Intelligent production turnover method based on RFID

An intelligent production and RFID tag technology, applied in the field of warehousing and logistics, can solve the problems of limited amount of stored information, affecting applications, easy damage and contamination, etc., to achieve the effect of improving production turnover efficiency, reducing labor costs, and reducing perceived errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the drawings and specific embodiments, so that those skilled in the art can understand.

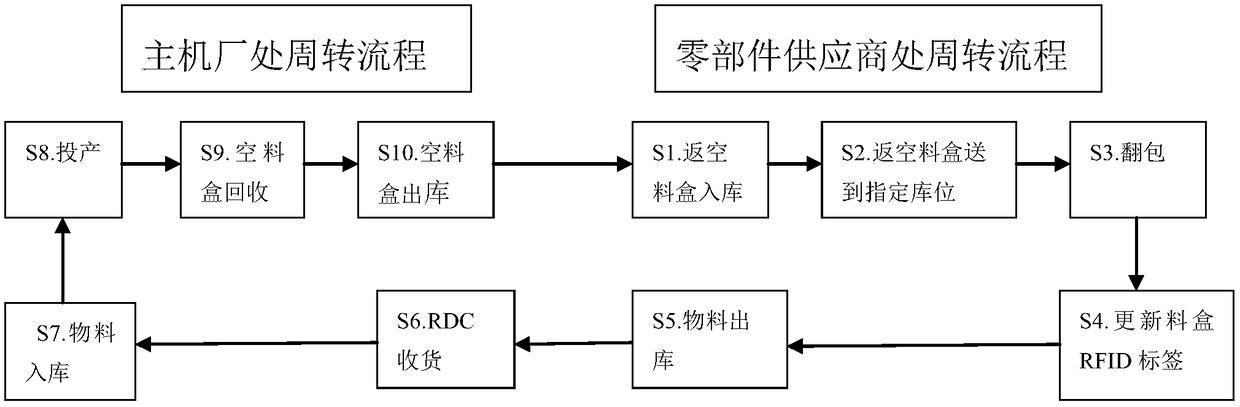

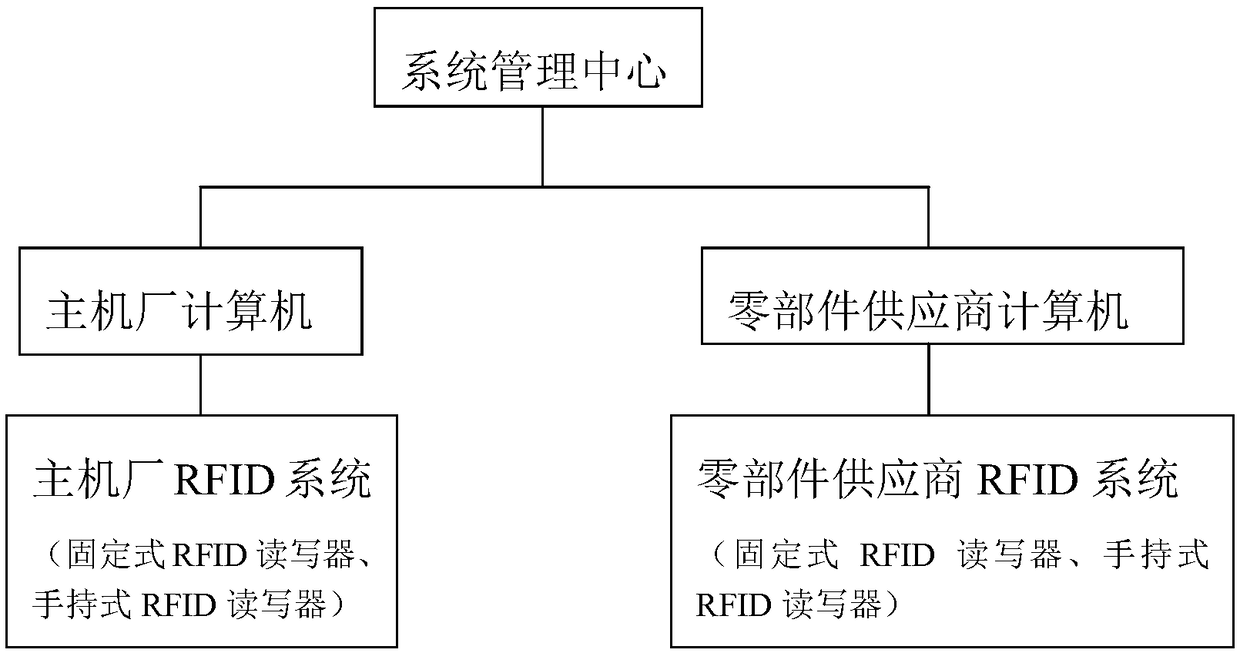

[0035] Such as figure 1 As shown, the RFID-based intelligent production turnover method includes the production turnover steps of parts supplier-main engine factory, specifically including the following steps:

