Curtain wall efficient mounting method

An installation method and curtain wall technology, applied in the direction of walls, auxiliary devices, building components, etc., can solve the problems of low welding efficiency, low installation and construction efficiency, and insufficient safety, so as to improve installation efficiency, reduce construction costs, improve The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

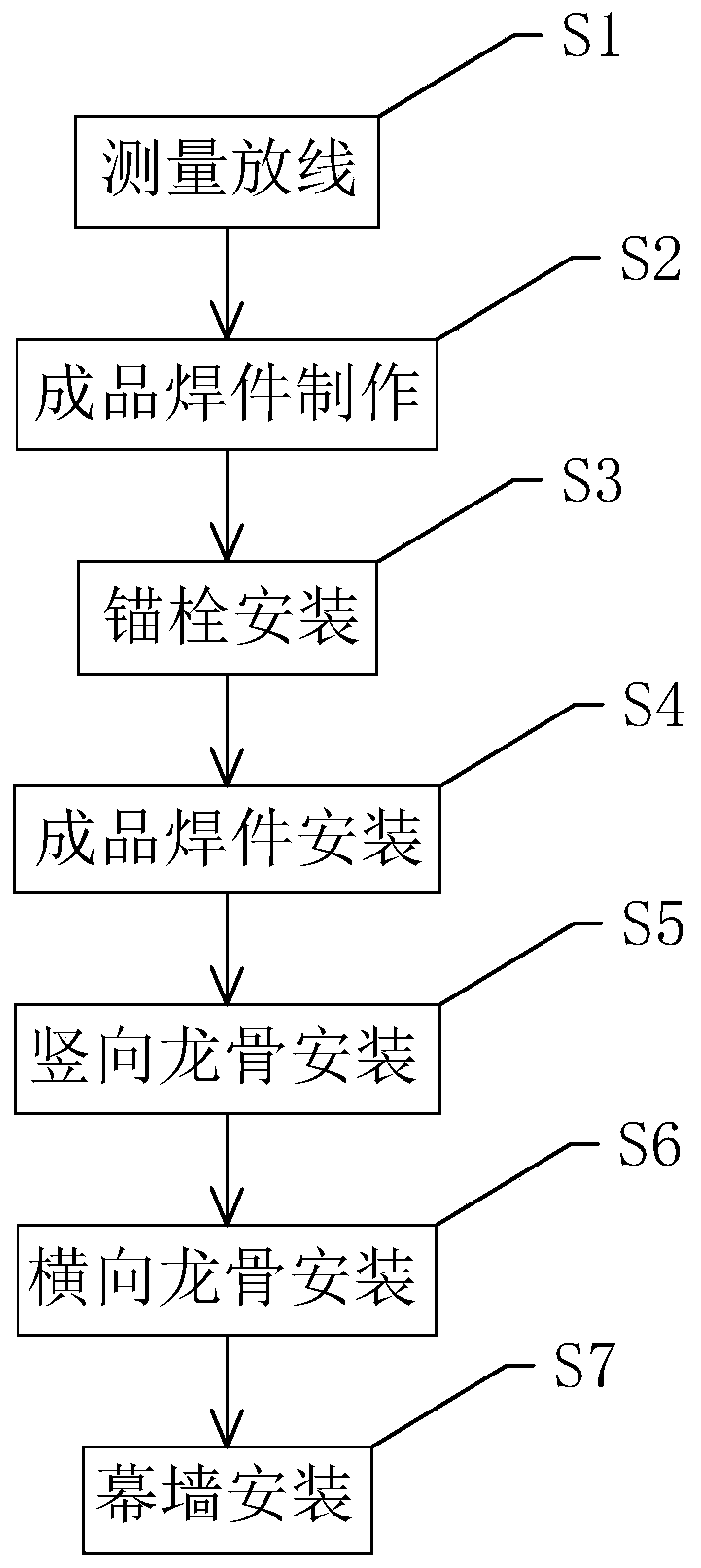

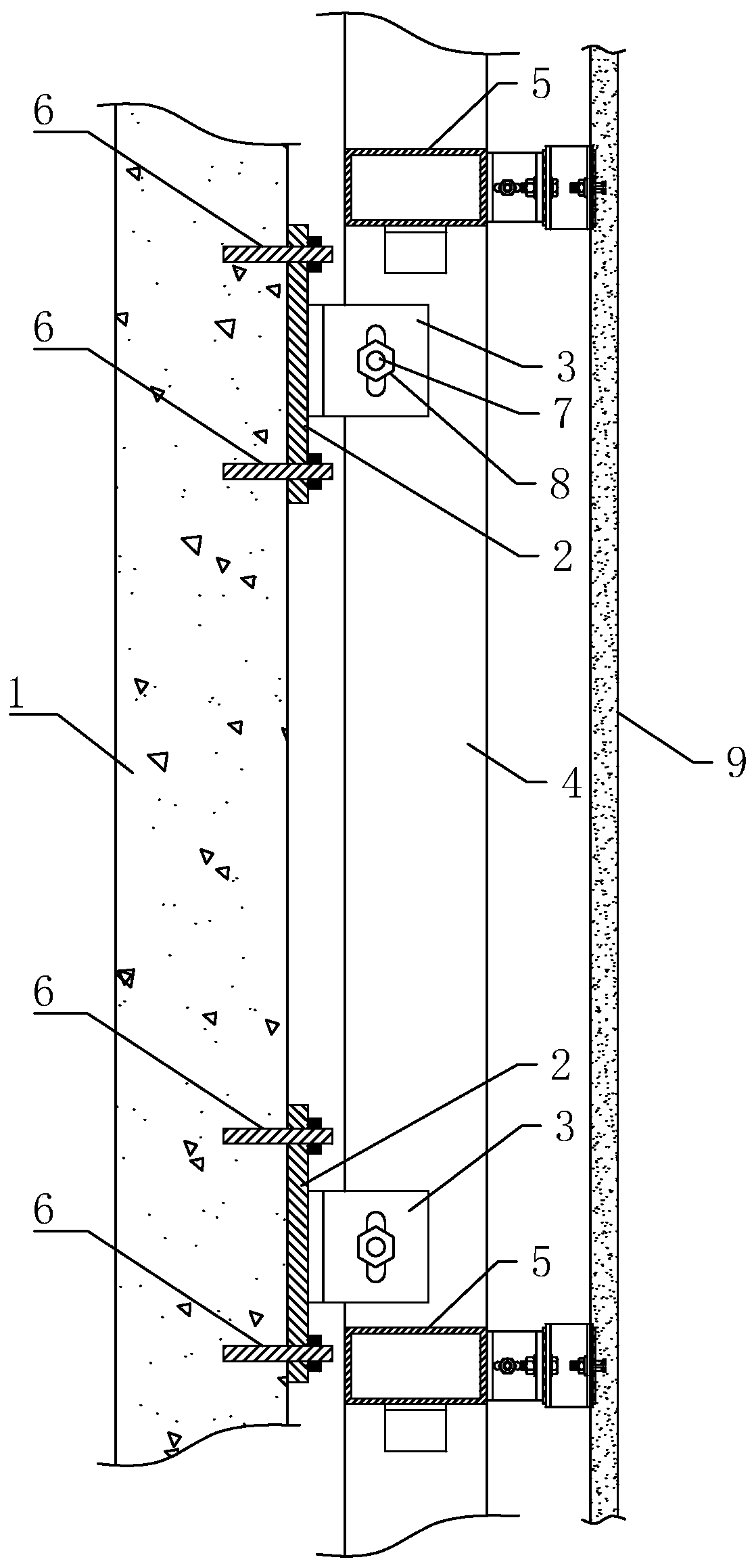

[0045] refer to figure 1 with figure 2 , is a curtain wall high-efficiency installation method disclosed by the present invention, comprising the following steps: measuring and setting out S1, making finished weldments S2, installing anchor bolts S3, installing finished weldments S4, installing vertical keels S5, installing horizontal keels S6 and Curtain wall installation S7.

