Patents

Literature

103 results about "Machine factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A machine factory is a company, that produces machines. These companies traditionally belong to the heavy industry sector in comparison to a more consumer oriented and less capital intensive light industry. Today many companies make more sophisticated smaller machines, and they belong to the light industry. The economic sector of machine factories is called the machine industry.

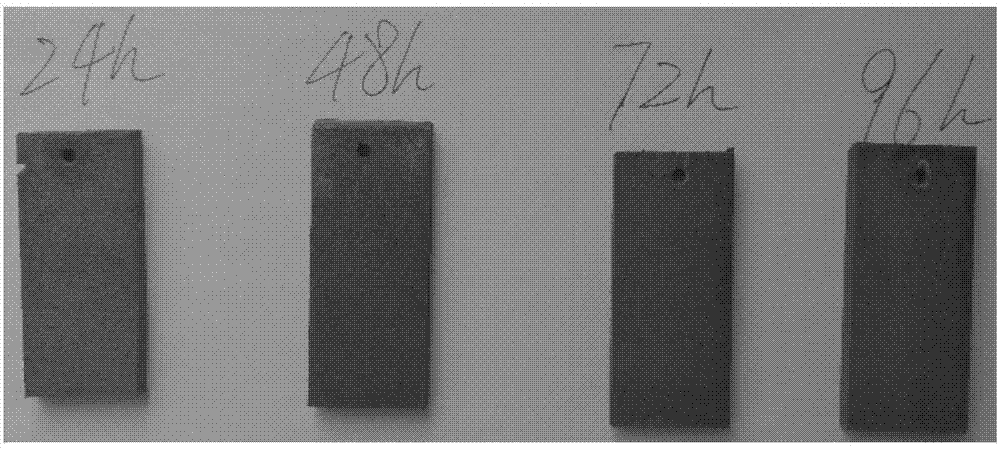

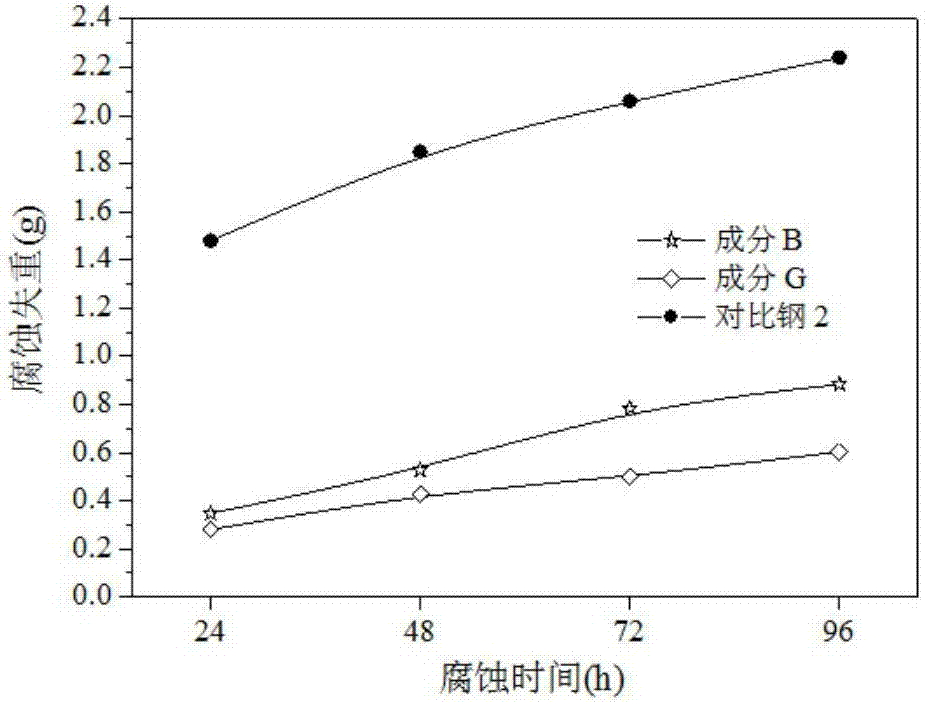

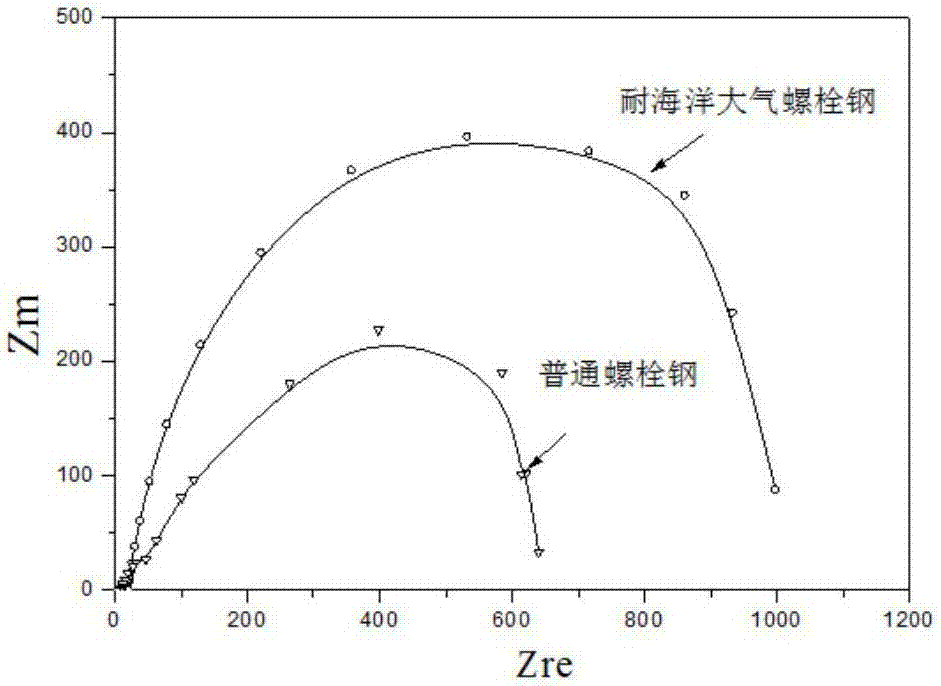

Coating-free ocean atmospheric corrosion resisting high-strength bolt steel for bridge structure and manufacturing method

InactiveCN107022718AAccelerated corrosionImprove low temperature resistanceFurnace typesHeat treatment furnacesToughnessImpurity

The invention discloses ocean atmospheric corrosion resisting high-strength bolt steel for a coating-free bridge structure and a manufacturing method, and belongs to the technical field of steel for bridge structure connection. The steel is prepared from, by weight, 0.16%-0.45% of C, 0.01%-2.2% of Si, 0.3%-2.5% of Mn, 0.001%-0.024% of P, 0.002%-0.025% of S, 0.0005%-0.0100% of B, 0.01%-0.50% of Ti, 0.01%-0.20% of V, 0.001%-0.15% of Al, 0.35%-3.2% of Cr, 0.2%-0.6% of Cu, 0.2%-2.5% of Ni and the balance Fe and trace impurities. The corrosion resisting index I, calculated according to a chemical ingredient prediction formula, of the high-strength weather-proof bolt steel is larger than or equal to 6.3, the properly produced bolt specification range is M16-30 mm, after the bolt steel is beaten into bolts through a bolt machining factory, oil hardening of 840 DEG C to 920 DEG C and tempering of 380 DEG C to 625 DEG C are included in a quenched-tempered heat treatment system, and optimum high toughness matching is obtained. The bolt steel has the beneficial effects that the 10.9-grade high-strength bolts are used for matching connection of coating-free bridge structure plates and profiles, and have excellent ocean atmospheric corrosion and low temperature resisting performance.

Owner:SHOUGANG CORPORATION

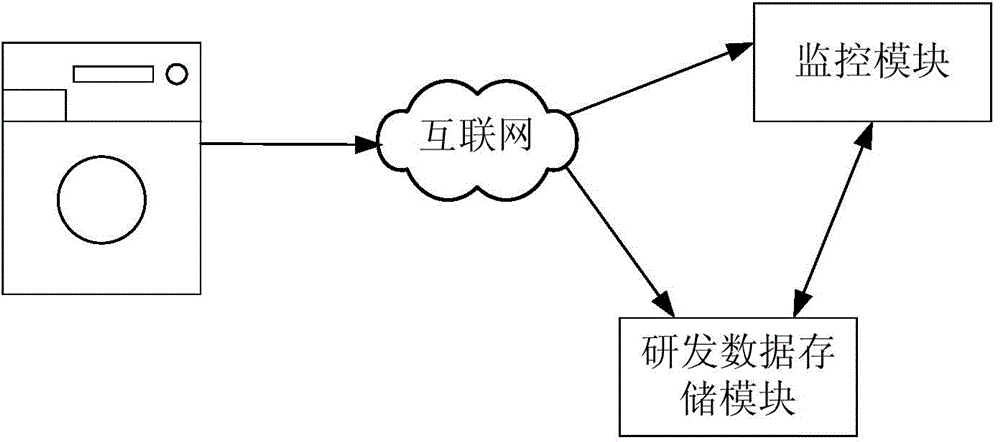

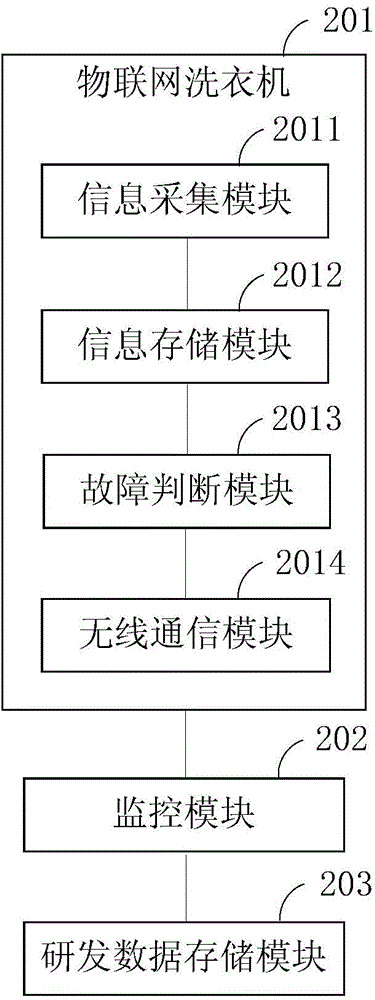

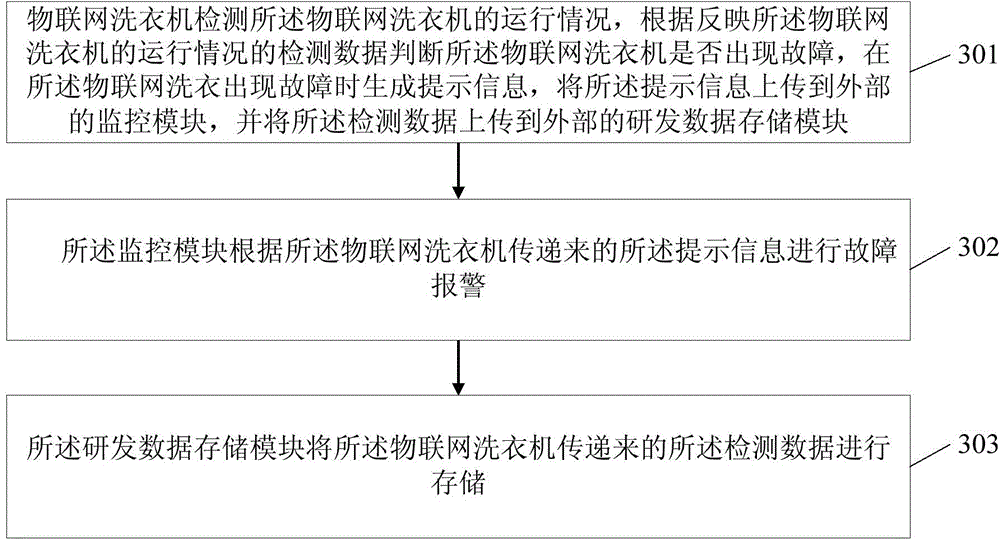

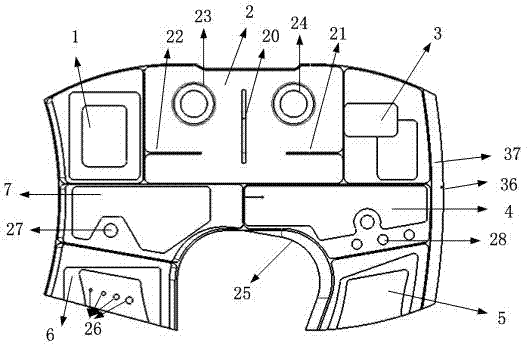

Internet-of-thing laundry system and method and internet-of-thing washing machine

InactiveCN104917801AEffective maintenanceSave manpower and material resourcesControl devices for washing apparatusTransmissionThe InternetResearch data

The invention discloses an internet-of-thing laundry system and method and an internet-of-thing washing machine. The internet-of-thing laundry system comprises the internet-of-thing washing machine used for detecting the operation condition of the internet-of-thing washing machine, judging whether the internet-of-thing washing machine has fault according to detection data reflecting the operation condition of the internet-of-thing washing machine, generating a reminding message when the internet-of-thing washing machine has fault, uploading the reminding message to a monitoring module and uploading the detection data to a research data storage module; the monitoring module connected with the internet-of-thing washing machine and used for carrying out fault alarming according to the reminding message transmitted from the internet-of-thing washing machine; and the research data storage module connected with the internet-of-thing washing machine and used for storing the detection data transmitted from the internet-of-thing washing machine. According to the internet-of-thing laundry system and method and the internet-of-thing washing machine, fault maintenance of the internet-of-thing washing machine can be carried out effectively, and manpower and material resources are saved when a washing machine factory develops new products.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Polypropylene composite material with low emission and excellent weather resistance and preparation method thereof

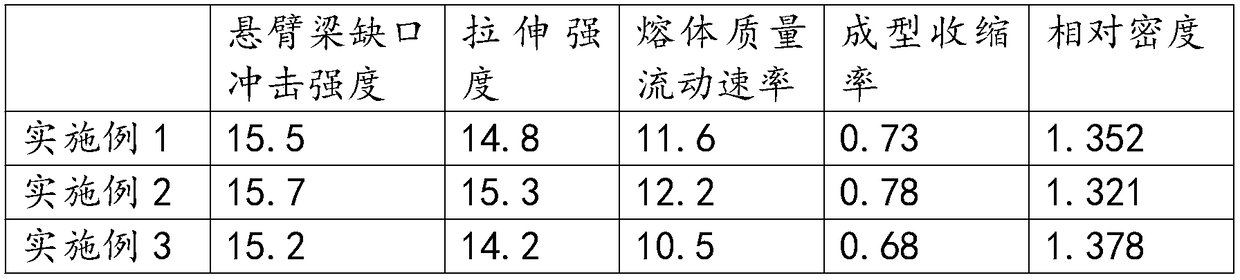

ActiveCN105199238AReduce degradationOvercome the disadvantage of adsorption equilibriumPolypropylene compositesPolymer science

The invention discloses a polypropylene composite material with low emission and excellent weather resistance and a preparation method thereof. The polypropylene composite material is prepared from 40%-90% of polypropylene, 5%-15% of flexibilizer, 18%-40% of mineral fillers, 7%-13% of water, 0.1%-3% of antioxidants, 0.02%-2% of light stabilizers and 0-3% of colorants. The method comprises the steps that the polypropylene, the flexibilizer, the mineral fillers, the antioxidants, the light stabilizers and the colorants are mixed, then the mixture is added to a double-screw extruder for melt blending, the vacuum degree of a sixth heating working area and a seventh heating working area is controlled to be over minus 0.05 MPa, the water is fed into the seventh heating working area of the double-screw extruder, vacuum extrusion granulation is conducted through the double-screw extruder, and the polypropylene composite material is obtained. According to the polypropylene composite material with the low emission and the excellent weather resistance and the preparation method thereof, the production technology is simple, the cost is low, the obtained polypropylene composite material can meet the requirements of automobile set machine factories at home and abroad, and a wide application prospect is achieved.

Owner:CGN JUNER NEW MATERIALS +1

Integrated airplane structural part numerical-control machining capacity test model and application thereof

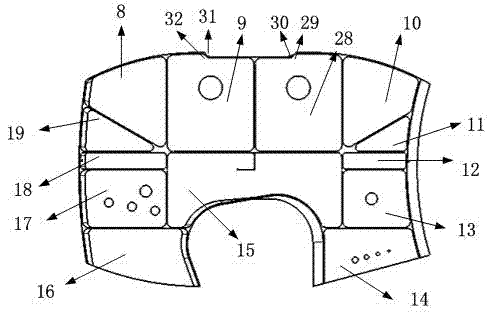

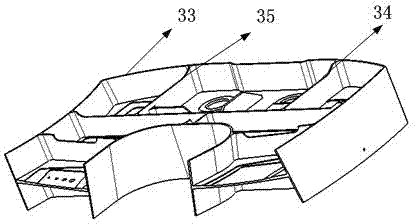

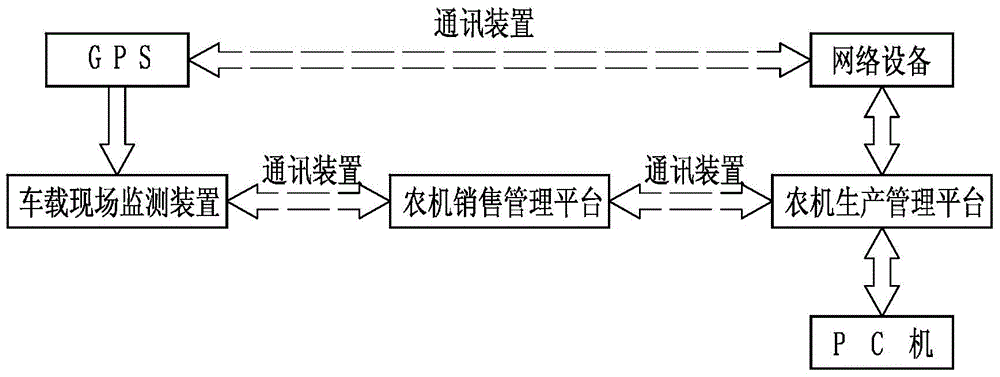

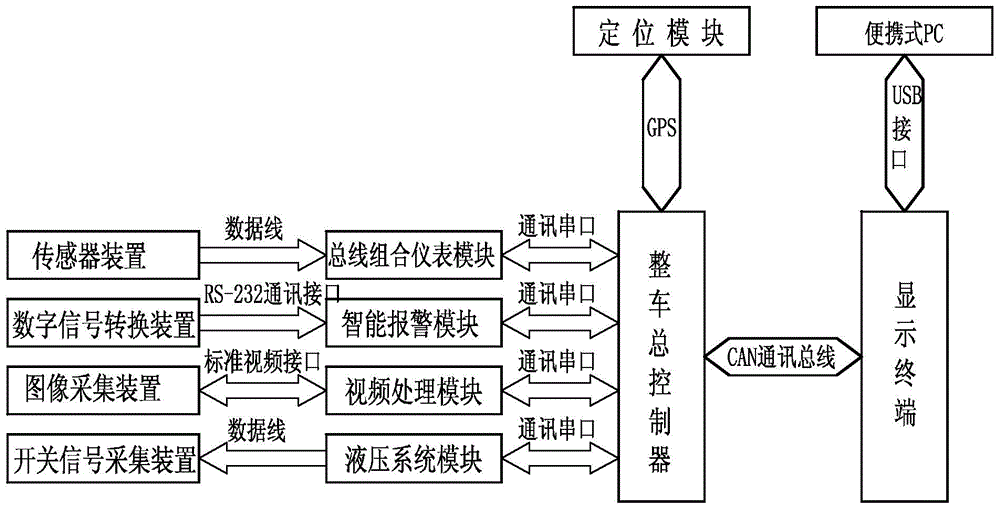

The invention discloses an integrated airplane structural part numerical-control machining capacity test model and the application thereof. The integrated airplane structural part numerical-control machining capacity test model is characterized in that the model is a double-sided part and includes airplane structural part typical machining characteristics and syntagmatic relation thereof, the machining characteristics include typical grooves, ribs, holes and outlines and the like and comprise intersection features, opening and closing angles and free-form surfaces, and the characteristics include typical dimensions such as web thickness, web area, difference of groove layers of a multi-layer groove, rib thickness, rig height and turning angle radius. Using the model can test efficiency and accuracy of general CAD (computer-aided design) / CAM (computer-aided manufacturing) software and special automatic programming systems and can further test airplane structural part machining capacity of numerical-control machine tools and airplane structural part machining technological levels, detection process, working hour predication and the like of numerical-control machining factories.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

