Modified polypropylene material for soft freezing layer drawer of refrigerator

A polypropylene material and soft freezing technology, applied in the field of polypropylene materials, can solve the problems of easy aging, high material price, and poor mechanical properties of products, and achieve high low-temperature impact resistance, good processing fluidity, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

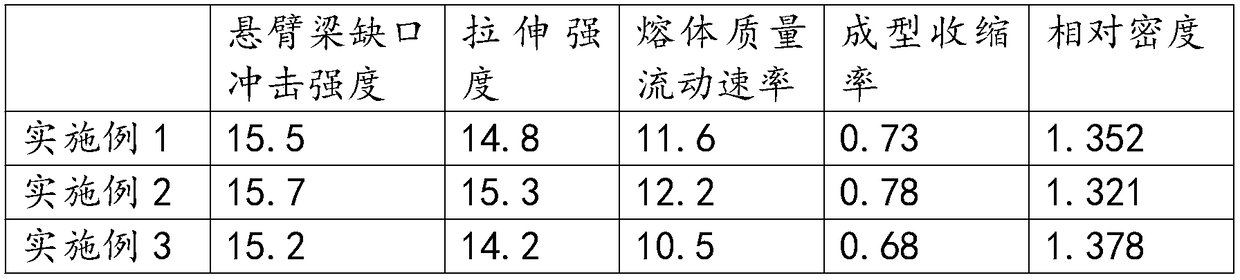

Examples

Embodiment Construction

[0014] The modified polypropylene material used in the refrigerator's soft freezer drawer, the percentage of raw and auxiliary materials is: PP: 30-40%; HDPE: 5-10%; LDPE: 5-10%; toughener: 3-8 %; mineral filling: 40-50%; functional additives 1-5%.

[0015] Further, the toughening agent is a polyolefin toughening agent.

[0016] Further, the polyolefin toughening agent is one of POE, EPDM, and POP.

[0017] Among them, POE is composed of octene and polyolefin resin, and the continuous phase and the dispersed phase appear as two-phase separated polymer blends. Its characteristics are: (1) The flexible chain bending of octene and the crystalline ethylene chain serve as physical cross-linking points, which make it have both excellent resistance and outstanding processability; (2) There is no unsaturated bond in the molecular structure of POE, It has excellent aging resistance; (3) POE has narrow molecular weight distribution, good fluidity, and good compatibility with polyolefi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com