Patents

Literature

54 results about "Comprehensive planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive planning is a process that determines community goals and aspirations in terms of community development. The result is called a comprehensive plan and both expresses and regulates public policies on transportation, utilities, land use, recreation, and housing. Comprehensive plans typically encompass large geographical areas, a broad range of topics, and cover a long-term time horizon. The term comprehensive planning is most often used by urban planners in the United States.

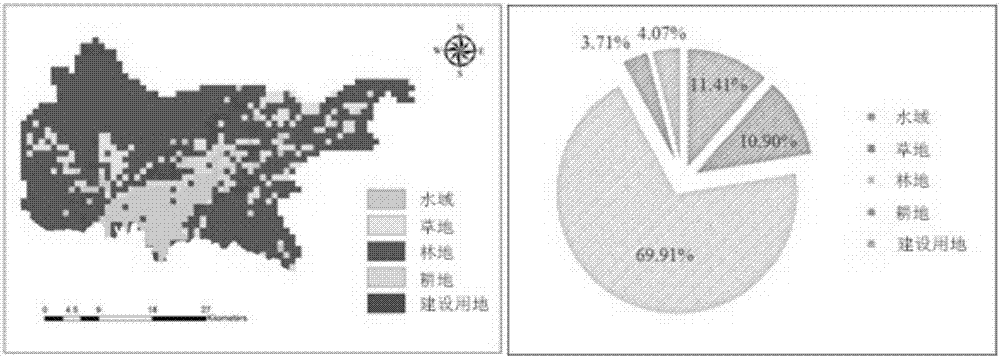

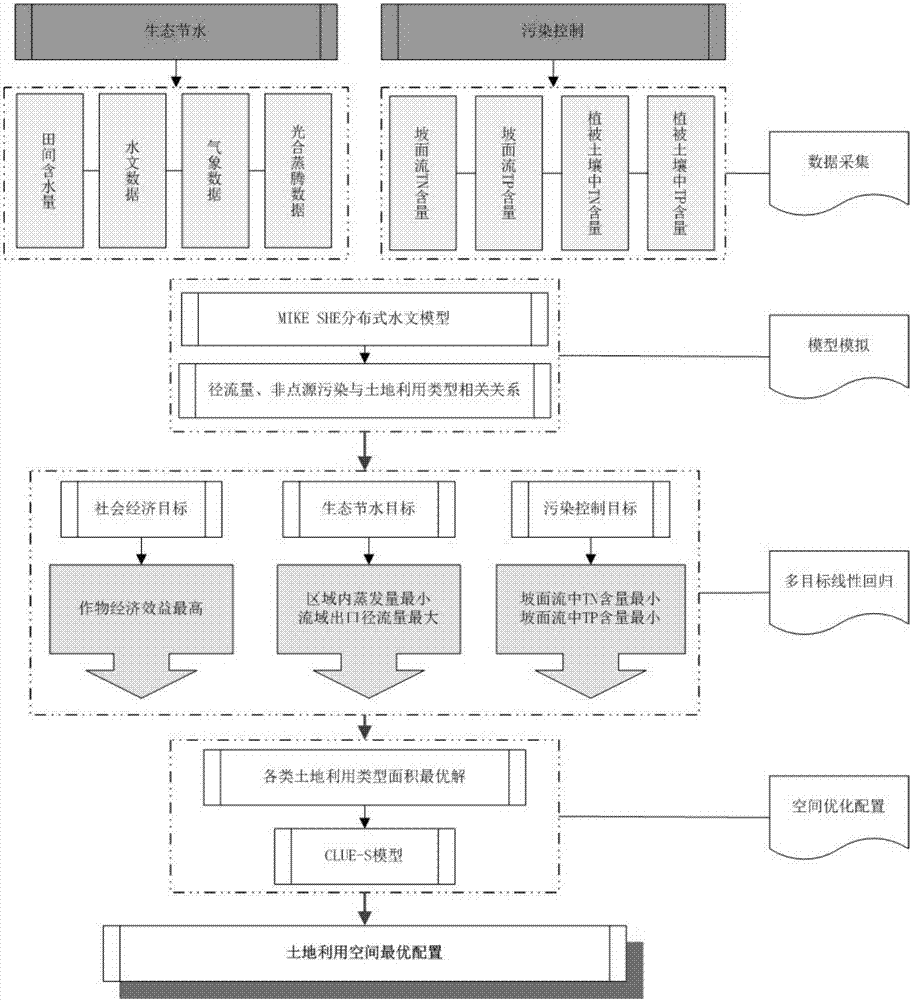

Ecological water saving and pollution control integrated land utilization optimizing method

PendingCN107423566AImplement configurationForecastingSpecial data processing applicationsLand resourcesModel selection

The invention relates to the technical field of river basin water environment protection and river basin comprehensive planning and management and discloses an ecological water saving and pollution control integrated land utilization optimizing method. Aiming at characteristics and defects of researches in the field of land utilization structural optimization at present, the optimizing method avoids defects in the field of land resource structural allocation research, economic benefits and ecological benefits are selected as main optimizing targets according to realistic conditions of research areas, a multi-objective linear programming model and an improved CLUE-S model are combined in terms of model selection to form a model system for planning quantity structures and spatial arrangement of various land use types, and a goal of land resource allocation optimization of the research area is achieved.

Owner:BEIJING NORMAL UNIVERSITY

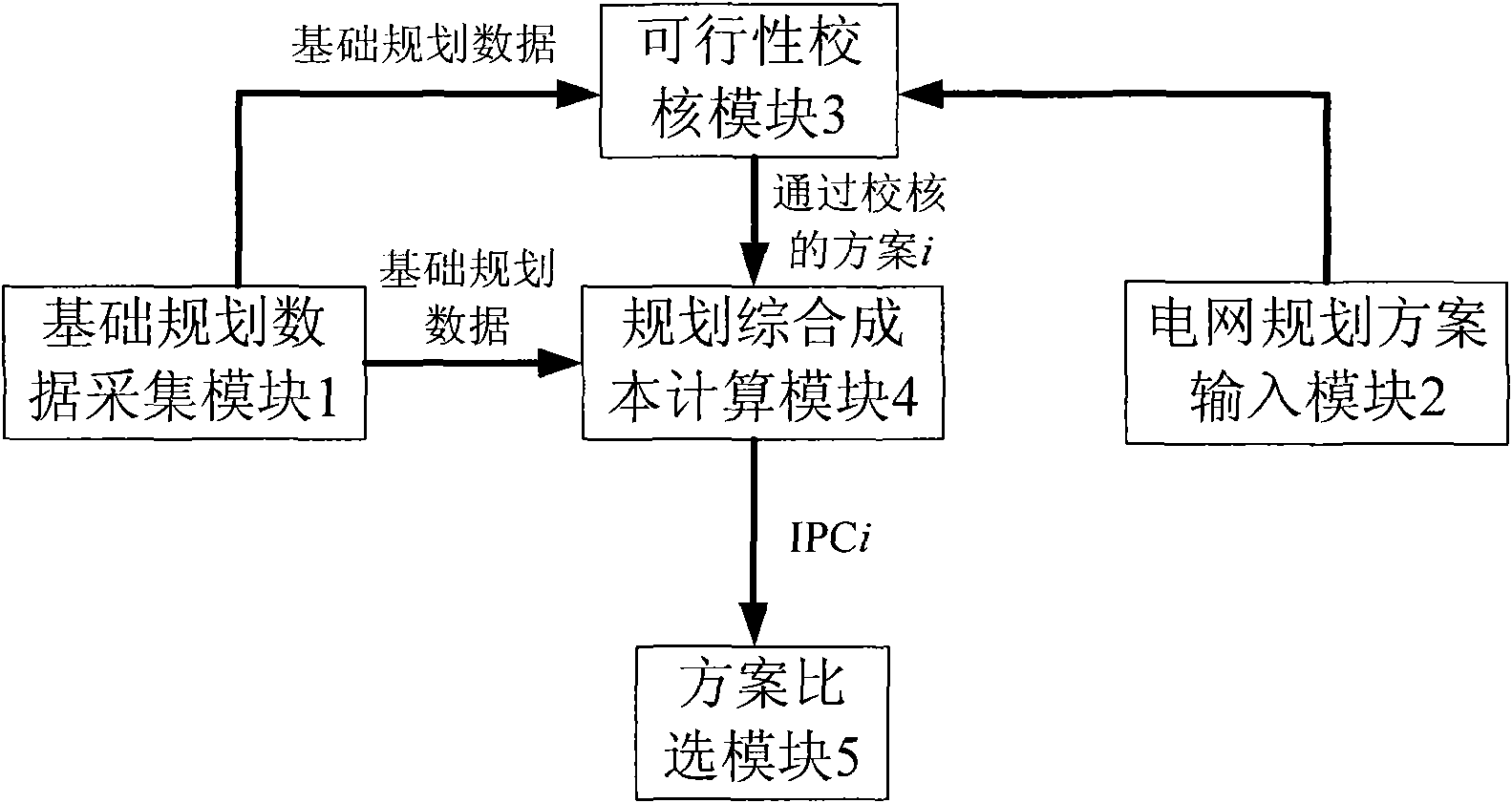

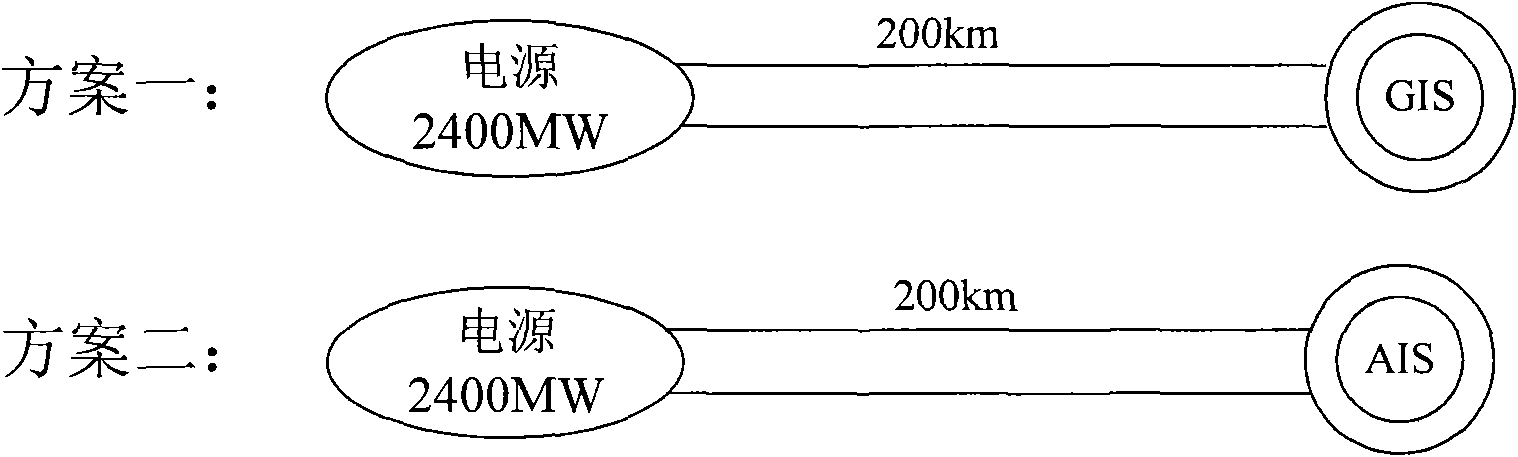

Comparing and selecting system of power transmission network planning scheme

ActiveCN101567561AScience of comparisonImprove securityForecastingInformation technology support systemComputer moduleEngineering

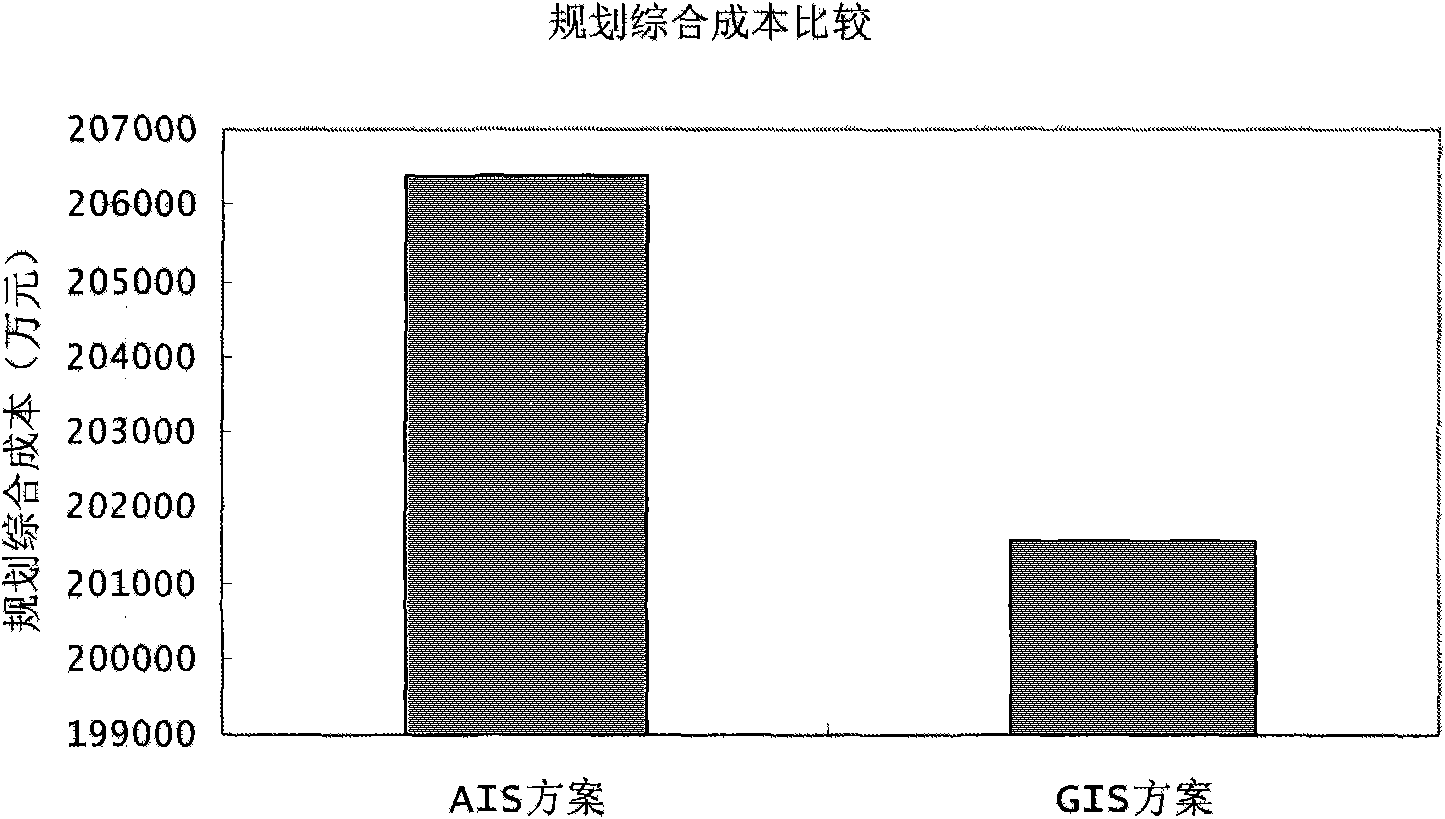

The invention relates to a comparing and selecting system of a power transmission network planning scheme, which is characterized by comprising a basic planning data collecting module, a power transmission network planning scheme input module, a feasibility check module, a comprehensive planning cost calculating module and a scheme comparing and selecting module; the basic planning data collecting module collects basic planning data; the power transmission network planning scheme input module inputs the power transmission network planning schemes and power transmission planning conditions to be compared and selected; the feasibility check module carries out electric calculation and check on the power transmission planning scheme to be compared and selected according to the basic planning data and the power transmission network planning conditions; and the comprehensive planning cost calculating module calculates the comprehensive planning cost of the power transmission network planning schemes meeting the electric calculation check conditions, the calculated results are input to the scheme comparing and selecting module and comparison and selection of the power transmission network schemes are carried out according to calculated comprehensive planning cost. The comparing and selecting system of the power transmission network schemes is beneficial to further improving the safe reliability of the planning schemes and simultaneously providing scientific basis for establishing risk input strategies and control measures in the power industry.

Owner:STATE GRID CORP OF CHINA +1

Outdoor underground three-period mining method of inclined, thick and large mineral deposit

InactiveCN102606161AIn line with the actual situationReduce duplication of investmentUnderground miningSurface miningOpen-pit miningComprehensive planning

The invention discloses an outdoor underground three-period mining method of an inclined, thick and large mineral deposit. The outdoor underground three-period mining method comprises the steps of dividing a life cycle of the mining the mineral deposit into an outdoor mining period, an mining transition period shifting from outdoor mining to underground and an underground mining period by the following two steps: creating an outdoor underground mining boundary division formula, according to a relationship between a limit stripping ratio function and an economic stripping ratio function, determining an outdoor underground mining boundary, and distinguishing the dividing of the life cycle of the mine; and on the basis of outdoor underground mining boundary division, determining a mining opportunity in each of three mining periods. According to the outdoor underground three-period mining method, three mining periods are subjected to unified comprehensive planning and designing, so that when the outdoor mining period is designed, a development system is considered to be utilized in the subsequent underground mining period, and when the mining operation transitions from outdoor mining period to the underground mining period, favorable factors such as related engineering and facilities and the like in the outdoor mining period are utilized as far as possible in the underground mining period at the same time. Therefore, repeated investment of the mine development system in construction can be effectively reduced. The outdoor underground three-period mining method can be widely applied to the mining of medium and thick or thick and large inclined or steep mineral deposits in the industries of black metal, nonferrous metal, coal, chemical and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Face recognition method and system

InactiveCN107423696AImprove accuracyGood coping strategyCharacter and pattern recognitionMarket data gatheringData informationResponse strategy

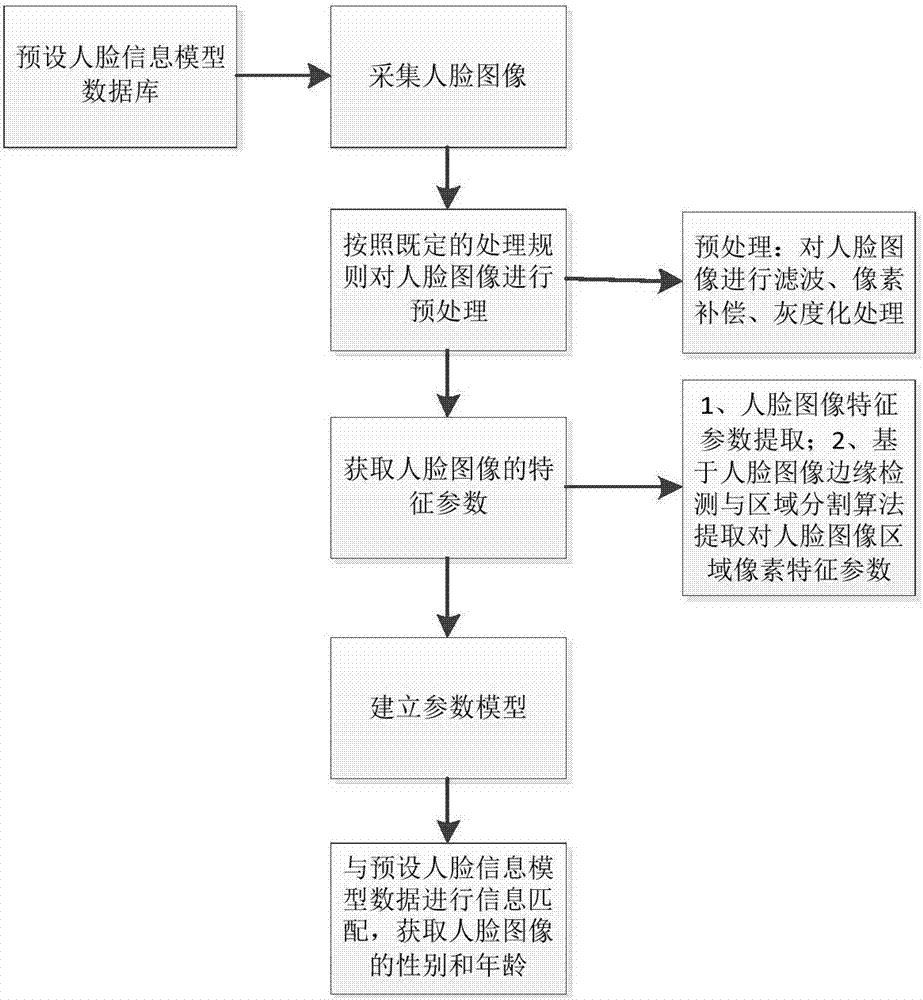

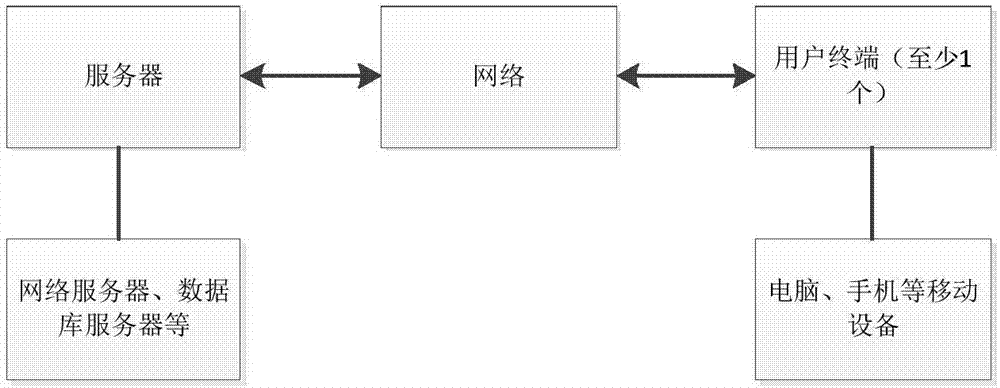

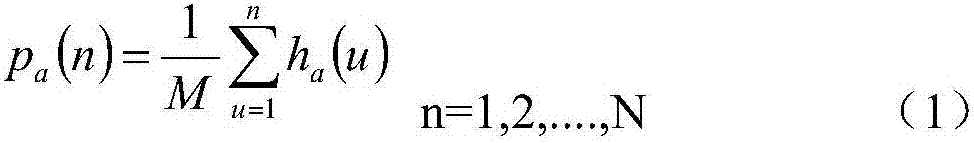

The invention provides a face recognition method and system. The method comprises a step of collecting a face image and carrying out preprocessing on the face image, a step of obtaining feature parameters of the face image and establishing parameter models which comprise an age model and a gender model, and a step of comparing the parameter model data with preset face information model data and obtaining the gender and age of the face image. According to the method and the system, through the combination of the age model and the gender model, the gender and age of the face image are identified, the accuracy of the face image identification are improved, a user can carry out more comprehensive planning according to an obtained accurate result, analysis can be gradually refined according to business requirements, the data collection of consumption of customers of different ages and different genders of active population in different regions is carried out, detailed and accurate data information is effectively provided for the customers to make better strategies.