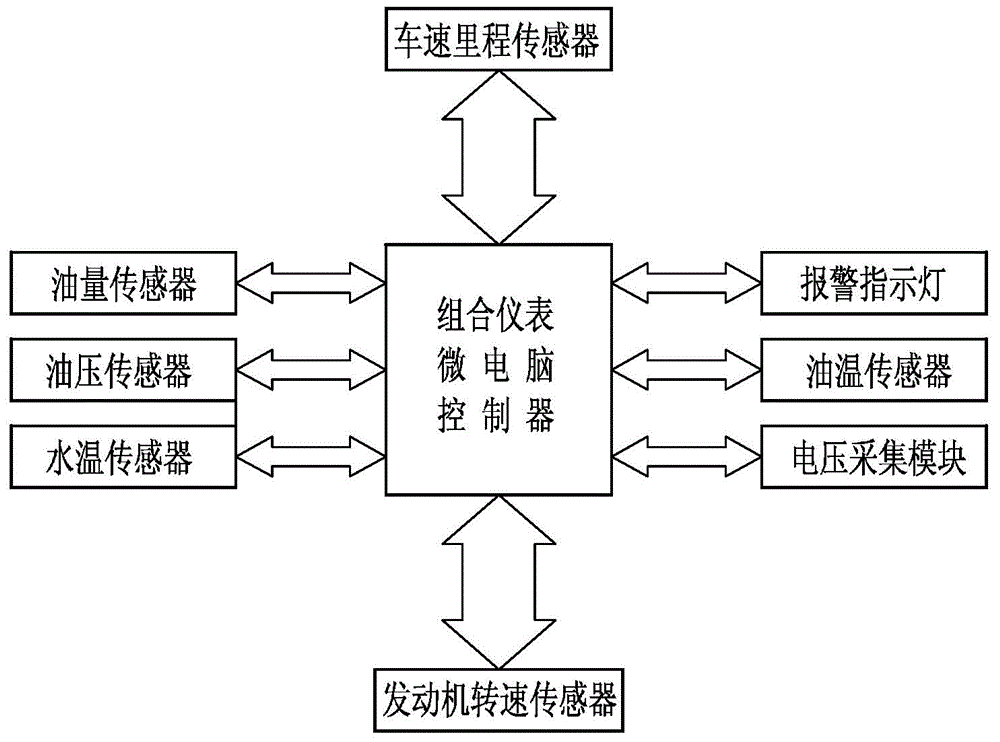

Agricultural machinery intelligent monitoring system

InactiveCN104793603ATimely transmissionGuaranteed normal transmissionProgramme total factory controlAgricultural engineeringPersonal information management

The invention discloses an agricultural machinery intelligent monitoring system. The agricultural machinery intelligent monitoring system comprises a vehicle-mounted field monitoring device, an agricultural machinery selling management platform and an agricultural machinery producing management platform which are connected with each other; the vehicle-mounted field monitoring device comprises a finished vehicle general controller, wherein the input end of the finished vehicle general controller is connected with a bus combination instrument module, an intelligent alarm module, a video processing module and a hydraulic system module, respectively; the output end of the finished vehicle general controller is connected with a display terminal and a positioning module by a data transmission device; the display terminal is connected with a portable PC by an interface device. The using field, the intermediate selling and the remote producer form an intelligent management system for sharing and managing information data. By the system, under the condition that the situation of the machinery is detected and held completely, through comprehensive analysis, the whole course information management of complete machine factory-dealer-user-field-production process-harvesting, the harvesting processes of agricultural products are controllable, the faults can be traced back, and the problems can be solved.

Owner:潍坊科科电气有限公司

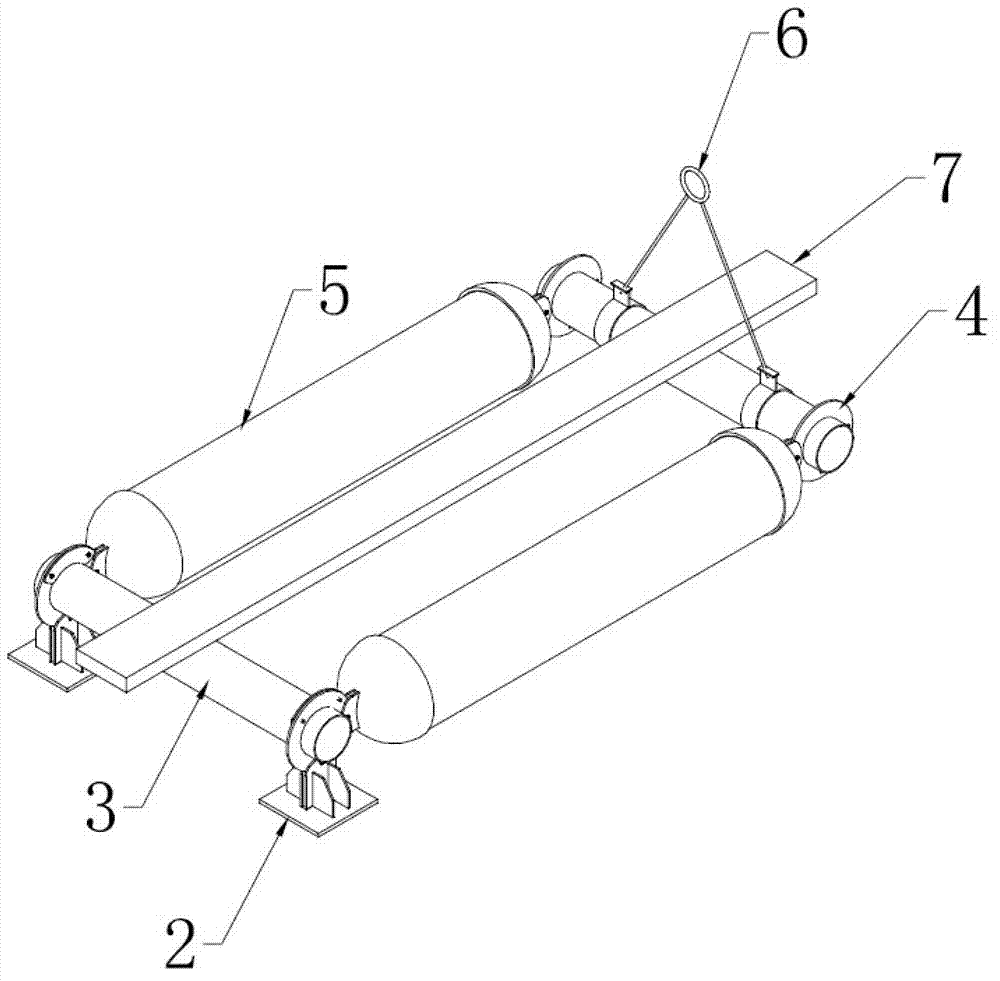

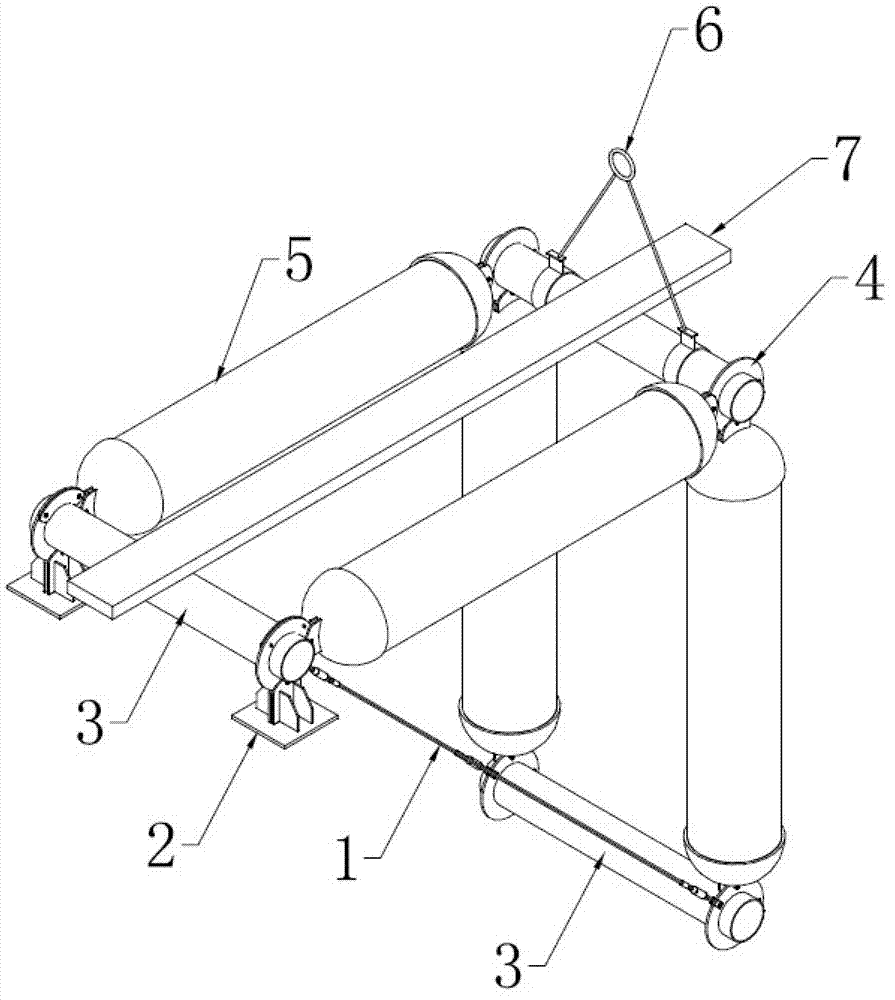

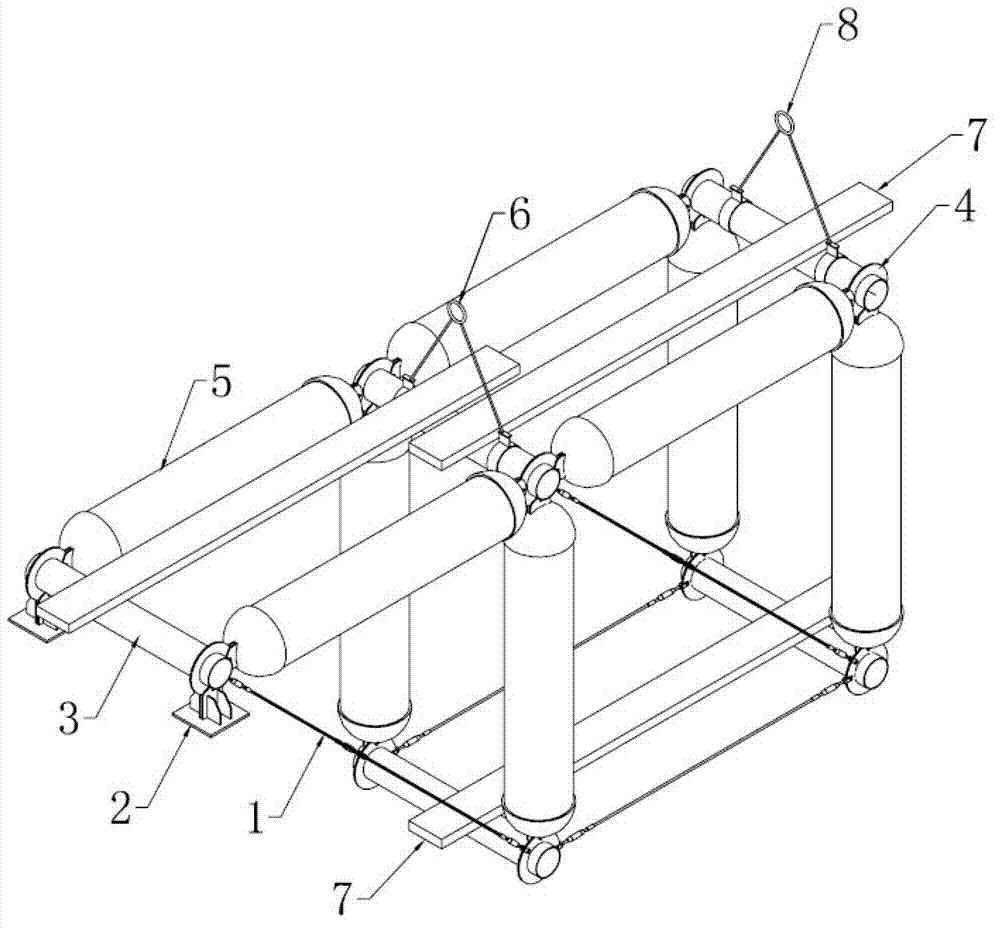

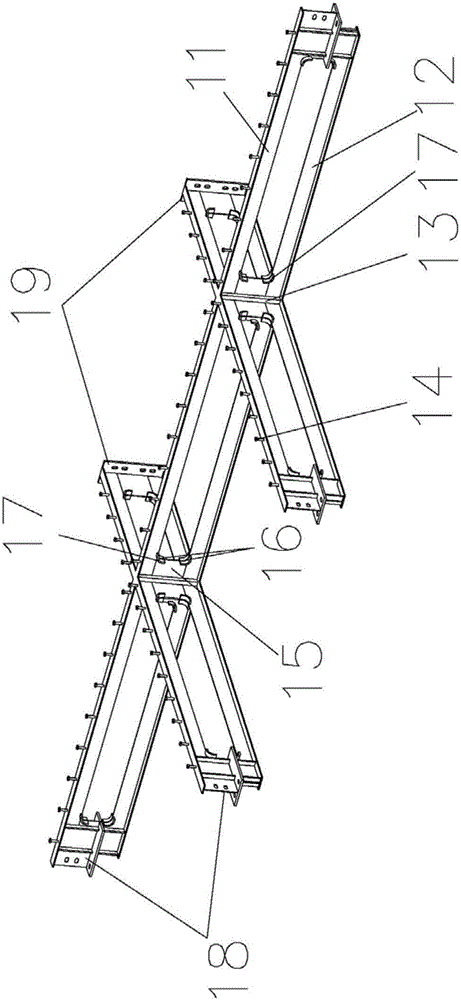

Rapid construction method for truss with pneumatic membrane compression bar

The invention belongs to the technical field of construction and relates to a rapid construction method for a truss with a pneumatic membrane compression bar. The method for the truss with the pneumatic membrane compression bar comprises the following steps that: 1, the length of a pre-stress inhaul cable of the truss is determined in a machining factory and installation and adjustment allowance is reserved; 2, arrangement of support seat foundation and base is completed at a construction site; 3, 50KPa to 70KPa interior air pressure is inflated in an air bag of the pneumatic membrane compression bar; 4, two trusses are assembled; 5, a next truss is arranged in a spliced mode based on the two existing trusses; 6, more trusses are installed through the method of step 5 until assembly in the spliced mode of a whole truss structure is completed; 7, post construction tasks of the whole truss structure are completed with an installed truss structure as a working face; and 8, an air inflating device is connected with the air bag of the pneumatic membrane compression bar so that all construction of the whole truss structure is finished. The method for the truss with the pneumatic membrane compression bar is simple in steps, low in cost, capable of achieving construction without a scaffold and with construction devices in small number, applicable to the condition that the pneumatic membrane truss structure serves as a temporary structure and significant to earthquake relief work and rebuilding work after an earthquake.

Owner:江苏中闽重工科技有限公司

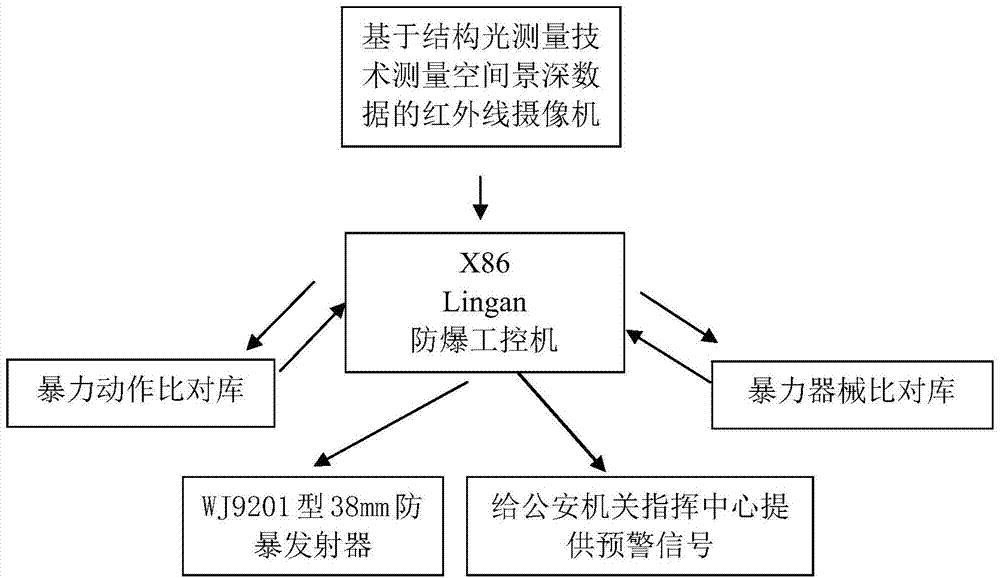

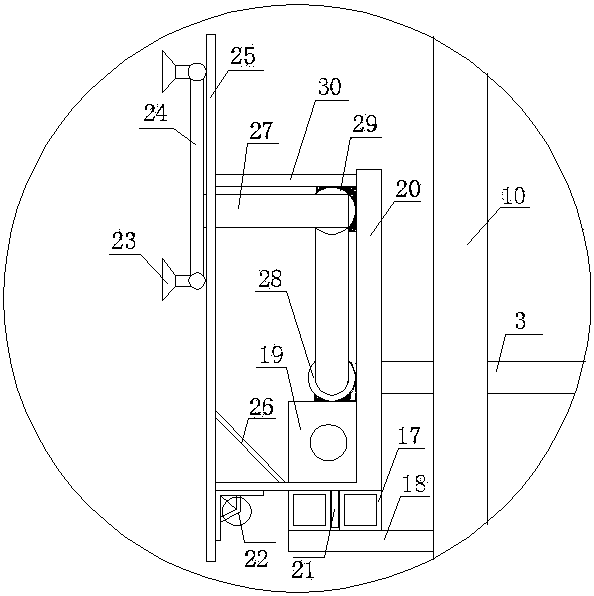

Device for automatically recognizing human body malignant violent terrorism actions and emitting violence preventing substances

InactiveCN104516295AEffective automatic identificationStop the worsening of violent terrorist incidents in timeProgramme controlComputer controlHuman bodySTUN

The invention relates to a device for automatically recognizing human body malignant violent terrorism actions and launching violence preventing substances. The device comprises an intelligent recognizing terminal and electric executing mechanism for automatically launching stun grenades. The intelligent recognizing terminal comprises an infrared camera which measures space field depth data on the basis of the structure light measuring technology, an X86 industrial personal computer and a violence preventing control device. The infrared camera and the violence preventing control device are connected to the X86 industrial personal computer. A violent action comparison library and a violent instrument comparison library are further disposed in the X86 industrial personal computer. The intelligent recognizing terminal can recognize high-danger actions of knife slashing and armed violent attack in real time and uses an electric control percussion type WJ9201 type 38mm violence preventing launcher which is developed by the Zhejiang Xinhua machine factory to automatically launch the 38mm stun grenades so as to stop continuous deterioration of the violent terrorism behaviors. The device can effectively automatically recognize the high-danger actions and launch the violence preventing substances according to needs, and the continuous deterioration of violent terrorism events can be stopped timely.

