Giant concrete-filled steel tubular inclined column and inclined strut transferring joint structure

A technology of steel pipe concrete and transfer nodes, which is applied in the direction of building structure and construction, and can solve the problems of reduced space for transfer floors, low bearing capacity of reinforced concrete components, and difficulties in pouring and tamping concrete for welding construction, so as to solve the welding workload The effect of large size, guaranteed construction quality and good lateral force resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but are not intended to limit the protection scope of the present invention.

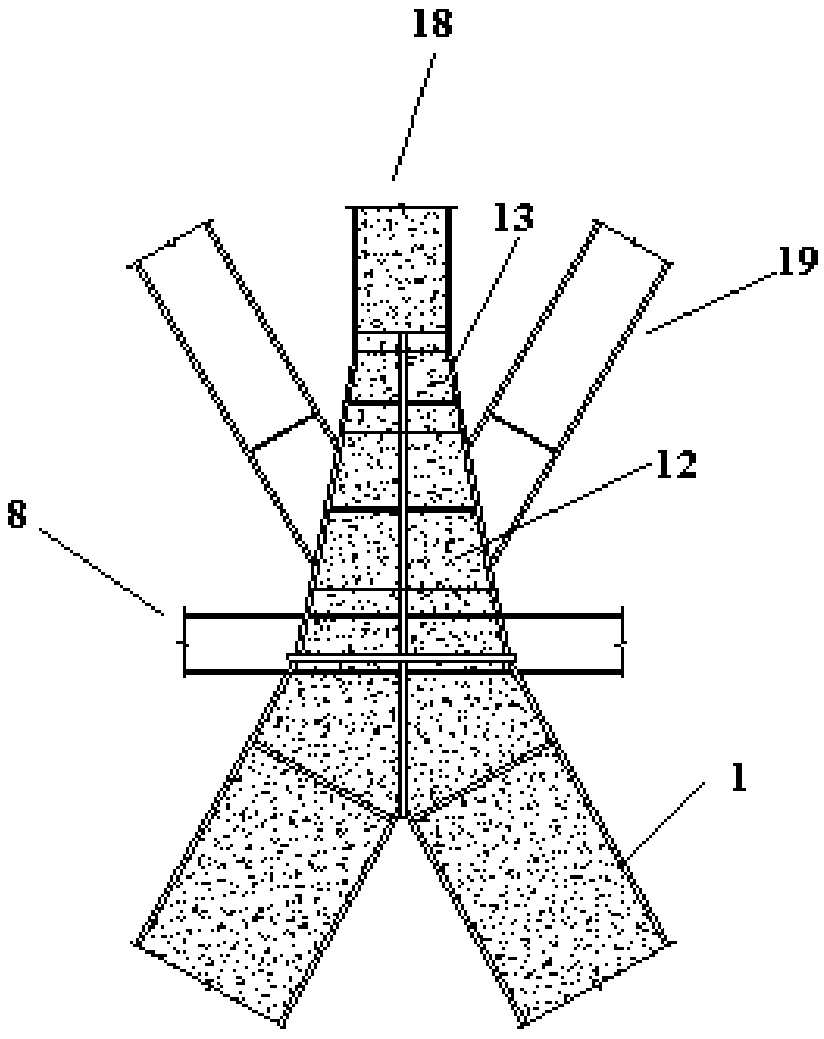

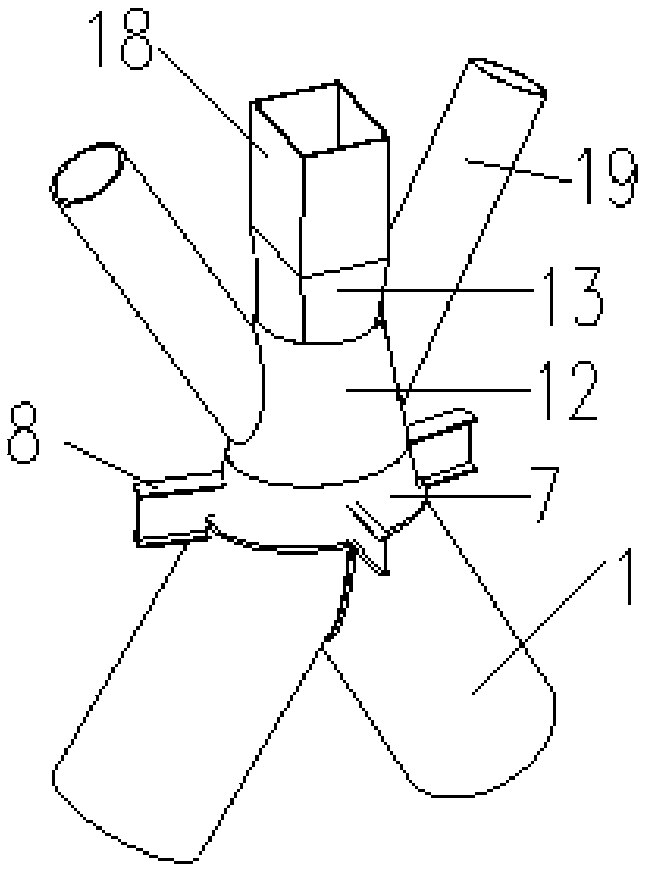

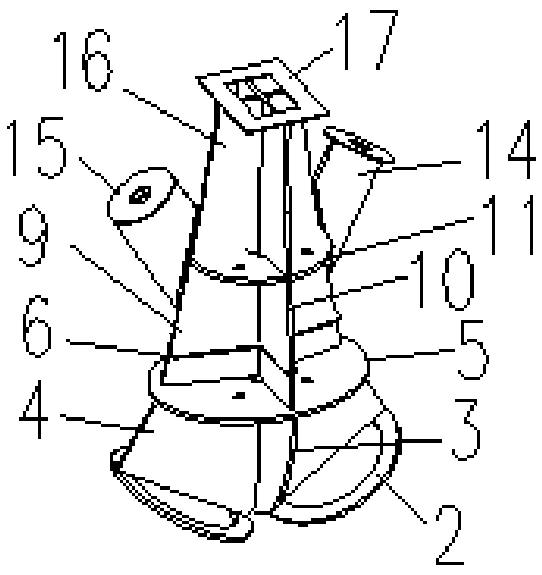

[0074] See attached Figure 1-3 In the embodiment of the present invention, a giant concrete-filled steel tube diagonal column and diagonal brace conversion node structure includes diagonal pillars 1, frame columns 18, diagonal braces 19, conversion components and frame beams 8, diagonal braces 19 are fixedly connected to the conversion components, and frame columns 18 is fixedly connected to the conversion member, the conversion member is fixedly arranged on the top of the inclined pillar 1, and the frame beam 8 is fixedly connected or hingedly connected to the conversion member. The conversion member includes three parts: an ellipse conversion part 7, a large circle to a small circle conversion part 12, and a circle to a square conversion part 13. The square-changi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com