Patents

Literature

32results about How to "Reduce on-site welding workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

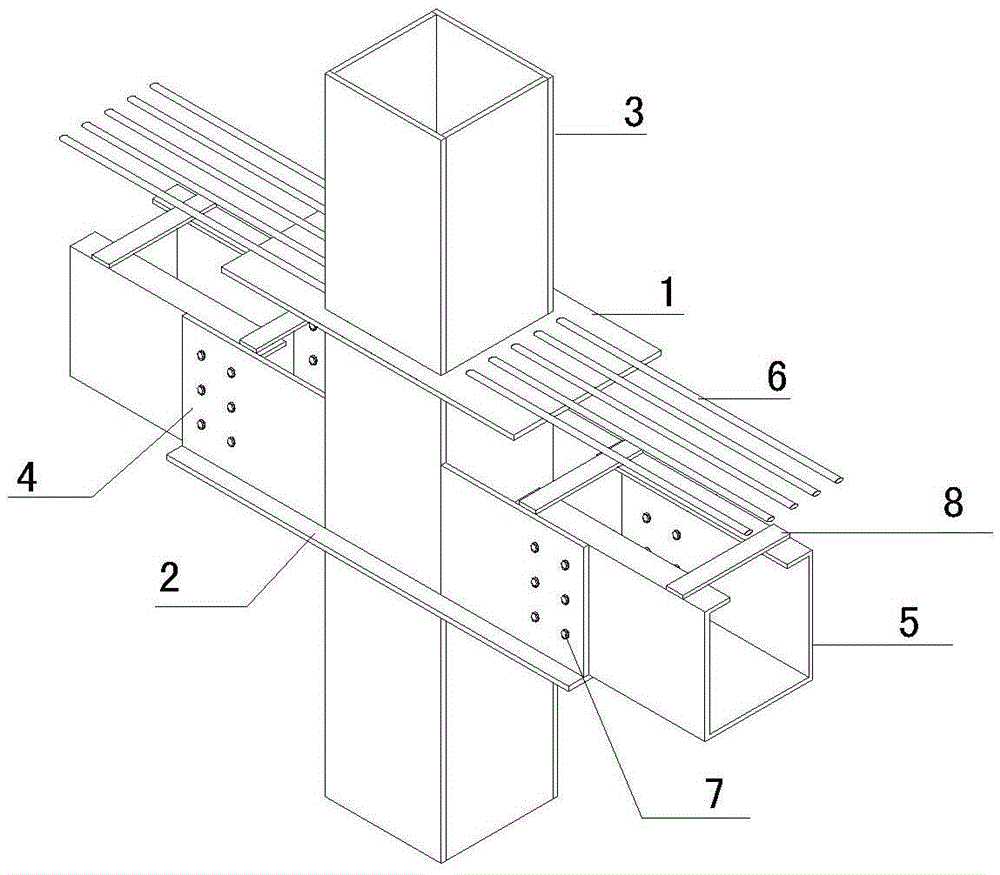

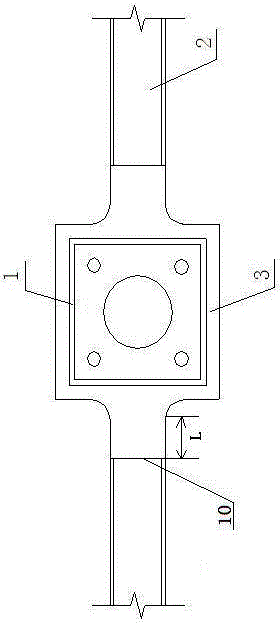

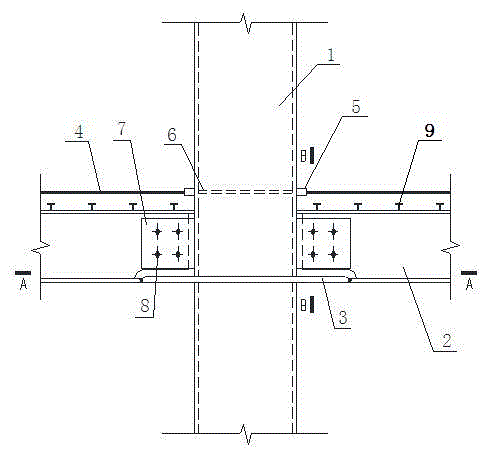

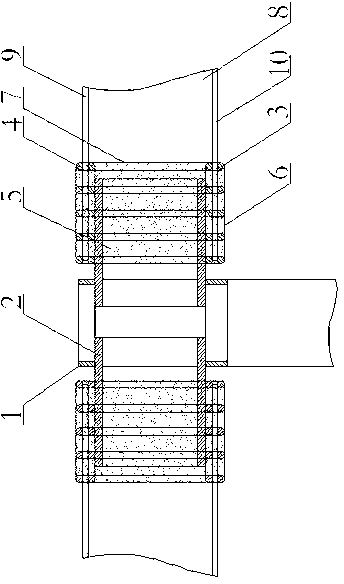