Owner:CHONGQING KAIZE TECH

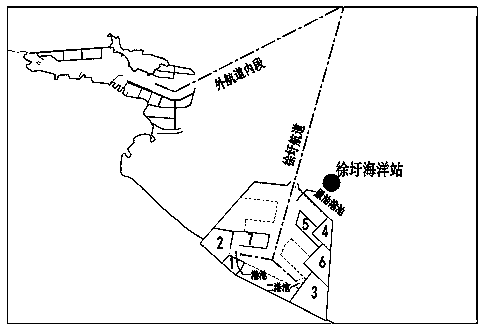

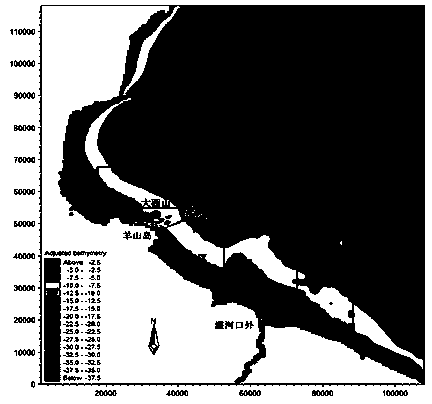

Design method for preventing and reducing silt in construction field of encircling type port area

InactiveCN103397615ASolve the spoil problemDesign scienceBreakwatersQuaysMathematical modelEngineering

The invention relates to a design method for preventing and reducing silt in the construction field of an encircling type port area. The design method for preventing and reducing the silt in the construction filed of the encircling type port area is characterized by comprising the first step of establishing and verifying a sediment mathematical model under the combined action of wave currents, the second step of calculating back-silting in the construction period of the encircling type port area, the third step of analyzing back-silting influencing factors in the construction period of the encircling type port area, and the fourth step of forming the measures of preventing and reducing the silt in the construction period of the encircling type port area. The design method for preventing and reducing the silt in the construction period of the encircling type port area has the obvious advantages that the design method for preventing and reducing the silt in the construction period of the encircling port area is achieved through comparison analysis of back-silting influence factors in the port area, and the design method is scientific in design, obvious in silt reducing effect and capable of coinciding with the comprehensive planning of the port area; the method for preventing and reducing the silt can solve the problem of spoil produced in silt coast development in the construction period of the encircling type port area, and can meet the basic requirement for ecological port construction in China. The design method for preventing and reducing the silt in the construction field of the encircling type port area is widely suitable for project planning design for preventing and reducing the silt of harbor basins and channels in the construction period of silt coast encircling type port areas.

Owner:HOHAI UNIV

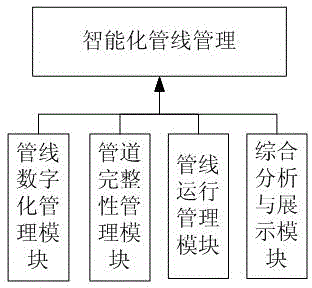

Intelligent pipeline management system

The invention discloses an intelligent pipeline management system. The intelligent pipeline management system comprises a digital pipeline management module, a pipeline integrity management module, a pipeline operation management module, an emergency response management module and a comprehensive analysis and display module. The intelligent pipeline management system is capable of further adapting to pipeline service development requirements to guarantee effective linkage of upstream and downstream services, and comprehensive planning and designing of pipeline service development are facilitated to provide a basis for energy supply and optimization of resource allocation.

Owner:PACIA TECH & SCI CO LTD

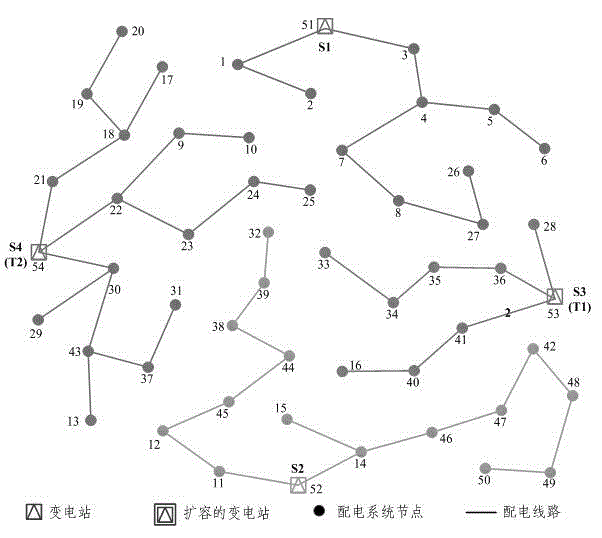

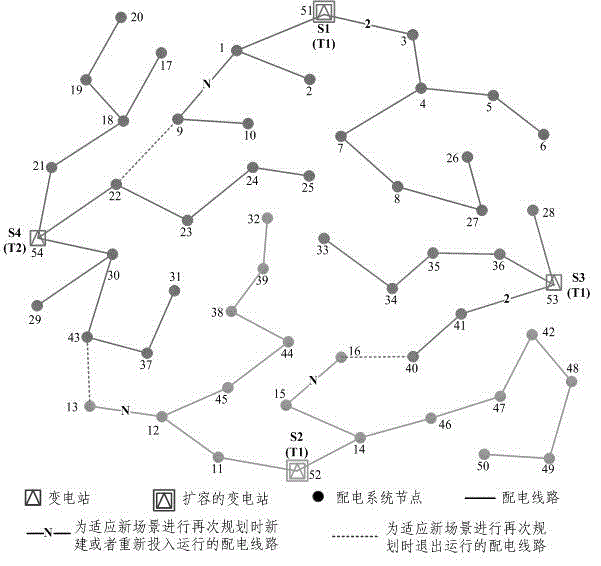

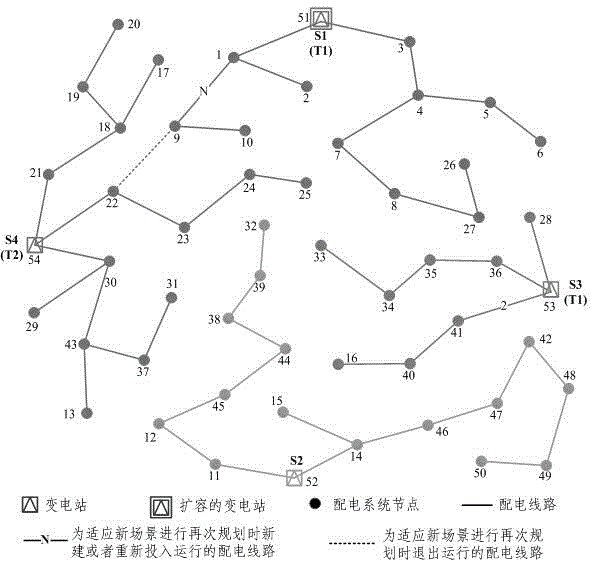

Power distribution system comprehensive planning method suitable for electric car large-scale application

ActiveCN104463464AAvoid economic risksImprove adaptabilityForecastingResourcesComputing MethodologiesElectric power distribution

The invention discloses a power distribution system comprehensive planning method suitable for electric car large-scale application. The method includes the following steps that firstly, according to a free charging mode and a sequential charging mode, methods for calculating electric car charging loads are provided respectively, and a feasible real-time dispatching strategy is provided for the sequential charging mode; secondly, starting from the three uncertain factors of the annual common load development level of the planning level, the electric car ownership and the condition whether the sequential charging strategy can be smoothly implemented or not, a set of future possible scenes is established; finally, a power distribution system flexible planning method suitable for cost is developed. According to the power distribution system comprehensive planning method, an initial establishment scheme with the small cost sum can be provided for investors and economic risks are avoided.

Owner:国网浙江省电力公司电动汽车服务分公司 +1

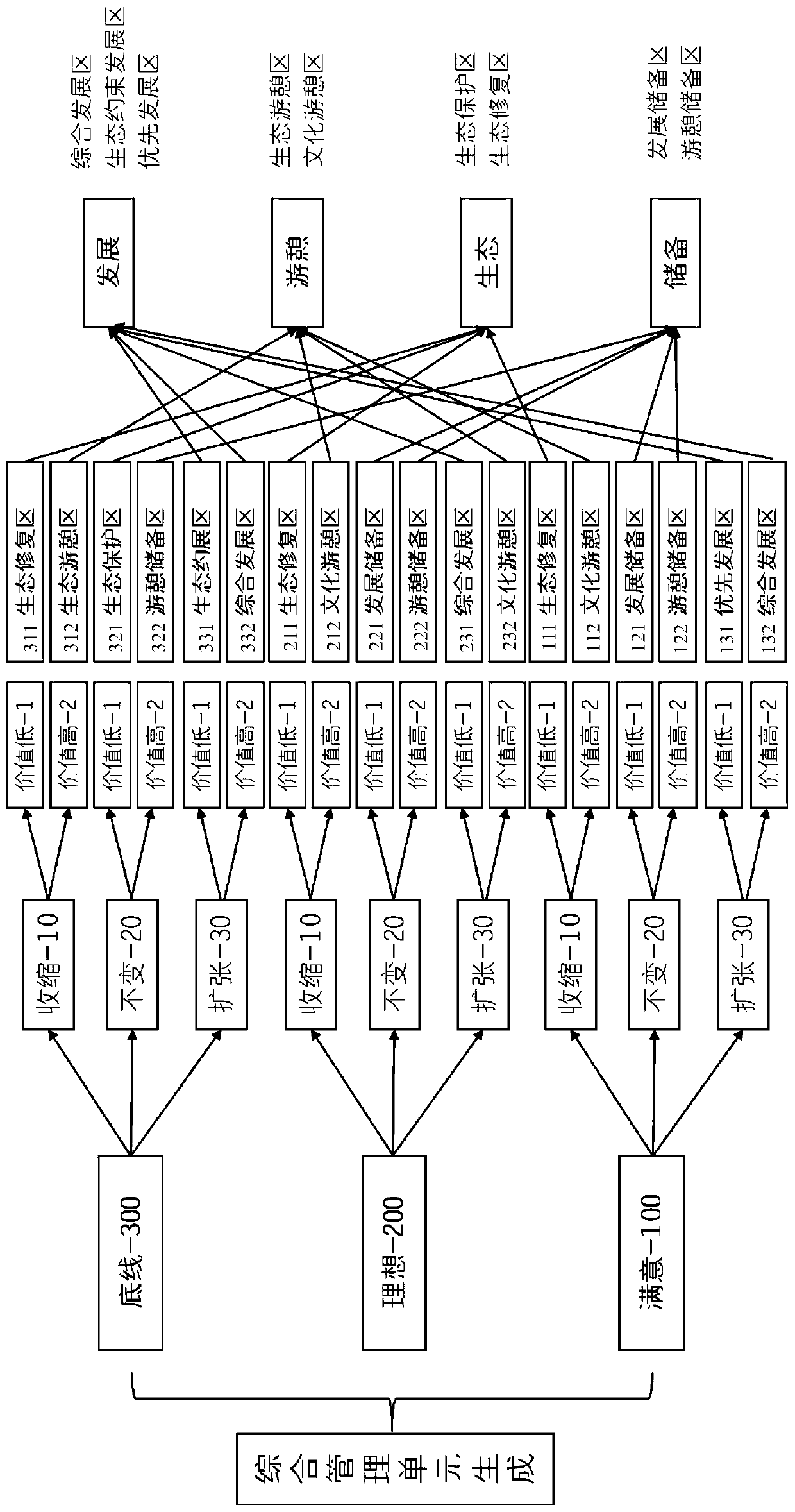

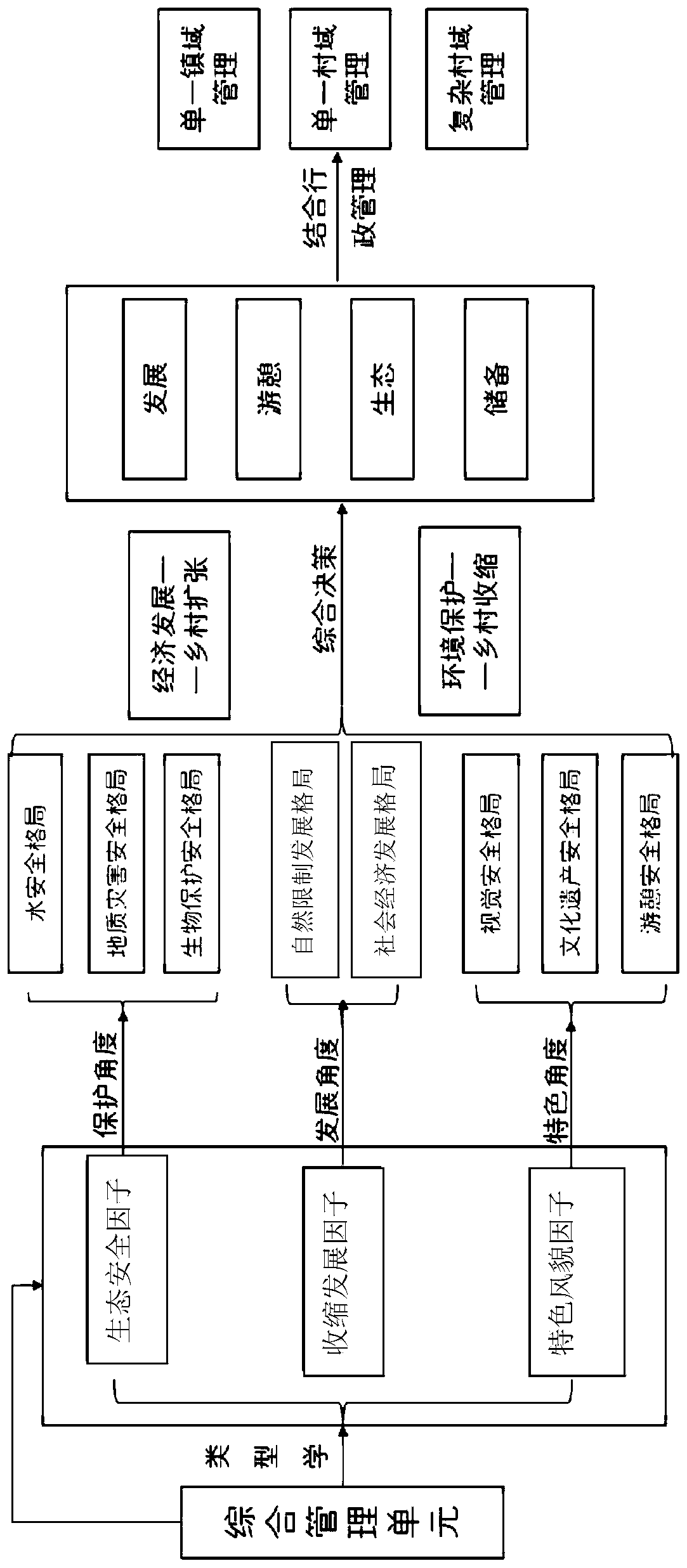

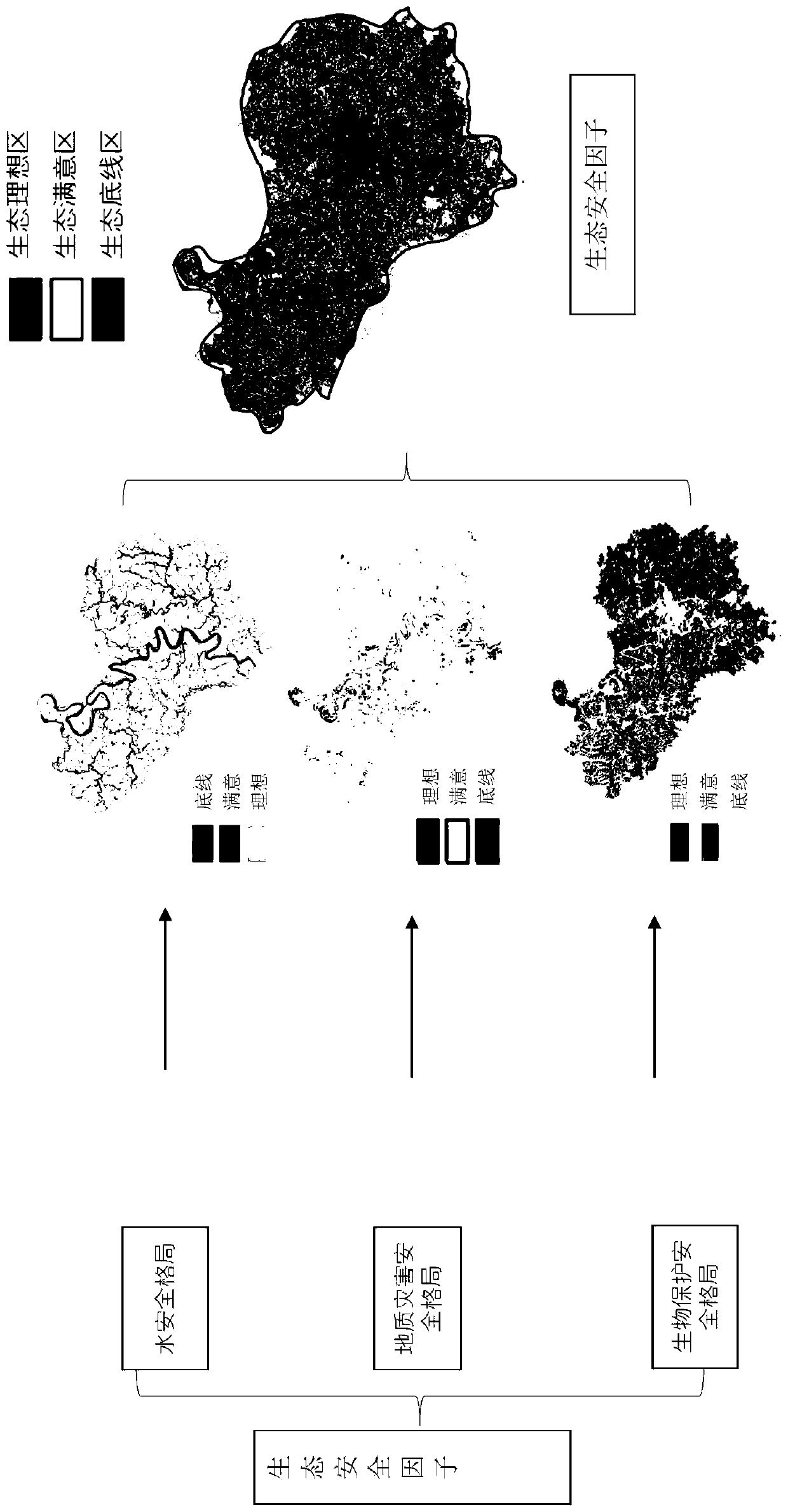

Landscape comprehensive management unit division method

PendingCN111210142ABreak through a single featureEasy to manageResourcesEvaluation resultManagement unit

The invention discloses a landscape integrated management unit division method. The method comprises the steps of determining evaluation factors of landscape feature management unit division; obtaining an evaluation result of the evaluation factor; grading the evaluation results of the evaluation factors, and determining the category of the development direction. According to the invention, different landscape management unit features of the target area are obtained by evaluating, superposing and grading the landscape feature units of the target area, and the landscape management unit of the target area is combined with the administrative management unit to perform differentiated management on the target area. According to the invention, landscape unit planning is carried out from the county scale, comprehensive planning is carried out on the target area by combining the natural and humanistic characteristic comprehensive management unit, and correction is provided for existing planning development.

