Patents

Literature

79results about How to "Injection is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

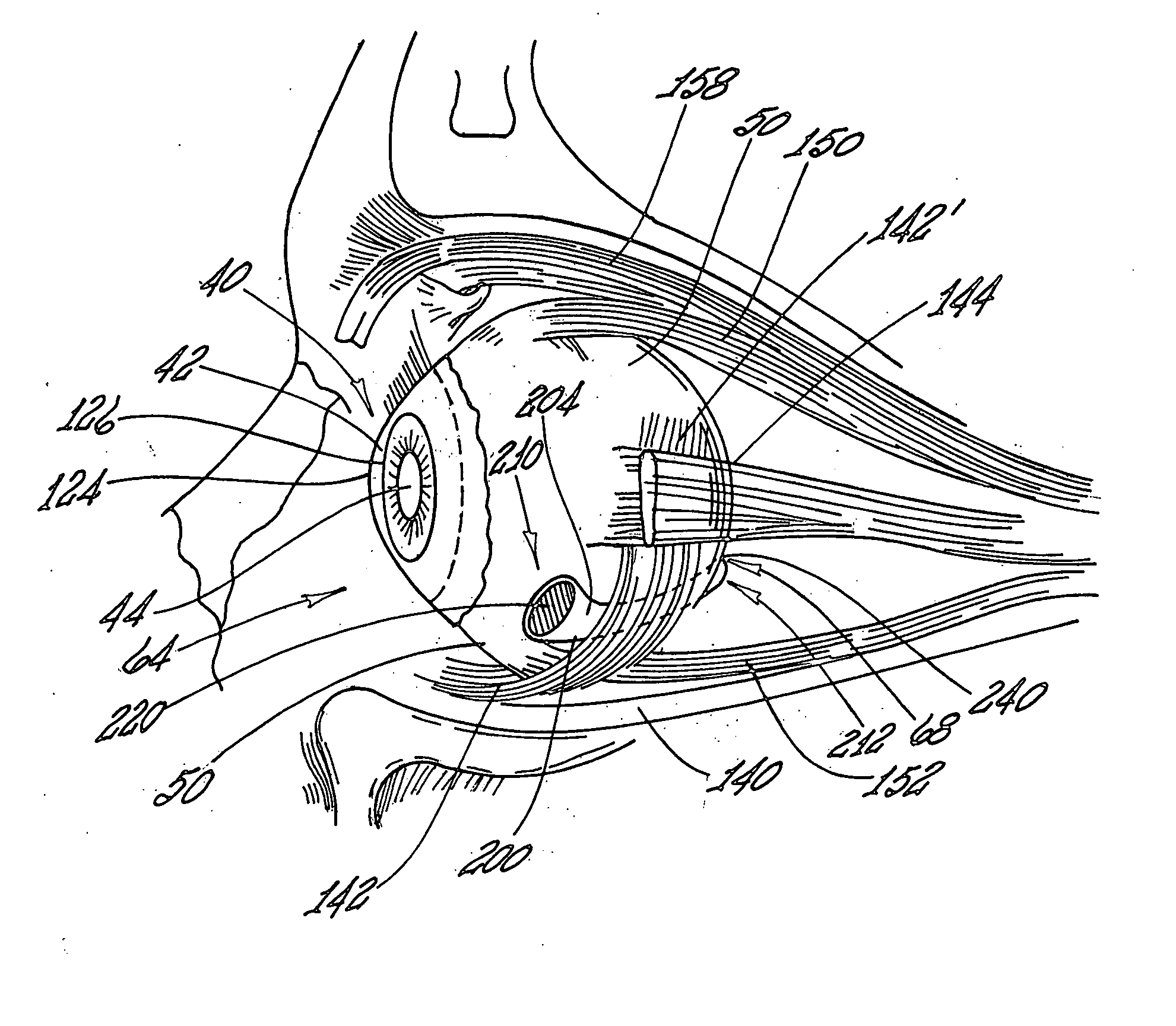

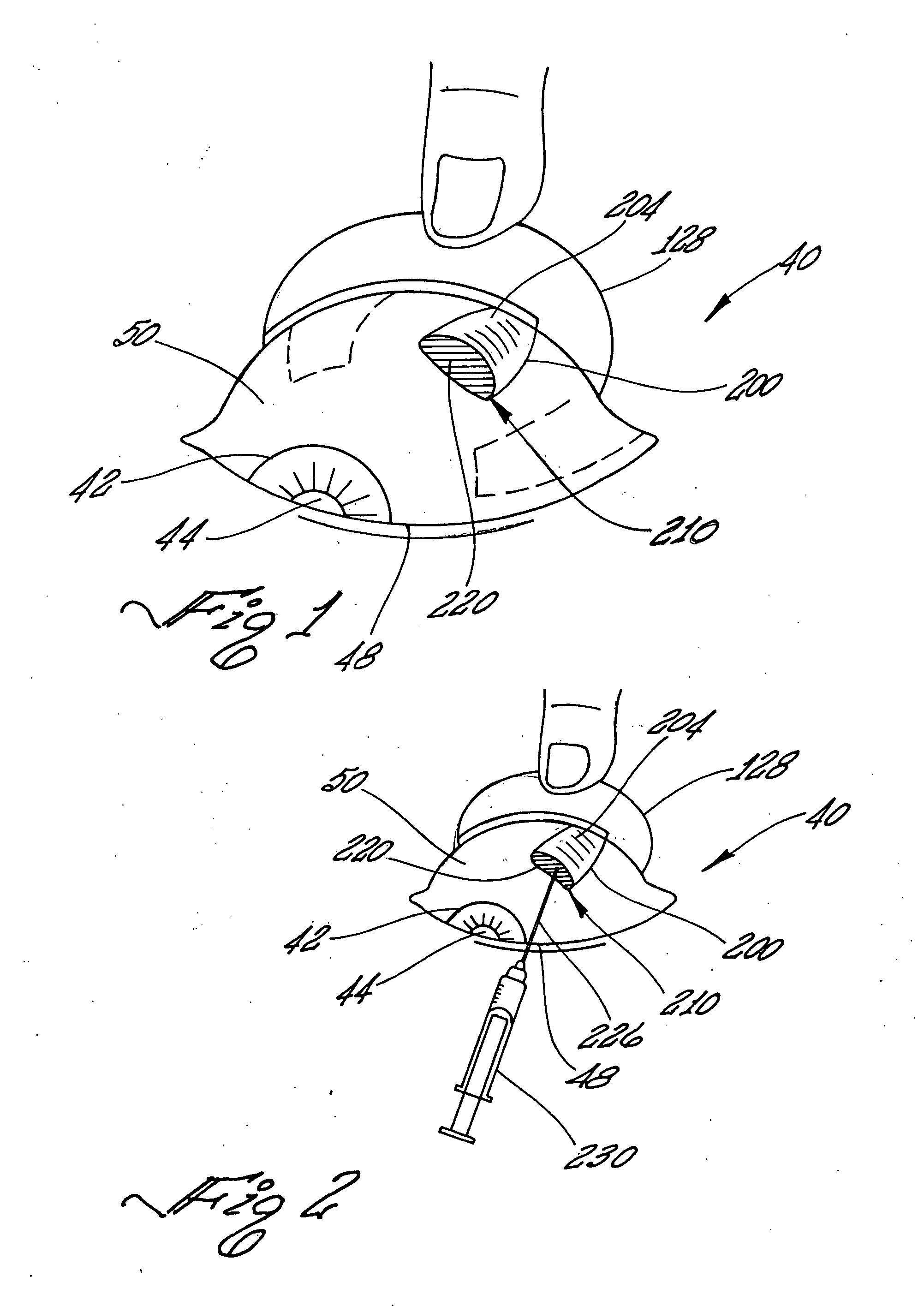

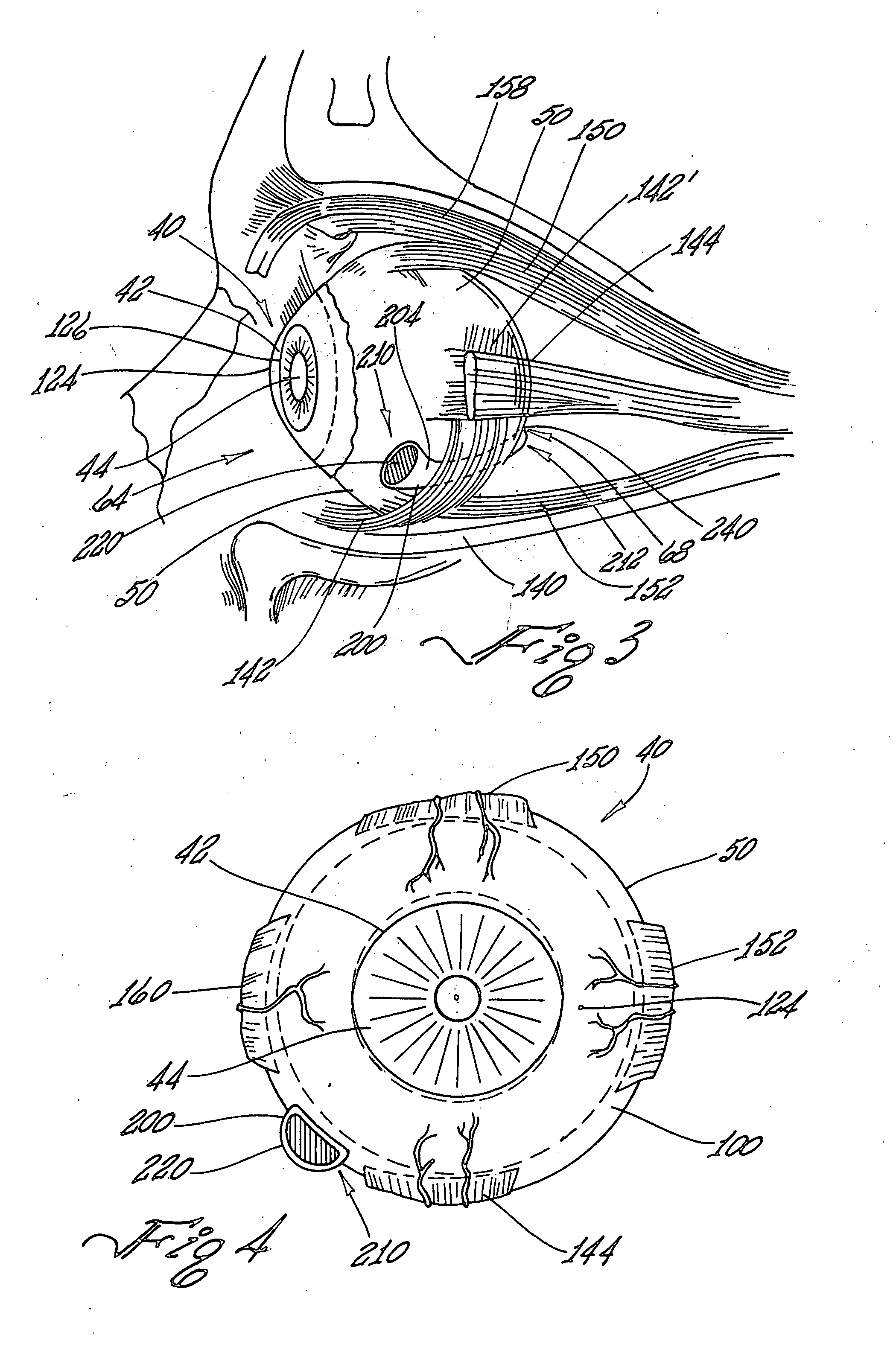

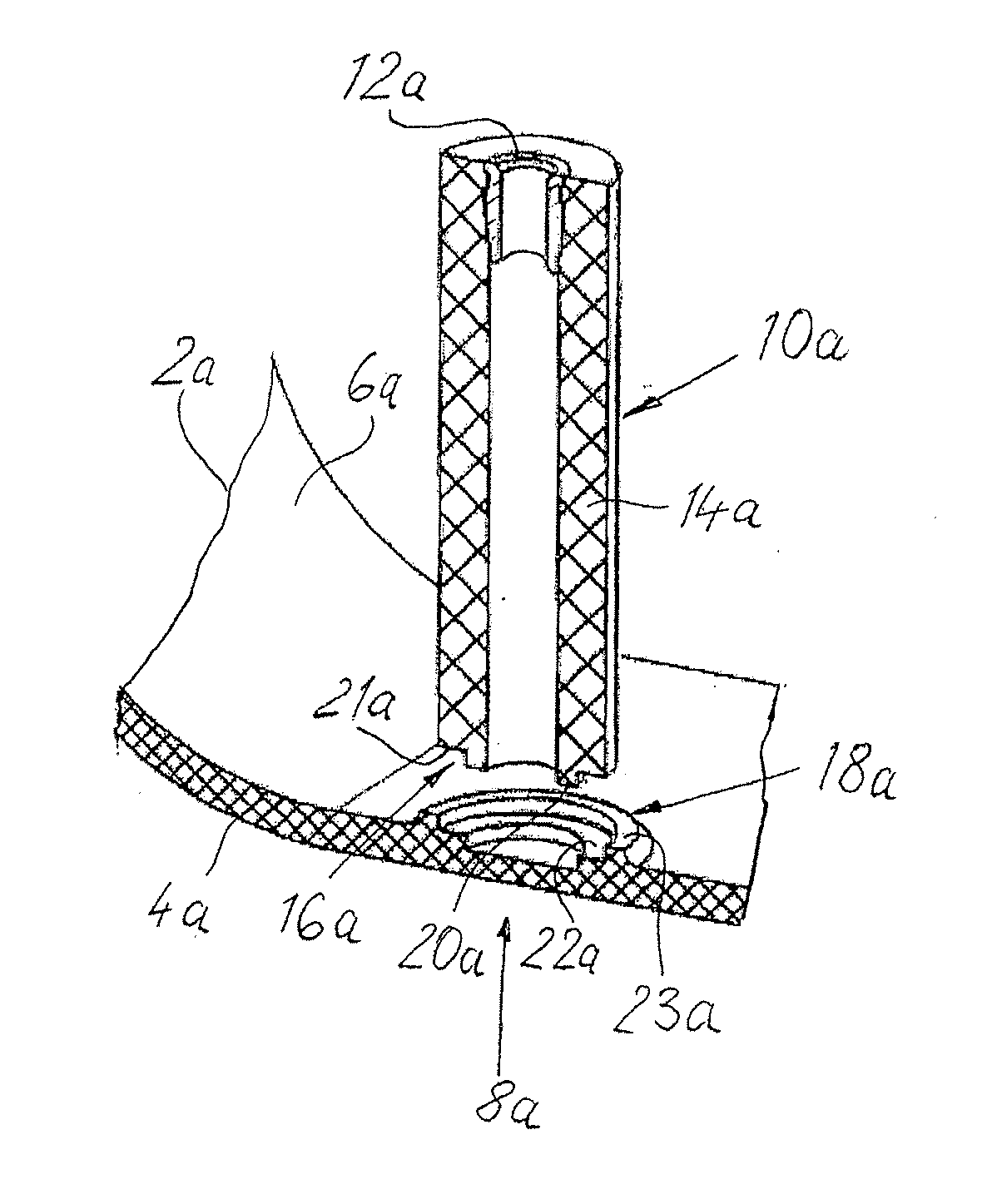

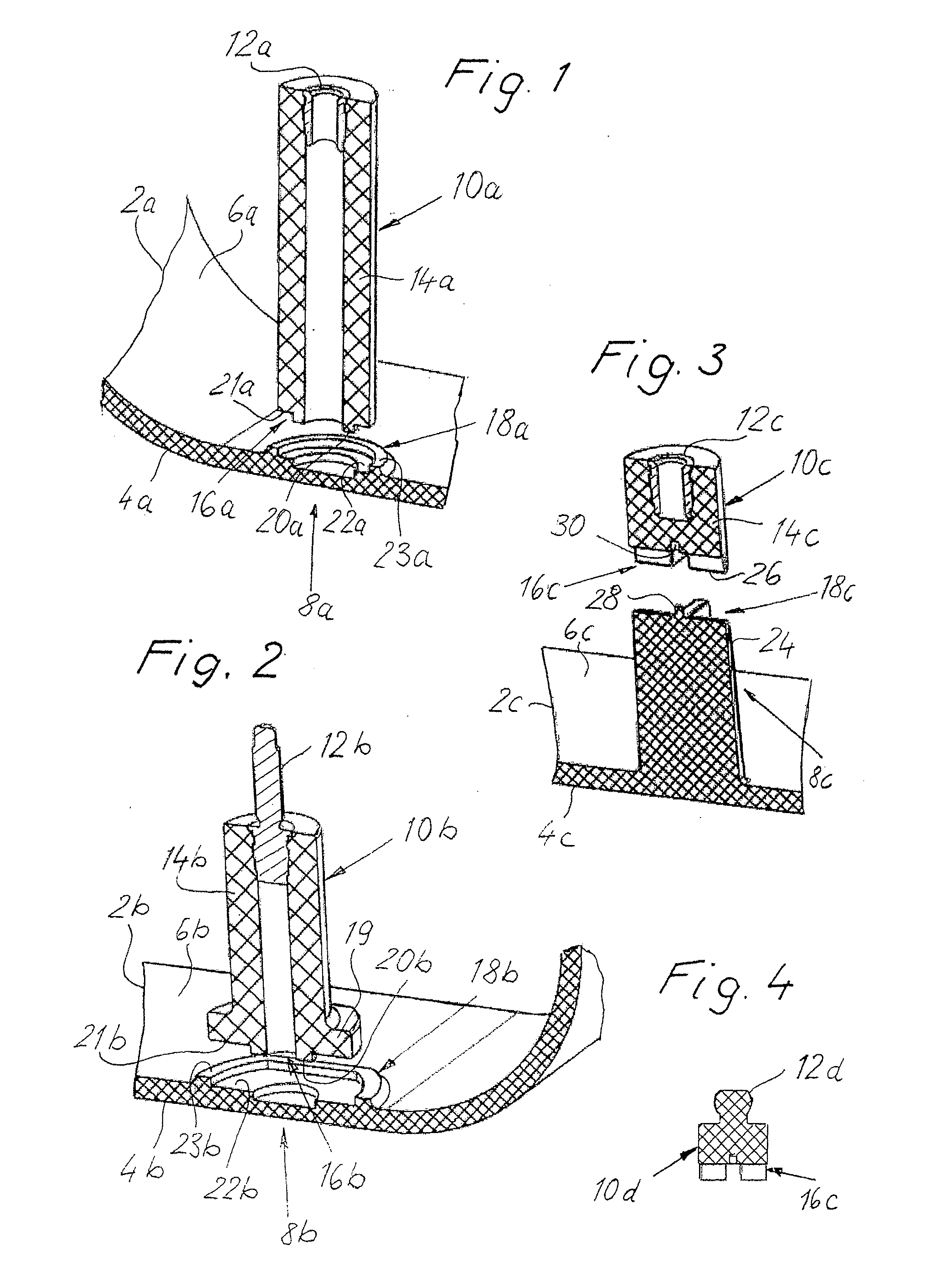

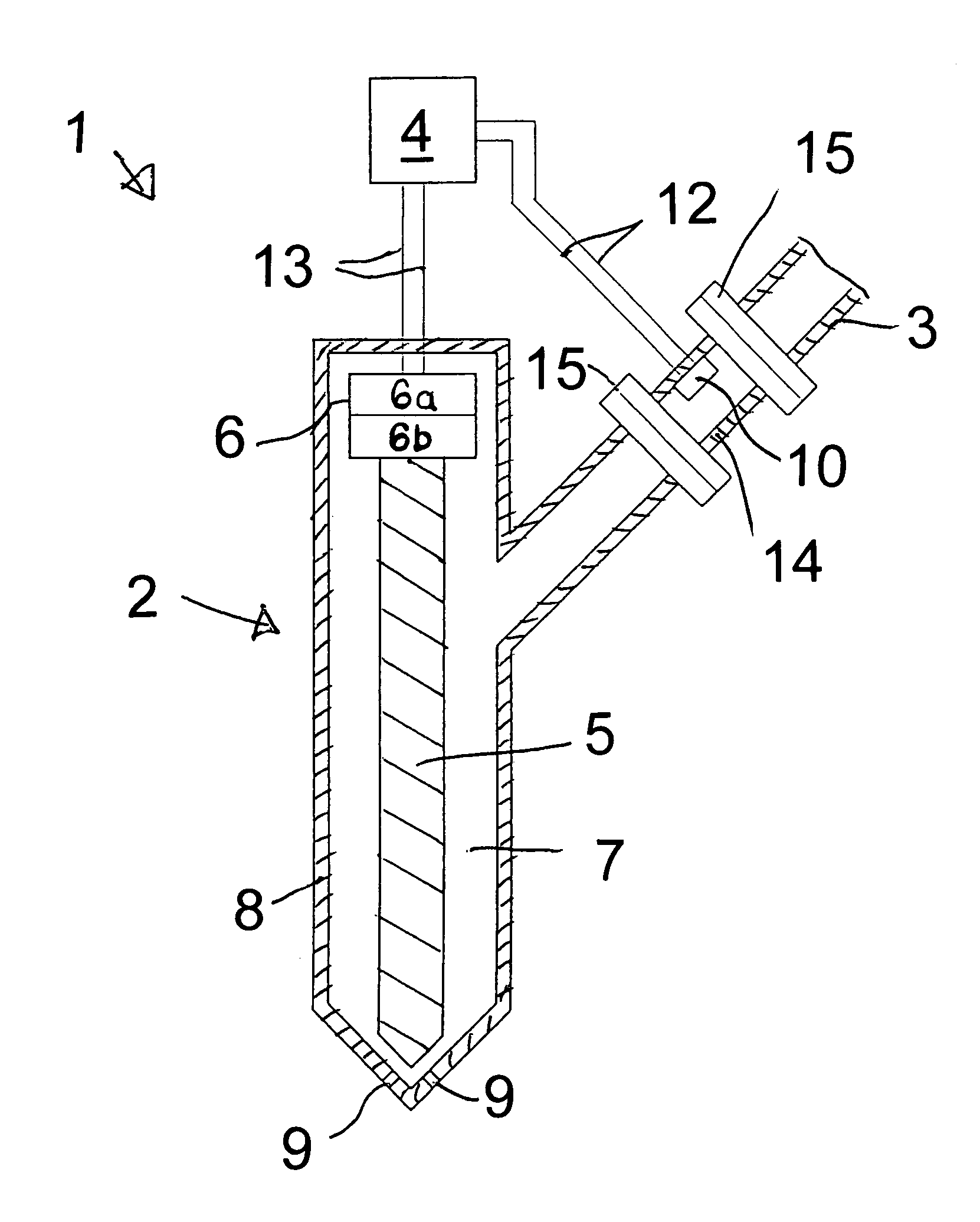

Implantable delivery device for administering pharmacological agents to an internal portion of a body

InactiveUS20060258994A1Injection is simpleGood curative effectMedical applicatorsEye treatmentProximateImplanted device

An implantable refillable device to deliver pharmacologic agents through a sclera to an internal portion of an eye is shown. The device comprises a hollow reservoir and a delivery tube. The delivery tube has a proximal end and a distal end. The proximal end communicates with the hollow reservoir and the distal end terminates in a dispensing outlet. The delivery tube is configured in a selected shape to extend from the hollow reservoir anterior in an eye to a posterior segment posterior in an eye adjoining a sclera. The second end is configured to position the dispensing outlet in contact with or contiguous the sclera and is located posteriorly in an eye and proximate to an internal portion of an eye to be treated with a pharmacologic agent. An implantable device to deliver pharmacologic agents through an outer surface tissue of an organ is also shown.

Owner:AVERY ROBERT L

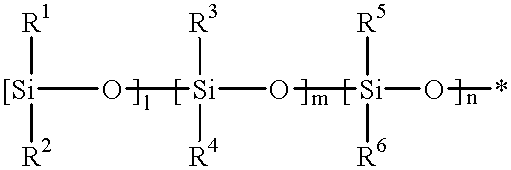

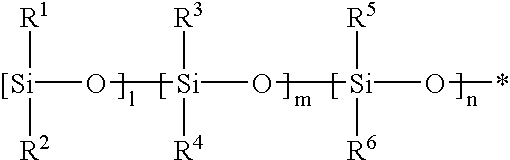

Injectable intraocular lens

InactiveUS6361561B1Reduce post-injection manipulationInjection is simpleSurgical adhesivesTissue regenerationIntraocular lensMedicine

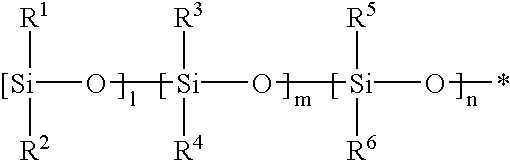

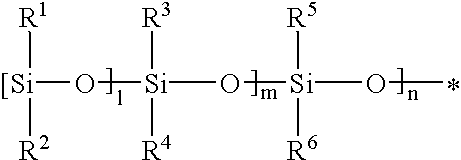

Polysiloxanes suitable for the preparation of intraocular lenses by a crosslinking reaction, having a specific gravity of greater than about 1.0, a refractive index suitable for restoring the refractive power of the natural crystalline lens and a viscosity suitable for injection through a standard cannula are provided. Moreover, injectable intraocular lens material based on these polysiloxanes and methods of preparing intraocular lenses by direct injection into the capsular bag of the eye are also disclosed.

Owner:PHARMACIA AB +1

Injectable intraocular accommodating lens

InactiveUS6613343B2Reduce post-injection manipulationInjection is simpleHair cosmeticsPharmaceutical delivery mechanismOphthalmologyRefractive index

The present invention relates to compositions comprising polysiloxanes suitable for the preparation of accommodating intraocular lenses, having a specific gravity of greater than about 1.0, a refractive index suitable for restoring the refractive power of the natural crystalline lens and a viscosity suitable for injection through a standard cannula. The present invention includes intraocular lenses made from said polysiloxane compositions having a Young's modulus less than about 10 kPa.