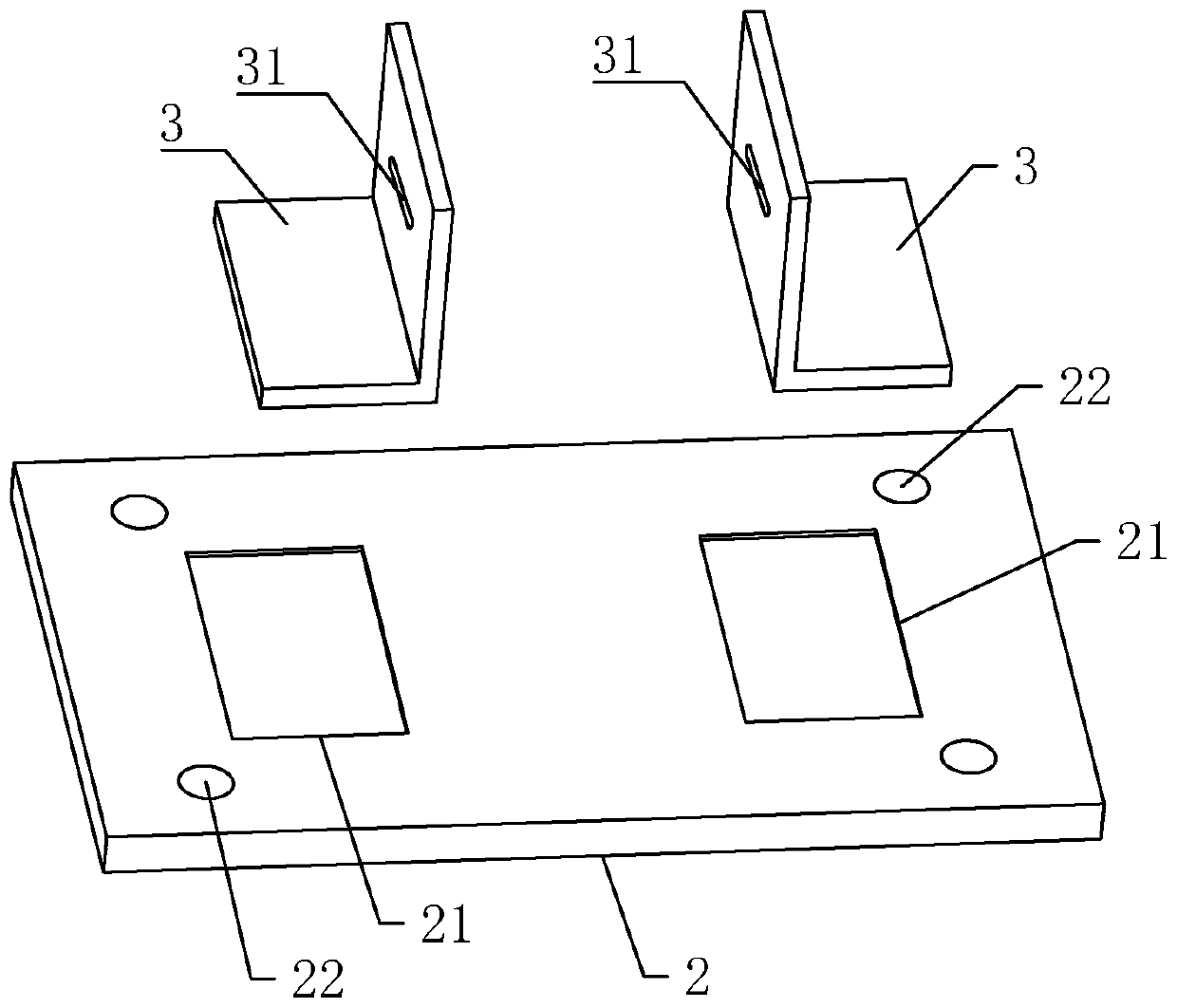

[0046]Measurement and setting-out S1: The staff measure and release the axis of the building 1, the central axis of each vertical keel 4, the horizontal line of each horizontal keel 5, and the horizontal line of each row of finished weldments in advance; finished weldment production S2: custom pre-set Embedded plate 2 and connecting piece 3, pre-welded embedded plate 2 and connecting piece 3 into finished weldments in the processing factory or on the ground at the construction site; anchor bolt installation S3: according to the central axis of each vertical keel 4 and each row of finished products T...

Embodiment 2

[0055] refer to figure 2 with Figure 4 , is an efficient curtain wall installation method disclosed in the present invention. The difference from Embodiment 1 is that the welding positioning marks 21 are specifically four straight line scratches surrounded by a rectangle. After the pre-embedded board 2 is produced, the staff can Use paint to mark straight line scratches on the welding surface of the embedded board 2, which is convenient to operate and high in efficiency.

[0056] During the welding operation, one worker is installed full-time to do the marking work with a paint pen, and another worker is installed to do the welding work full-time. By installing two people to do the marking and welding work separately and assist in the matching work, the welding efficiency can be further improved. It can increase the forming speed of finished weldments.

Embodiment 3

[0058] refer to figure 2 with Figure 5 , is an efficient curtain wall installation method disclosed in the present invention. The difference from Embodiment 1 is that the welding positioning marks 21 are specifically four positioning points located at the four corners of a rectangle. After the pre-embedded board 2 is produced, the staff can Use paint to mark the positioning points on the welding surface of the embedded board 2, which is convenient to operate and high in efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com