Owner:PEKING UNIV

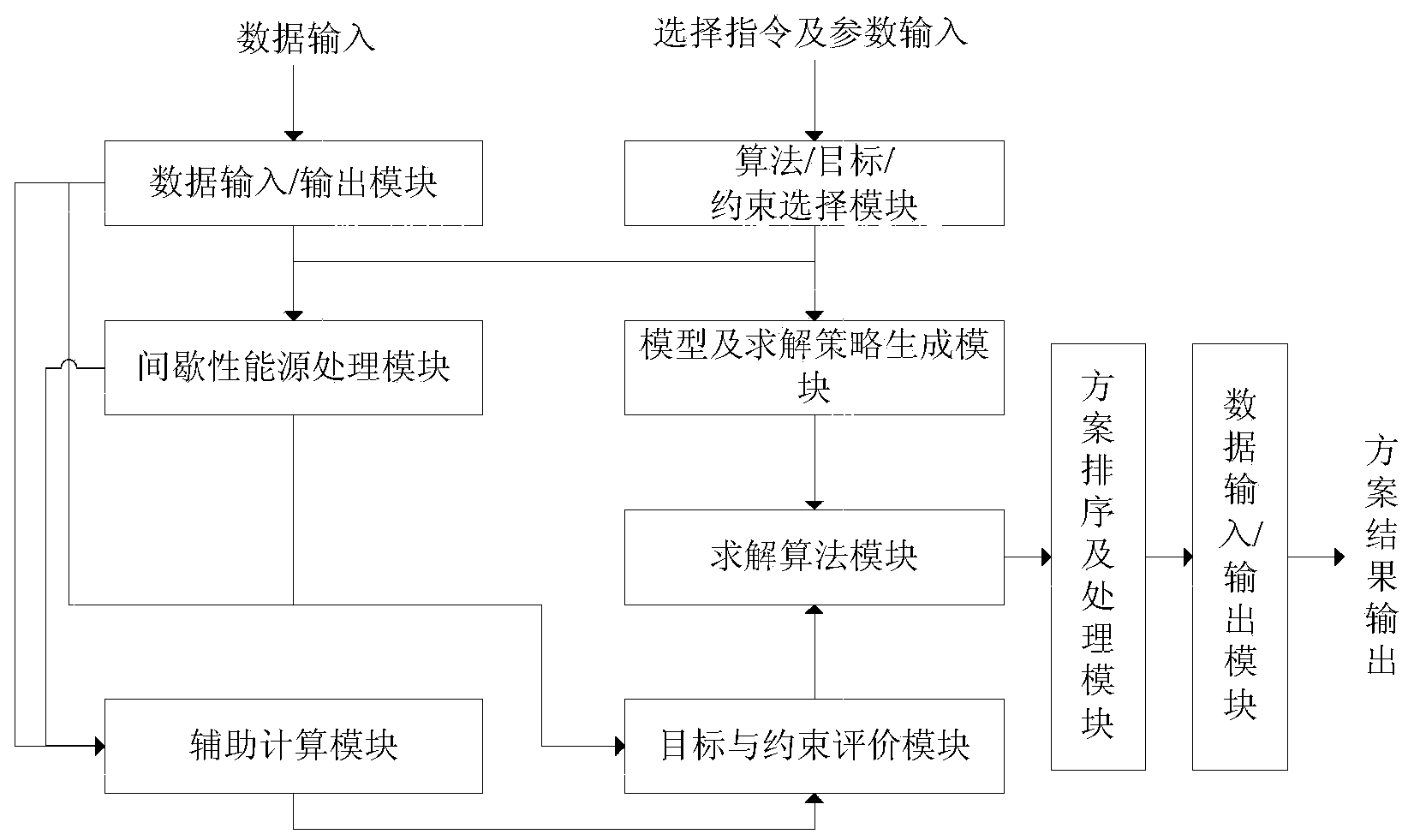

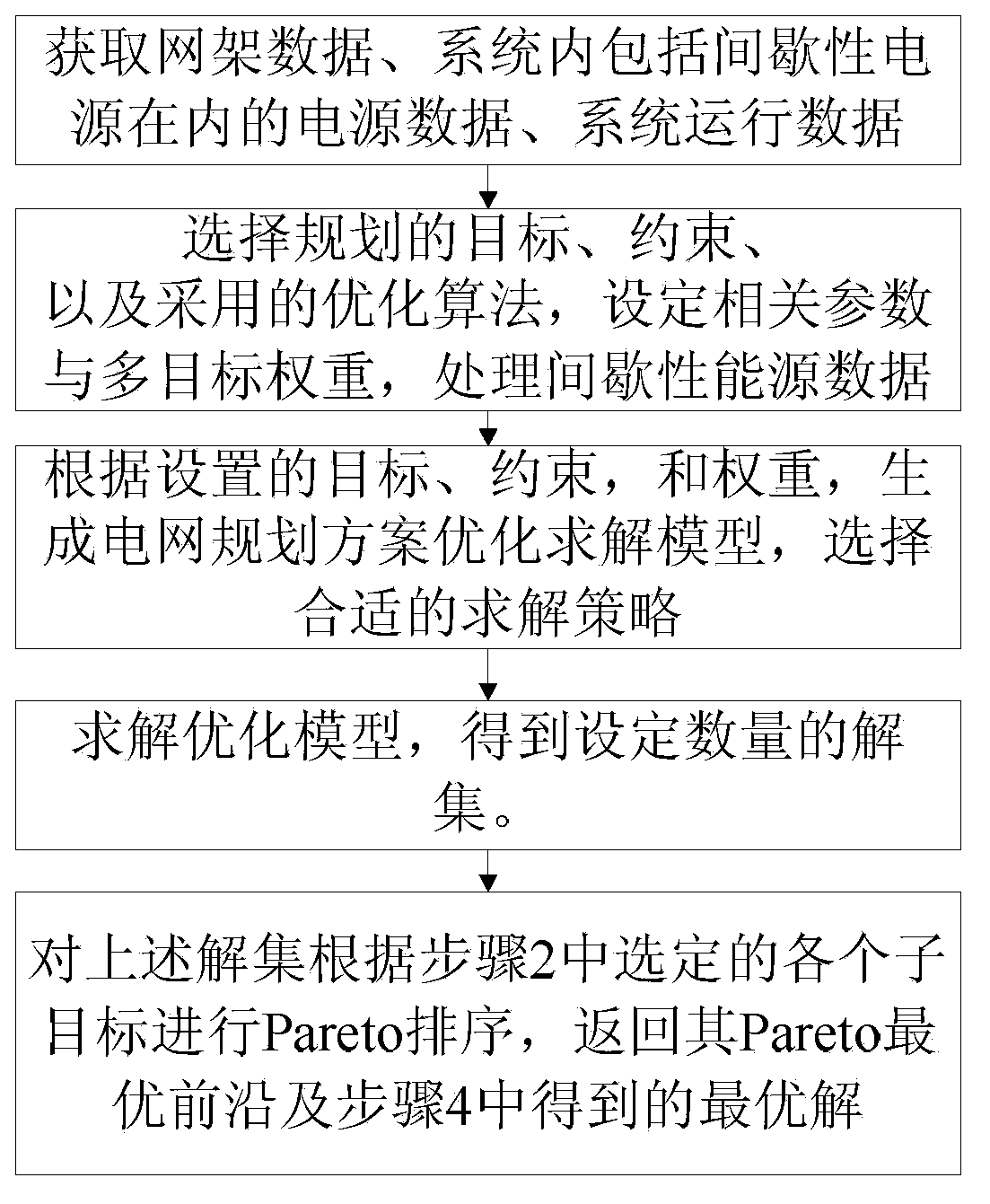

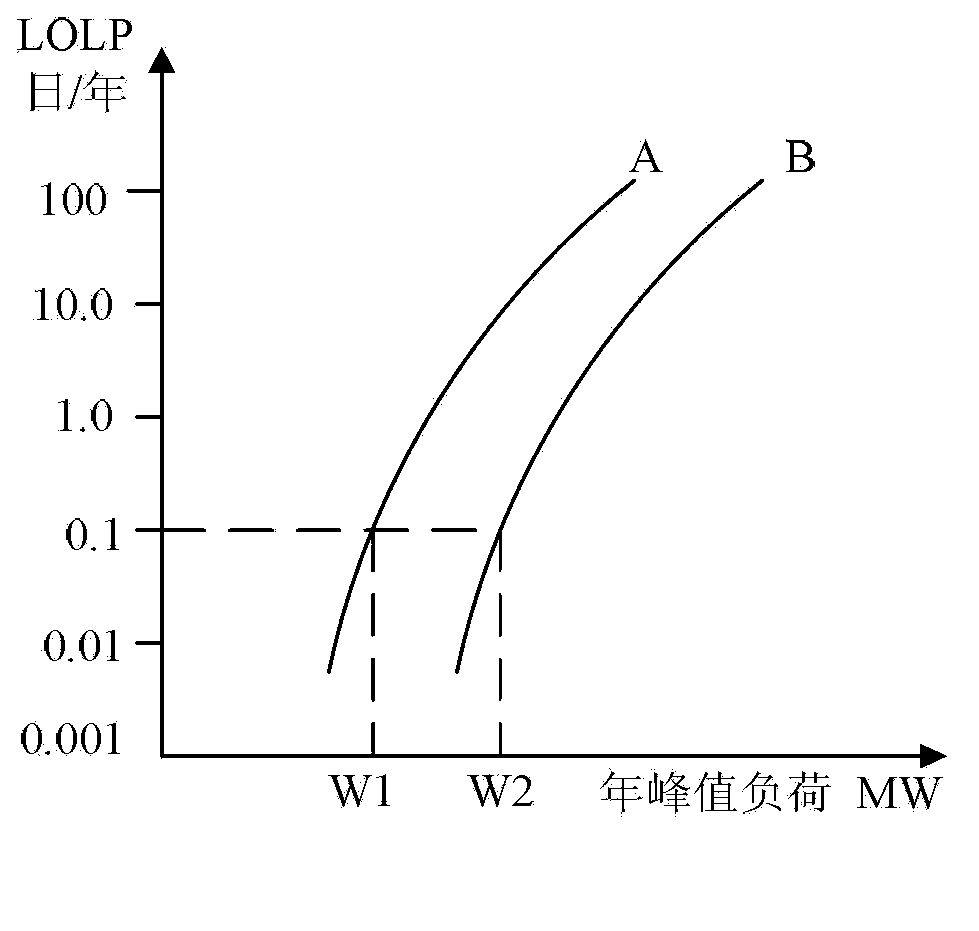

Regional power grid planning system containing high permeability intermittent energy and method thereof

InactiveCN103413194AImprove computing efficiencyImprove effectivenessTechnology managementResourcesGeneration processPower grid

The invention discloses a regional power grid planning system containing high permeability intermittent energy and a method thereof, and the system provides multi-objective and multi-constraint selections and has high efficiency. According to the system and the method, different planning requirements are satisfied through providing optional multiple objectives, multiple constraints and multiple algorithms, at the same time, the application of a stochastic production simulation parsing algorithm of a power grid to the generation process of a planning scheme is considered, and quick solution can be carried out. According to the system and the method, an intermittent power supply which is equivalent to a normal unit assembly in a method processing system is employed, and the computational efficiency of the stochastic production simulation is raised obviously. At the same time, a weighing method is employed to process multiple objectives, the feedback of a follow-up evaluation decision-making process can be received at the same time, and the constant revision of the scheme is facilitated. Finally, a solution set sent by the regional power grid comprehensive planning method is a noninferior solution after pareto optimization, thus the improvement of the overall effectiveness of the solution set on the basis that a solution flexibility is maintained is assisted, and the follow-up planning work process is facilitated.

Owner:SOUTHEAST UNIV

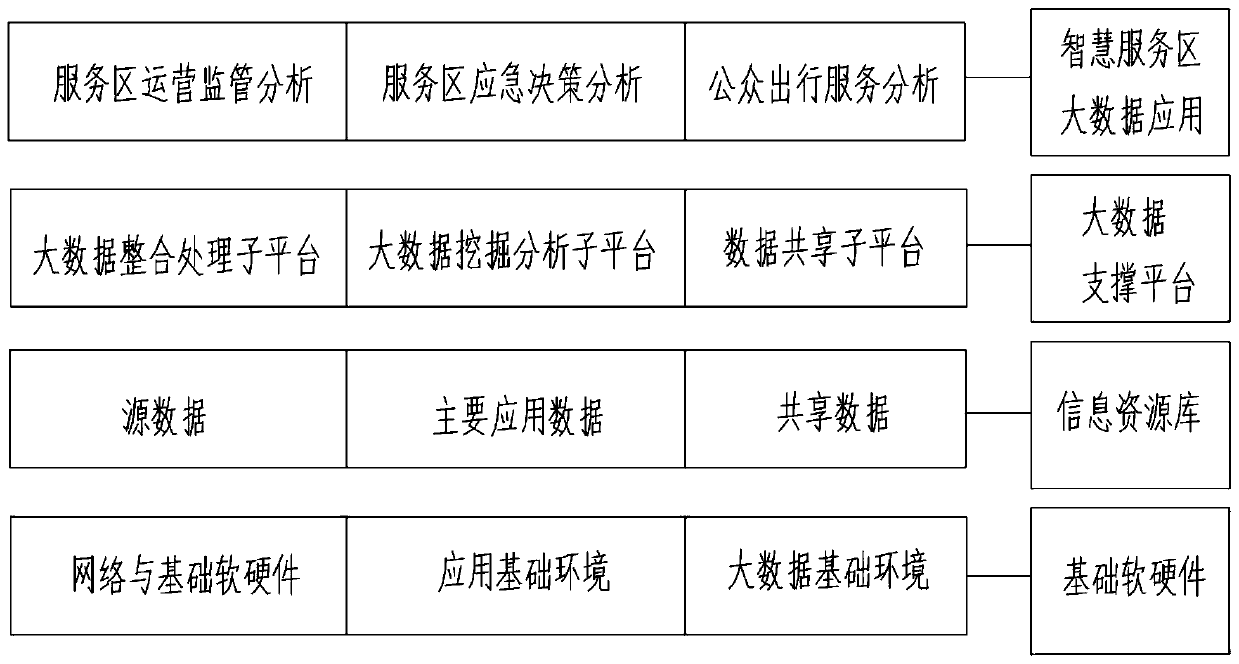

A service area big data intelligent service platform

PendingCN109727173AAchieving Collaborative SupervisionImprove efficiencyData processing applicationsInformation resourceIntelligent management

The invention discloses a service area big data intelligent service platform, which adopts a layered design and comprises a basic software and hardware layer, an information resource library layer, abig data support platform layer and an intelligent service area big data application layer from bottom to top. After the design is adopted, tThe service area big data intelligent service platform hasthe advantages that Guided by the intelligent management and service demand of the expressway service area, with innovation as the driving force and new technologies such as big data, cloud computingand artificial intelligence as the core support, the big data intelligent service platform of the expressway service area was designed and constructed., comprehensive planning and integration of massinformation resources required by cooperative supervision of the expressway service area and public service and service value mining are achieved, and the use efficiency and the application level of expressway traffic service resources are improved.

Owner:贵州银智科技发展有限公司

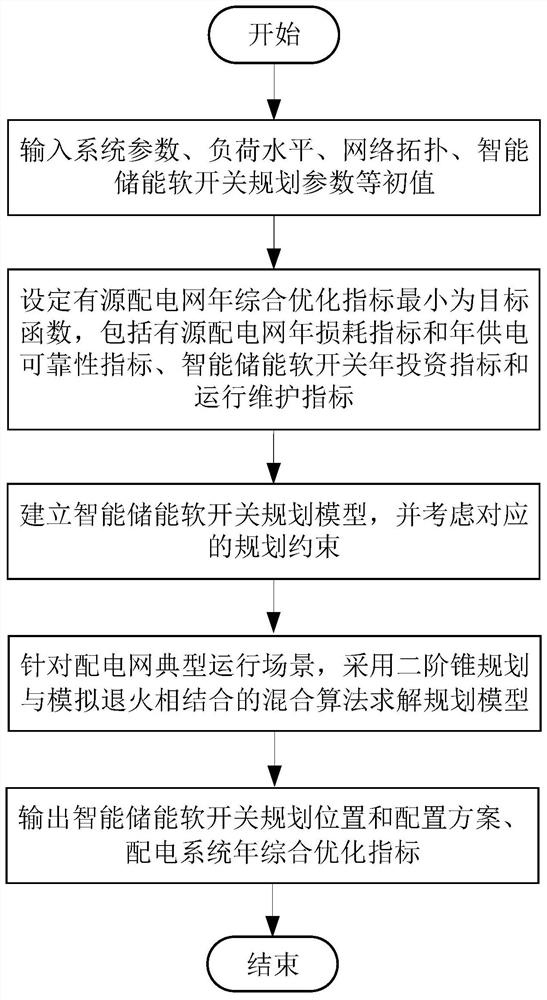

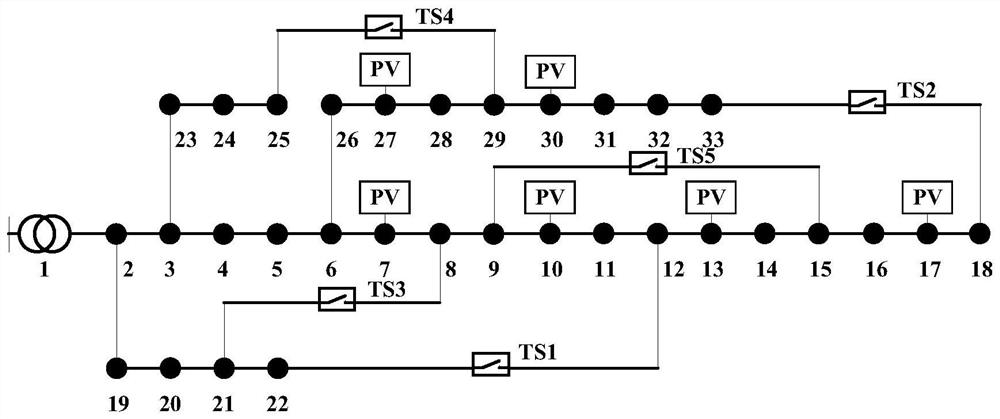

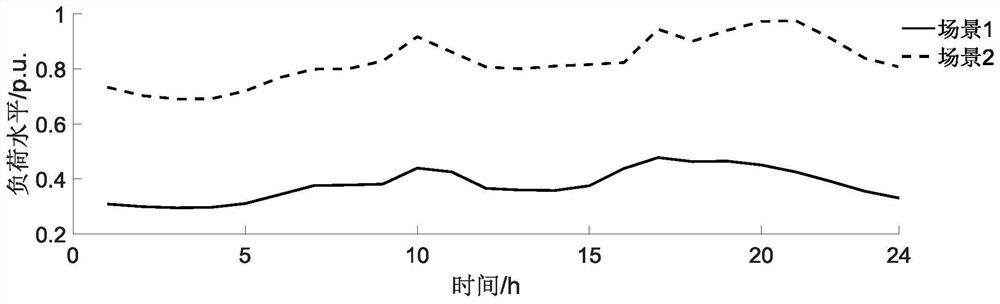

Power distribution network intelligent energy storage soft switch comprehensive planning method and system

InactiveCN111682585AEnsure power supply reliabilityReduce configuration costsSingle network parallel feeding arrangementsAc network load balancingSoft switchingSimulated annealing

The invention relates to a power distribution network intelligent energy storage soft switch comprehensive planning method and system, and the method is characterized by comprising the following steps: 1) collecting related parameters of a to-be-planned power distribution system; 2) establishing an intelligent energy storage soft switching planning model; and 3) for a given typical operation sceneof the power distribution network and related parameters of the power distribution system, solving the intelligent energy storage soft switch coordination planning model by adopting a hybrid algorithm combining second-order cone programming and simulated annealing to obtain an optimal intelligent energy storage soft switch planning scheme. The effect of improving the power supply reliability of the active power distribution network by the intelligent energy storage soft switch is fully considered, and the method and system can be widely applied to the field of intelligent energy storage softswitch comprehensive planning in the active power distribution network.