Owner:AMO GRONINGEN

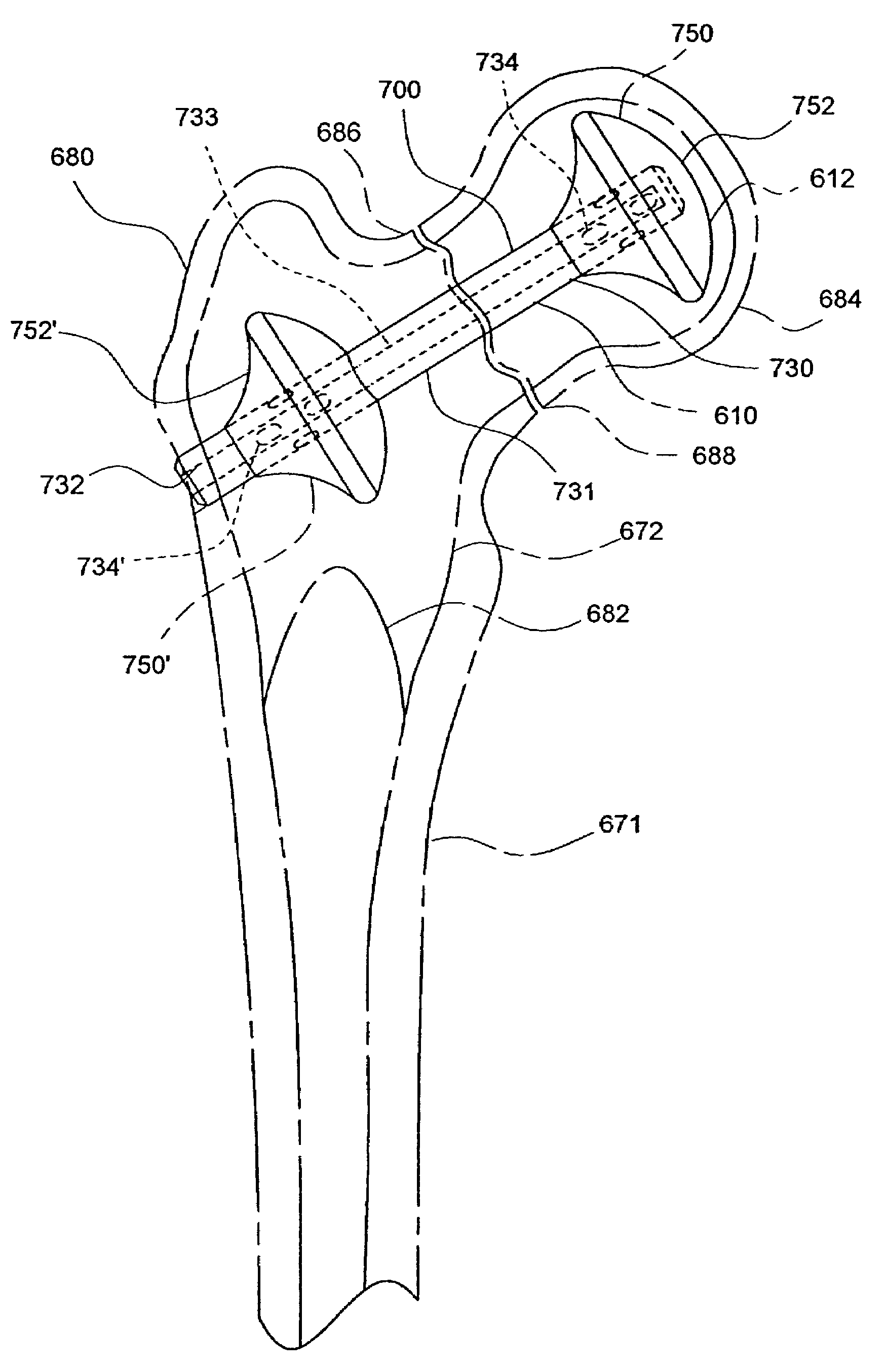

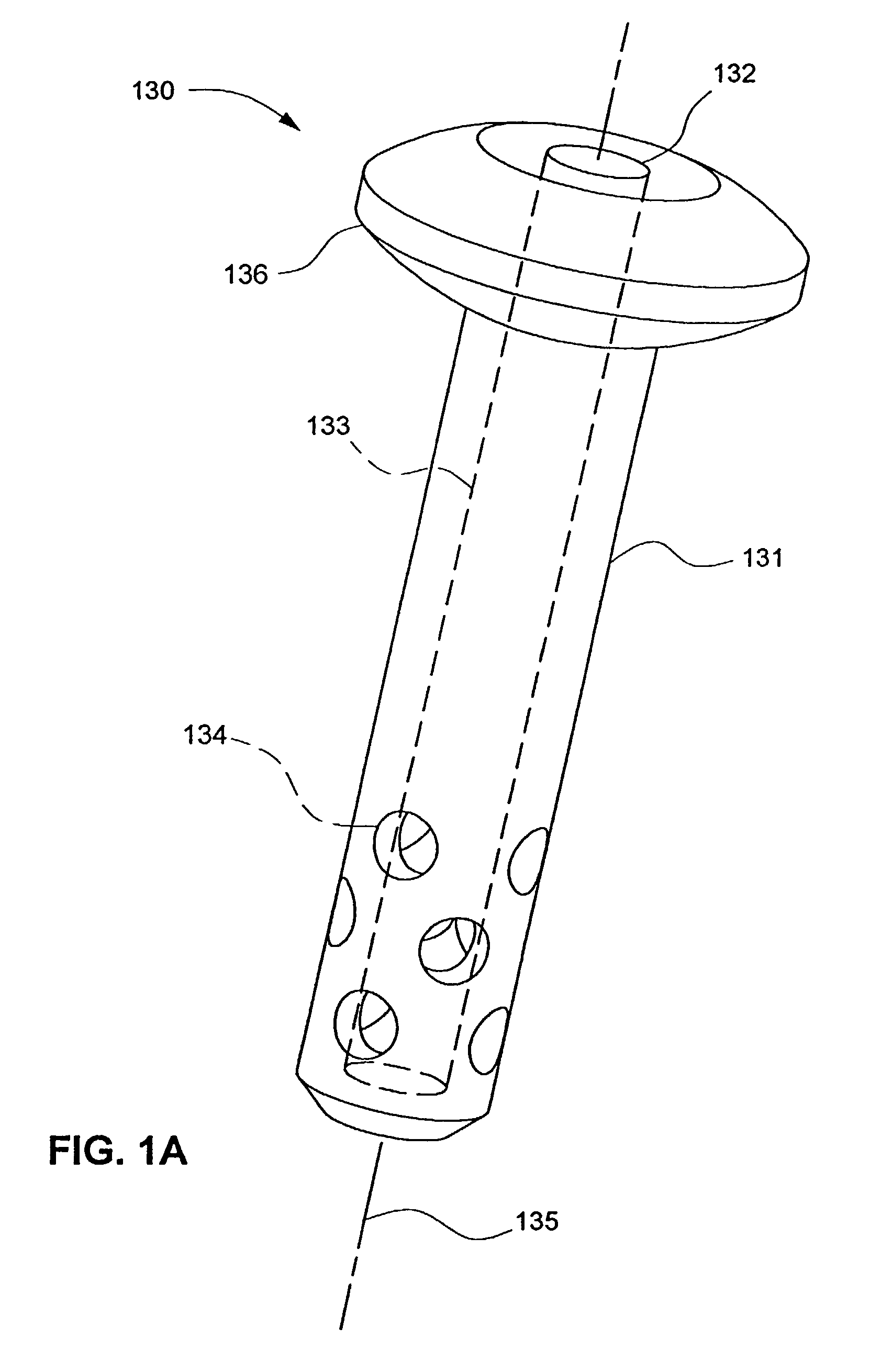

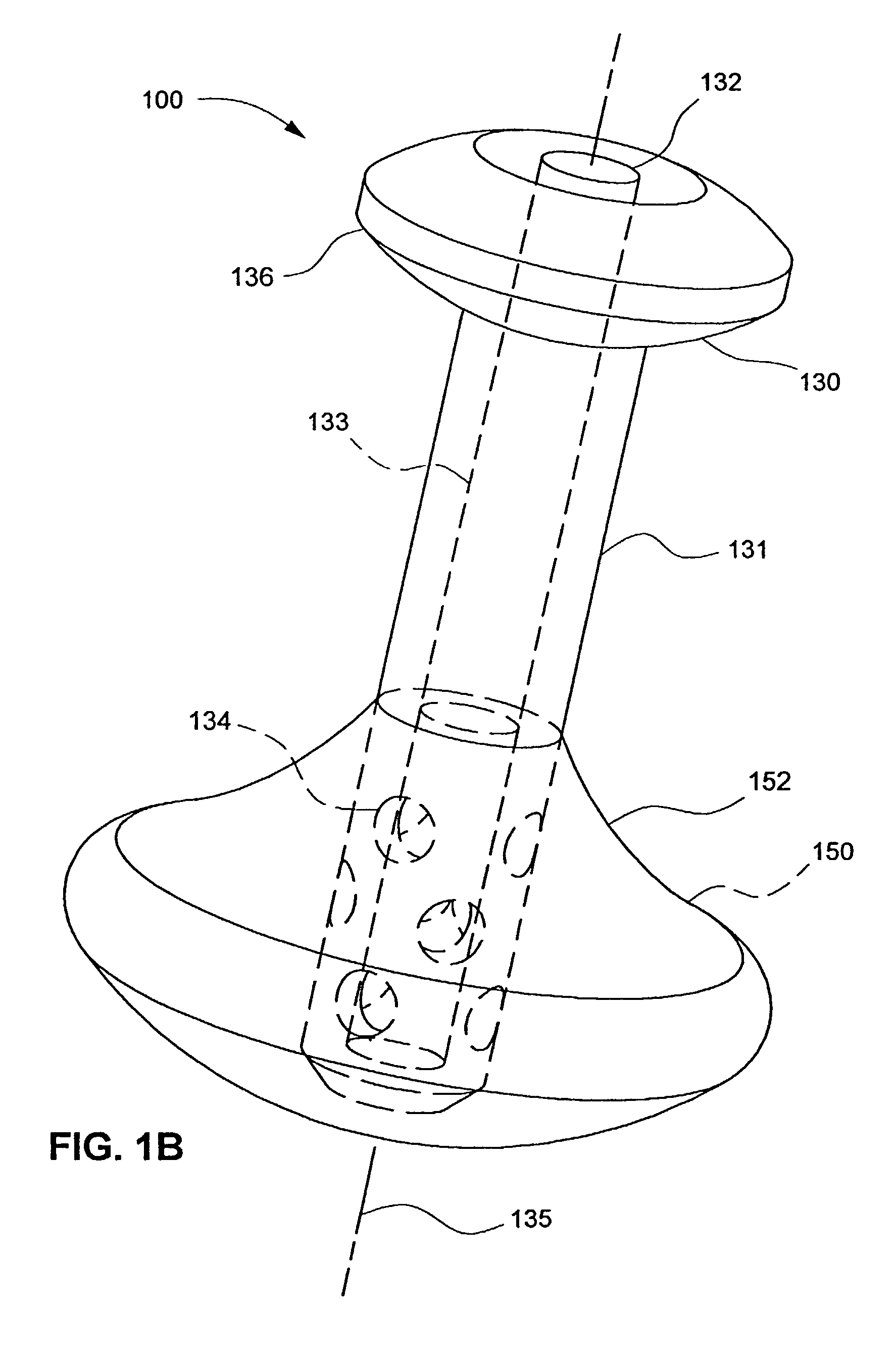

Orthopaedic implant fixation using an in-situ formed anchor

InactiveUS7488320B2Reduce stressReduce the possibilitySuture equipmentsInternal osteosythesisSuture anchorsPlastic surgery

An orthopaedic implant fixation using a surgically created bone cavity as a mold for forming an anchor from an in-situ hardenable material. An in-situ formed anchor of the present invention is especially useful for attaching an implant to osteoporotic cancellous bone. The injectable nature of the in-situ formed anchor allows implants to be adapted to minimally invasive surgical techniques. The present invention can be adapted to numerous implants or implant system components to include fasteners, pins, nails, intramedullary nails, and suture anchors. Applications include bone fracture fixation, bone fracture prevention, and soft-tissue repair.

Metal nano-void photonic crystal for enhanced raman spectroscopy

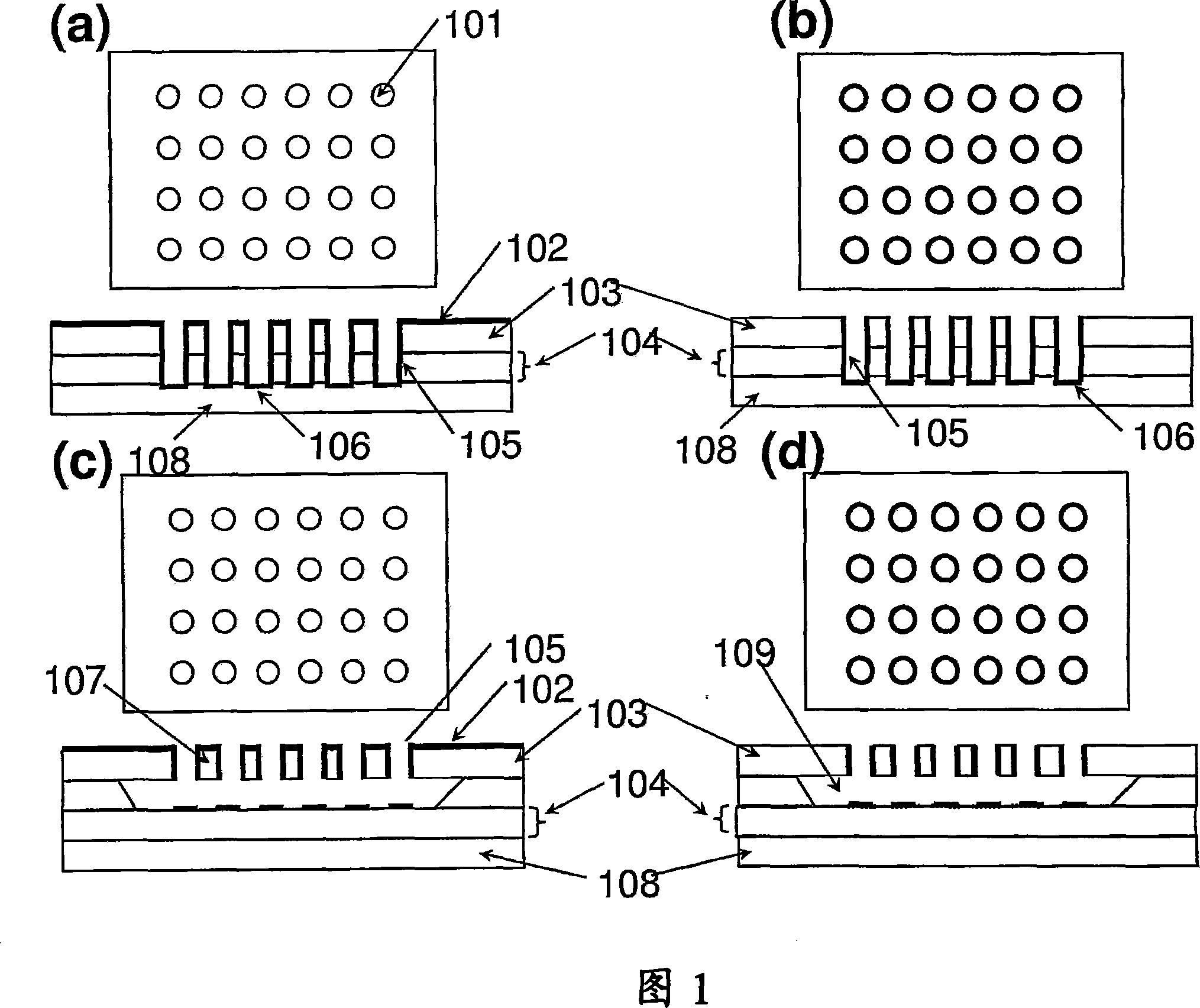

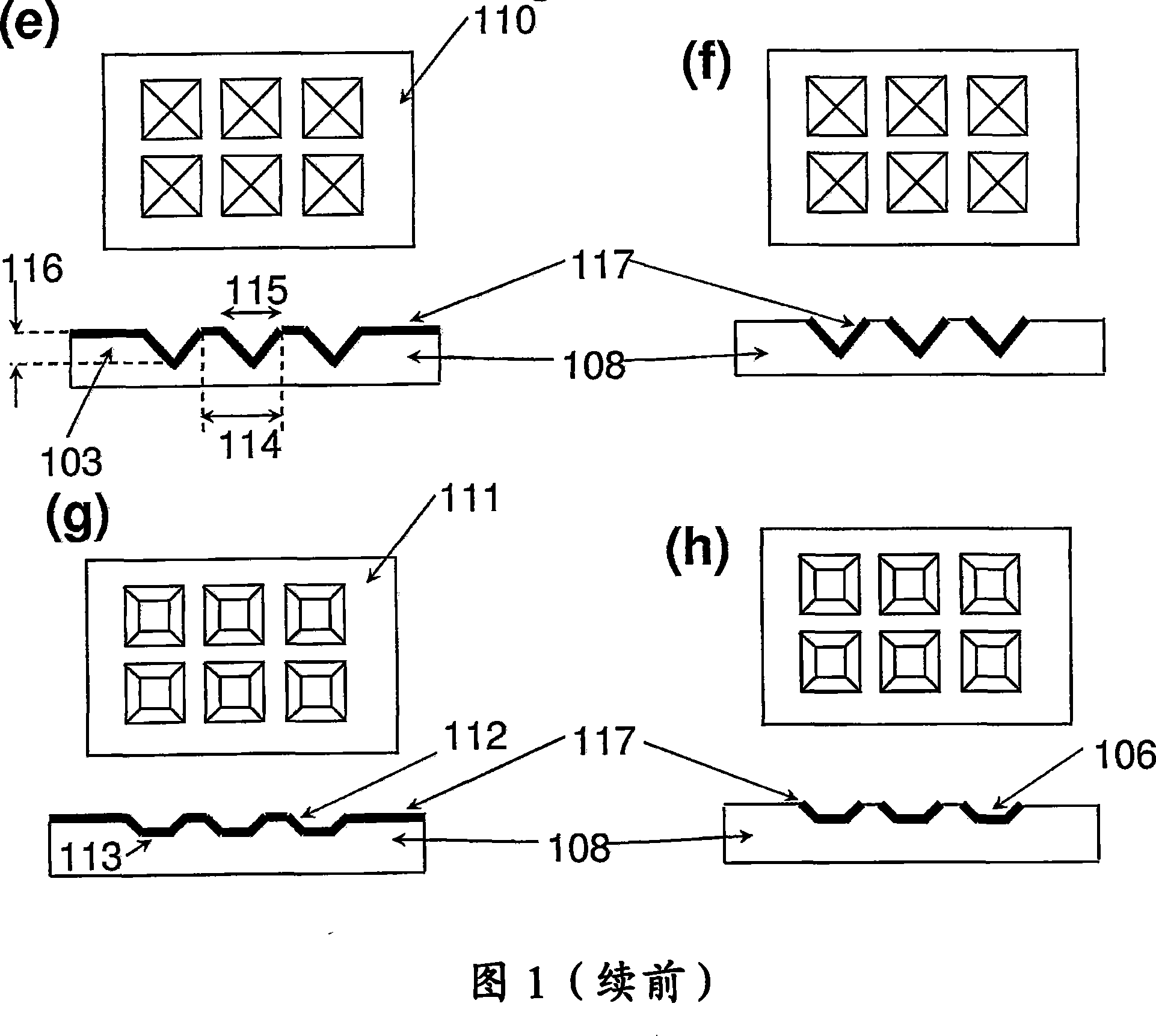

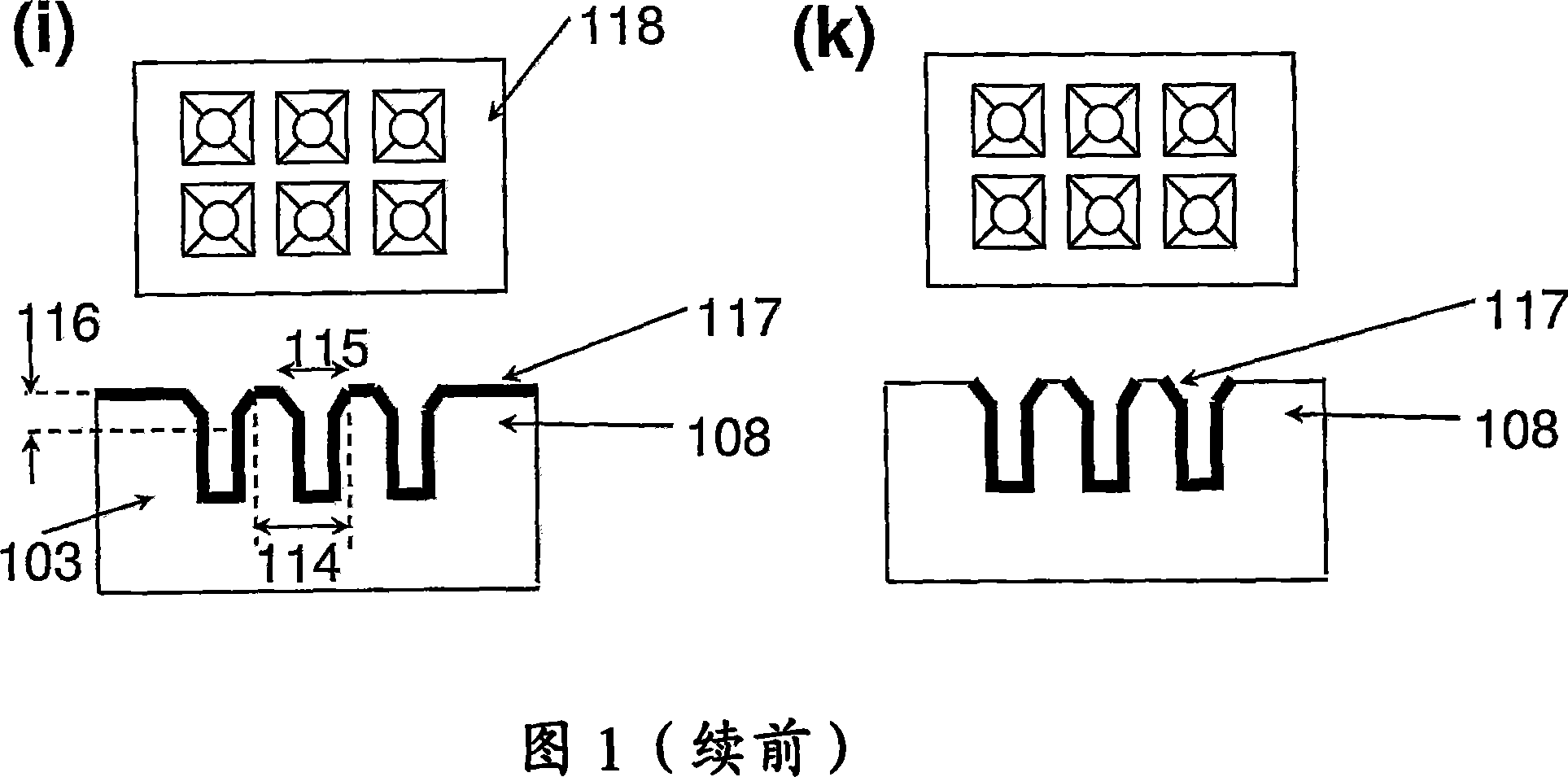

InactiveCN101057132AInjection is simpleSimple and more reproducible injectionMaterial nanotechnologyScattering properties measurementsOptical radiationAnalyte

A planar optical platform for generating a Raman signal from a foreign object comprises an input region and an output region, for receiving and extracting optical radiation, optically coupled to a plasmonic band structure region. The plasmonic band structure region comprises a layer of a first material, having a first refractive index, patterned with an array of sub-regions of a second material, having a second refractive index, wherein a side-wall of each sub-region is coated with a metallodielectric layer. The array of sub-regions gives rise to a plasmonic band structure and, in use, each sub-region confines a plasmon resonance excited by optical radiation coupled into the plasmonic band structure region, which gives rise to a Raman signal from a foreign object placed proximate the plasmonic band structure region. The platform may be incorporated into a spectroscopic measurement system and is particularly useful for surface-enhanced Raman spectroscopy of analyte molecules.

Owner:D3 TECH

Injectable intraocular accommodating lens

InactiveUS20020071856A1Reduce post-injection manipulationInjection is simpleHair cosmeticsPharmaceutical delivery mechanismMedicineRefractive index

The present invention relates to compositions comprising polysiloxanes suitable for the preparation of accommodating intraocular lenses, having a specific gravity of greater than about 1.0, a refractive index suitable for restoring the refractive power of the natural crystalline lens and a viscosity suitable for injection through a standard cannula. The present invention includes intraocular lenses made from said polysiloxane compositions having a Young's modulus less than about 10 kPa.

Owner:AMO GRONINGEN

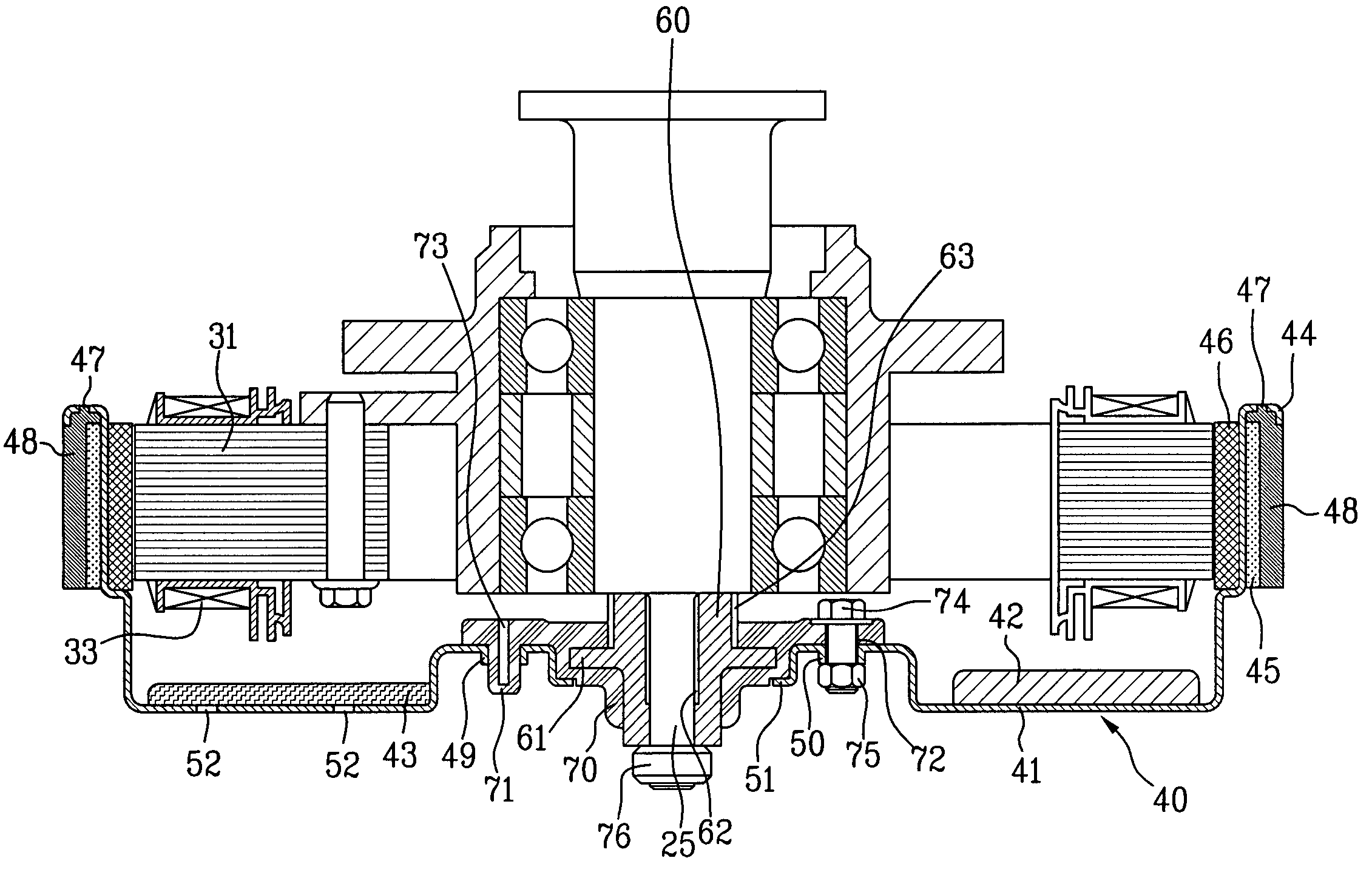

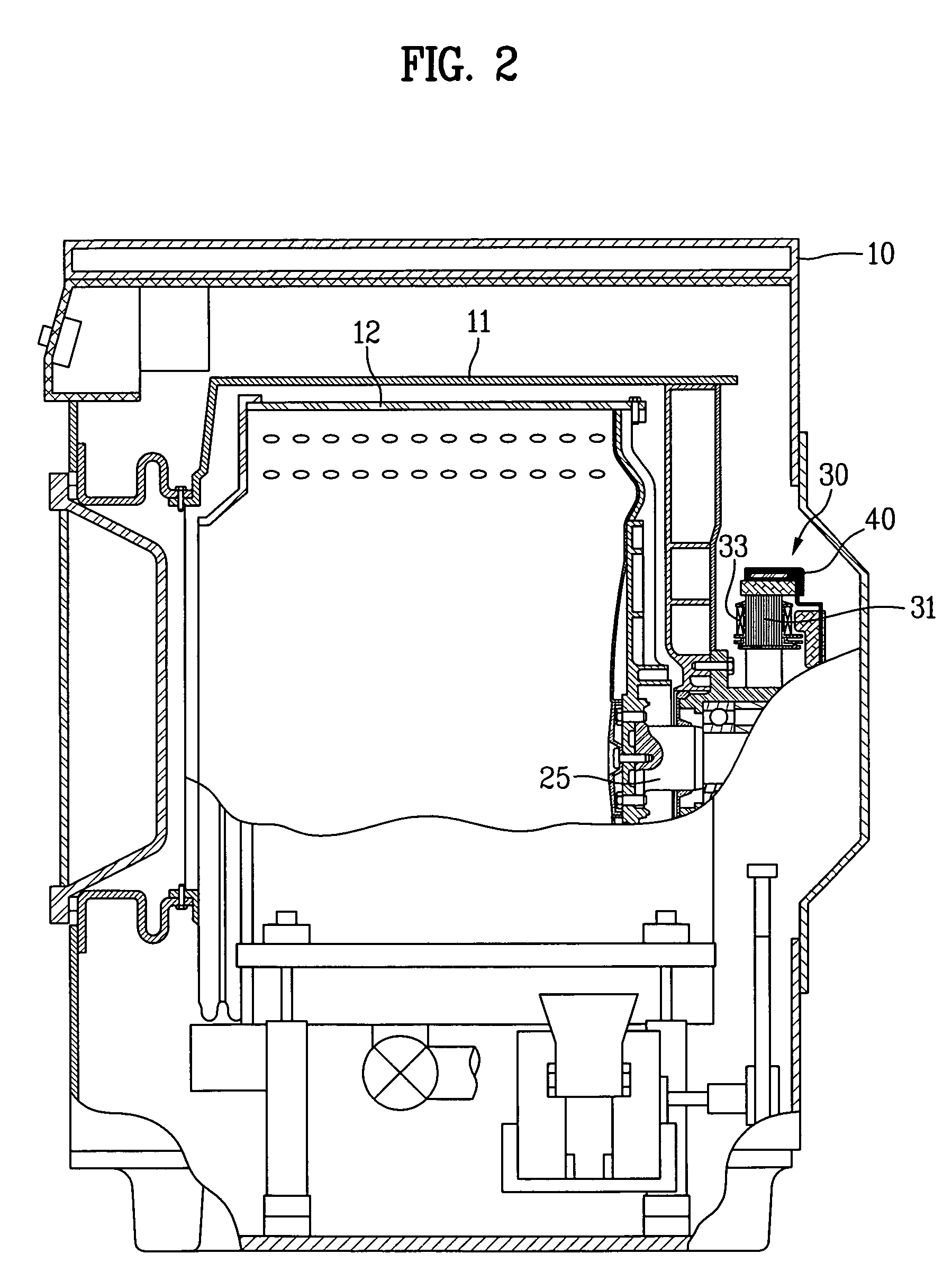

Motor for washing machine

InactiveUS20050140232A1Improve securityEasy to manufactureMagnetic circuit rotating partsOther washing machinesDrive shaftMagnet

A motor for a washing machine including a driving shaft coupled to a drum, a stator for forming a magnetic field with a coil wound on a core, and a rotor rotatably mounted on an outside of the stator coupled to the driving shaft for driving the driving shaft, wherein the rotor includes a rotor frame having magnets attached to an inside surface of an outer end, a back yoke on an outside surface of the outer end for reinforcing the rotor frame and forming a magnetic path, a shaft supporting housing at a center of the rotor frame having one end portion of the driving shaft secured thereto, a bushing of a non-conductive resin having the shaft supporting housing formed as one body at a center, the bushing being secured to the rotor frame, and fastening members for fastening the bushing to the rotor frame.

