Phosphorus-contained flameproof additive agent for lithium ion cell electrolysing solution and method of use thereof

A flame retardant additive, lithium ion battery technology, applied in secondary batteries, chemical instruments and methods, circuits, etc. Flammability, good charge-discharge performance, little effect on conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

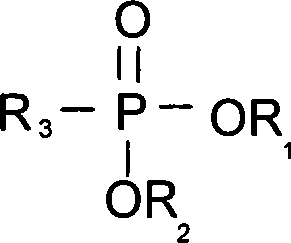

[0019] This phosphorus-containing flame retardant additive is a phosphorus-containing organic compound whose basic structural formula is as follows

[0020]

[0021] That is, the R in the general formula 1 , R 2 , R 3 Both are alkyl CH 3 ; where R 1 , R 2 , R 3 The number of carbon atoms n is 1.

[0022] The GV-2100size#1 type falling ball viscometer produced by Barnant Company is used to measure the phosphorus-containing flame-retardant additive (C) of this embodiment 1 and the existing two kinds of phosphorus-containing flame-retardant additives (A), (B) (wherein n= 1) and compare the viscosity (measurement range: 1-10Pa·s), record the time when the steel ball falls from the first baseline to the measurement baseline. For A, B, C were measured in parallel five times to get the average value. Calculation method: at a certain temperature, the viscosity of the liquid to be tested η=k×(ρ 刚球 -ρ 待测液 ) × t. Among them, k is the viscosity coefficient (0.3); ρ 刚球 is th...

Embodiment 2

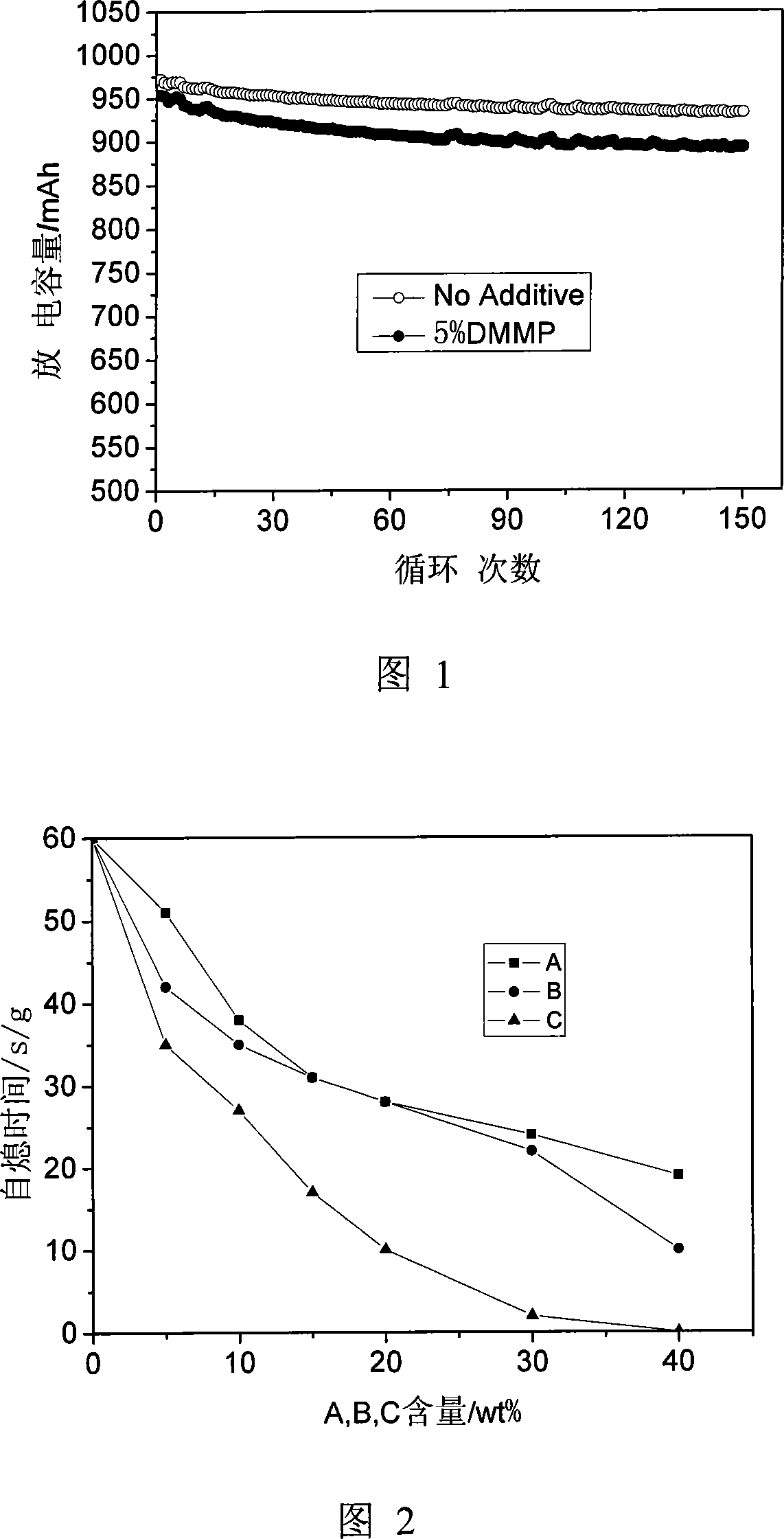

[0027] The using method of the phosphorus-containing flame retardant additive provided by embodiment 1 is: the dimethyl carbonate (DMC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) are according to 1: 1: 1 (mass ratio) Mixed in proportion and made into 1M LiPF 6 The electrolyte solution, and then add 2wt% vinylene carbonate (VC) and the above-mentioned phosphorus-containing organic compound with a weight ratio of 5wt% therein to obtain a lithium-ion battery flame-retardant electrolyte.

