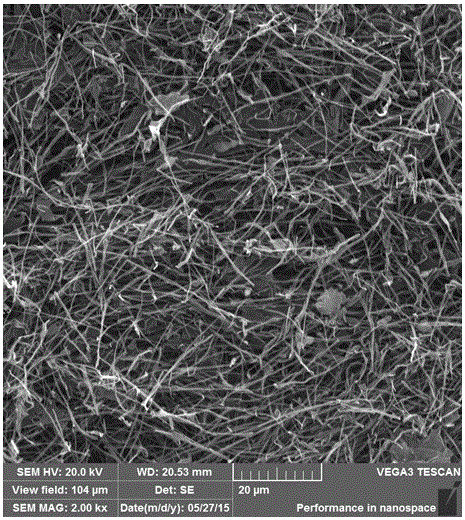

Preparation method of graphene nanoscroll/sulfur composite material and application of graphene nanoscroll/sulfur composite material

A composite material, graphene technology, applied in electrode carriers/current collectors, electrical components, electrochemical generators, etc., can solve the problems of poor cycle stability of lithium-sulfur batteries, affecting the utilization of active materials, and increasing the internal impedance of batteries, etc. Achieve good cycle stability, improve utilization, and improve cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

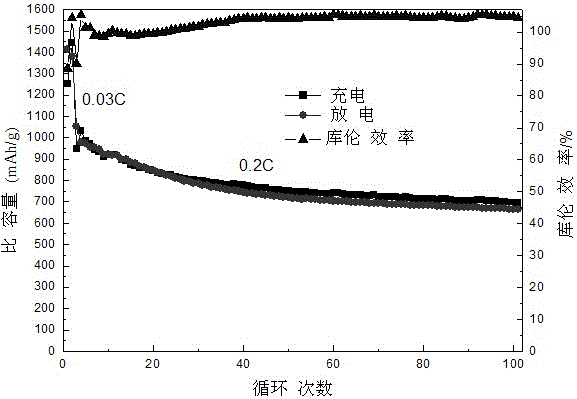

Embodiment 1

[0038] 1), the preparation of pre-oxidized graphite:

[0039] Add 39mL of concentrated sulfuric acid (98%) into a three-necked flask, then weigh 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide and add them to the three-necked flask successively, mix well; then add 5g of natural flake graphite powder (325 mesh), Then place it in a constant temperature water bath and react for 6 hours under stirring at 80°C; slowly pour the reactant into a beaker filled with 700ml of deionized water for dilution, transfer the diluted liquid to a Buchner funnel for filtration, and wash until the filtrate into neutral. The obtained filter cake was dried under vacuum at 100° C. for 10 h, and the obtained solid matter was pre-oxidized graphite.

[0040] 2), the preparation of graphite oxide:

[0041]Weigh 2.5g of pre-oxidized graphite and 1.25g of sodium nitrate powder into a round-bottomed flask filled with 57.5mL of concentrated sulfuric acid (98%), slowly add 7.5g of potassium per...

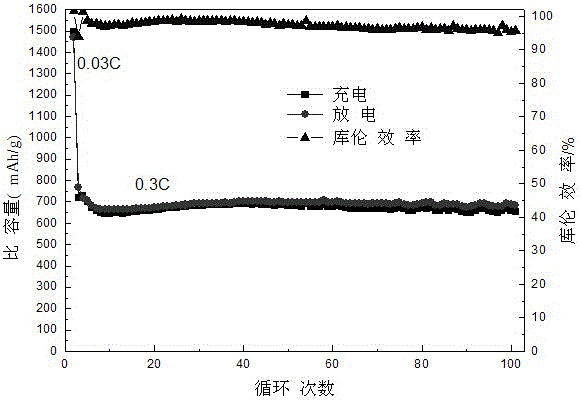

Embodiment 2

[0050] 1), the preparation of pre-oxidized graphite:

[0051] Mix 3g of natural flake graphite (200 mesh) with 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide into a three-necked flask filled with 50mL of concentrated sulfuric acid (98%), mix well under magnetic stirring conditions, and then place at constant temperature In a water bath, react at 80°C for 6 hours; after the reaction, dilute with deionized water, then filter and wash with a Buchner funnel until the filtrate becomes neutral. The filter cake was dried under vacuum at 80° C. for 20 h, and the obtained solid matter was pre-oxidized graphite.

[0052] 2), the preparation of graphite oxide:

[0053] Weigh 2.5g of pre-oxidized graphite and 1.25g of sodium nitrate powder into a round-bottomed flask filled with 57.5mL of concentrated sulfuric acid (98%). Slowly add 10g of potassium permanganate in an ice-water bath to control the temperature of the reaction system. After reacting for 3 hours at 20°C, rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com