Owner:LG ELECTRONICS INC

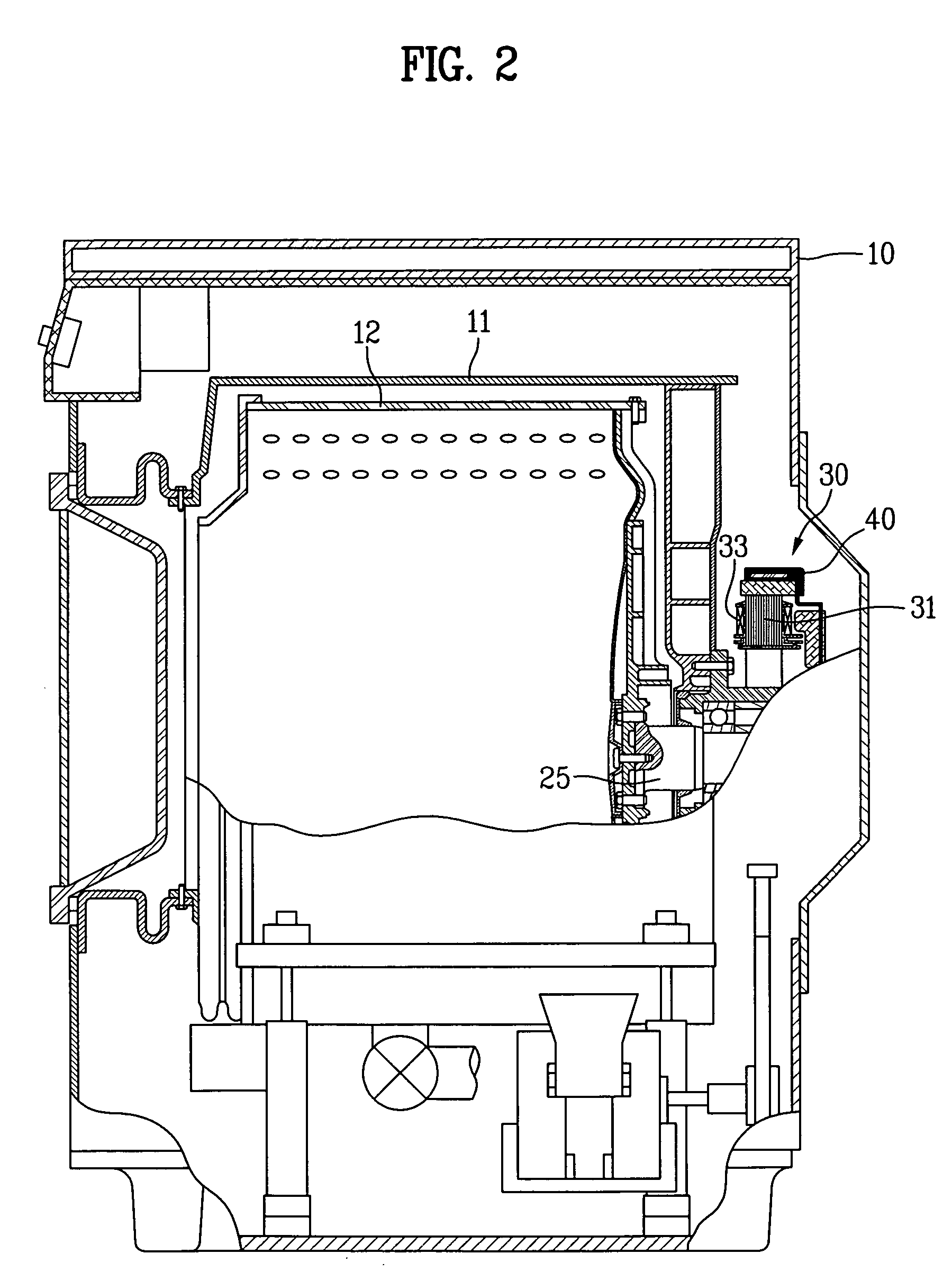

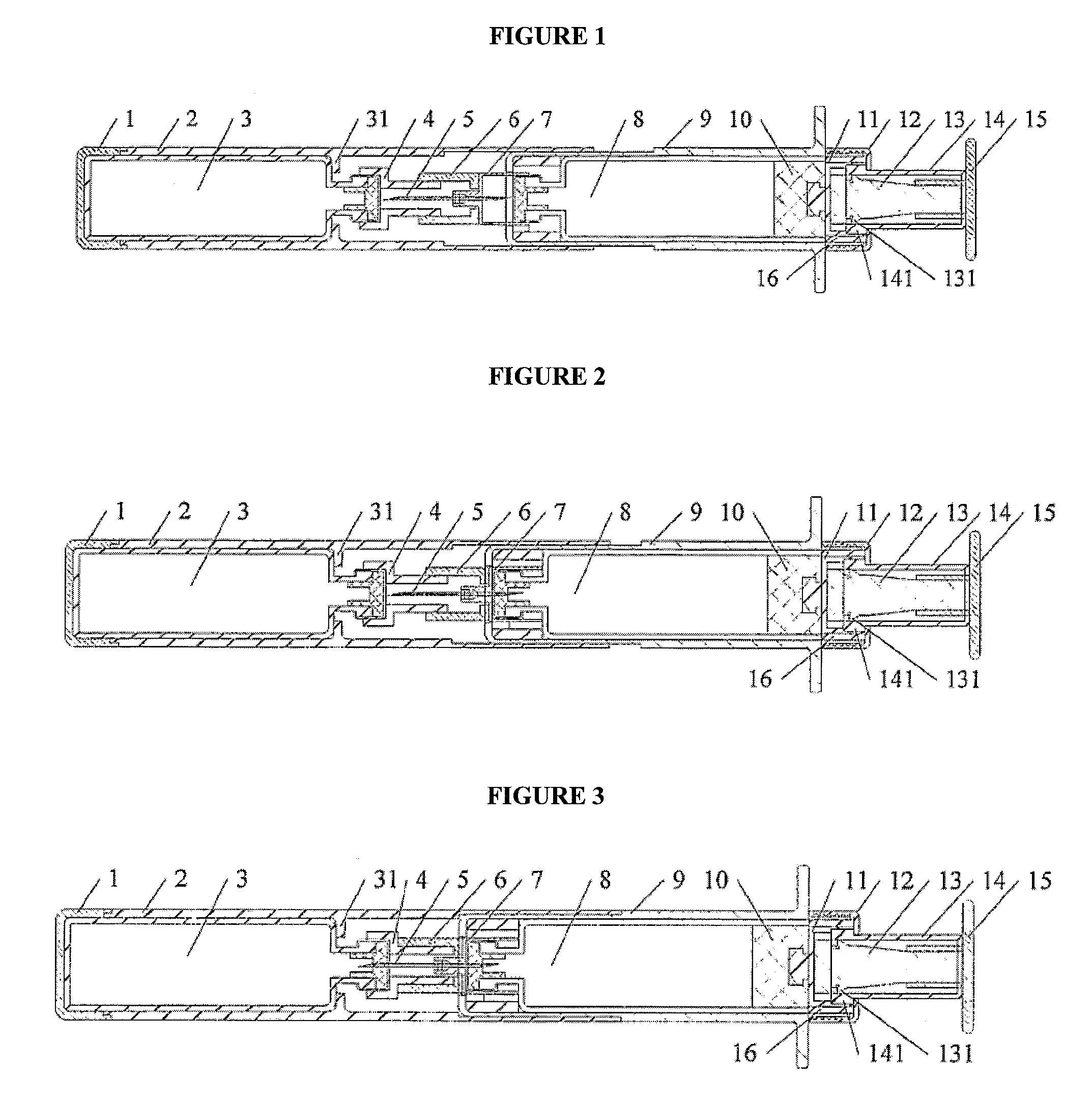

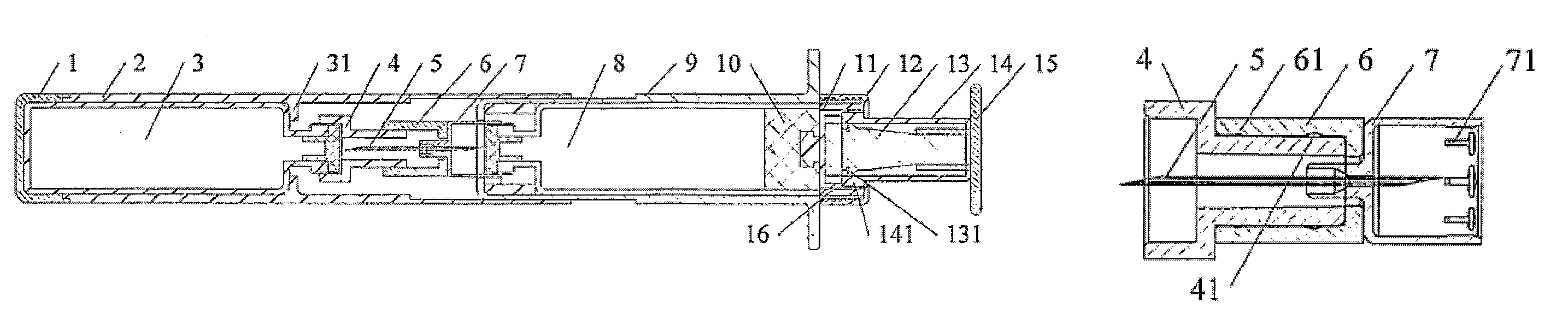

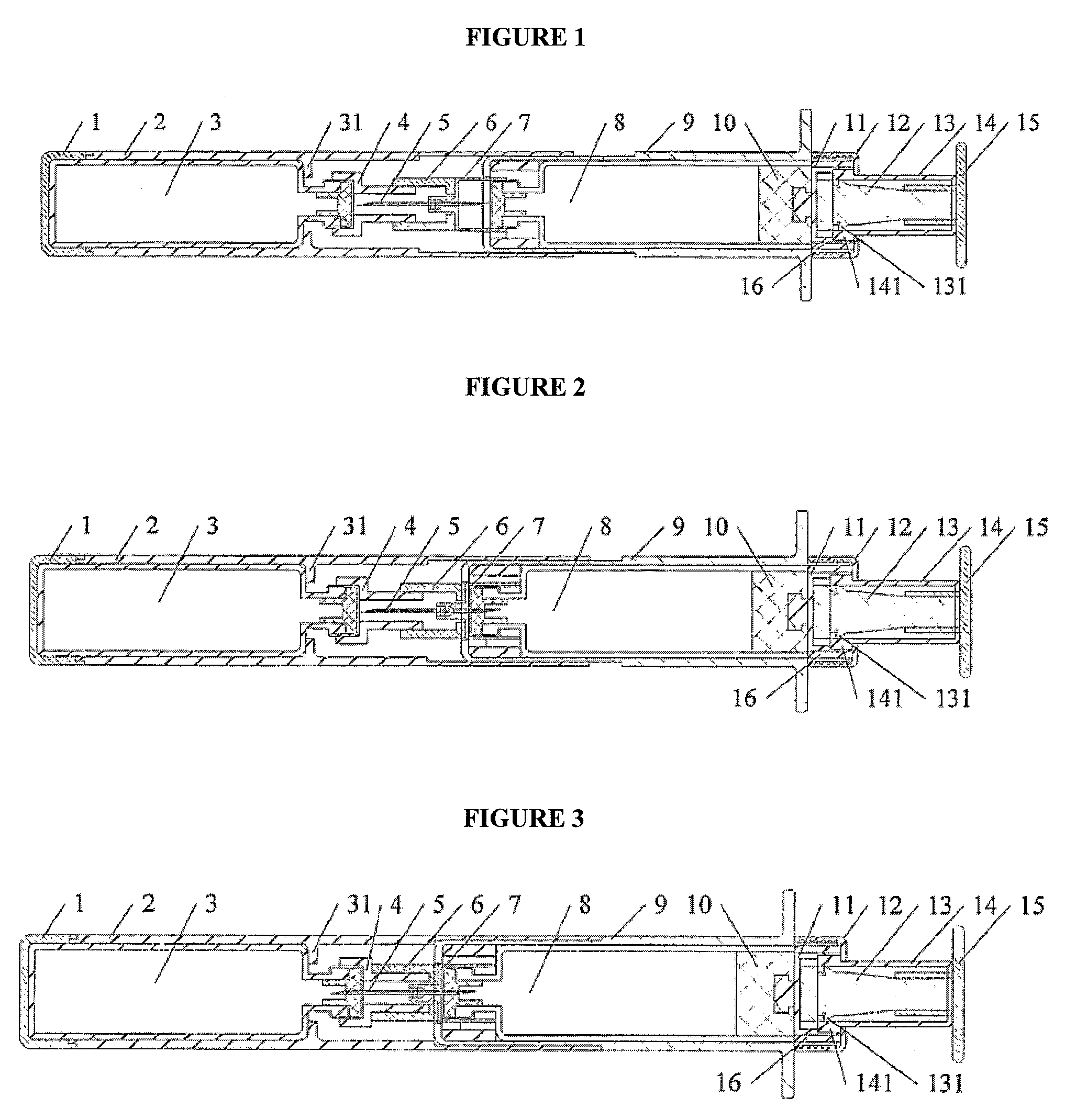

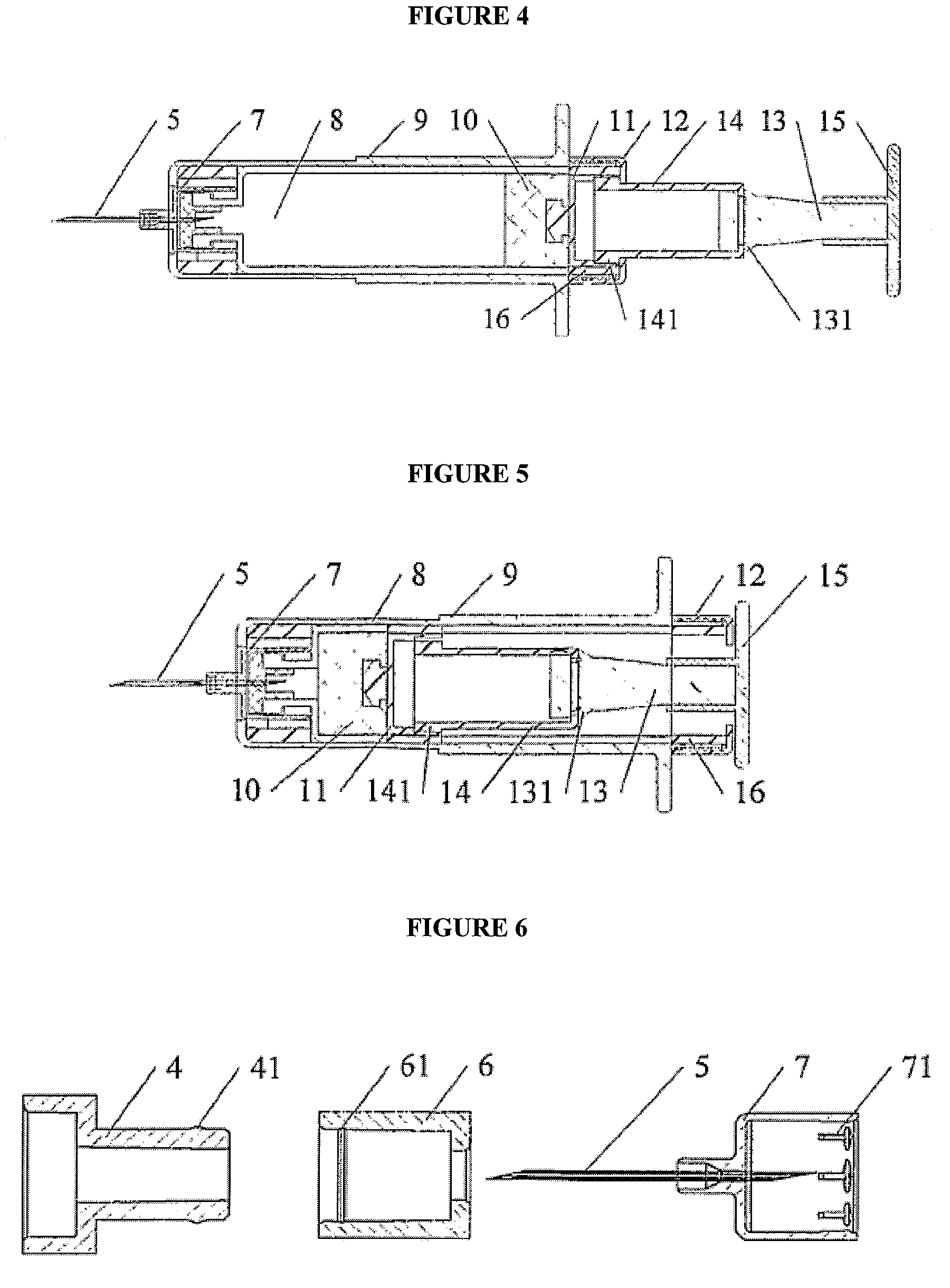

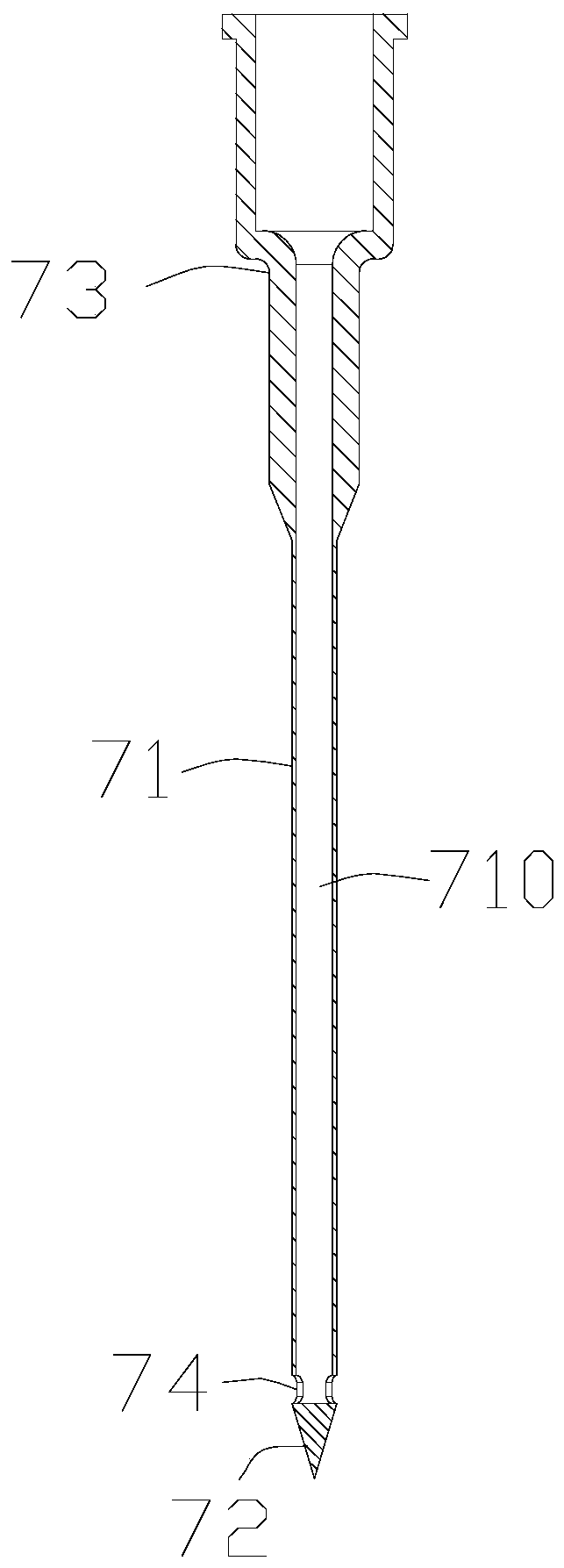

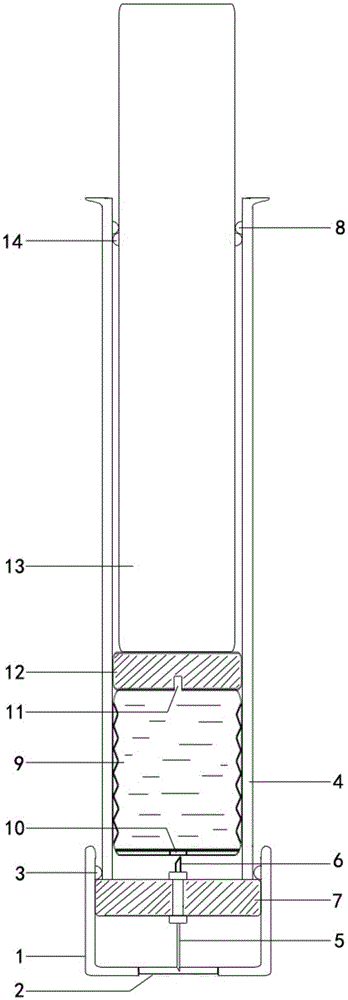

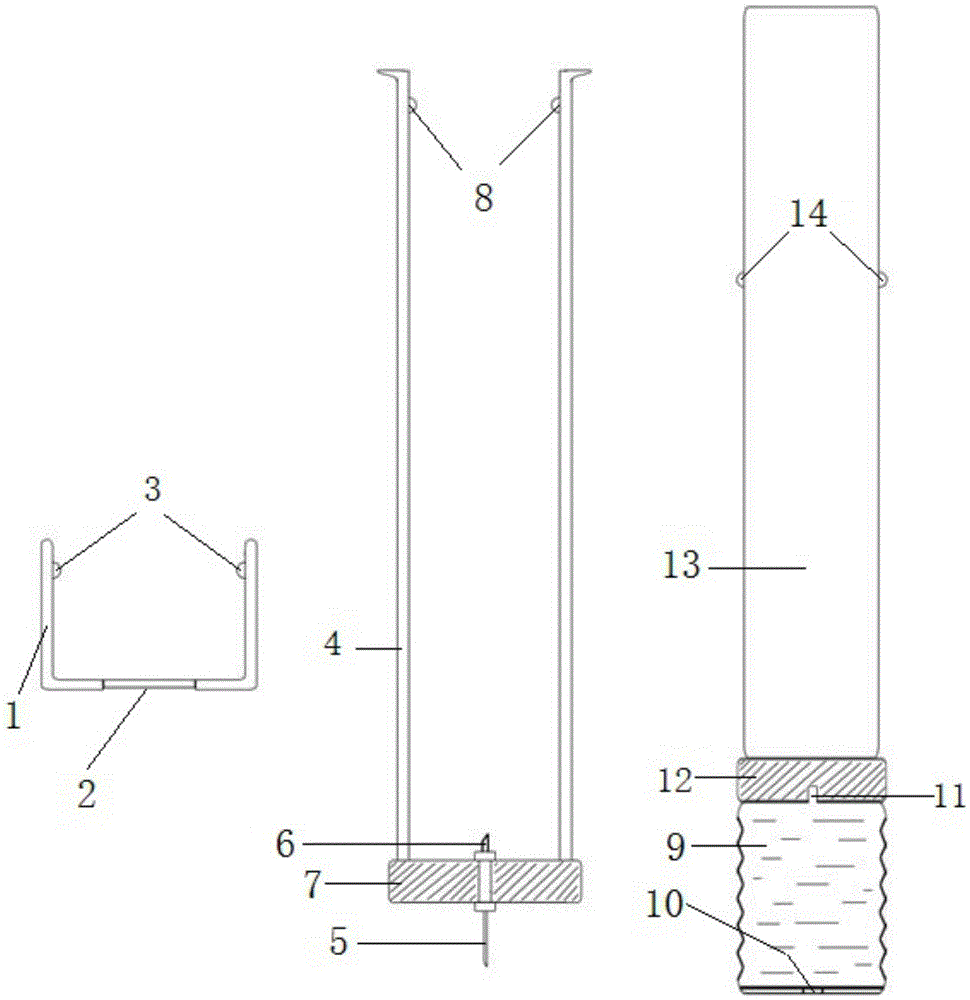

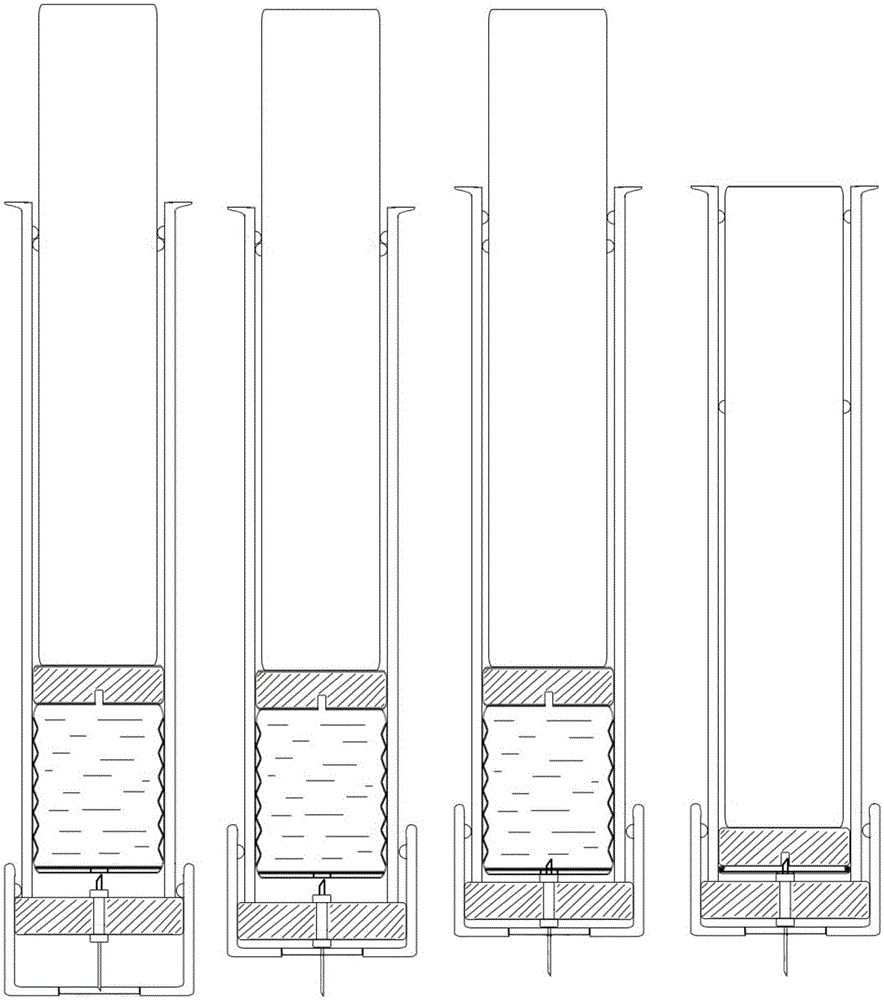

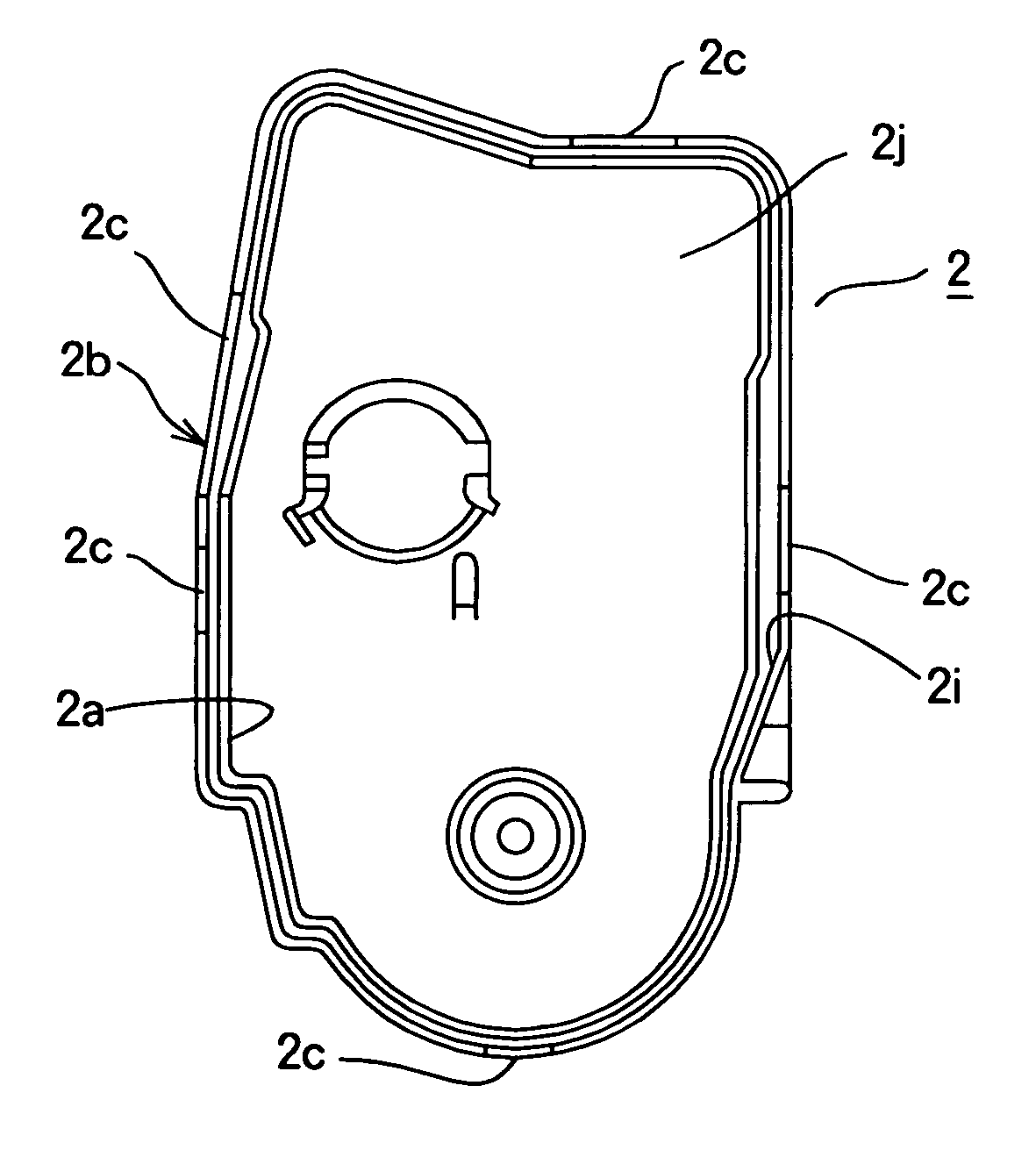

Sterile Drug-Mixing Syringe

InactiveUS20090326448A1Easy to operateInjection is simpleDiagnosticsInfusion syringesNeedle puncturePush pull

The invention is directed to a menstruum prepositioned type sterile drug-mixing syringe and a menstruum separately positioned type sterile drug-mixing syringe including a shell, a needle, a piston and a push-pull rod assembly. The syringe further includes a menstruum bottle, a solute bottle, a sliding sleeve and a needle loading assembly. The menstruum bottle may be fixed to the inner wall of a sliding sheath, and the solute bottle may be fixed to the inner of the shell. Piston may be disposed within the solute bottle. The sliding sleeve may be socketed to the front end of the shell in advance or disposed by other ways. The mouth of the menstruum bottle may be opposite to the mouth of the solute bottle and may be connected by a needle, which has two piercing tips, wherein the needle punctures and is securely connected to the needle loading assembly.

Owner:HUO PINGAN +5

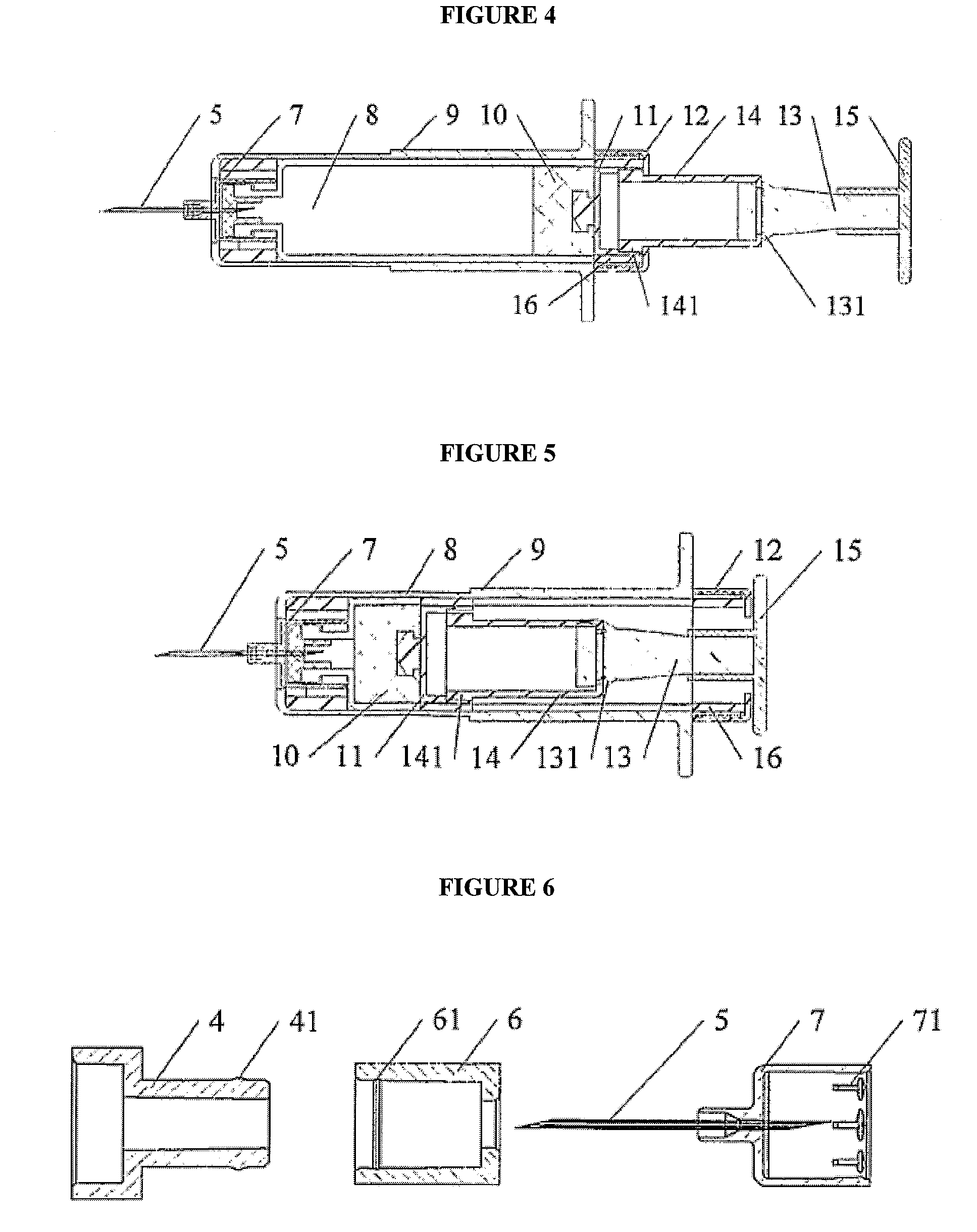

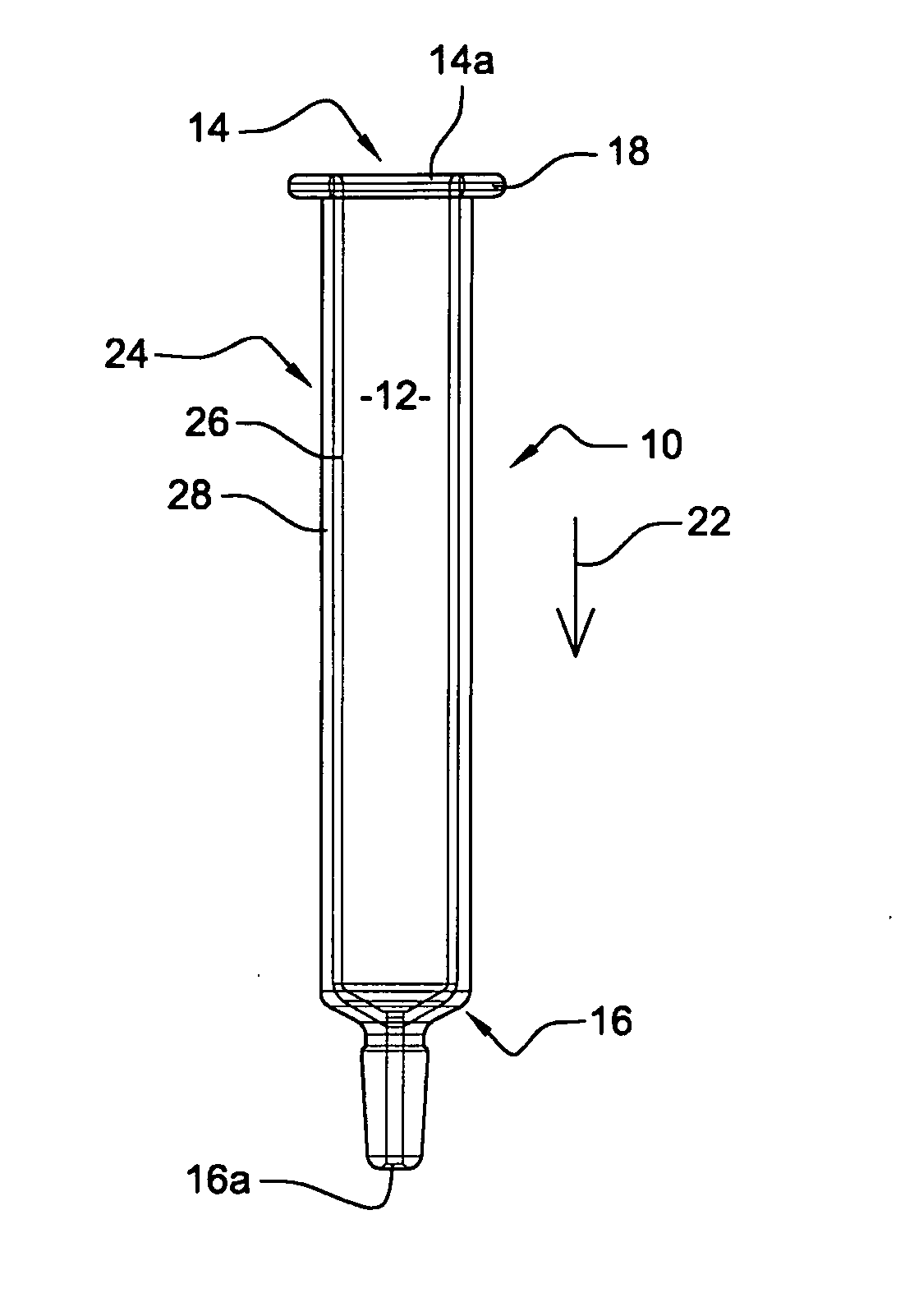

Device For Injecting A Pharmaceutical Liquid, Configured To Be Pre-filled

InactiveUS20150224263A1Satisfactory impermeabilityPrevent evaporationInfusion syringesMedical devicesPlastic materialsEngineering

An injection device which is configured to be pre-filled, including a vessel for storing the liquid, having two opposing ends, each provided with an opening, referred to as proximal end and distal end, and arranged to receive a sliding piston in order to exert pressure on the liquid. The vessel includes a wall including at least two vertically adjacent layers, each including vertically adjacent plastic material, the first and second layers having different gas permeability.