Owner:STATE GRID ECONOMIC TECH RES INST CO +2

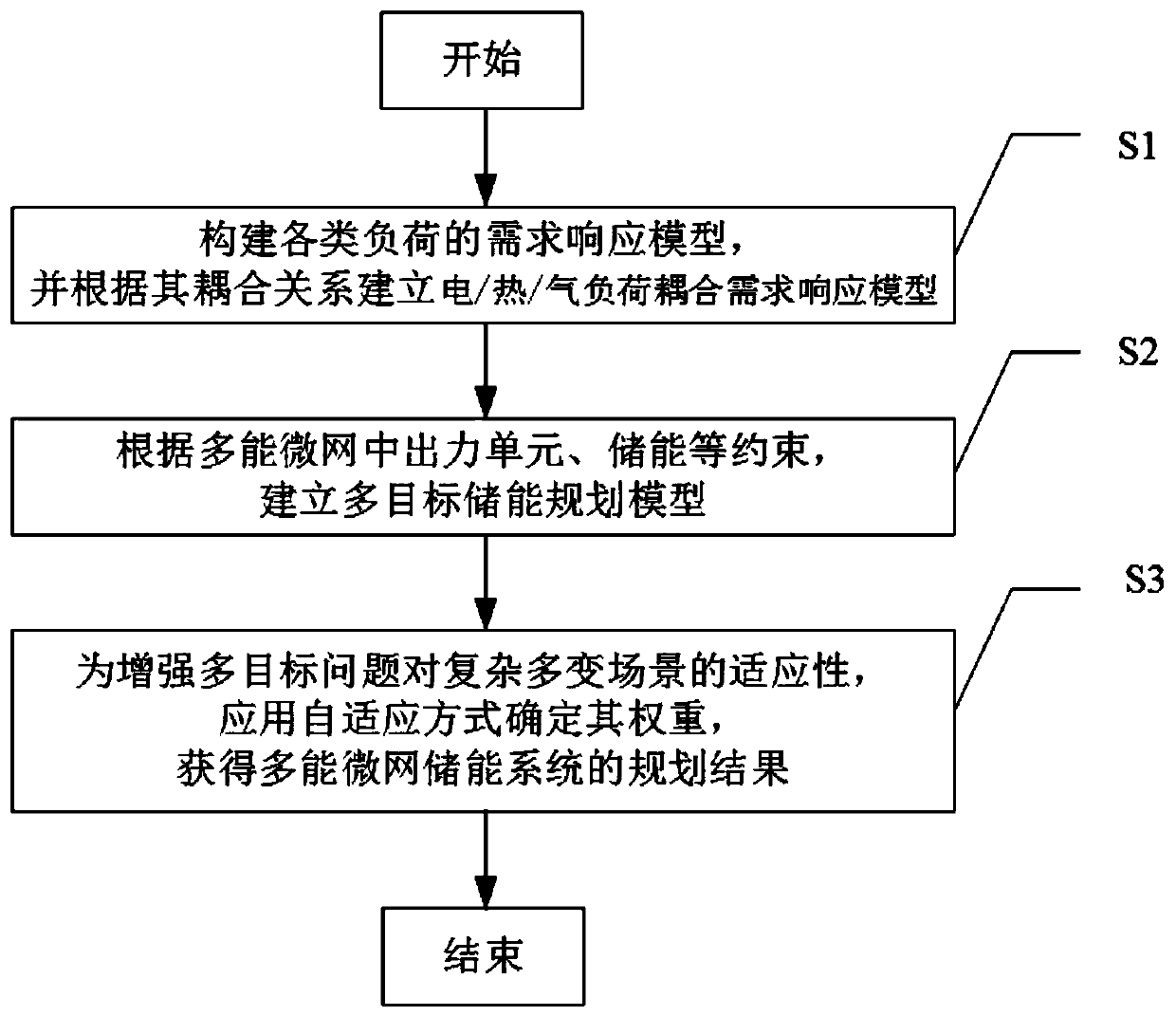

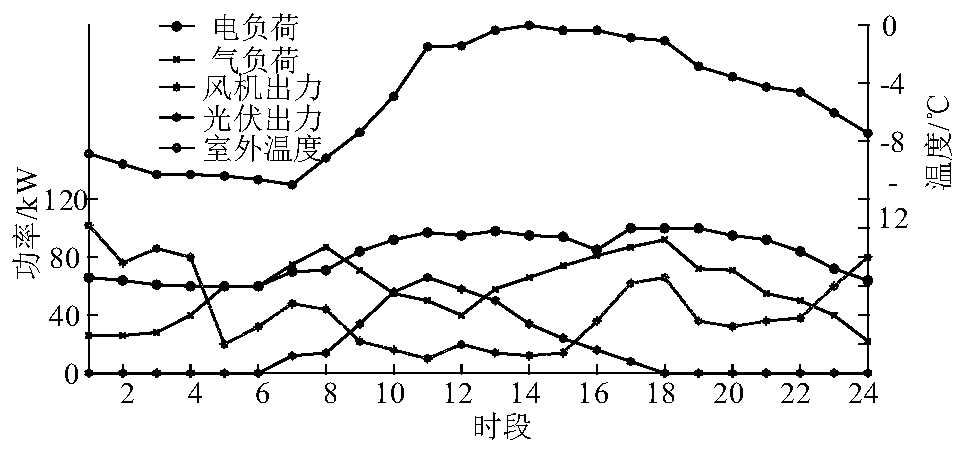

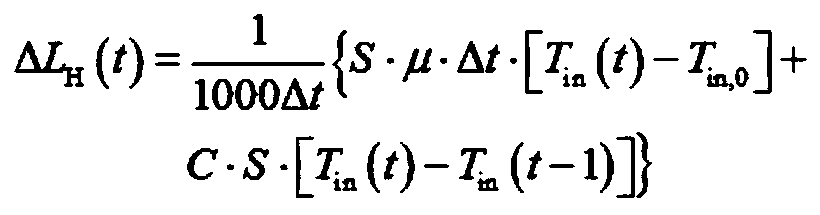

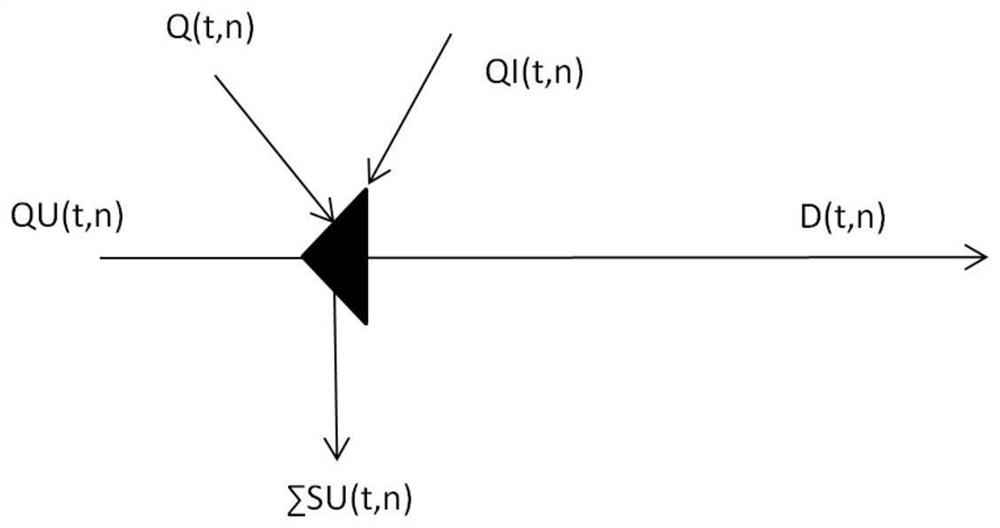

Comprehensive optimal configuration method for multiple energy storage capacities of multi-energy microgrid

InactiveCN110705737AImprove economyPromote environmental protectionForecastingResourcesMicrogridControl engineering

The invention discloses a comprehensive optimization configuration method for multiple energy storage capacities of a multi-energy microgrid, the comprehensive optimization configuration method comprises the steps of S1, respectively constructing demand response models of various loads, and establishing an electricity / heat / gas load coupling demand response model according to a coupling relationship of the various loads; S2, constructing a microgrid multi-target energy storage configuration model according to constraint conditions in the multi-energy micro-grid; and S3, determining a weight factor based on the adaptive dynamic weight factor optimization model to obtain a planning result of the microgrid multi-target energy storage configuration model. The invention aims at a multi-energy microgrid containing wind-solar power generation and electricity / heat / gas load. On the basis of building virtual heat storage, transferable characteristics of electrical load and gas load are considered, a multi-energy microgrid multi-energy storage capacity comprehensive planning multi-objective optimization model considering coupling demand response is established with economic cost and carbon emission as objectives, and a self-adaptive dynamic weight factor is adopted to adapt to flexibility and variability of a planning scene.

Owner:SICHUAN UNIV

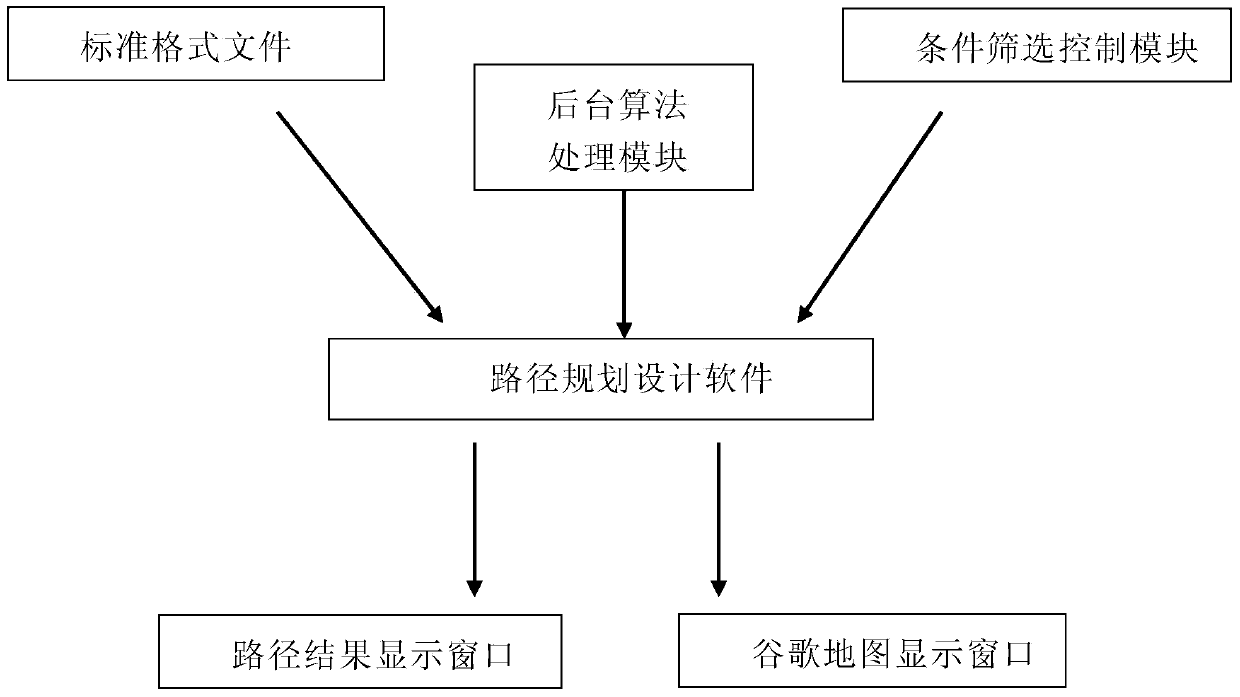

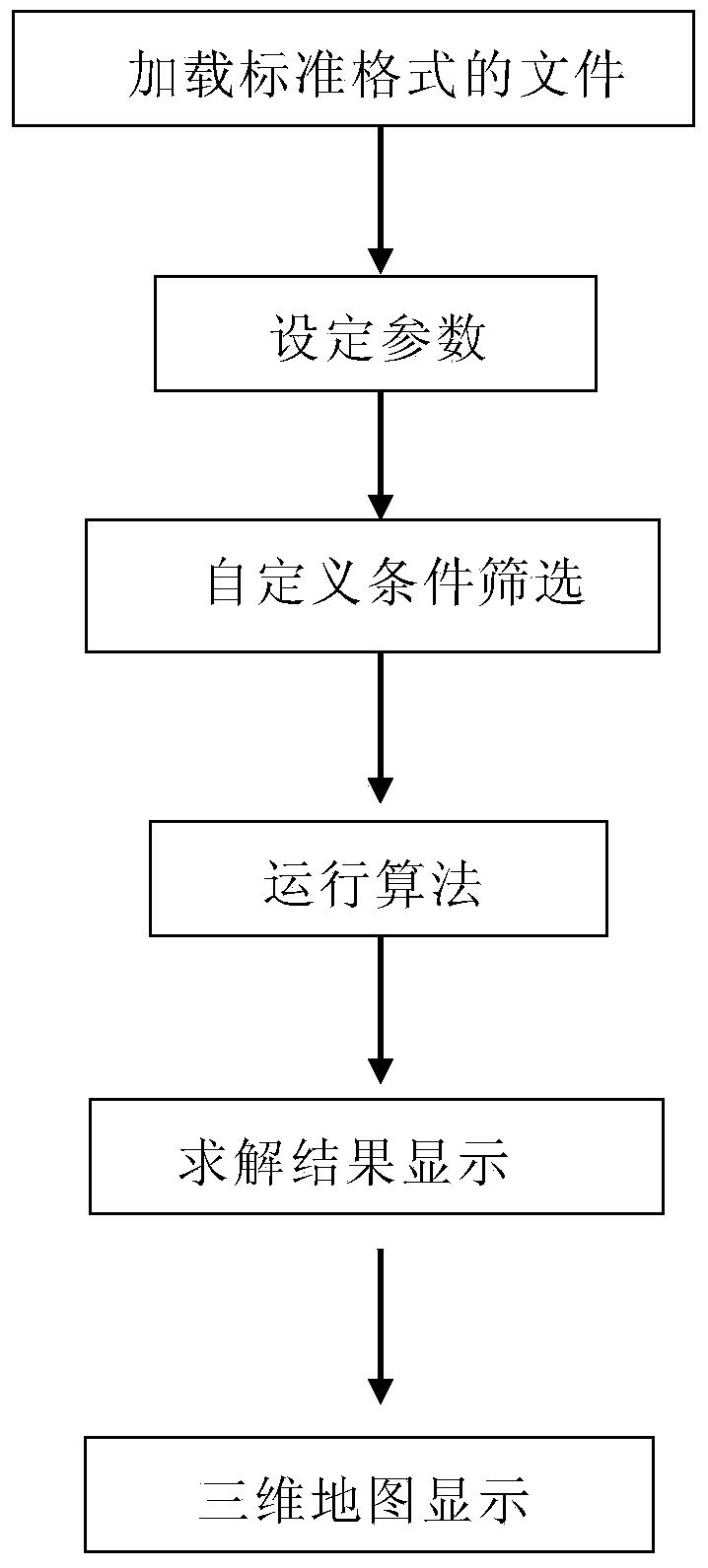

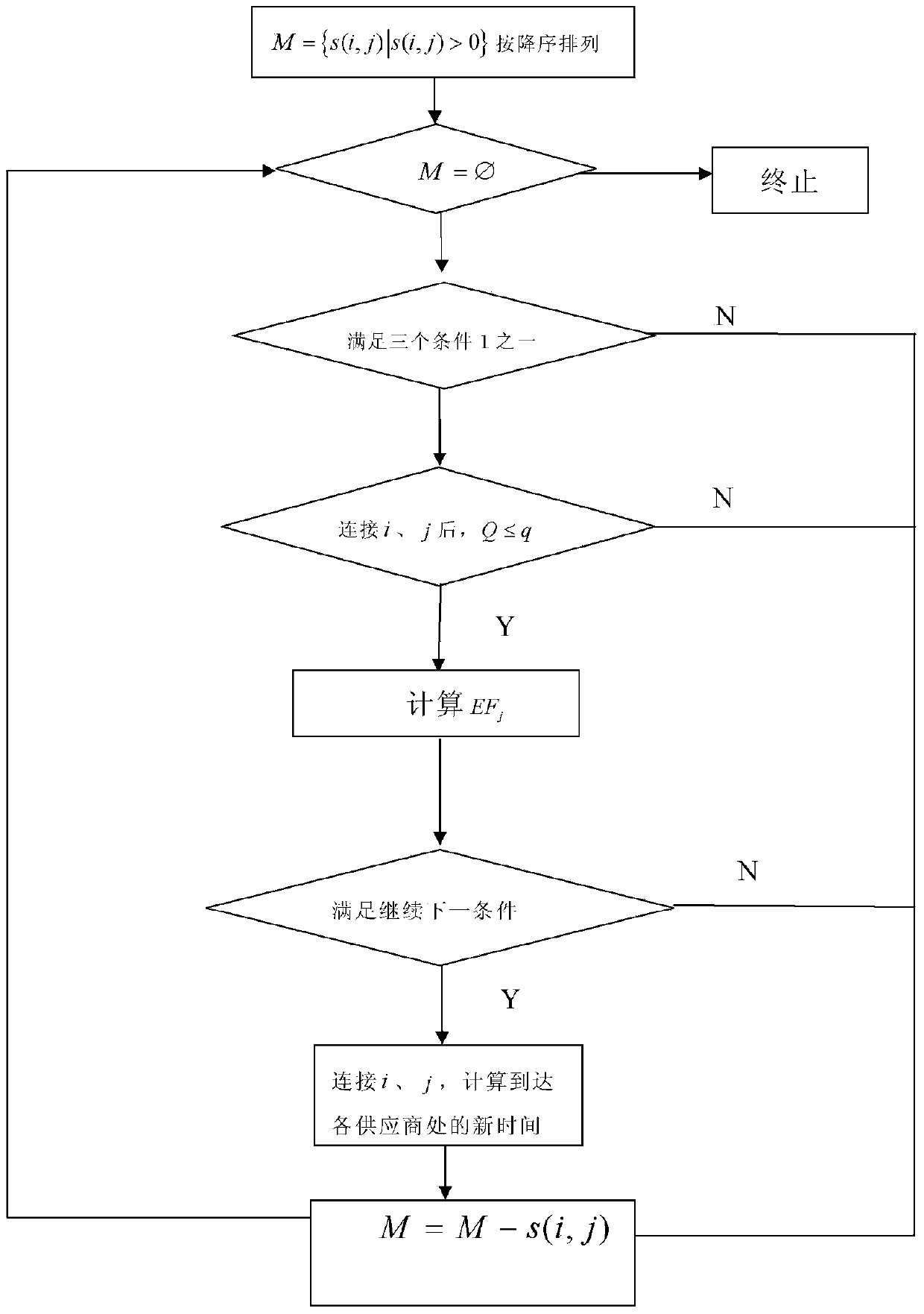

Comprehensive planning method for paths of vehicles for picking up goods

InactiveCN103745021AHigh precisionIncrease load rateSpecial data processing applicationsImproved algorithmTransport engineering

Provided is a comprehensive planning method for paths of vehicles for picking up goods. The method includes the steps that an improved C-W path planning algorithm is improved based on introduction of time windows and vehicle types as restriction, suppliers are selected according to constraint conditions of the distance between the suppliers and a main machine factory and the frequency for picking up the goods, carrying out solution by using the improved C-W algorithm to obtain corresponding planning paths and corresponding loading rates of the vehicles, and a proper type of vehicles can be selected to transport the goods according to the solving results. According to the comprehensive planning method, complete and visualized path planning software can be developed, and the paths can be displayed in Google maps through the API technology, and transportation management personnel and drivers of enterprises can conveniently use the comprehensive planning method.

