Connecting structure of beam-column joint of steel pipe concrete combined column

A technology of steel pipe concrete and connection structure, which is applied in the direction of building structure and construction, and can solve problems such as brittle failure at joints, large residual stress of steel, and influence on external wall installation, so as to avoid welding work on the construction site and eliminate three Concentration of axial stress and high degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

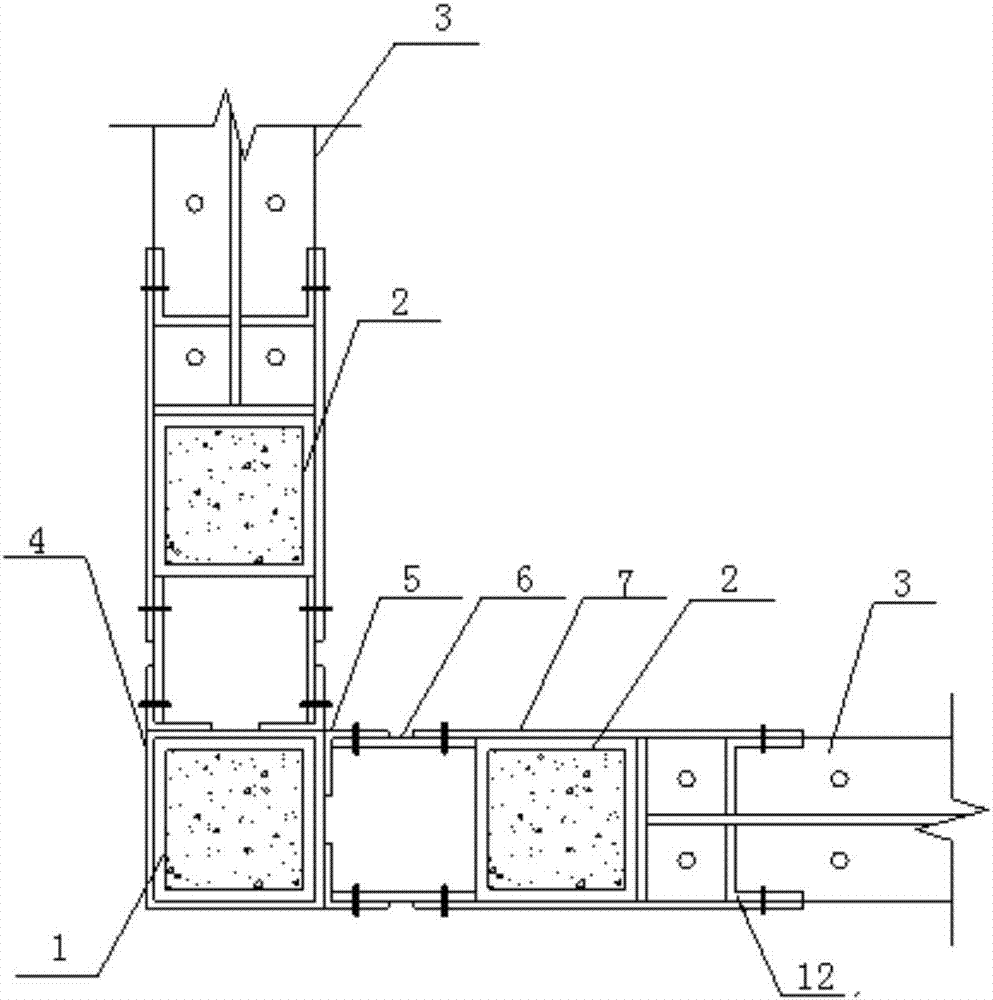

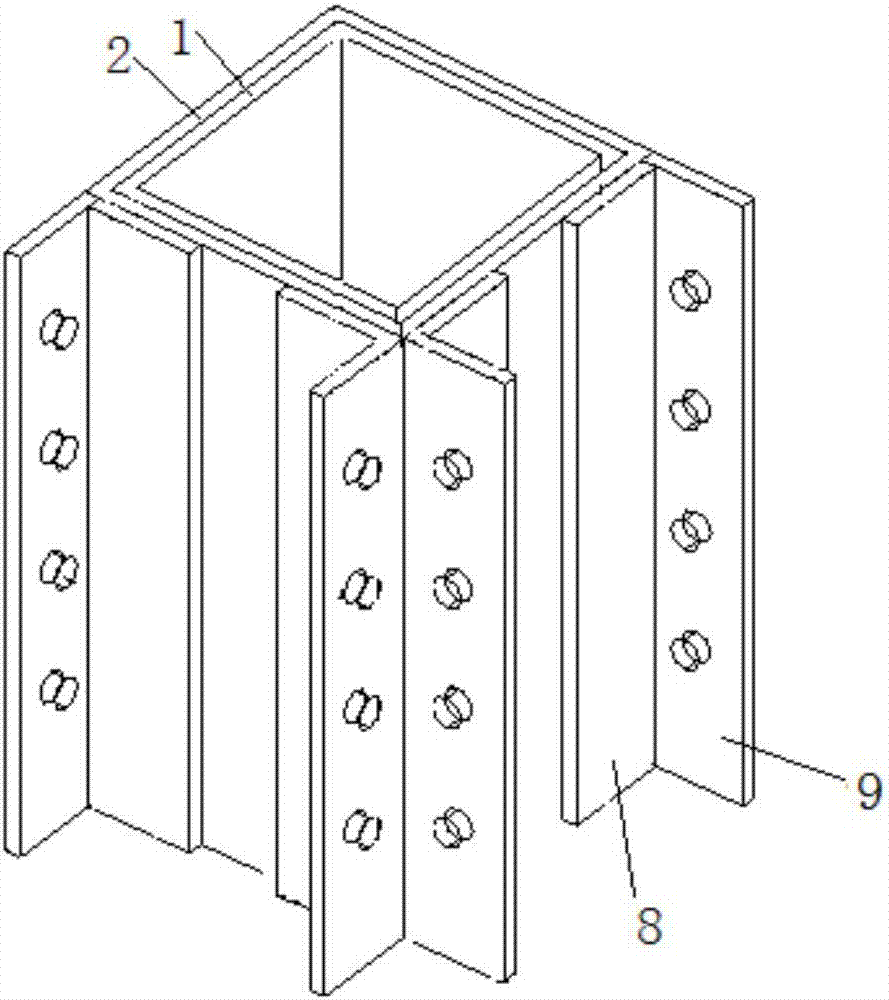

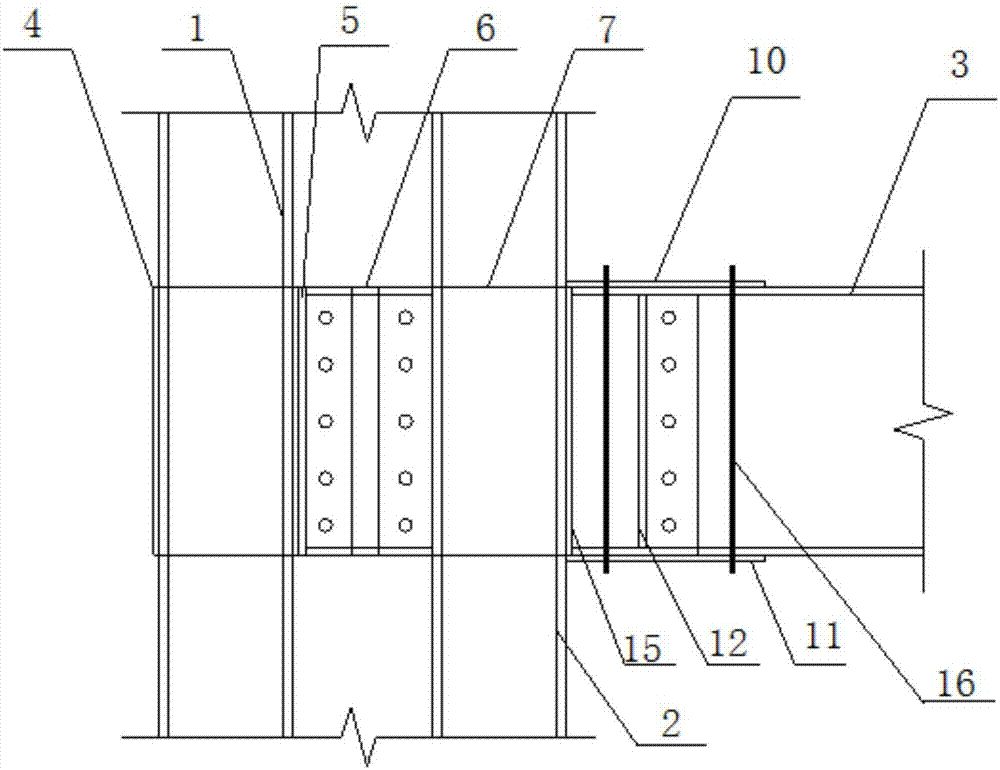

[0028] Such as Figure 1-4 As shown, the connection structure of the steel pipe concrete composite column-beam-column joint of the present invention comprises a central square steel pipe 1, side-end square steel pipes 2 and H-shaped steel beams 3, and the central square steel pipe and the side-end square steel pipes are connected by a column connection assembly .

[0029] The column connection assembly includes sleeve 4, column angle steel connector 5, connecting plate I6 and connecting plate II7. The sleeve is welded on the central square steel pipe. A column angle steel connector, the column angle steel connector includes side I8 and side II9 perpendicular to each other, side I is welded on the sleeve, side II is on the same plane as the side of the sleeve; connecting plate II is symmetrically arranged on the side The two sides of the end square steel pipe are on the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com