Owner:NEMERA LA VERPILLIERE SAS

Sterile drug-mixing syringe

InactiveUS8007461B2Easy to operateInjection is simpleInfusion syringesDiagnosticsNeedle punctureBottle

The invention is directed to a menstruum prepositioned type sterile drug-mixing syringe and a menstruum separately positioned type sterile drug-mixing syringe including a shell, a needle, a piston and a push-pull rod assembly. The syringe further includes a menstruum bottle, a solute bottle, a sliding sleeve and a needle loading assembly. The menstruum bottle may be fixed to the inner wall of a sliding sheath, and the solute bottle may be fixed to the inner of the shell. Piston may be disposed within the solute bottle. The sliding sleeve may be socketed to the front end of the shell in advance or disposed by other ways. The mouth of the menstruum bottle may be opposite to the mouth of the solute bottle and may be connected by a needle, which has two piercing tips, wherein the needle punctures and is securely connected to the needle loading assembly.

Owner:HUO PINGAN +5

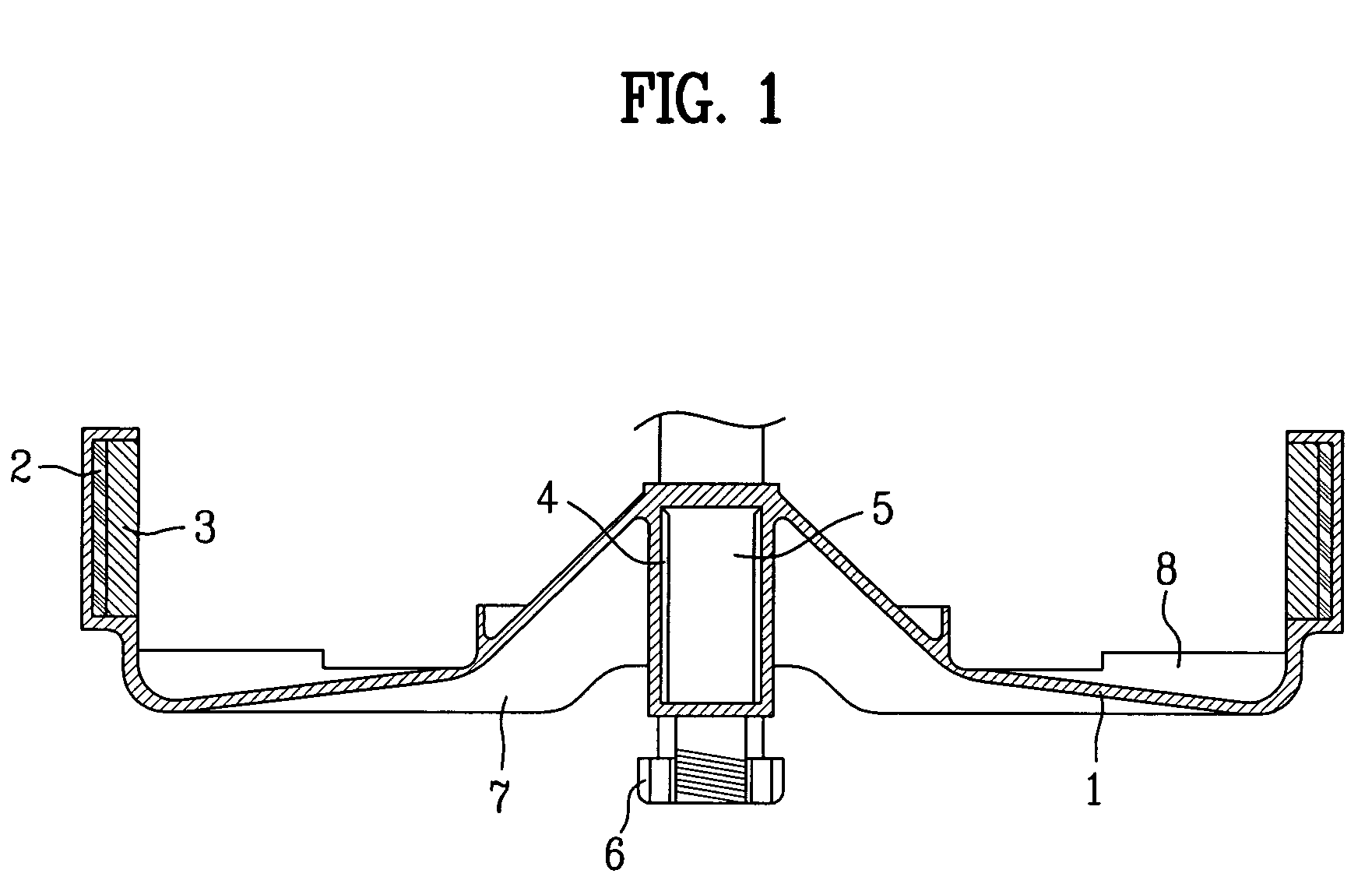

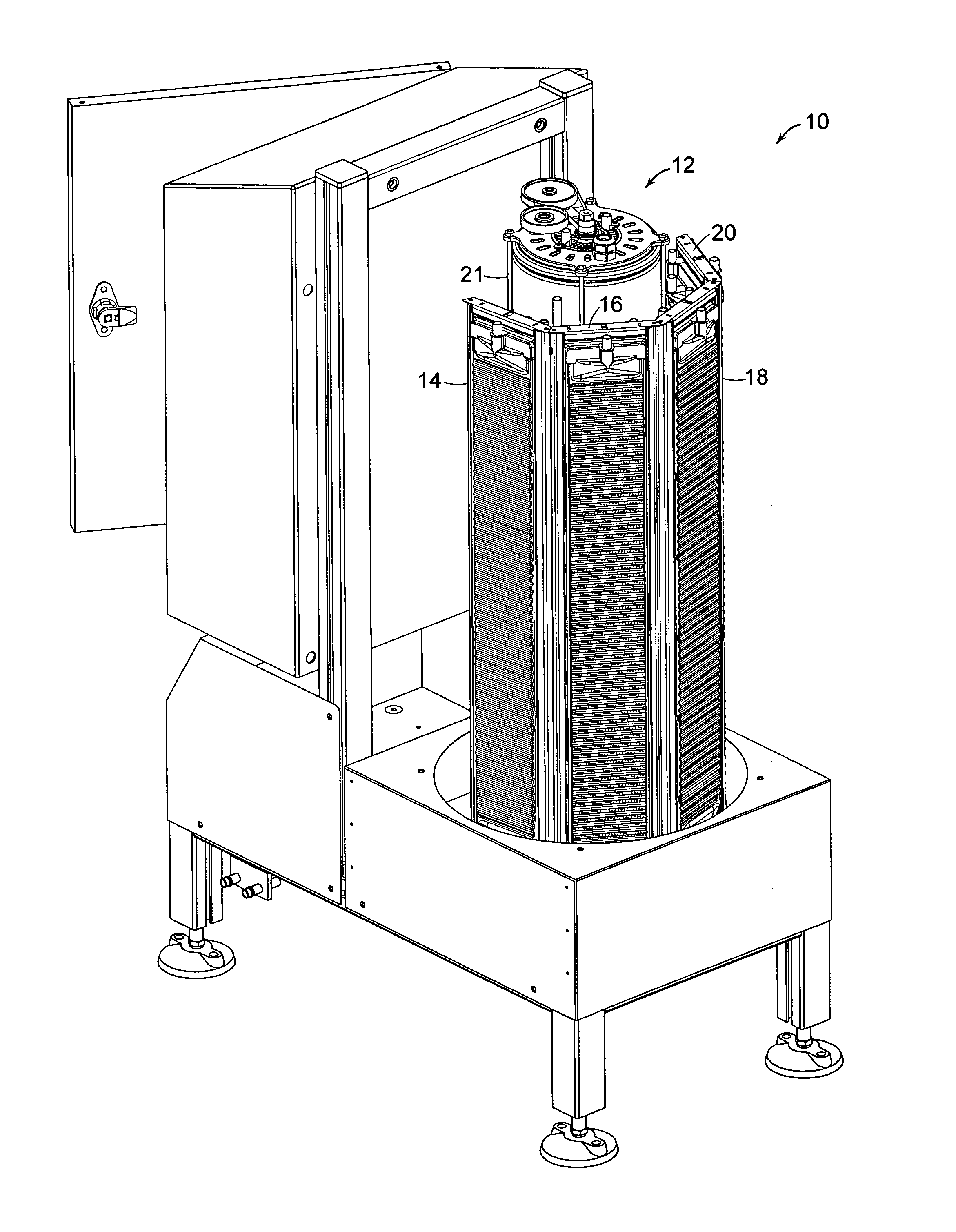

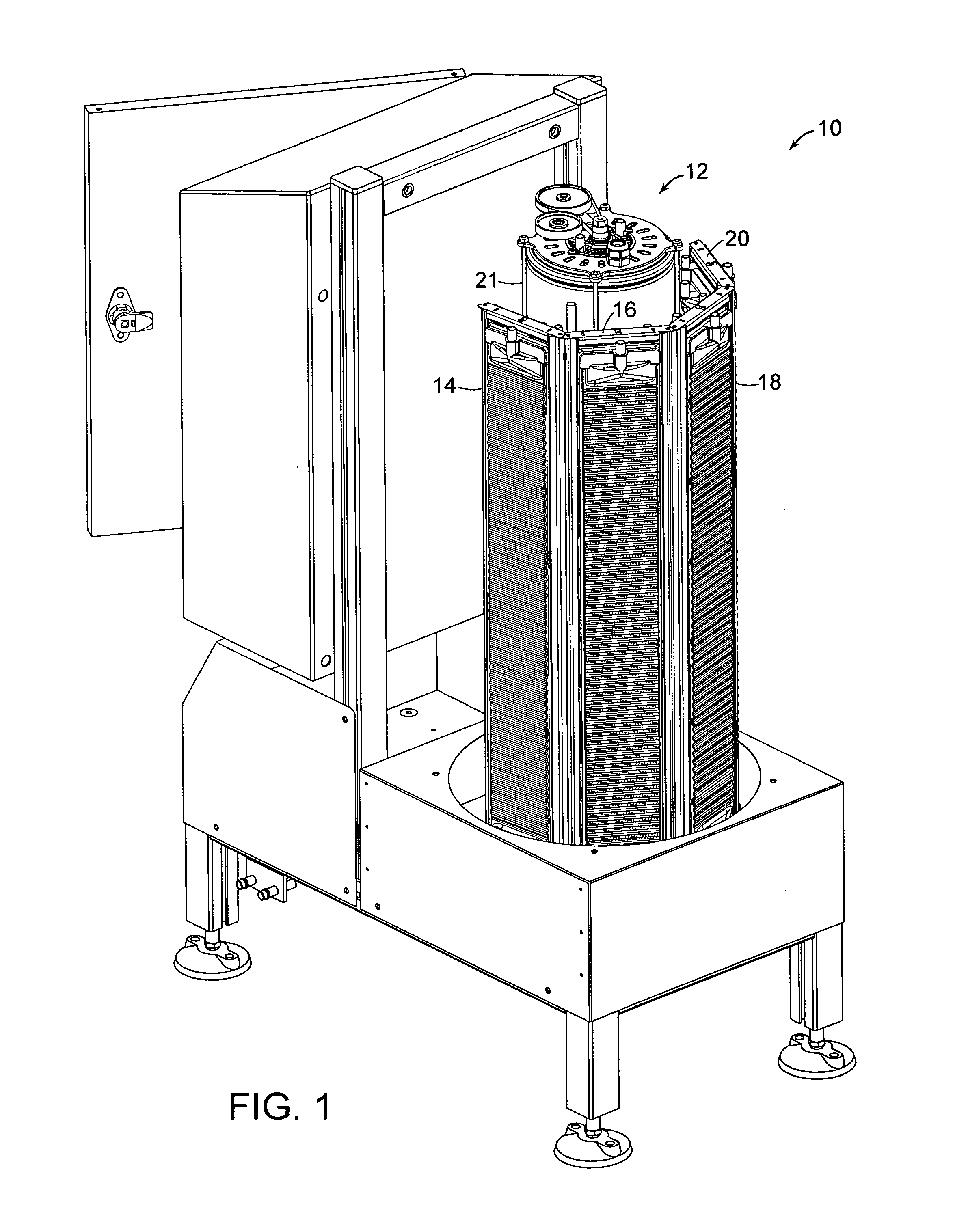

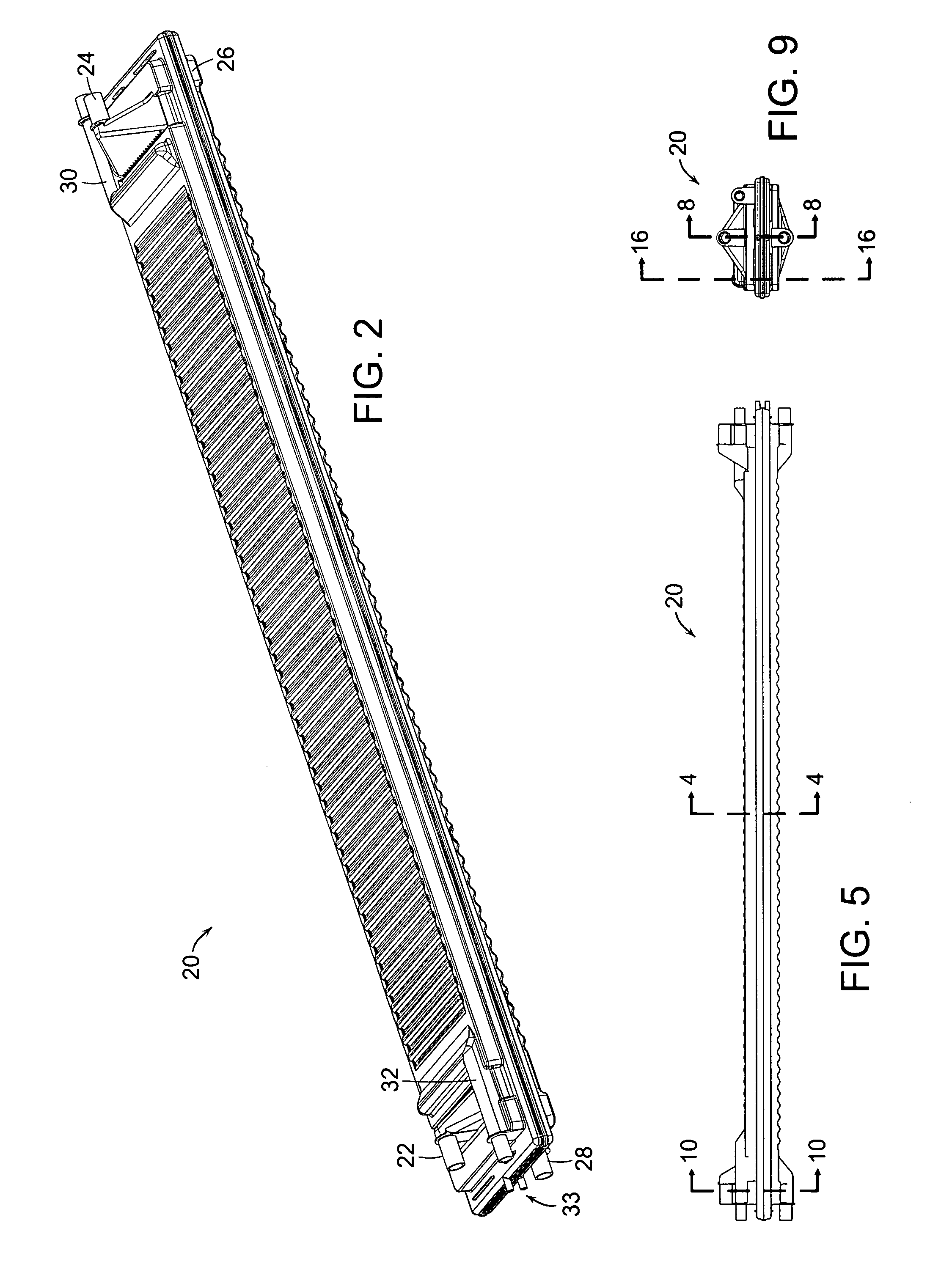

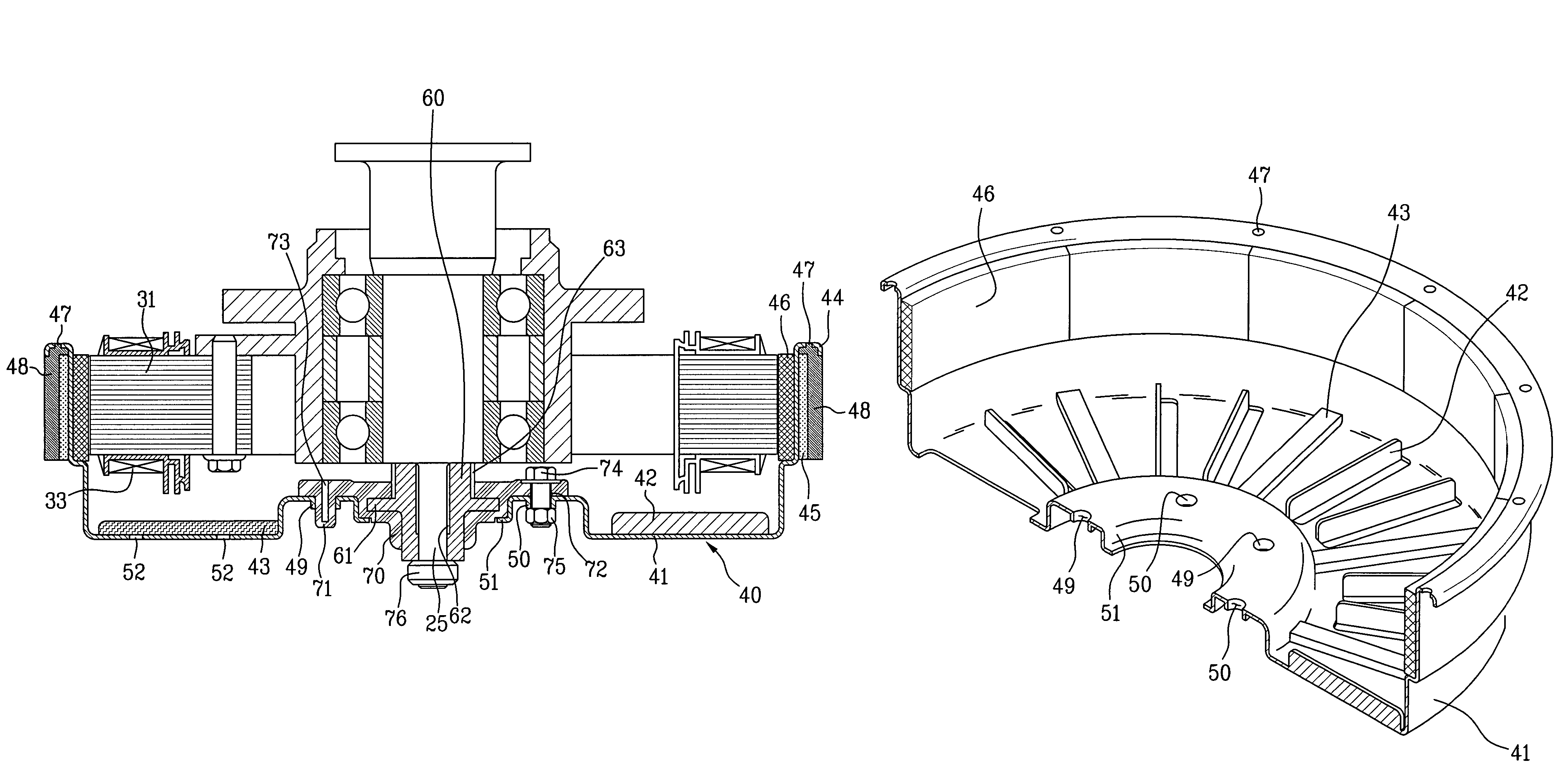

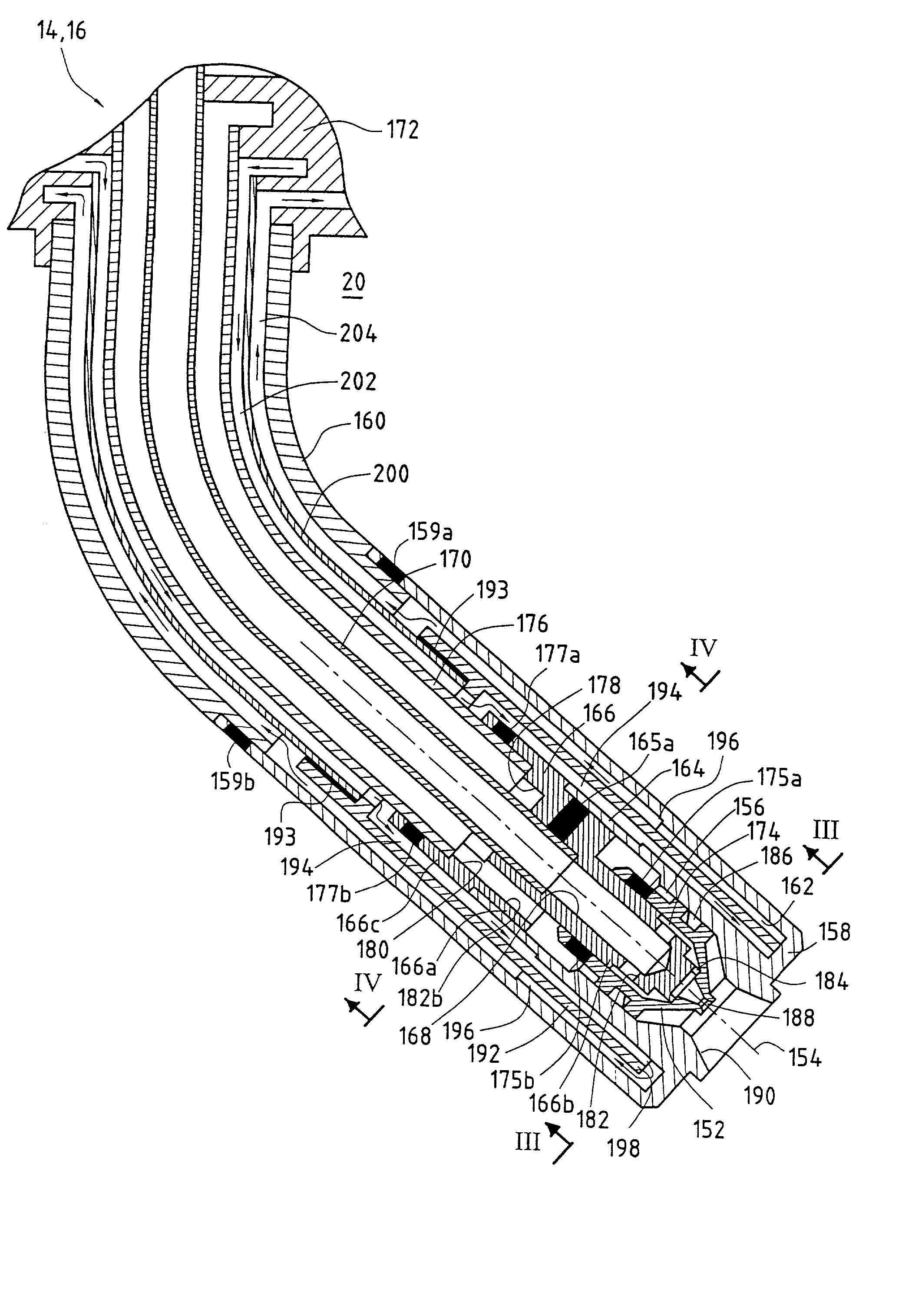

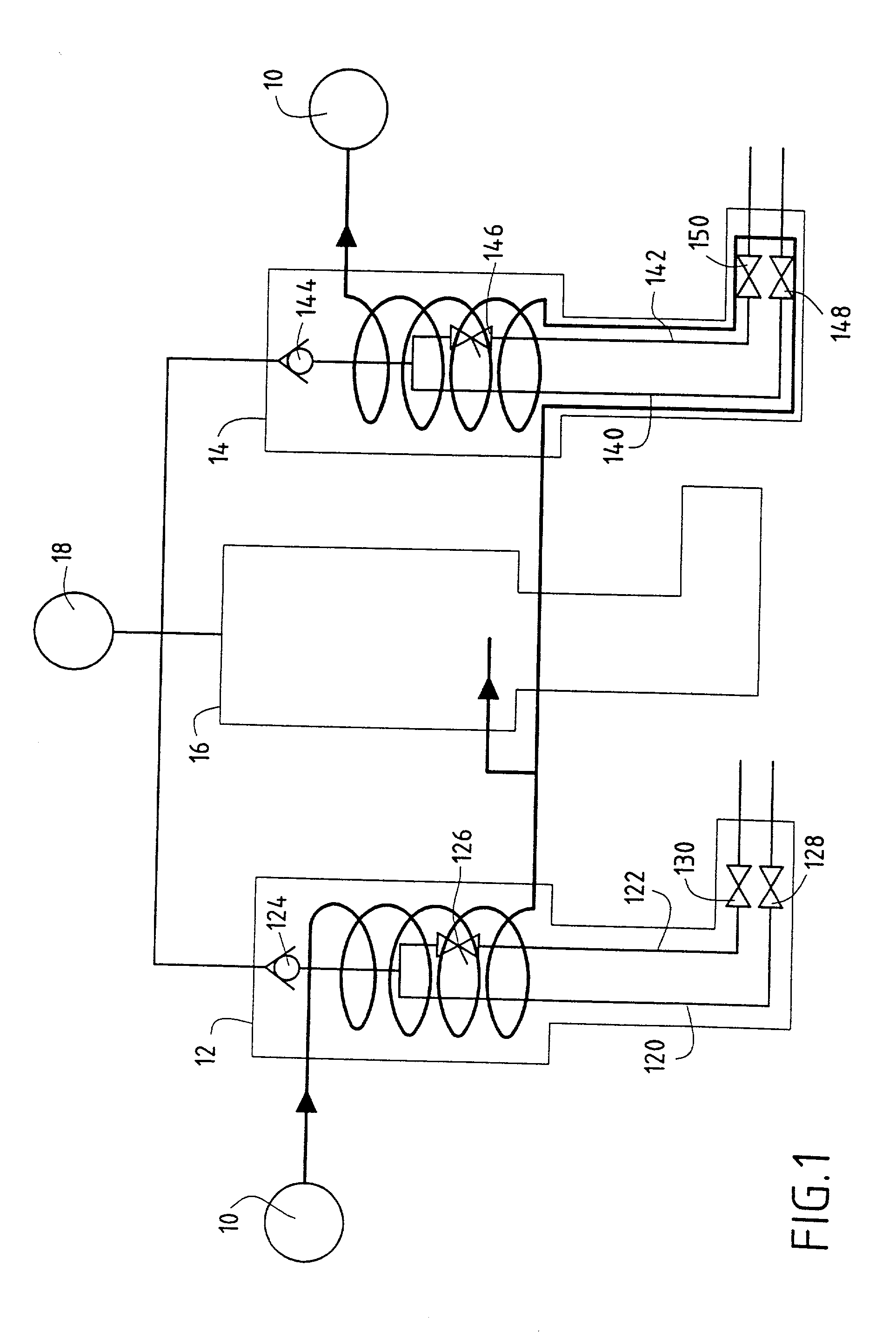

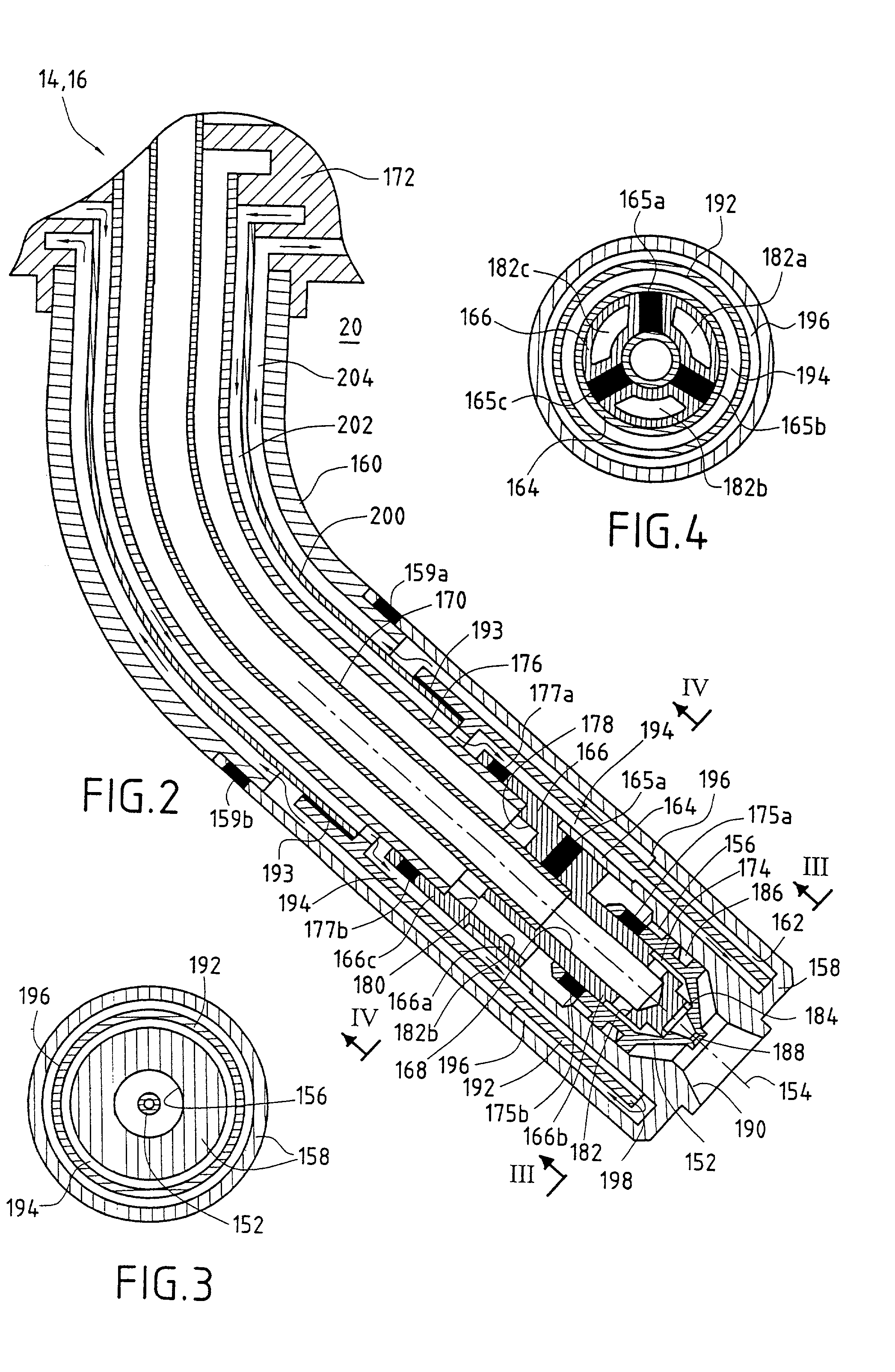

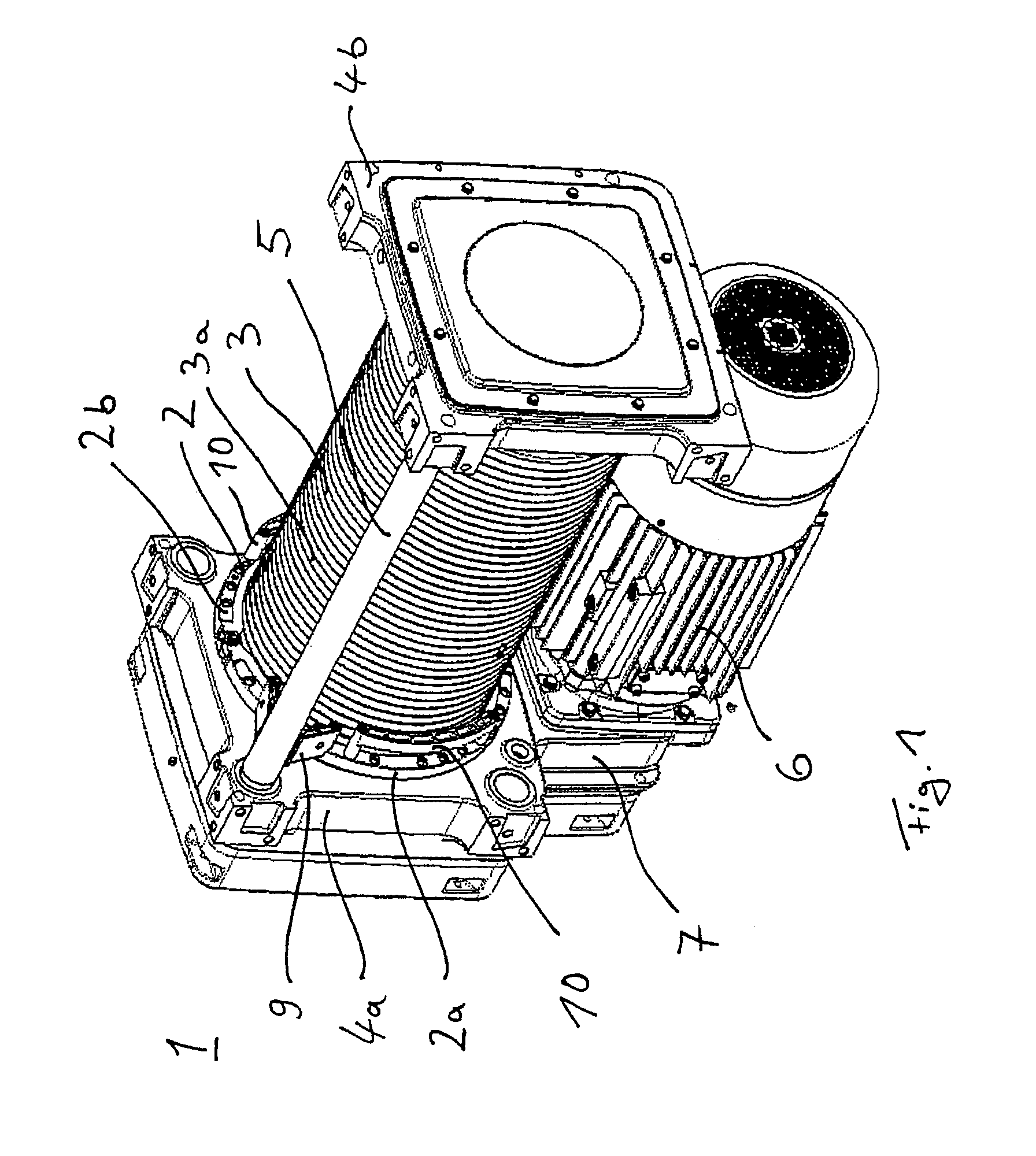

Heat-exchanger sealing

A distiller's counterflow-heat-exchanger module includes thermally conductive distillate and concentrate dividers across which heat flows to an influent liquid from distillate and concentrate liquids, respectively. The distillate divider's shape is convoluted in such a manner as to form alternating distillate and influent channels having end openings. A peripheral gasket is so over-molded onto the distillate divider that it forms plugs that seal the end openings from each other and further forms a ridge providing surfaces against which opposed generally planar parallel surfaces of cover members can be urged to form a peripheral seal.

Owner:ZANAQUA TECH

Motor for washing machine

InactiveUS7397158B2Improve securityEasy to manufactureMagnetic circuit rotating partsOther washing machinesDrive shaftMagnet

A motor for a washing machine including a driving shaft coupled to a drum, a stator for forming a magnetic field with a coil wound on a core, and a rotor rotatably mounted on an outside of the stator coupled to the driving shaft for driving the driving shaft, wherein the rotor includes a rotor frame having magnets attached to an inside surface of an outer end, a back yoke on an outside surface of the outer end for reinforcing the rotor frame and forming a magnetic path, a shaft supporting housing at a center of the rotor frame having one end portion of the driving shaft secured thereto, a bushing of a non-conductive resin having the shaft supporting housing formed as one body at a center, the bushing being secured to the rotor frame, and fastening members for fastening the bushing to the rotor frame.

Owner:LG ELECTRONICS INC

Method of assembling a fuel injector for the combustion chamber of a turbomachine

InactiveUS20020073708A1Minimal numberSpace minimizationBurnersValve arrangementsCombustion chamberEngineering