Owner:CHENGDU LINGGAN TECH

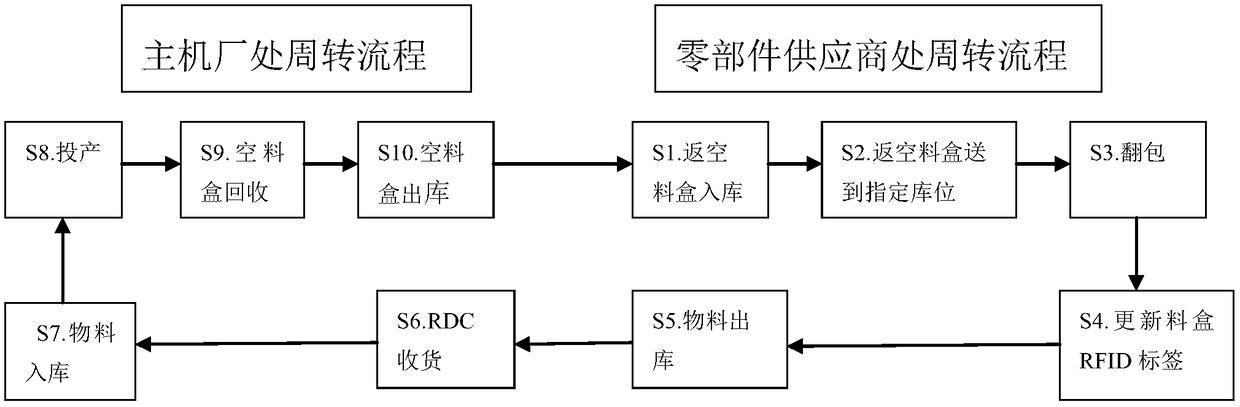

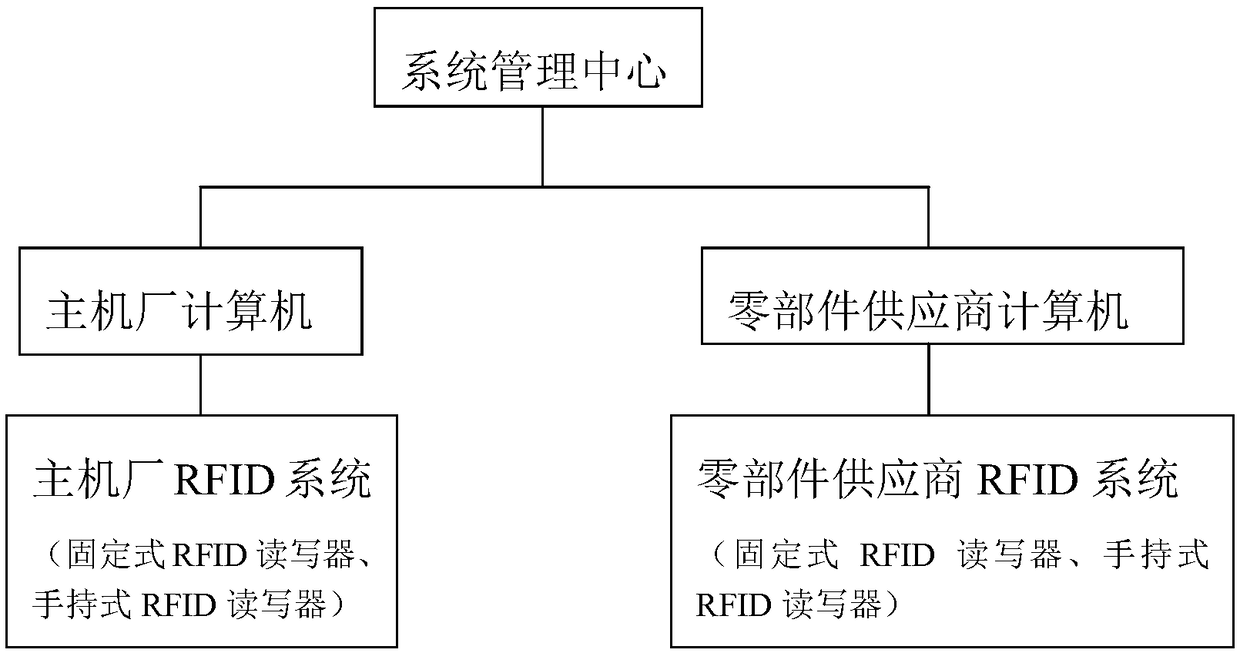

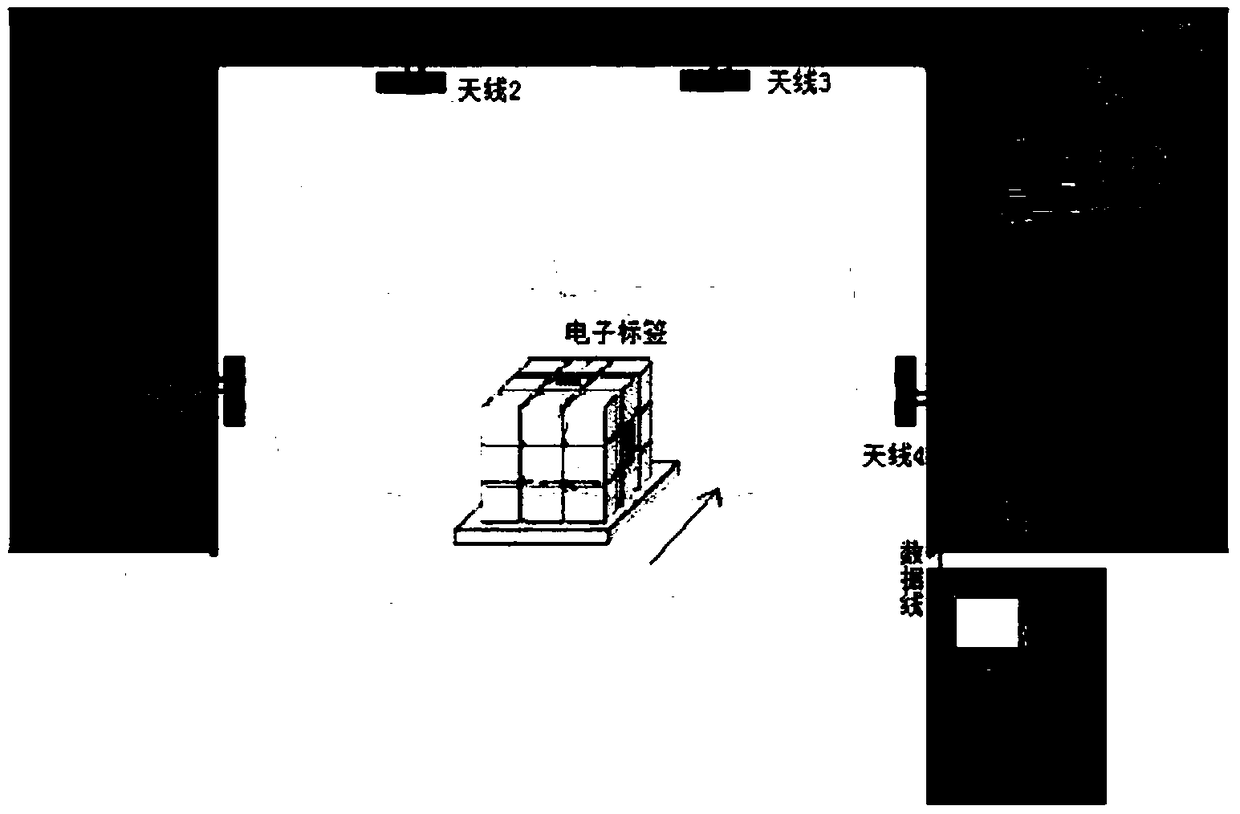

Intelligent production turnover method based on RFID

InactiveCN109325719AAccurate accessImprove production turnover efficiencyAutomatic card filesLogisticsSystems managementComputer science

The invention discloses an intelligent production turnover method based on RFID. After the RFID tag is bound to the material and the RFID reader on the door of the warehouse entry and exit passage identifies the tag, the warehouse entry management and the warehouse exit management are automatically realized, and the information is transmitted to the shared system management center of the main machine factory and the spare part factory, which matches the information of the shipment and the incoming goods, so as to ensure the accurate incoming and outgoing of the goods. In the process of material turnover, the only bar code and the RFID technology achieve transparent flow of information, thereby ensuring the effective connection between the main plant and parts factory, the efficiency of production turnover is conducive to being improved, and the labor costs and mistakes are effectively reduced.

Owner:CHONGQING CHANGAN MINSHENG APLL LOGISTICS

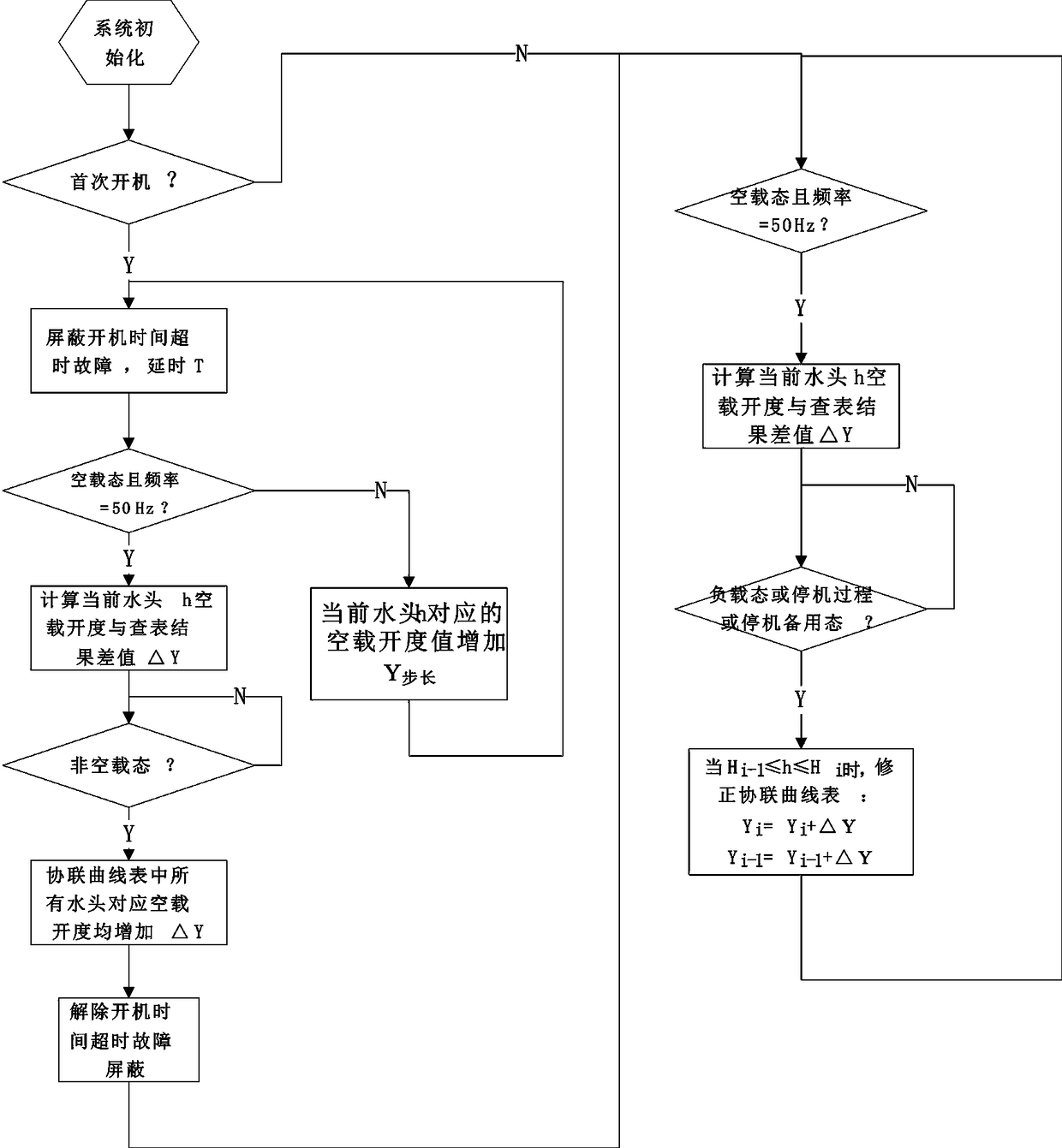

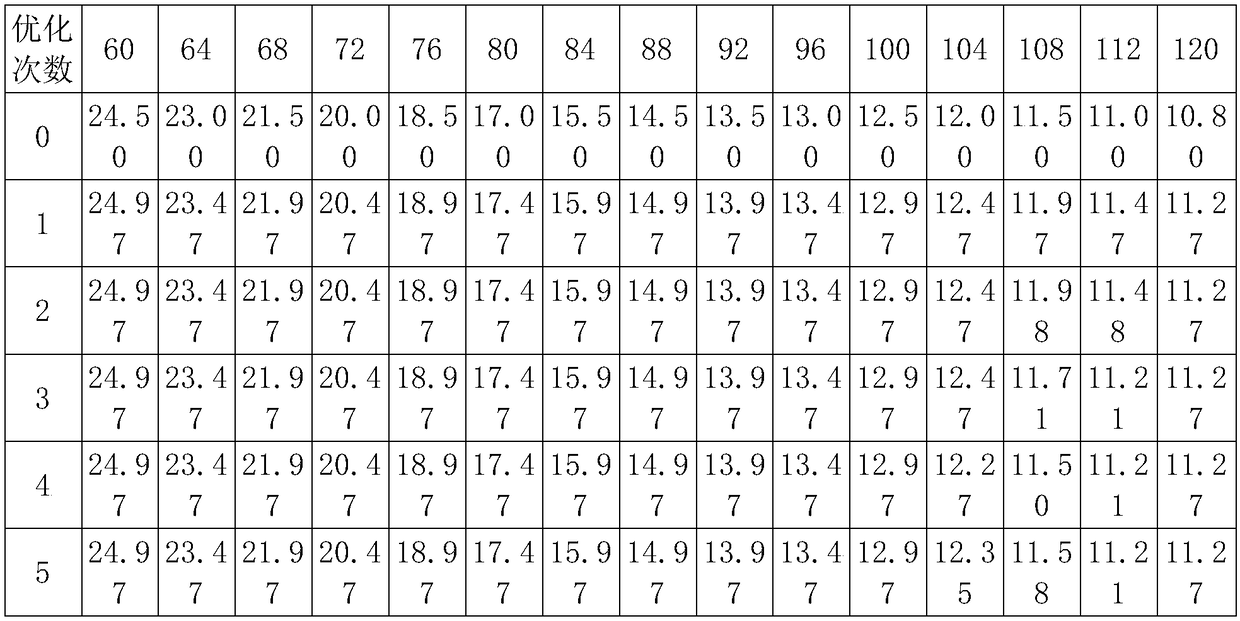

Self-correcting and self-adapting control method of water head and no-load opening degree combination curve of speed governor

ActiveCN108708818ARealize real-time self-correction and self-adaptive functionRaise the level of intelligent automationHydro energy generationMachines/enginesOriginal dataUnit speed

A self-correcting and self-adapting control method of a water head and no-load opening degree combination curve of a speed governor comprises the steps of initializing a system, and reading original data, supplied by a main machine factory, of the water head and no-load opening degree combination curve; detecting whether the unit speed governor is started for the first time; if the unit speed governor cannot enter a no-load state, automatically accumulating the no-load opening degree corresponding to a current water heat through an electric control system of the speed governor based on a certain period T and a certain step length Y until the unit speed governor can normally enter the no-load state; if the unit speed governor enters the no-load state and the unit frequency is stably close to 50Hz, recording the current water head h and the no-load opening value y; correcting a water head and no-load opening degree combination curve table for the first, and releasing the shielding to theuptime time out fault; and correcting the water head and no-load opening degree combination curve table in real time. The method aims at solving a series of unit running problems caused by unreasonable setting of the water head and no-load opening degree combination curve of the speed governor in the unit parallel operation process.

Owner:CHINA YANGTZE POWER

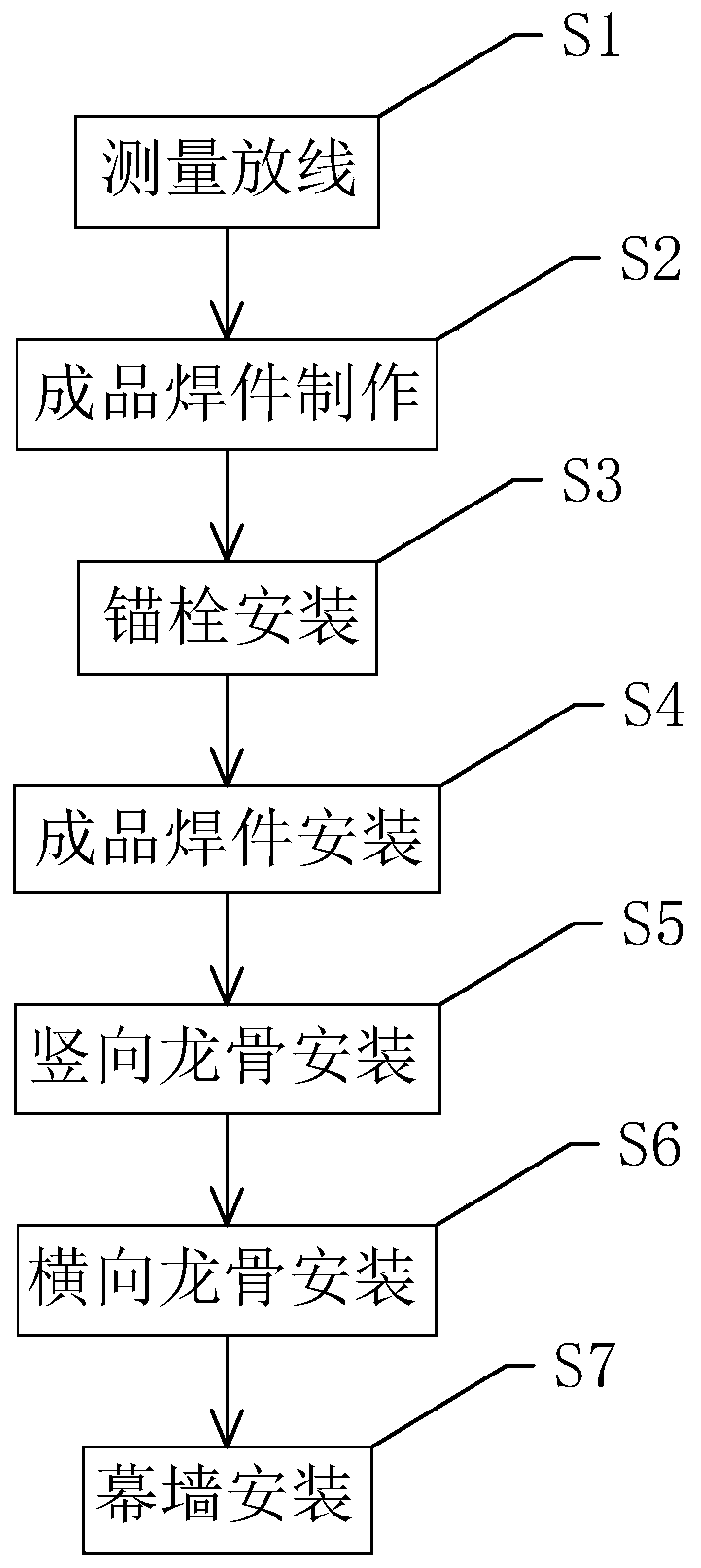

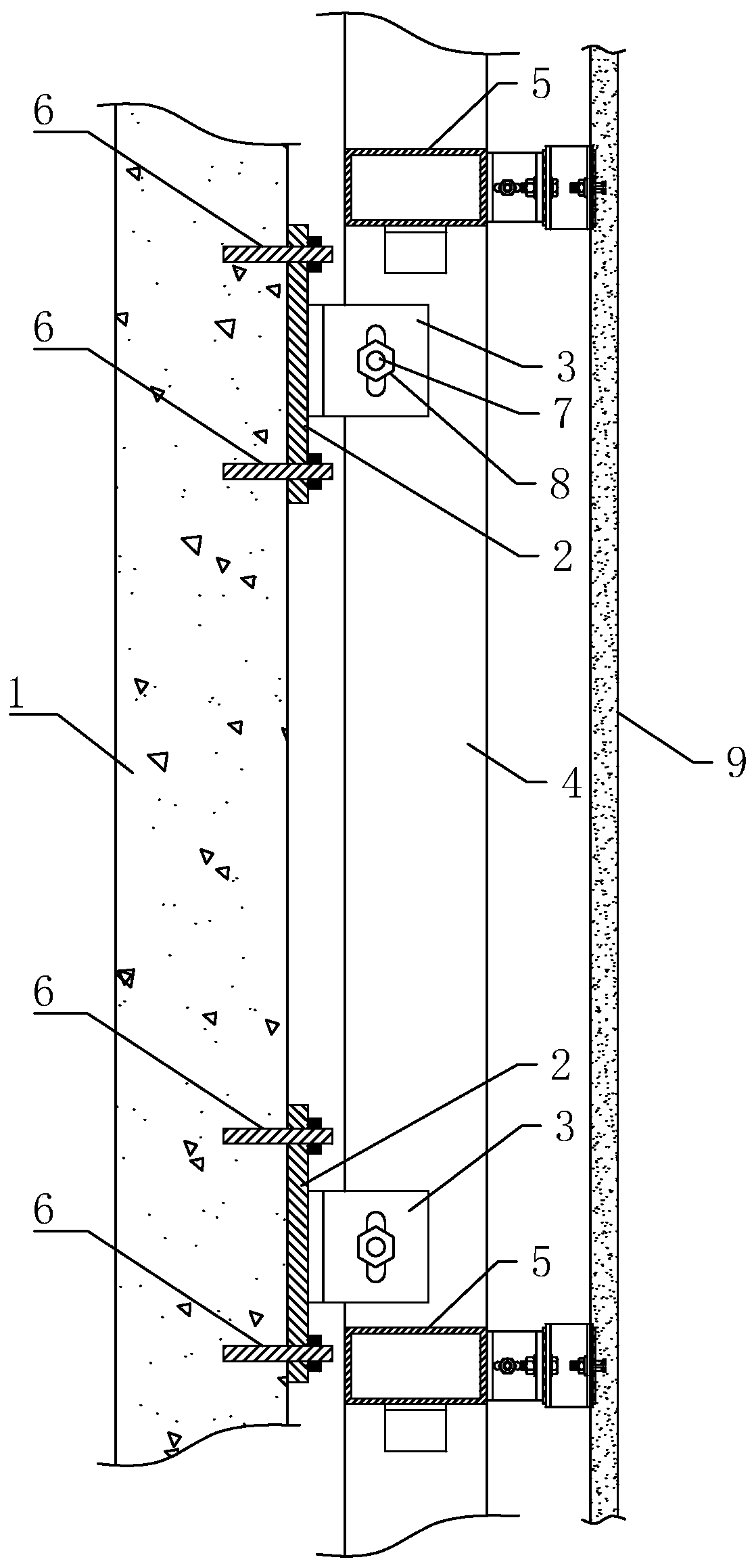

Curtain wall efficient mounting method

InactiveCN110984446AImprove installation efficiencyImprove efficiencyWallsWelding/cutting auxillary devicesKeelArchitectural engineering

The invention relates to a curtain wall efficient mounting method. The curtain wall efficient mounting method comprises the following steps that surveying and setting out are conducted, specifically,workers survey and set out axes of a building, central axes of vertical keels, horizontal lines of transverse keels and horizontal lines of finished weldments in advance; the finished weldments are manufactured, specifically, preburied plates and connecting pieces are customized, and the preburied plates and the connecting pieces are welded in advance in a machining factory or a construction siteground; anchor bolts are mounted, specifically, mounting points of the finished weldments are determined, and the anchor bolts are mounted on the mounting points of the building; the finished weldments are mounted, specifically, the preburied plates of the finished weldments are fixed to the outer surface of the building through the anchor bolts; the vertical keels are mounted, specifically, the vertical keels are fixedly mounted on the multiple sets of finished weldments located on the same central axis; the transverse keels are mounted, specifically, the transverse keels are horizontally andfixedly mounted on the two sides of the vertical keels; and a curtain wall is mounted, specifically, curtain wall face plates are mounted on the outer side faces of the corresponding transverse keels. The curtain wall efficient mounting method has the effects of high mounting efficiency, safe construction and low construction cost.

