Valve module for supplying in particular gaseous media

A gas medium and valve module technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems that cannot fully meet the special requirements of gas medium, and achieve the effects of optimized sealing, favorable cost, and optimized closing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

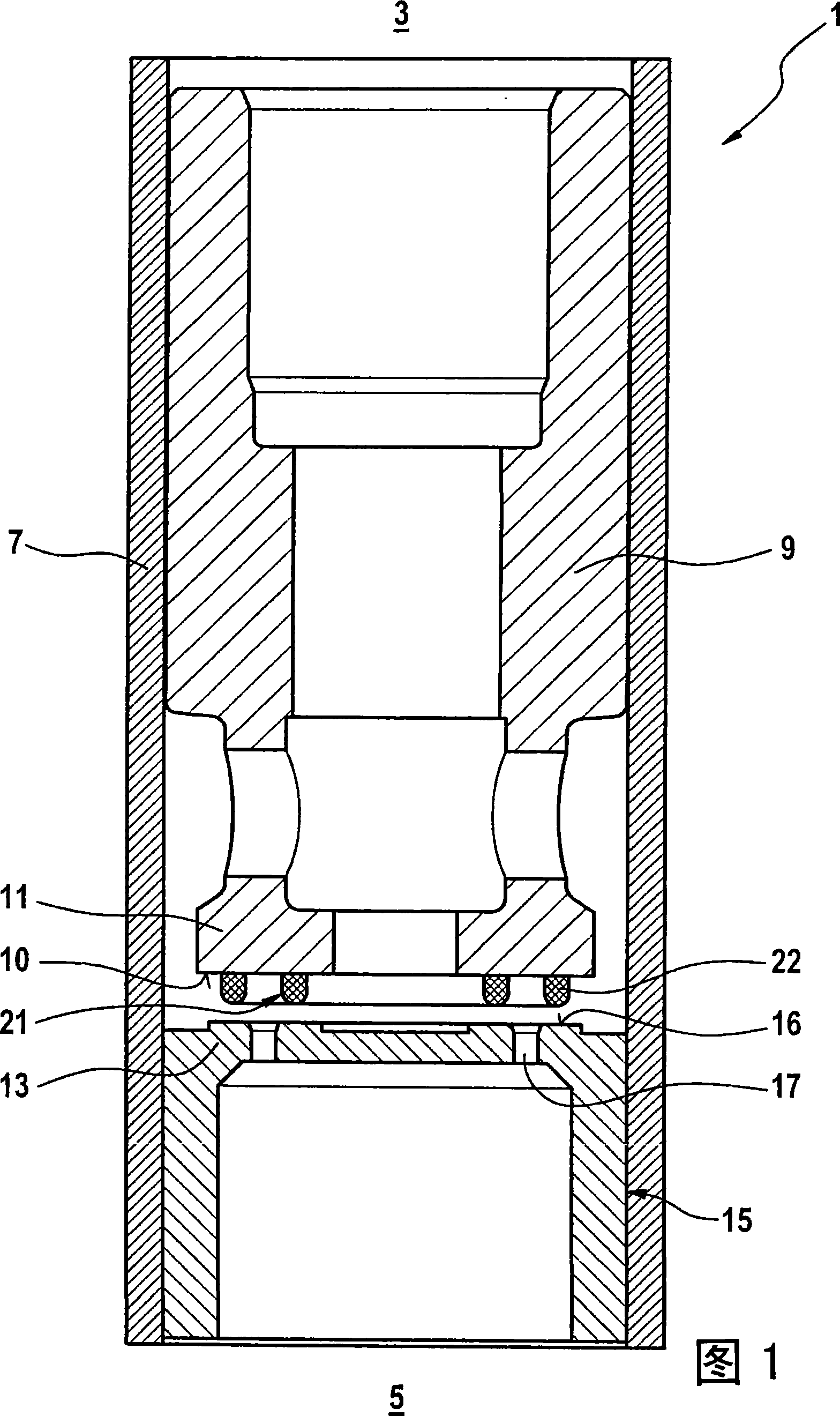

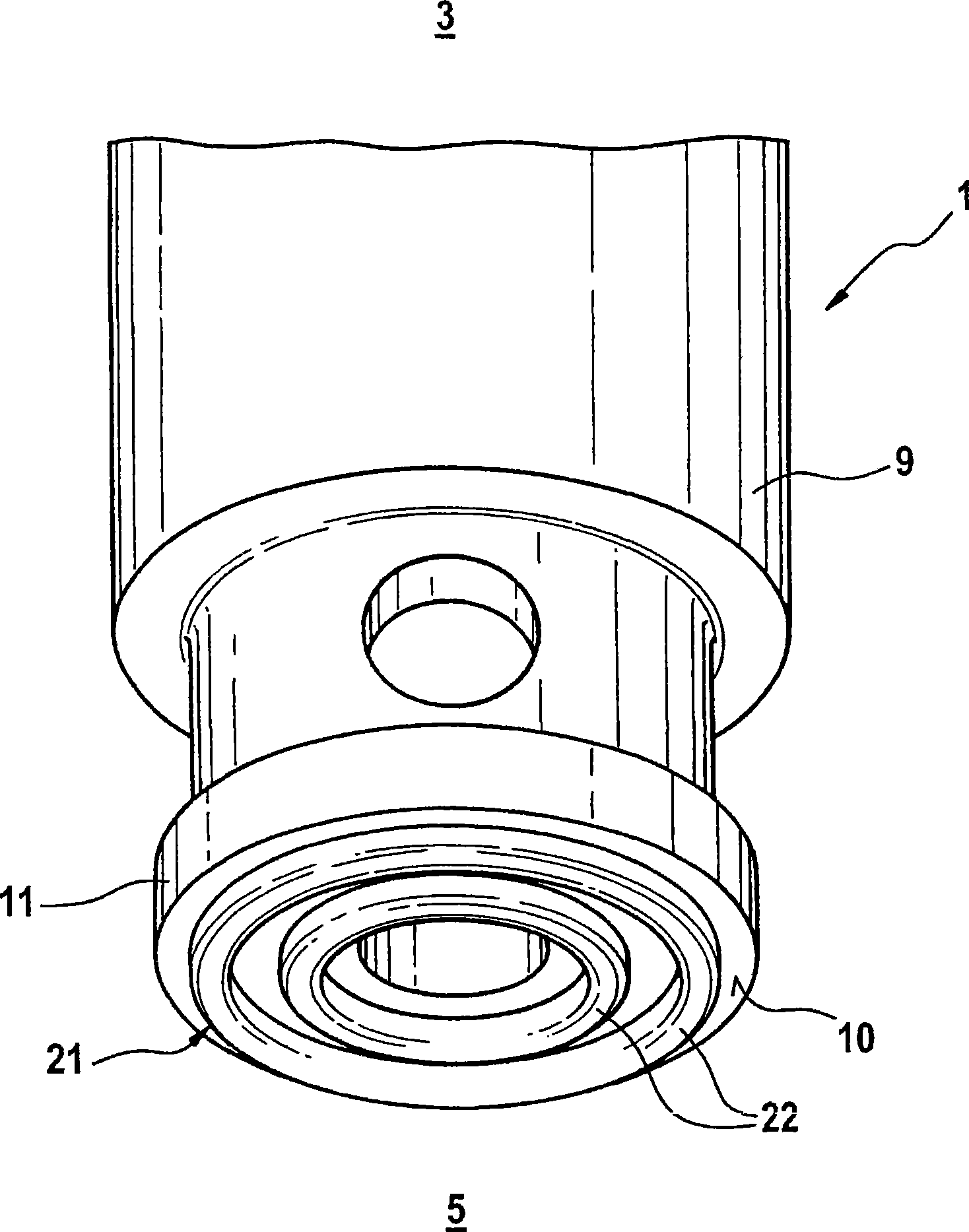

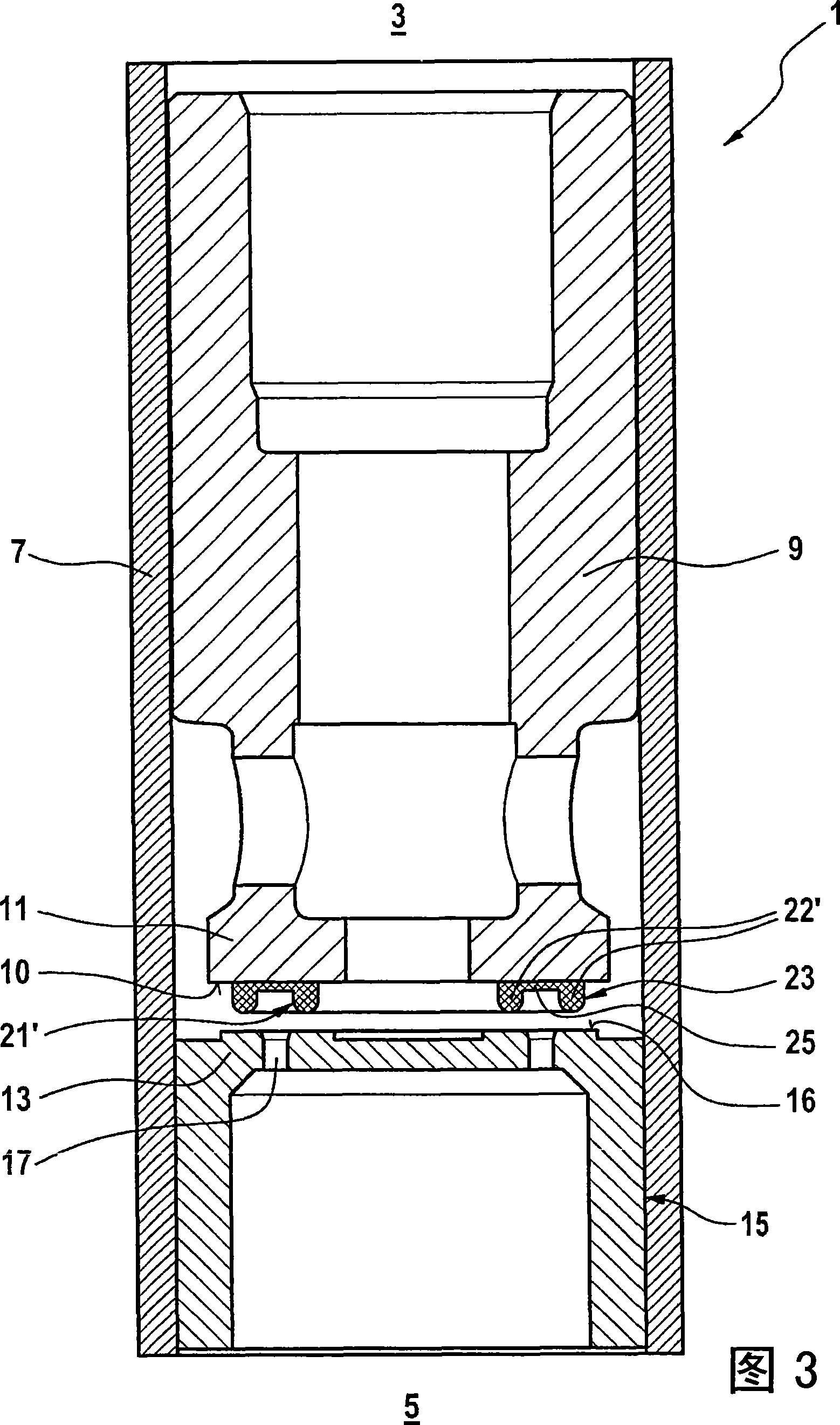

[0023] The figures each show schematically a valve module 1 of an injection valve designed for use on a fuel cell or a gas engine of a motor vehicle and for regulating a fluid flow from an inflow side 3 to an outflow side 5 .

[0024] According to known designs, the gas injection valve can be constructed as a multi-part housing, in which a solenoid operating unit is arranged with a field coil which surrounds the described valve module 1 .

[0025] The valve module 1 contains a valve sleeve 7 which can be produced by deep drawing or other forming techniques and consists of a non-magnetic material. A soft magnetic valve armature 9 having a valve closing element 11 for cooperating with a valve seat 13 of a valve seat body 15 is arranged axially displaceable in the valve sleeve 7 .

[0026] In the embodiment shown, the valve seat 13 is formed on a valve seat body 15 which is inserted into the valve sleeve 7 and fastened thereto, for example by welding, the valve seat body 15 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com