An assembly method in which a brazing metal is initially filled into radial wells pierced in an annular injection piece having first injection orifices for discharging a primary fuel, and in a cylindrical endpiece surrounding the annular injection piece and having secondary injection orifices for discharging a secondary fuel; thereafter the annular injection piece is fitted inside the cylindrical endpiece and these pieces are together fitted on a first tube for feeding primary fuel and a second tube for feeding secondary fuel and surrounding the first tube, and also to an outer wall of the injector; finally, the end portion of the injector as assembled in this way is placed in an enclosure where it is heated so as to melt the brazing metal to unite the parts.

Owner:HISPANO SUIZA SA

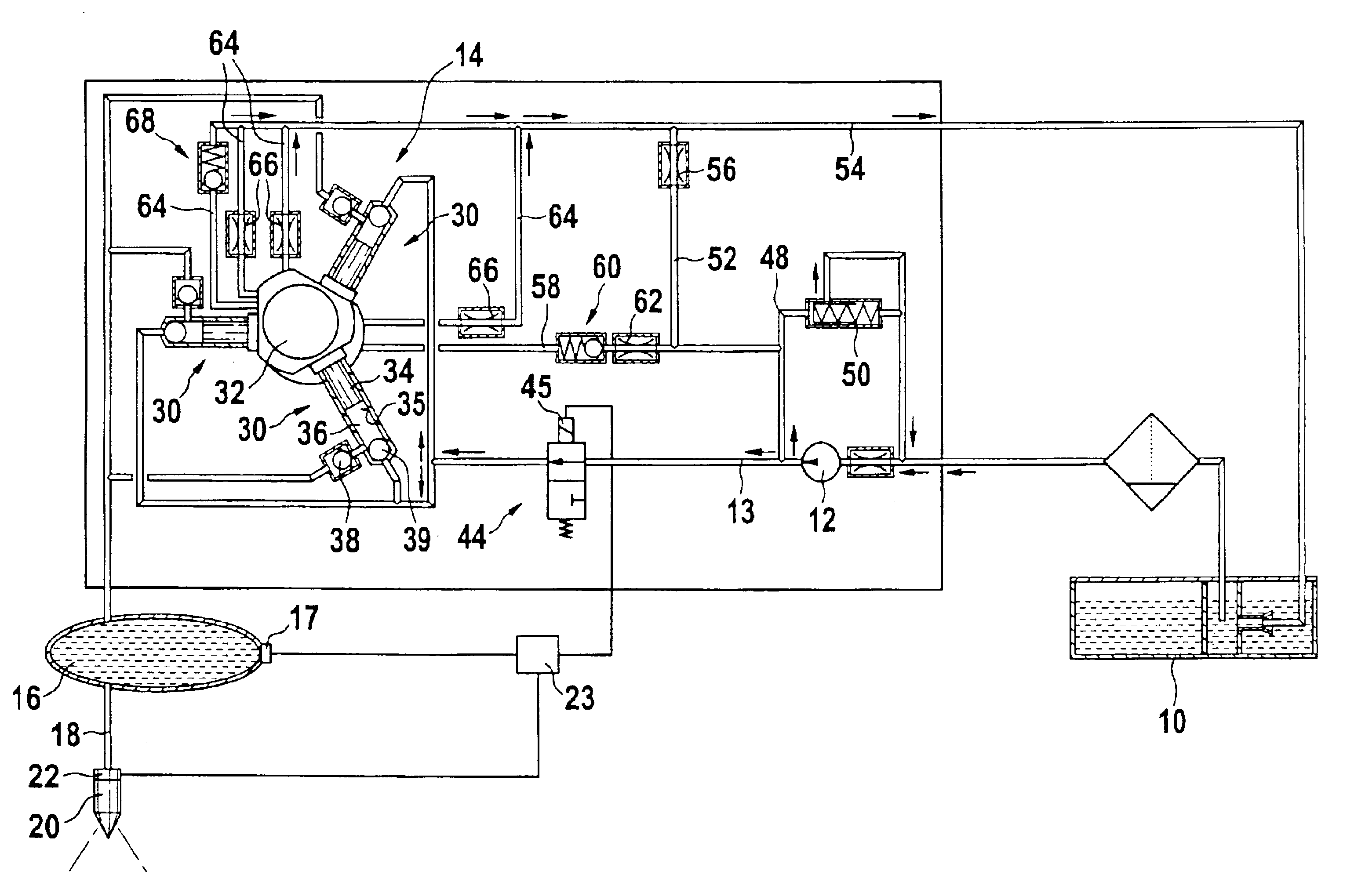

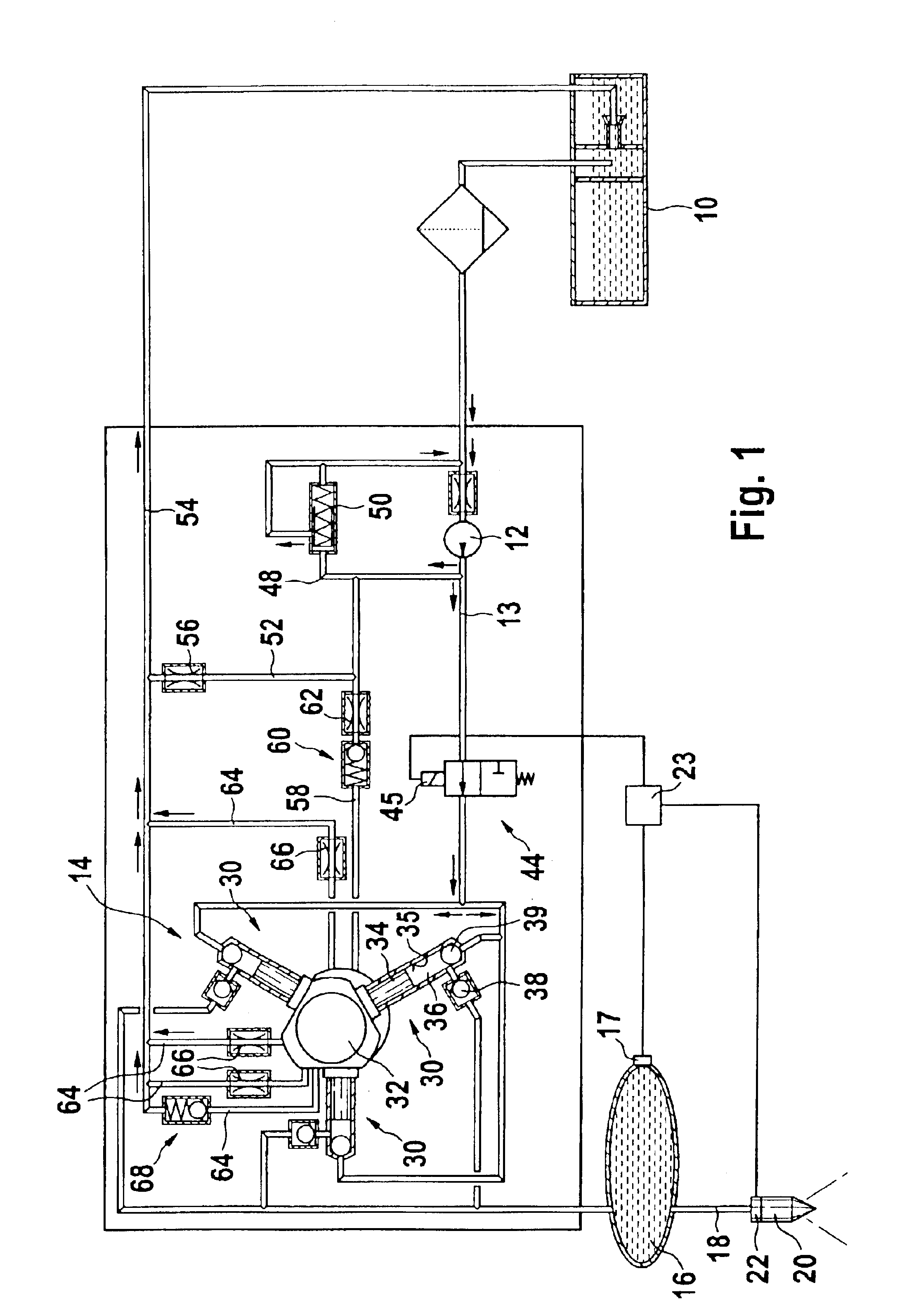

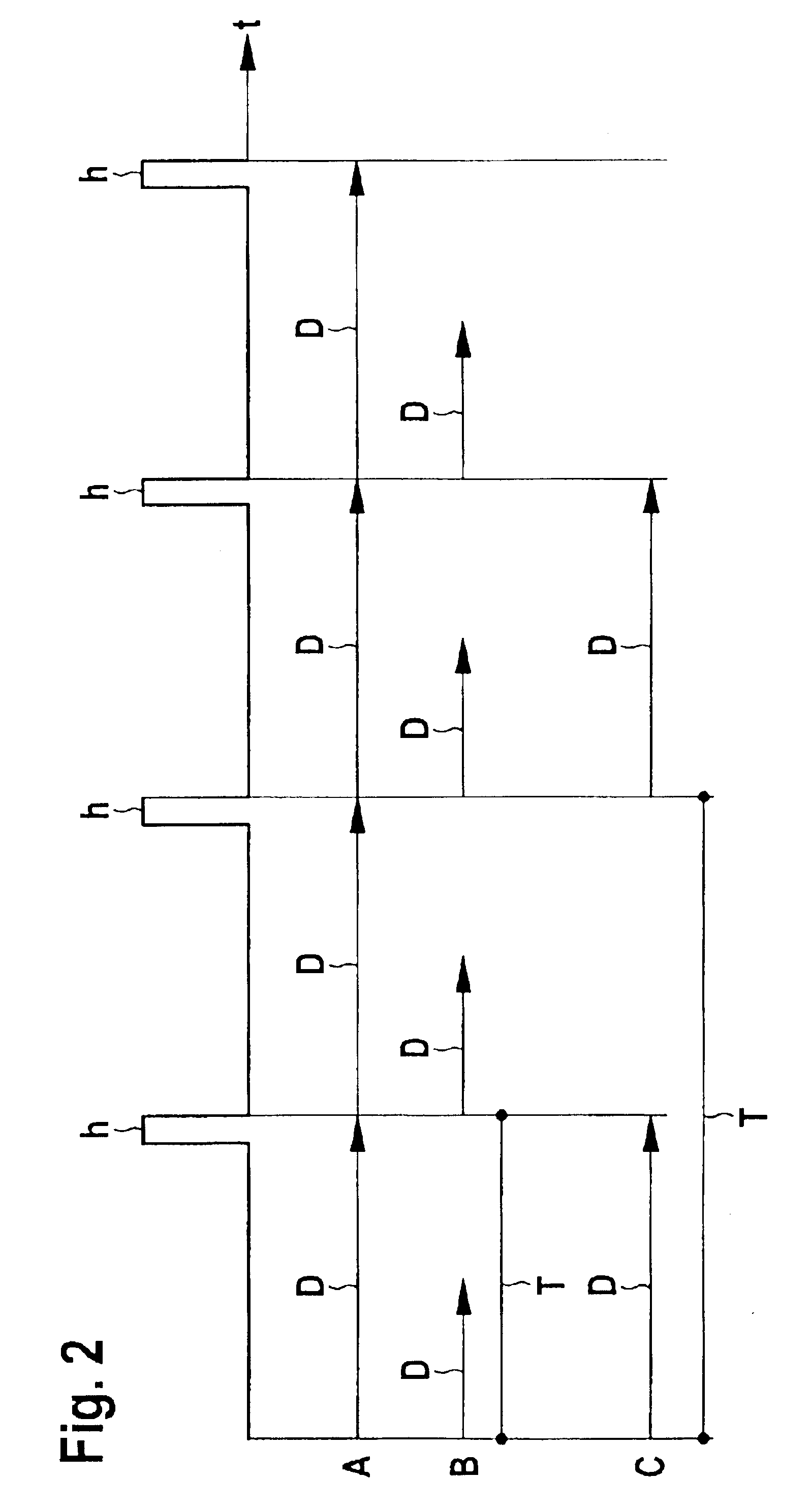

Fuel injection system for an internal combustion engine

InactiveUS6976473B2Improve volumetric efficiencyImprove efficiencyElectrical controlLow pressure fuel injectionFuel tankEngineering

The fuel injection system has a high-pressure pump, by which fuel is pumped into a reservoir, with which injectors disposed on cylinders of the engine communicate. A feed pump pumps fuel out of a fuel tank to the high-pressure pump and a fuel metering device triggered by a control unit and disposed between the feed pump and the high-pressure pump controls the fuel quantity delivered to the high-pressure pump. The fuel metering device is formed by a clocking valve, which is opened and closed in pulse-width-modulated fashion by the control unit, and the fuel quantity delivered to the intake side of the high-pressure pump is proportional to the opening duration of the clocking valve.

Owner:ROBERT BOSCH GMBH

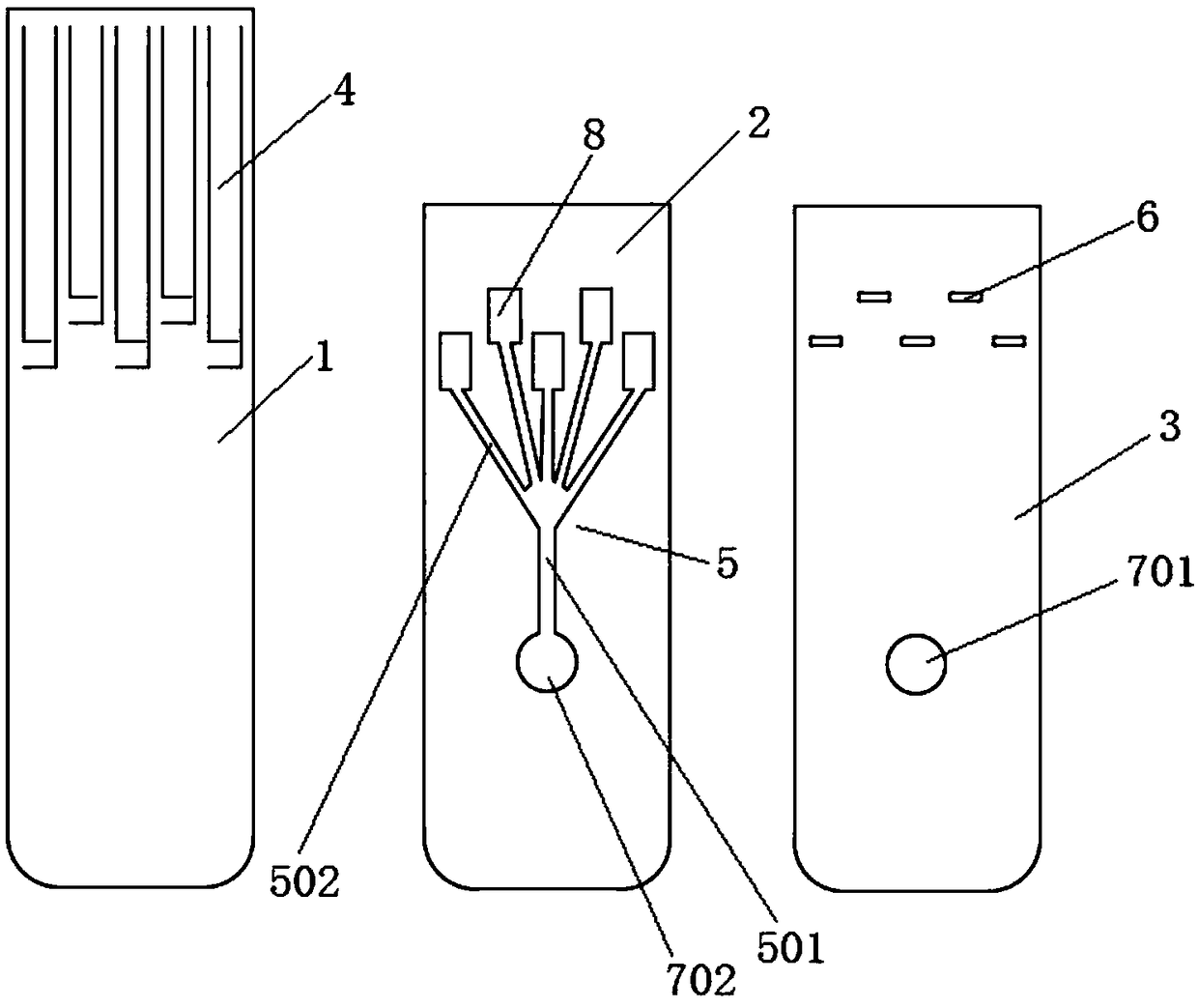

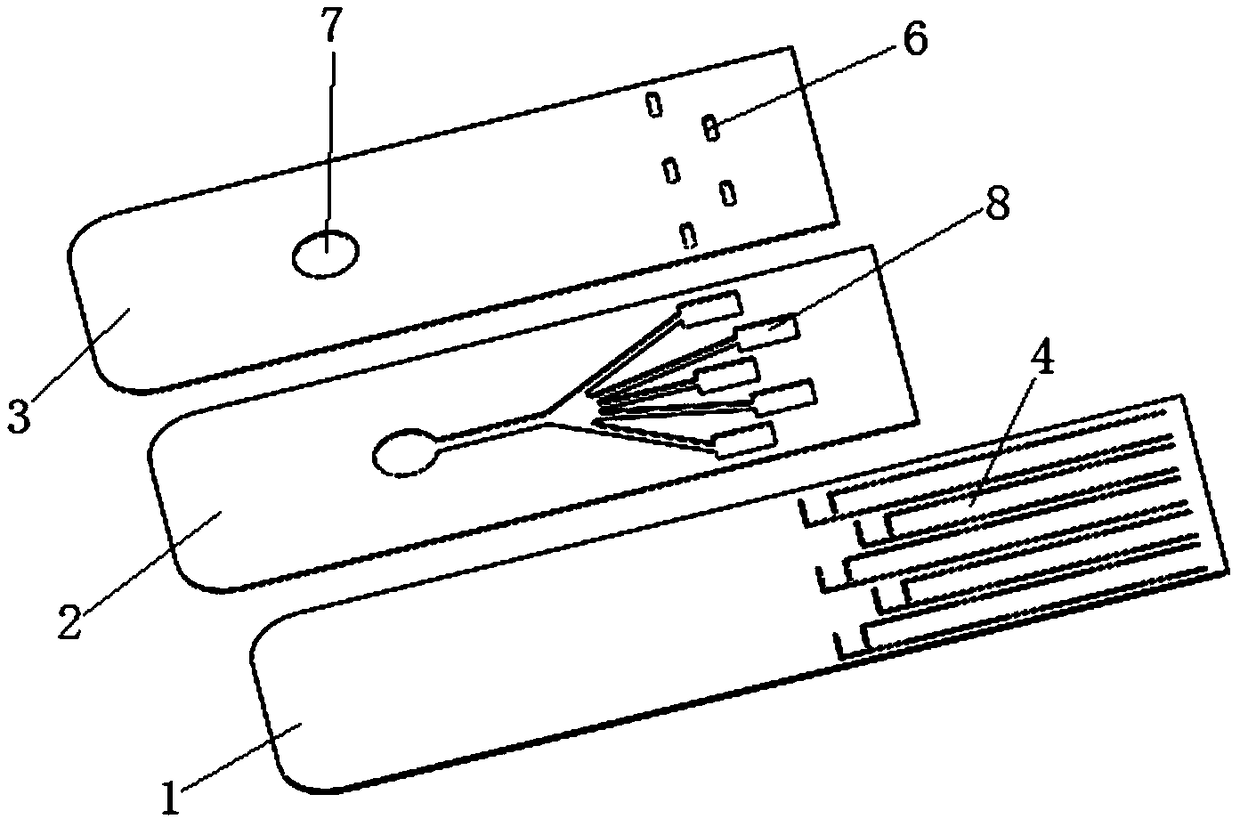

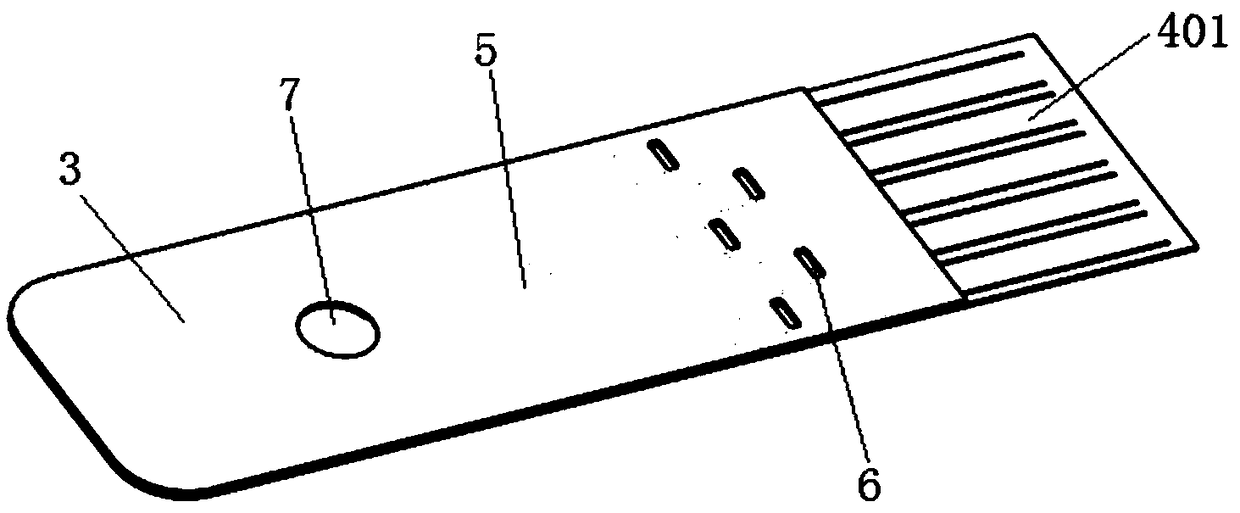

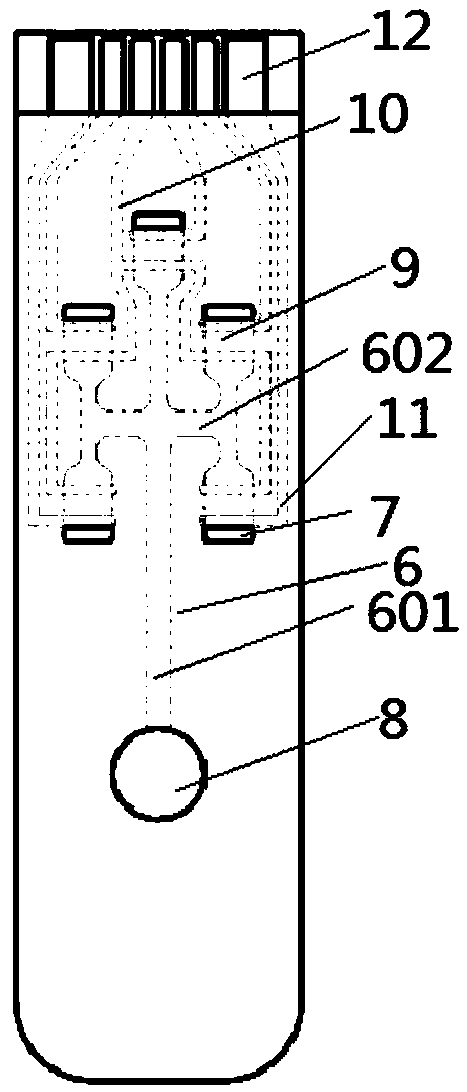

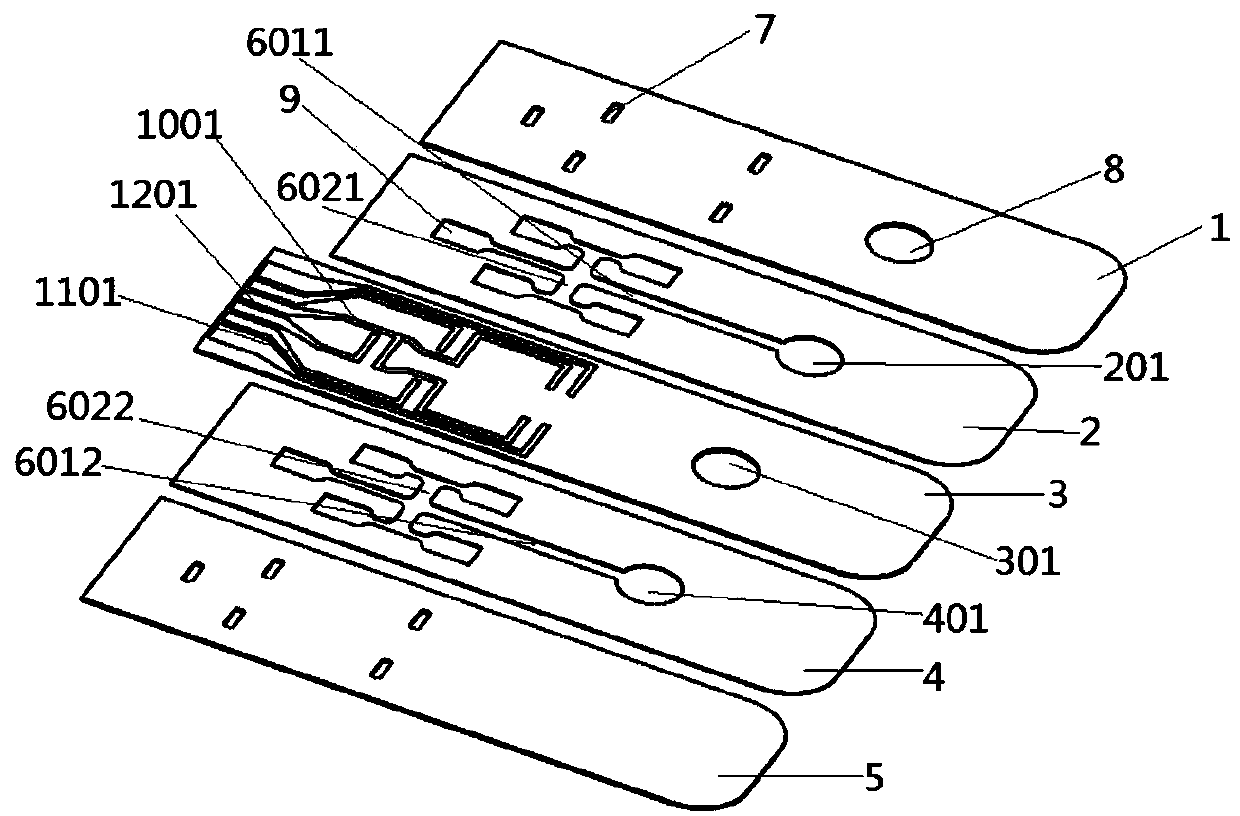

Multi-channel quick detection micro-fluid detecting chip

PendingCN108745429ASimple structureEasy to operateLaboratory glasswaresMicrofluidic channelReaction chamber

The invention discloses a multi-channel quick detection micro-fluid detecting chip. The multi-channel quick detection micro-fluid detecting chip comprises a chip body, wherein a chip sampling hole, aplurality of detecting rooms which are independent from one another and micro runners are arranged on the chip body; the chip sampling hole is communicated with the detecting rooms through the micro runners; the chip body further comprises an electrode; the detecting rooms are connected with the electrode; each micro runner comprises a main-flow channel and a plurality of branch micro-fluid channels, the tail end of the main-flow channel is divided into the branch micro-fluid channels, and the branch micro-fluid channels are in one-to-one correspondence and communication with the detecting rooms which are independent from one another; and the other end of the main-flow channel is communicated with the chip sampling hole. According to the multi-channel quick detection micro-fluid detectingchip disclosed by the invention, the main-flow channel and the branch micro-fluid channels are arranged for guiding flow of a blood sample, so that samples can be injected into the reaction chambers at the same time from one sample chamber, and the samples are not contained, and therefore, sample injection is easy, the samples can be detected at the same time, and the multi-channel effect is achieved; and the chip is simple in structure, is convenient to operate, improves detecting efficiency, reduces consumption of resources, and reduces cost.