Owner:天邑昊建筑装饰工程有限公司

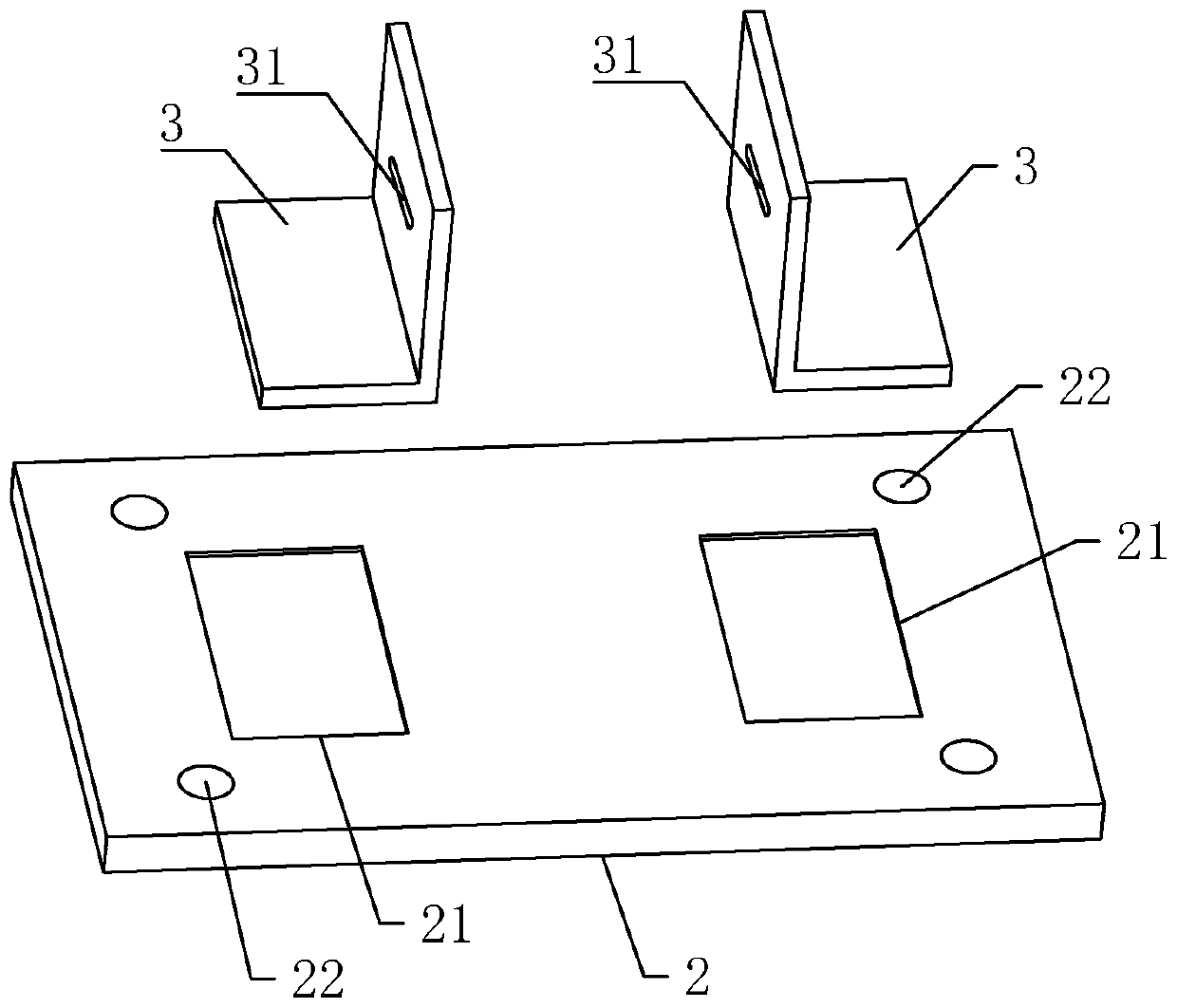

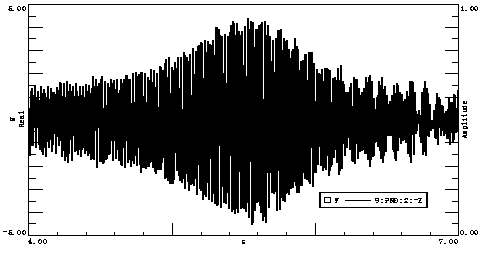

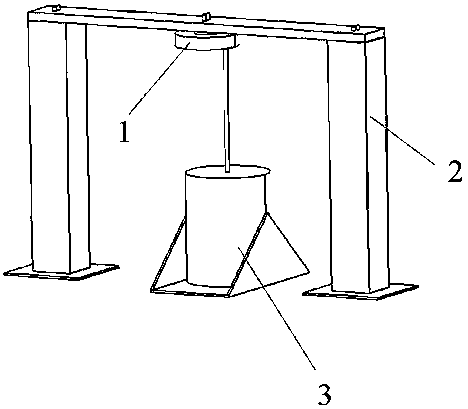

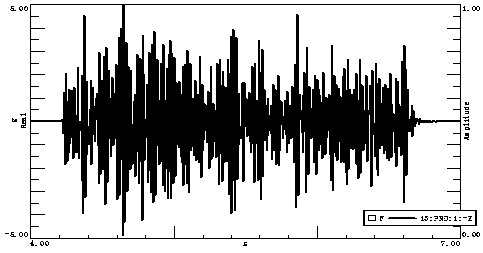

Dynamic absorber frequency testing method

ActiveCN107144435AShorten the time periodImprove R&D efficiencyVibration measurement in solidsVehicle suspension/damping testingResearch efficiencyWorking temperature

The invention relates to the vehicle NVH field and more particularly, to a dynamic absorber frequency testing method, comprising: through a temperature and an exciting force, which are boundary conditions obtained by a station frame simulating dynamic absorber on an entire vehicle accurately obtaining the absorber frequency; arranging the testing points for the station frame vibration exciter and processing the data; modulating the dynamic absorber frequency; and verifying the dynamic absorber frequency accuracy. The beneficial effects of the method proposed by the invention are as follows: 1) the method puts forward the boundary conditions that influence the dynamic absorber frequency: the magnitude of the exciting force and the working temperature; 2) through the simulation of the boundary conditions for the dynamic absorber, it is possible to test out the dynamic absorber frequency, and with the application of a simple intrinsic frequency theoretical equation, it is possible to work out a dynamic absorber that meets the frequency requirement; and 3) with the method, the time period taken by a vehicle main machine factory to test and develop the dynamic absorber can be shortened and the research efficiency for the dynamic absorber is raised.

Owner:JIANGLING MOTORS

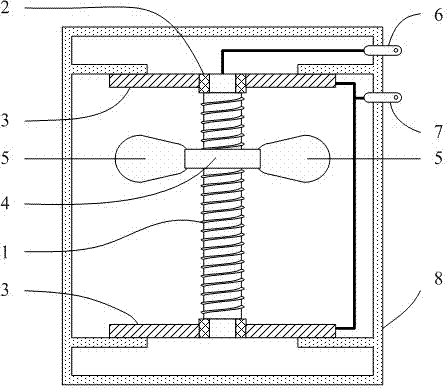

Mechanical delay switch

InactiveCN103681028ARealize the function of delay controlSimple structureElectric switchesEngineeringMachining

The invention provides a mechanical delay switch. The mechanical delay switch comprises a screw rod and two base plates which are fixedly installed at the two ends of the screw rod through insulating pieces, and the screw rod and the base plates are made of electric conduction materials. The screw rod is in threaded connection with a nut piece, at least two balance weight pieces with the same weight are fixedly arranged on the outer side of the nut piece, the balance weight pieces are evenly distributed in the horizontal circumference direction, and the nut piece can freely slide downwards in a rotating mode on the screw rod through the gravity of the balance weight pieces. The balance weight pieces and the nut piece are made of electric conduction materials, the balance weight pieces are conducted with the screw rod through the nut piece, and when the nut piece rotates to the end of the screw rod, the balance weight pieces can make contact with the base plates at the ends of the screw rod. One end of the screw rod is electrically connected to a first output electrode. The two base plates are connected in parallel through a wire and then electrically connected to a second output electrode. The mechanical delay switch is simple in structure, all components of the mechanical delay switch can be produced in a machining mode, and the mechanical delay switch is suitable for being produced and manufactured in machining factories.

Owner:重庆市合川区何茗机械加工厂

Method for assembling large-span steel frame by utilizing temporary supporting bed jig

InactiveCN110924693AAvoid installationReduce security risksBuilding material handlingSteel frameLong span

The invention discloses a method for assembling a large-span steel frame by utilizing a temporary supporting bed jig, and belongs to the technical field of steel structure frame assembly. The temporary bed jig is arranged on the middle position of the large-span steel frame; the height of the temporary bed jig is the same as the bottom elevation of the frame; the frame is manufactured into two sections in a machining factory and the two sections are conveyed to the site for assembly; then the two sections of the frame are assembled by utilizing a crane; then the two sections of the frame are welded and fixed on the temporary supporting bed jig; then the temporary supporting bed jig is disassembled; and the large-span steel frame is assembled. The method has the advantages that the method is simple and easy to operate; midair single part assembly of frame supporting rod components is avoided, so that safety hazard is greatly lowered; meanwhile, assembly time is saved; labor and materials are saved; and construction cost is lowered.

Owner:BEIJING SHOUGANG CONSTR GROUP

System with electric welding machine capable of getting access to Internet

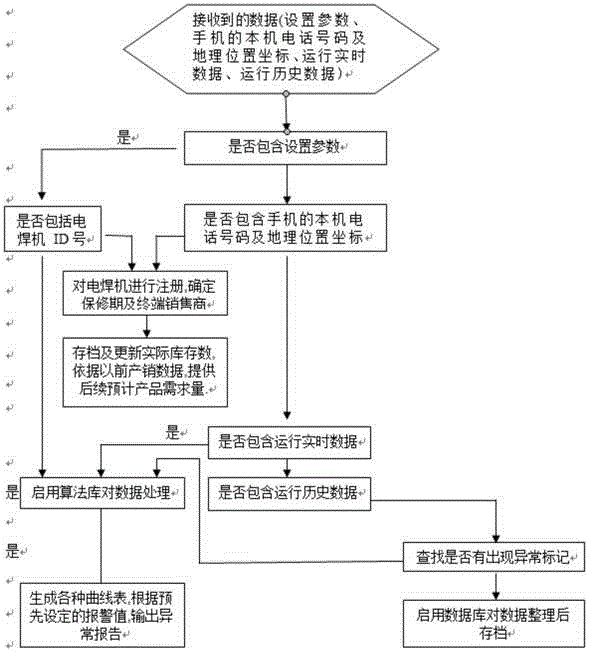

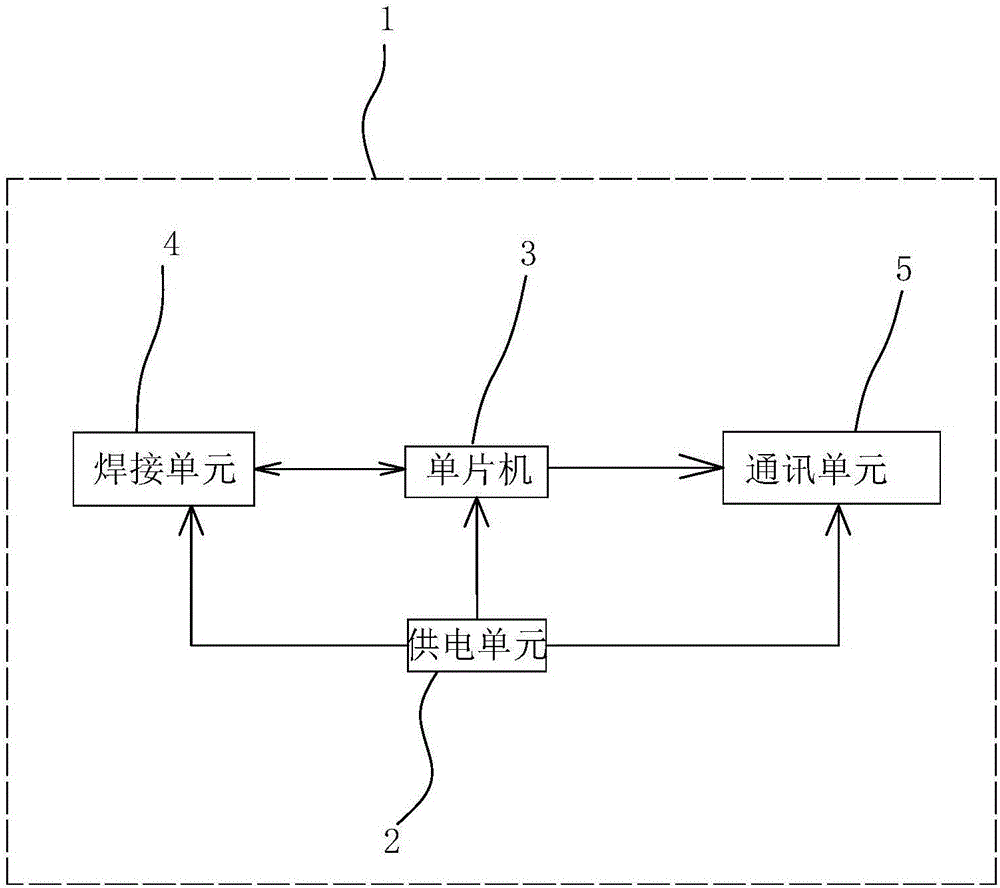

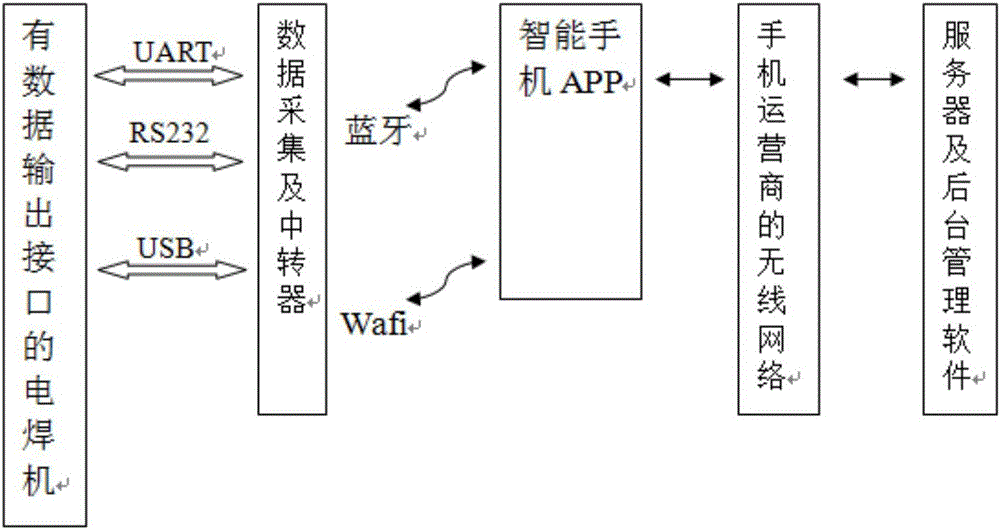

InactiveCN105867244AImprove service experienceImprove user experienceProgramme controlComputer controlThe InternetSoftware engineering

The invention discloses a system with an electric welding machine that can be connected to the Internet, including a smart phone capable of running APP software, a server and background management software, and an electric welding machine with a communication unit and a data communication interface. And the relay device is connected with the APP software of the smart phone, and all the real-time data, historical data, and setting parameters of the welding machine are sent to the smart phone through data collection and the transfer device, and the smart phone communicates with the server and the background management software through the wireless network connect. The present invention can perform data monitoring, remote fault diagnosis, and software upgrade for any number of electric welding machines, provide better service and user experience for electric welding machine users, and provide electric welding machine manufacturers with improved product quality and big data management for production and sales. Great solution.

Owner:上海希汉智能电气有限公司

Modified polypropylene material for soft freezing layer drawer of refrigerator

InactiveCN109233095AImprove aging resistanceImprove processing fluidityEnvironmental resistancePolyolefin

The invention relates to a polypropylene material, and in particular relates to a modified polypropylene material for a soft freezing layer drawer of a refrigerator. The modified polypropylene material which is capable of replacing a conventional material, namely polyolefin, is prepared through physical commixing modification by adopting a polyolefin material with relatively low price, inorganic minerals, functional aids and the like; the modified polypropylene material is non-toxic and environmentally-friendly, good in processing flowability, excellent in mechanical property and good in low-temperature impact resistance, has a molding shrinkage rate being equivalent to that of ABS (Acrylonitrile Butadiene Styrene) or HIPS (High Impact Polystyrene), and can replace ABS or HIPS to be moldedinto products that meet the requirements of a main machine factory under the condition that sizes of injection molds are not changed; as the modified polypropylene material has no unsaturated doublebond, the aging resistance of the material is higher than that of ABS or HIPS; due to the adoption of the polyolefin material with low cost and a large amount of inorganic minerals for filling, the comprehensive cost of the modified polypropylene material is reduced by 10-15% compared with that of the conventional ABS and HIPS, and great economic benefits can be made.