[0028] In order to measure the charging and discharging effect of the battery using the electrolyte prepared in this example, the following operations are performed: use N-methyl-2 pyrrolidone (NMP) and LiCoO 2 (produced by OMG Company of the United States), acetylene black, and polyvinylidene fluoride (PVDF) (mass ratio: 85%:8%:7%) are evenly mixed and then coated on the aluminum foil current collector, and vacuum-dried at 120°C for 12 hours to prepare Positive sheet. Mix artif...

Embodiment 3

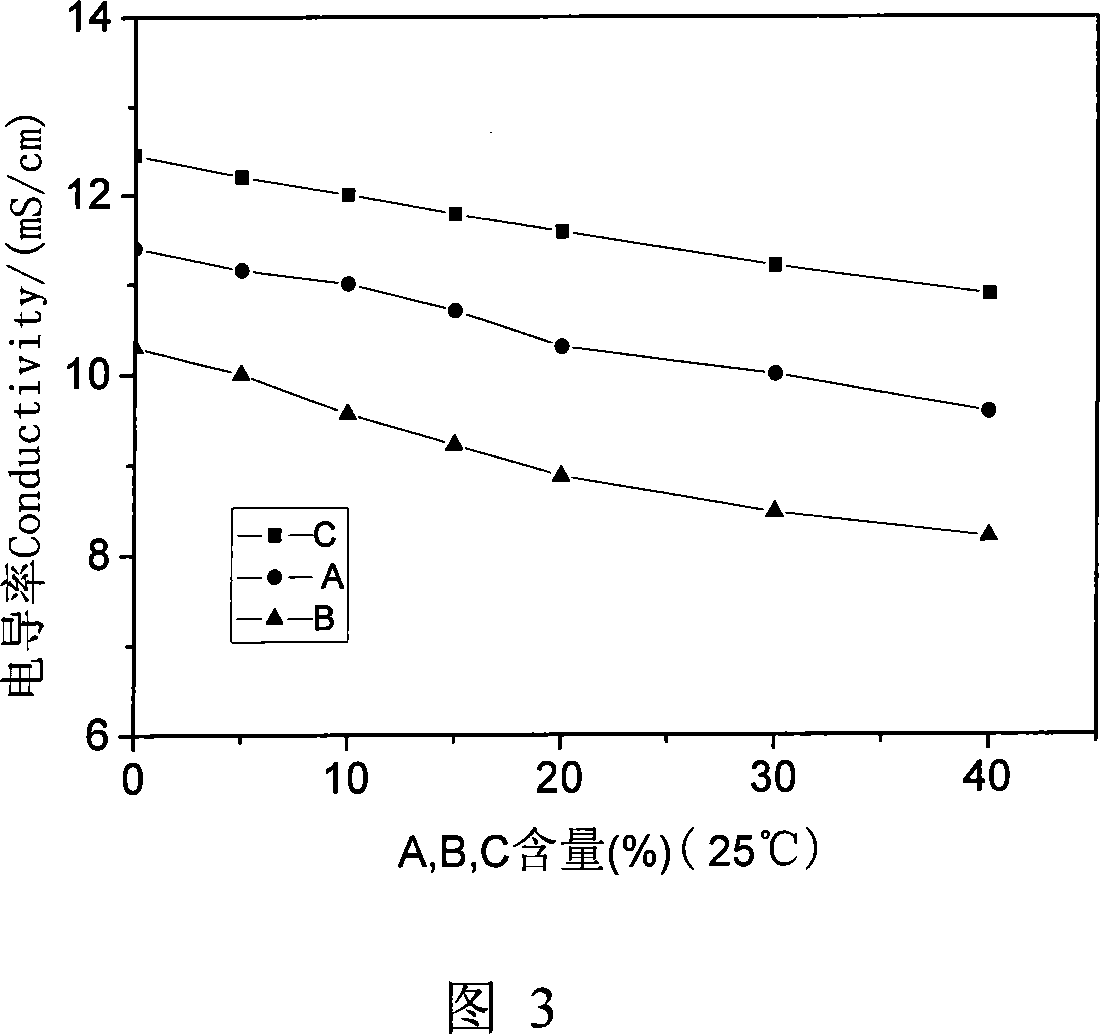

[0030] Another using method of the phosphorus-containing flame retardant additive provided by embodiment 1 is: mix dimethyl carbonate (DMC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) according to 1: 1: 1 (mass ratio ) ratio, and dubbed 1M LiPF 6 The electrolyte solution, and then add the above-mentioned phosphorus-containing organic compound with a weight ratio of 5wt%, 10wt%, 15wt%, 20wt%, 30wt%, 40wt%, and dissolve it to obtain a lithium-ion battery flame-retardant electrolyte.

[0031] In order to evaluate the flammability of the lithium-ion battery electrolyte, the self-extinguishing time (Self-extinguishing time) can be used to measure it specifically. The specific steps are to make a glass wool ball with a diameter of 5mm from glass wool, weigh it and place it in a folded On the "O"-shaped thin iron wire, use a syringe to take out the electrolyte solution with different proportions of flame-retardant additives, inject it on the glass wool and ignite it qui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com