Method for installing track device of sintering machine production line

An installation method and production line technology, which is applied in the field of track device installation of sintering machine production line, can solve the problems of low installation accuracy of sintering machine, overturning and reinstalling, error accumulation, etc., and achieve the goal of reducing engineering cost, high installation accuracy and improving installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

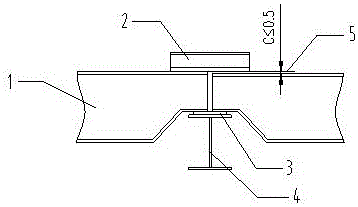

[0034] The installation method of the track device of the sintering machine production line of the present invention, the track device is divided into a head curve, a tail curve and a middle horizontal track, including the following steps:

[0035] a. Acceptance of track installations before installation

[0036] The head curve, the tail curve and the middle horizontal track need to be inspected before installation, and the acceptance includes the appearance and size inspection of the track; if problems with the appearance and size are found during the acceptance process, they should be corrected before the track installation is hoisted.

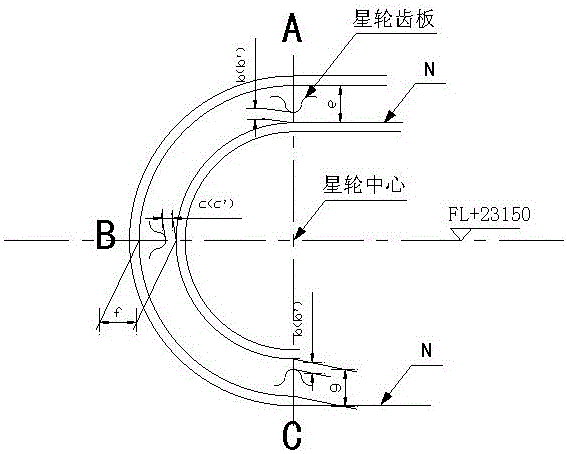

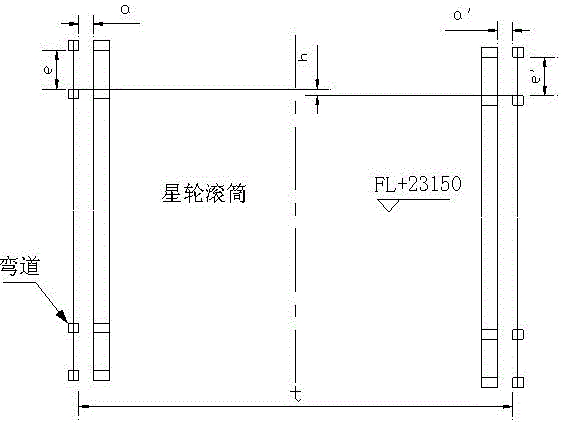

[0037] see now Figure 1-2 , figure 1 It is a schematic diagram of installation of the head curve of the embodiment of the present invention, figure 2 It is a schematic diagram of installation of another head bend according to the embodiment of the present invention.

[0038] b. Head bend installation

[0039] The head curve installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com