Owner:JIANGSU KAINUO PLASTICS

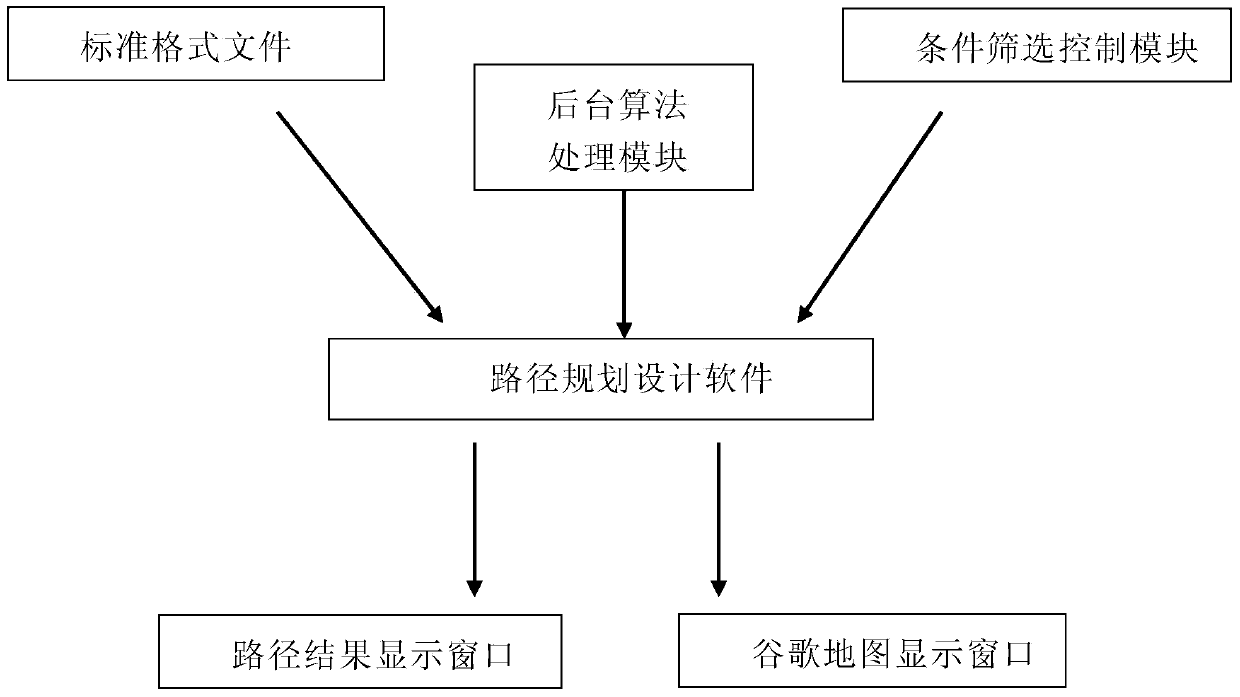

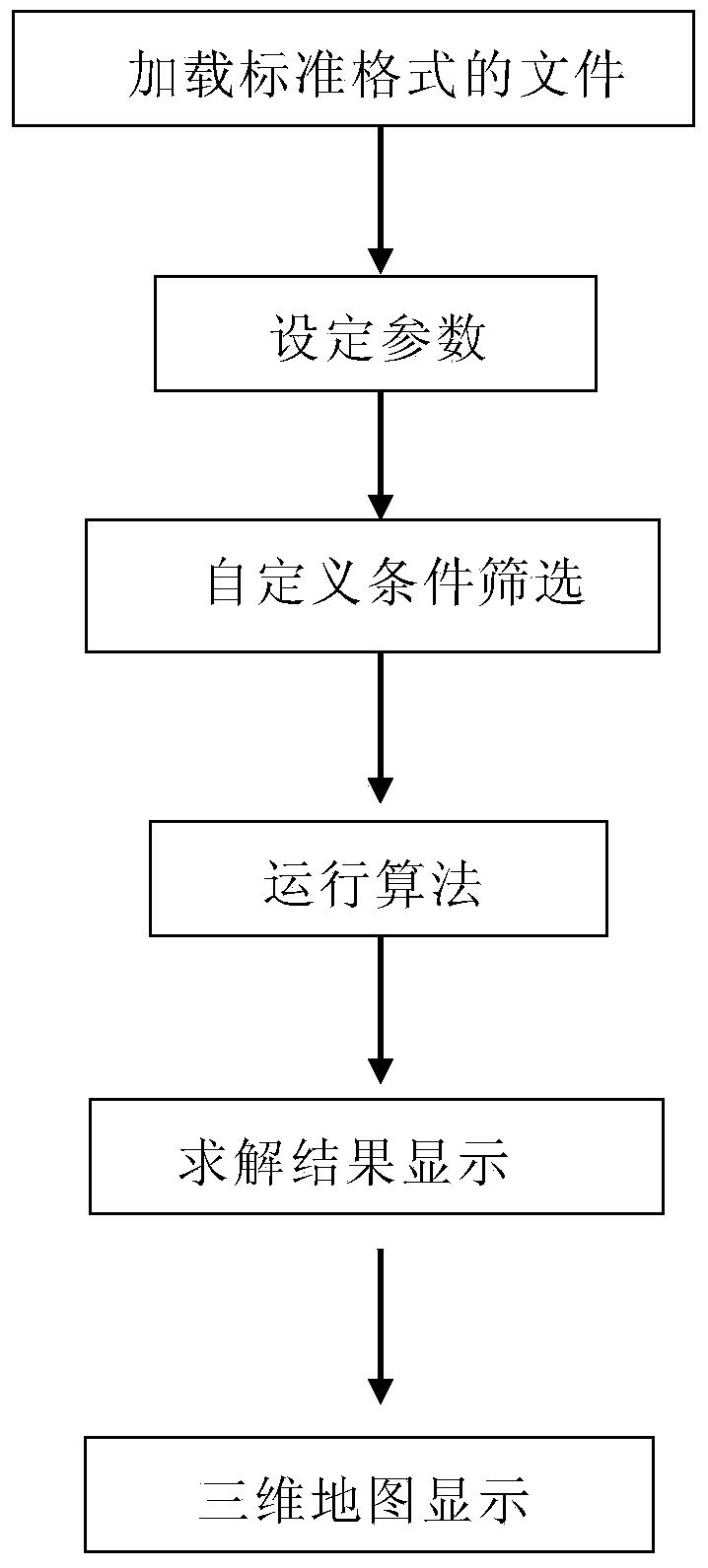

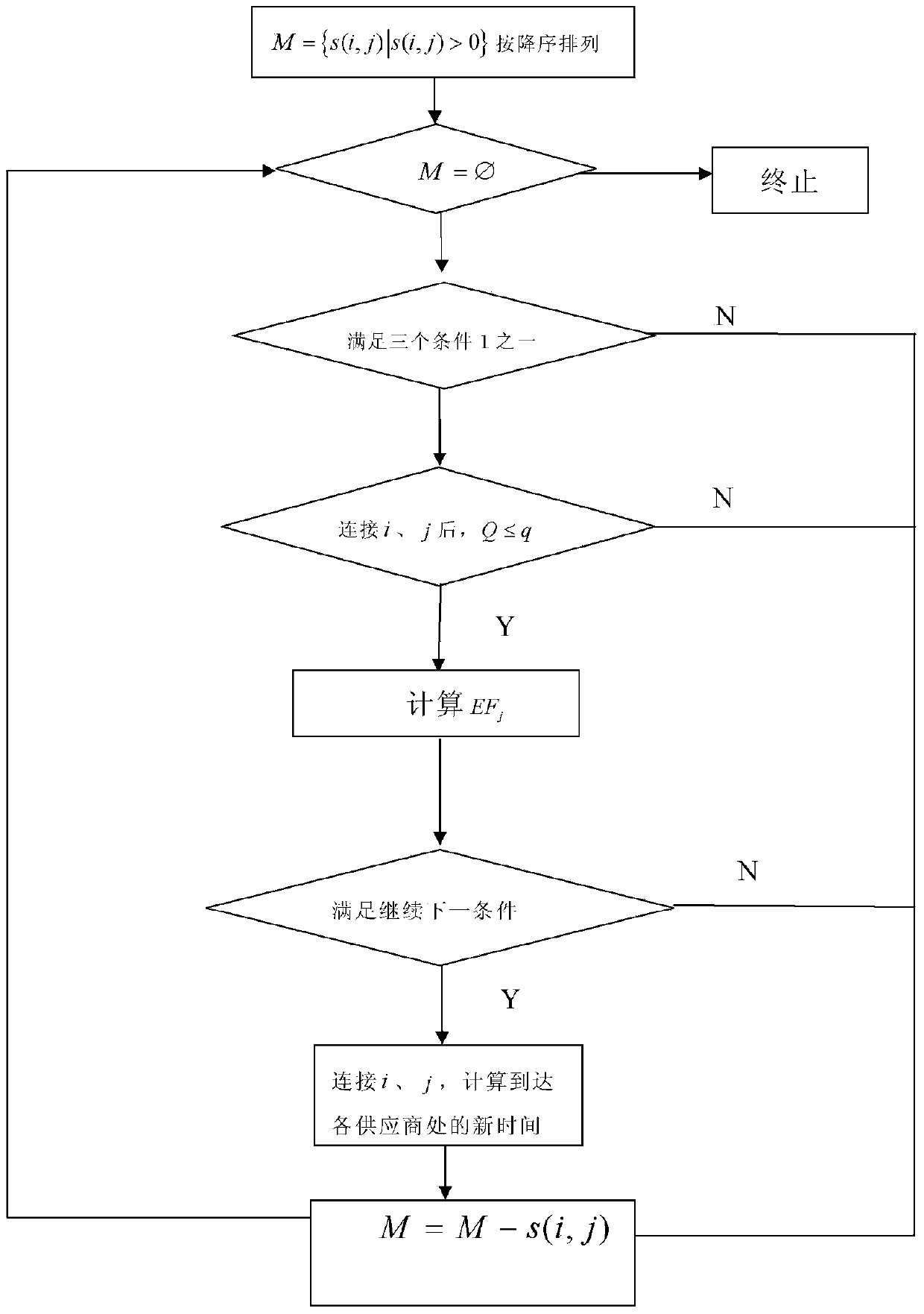

Comprehensive planning method for paths of vehicles for picking up goods

InactiveCN103745021AHigh precisionIncrease load rateSpecial data processing applicationsImproved algorithmTransport engineering

Provided is a comprehensive planning method for paths of vehicles for picking up goods. The method includes the steps that an improved C-W path planning algorithm is improved based on introduction of time windows and vehicle types as restriction, suppliers are selected according to constraint conditions of the distance between the suppliers and a main machine factory and the frequency for picking up the goods, carrying out solution by using the improved C-W algorithm to obtain corresponding planning paths and corresponding loading rates of the vehicles, and a proper type of vehicles can be selected to transport the goods according to the solving results. According to the comprehensive planning method, complete and visualized path planning software can be developed, and the paths can be displayed in Google maps through the API technology, and transportation management personnel and drivers of enterprises can conveniently use the comprehensive planning method.

Owner:SHAANXI UNIV OF SCI & TECH

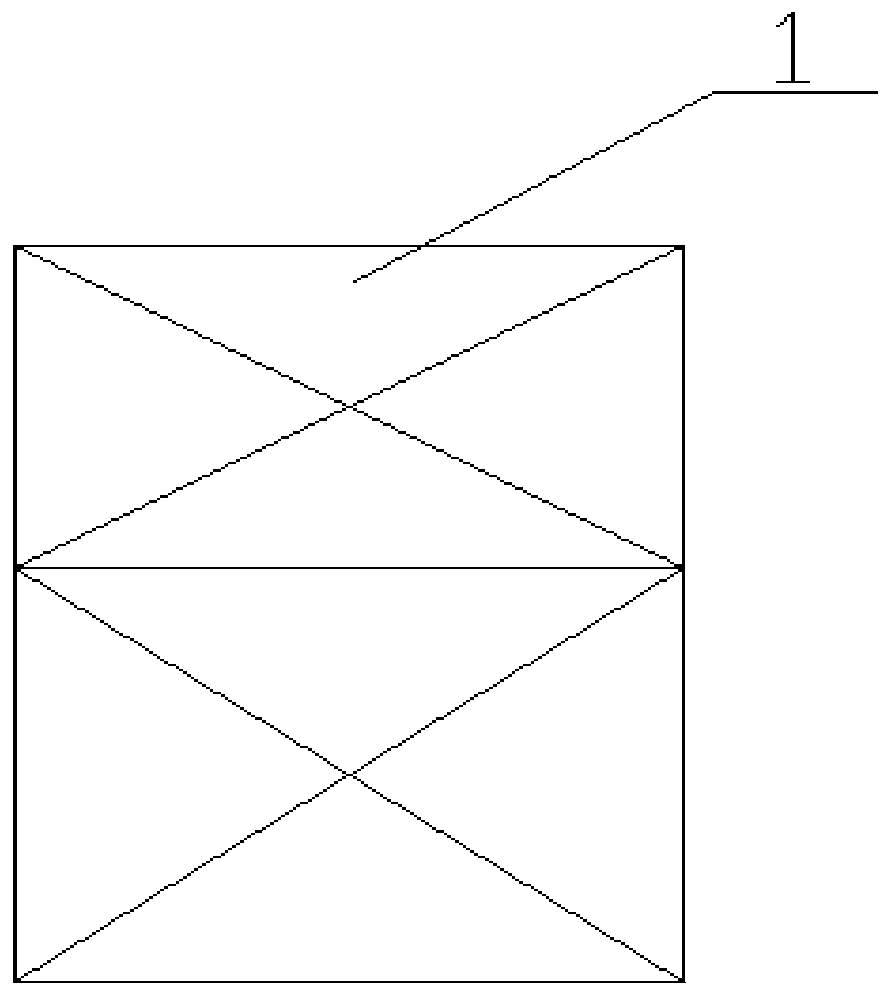

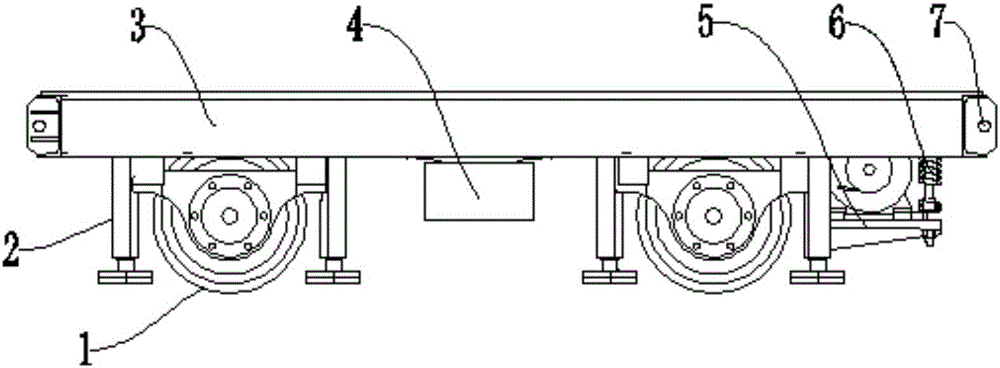

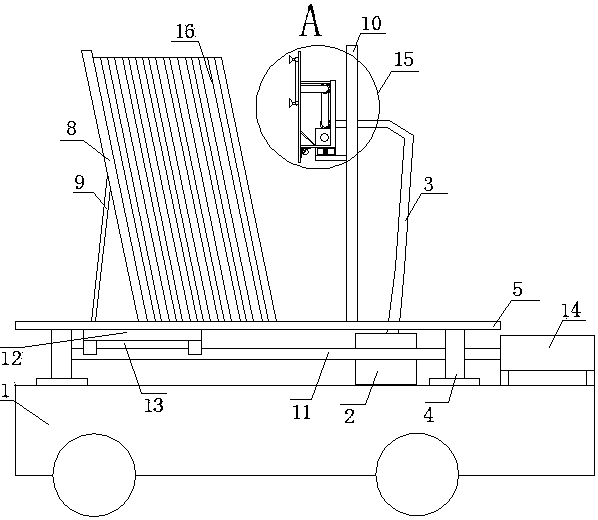

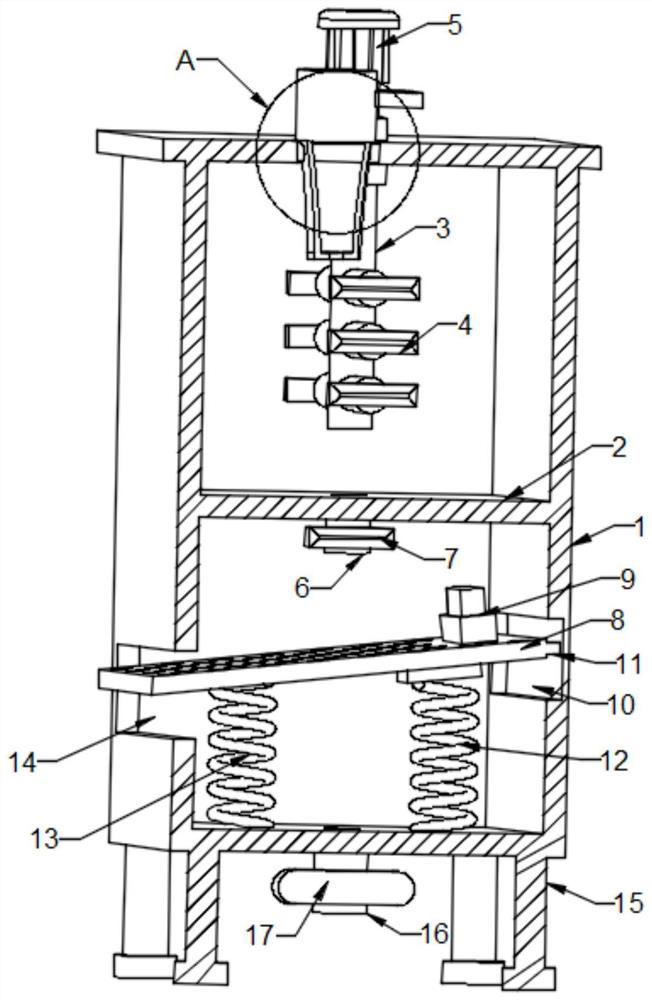

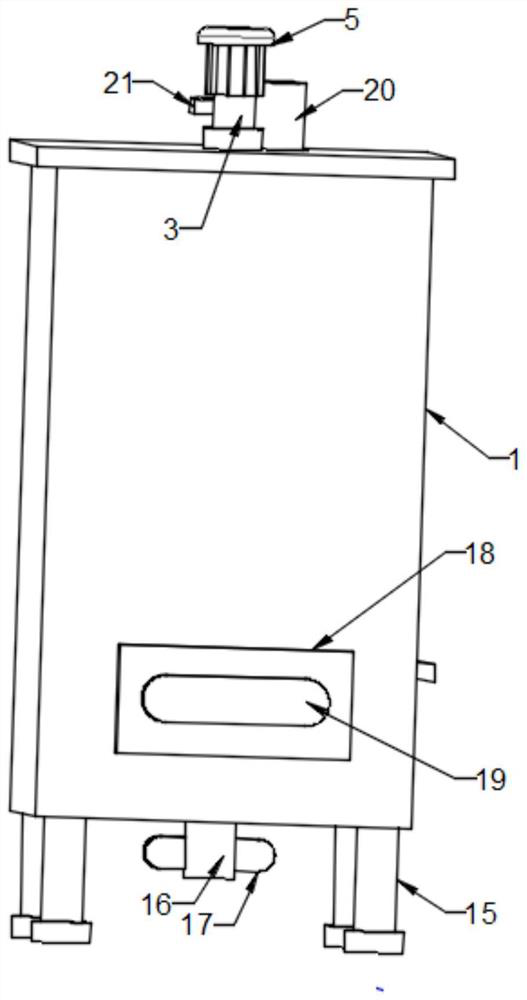

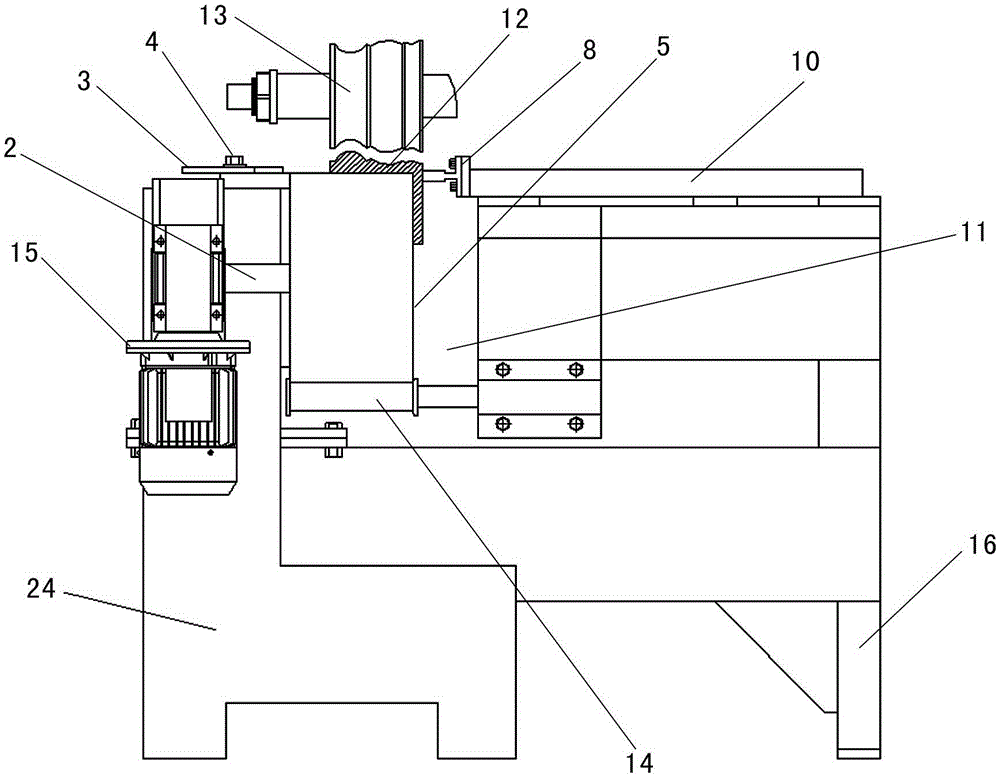

Multifunctional iron scrap cleaning device used for machining factory

InactiveCN106115137AImprove cleaning efficiencyImprove transportation efficiencyRefuse gatheringWireless controlVehicle frame

The invention discloses a multifunctional iron chip cleaning device for mechanical processing factories, which comprises a vehicle frame, an intelligent controller, an electromagnetic sucker, and a hydraulic lifter. Traction chucks are arranged at both ends of the vehicle frame. There is a battery box, the intelligent controller is installed on the upper side of the vehicle frame, control buttons are arranged on the intelligent controller, a wireless receiver is installed on the upper side of the vehicle frame, and a A motor base, a spring shock absorber is installed on the motor base, a motor is installed above the motor base, a governor is installed above the vehicle frame, a rotating shaft is installed on the vehicle frame, and the two ends of the rotating shaft are installed There are wheels, a manual brake lever is installed on one side of the vehicle frame, and the hydraulic lifter is installed below the vehicle frame. The beneficial effect is that: the invention integrates the functions of iron filings cleaning and workpiece conveying, can be controlled wirelessly, is convenient to use, and improves the cleaning and transportation efficiency of iron filings.

