<y<1;

[0033] 4) Water washing: soak the pyrolysis product in 80g of dilute hydrochloric acid for 30 minutes, wash with 400g of d...

Embodiment 2

[0038] 1) Carbon coating: SiO x Mix evenly with the carbon source, pass into the protective gas, carry out the vapor phase deposition reaction in the tube furnace, cool to room temperature after the reaction is completed, and obtain SiO with a carbon coating mass percentage of 5wt%. x / C material, coated with SiO x The reversible gram capacity of / C material is 1620mAh / g, where 0<x<2;

[0039] 2) Mixing: Take 200g of carbon-coated SiO x / C material, add 40g reducing agent LiAlH 4 , fully mixed evenly in the ball mill equipment;

[0040] 3) Pyrolysis: Put the uniformly mixed material into a tube furnace, feed nitrogen gas, the gas flow rate is 120mL / min, raise the temperature to 500°C at a rate of 5°C / min and keep it warm for 1 hour, continue feeding nitrogen gas, and calcining Naturally cool after reduction to obtain SiO y / C material, where 0<y<1;

[0041] 4) Water washing: soak the pyrolysis product in 80g of dilute hydrochloric acid for 30 minutes, wash with 400g of d...

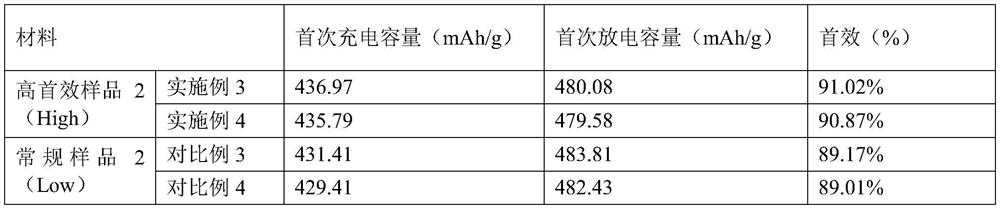

Embodiment 3

[0046] 1) Carbon coating: SiO x Mix evenly with the carbon source, pass into the protective gas, carry out the vapor phase deposition reaction in the tube furnace, cool to room temperature after the reaction is completed, and obtain SiO with a carbon coating mass percentage of 5wt%. x / C material, coated with SiO x The reversible gram capacity of / C material is 1620mAh / g, where 0<x<2;

[0047] 2) Mixing: Take 200g of carbon-coated SiO x / C material, add 40g reducing agent LiAlH 4 , fully mixed evenly in the ball mill equipment;

[0048] 3) Pyrolysis: Put the uniformly mixed material into a tube furnace, feed nitrogen gas, the gas flow rate is 120mL / min, raise the temperature to 500°C at a rate of 5°C / min and keep it warm for 1 hour, continue feeding nitrogen gas, and calcining Naturally cool after reduction to obtain SiO y / C material, where 0<y<1;

[0049] 4) Water washing: soak the pyrolysis product in 80g of dilute hydrochloric acid for 30 minutes, wash with 400g of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com