Owner:NANJING LANSION BIOTECH CO LTD

Multi-channel microfluidic coagulation detection chip with five-layer structure

PendingCN109682878ASimple structureCompact structureMaterial analysis by electric/magnetic meansLaboratory glasswaresCoagulation indexMicrofluidic channel

Owner:NANJING LANSION BIOTECH CO LTD

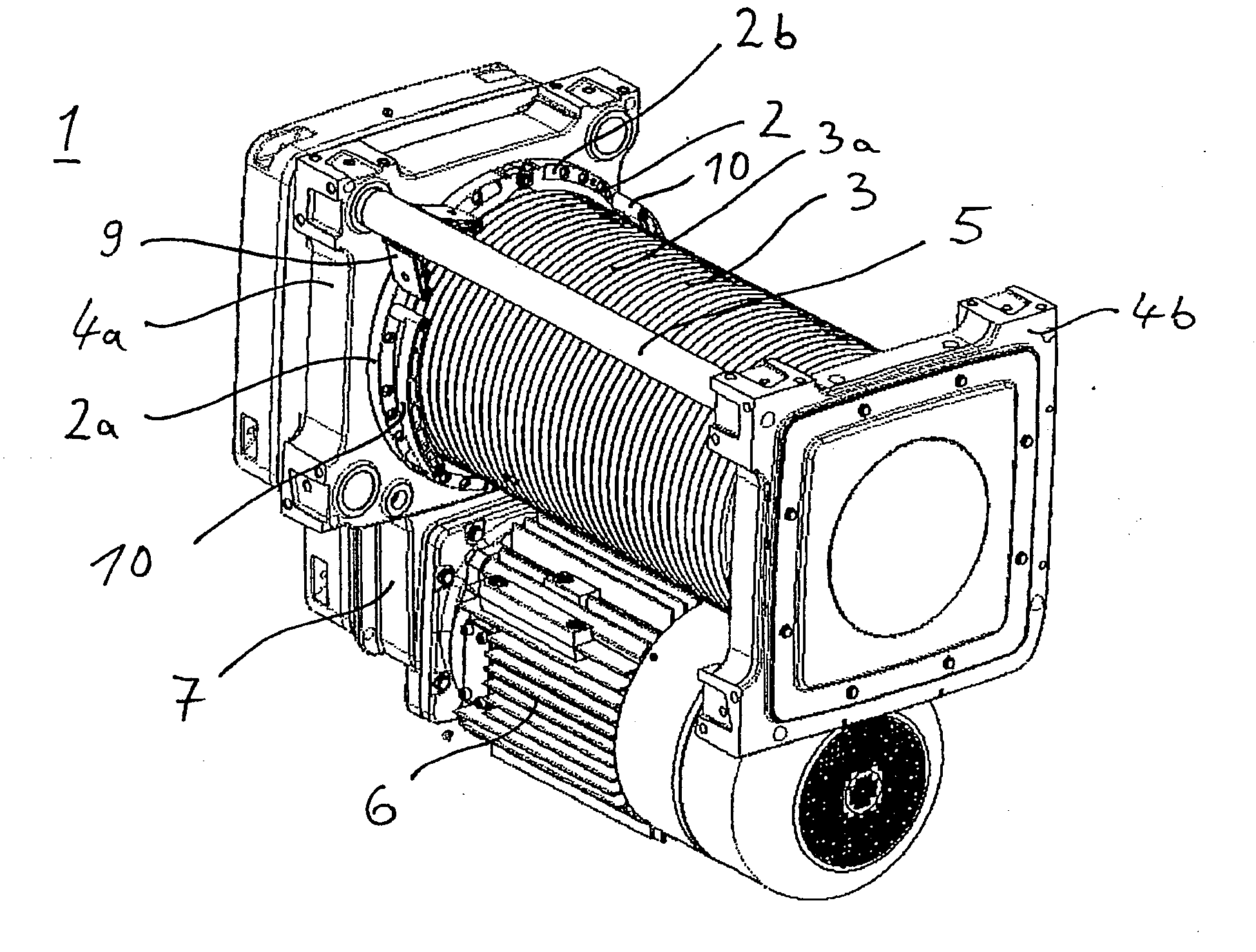

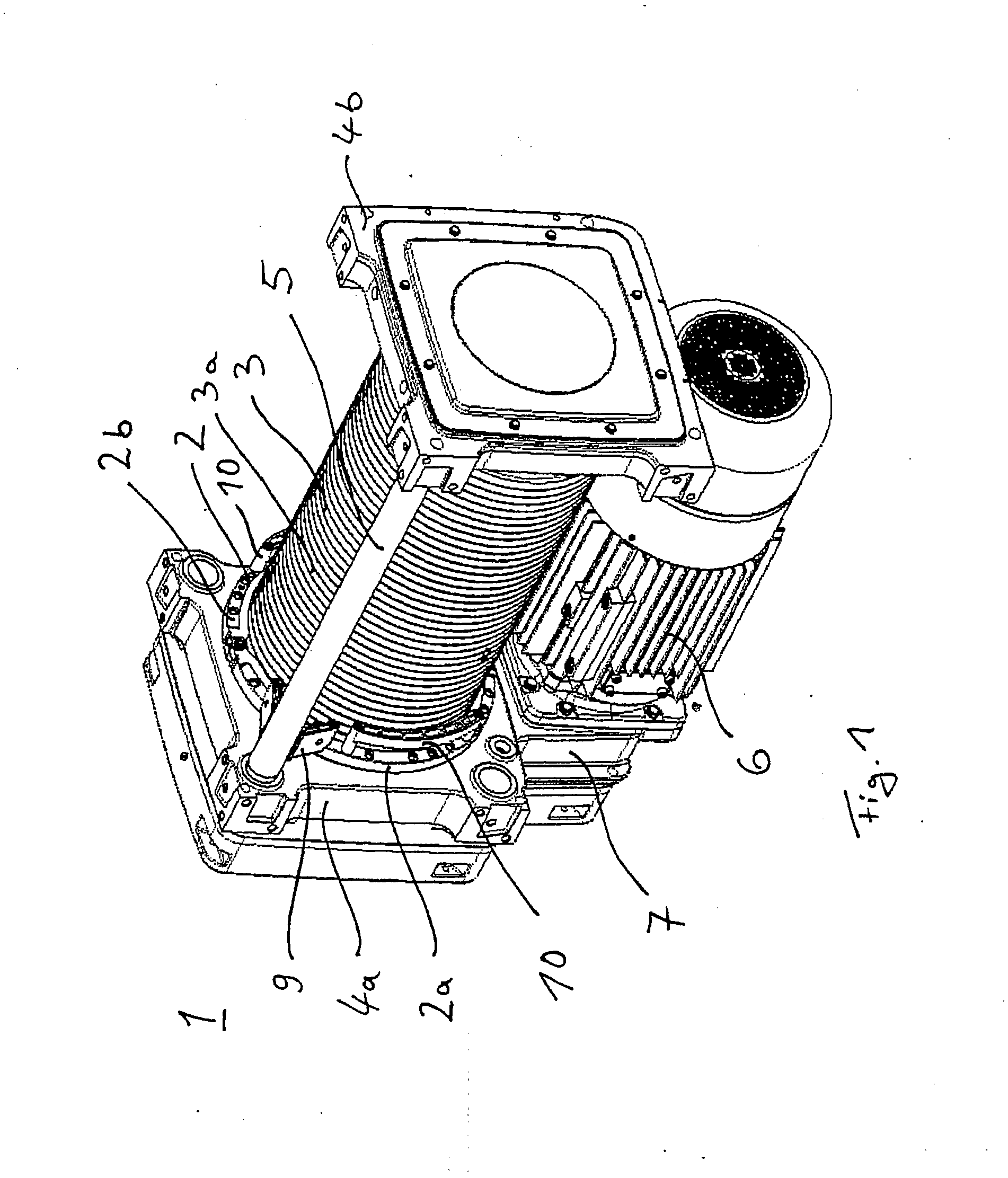

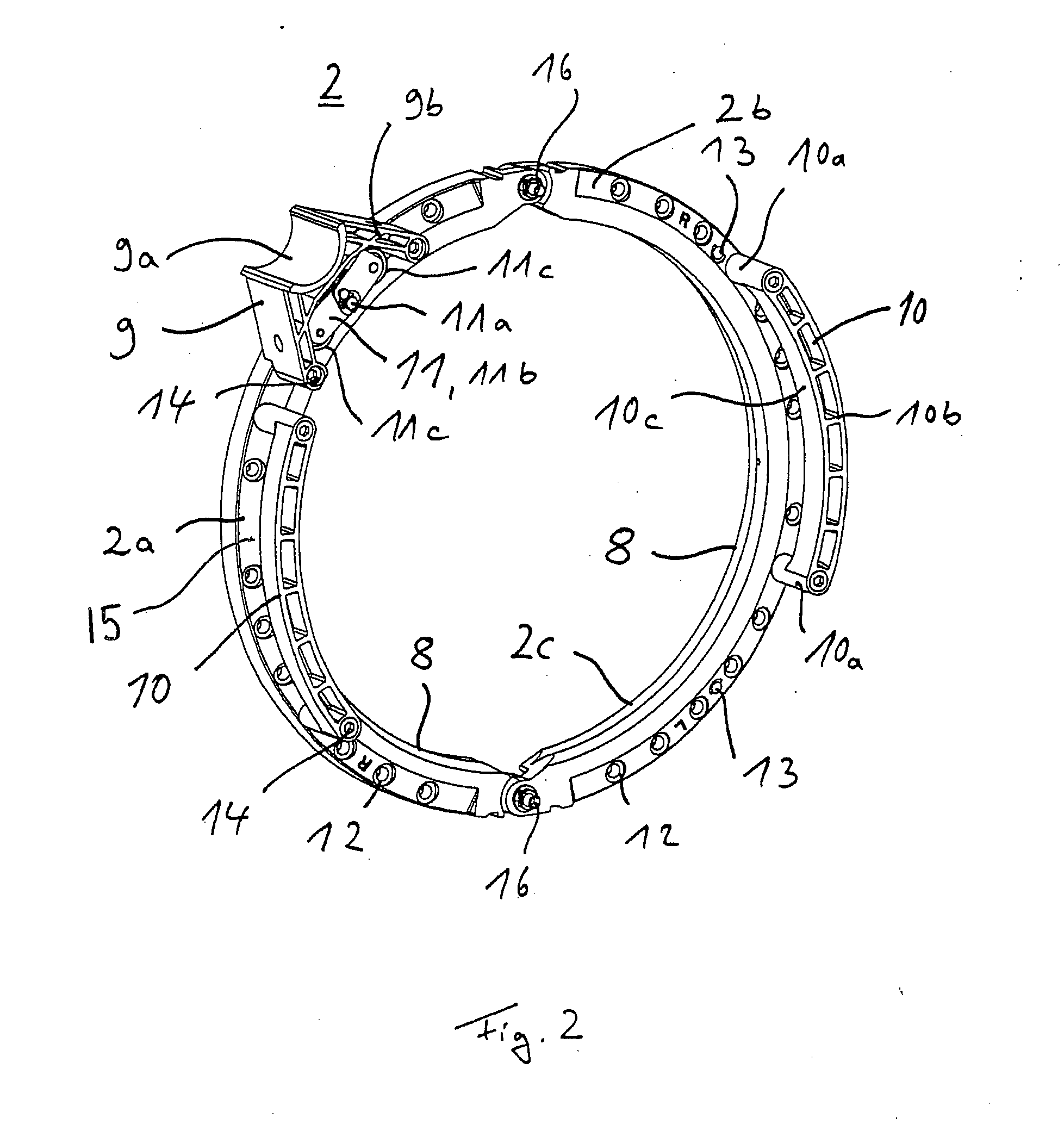

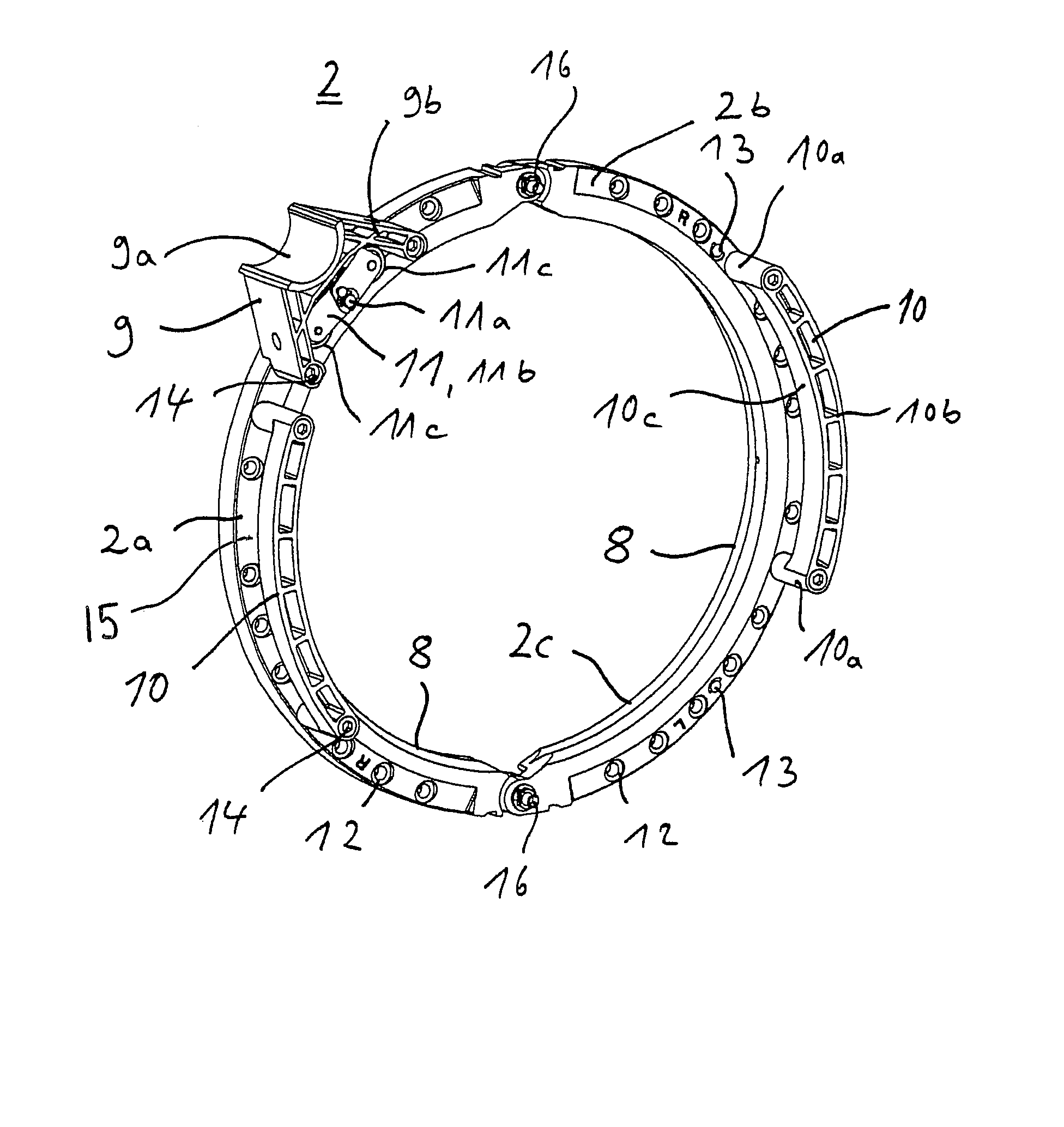

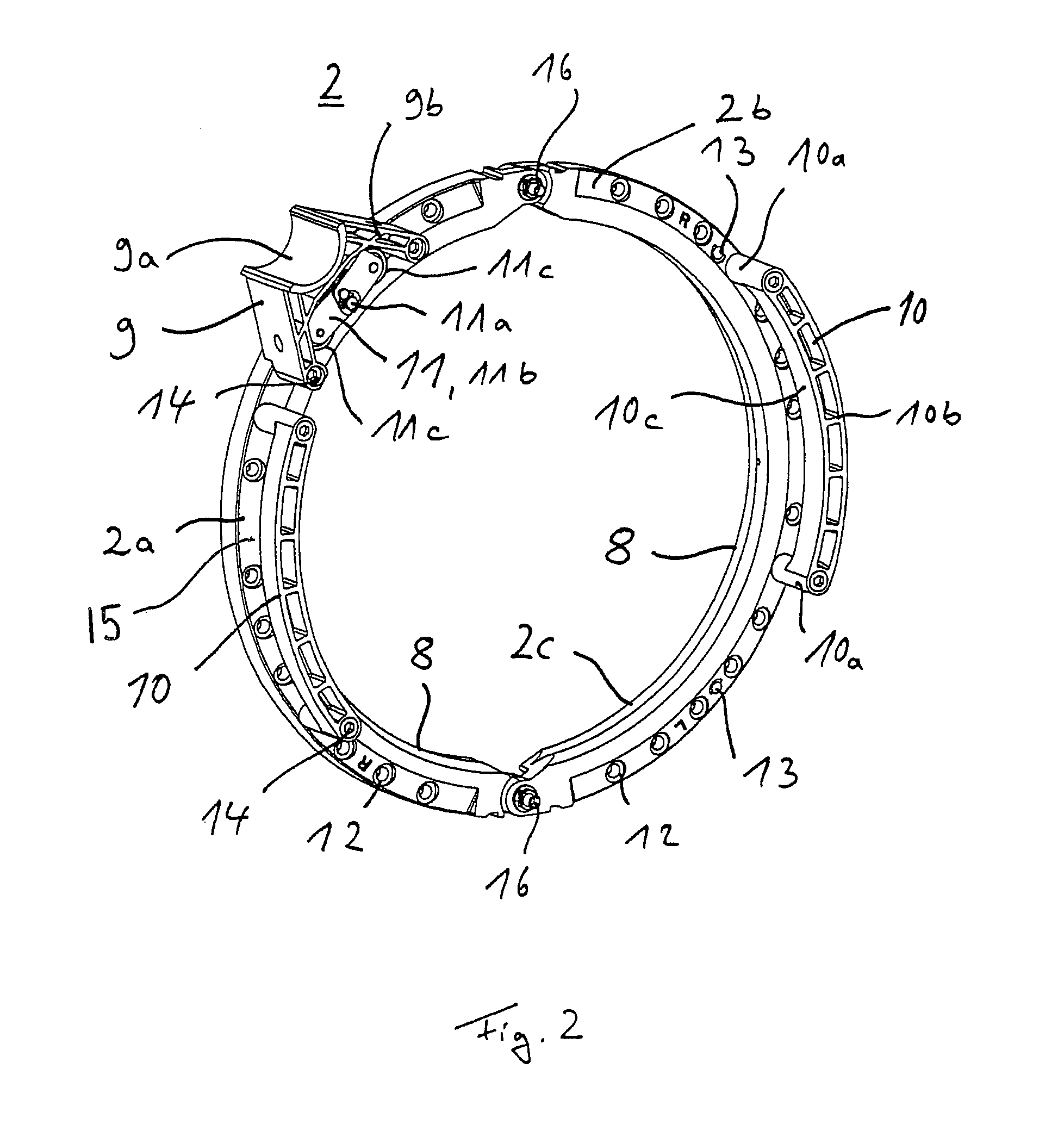

Cable guide of a cable winch

ActiveUS20070075174A1Easy to adaptSimple configurationFilament handlingWinding mechanismsModular designWinch

A cable guide of a cable winch, such as a cable hoisting winch, includes a cable drum having at least one cable groove and a cable guide having at least two base segments expanding into a ring. The two base segments are guided in the cable groove by at least one engaging element and are supported against the cable winch by at least one torque support. Elements for guiding and holding down a cable are arranged on the base segments. To create a simplified and optionally modular design of a cable guide, the base segments may be configured such that at least one torque support and at least one add-on element for guiding and holding down a cable can be secured in a desired arrangement on the base segments.

Owner:KONECRANES GLOBAL

Method for producing a fastening arrangement of a fixing dome on a thin-walled component

InactiveUS20080251196A1High cost-effectivenessMinimize dangerLamination ancillary operationsLaminationThin walledAdhesive

A method is described for producing a fastening arrangement of a column-shaped fixing dome of synthetic material on a thin-walled component of synthetic material, for example, a housing. The fixing dome and the thin-walled component are produced separately from each other. Here, a fastening element is integrated in the fixing dome, and an end of the fixing dome is formed as a joining section. In addition, on the inner side of the component, a joining section is built that is matched to the joining section of the fixing dome, in order to build a join connection with said join section for positioning the fixing dome on the component. The join section of the component and / or the join section of the fixing dome are now wetted with an non-curing adhesive. Subsequently, the component and the fixing dome are joined for producing the join connection and through light curing of the adhesive are fixedly connected together.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

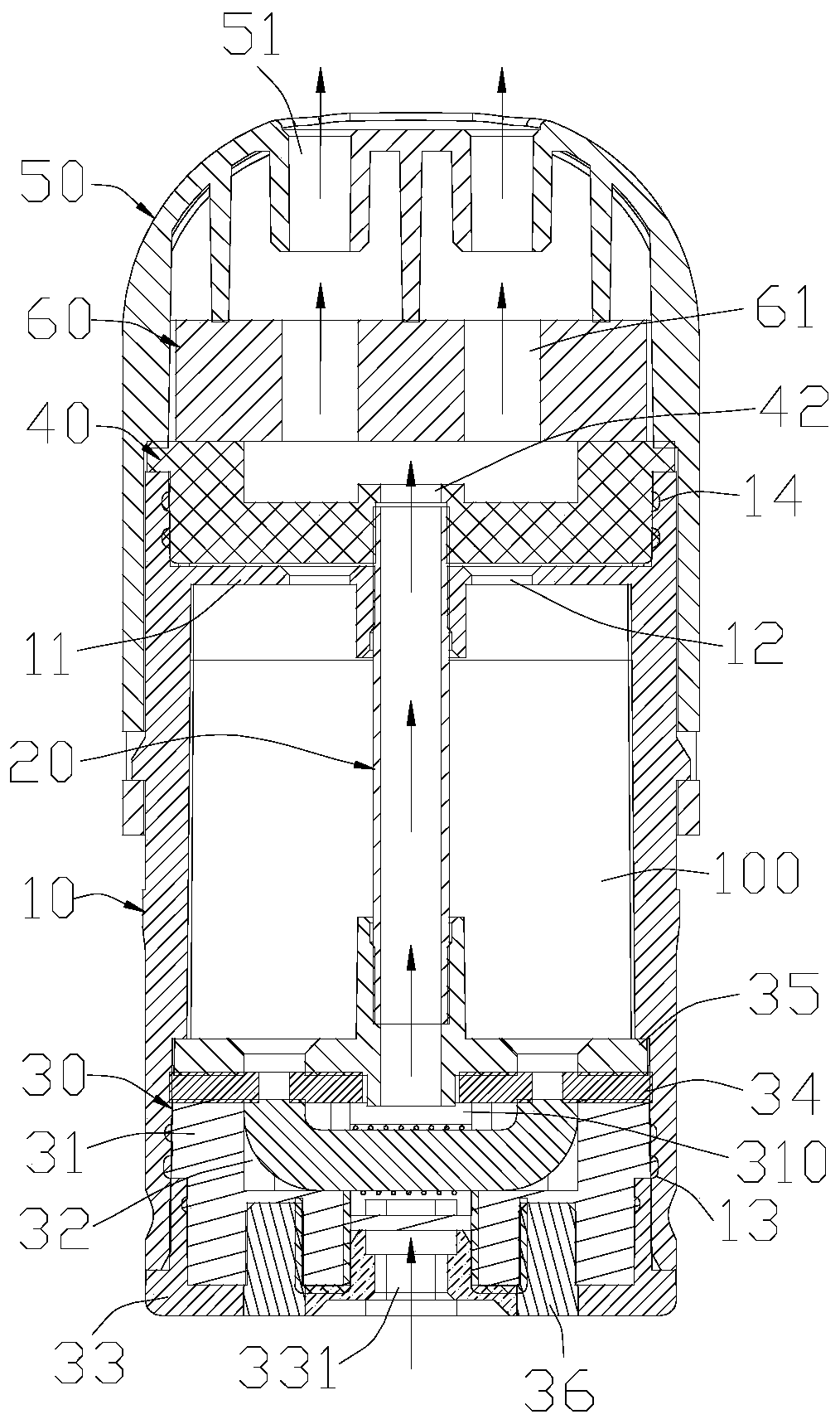

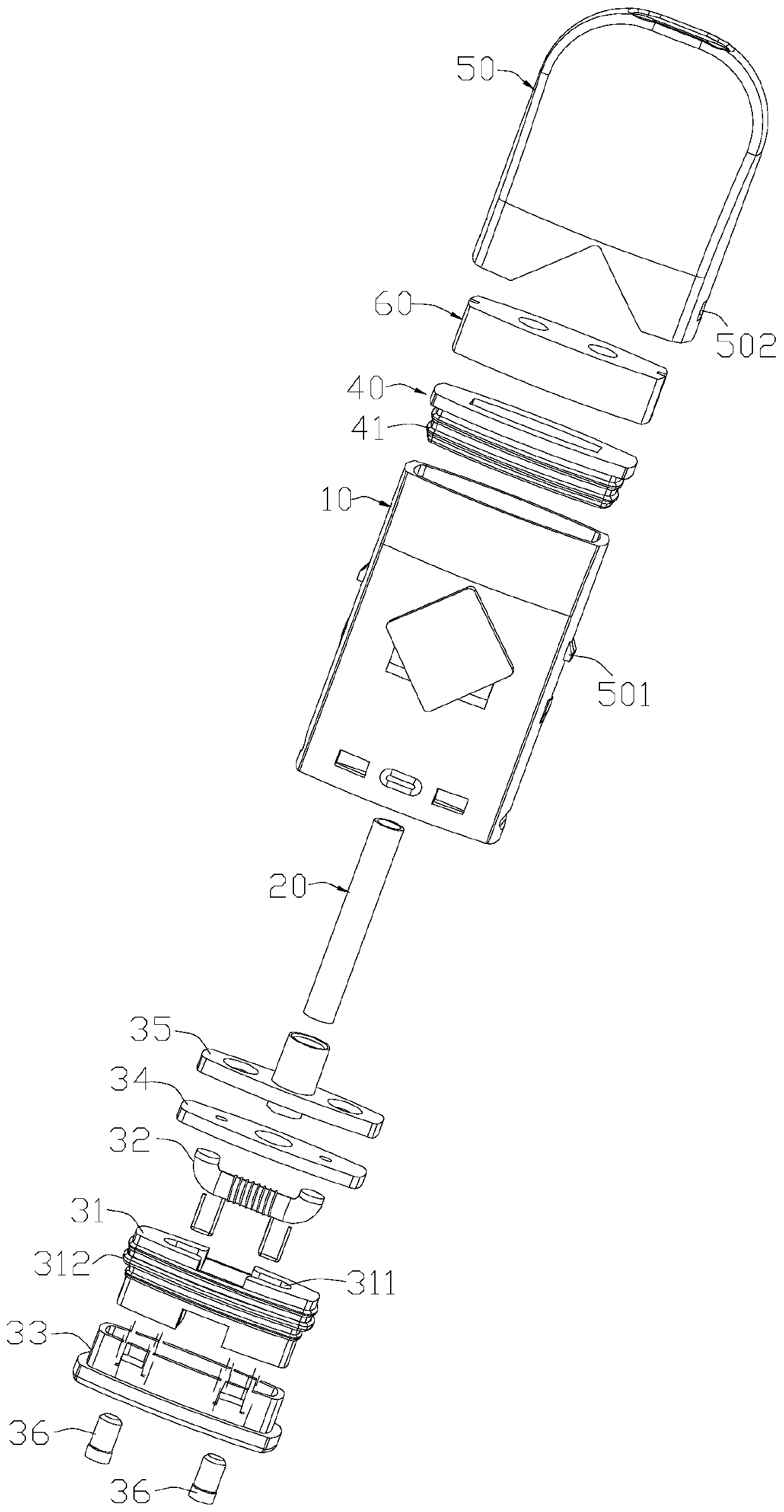

Electronic cigarette atomizer and liquid injection method thereof

The invention discloses an electronic cigarette atomizer and a liquid injection method thereof. The electronic cigarette atomizer comprises a shell, an air guide pipe, an atomization assembly and an elastic plug. The first end of the shell is open, and an end plate is arranged in the opposite second end. The atomization assembly is arranged at the first end of the shell in a matched mode. One end of the gas guide pipe is inserted into the atomization assembly, and the other end of the gas guide pipe penetrates out of the end plate. A liquid storage bin surrounding the periphery of the gas guide pipe is formed between the gas guide pipe and the inner wall of the shell. A liquid injection hole communicated with the liquid storage bin is formed in the end plate. The elastic plug is arranged on the end plate in a matched mode to cover and seal the liquid injection hole. According to the electronic cigarette atomizer, the liquid storage bin is closed. When liquid is injected, the elastic plug is punctured by the liquid injection needle to enter the liquid storage bin. The operation of opening the bottom connecting base or the positioning pin of the atomizer in the prior art is not needed. The situations of liquid leakage and the like are avoided. After liquid is injected, the elastic plug can recover to close the punctured hole. The other hole sealing operation is not needed, and liquid leakage in the assembling and transporting processes can be effectively prevented.

