Method for manufacturing eccentric ring in profiling method

An eccentric ring and component technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high measurement requirements, difficult processing, measurement errors, etc., and achieve the effect of high precision and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

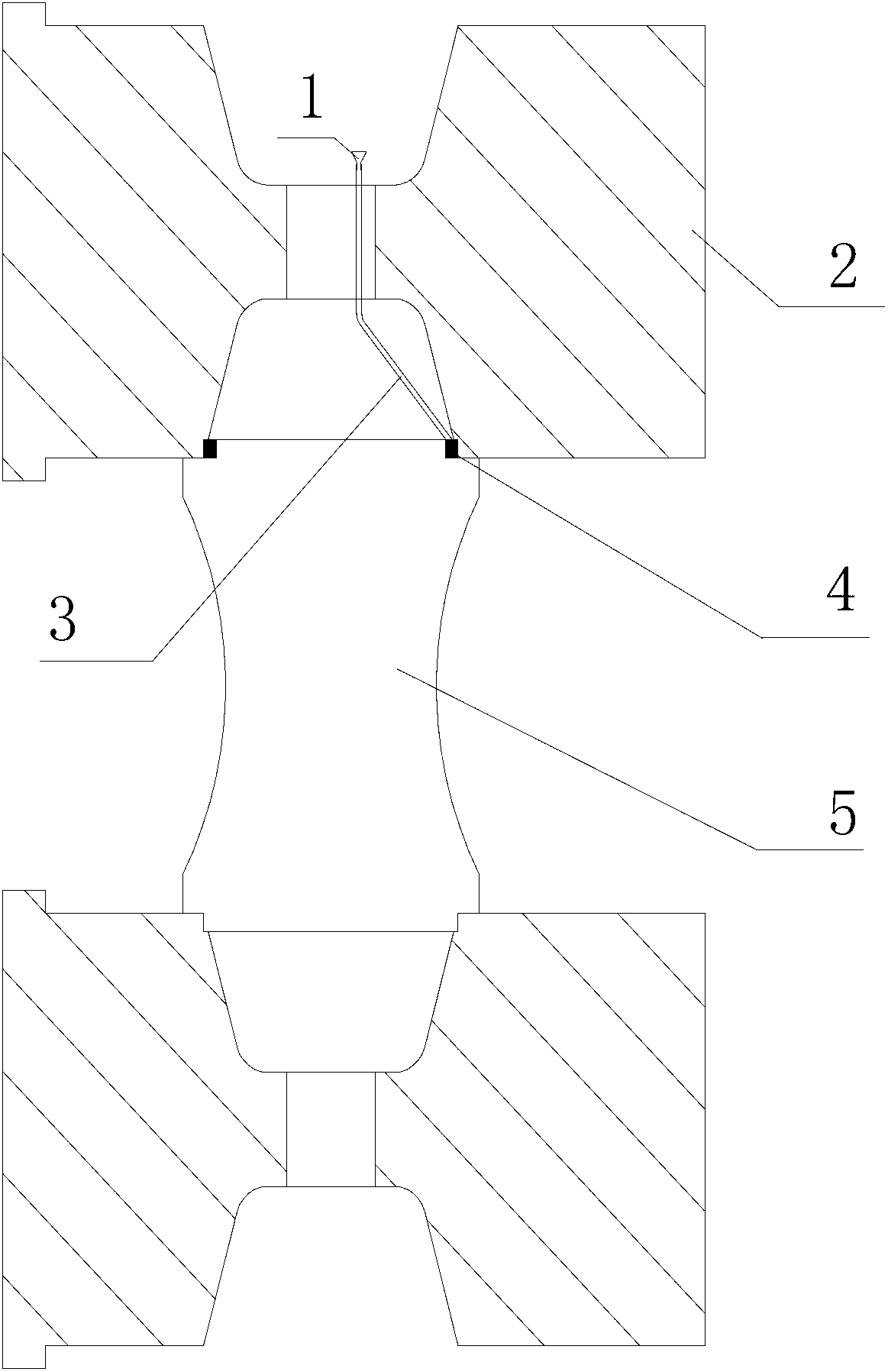

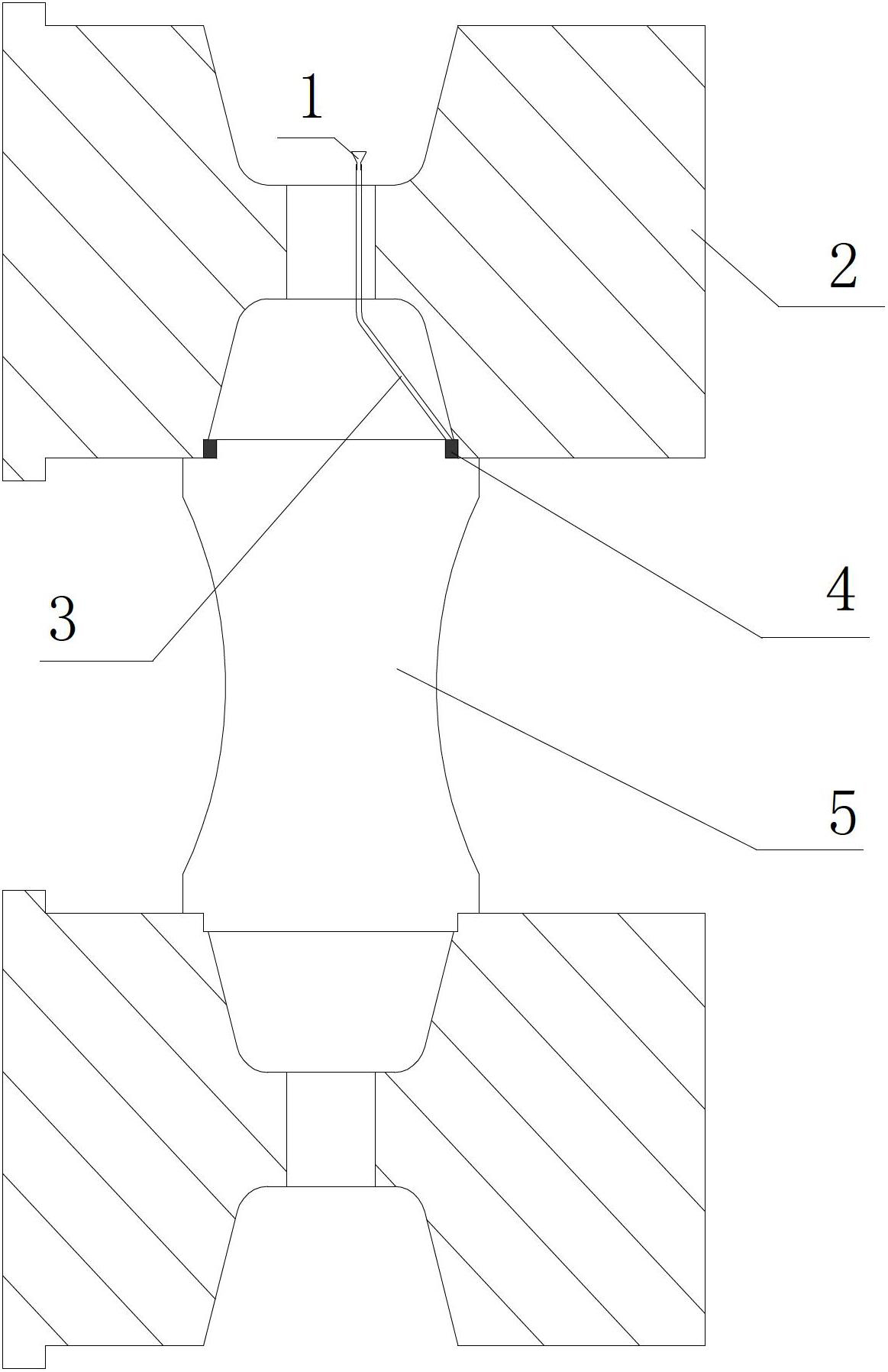

[0009] As shown in the figure: a method of making eccentric rings by profiling method is: after the installation and acceptance of the upper and lower two-piece components 2 and 5, clean the eccentric area of the upper and lower two-piece components. Apply a layer of lubricating grease evenly to the junction of the components, use a synchronous hydraulic jack to drop the upper component back onto the lower component, and then center the upper and lower components. After the centering meets the design requirements, the eccentric ring model can be made . Mix gypsum and water to make gypsum slurry, and inject it into the position of the eccentric sleeve through the funnel 1 and the soft plastic tube 3 to make a gypsum model 4 . After the gypsum model is hardened, use a synchronous hydraulic jack to slowly raise the upper component, mark the corresponding position between the plaster model and the lower component, and take out the upper and lower components for trial assembly. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com