Owner:SUQIAN HUAIHAI TECH SERVICES

Method for manufacturing eccentric ring in profiling method

The invention discloses a method for manufacturing an eccentric ring in a profiling method. After the installation of an upper assembly and a lower assembly is subjected to inspection, eccentric areas of the upper and lower assemblies are blown and cleaned, the upper assembly falls back to the lower assembly under the action of a synchronous hydraulic jack, so that the upper assembly and the lower assembly are aligned to each other, and an eccentric ring model can be manufactured after the alignment meets design requirements; gypsum slurry is injected to the position of the eccentric ring to form a gypsum model; after the gypsum model is hardened, the upper assembly is raised by the synchronous hydraulic jack; a mark is made on the gypsum model corresponding to the lower assembly, and the upper and lower assemblies are taken out for trial assembly; and the model can be delivered to a machining factory after meeting the requirements, and then the eccentric ring is machined by a profiling machine tool. The method is simple and feasible, and the accuracy of the manufactured eccentric ring is high.

Owner:MCC TIANGONG GROUP

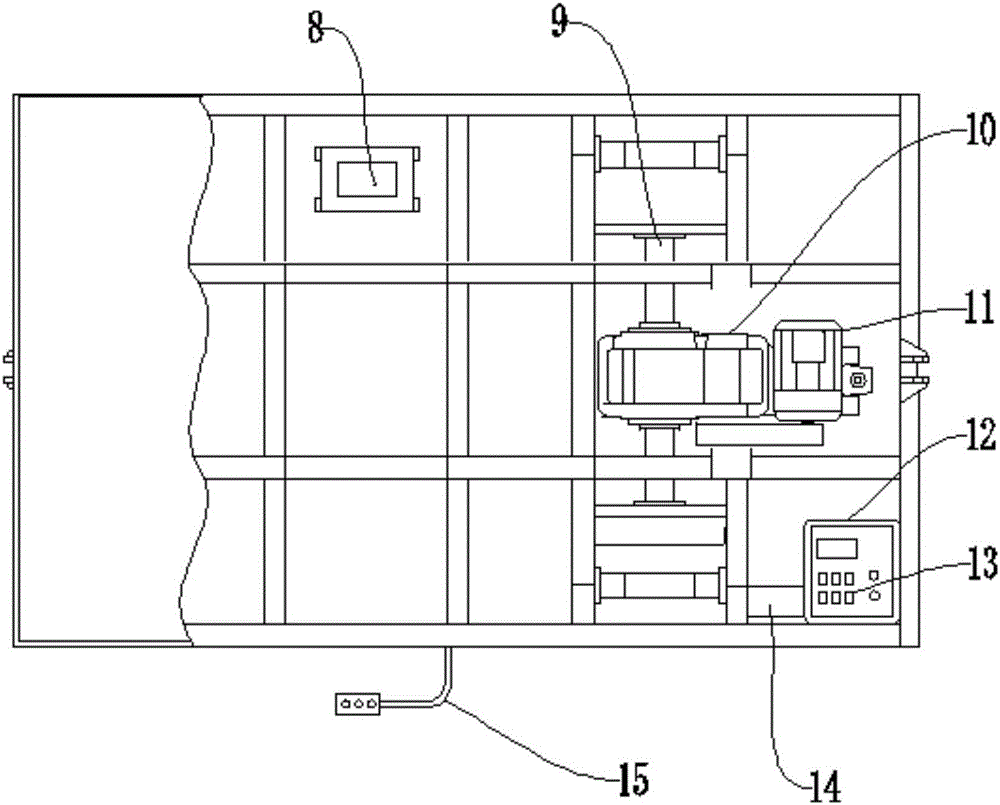

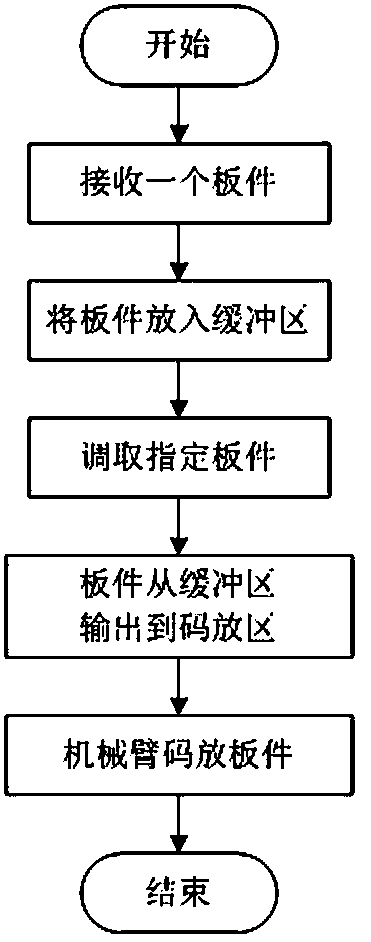

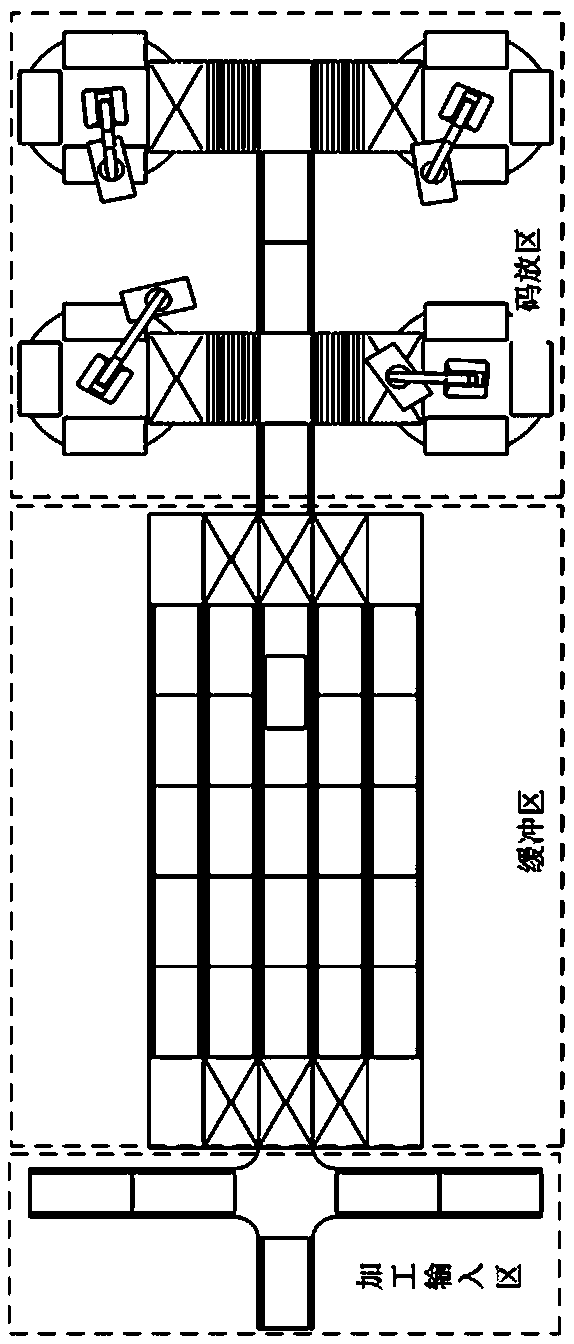

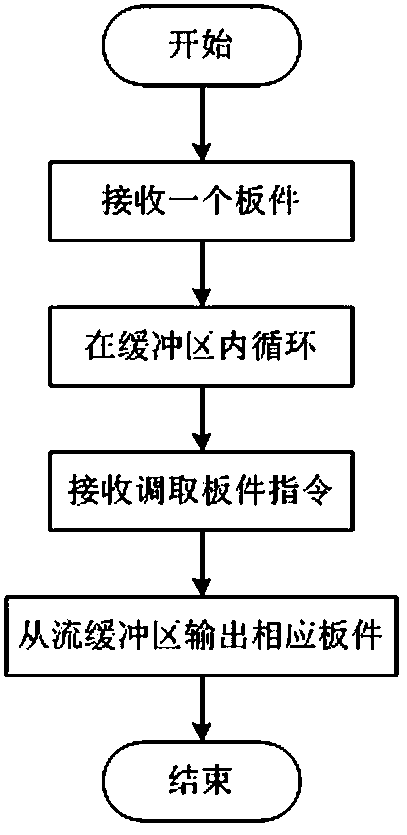

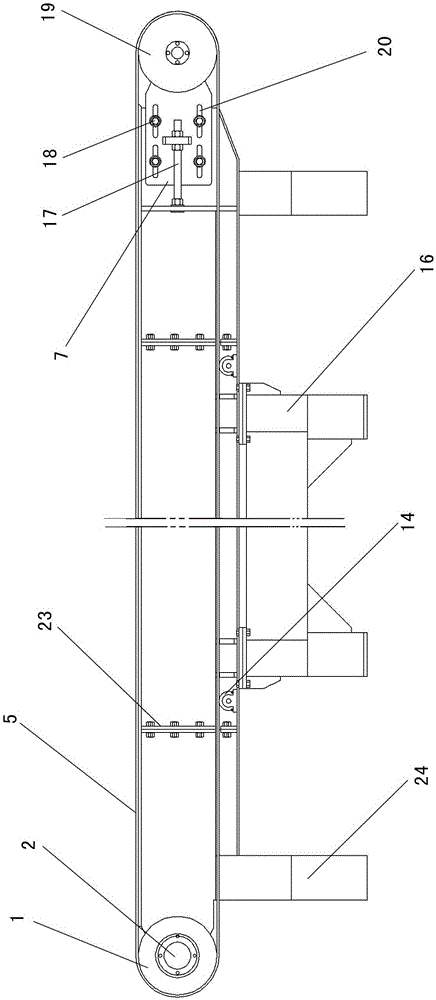

Special-shaped furniture board stacking method

InactiveCN109436813AEffective classificationFast and efficient stackingStacking articlesEngineeringProcess plant

The invention discloses a special-shaped furniture board stacking method. The method divides a stacking flow line into three areas, namely the input area, the buffer area and the stacking area. The input area is connected with a machining area; workers place machined boards on the flow line in the input area; the buffer area is used for buffering the boards from the input area; and the stacking area dynamically plans subsequent stacking of the boards according to the information of the boards in the buffer area and the stacking conditions. The special-shaped furniture board stacking method realizes stacking of special-shaped furniture boards randomly input, can be applied to a furniture machining factory, realizes quick and effective classification and stacking of multiple sets of furniture, provides convenience for subsequent box sealing, loading and transportation, greatly reduces the place needed to stack the boards in the furniture factory, realizes real-time generation, real-timeclassification and real-time stacking, and improves the working efficiency of the furniture factory.

Owner:CSSC MARINE POWER

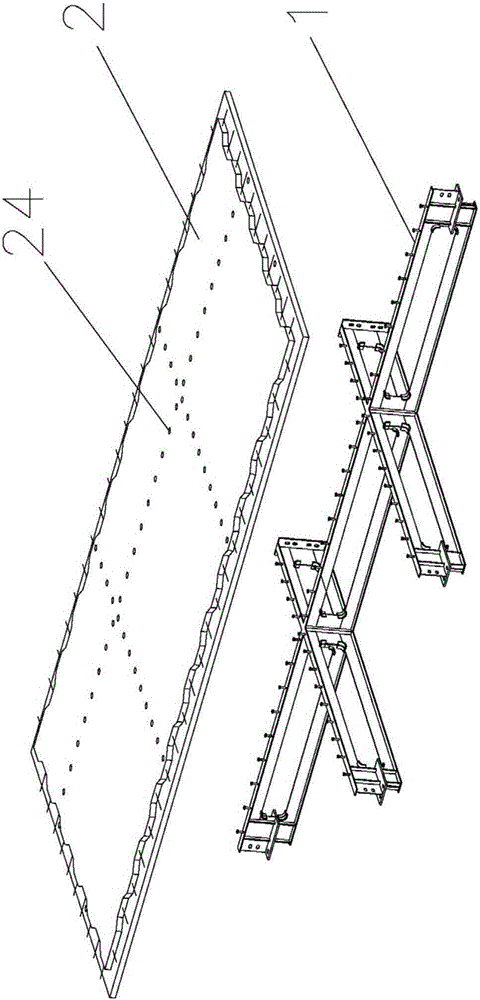

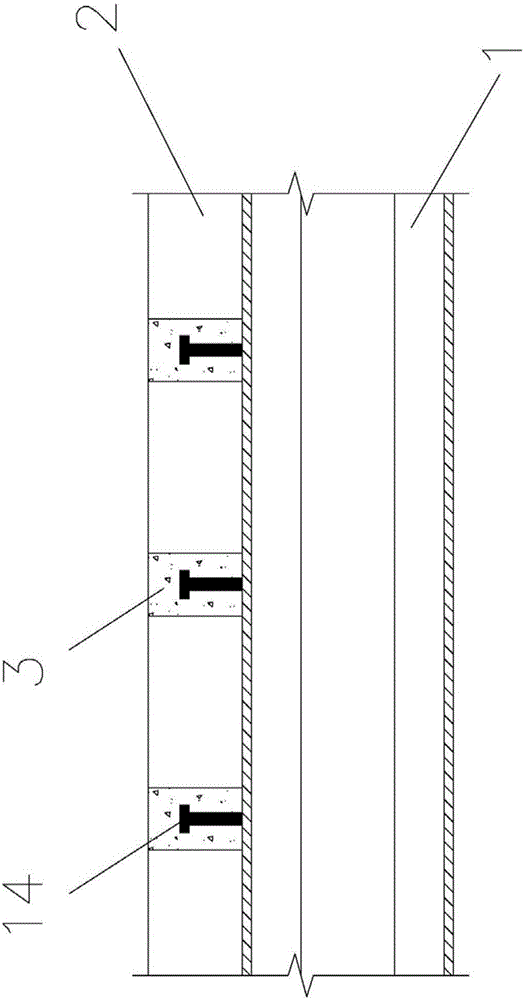

Fabricated floor structure module and manufacturing method thereof

The invention relates to a fabricated floor structure module and a manufacturing method thereof. The fabricated floor structure module comprises an open web steel truss, a prefabricated partial composite floor slab and micro-expansive concrete, wherein a plurality of anti-shear studs are arranged on the upper surface of the open web steel truss; the prefabricated partial composite floor slab is supported by the open web steel truss, and a plurality of through holes are formed in the prefabricated partial composite floor slab in a penetration mode; the anti-shear studs are inserted into the through holes of the prefabricated partial composite floor slab; the through holes are filled with the micro-expansive concrete, and the anti-shear studs are buried by the micro-expansive concrete. The environment problem caused by erecting a formwork for concrete floor slab pouring in a steel structure machining factory is avoided, and the concrete floor slab and the open web steel truss can be prefabricated and transported separately, so that transport weight is reduced; meanwhile, through effective construction, the integrity of the prefabricated floor slab can be ensured, and the fabricated construction technology is convenient to use and environmentally friendly.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

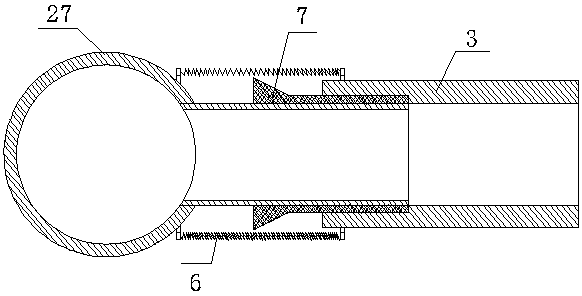

Sheet airing machine

InactiveCN108278864ALow costLabor savingDrying solid materialsDrying machines with local agitationFixed frameWood machining

The invention relates to a sheet airing machine. The sheet airing machine comprises a trolley. Thin wood sheets needing to be aired are placed on the trolley, and the trolley is provided with an exhaust fan, an air suction hose, a base support, a base plate, sliding wheels, a transverse plate, an inclined plate, an inclined plate supporting rod, a vertical beam, a threaded rod, a threaded base, athreaded connecting piece, a motor and a thin plate sucking and moving device. The vertical beam is fixed to the base plate, and the thin plate sucking and moving device is arranged on the vertical beam. The tail of the air suction hose is connected with the thin plate sucking and moving device. The thin plate sucking and moving device comprises a groove steel strip, a transverse outlet beam, a cylinder, a bending frame, an inserting groove plate, a spring clamping sheet, a rubber suction head, an air pipe, a fixing frame plate and a bounce preventing ejector piece. The sheet airing machine issuitable for being used by a wood machining factory, low in cost and capable of saving labor force.

Owner:韦汉宇

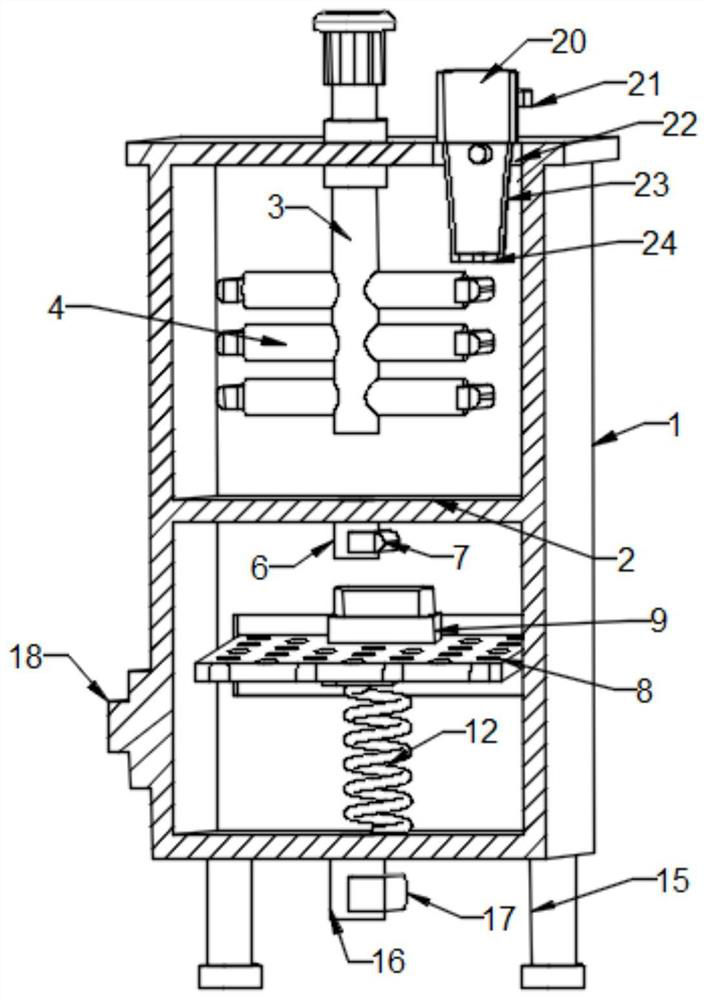

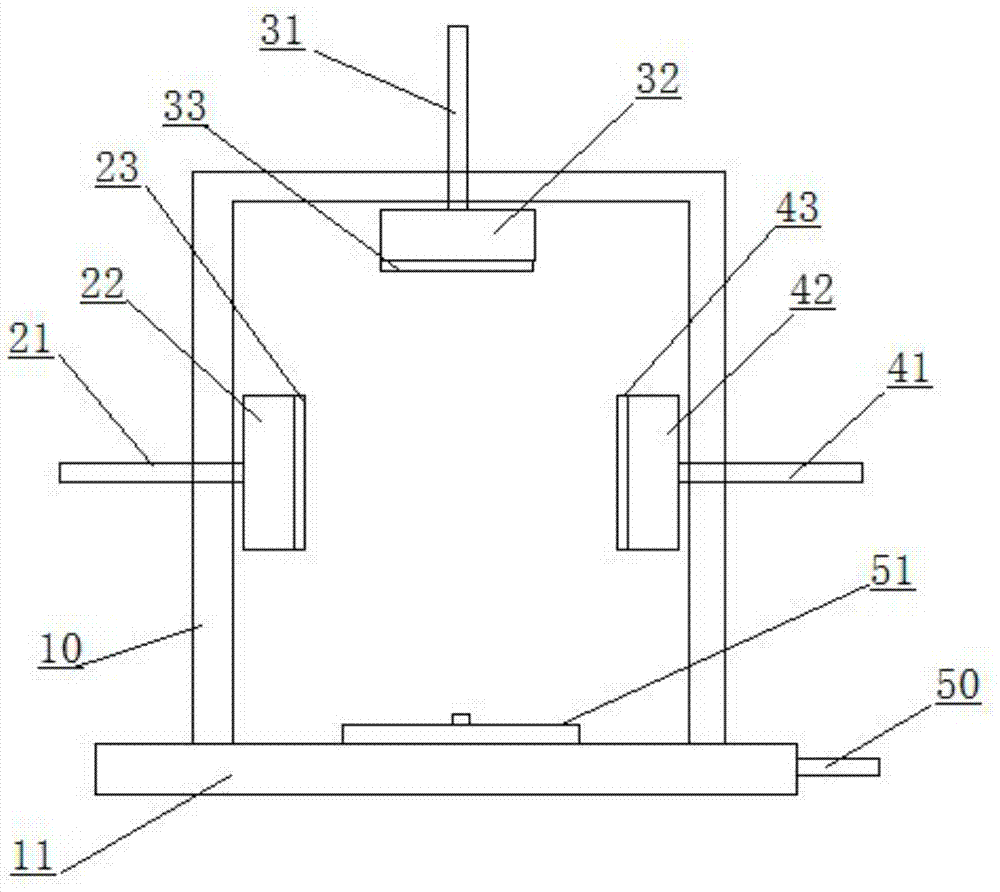

Stirring device suitable for machining lubricating oil stirring

InactiveCN112619479AImprove flowReduce viscosityRotary stirring mixersTransportation and packagingOil canThermodynamics

The invention relates to the technical field of lubricating oil stirring, in particular to a stirring device suitable for machining lubricating oil stirring, and solves he problems that in the prior art, a stirring mode wastes time and labor, the phenomenon of uneven stirring is likely to occur, and meanwhile, after lubricating oil is opened, impurities enter lubricating oil in a machining factory, and the normal use of the lubricating oil is influenced if the impurities are not filtered and removed. A stirring device suitable for machining lubricating oil stirring comprises a box body, a partition plate is arranged in the middle of an inner cavity of the box body, the outer wall of the partition plate is fixedly connected with the inner wall of the box body, and a driving motor is fixedly connected to the top of the box body through bolts. Primary filtering is conducted on lubricating oil before stirring through a funnel, the viscosity of the lubricating oil is reduced, meanwhile, the problem that in the prior art, time and labor are wasted when manual stirring is adopted is solved, the stirred lubricating oil is filtered through vibration of a filter plate, and the lubricating oil can be mixed again to reduce the viscosity.