Owner:O NET AUTOMATION TECH SHENZHEN

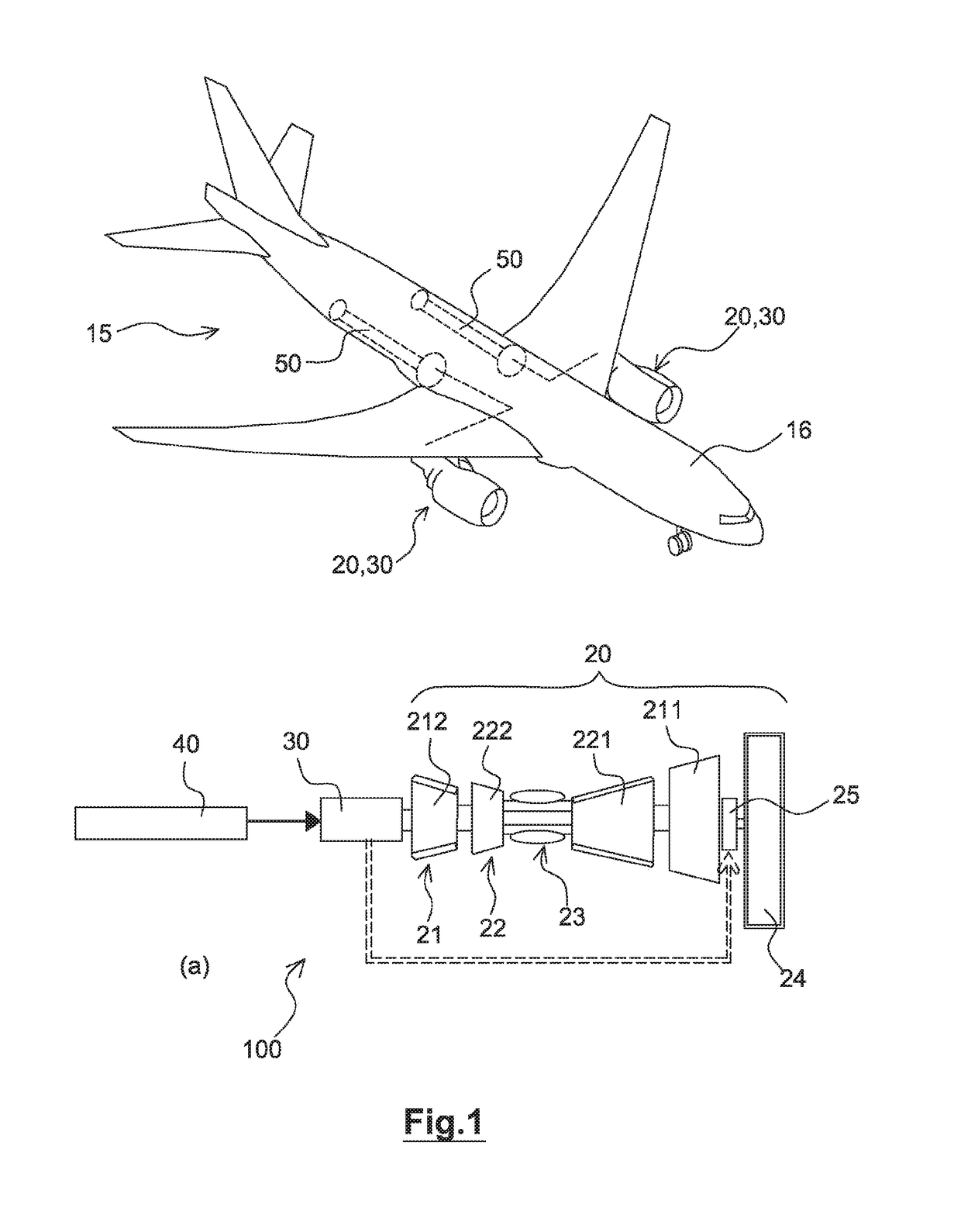

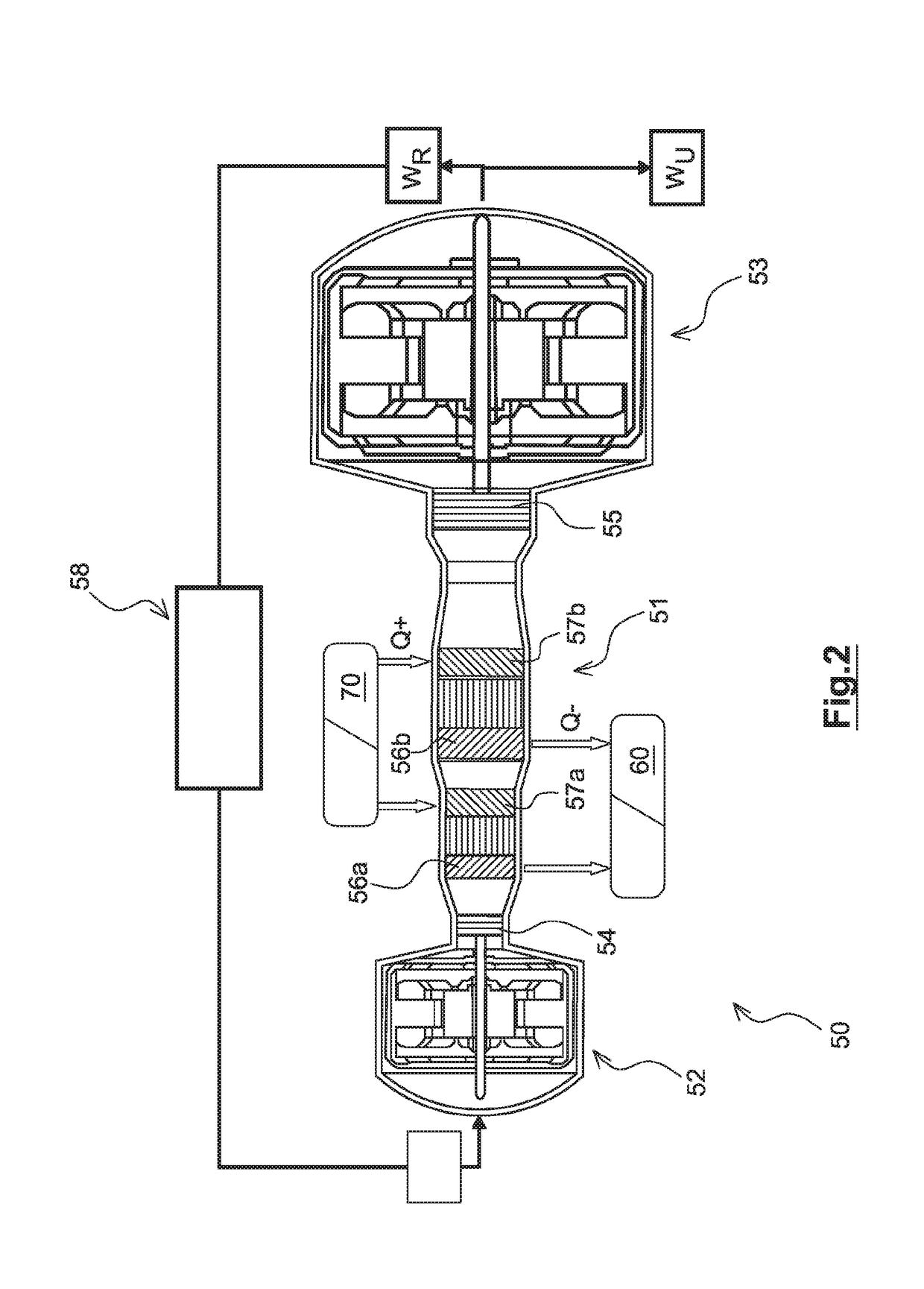

Hybrid power or thrust generator and vehicle including such a generator

InactiveUS20180363564A1Easily variableIncrease productionPower installationsEfficient propulsion technologiesElectricityAlternator

A hybrid power or thrust generator including at least one thermodynamic turbine engine and at least one electric power generator. An electric power generator is electrically connected to at least one electric motor, mechanically and rotatably coupled to one or more rotating portions of the thermodynamic turbine engine, and the electric power generator operates simultaneously with the thermodynamic engine so as to supply the electric motor(s) to reduce the power drawn from the turbines of the thermodynamic turbine engine in operation. The electric power generator may comprise a thermoacoustic engine driving a linear electric alternator. The generator is advantageously implemented in a vehicle, such as an aircraft.

Owner:AIRBUS SAS

Polypropylene composite material with low emission and excellent weather resistance and preparation method thereof

ActiveCN105199238AReduce degradationOvercome the disadvantage of adsorption equilibriumPolypropylene compositesPolymer science

The invention discloses a polypropylene composite material with low emission and excellent weather resistance and a preparation method thereof. The polypropylene composite material is prepared from 40%-90% of polypropylene, 5%-15% of flexibilizer, 18%-40% of mineral fillers, 7%-13% of water, 0.1%-3% of antioxidants, 0.02%-2% of light stabilizers and 0-3% of colorants. The method comprises the steps that the polypropylene, the flexibilizer, the mineral fillers, the antioxidants, the light stabilizers and the colorants are mixed, then the mixture is added to a double-screw extruder for melt blending, the vacuum degree of a sixth heating working area and a seventh heating working area is controlled to be over minus 0.05 MPa, the water is fed into the seventh heating working area of the double-screw extruder, vacuum extrusion granulation is conducted through the double-screw extruder, and the polypropylene composite material is obtained. According to the polypropylene composite material with the low emission and the excellent weather resistance and the preparation method thereof, the production technology is simple, the cost is low, the obtained polypropylene composite material can meet the requirements of automobile set machine factories at home and abroad, and a wide application prospect is achieved.

Owner:CGN JUNER NEW MATERIALS +1

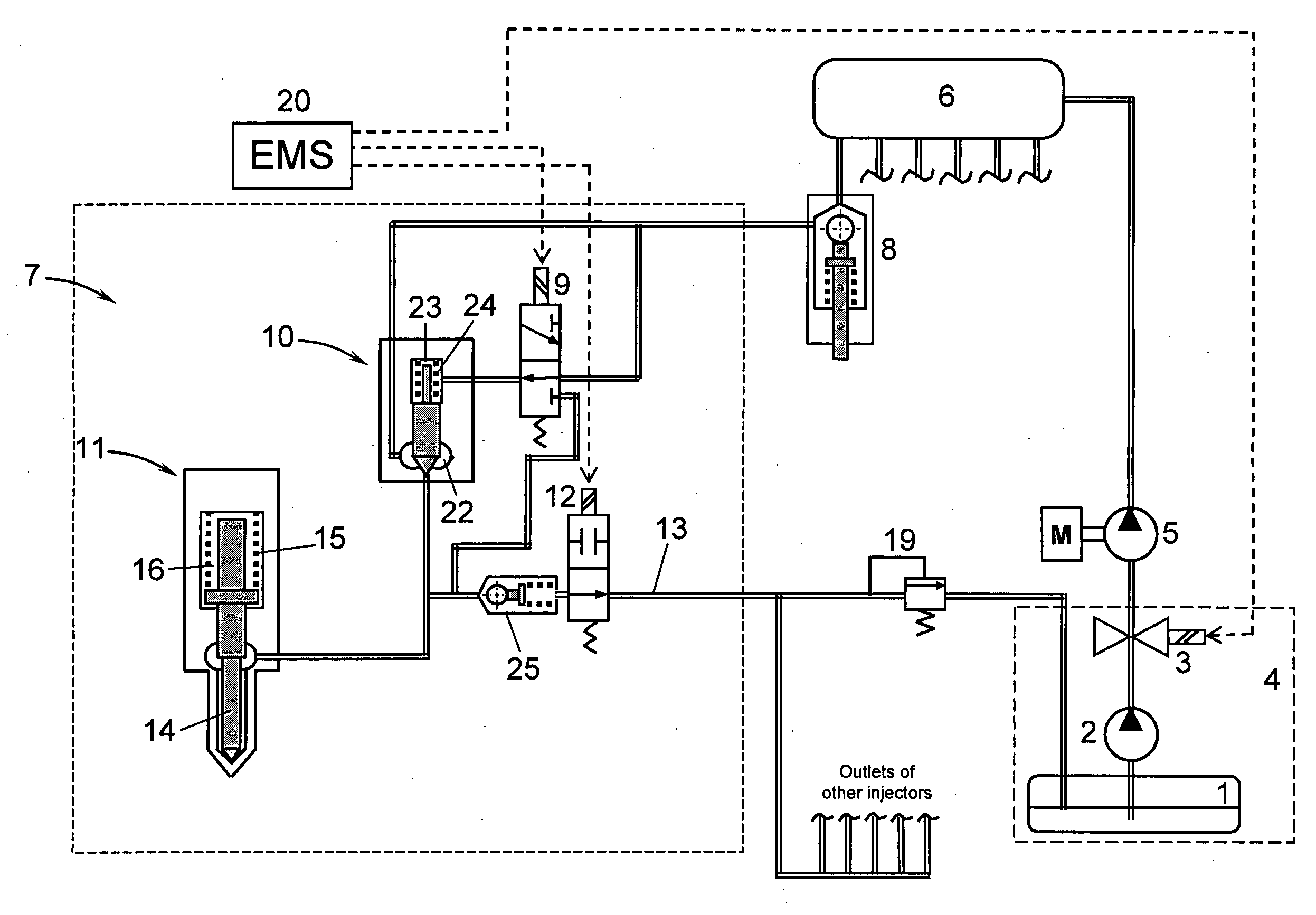

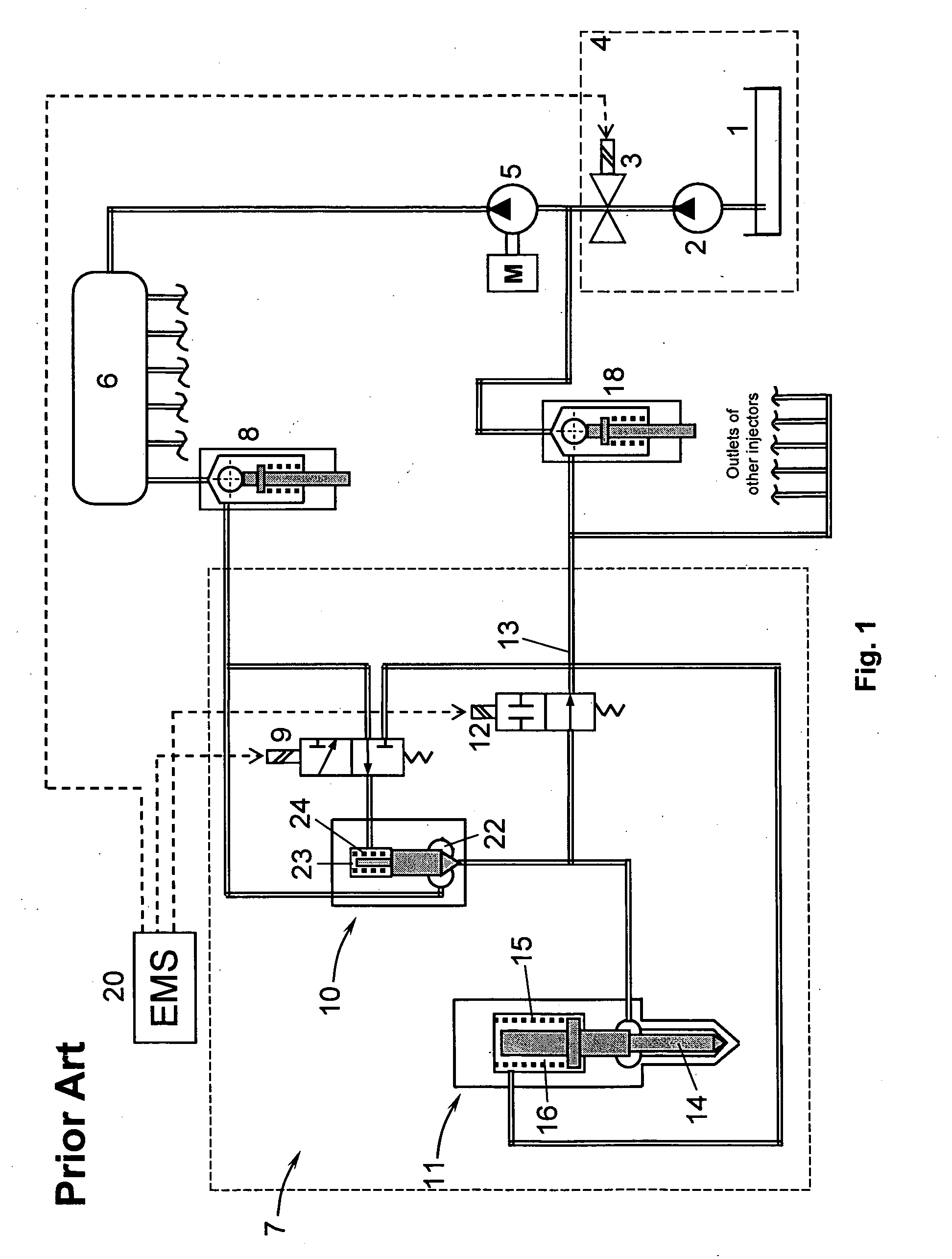

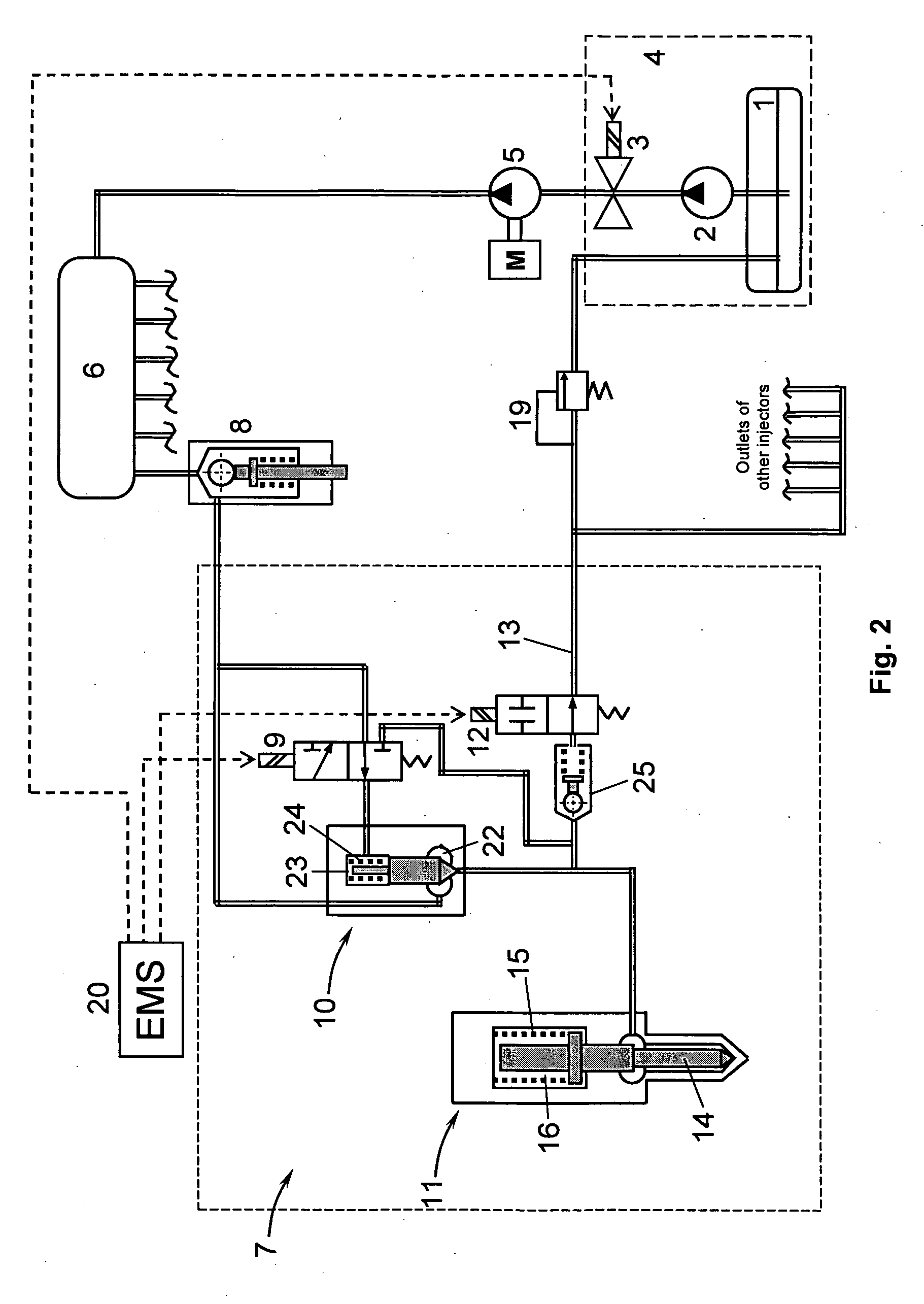

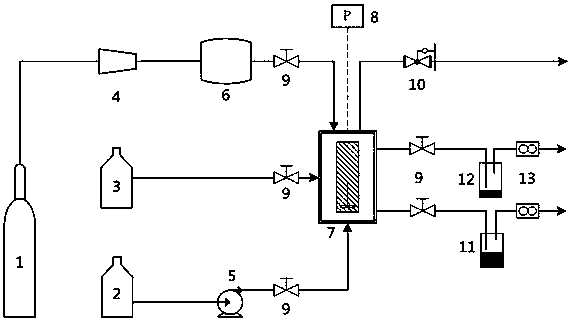

Fuel injection system

InactiveUS20110005494A1Prevent leakageIncreased control leakageInternal combustion piston enginesFuel supply apparatusAutomatic balancing valvesIsolation valve

A fuel injection system for an internal combustion engine includes an engine management system (EMS), a return line connected to a low-pressure fuel system, a common rail for storing and supplying a relatively high-pressure fuel to an injector, and an automatic isolating valve installed between the common rail and the injector. The injector has a nozzle for injecting fuel into the engine. A valve is operated by the EMS and installed between the common rail and the nozzle. A spill valve is operated by the EMS and connected by its inlet to the outlet of the valve and by its outlet to the return line. A check valve is installed between the nozzle and the return line, the inlet of the check valve being connected to the inlet of the nozzle.

Owner:VOLVO LASTVAGNAR AB

Cable guide of a cable winch

ActiveUS7374126B2Easy to adaptSimple configurationFilament handlingWinding mechanismsModular designWinch

Owner:KONECRANES GLOBAL

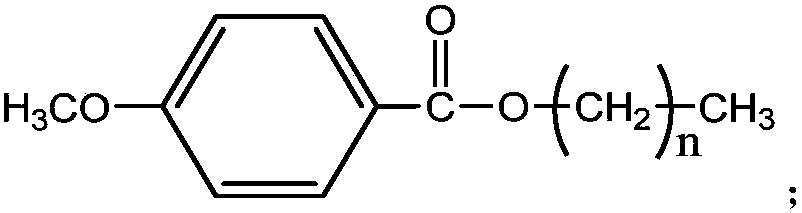

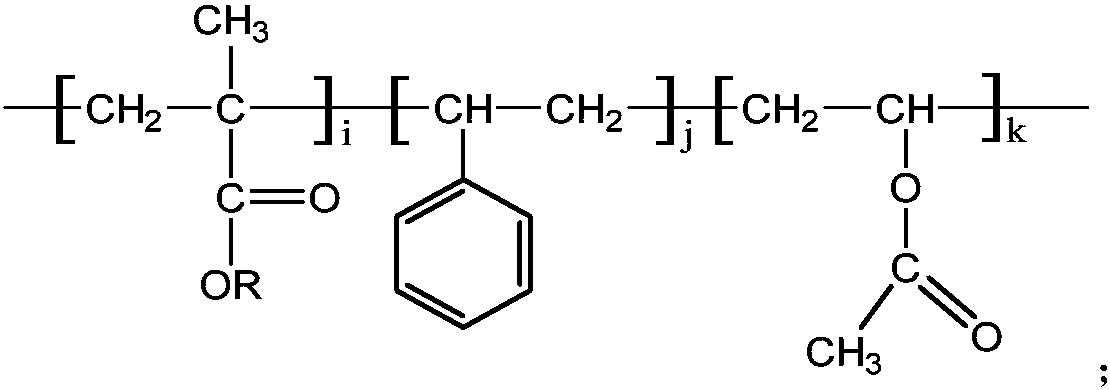

Chemical additive for improving recovery ratio of high-deep thickened oil CO2 gas flooding process

ActiveCN107828402ALow viscosityImprove liquidityDrilling compositionCarvacryl acetateMethyl benzoate

The invention discloses a chemical additive for improving the recovery ratio of a high-deep thickened oil CO2 gas flooding process. The chemical additive consists of a solubilizer and a viscosity reducer, and the weight ratio of the solubilizer to the viscosity reducer is (1-6):1, wherein wherein the solubilizer is a p-methyl benzoate compound and the viscosity reducer is a long-chain methacrylate-styrene-vinyl acetate copolymer. The chemical additive disclosed by the invention not only can enhance the capacity of CO2 of dissolving in thickened oil, reduce the minimum mixed-phase pressure between the thickened oil and the CO2, and form CO2 mixed-phase displacement, but also can greatly reduce the viscosity of the thickened oil, and improve the flowing property of the thickened oil, so thatthe recovery ratio of the thickened oil can be improved. The chemical additive has the advantages of high efficiency, high economical efficiency, low energy consumption and the like, and is especially suitable for high-deep low-permeability reservoirs with high formation pressure, high crude oil viscosity and low permeability, and has a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

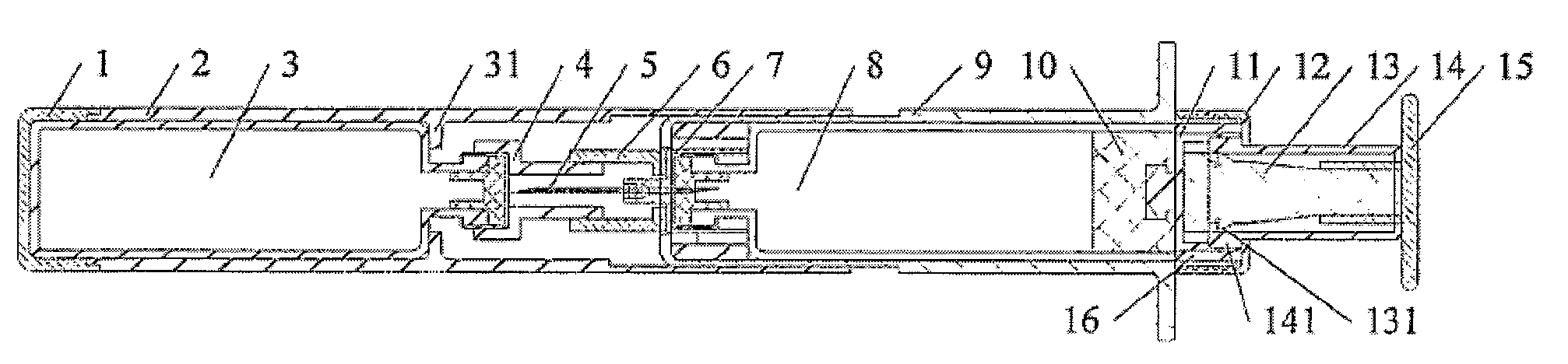

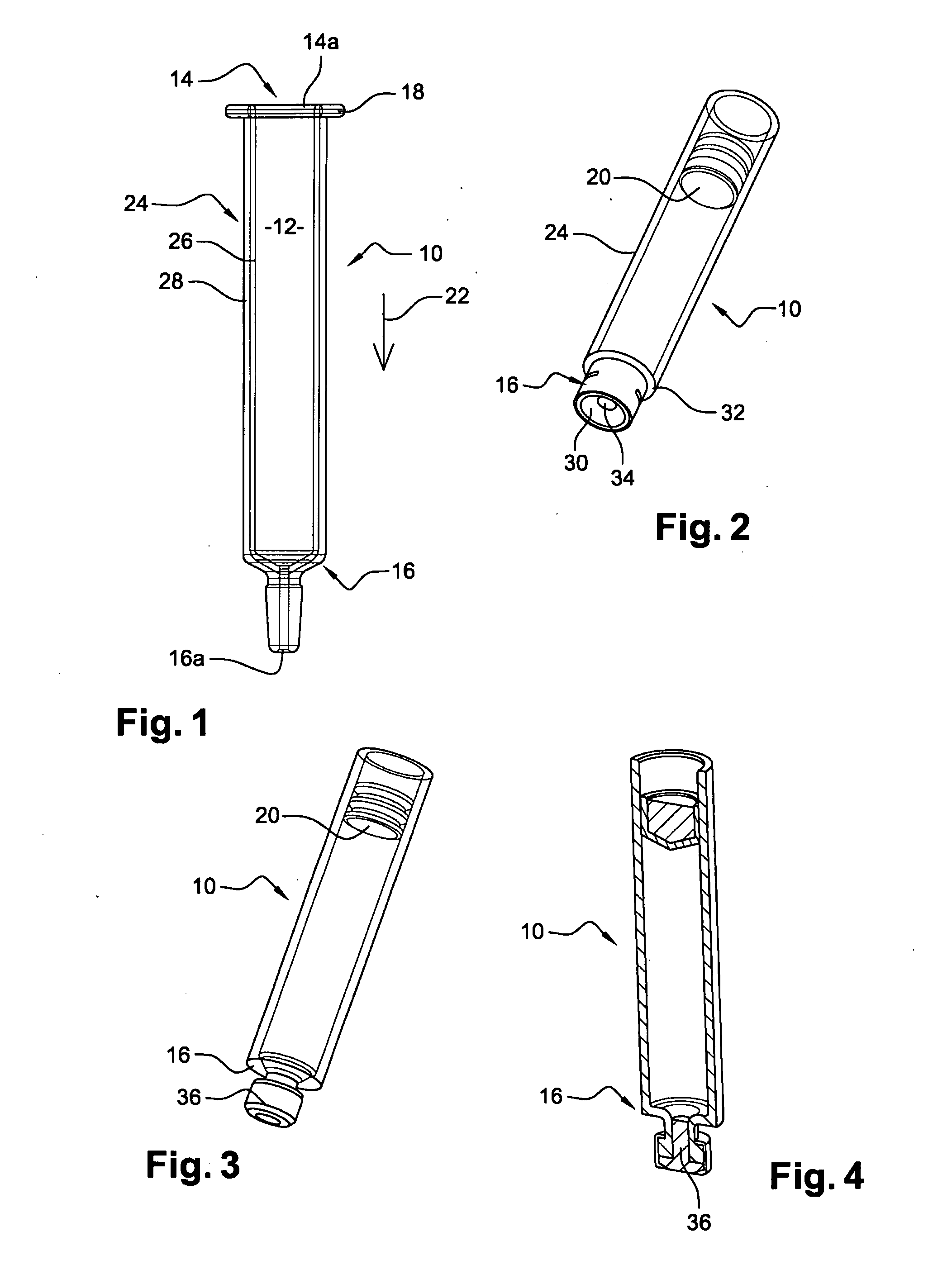

Disposable press-type first-aid injector for pre-filled medicine liquid

InactiveCN105617488AReduce sizeEase of self-injectionInfusion syringesInfusion needlesCross infectionBlood vessel

The invention relates to a disposable press-type first-aid injector for pre-filled medicine liquid.The injector is composed of an outer sleeve, a middle sleeve, a double-head needle, an inner push plug, a push rod and a compressible medicine storing bag; the double-head needle is fixed at the front end of the middle sleeve, the front end of the outer sleeve and the front end of the compressible medicine storing bag fixed at the front end of the inner push plug are each provided with a small hole covered with flexible glue, the small holes can be punctured by the double-head needle from the inside and the outside respectively, and first-aid medicine liquid is stored in the medicine storing bag in advance.The injector has the advantages that a needle body is moderate in size and suitable for being held and pressed, the injecting action is simple and can be completed only through a single hand, and therefore a wounded person can be conveniently and independently injected with the medicine liquid; the individually-packaged pre-filled medicine liquid is stored in the injector, the medicine liquid does not need to be extracted again in the operation process, and therefore pollution can be avoided; the length of the portion, piercing into a body, of the needle tip of the injector is fixed and small, the organs and tissue such as the nervus vascularis are not prone to damage, and the disposability is achieved, so that cross infection is avoided; the structure is simple, the manufacturing cost is low, no complex mechanical device exists, and mechanical failures can be prevented from occurring in the operation process.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Device for controlling and/or regulating the fuel quantity supplied to an internal combustion engine

InactiveUS7096855B2Overcome the influence of errorEasy to controlElectrical controlEngine testingInternal combustion engineActuator

In a device for controlling the fuel quantity supplied to an internal combustion engine via a fuel supply line and an injection nozzle which includes a nozzle needle and an actuator for controlling the position of the nozzle needle, wherein a sensor for the detection of injection parameters is provided which supplies injection parameter data to a control unit for determining, on the basis of the sensor data, control parameters for the actuator of the injection nozzle, the sensor is a mass flow sensor arranged in the fuel supply line.

