Integrated airplane structural part numerical-control machining capacity test model and application thereof

A technology for aircraft structural parts and test models, applied in computer control, simulator, program control, etc., can solve problems such as increased judgment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

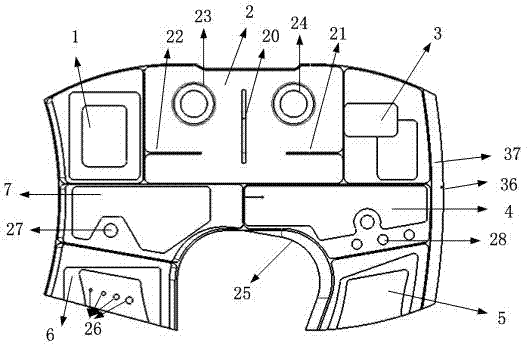

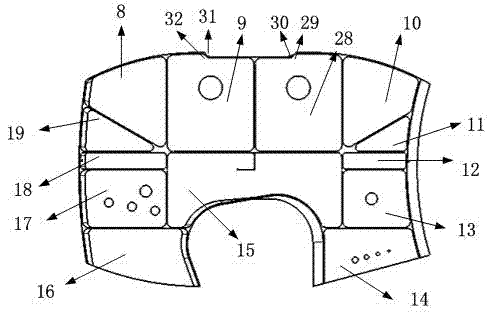

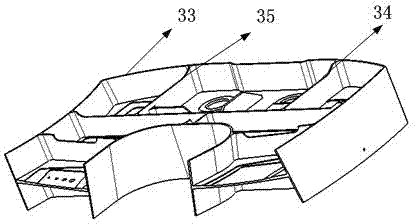

[0038] Such as Figure 1-3 shown.

[0039] An integrated CNC machining capability test model for aircraft structural parts. It is a double-sided part. One side has different web heights and different rib top heights. It is defined as the front side, and the other side has the same web height and rib top height. for the negative side. Its overall structure is similar to an n-shape, with a c-shaped notch running through the front and back, and the front is provided with multi-layer grooves 2 including convex platforms, convex depressions, concave depressions, intersecting independent ribs and open ribs, The two sides of the multi-layer groove 2 are respectively adjacent to the multi-layer groove 1 and the multi-layer groove 3 with intersecting characteristics of nesting, and the other side of the multi-layer groove 2 opposite to the outer contour is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com