Preparation method of nitrogen-doped graphene/copper sulfide/hollow sulfur composite material

A technology of nitrogen-doped graphene and composite materials, which is applied in the field of nanomaterial synthesis, can solve problems such as slow migration speed, reduced utilization rate of sulfur active materials, and slow electrochemical reaction kinetics, so as to improve electronic conductivity and Ionic conductivity, improving electrochemical performance, and reducing the effect of shuttling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

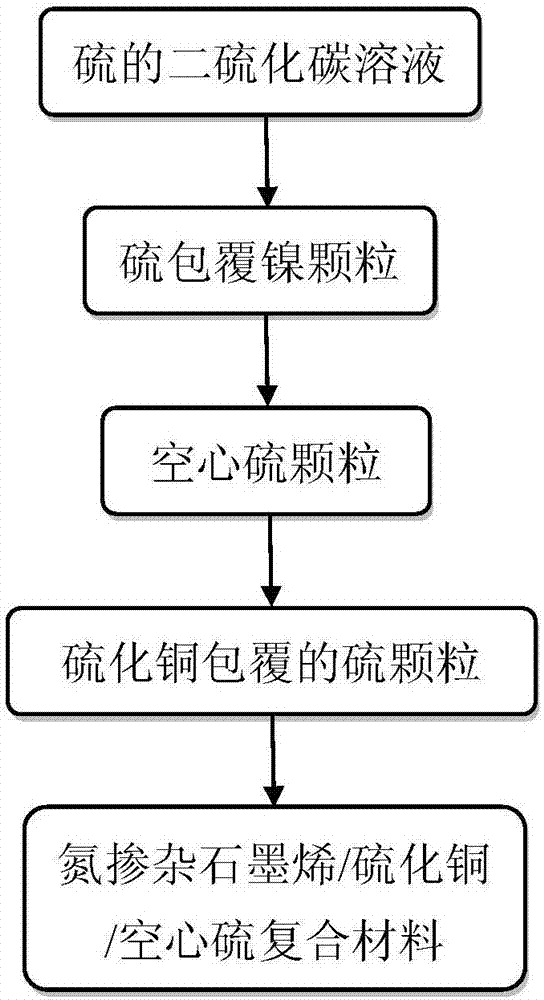

Method used

Image

Examples

Embodiment 1

[0020] (1) Add 100g of sulfur powder into carbon disulfide, stir and dissolve to form a solution of 1g / mL;

[0021] (2) 5g of high-purity nickel powder was passed through a high-energy ball mill, ball-milled for 0.5 hours, added to the above solution after ball-milling, stirred to form a uniform suspension, mechanically stirred for 0.5 hours, and spray-dried to form sulfur-coated spherical particles;

[0022] (3) Add spherical particles into 1 mol / L ferric chloride solution, stir and react for 5 hours, wash with water and filter.

[0023] (4) The filtered precipitate was added to a solution containing 10g of copper chloride, 10g of thioacetamide and 1g of sodium dodecylbenzenesulfonate, stirred into a homogeneous suspension, heated to 60°C and stirred for 30 minutes , centrifugation and washing to obtain copper sulfide-coated sulfur particles;

[0024] (5) Add 10 g of nitrogen-doped graphene to water and ultrasonically disperse to form a suspension with a uniform concentratio...

Embodiment 2

[0026] (1) Add 100g of sulfur powder into carbon disulfide, stir and dissolve to form a solution of 5g / mL;

[0027] (2) 20g of high-purity nickel powder was passed through a high-energy ball mill, ball-milled for 2 hours, added to the above solution after ball-milling, stirred to form a uniform suspension, mechanically stirred for 1 hour, and spray-dried to form sulfur-coated spherical particles;

[0028] (3) The spherical particles were added to the 2mol / L ferric chloride solution, stirred and reacted for 1 hour, washed with water and filtered.

[0029] (4) The filtered precipitate was added to a solution containing 20 g of copper chloride, 15 g of thioacetamide and 2 g of sodium dioctyl succinate sulfonate, stirred into a homogeneous suspension, heated to 90°C and stirred for 5 minutes , centrifugation and washing to obtain copper sulfide-coated sulfur particles;

[0030] (5) Add 20 g of nitrogen-doped graphene into water and ultrasonically disperse to form a suspension wit...

Embodiment 3

[0032] (1) Add 100g of sulfur powder to carbon disulfide, stir and dissolve to form a solution of 2g / mL;

[0033] (2) 10g of high-purity nickel powder was passed through a high-energy ball mill, ball-milled for 1 hour, added to the above solution after ball-milling, stirred to form a uniform suspension, mechanically stirred for 0.6 hours, and spray-dried to form sulfur-coated spherical particles;

[0034] (3) The spherical particles were added to the 1.5mol / L ferric chloride solution, stirred and reacted for 3 hours, washed with water and filtered.

[0035] (4) The filtered precipitate was added to a solution containing 15g of copper chloride, 12g of thioacetamide and 1.5g of sodium octadecyl sulfate, stirred into a homogeneous suspension, heated to 70°C and stirred for 15 minutes. Centrifuge and wash to obtain copper sulfide-coated sulfur particles;

[0036] (5) 15g nitrogen-doped graphene was added into water and ultrasonically dispersed to form a suspension with a uniform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com