Conductive adhesive for positive electrode of lithium-sulfur battery and preparation method of conductive adhesive

A conductive binder and lithium-sulfur battery technology, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problem of large amount of binder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of a conductive binder for a positive electrode of a lithium-sulfur battery, the method comprising:

[0037] The doped conductive polymer material is dissolved in a good solvent until completely dispersed to obtain a conductive binder for the positive electrode of the lithium-sulfur battery.

[0038] According to the present invention, the source of the doped polymer material is not particularly limited, and may be a commercially available product or a self-made product.

[0039] According to the present invention, the dispersion method is not particularly limited, and varies according to the type of the doped polymer material, preferably including grinding, stirring, ultrasonication or pulverization, and the dispersion time depends on the type of the doped polymer material It is selected based on its dispersive performance, and there are no special restrictions.

[0040] The conductive binder obtained above is mad...

Embodiment 1

[0052] Doped polyaniline (the synthesis steps of doped polyaniline refer to the synthesis of sulfuric acid doped polyaniline (PANI) in this document (J.Mater.Chem.A, 2015.3, 7215-7218.).) Dissolved in The m-cresol / chloroform mixed solution is completely dispersed to obtain a conductive adhesive, and the mass fraction of the doped polyaniline is 0.25%.

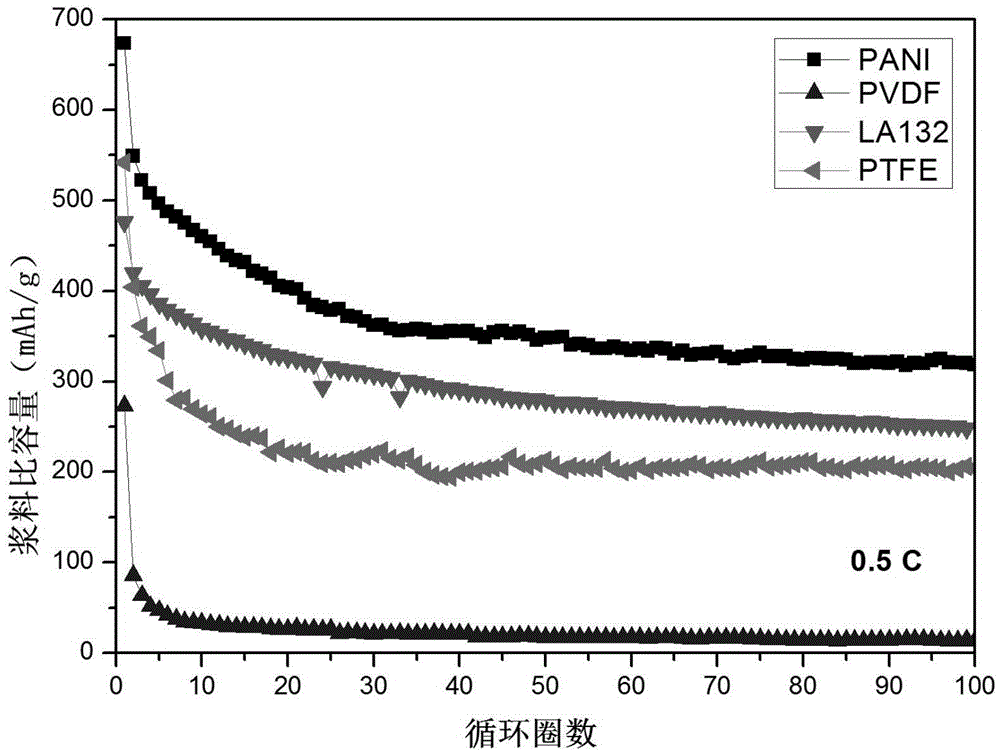

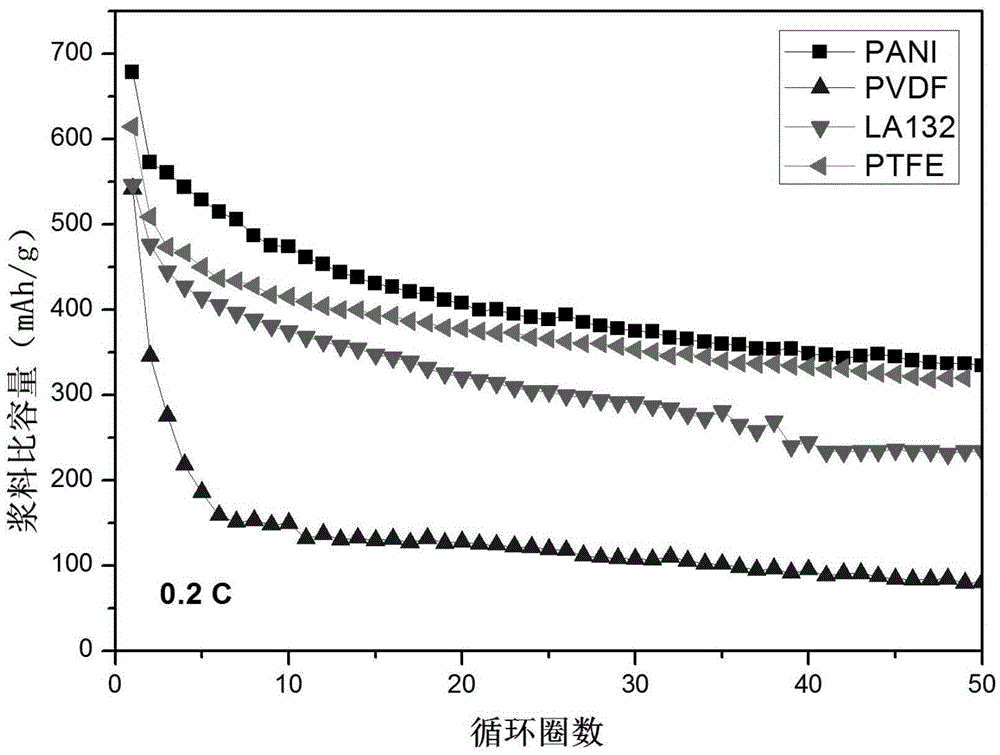

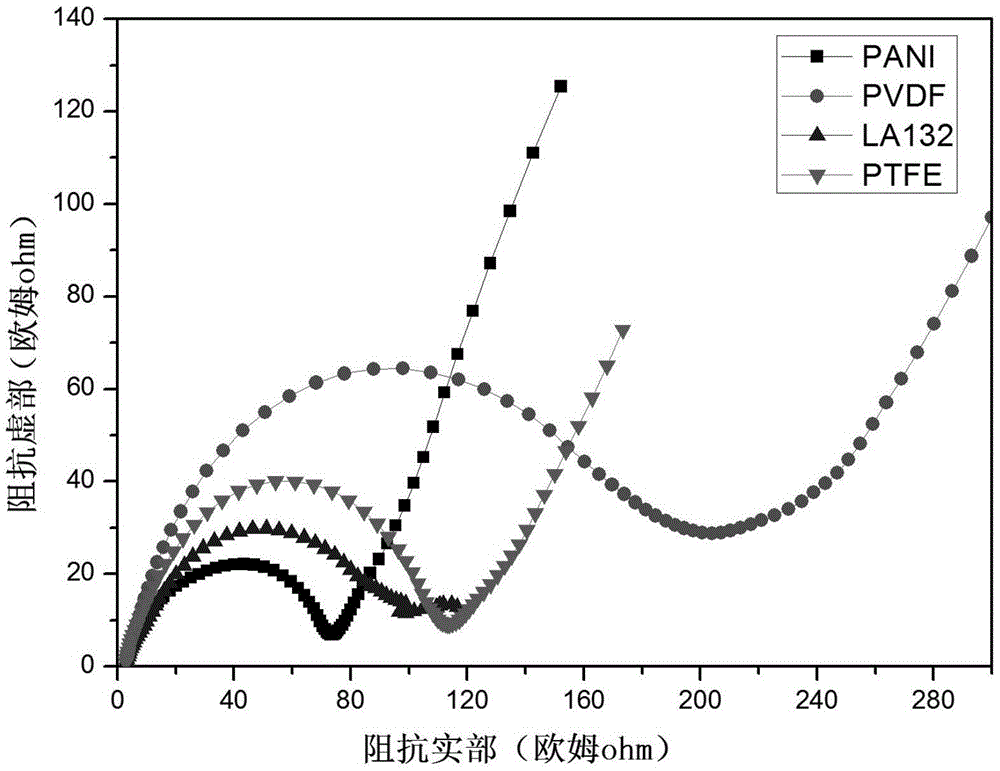

