Polypropylene composite material with low emission and excellent weather resistance and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of polypropylene composite materials with low emission and excellent weather resistance and its preparation, can solve the problem of long contact time between eluent and polypropylene composite materials, which affects the mechanical properties and weather resistance of finished products , water or jellyfish pellets are difficult to add, to achieve the possible effects of easy implementation and operation, overcoming the shortcomings of adsorption balance, and reducing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 68.5 parts by weight of polypropylene BJ368MO, 10 parts by weight of POE (8150), 20 parts by weight of 10000 mesh talcum powder, 0.2 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant 168, 0.1 parts by weight of light stabilizer and 1 part by weight of Carbon black was added into a high-speed mixer with a rotation speed of 1000rpm and mixed for 5 minutes to obtain a mixture, and then the mixture was added to a twin-screw extruder from the feed port for melt blending. The aspect ratio of the twin-screw extruder was 52: 1. The twin-screw extruder includes 11 heating working areas connected in sequence. The temperature of the 11 heating working areas of the twin-screw extruder from the feeding port to the extrusion granulation is: 195 ° C ~ 200 ° C, 195 ° C ~ 200℃, 200℃~205℃, 200℃~205℃, 205℃~210℃, 205℃~210℃, 205℃~210℃, 210℃~215℃, 205℃~210℃, 205℃~210℃ , 200 ℃ ~ 205 ℃, two high-power vacuum pumps are installed in the 5th heating work area and the 8th hea...

Embodiment 2

[0041] The amount of water injected into the seventh heating working area was changed from 8 parts by mass to 10 parts by mass, and the other formulations and steps were the same as in Example 1 to obtain a polypropylene composite material with low emission and excellent weather resistance.

Embodiment 3

[0043] The amount of water injected into the 7th heating working area is changed from 8 parts by mass to 12 parts by mass, and other formulas and steps are the same as in Example 1.

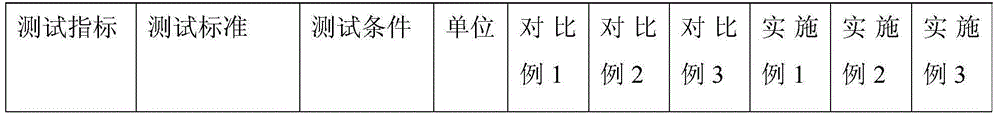

[0044] The polypropylene composite materials prepared in Comparative Examples 1-3 and the polypropylene composite materials prepared in Examples 1-3 with low emission and excellent weather resistance were injected into standard specimens, and their mechanical properties and weather resistance were tested. The results are shown in the table 1.

[0045] Table 1 The mechanical and weather resistance properties of imported materials

[0046]

[0047]

[0048] It can be seen from Table 1 that using the method of the present invention to carry out air stripping treatment on PP, when the water injection amount is greater than 8 parts by mass, the TVOC value of the material system can be effectively reduced, and the TVOC value is ≤ 20UgC / g. With the further increase of the water injection volume, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com