Owner:SHAANXI UNIV OF SCI & TECH

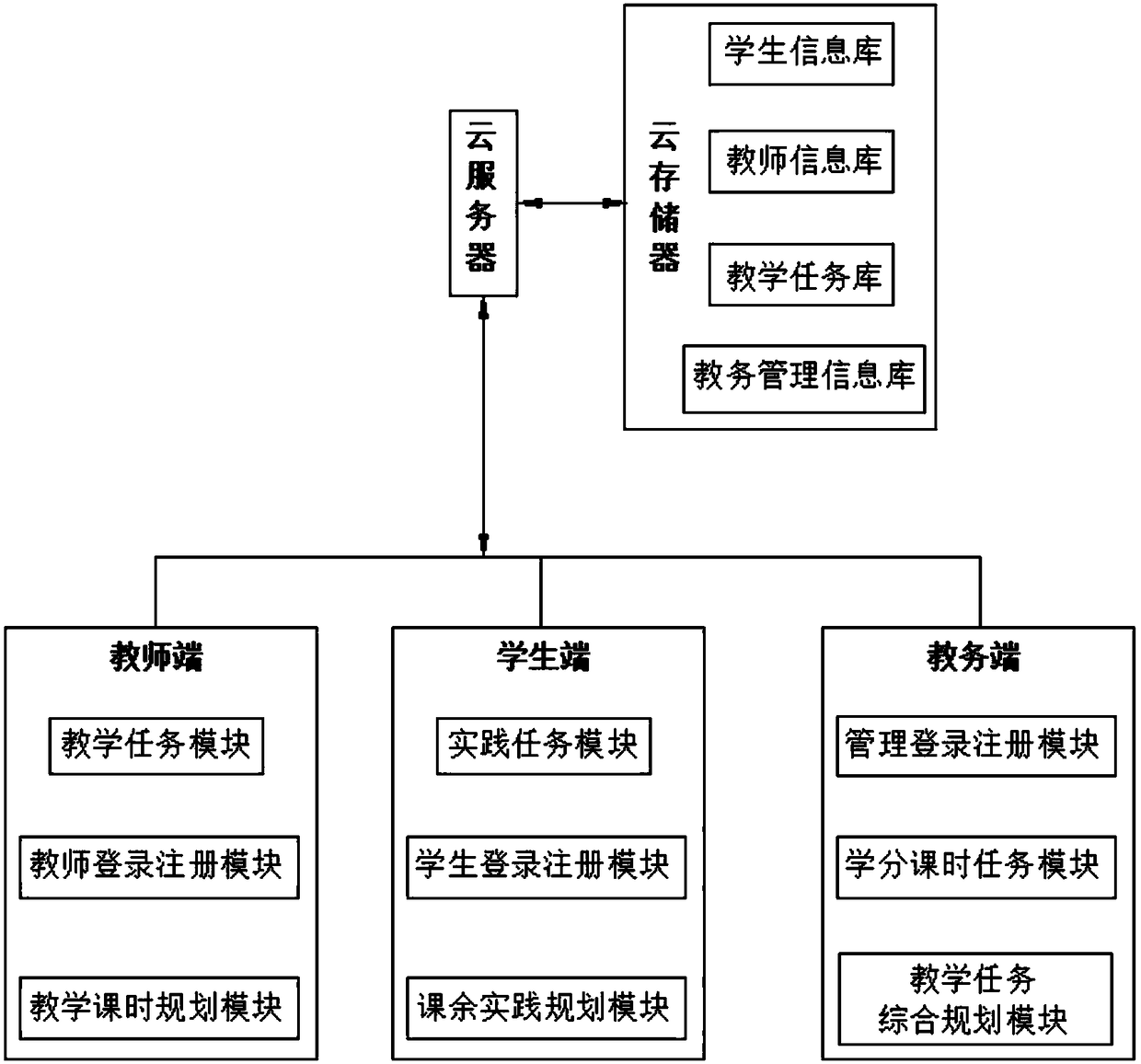

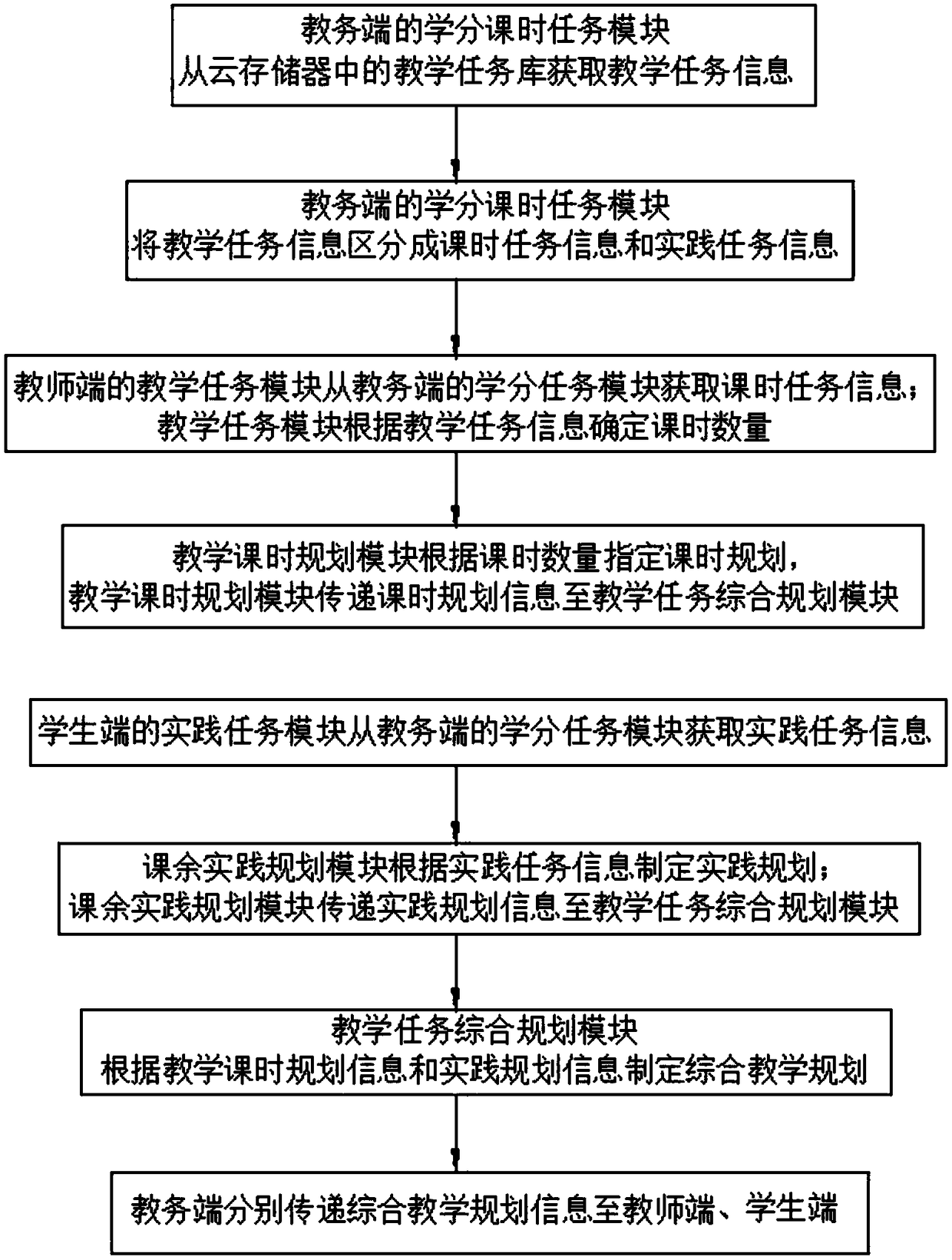

Education big data based study planning system and method

InactiveCN108133358AImprove learning efficiencyAchieving Coordinated PlanningOffice automationElectrical appliancesSoftware developmentStudy planning

The invention discloses an education big data based study planning system and relates to the technical field of software development of study planning systems and methods. The system comprises a cloudserver, a teacher side, a student side and a teaching affair side, wherein the cloud server is in communication with the teacher side, the student side and the teaching affair side respectively through a network; a teaching affair side server is in communication with the teacher side and the student side respectively through the network; the teacher side comprises a teacher logining and registering module, a teaching task module and a teaching time planning module; the student side comprises a student logining and registering module, a practice task module and an after-school practice planning module; and the teaching affair side comprises a management logining and registering module, a credit hour task module and a teaching task comprehensive planning module. According to the system disclosed by the invention, the credit hour task module and the teaching task comprehensive planning module are arranged at the teaching affair side and the teaching task module and the teaching time planning module are arranged at the teacher side to realize the coordinated planning of students, teachers and teaching affair administration staff, so that the study efficiency of the students is increased and convenience is brought to school management.

Owner:安徽华久信科技有限公司

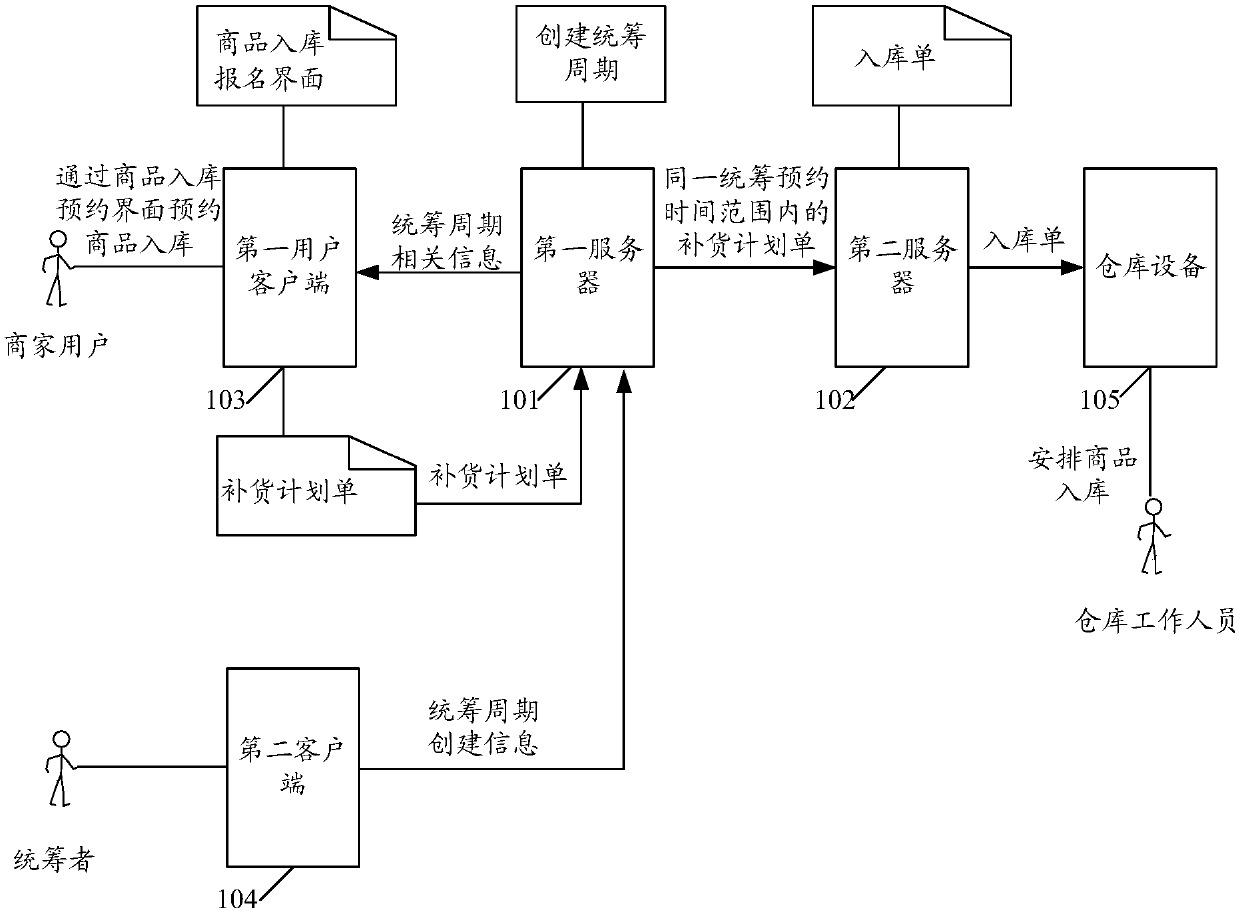

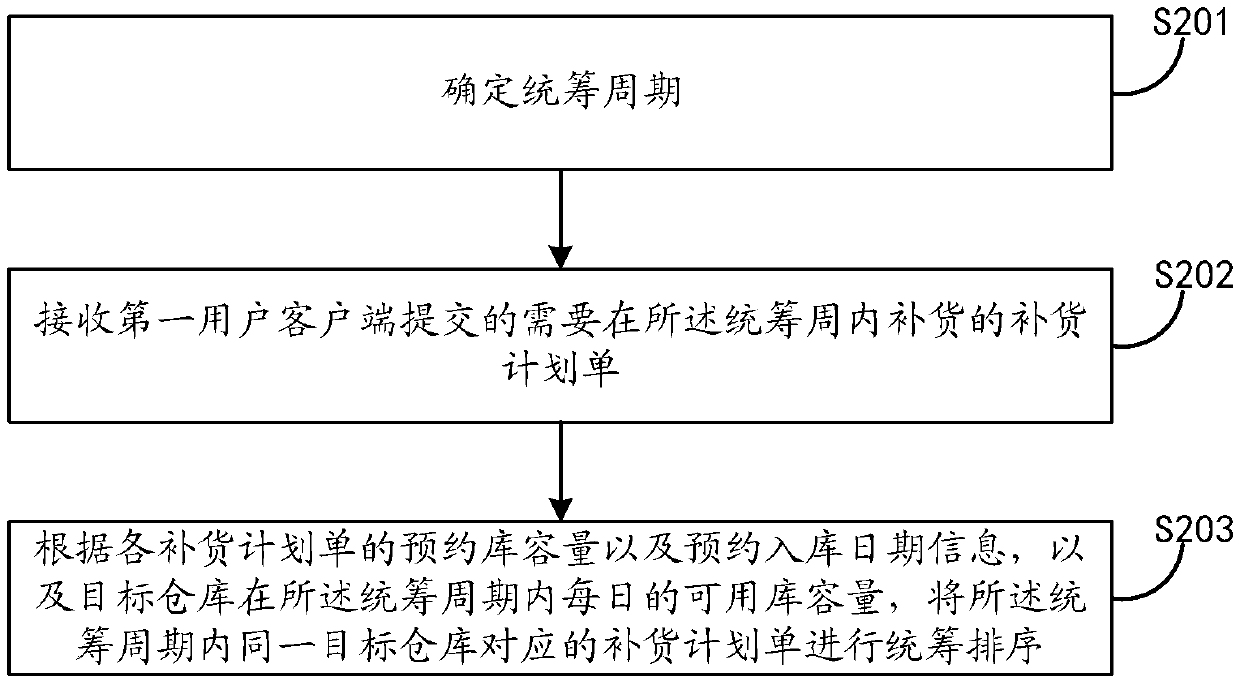

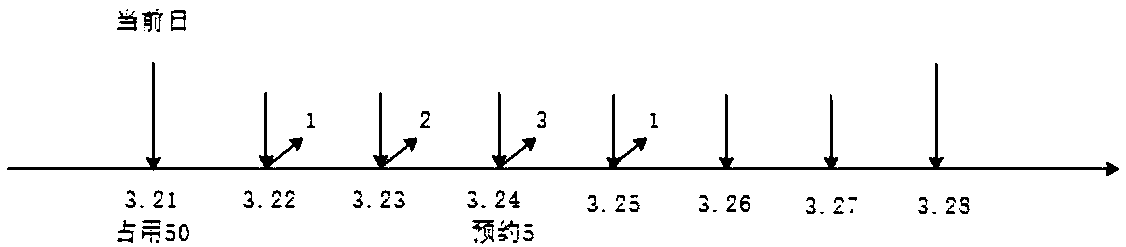

Warehousing resource allocation method and device and computer system

The invention provides a warehousing resource allocation method and device and a computer system. The warehousing resource allocation method comprises the steps: determining a comprehensive planning period; receiving a replenishment plan sheet which is submitted by a first user client and needs to be replenished in the overall planning cycle, the replenishment plan sheet comprising the reservation warehouse capacity and reservation warehouse-in date information about commodity warehouse-in reserved by the first user, and the reservation warehouse-in date being within the date range of the overall planning cycle; and according to the reserved warehouse capacity and the reserved warehousing date information of each replenishment plan sheet and the daily available warehouse capacity of the target warehouse in the overall planning period, carrying out overall planning and sorting on the replenishment plan sheets corresponding to the same target warehouse in the overall planning period so as to generate a warehousing sheet for the target warehouse according to an overall planning and sorting result. According to the embodiment of the invention, automatic overall sorting of the replenishment plans can be realized.

Owner:ALIBABA GRP HLDG LTD

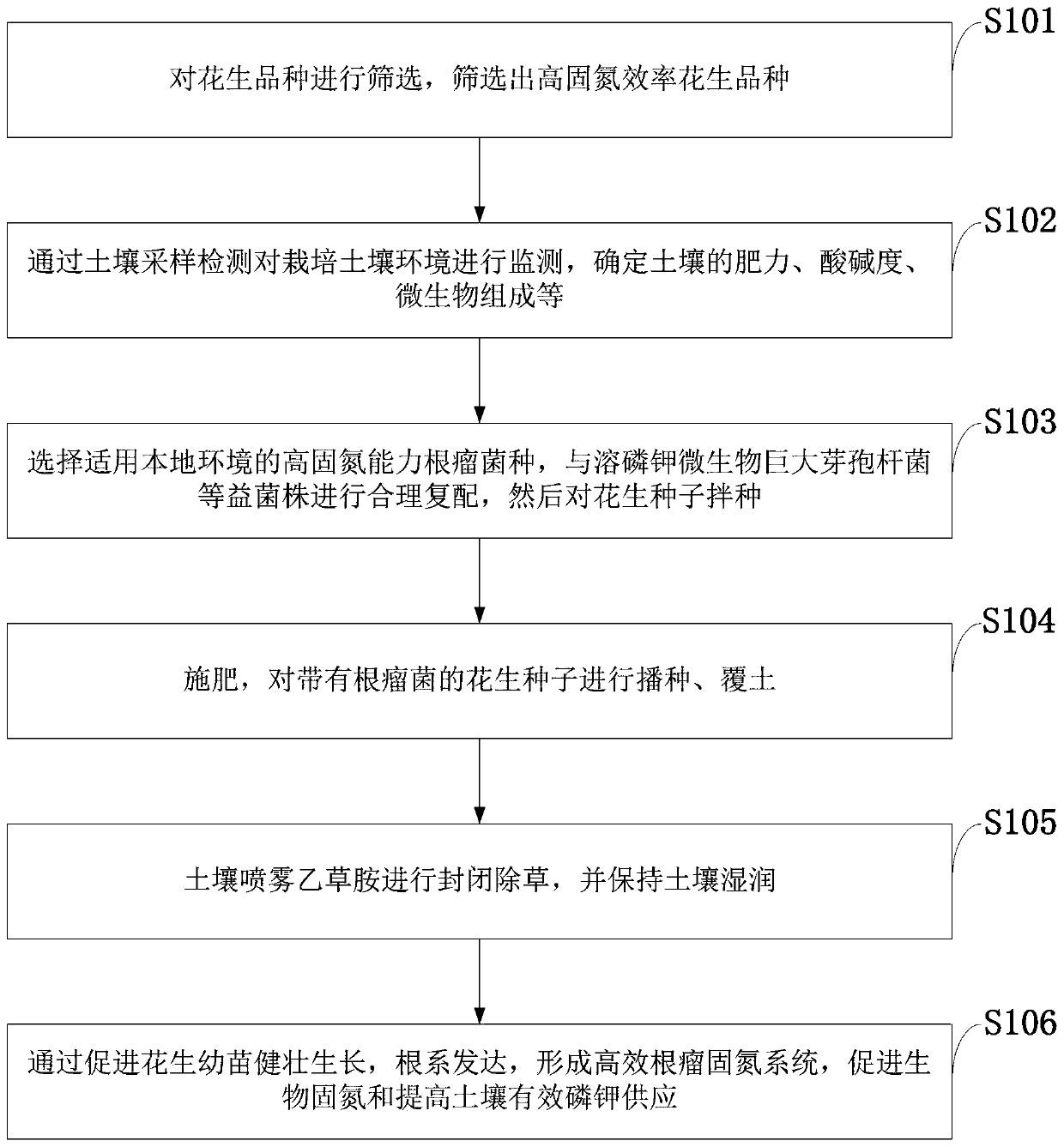

Method for promoting peanut root nodule to fix nitrogen

InactiveCN109769615AGuaranteed survival rateEnsure normal growth and reproductionFabaceae cultivationEarth material testingBacillus megateriumPlant nodule

The invention belongs to the technical field of root nodule nitrogen fixation and discloses a method for promoting peanut root nodule to fix nitrogen, which comprises the following steps of: screeningpeanut varieties, selecting peanut varieties which are planted locally and have early nodule formation and large root nodule formation, monitoring the physicochemical properties of cultivation soil,determining the fertility level, pH value, microorganism composition and the like of the soil; applying 15 kg of ammonium sulfate, 20 kg of nitrogen-phosphorus-potassium compound fertilizer (N-P2O5-K2O=15-15-15) and 50 kg of calcium-magnesium phosphate fertilizer in every 666.67 square meters of sowing furrows, and the furrows are covered with soil so that the depth of the furrows is 3-5 cm; mixing a nitragin used for local place with water to obtain paste, mixing and stirring the paste with peanut seeds and seeding, in addition, reasonably compounding peanut root nodule nitrogen fixation strains with beneficial strains such as phosphorus and potassium soluble microorganism bacillus megaterium, so that the absorption of nutrients by peanuts and the growth of root systems are promoted, andthe root nodule nitrogen fixation effect is improved. The method has comprehensive planning, can give full play to the function of root nodule nitrogen fixation, reduces the influence of soil factorson the root nodule nitrogen fixation, and can greatly reduce the use amount of fertilizer.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