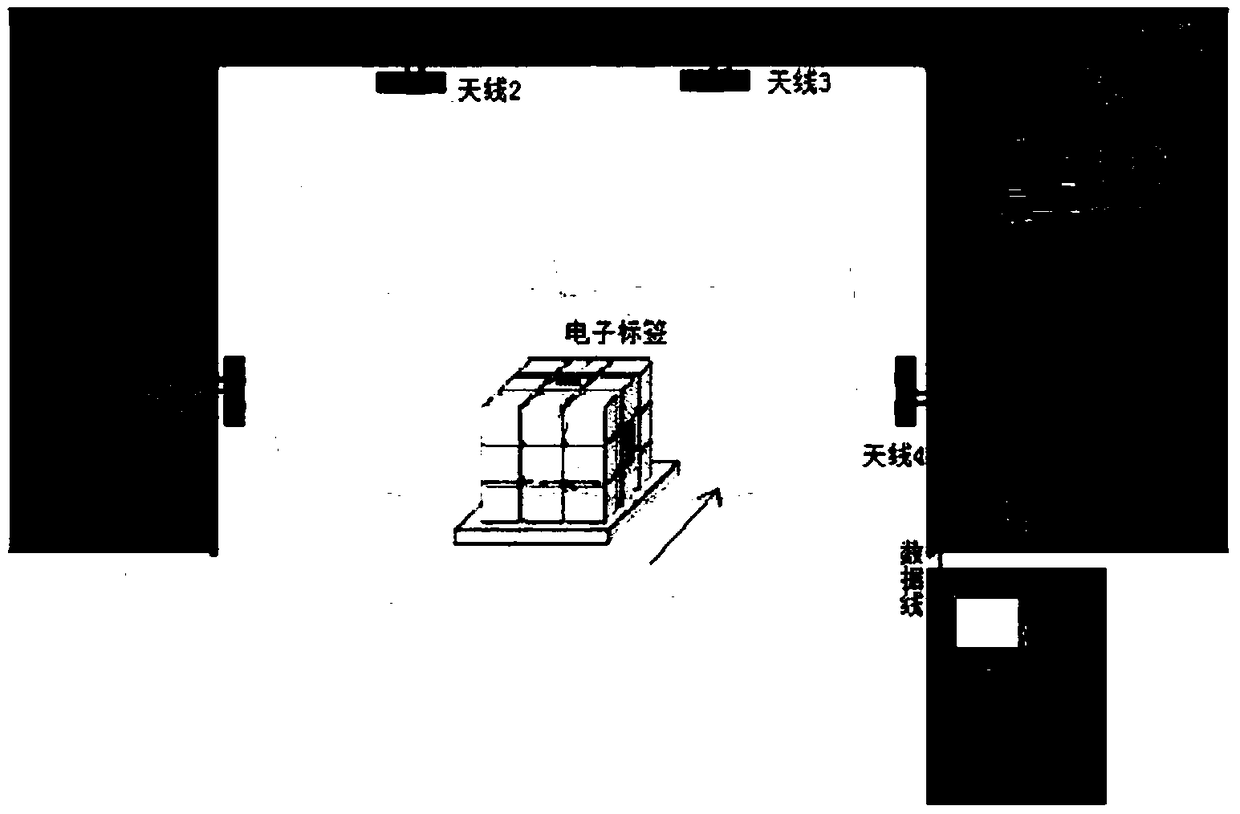

[0036] S1. Return empty material boxes into storage: The fixed RFID reader on the access door of the component supplier automatically scans the RFID tags attached to the empty material boxes returned from the OEM, and sends the storage information to Zero Component supplier computer, component supplier computer uploads information to the warehouse management system (WMS system) of the system management center, and the system management center matches the warehouse-in information with the warehouse-out information of the enterprise resource planning system (ERP system), if any If there is an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com