Owner:YIWU INDAL & COMMERICAL COLLEGE

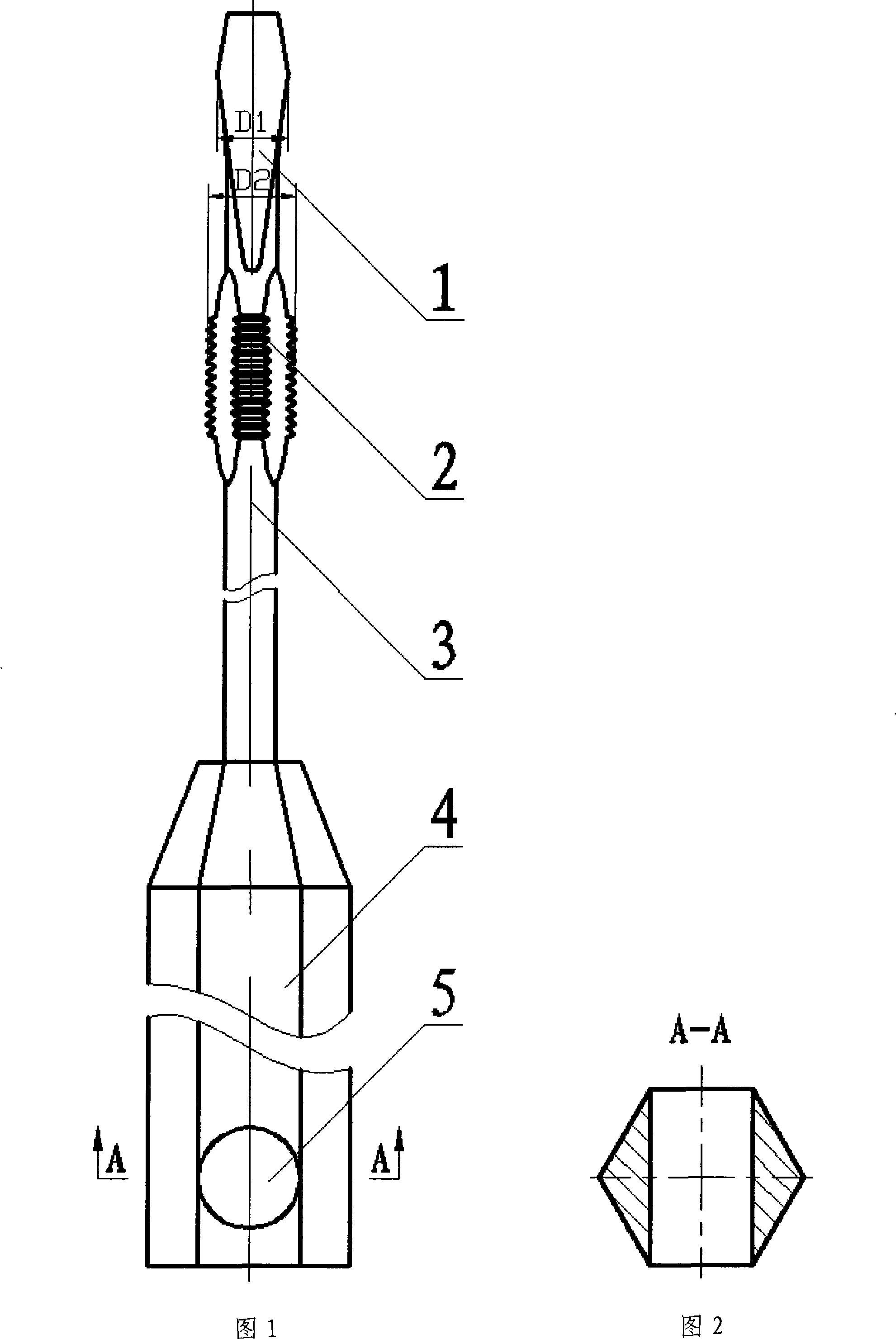

Screw rotating tool

InactiveCN101249645AReasonable designSimple structureThread cutting machinesSpannersEngineeringHardware tool

The invention discloses a screwdriver which can tap the hole, belonging to the field of hardware tools. At present, screwdriver and screw tap are hardware which is often used in machining factory. However, problems such as strong pertinence of operation object and weak universality and single function exists in the prior hardware. The screwdriver aims to provide a screwdriver which has the function of screw tap by arranging screw tap cutting head 2 on the rotating rod 3 of the screwdriver to realize the goal of multifunction. To have better function, the rotating handle of the screwdriver is provided with a force applying device. The screwdriver has the advantages of rational design, simple structure and convenient use, thus being applicable to various machining places.

Owner:韦继翀 +1

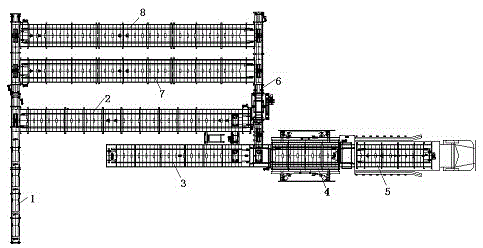

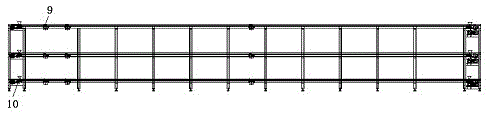

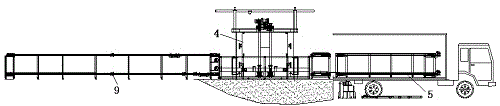

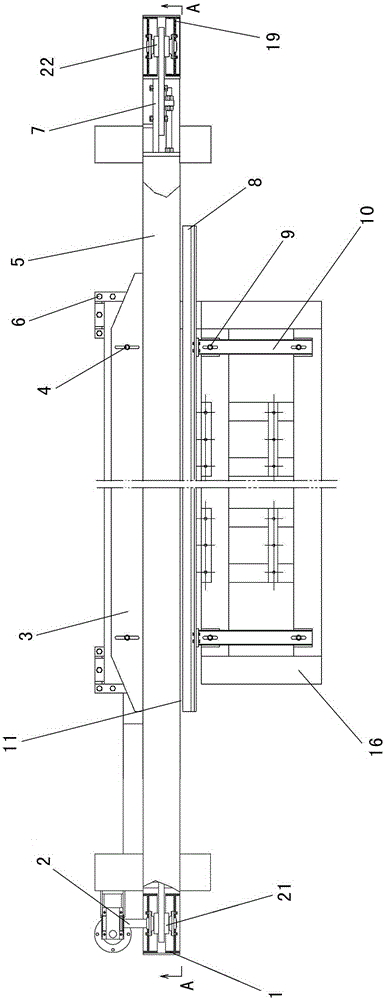

Multilayer storage and transport assembly line

InactiveCN105460476AReduce in quantityIncrease productivityStorage devicesAssembly lineIndustrial engineering

The invention discloses a multilayer storage and transport assembly line and belongs to the field of transport assembly lines. The multilayer storage and transport assembly line comprises a loading region and a transport channel and further comprises a temporary storage region, a joint region and a tray storage region. One end of the transport channel is fixedly connected with the tray storage region, the other end of the transport channel is fixedly connected with the temporary storage region, the transport channel is perpendicular to the tray storage region, and the loading region is connected with the temporary storage region through the joint region. By the adoption of the technical scheme, the number of operators can be reduced in the main machine factory goods supply process, storage design is performed through the multilayer structure of the transport assembly line, the area of a workshop is reasonably used, the production efficiency of a whole workshop is improved, and therefore part production cost and whole workshop production cost are reduced.

Owner:WUHU HENGXIN AUTO INTERIOR TRIM COMPANY

Dual-purpose continuous grinding machine for planar and angular stone lines

ActiveCN106808344AImprove processing efficiencyLow costGrinding machinesGrinding feedersDrive wheelDual purpose

The invention belongs to the technical field of stone machining machinery and particularly relates to a continuous grinding machine which is capable of grinding both planar and angular stone lines. For improvement, an angular stone positioning backup plate is arranged opposite to a planar grinding adjustment backup plate of a conveying belt, and a drooping gap is reserved between the angular stone positioning backup plate; a driven wheel is provided with a tensioning mechanism, and rotary bearings of a driving wheel and the driven wheel are positioned between upper and lower portions of the conveying belt. The continuous grinding machine is simple in structure, low in cost, capable of grinding both planar and angular stone lines and suitable for different demands of stone machining factories.

Owner:保文明

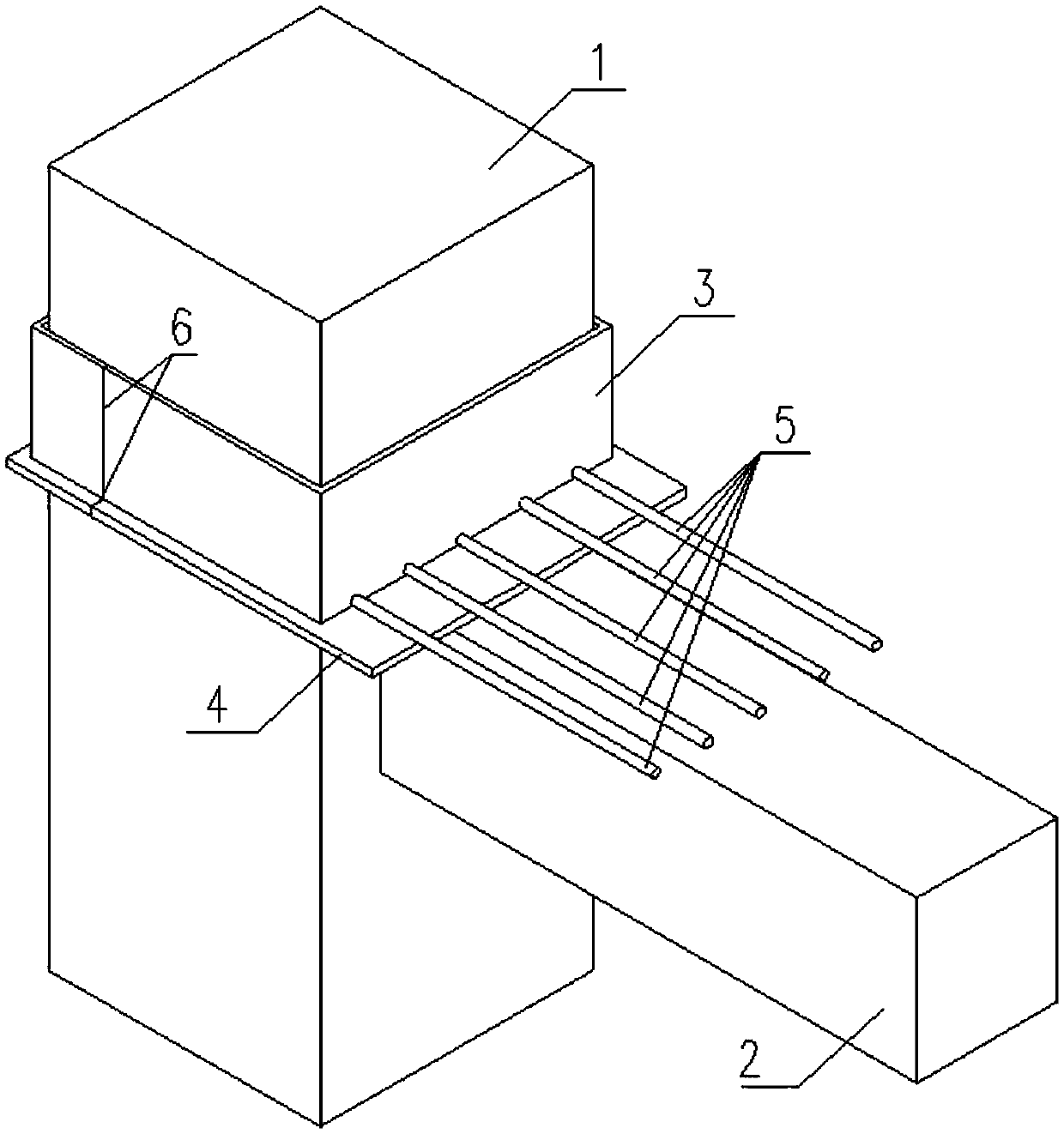

Steel joint for reinforcing and anchoring concrete beam and anchoring method

InactiveCN109537930AReduce productionReduce installation difficultyBuilding repairsConcrete beamsElement analysis

The invention discloses a steel joint for reinforcing and anchoring a concrete beam. The steel joint comprises a concrete column of an original structure and the to-be-reinforced beam, the concrete column of the original structure is sleeved with a horizontal ring plate and a ring hoop plate, the ring hoop plate is arranged on the horizontal ring plate, one end of the horizontal ring plate is located on the to-be-reinforced beam, and a plurality of newly-arranged longitudinal reinforcing steel bars are connected to the side, close to the to-be-reinforced beam, of the ring hoop plate. The invention further discloses an anchoring method of the steel joint for reinforcing and anchoring the concrete beam. The method comprises the steps of determining the sizes of the outer profiles of the ringhoop plate and the horizontal ring plate; determining the strength grade and thickness of steel of the ring hoop plate and the horizontal ring plate; establishing a finite element analysis model of the steel joint; producing the steel joint in a machining factory, reserving two splicing welding joints, and conducting welding after on-site splicing is completed; splicing and welding the steel joint on site, and pouring structural glue between the steel joint and the concrete column of the original structure. By means of the steel joint for reinforcing and anchoring the concrete beam and the anchoring method, the construction is convenient, the newly-arranged longitudinal reinforcing steel bars are stably anchored, the damage to the original structure is small, and the applicability is high.

Owner:BEIJING ACAD OF BUILDING ENG +1

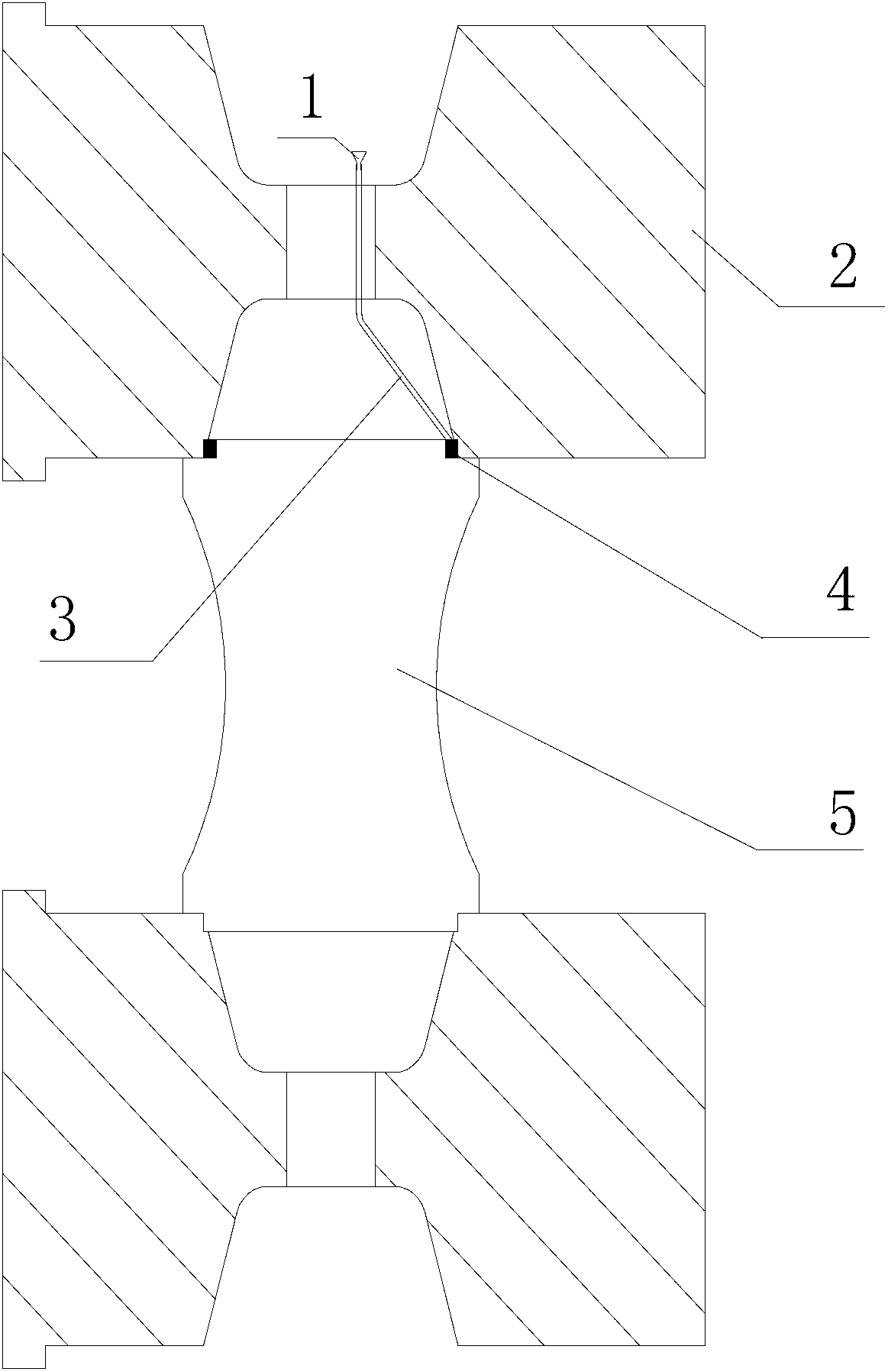

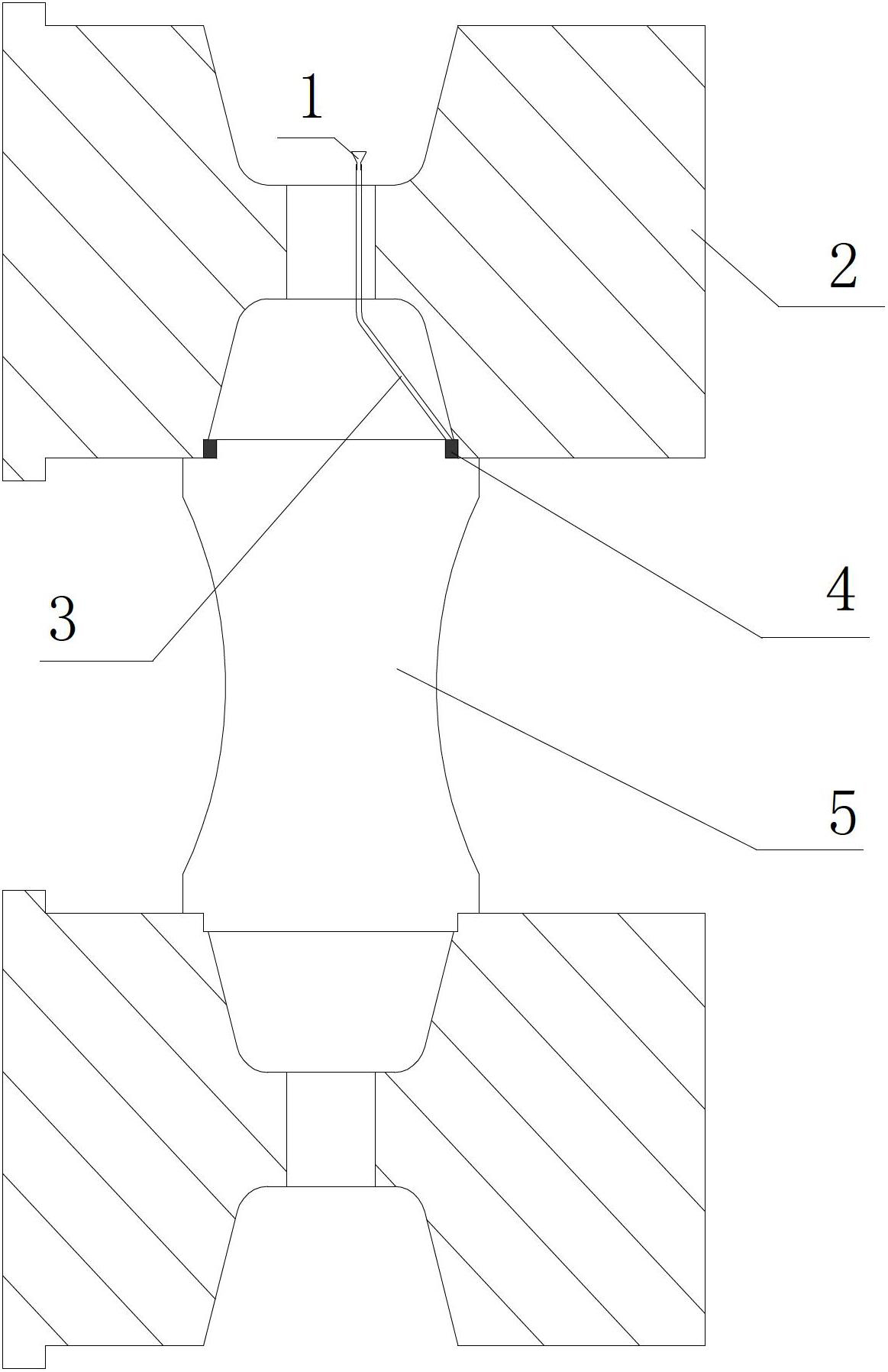

Airtightness detection tool for castings

InactiveCN104713683AQuick checkReduce processing costsDetection of fluid at leakage pointBreatherEngineering