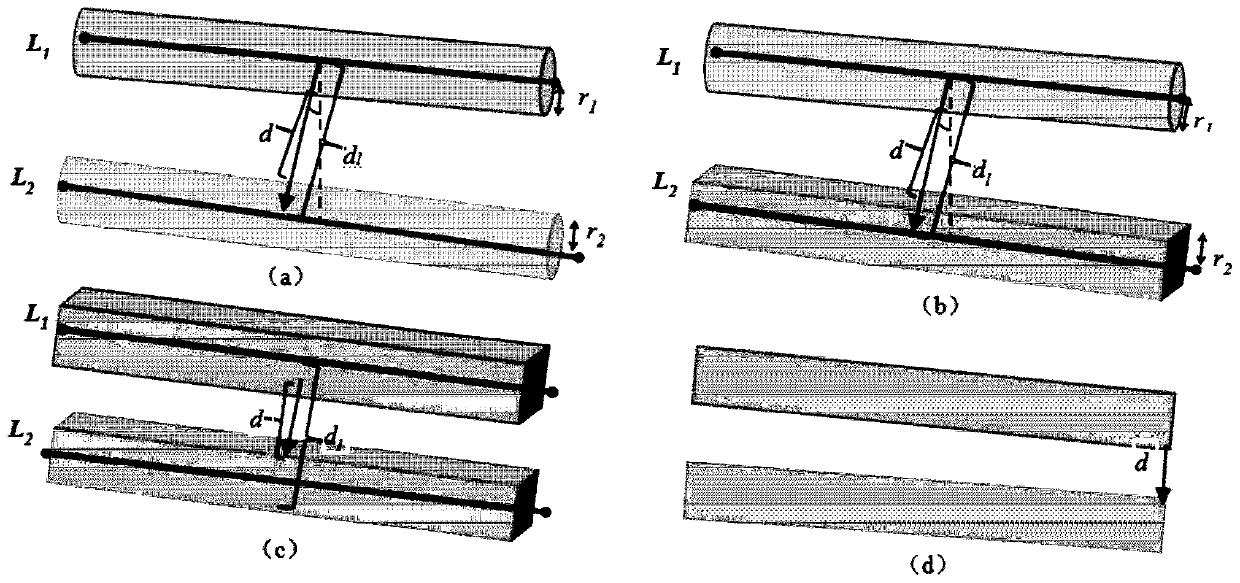

External damage prevention detection method and system for a power cable

InactiveCN109918815AEasy to adjust for constructionSpecial data processing applicationsPower cableCollision analysis

The invention relates to an external damage prevention detection method for a power cable, and the method comprises the following steps: 1, building a power cable collision analysis rule base with a power cable as a target based on the safety distance between the power cable specified by an urban engineering pipeline comprehensive planning specification and various municipal pipelines or buildings / structures; 2, acquiring basic information of the power cable, whether the actual distance between the municipal pipeline or building / structure and the power cable is matched with the power cable collision analysis rule base or not is judged category by category; Therefore, a part or all of the power cables which are not matched with the power cable collision analysis rule base are found out andserve as power cable objects which may have external damage hidden dangers, and then information of the power cable objects which may have the external damage hidden dangers is output. According to the invention, the possible external damage condition of the power cable can be rapidly detected and information can be output to remind related personnel, so that the construction adjustment is facilitated.

Owner:JIANGSU ELECTRIC POWER CO +1

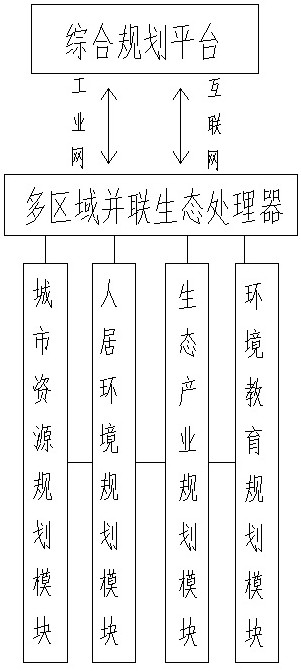

Ecological city comprehensive planning system and method

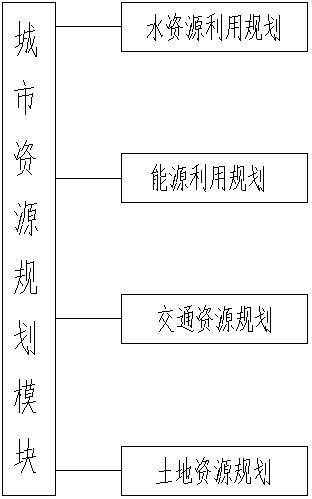

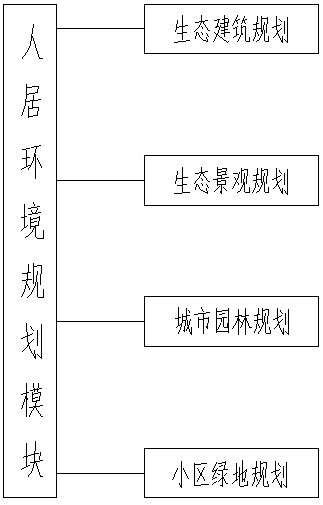

PendingCN111695772AEffectively combined with effective implementationEfficient integrationResourcesEnvironmental resource managementData acquisition

The invention relates to an ecological city comprehensive planning system and method; a comprehensive planning platform is included, the comprehensive planning platform is connected with at least onemulti-region parallel ecological processor through an industrial network. Each multi-region parallel ecological processor is connected with the urban resource planning module, the human settlement environment planning module, the ecological industry planning module and the environment education planning module in a wired industrial network connection mode; the urban resource planning module, the human settlement environment planning module, the ecological industry planning module and the environment education planning module are connected with one another through an industrial network; according to the invention, an efficient computer integrated data analysis method is adopted, and all intelligent and automatic data acquisition and analysis methods are adopted, so that data is effectivelyintegrated and analyzed, human resources are saved, the working and operating efficiency is improved, the planning result is accurate and errorless, and the requirements of current ecological city comprehensive planning are met.

Owner:史解放

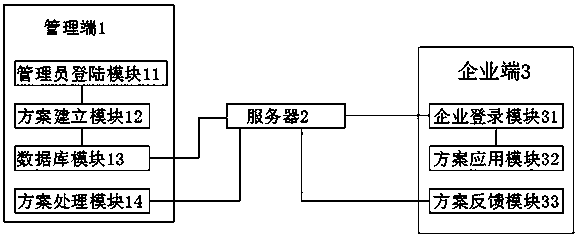

Marketing comprehensive planning service system

PendingCN108062628AHigh degree of intelligenceEasy to useResourcesSpecial data processing applicationsApplication moduleWorld Wide Web

The invention discloses a marketing comprehensive planning service system which comprises a management terminal, a server and an enterprise terminal. The management terminal comprises an administratorlogging-on module, a plan establishing module and a database module. The administrator logging-on module is used for member account number registering and member account number logging-on by an administrator. The plan establishing module is used for releasing a marketing plan by the administrator and furthermore transmits the marketing plan to the database module for storage. The enterprise terminal comprises an enterprise logging-on module and a plan application module. The enterprise logging-on module is used for enterprise member account number registering and logging-on by enterprise personnel. The plan application module is used for receiving the marketing plan transmitted from the server and displays the marketing plan for clicking and viewing by a user. The marketing comprehensiveplanning service system has advantages of high intelligence degree, high efficiency, etc.

Owner:广州新濠网络科技有限公司

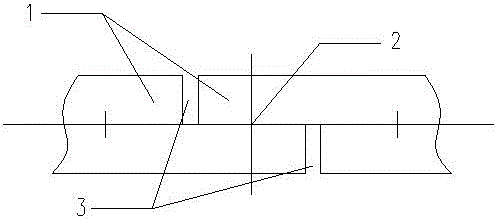

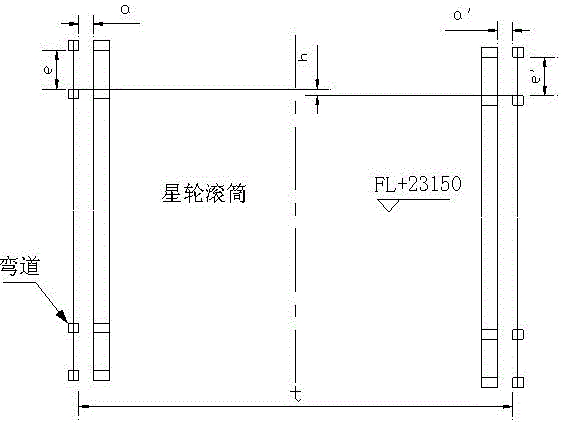

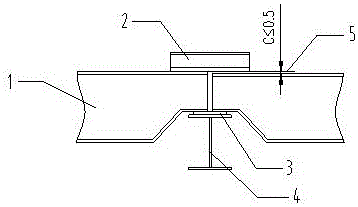

Air box and air box end seal installation method of sintering machine production line

InactiveCN107436095AAdvantages of the sealed installation methodEasy to operateFurnace componentsFurnace typesProduction lineWear resistant

The invention discloses an air box and air box end seal installation method of a sintering machine production line. The method is characterized by comprising the following steps: a, after an air box side beam is installed in place, checking the elevation, levelness and center deviation of the side beam; b, before slideways are installed, carefully measuring the machining size of each slideway and recording the machining sizes; c, coating contact surfaces of the slideways and the side beam with high-temperature-resistant sealants; d, when an air box floating beam is installed, adjusting the gap between the floating beam and a framework cross beam to 0.1-0.5 mm by adjusting a gasket group; e, before an air box is installed, cleaning up oil stains and rust on flange faces; and f, carefully checking the machining quality with all parties before installing air box end seals, and especially checking square wear-resistant lining plates on the surfaces of the end seals. The air box and air box end seal installation method of the sintering machine production line has the advantages that comprehensive planning is achieved, an overall arrangement is achieved, the operability is high, the mounting precision of the air box and the air box end seals of the sintering machine production line is high, the steps are connected and coordinated smoothly, the installation efficiency is improved, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

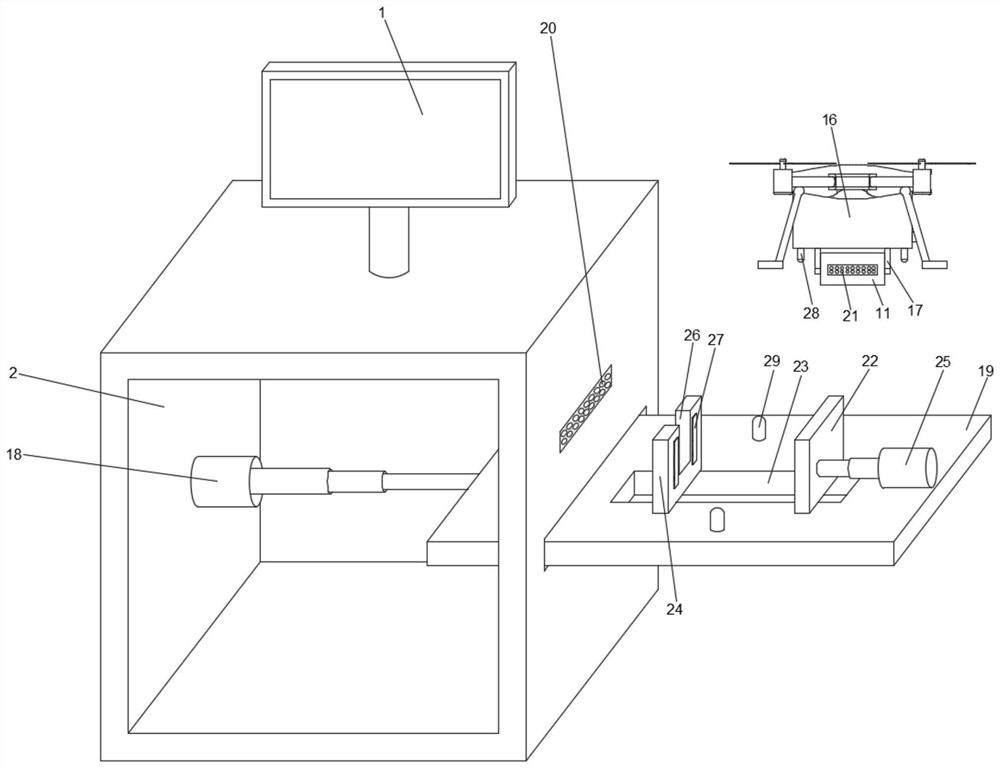

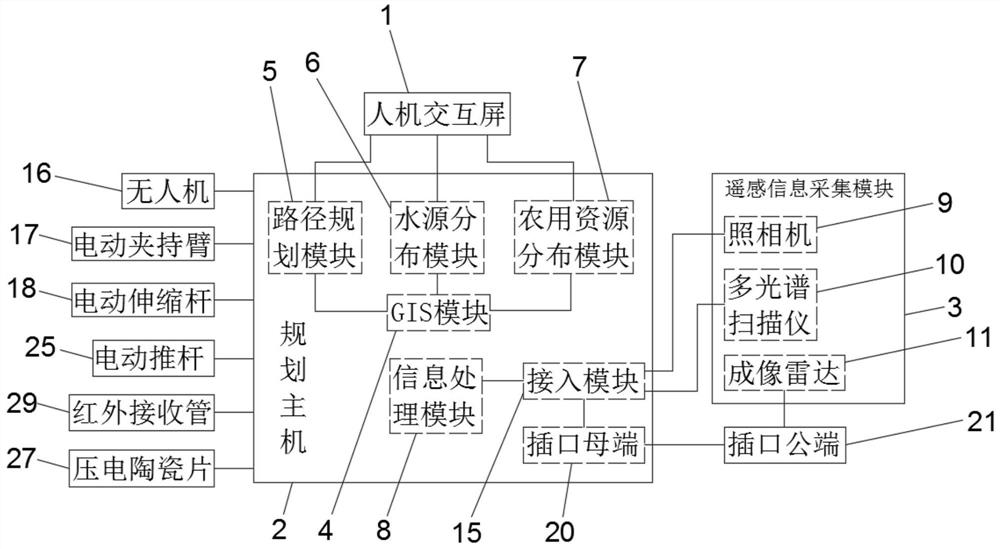

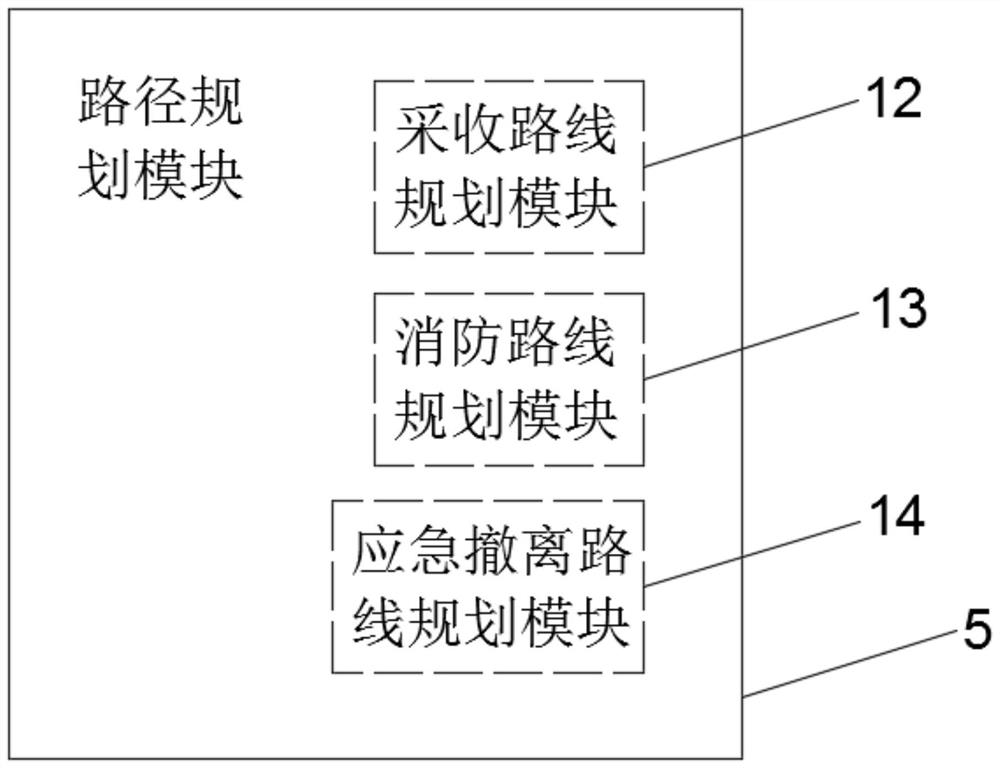

Tropical farm planning and management system based on GIS and remote sensing technology

PendingCN112580873ARealize the planAchieve drainageMeasurement devicesForecastingInformation processingEnvironmental resource management

The invention provides a tropical farm planning and management system based on a GIS and a remote sensing technology, and the system comprises a man-machine interaction screen, a planning host, and aremote sensing information collection module; the interior of the planning host is provided with a GIS module, a path planning module, a water source distribution module, an agricultural resource distribution module, and an information processing module; the remote sensing information acquisition module comprises a camera, a multispectral scanner and an imaging radar; the remote sensing information acquisition module acquires terrain, terrain, water source information and the like of a farm, the acquired data is transmitted to the planning host, and the planning host draws a map and superposesall resources according to GIS information. A harvesting route, a fire-fighting route, an emergency evacuation route, a planting route, a sewage drainage route and the like can be planned through thearranged route planning module, comprehensive planning and management of a farm are achieved, and effective utilization of resources and reasonability of crop planting are guaranteed.

Owner:海南金垦赛博信息科技有限公司

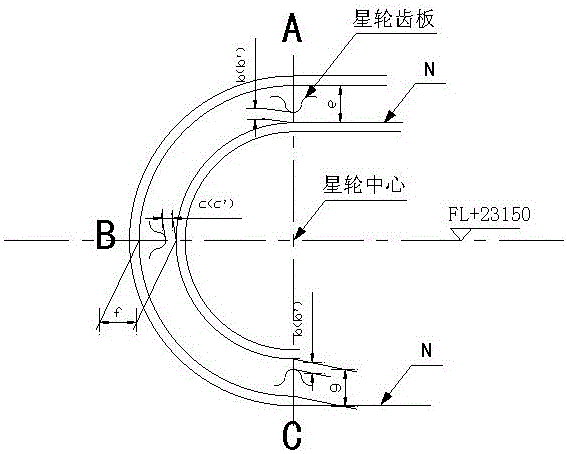

Method for installing track device of sintering machine production line

InactiveCN107436089AEasy to operateImprove installation accuracyCharge manipulationFurnace typesProduction lineOperability

The invention discloses a method for installing a track device of a sintering machine production line. The track device is divided into a head curve, a tail curve and a middle horizontal track. The method is characterized by comprising the following steps: a, checking and accepting the track device before installation of the track device; b, installing the head curve; c, installing the middle horizontal track; d, adjusting the elevation of the middle horizontal track by utilizing a gasket group below bearing beams; e, installing the tail curve; f, after the elevation of a track is adjusted, using a special measurement tool to adjust the track gauge of the track; and g, when the middle horizontal track and the bearing beams are installed, checking a long hole direction of reserved expansion gaps and expansion joints. The method for installing the track device of the sintering machine production line has the advantages that comprehensive planning is achieved, an overall arrangement is achieved, the operability is high, the mounting precision of the track device of the sintering machine production line is high, the steps are connected and coordinated smoothly, the installation efficiency is improved, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

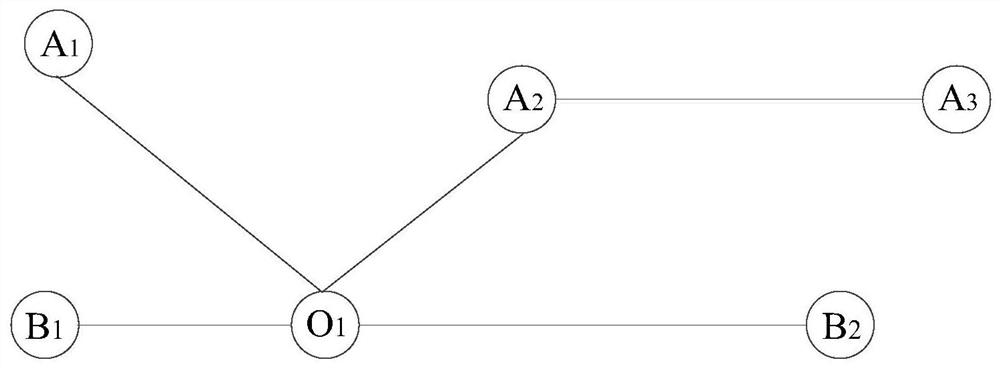

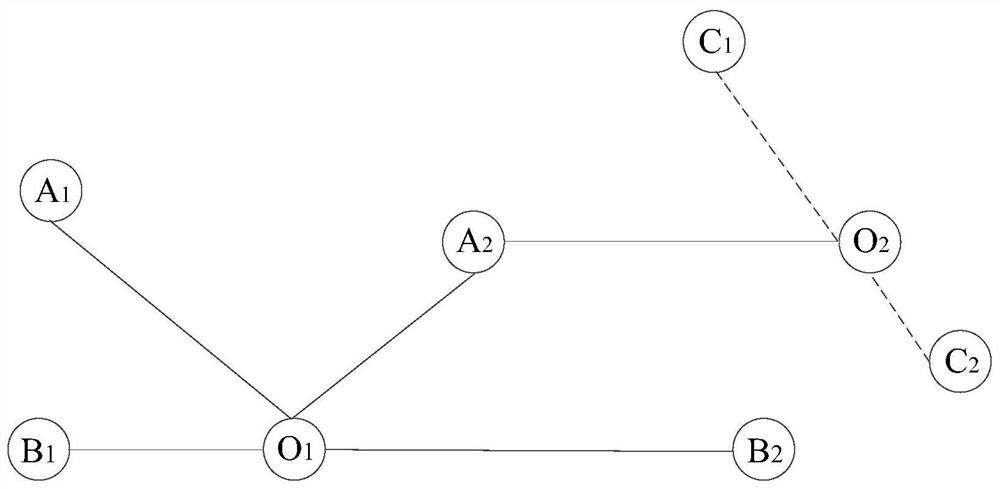

Urban rail transit planning method, server and computer readable storage medium

The invention relates to the technical field of urban rail transit. The invention discloses an urban rail transit planning method, a server and a computer readable storage medium. The planning methodof the urban rail transit comprises the following steps of: planning the urban rail transit; determining planning parameters of the urban rail transit according to the layout information of the urbanrail transit; wherein the planning parameters comprise part or all of a layout evaluation value used for representing the layout rationality of the urban rail transit, a layout reference value used for representing the resource allocation priority in the urban rail transit and a layout recovery value used for representing the damage influence degree in the urban rail transit. The planning method of the urban rail transit can realize comprehensive planning of the urban rail transit.