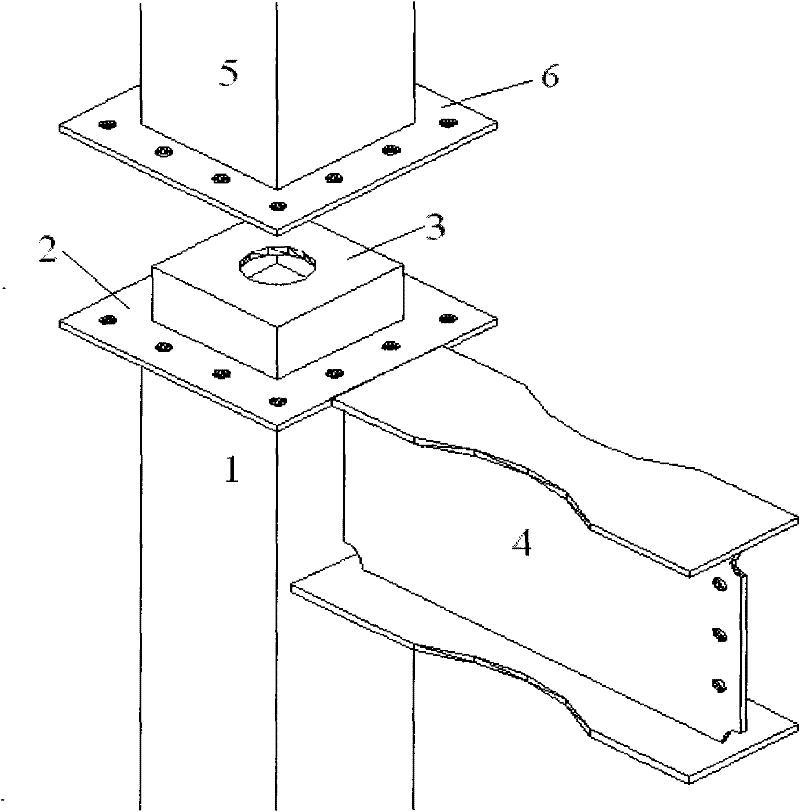

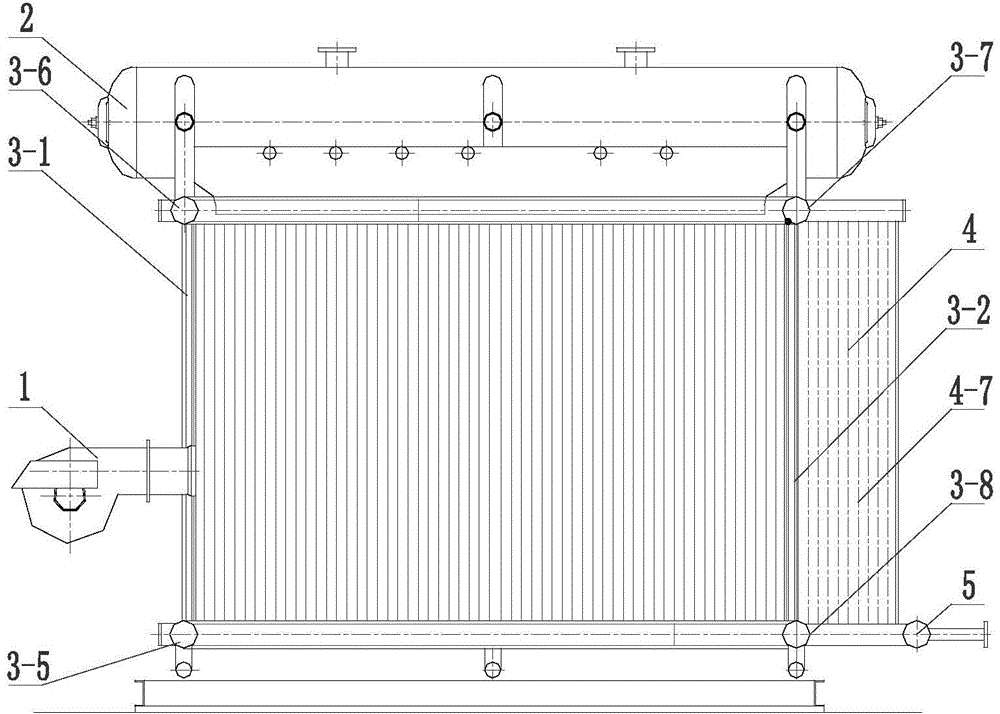

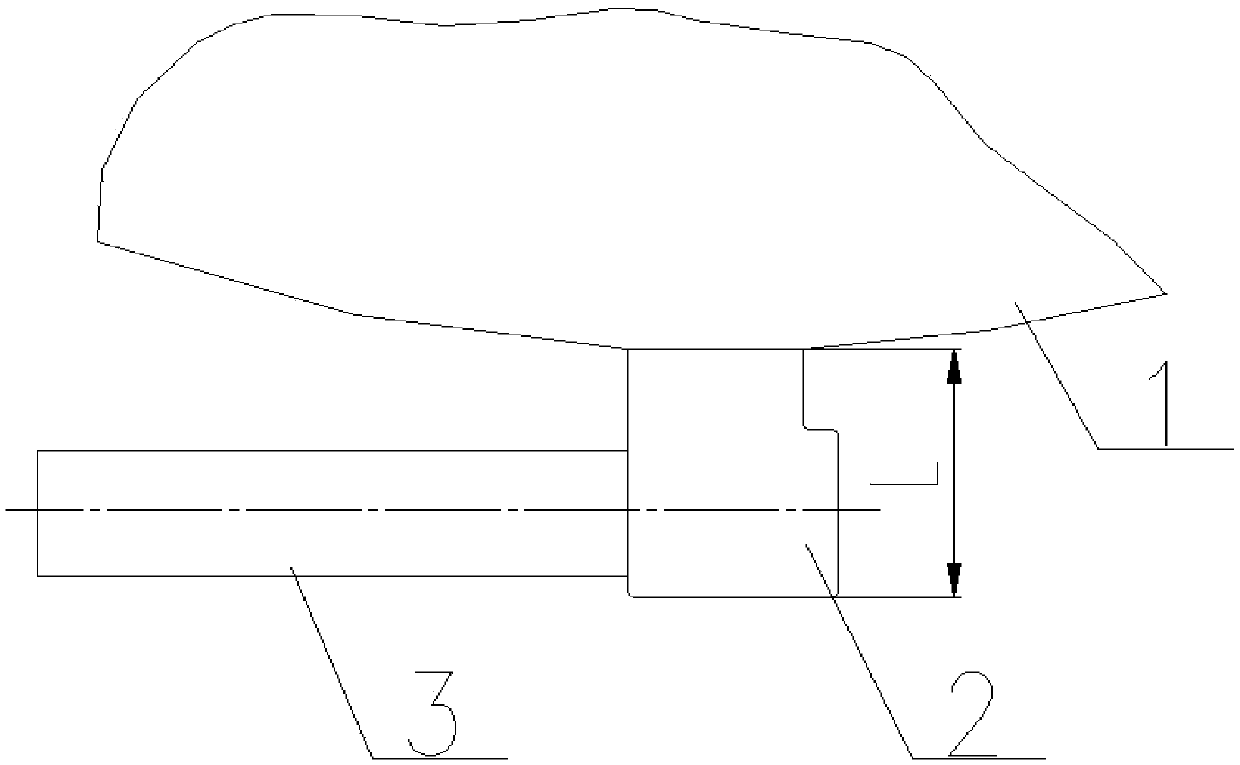

