Tungsten-copper alloy prepared from copper-cerium alloy and preparation method thereof

A tungsten-copper alloy and alloy technology, applied in the field of tungsten-copper alloy preparation, can solve the problems of accelerated material failure, reduced material performance, loss of electrical conductivity, etc., to achieve improved alloy performance, low electrical conductivity, and increased maximum compression stress value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

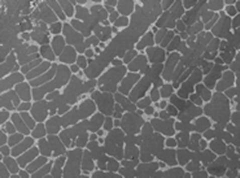

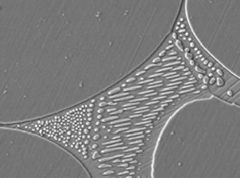

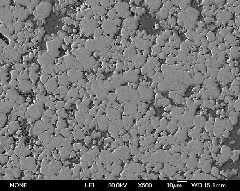

Image

Examples

Embodiment 1

[0024] Step a. Place the corundum crucible in a ZRS-18Q vacuum furnace for heat preservation. The temperature is controlled at 300°C and preheated for 10 minutes.

[0025] Step b. Weigh strip cerium and copper, wherein cerium is 0.6% of copper, the quality of cerium weighed is 1.19g, the quality of copper is 198g, including copper rod 188g and copper powder 10g.

[0026] Polish the cerium surface with sandpaper, put it into a 188g copper rod drilled with blind holes, seal it with 10g copper powder, put it upside down into a corundum crucible, put it in a vacuum furnace, keep it warm at 920°C for 15 minutes, and keep it at 1150°C for 30 minutes. Finally, cool to room temperature with the furnace.

[0027] Step c. Stack the copper-cerium alloy and the tungsten skeleton together, put them into a graphite crucible, place them in a high-temperature hydrogen atmosphere sintering furnace, sinter the tungsten skeleton at 1040°C for 1 hour, and then infiltrate copper at 1250°C for 3 ho...

Embodiment 2

[0028] Example 2 (cerium is 1.2%)

[0029] Step a. Place the corundum crucible in a ZRS-18Q vacuum furnace for heat preservation. The temperature is controlled at 310°C and preheated for 12 minutes.

[0030] Step b. Weigh strip cerium and copper, wherein cerium is 1.2% of copper, the quality of cerium weighed is 2.34g, and the quality of copper is 195g, including copper rod 185g and copper powder 10g.

[0031] Polish the cerium surface with sandpaper, put it into a 185g copper rod drilled with blind holes, seal it with 10g copper powder, put it upside down into a corundum crucible, put it in a vacuum furnace, keep it warm at 900°C for 20 minutes, and keep it at 1050°C for 35 minutes. Finally, cool to room temperature with the furnace.

[0032] Step c. Stack the copper-cerium alloy and the tungsten skeleton together, put them into a graphite crucible, place them in a high-temperature hydrogen atmosphere sintering furnace, sinter the tungsten skeleton at 1000°C for 1.2 hours, a...

Embodiment 3

[0033] Embodiment 3 (cerium is 1.8%)

[0034] Step a. Place the corundum crucible in a ZRS-18Q vacuum furnace for heat preservation. The temperature is controlled at 290°C and preheated for 11 minutes.

[0035] Step b. Weigh strip cerium and copper, wherein cerium is 1.8% of copper, the quality of cerium weighed is 3.66g, and the quality of copper is 193g, including 183g of copper rod and 10g of copper powder.

[0036] Polish the cerium surface with sandpaper, put it into a 193g copper rod drilled with blind holes, seal it with 10g copper powder, put it upside down into a corundum crucible, put it in a vacuum furnace, keep it at 910°C for 18 minutes, and at 1100°C for 32 minutes. Finally, cool to room temperature with the furnace.

[0037] Step c. Stack the copper-cerium alloy and the tungsten skeleton together, put them into a graphite crucible, place them in a high-temperature hydrogen atmosphere sintering furnace, sinter the tungsten skeleton at 1020°C for 1 hour, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com