Owner:中国兵器科学研究院

Satellite demand planning system and method based on order overall planning

PendingCN114022170AShort response timeReduce work complexityBuying/selling/leasing transactionsResourcesData miningImaging data

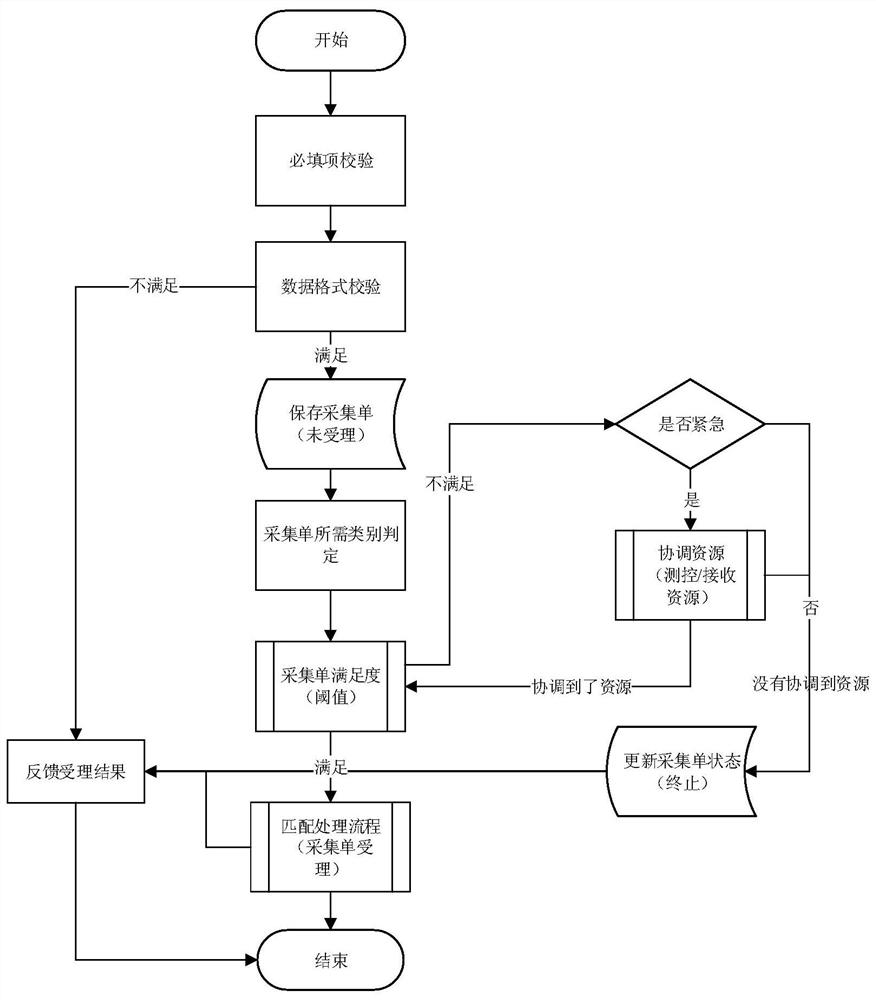

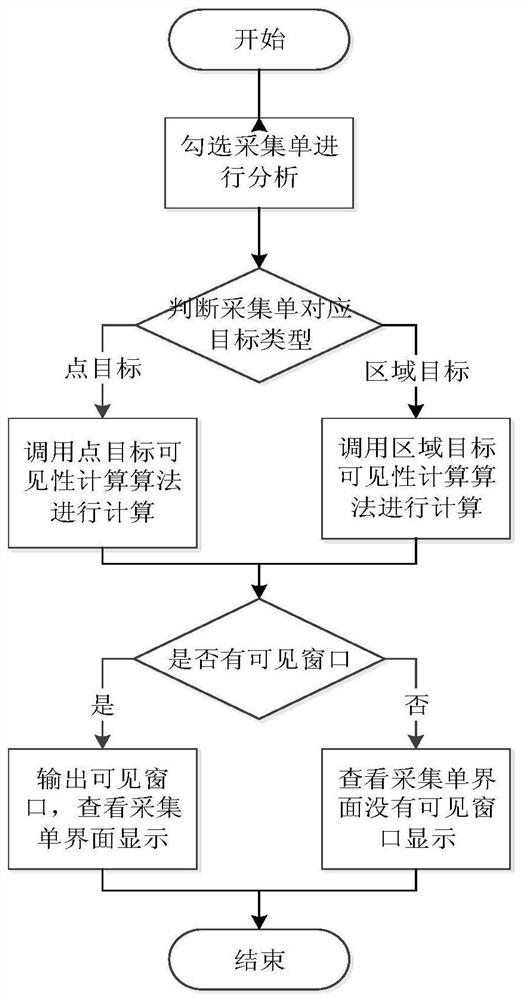

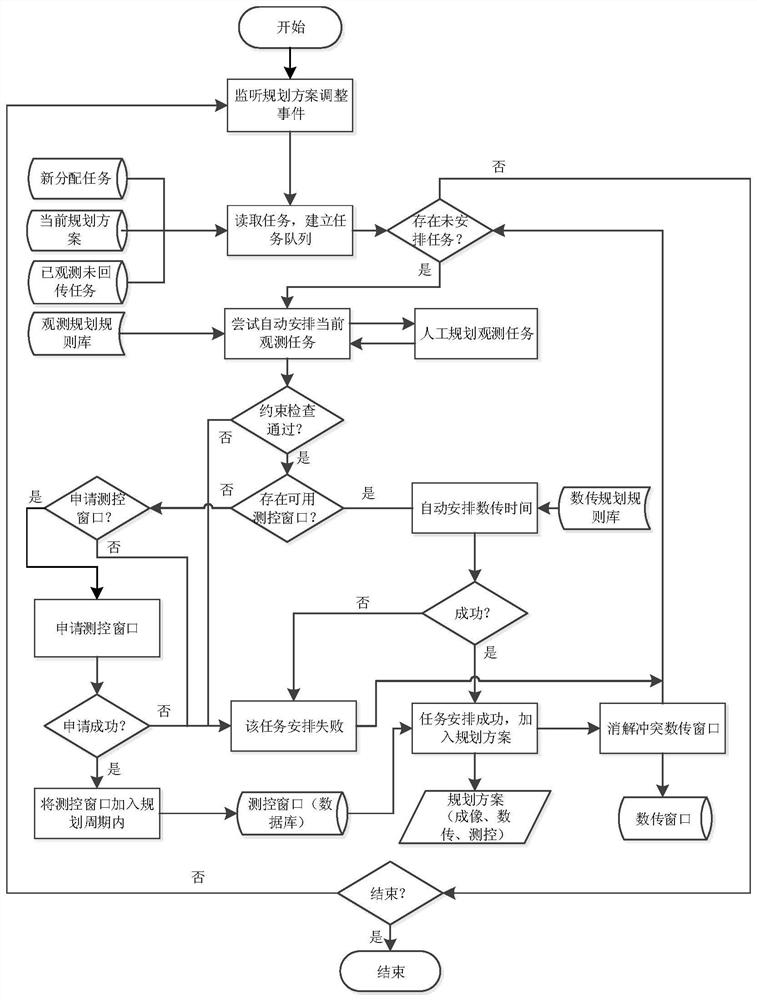

The invention provides a satellite demand planning system and method based on order overall planning. The system comprises a collection list management module, a comprehensive planning module, a collection list planning module, a closed-loop management module, and a GIS visual display module. Management and acceptance information feedback are carried out on the collection list; analyzing the collection list, determining a visible time window of an collection list task, and comprehensively managing the priority of the collection list task; according to the satellite capability condition and the ground use requirement, satellite planning scheduling is carried out, observation task conflicts and received resource use conflicts are eliminated, the performability of an collection list is comprehensively analyzed in combination with the weather condition and the historical imaging data condition, and an observation task planning plan is generated; and collecting all product information meeting requirements in the life cycle of the related collection lists, and determining the completion condition of the collection lists by comparing the collection areas with completed products so as to implement closed-loop management.

Owner:CHINA CENT FOR RESOURCES SATELLITE DATA & APPL

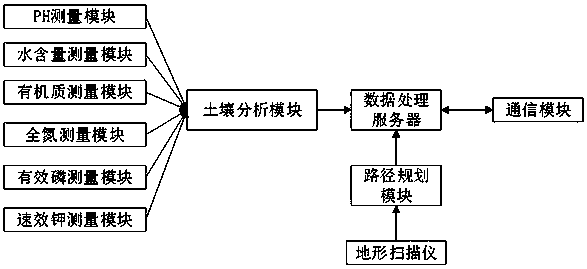

Plantation planning system based on big data

The invention discloses a plantation planning system based on big data. The system comprises a data processing server, the data processing server is connected with a soil analysis module, a path planning module and a communication module, and the soil analysis module is connected with a PH measuring module, a water content measuring module, an organic matter measuring module, a total nitrogen measuring module, an available phosphor measuring module and an available potassium measuring module. The beneficial effects of the system are that the big data is combined with field soil, climate and rainfall conditions, comprehensive planning from the applicability to price prediction of planting crops is realized, and scientific choices are made; and a comprehensive plan is provided, such as landform reconstruction, road reconstruction and reservoirs.

Owner:四川久久合创信息技术有限公司

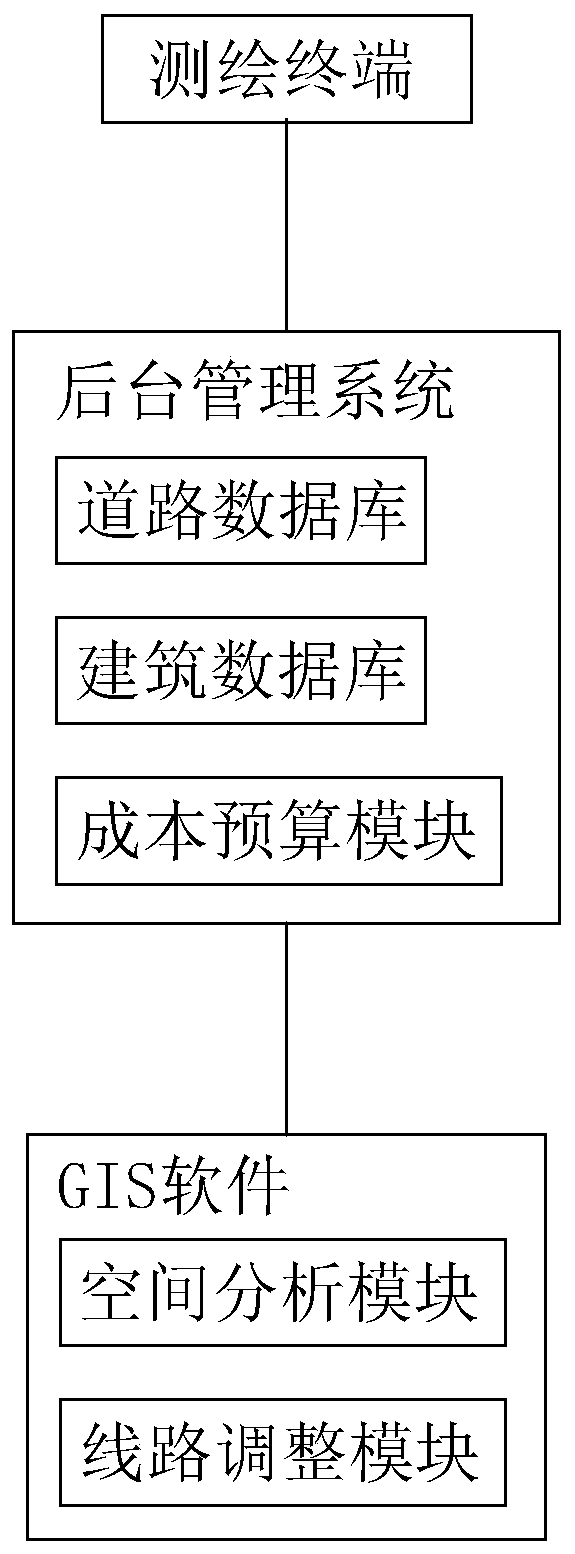

Power distribution network comprehensive planning system and method in electric power engineering design

PendingCN111475598AStatistics shortcutStatistically accurateGeographical information databasesResourcesPower engineeringElectric cables

The invention relates to a power distribution network comprehensive planning system in electric power engineering design, which belongs to the technical field of power industry, and comprises GIS software and a background management system, wherein the background management system comprises a road database and a building database, the road database stores urban road information, and the building database stores urban building information; the GIS software comprises a spatial analysis module; and the GIS software is connected to the road database and the building database through a network, displays the road information and the building information on the GIS software so as to carry out topology analysis and attribute assignment on a preliminary planning route diagram, and imports the preliminary planning route diagram into the space analysis module to carry out intersection analysis, so as to obtain a result drawing of cables. According to the power distribution network comprehensive planning system , attribute features are given to an existing topographic map by the GIS software, space analysis is adopted for marking and counting roads and buildings within the cable erection range, the problem of complex work of manual one-by-one counting is solved, and road and building counting becomes faster.

Owner:四川北宸电力设计咨询有限公司

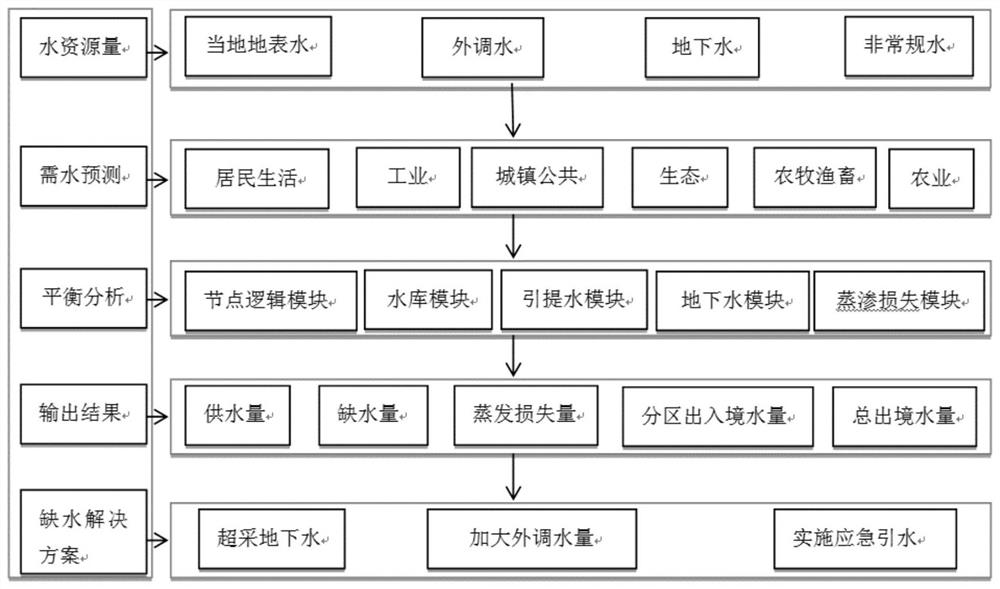

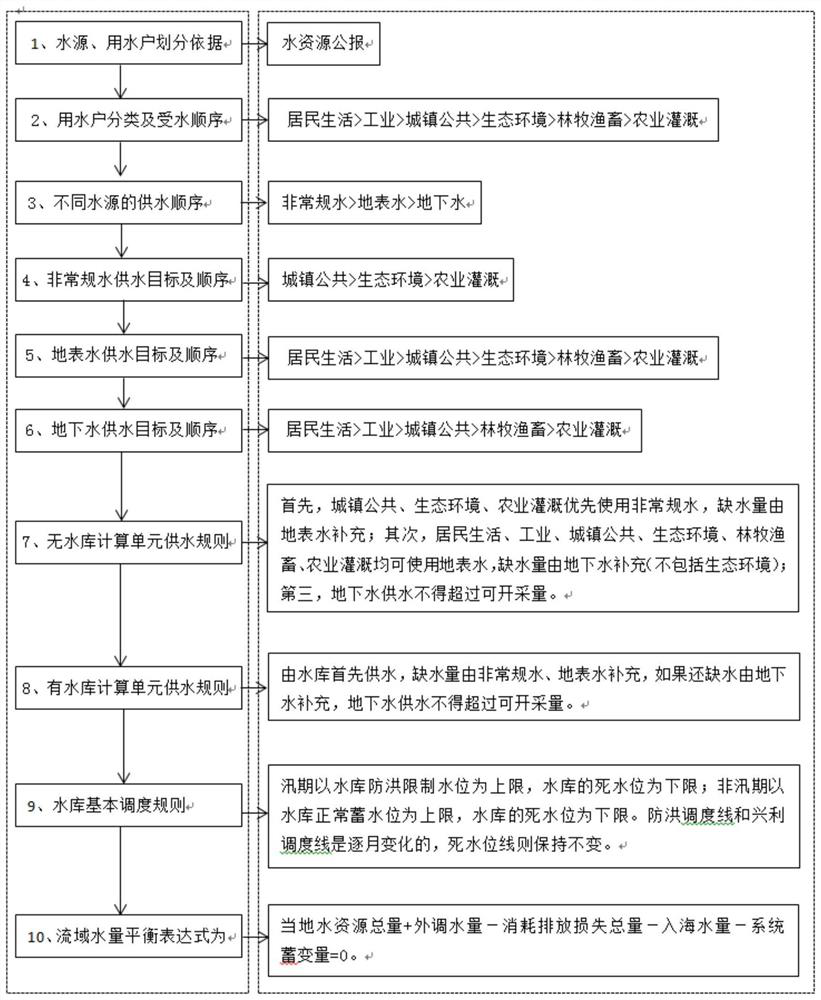

Water resource simulation method based on double sequencing of water sources and water users

PendingCN112053256AImprove configuration scienceReduce miningData processing applicationsGeneral water supply conservationWater useWater source

The invention provides a water resource simulation method based on double sequencing of a water source and a water user. A simulation model is researched and developed by taking a double sequencing rule of the water source and the water user as starting points. For a water source, the water supply sequence is as follows: unconventional water is the first, surface water is the second and underground water is the third. For water users, the water receiving priorities are sorted as follows: industrial water supply can be performed only after the living water requirements of residents are completely met, urban public water supply can be performed only after the industrial water requirements are completely met, and so the like. According to the water resource simulation system and method takingwater source and water user double sorting as the rule, the water supply reality is fully considered in the water source water supply sequence, the water resource allocation scientificity can be improved, and the water resource simulation system and method can be applied to the fields of basin water resource comprehensive planning, water resource simulation scientific research, water ecological protection and planning and the like.