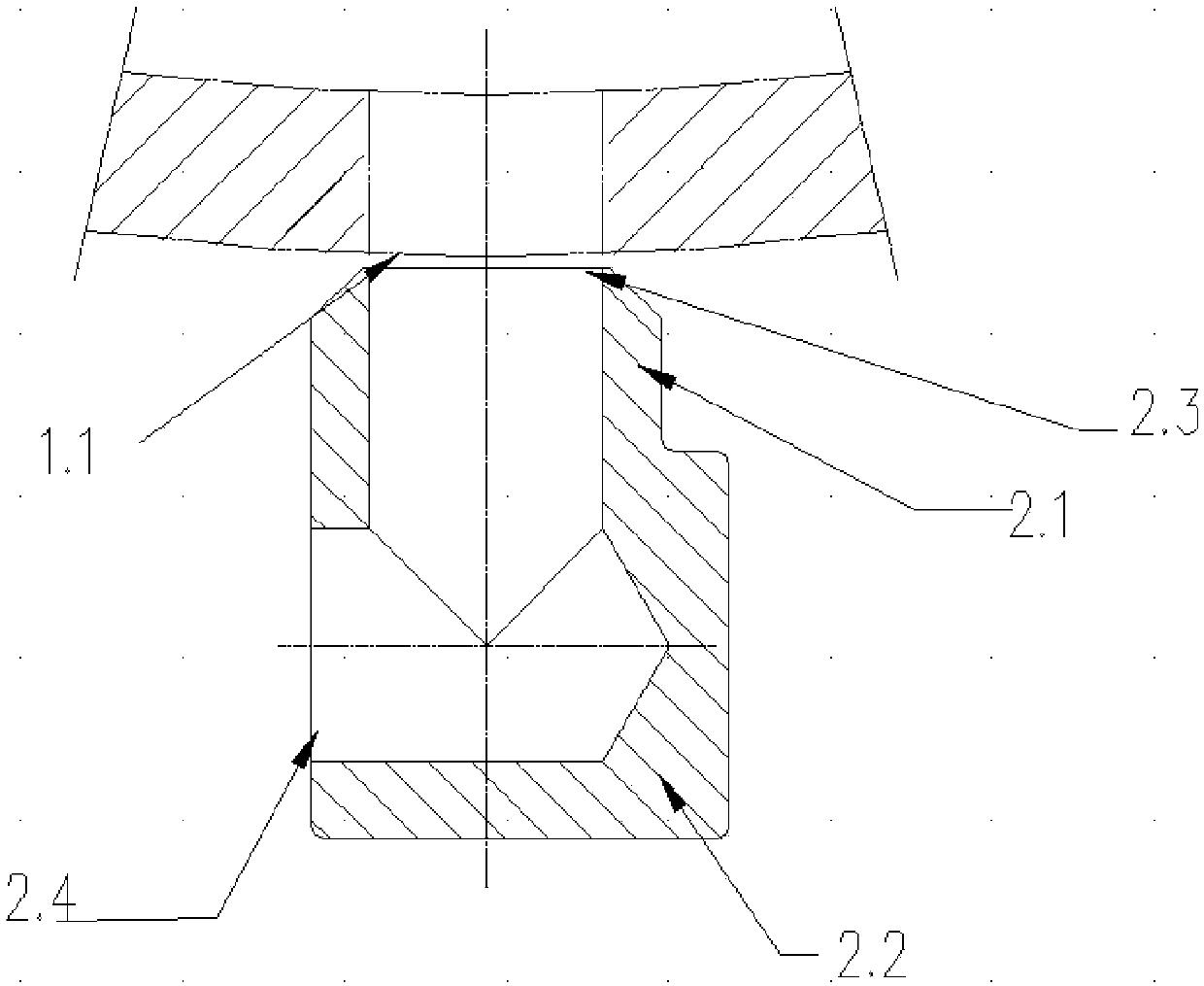

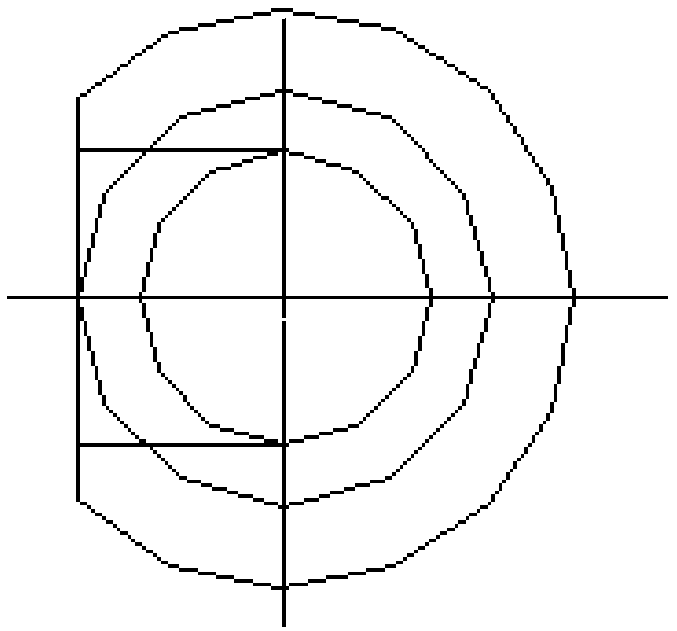

Steel-encased concrete composite beam-steel pipe column connection joint

InactiveCN105569191AReduce welding workloadEasy constructionBuilding constructionsSteel tubeBending moment