Owner:DAIMLER AG

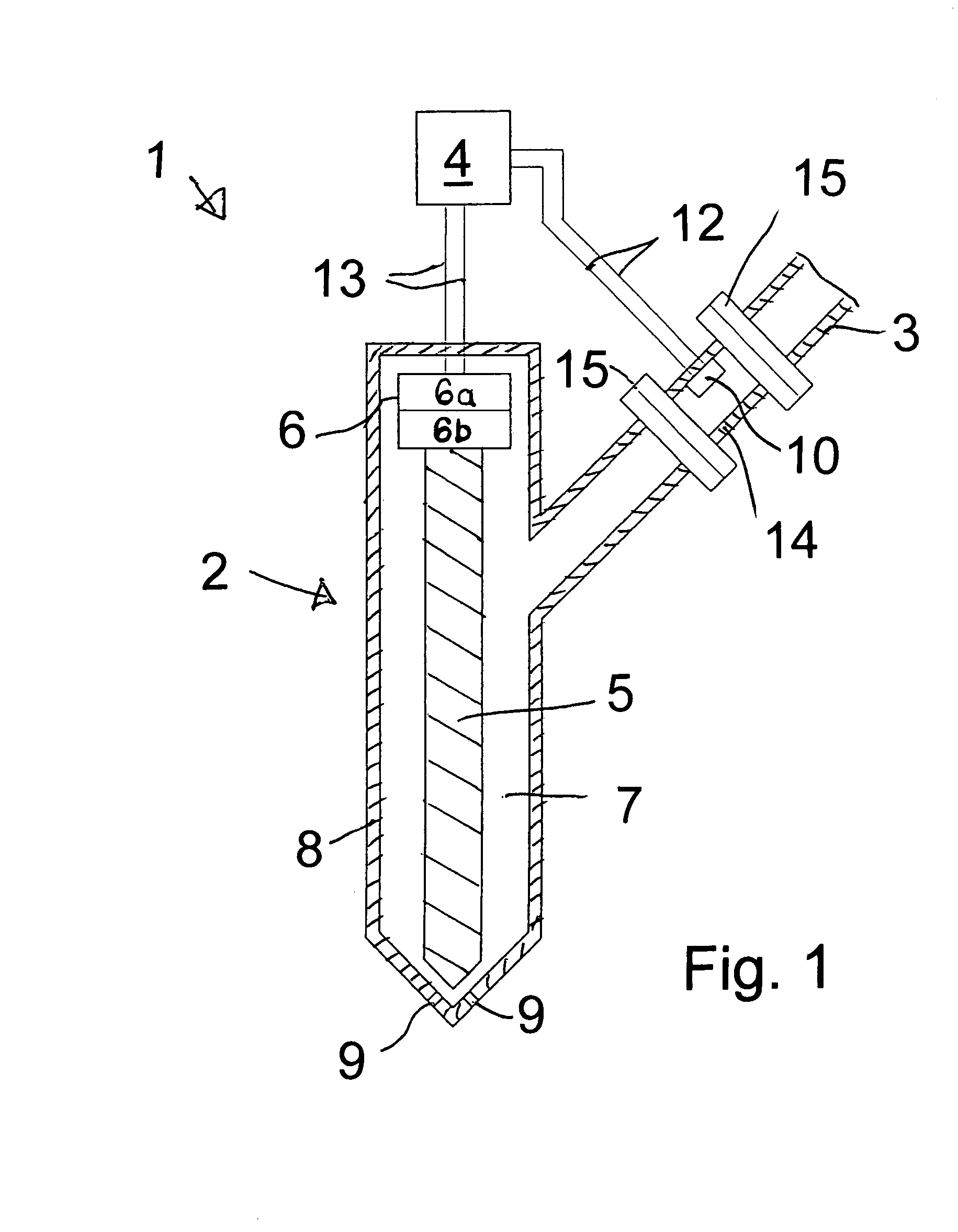

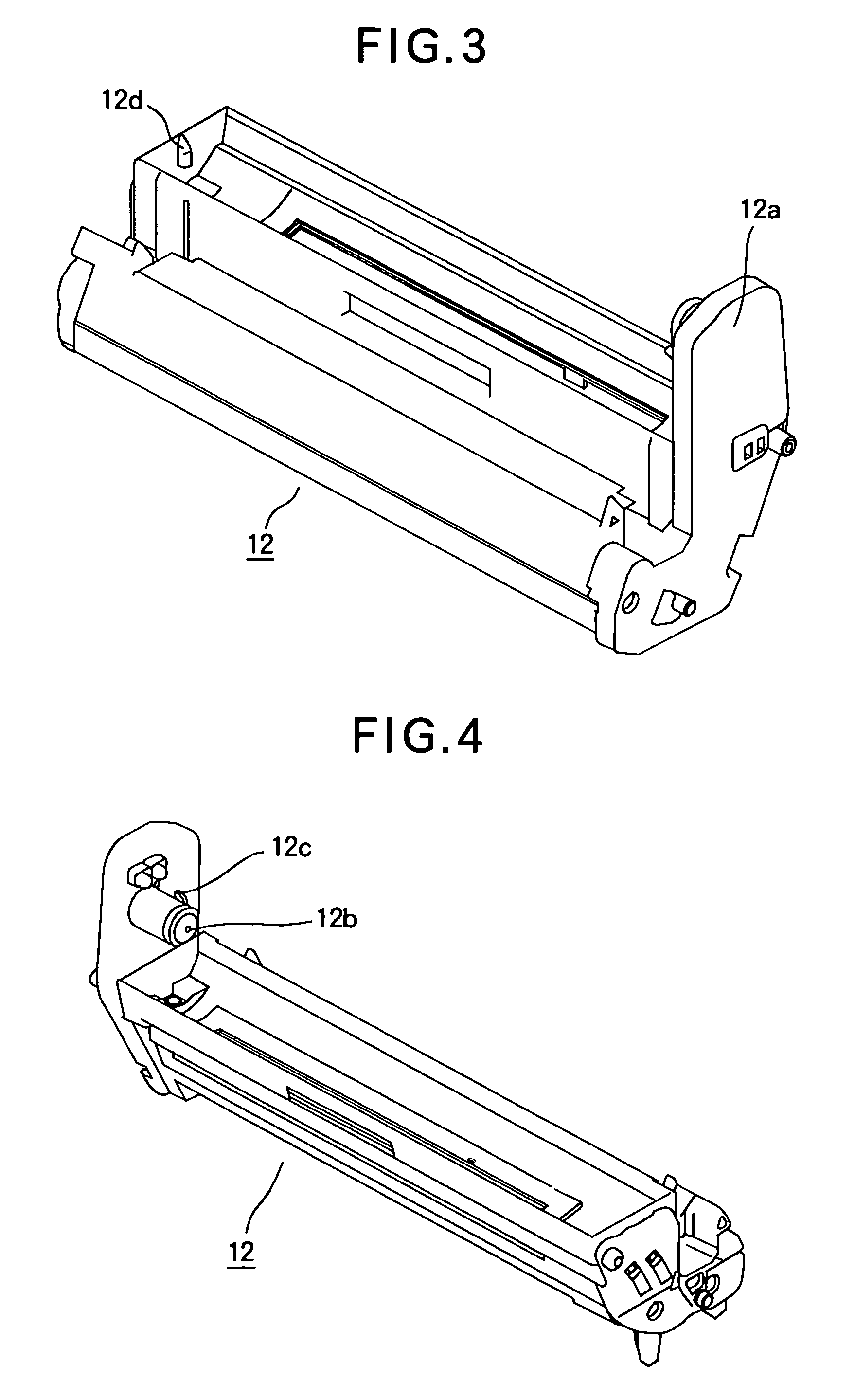

Fitting construction and developer holding unit and image forming apparatus that use the fitting construction

ActiveUS20050169676A1Low costInjection is simpleCapsPowdered material dispensingImaging equipmentBuilding construction

A fitting construction for a developer holding apparatus includes a housing member and a lid. The housing member has a developer chamber having a first wall that defines an opening. The lid fittingly closes the opening, the lid having a smaller tensile modulus of elasticity than the housing member and a groove that is formed in a peripheral portion of the lid and receives the projection therein. The groove extends all around the opening. The first wall fittingly engages into the groove to seal the opening. The lid includes a second wall that closes the opening, an third wall that projects from the second wall, and an fourth wall that projects from the second wall and extends to surround the third wall to define the groove between the third wall and the fourth wall.

Owner:OKI ELECTRIC IND CO LTD

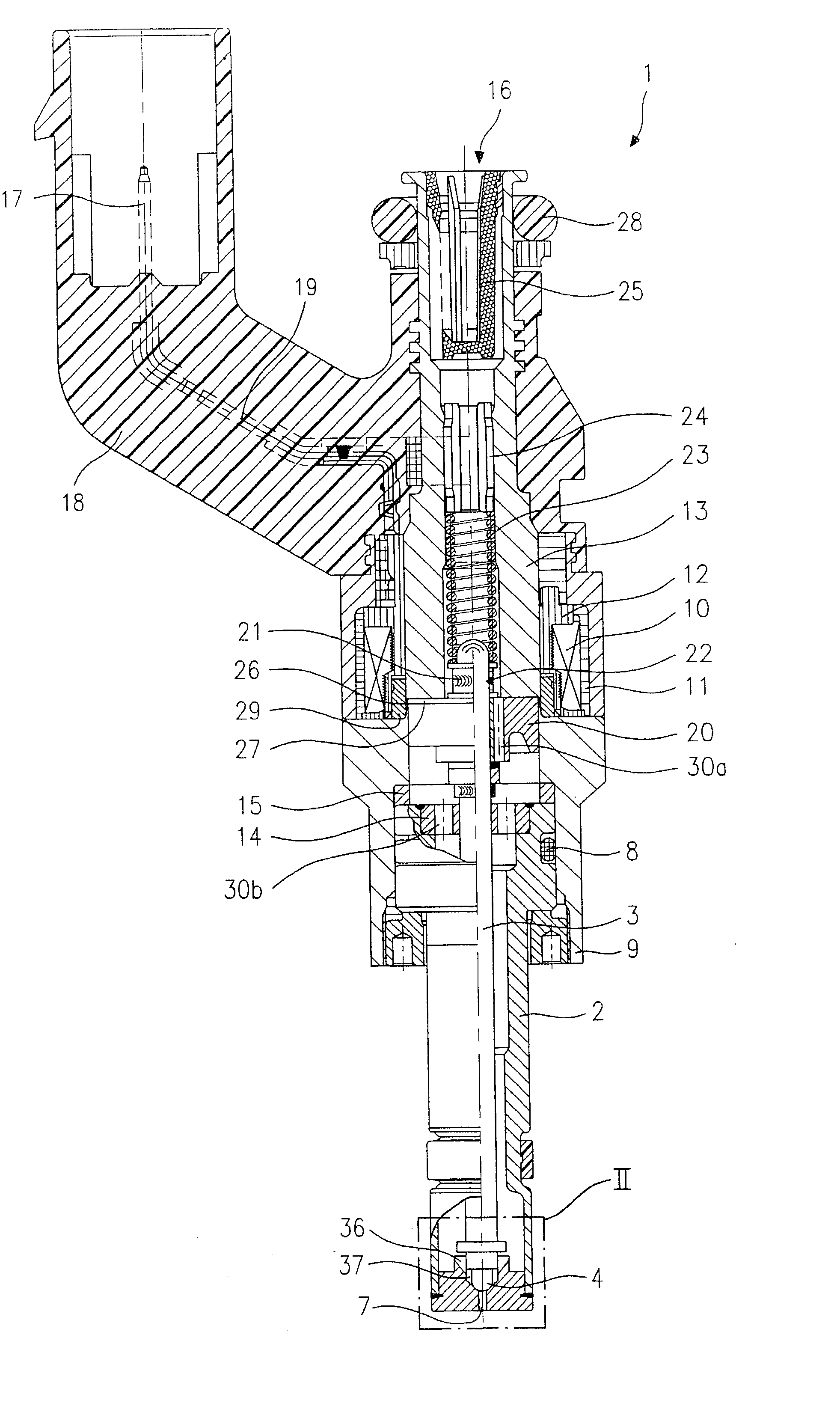

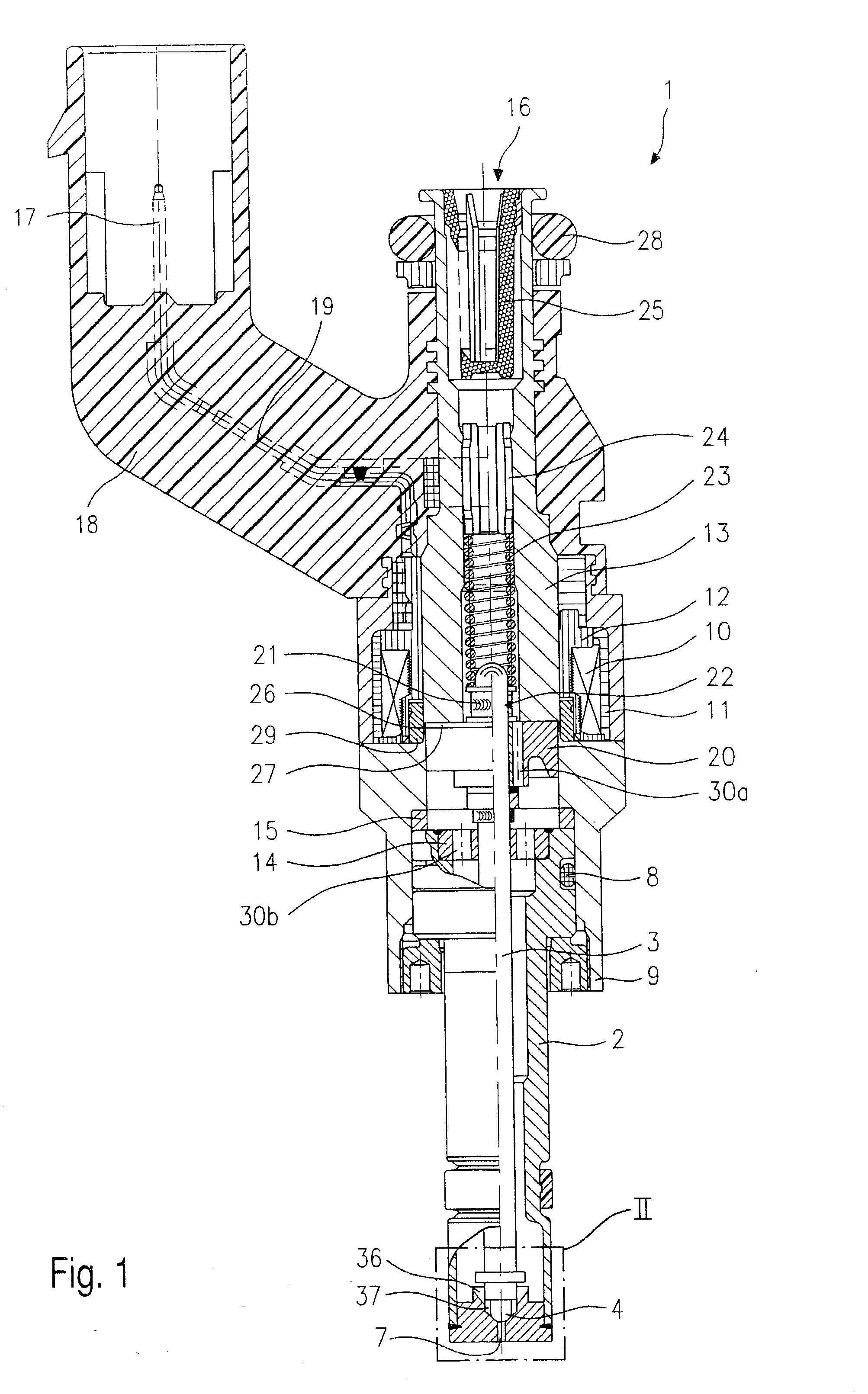

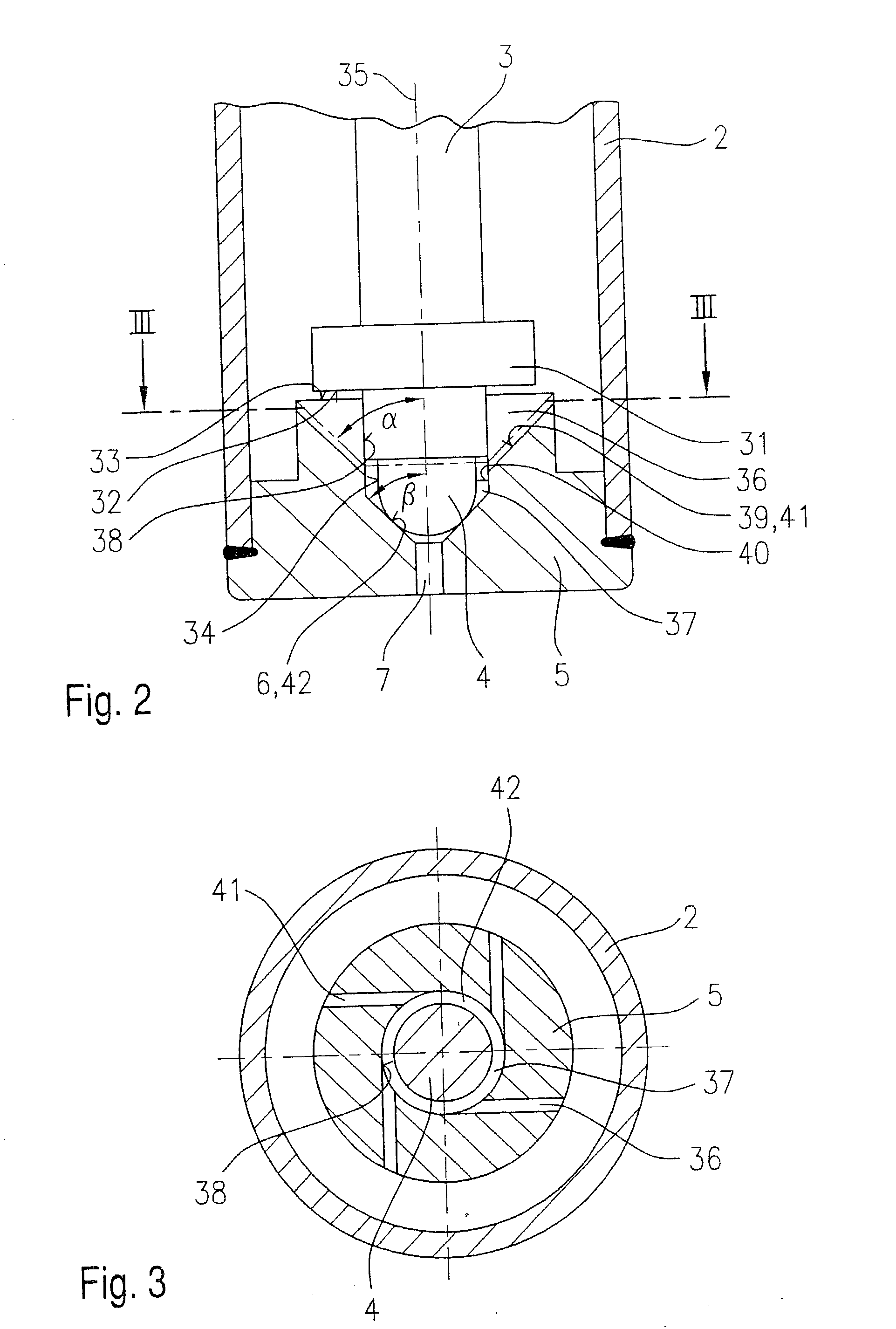

Fuel injection valve

InactiveUS20030047623A1No loss in circumferential speedEmission reductionSpray nozzlesMachines/enginesCombustionEngineering

A fuel injector for fuel injection systems of internal combustion engines includes a valve needle and a valve-closure member mechanically linked to it, which cooperates with a valve-seat surface situated in a valve-seat member to form a sealing seat, and at least one swirl-producing element which is situated upstream from the sealing seat in the valve-seat member. One or more swirl channels which are open toward the upstream side of the valve-seat member are incorporated into the upstream side of the valve-seat member as a swirl-producing element.

Owner:ROBERT BOSCH GMBH

Valve module for supplying in particular gaseous media

ActiveCN101384845AImprove sealingSimple configurationOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringInternal combustion engine

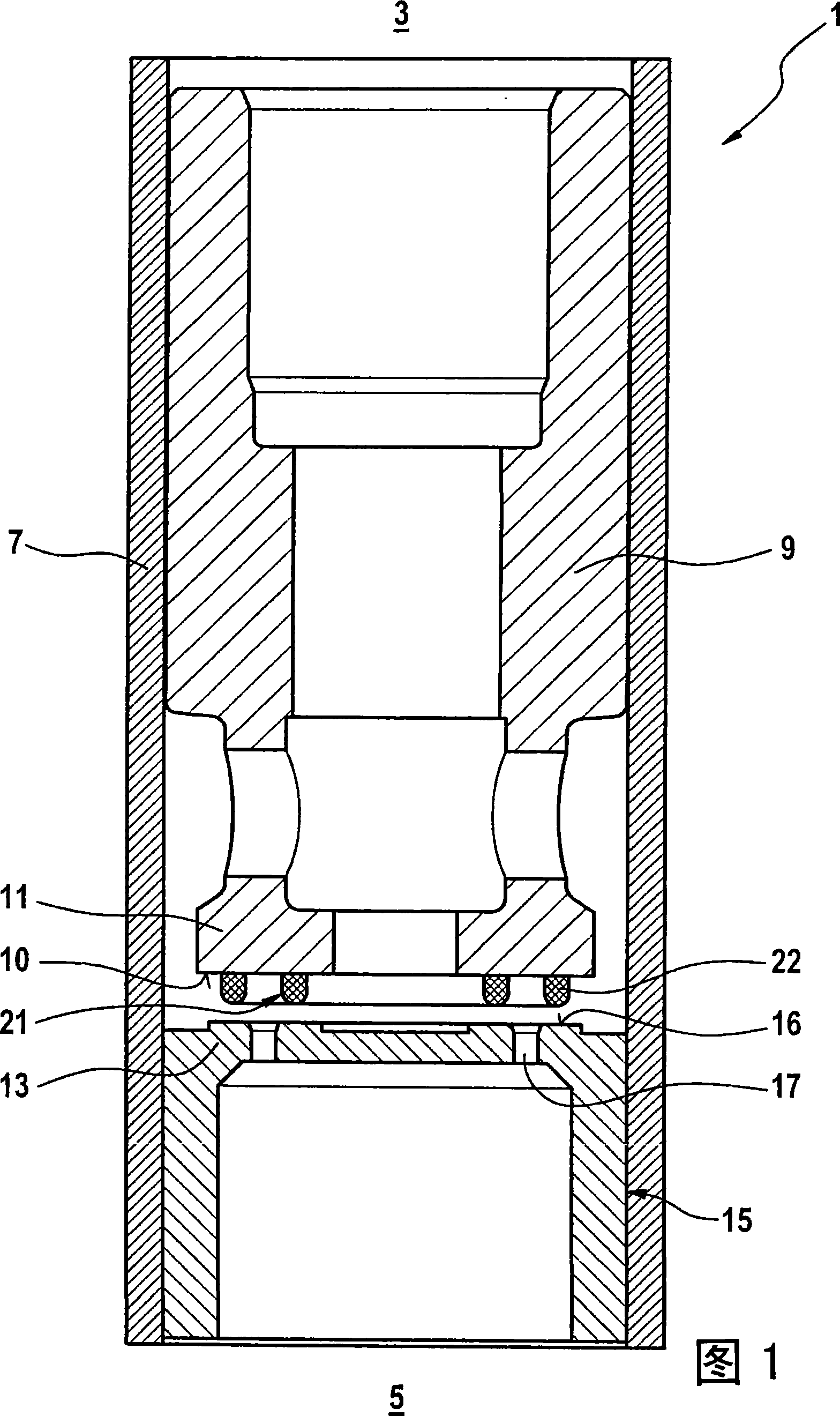

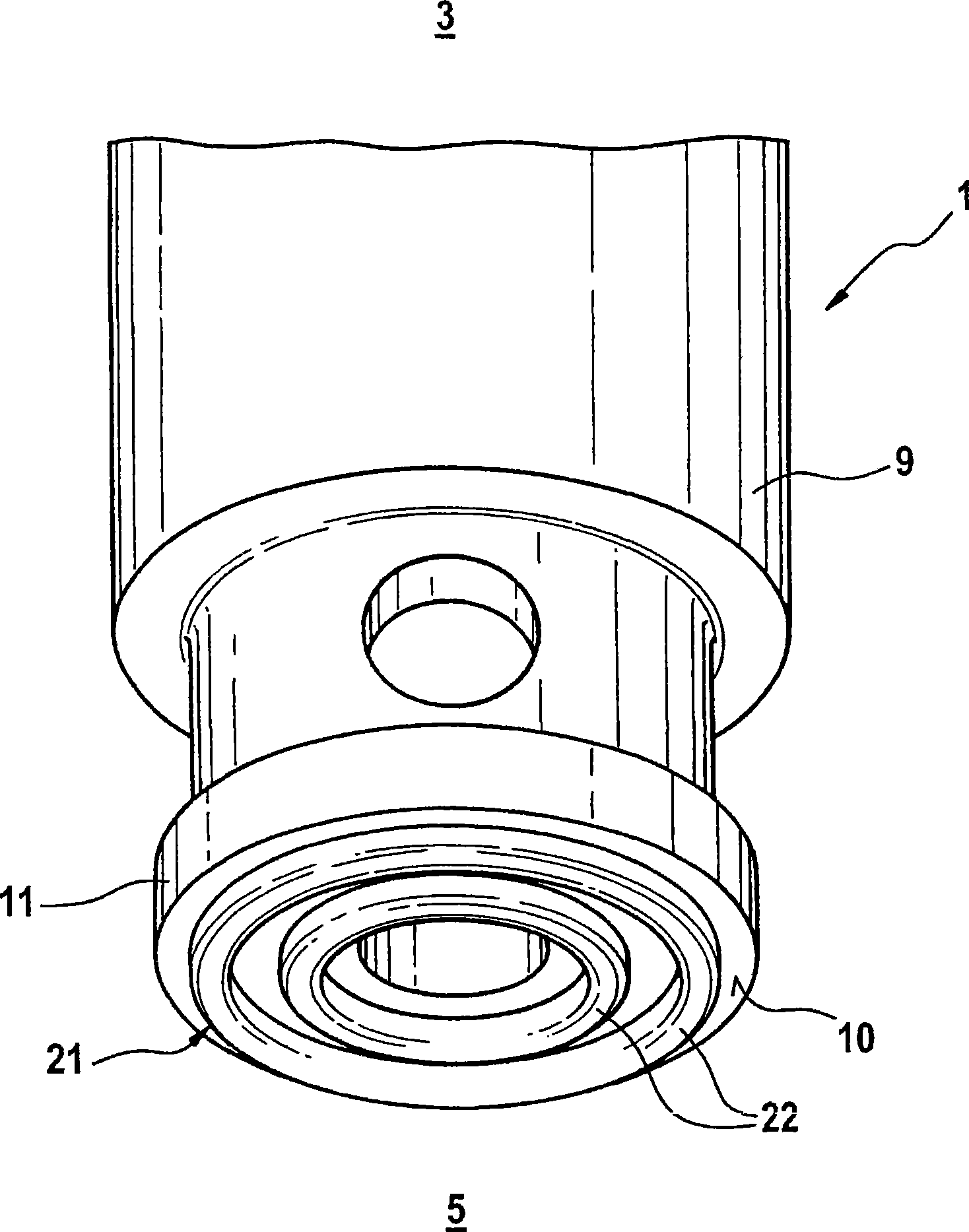

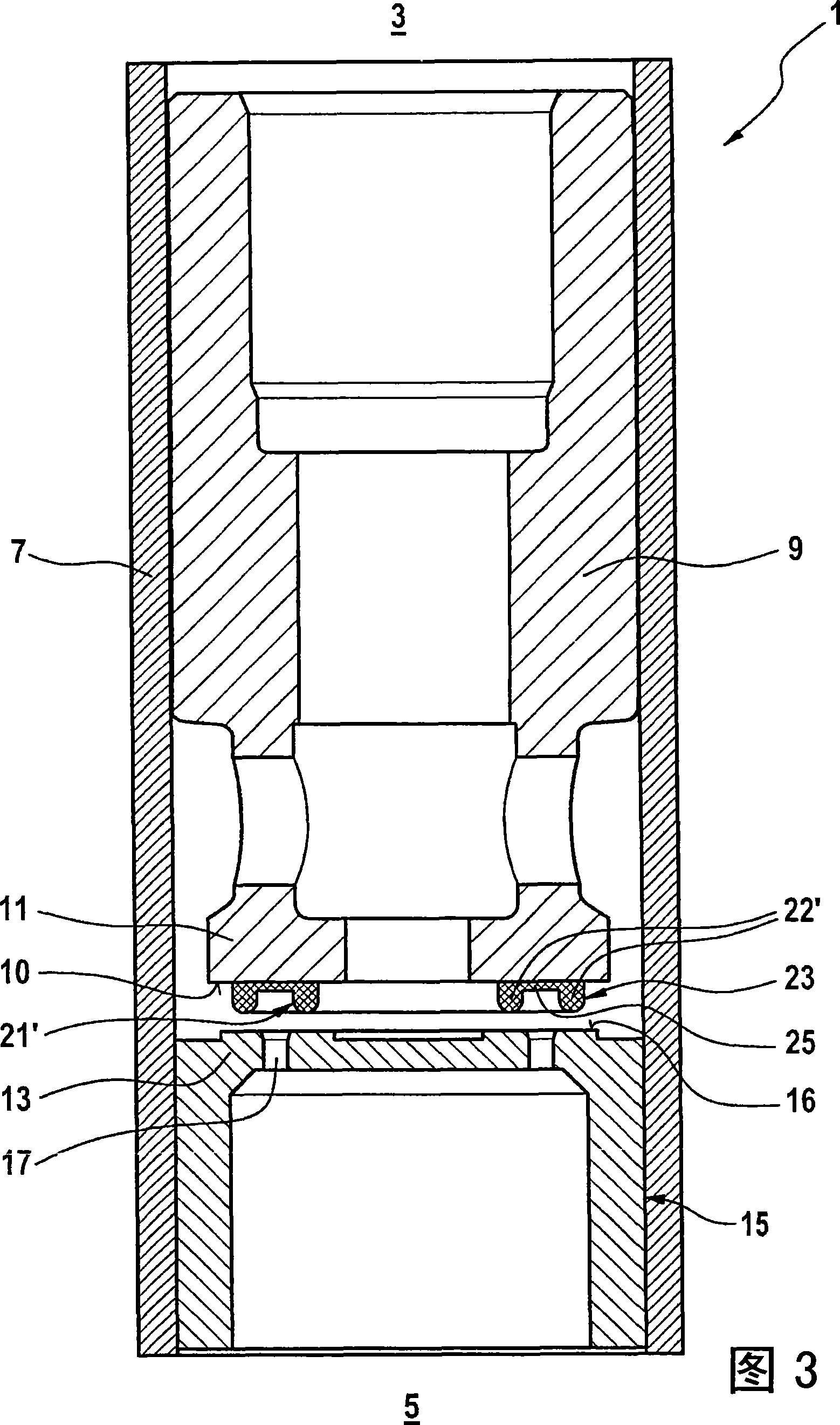

The invention relates to a valve module for supplying in particular gaseous media to an internal combustion engine. The valve module has a valve sleeve (7) in which a valve armature (9) having a valve closing member (11) is guided so as to be axially moveable relative to a valve seat body (15), which has a valve seat (13) and is fixedly arranged in the valve sleeve (7), in order to set a fluid flow between an inflow side and an outflow side (5). Here, according to the invention, a sealing device (21) which is composed of at least two annular sealing beads (22, 22', 22'') is provided, and the sealing device (21, 21', 21'') is arranged with respect to at least one passage opening (17) such that the at least one passage opening (17) is situated between the sealing beads (22, 22', 22'') in the closed position of the valve module (1).

Owner:ROBERT BOSCH GMBH

Injectable intraocular lens

InactiveUS20020055778A1Reduce post-injection manipulationInjection is simpleTissue regenerationIntraocular lensIntraocular lensRefractive index

The present invention relates to polysiloxanes suitable for the preparation of intraocular lenses by a crosslinking reaction, having a specific gravity of greater than about 1.0, a refractive index suitable for restoring the refractive power of the natural crystalline lens and a viscosity suitable for injection through a standard cannula. The present invention includes an injectable intraocular lens material based on said polysiloxanes and methods of preparing intraocular lenses by direct injection into the capsular bag of the eye.

Owner:PHARMACIA AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com