The invention provides an airtightness detection tool for castings. The airtightness detection tool comprises a support, a base, a trapezoid screw A, a cushion block A, a trapezoid screw B, a cushion block B, a trapezoid screw C, a cushion block C and a breather pipe, wherein the support and the base are of an integrated structure, and the cushion block A is installed at the left end of the support through the trapezoid screw A and can move leftwards and rightwards under screw rotation of the trapezoid screw A; the cushion block B is installed on the top of the support through the trapezoid screw B and can move upwards and downwards under screw rotation of the trapezoid screw B; the cushion block C is installed at the right end of the support through the trapezoid screw C and can move leftwards and rightwards under screw rotation of the trapezoid screw C; the breather pipe is connected to the base and is led into the base, and an outlet is formed in the center of the upper end of the base. The airtightness detection tool can quickly determine defective casting products through detection, reduces machining and assembling costs of a machining factory, shortens adjusting time and improves production efficiency.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

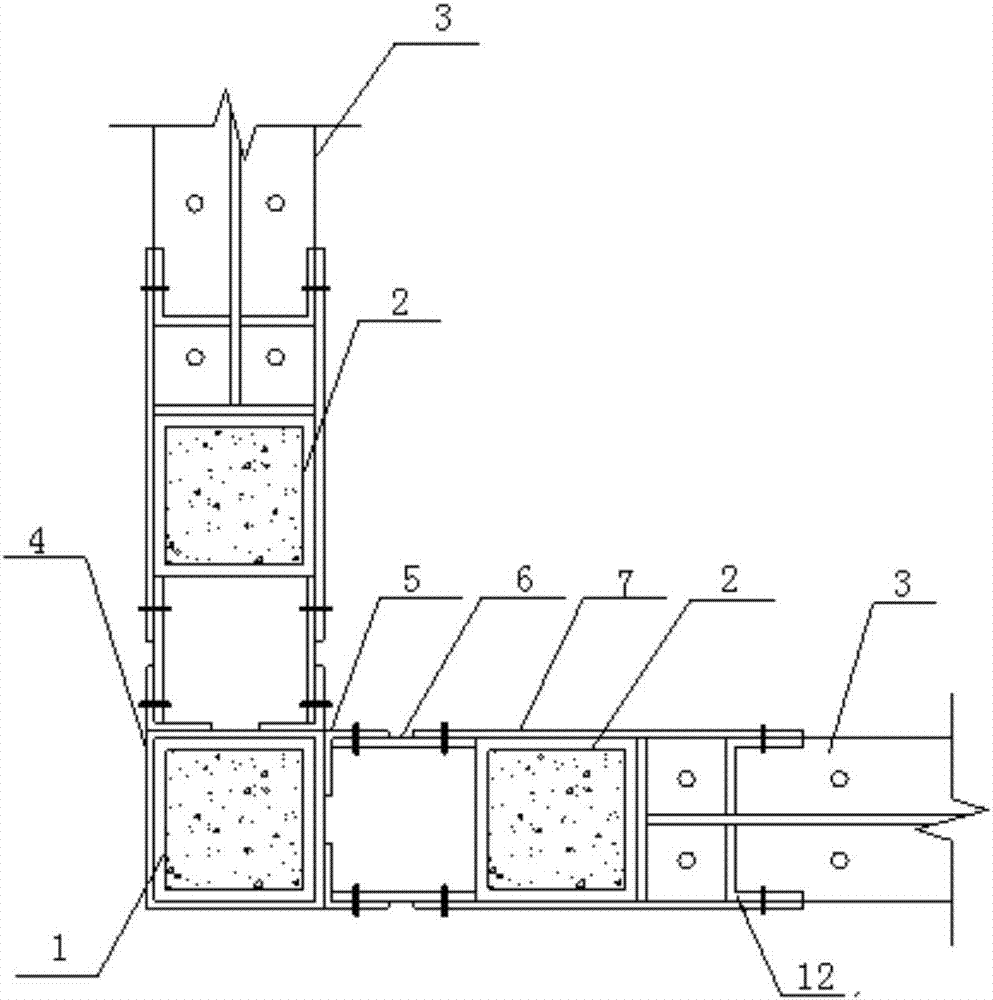

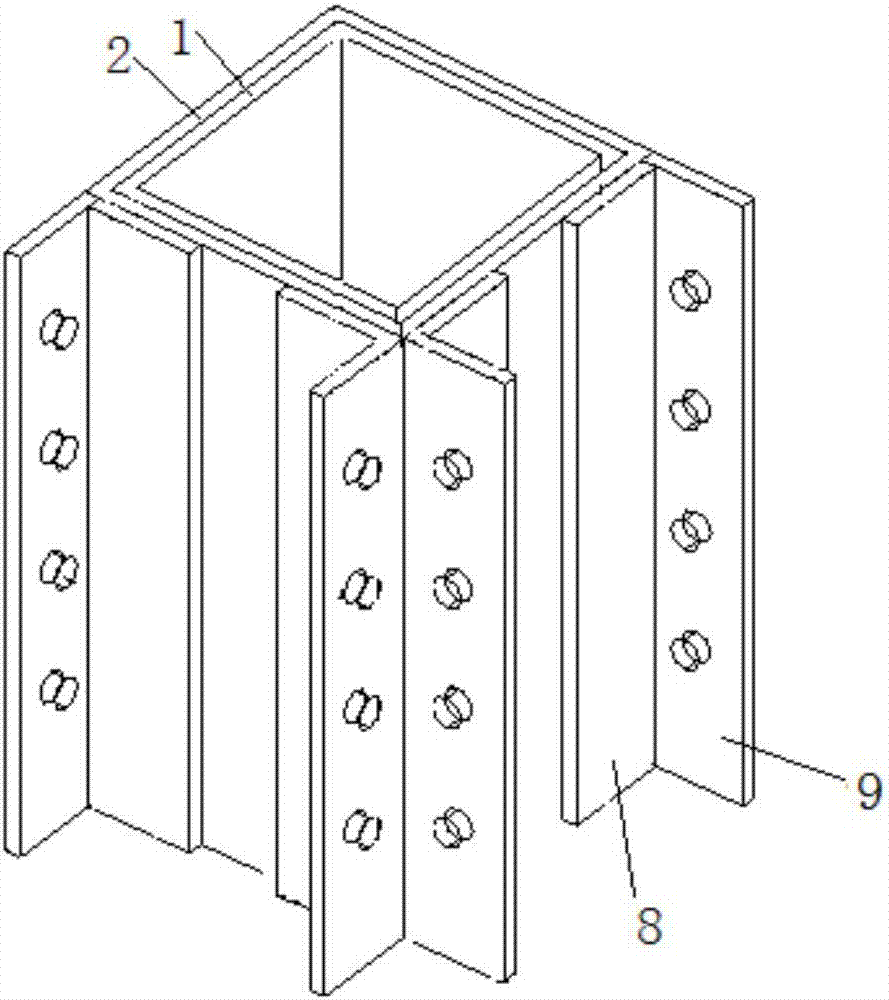

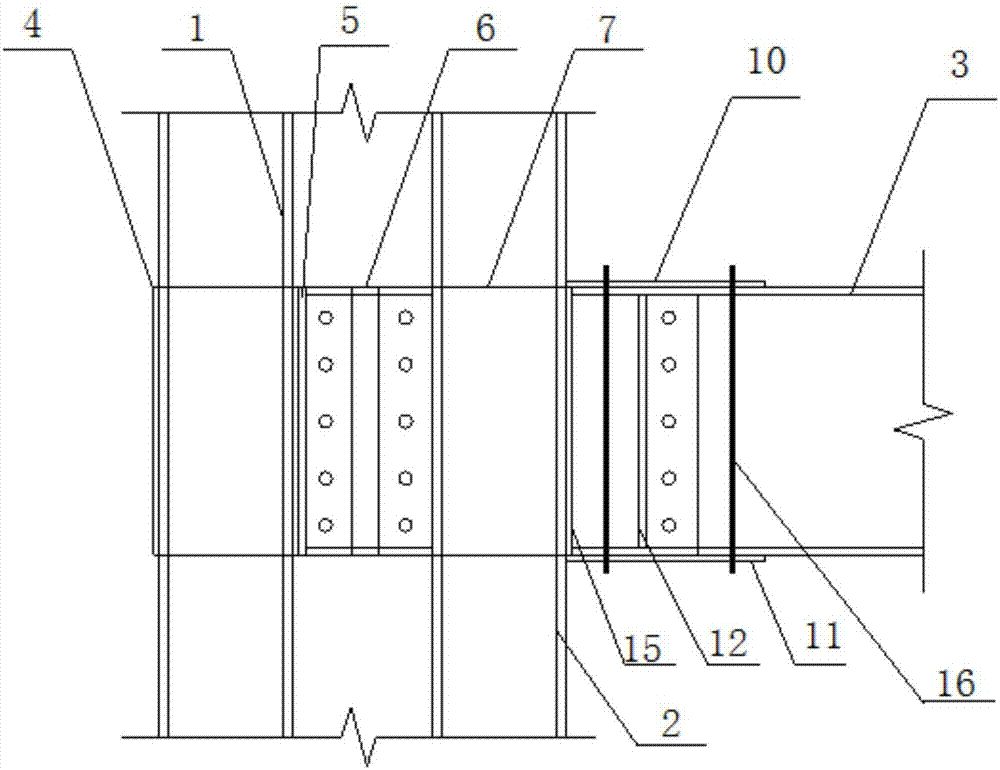

Connecting structure of beam-column joint of steel pipe concrete combined column

ActiveCN107355007APrevention and Control of TorsionHigh node stiffnessBuilding constructionsPlastic hingeMaterials science

The invention relates to the field of building structure structural parts, and discloses a connecting structure of a beam-column joint of a steel pipe concrete combined column. The connecting structure of the beam-column joint of the steel pipe concrete combined column comprises a center square steel pipe, an edge end square steel pipe and a steel beam. The center square steel pipe is connected with the edge end square steel pipe through a column connecting assembly. The edge end square steel pipe is connected with the steel beam through a beam connecting assembly. According to the connecting structure of the beam-column joint of the steel pipe concrete combined column, the center square steel pipe is connected with the end square steel pipe through the column connecting assembly, the rigidity of the joint is increased greatly, and meanwhile, twisting of the center square steel pipe and the end square steel pipe is prevented and controlled effectively; according to the connecting structure of the beam-column joint of the steel pipe concrete combined column, beams and columns are connected through bolts, direct welding is avoided, the purpose of beam-column separation is achieved, brittle failure which occurs in the beam-column joint is avoided effectively, so that plastic hinge offset is caused, and seismic requirements of strong column-weak beam and strong joint-weak structural part are met; and according to the connecting structure of the beam-column joint of the steel pipe concrete combined column, all structural parts and connecting parts are machined and completed in a machining factory, the beams and the columns on a construction site are connected by using the bolts, welding working on the construction site is avoided effectively, the degree of assembly is high, and installing is convenient and fast.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for reducing content of aldehyde and ketone VOC (volatile organic compounds) of automobile air-conditioning case housing

The invention discloses a method for reducing the content of aldehyde and ketone VOC (volatile organic compounds) of an automobile air-conditioning case housing. The method comprises the following processing steps: S1, boiling: setting the water temperature as 45-100 DEG C and placing the air-conditioning case housing in water for boiling for 1-2 h; and S2, ventilating and air drying: taking the boiled air-conditioning case housing out of water, ventilating and air drying, wherein the environment temperature for ventilating and air drying is set as 25-40 DEG C. Under the water temperature within the temperature range, aldehyde and ketone organic compounds in the air-conditioning case housing are extremely easily dissolved in water after volatilization due to a low boiling point, so that the VOC content of the air-conditioning case housing is reduced. According to the method for reducing the content of aldehyde and ketone VOC of the automobile air-conditioning case housing provided by the technical scheme of the invention, after the automobile air-conditioning case housing is subjected to boiling, ventilating and air drying, the content of aldehyde and ketone VOC of the air-conditioning case housing is reduced by 70%-80%, which meets the aldehyde and ketone VOC standards established by the main machine factories, and meanwhile the automobile passenger compartment is endowed with a comfortable and healthy environment; besides, the processing method is simple, good in operability and low in cost.

Owner:SOUTH AIR INT

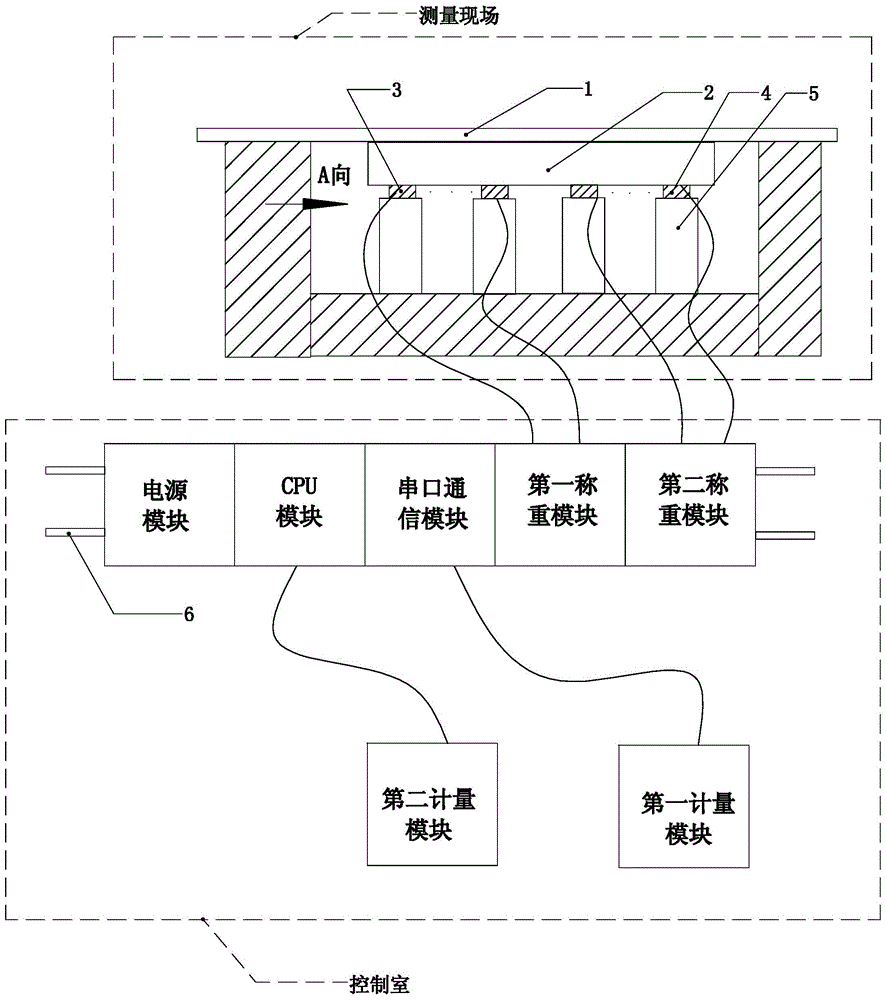

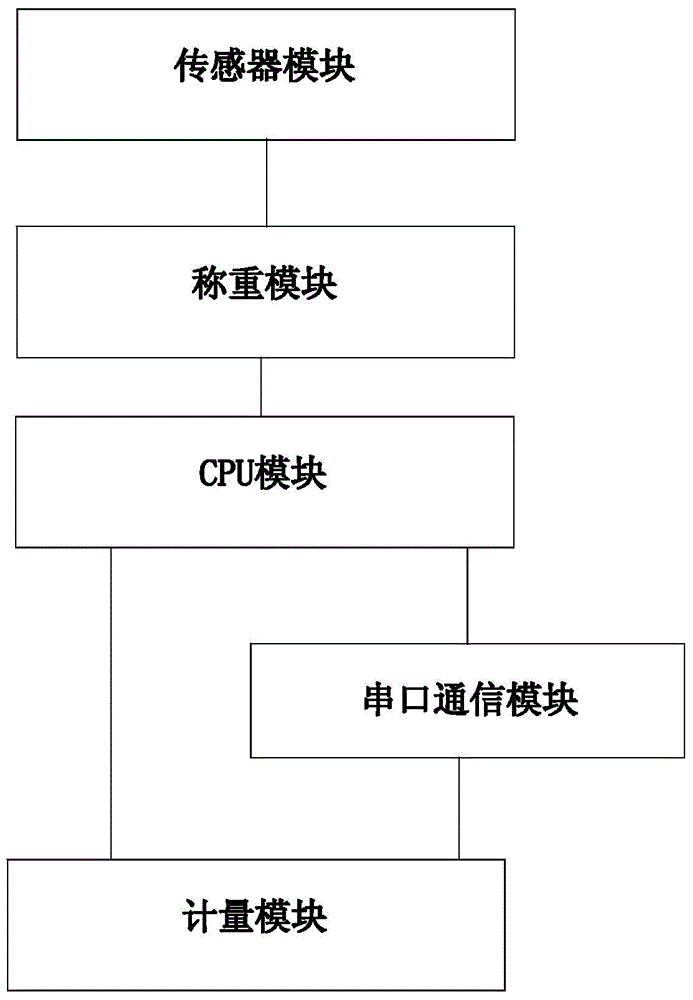

Dynamic railway scale high-speed data acquisition device and method

InactiveCN105181098AReduce assembly requirementsLow costSpecial purpose weighing apparatusComputer moduleTerminal equipment

The invention discloses a dynamic railway scale high-speed data acquisition device and a method, so as to solve problems that the device needs to be highly configured as dynamic data are unreliably measured. The device comprises a measurement terminal device arranged in a measurement field and a control device arranged in a control room, wherein the measurement terminal device comprises a weighing platform arranged below two bearing rails, a sensor module and a support; and the control device comprises a rack, a power supply module, a weighing module, a serial port communication module, a CPU module and a metering module. The invention also discloses a dynamic railway scale data acquisition method based on a PLC program and a dynamic railway scale weighing method. The problems that an ISA interface card needs to be arranged in a computer, and an industrial computer needs to be used can be solved, assembly requirements on the computer are reduced, self improvements according to needs can be carried out, the device does not depend on a weighing machine factory, the application cost is reduced, the use is flexible, universality is strong, and programming is convenient.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com