Owner:水利部海河水利委员会科技咨询中心

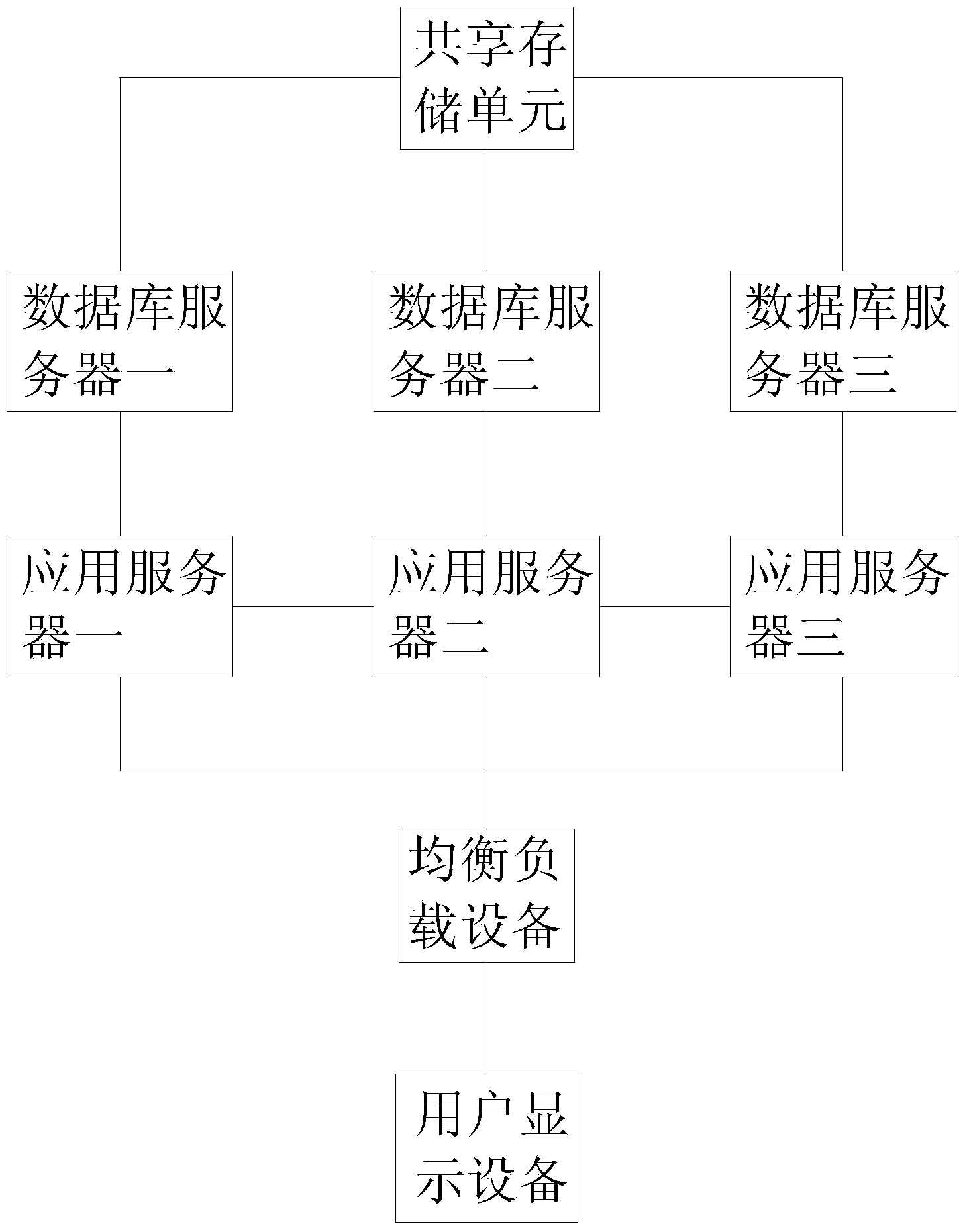

Province, prefecture and county comprehensive planning whole-process control integration platform

The invention discloses a province, prefecture and county comprehensive planning whole-process control integration platform which comprises a user display device which is connected with three control units. Each control unit is provided with a plan management module, a supervision monitoring module and an indicator early warning module. The plan management module, the supervision monitoring module and the indicator early warning module are respectively with the three data storage units. Different items are classified, so that unified management monitoring and early warning for an electric power project can be realized; displaying can be clear, convenience can be brought to a manager for operation and implementation, and error can be avoided.

Owner:STATE GRID CORP OF CHINA +2

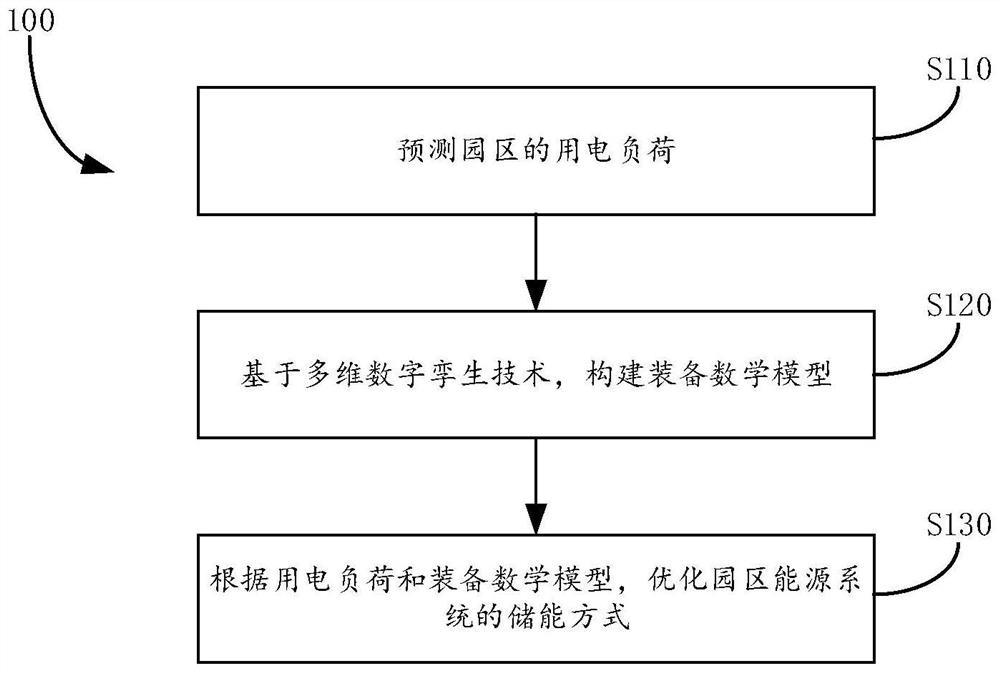

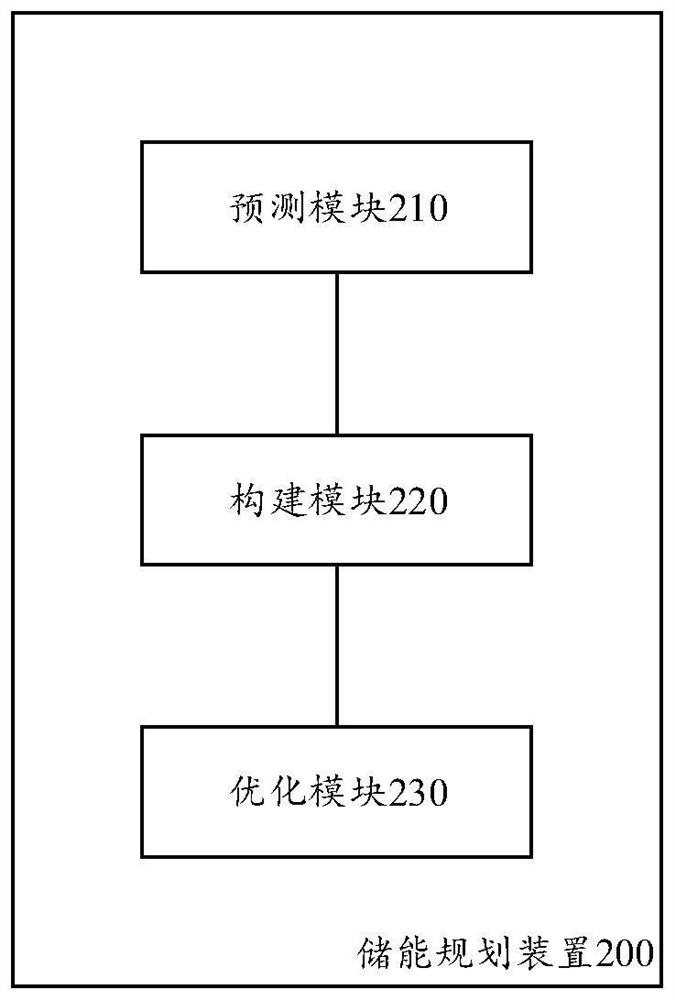

Park energy storage planning method, device and equipment based on digital twinning and medium

PendingCN114444850AOptimize energy storageAchieve zero heat emissionLoad forecast in ac networkDesign optimisation/simulationMathematical modelProcess engineering

The embodiment of the invention provides an energy storage planning method and device of a park energy system based on a multi-dimensional digital twinborn technology, electronic equipment and a computer readable storage medium. The energy storage planning method comprises the following steps: predicting an electrical load of a park; constructing an equipment mathematical model based on a multi-dimensional digital twinning technology; and optimizing the energy storage mode of the park energy system according to the electrical load and the equipment mathematical model. According to the invention, factors considered by energy storage planning are more comprehensive, and the planning is more reasonable.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV

Power angle stability-based direct current receiving end simultaneous stop overhaul scheme determination method and system

ActiveCN108428010AImprove work efficiencyImprove the quality of workForecastingResourcesRisk levelEnd system

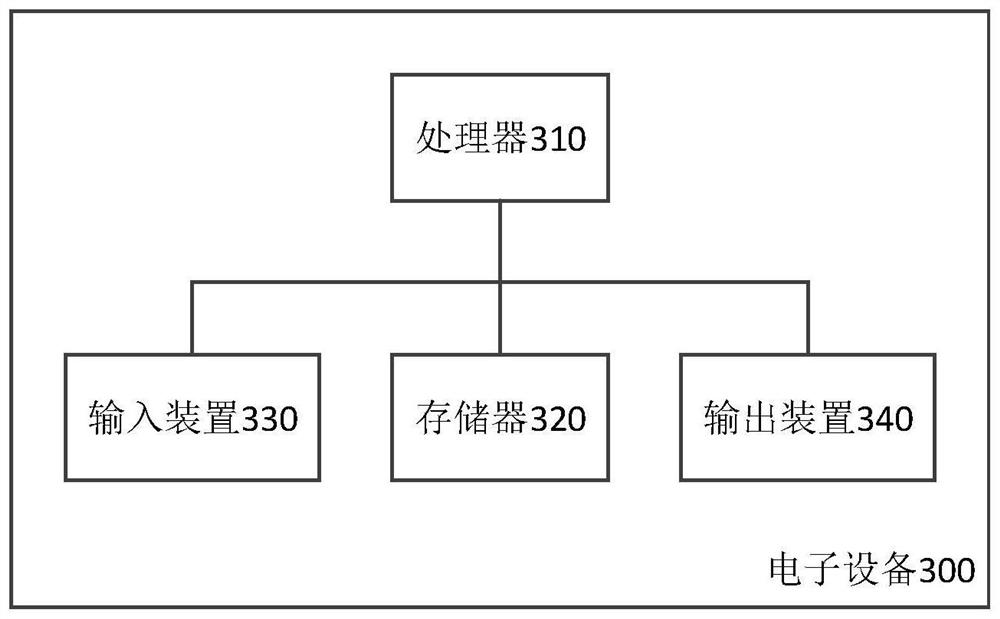

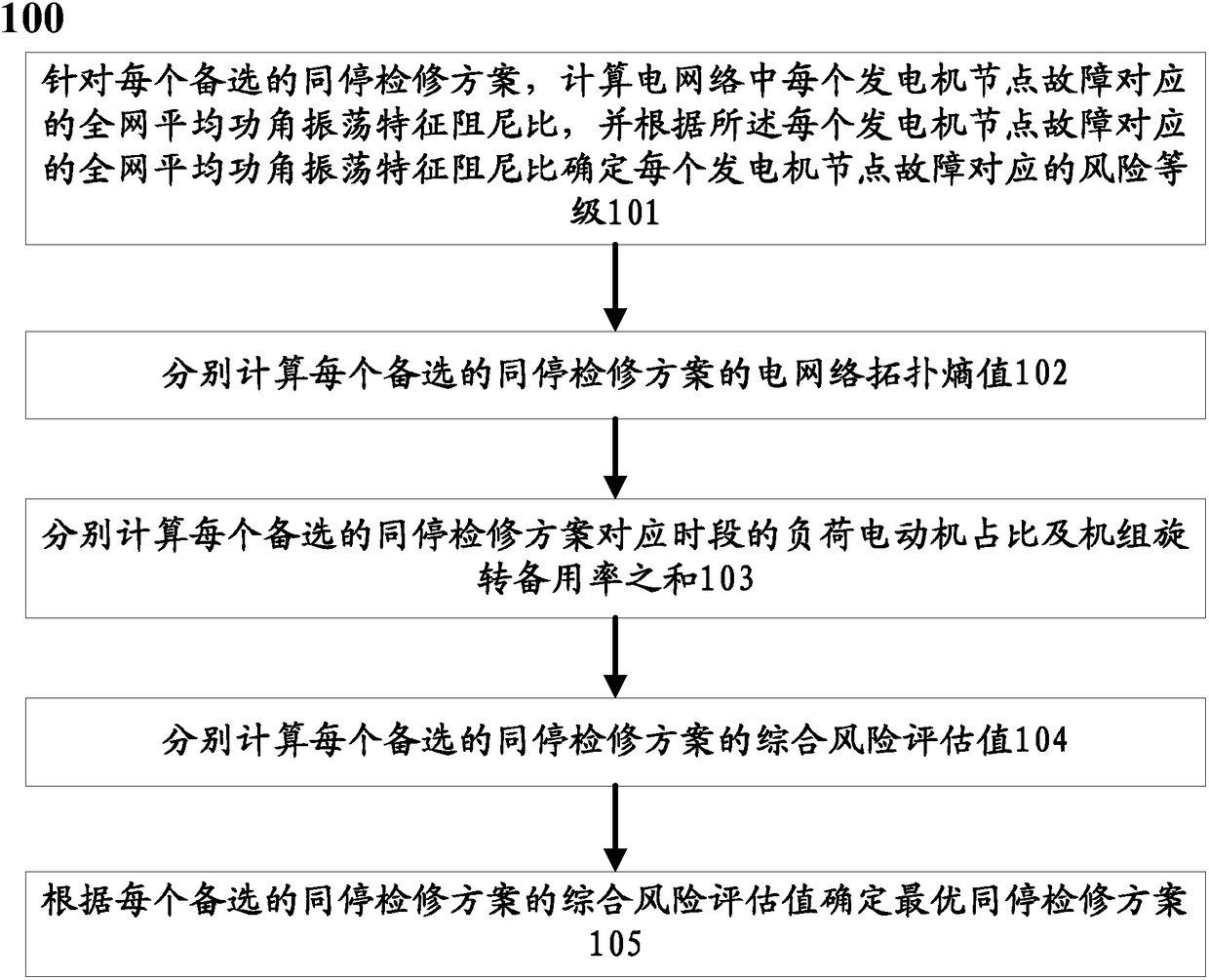

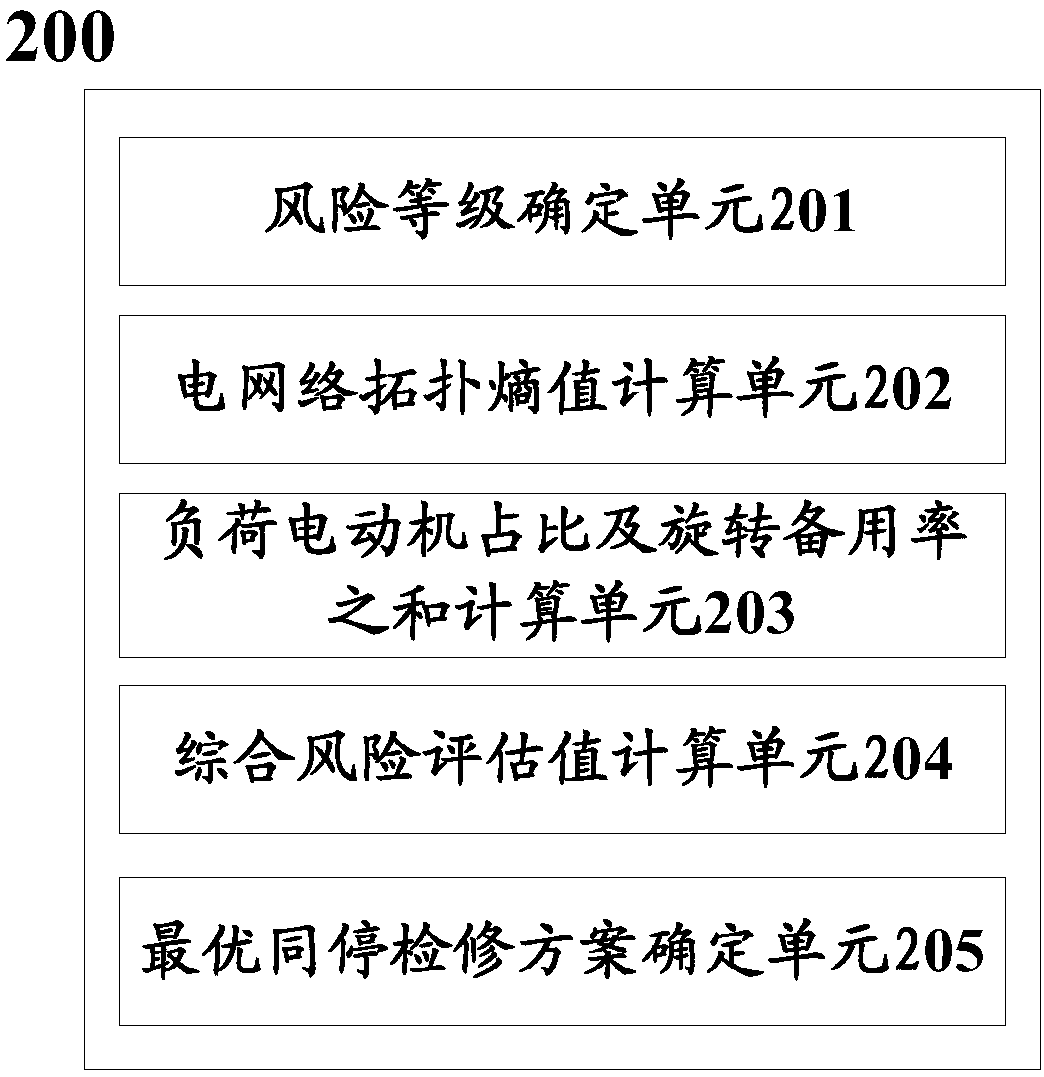

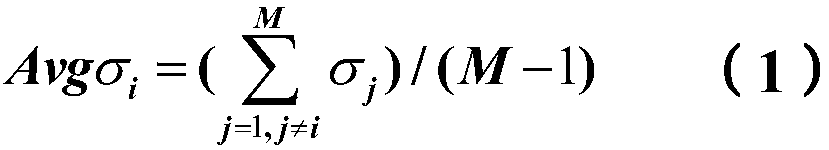

The invention discloses a power angle stability-based direct current receiving end simultaneous stop overhaul scheme determination method and system. The method comprises the steps of for each alternative simultaneous stop overhaul scheme, calculating a whole network average power angle oscillation characteristic damping ratio corresponding to each power generator node fault in an electric network, and determining a risk level corresponding to each power generator node fault; calculating an electric network topology entropy value of each alternative simultaneous stop overhaul scheme; calculating a sum of a load motor ratio and a unit spinning reserve rate in a time period corresponding to each alternative simultaneous stop overhaul scheme; calculating a comprehensive risk assessment valueof each alternative simultaneous stop overhaul scheme; and according to the comprehensive risk assessment value of each alternative simultaneous stop overhaul scheme, determining an optimal simultaneous stop overhaul scheme. The power angle stability problem of a receiving end system can be calculated directly through a simple numerical value to obtain the optimal scheme; quick assessment of the optimal scheme of overhaul power failure comprehensive planning is realized; and the working efficiency and quality of overhaul scheme assessment are improved.

Owner:CHINA ELECTRIC POWER RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com