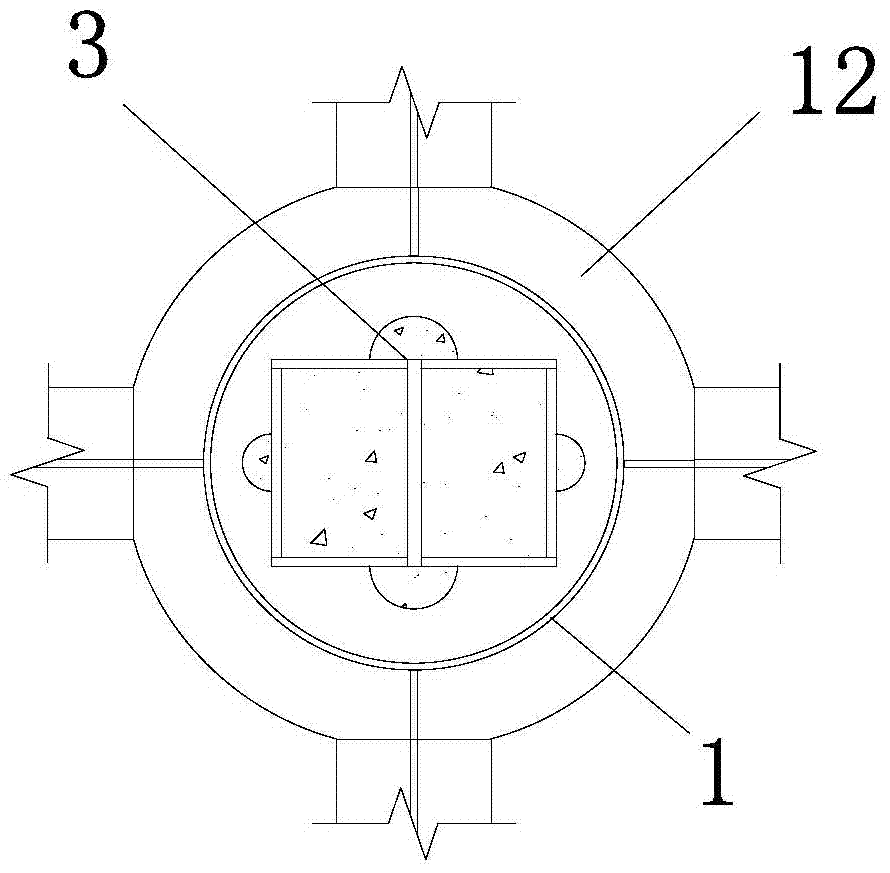

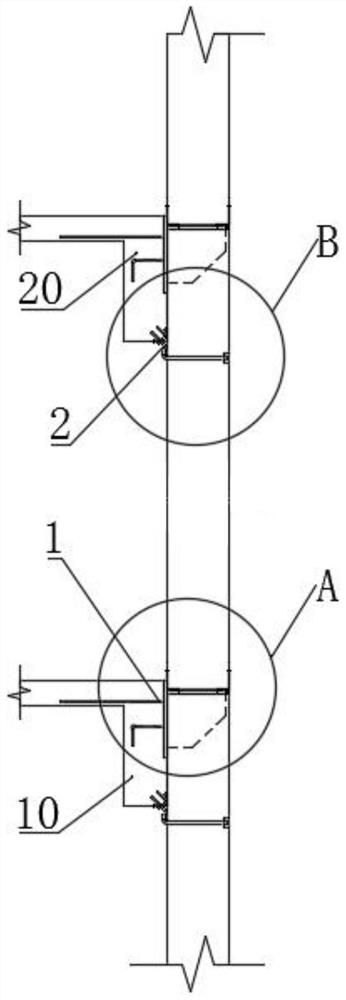

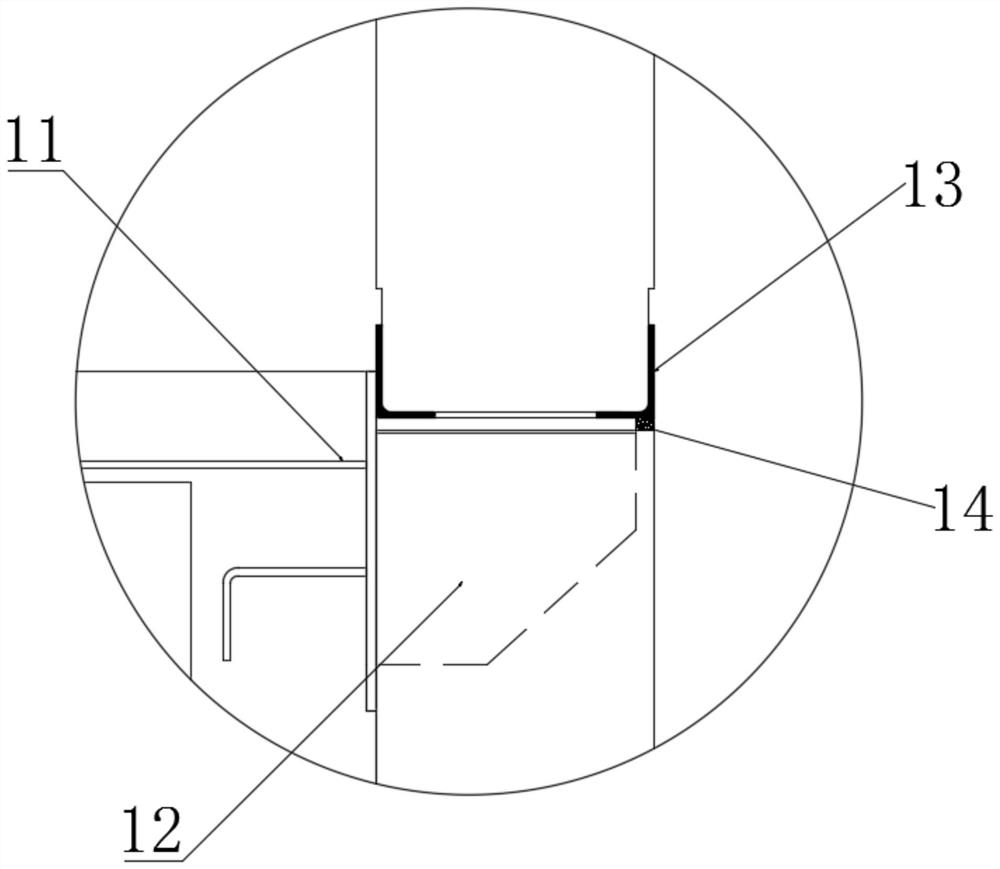

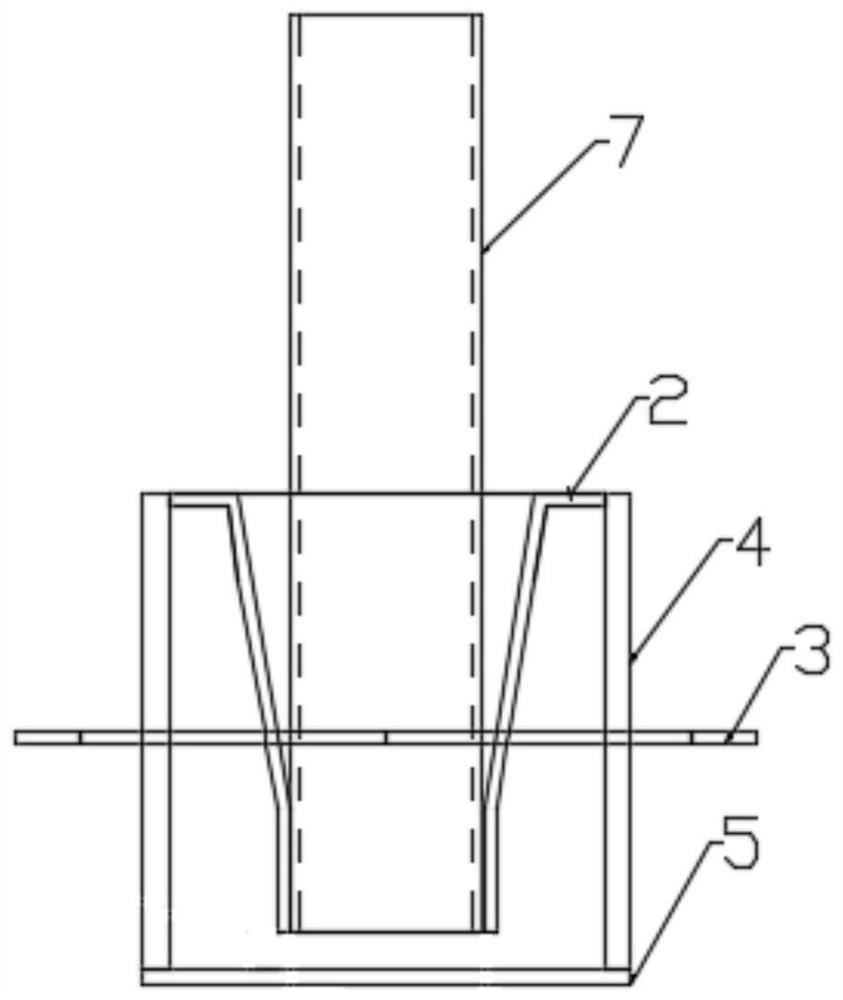

The invention discloses a steel-encased concrete composite beam-steel pipe column connection joint and a manufacturing method thereof. The joint comprises a steel pipe column, an upper through partition plate, a lower through partition plate, a lateral connection plate and the like; the upper through partition plate and the lower through partition plate are arranged on the steel pipe column in a transverse penetrating mode; hogging moment reinforcing steel