[0053] The conductive polyaniline binder that embodiment 1 is obtained is used for bonding active material to be the positive electrode of conductive macromolecule / sulfur composite (positive electrode active material is ultrathin sulfur wrapping polyaniline nanowire composite material S / PANI), at 0.5 Under 0.2C and 0.2C, the electrochemical performance of batteries assembled with different binders (PANI, PVDF, LA132 and PTFE) was tested respectively, and the results are as follows Figure 1-2 Shown:

[0054] figure 1 For example 1 of the present invention assembled lithium-sulfur battery cycle stability diagram at charge and ...

Embodiment 2

[0062] Doped polypyrrole (for the synthesis steps of doped polypyrrole, refer to the synthesis of hydrochloric acid-doped polypyrrole (PPY) with the highest conductivity in this document (Cellulose, 2015, 22:, 459-1467.).) In m-cresol / trichloromethane mixed solution until completely dispersed, a conductive adhesive is obtained, and the mass fraction of the doped polypyrrole is 0.25%.

[0063] The conductive polypyrrole binding agent that embodiment 2 is obtained is used for bonding active material to be the positive electrode of conductive macromolecule / sulfur composite (positive electrode active material is ultra-thin sulfur wrapping polyaniline nanowire composite material S / PANI), at 0.5 Under 0.2C and 0.2C, the electrochemical performance of batteries assembled with different binders (PPY, PVDF, LA132 and PTFE) was tested respectively, and the results are as follows Figure 7-8 Shown:

[0064] Figure 7 For example 2 of the present invention, assemble the lithium-sulfur b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com