bars are welded to the two ends of the end face of the upper through partition plate, the lower through partition plate and the lateral connection plate form a U-shaped device on the column side, and the U-shaped device can be made into a uniform cross-section or a variable cross-section form according to beam-column cross section size; a steel-encased girder is directly placed in the U-shaped device and connected with the U-shaped device through high-strength bolts. The steel-encased concrete composite beam-steel pipe column connection joint has the advantages that the welding work of the whole U-shaped device can be completed in a factory, a steel-encased girder bottom plate and a lateral plate are connected with the joint through high-strength bolts, the site welding work amount is greatly reduced, and construction and assembling are facilitated; the hogging moment reinforcing steel bars are directly welded to the upper through partition plate, the situation that steel pipe bearing capacity is weakened due to trepanning in the side wall of a steel pipe can be reduced, and force transfer is definite.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD +1

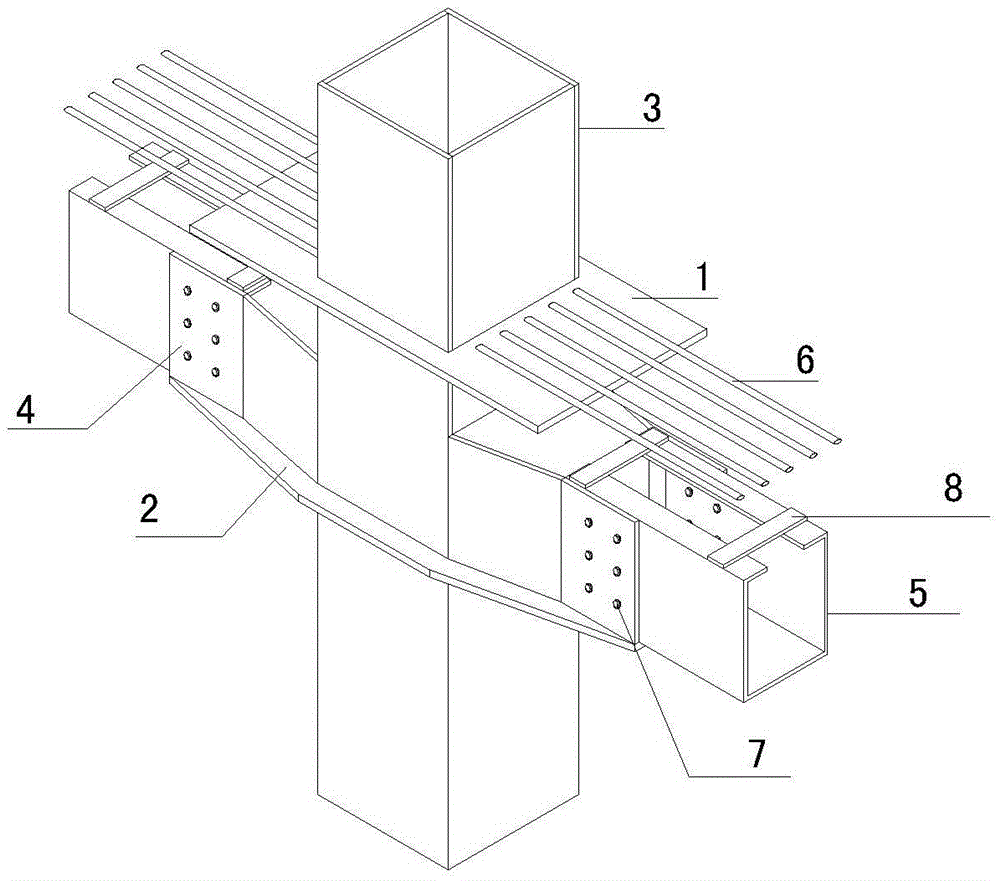

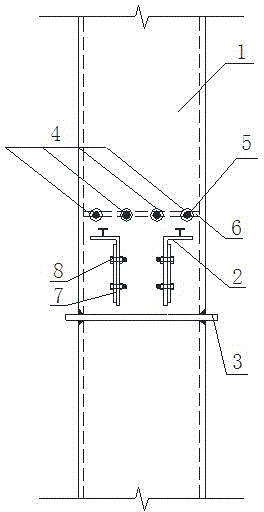

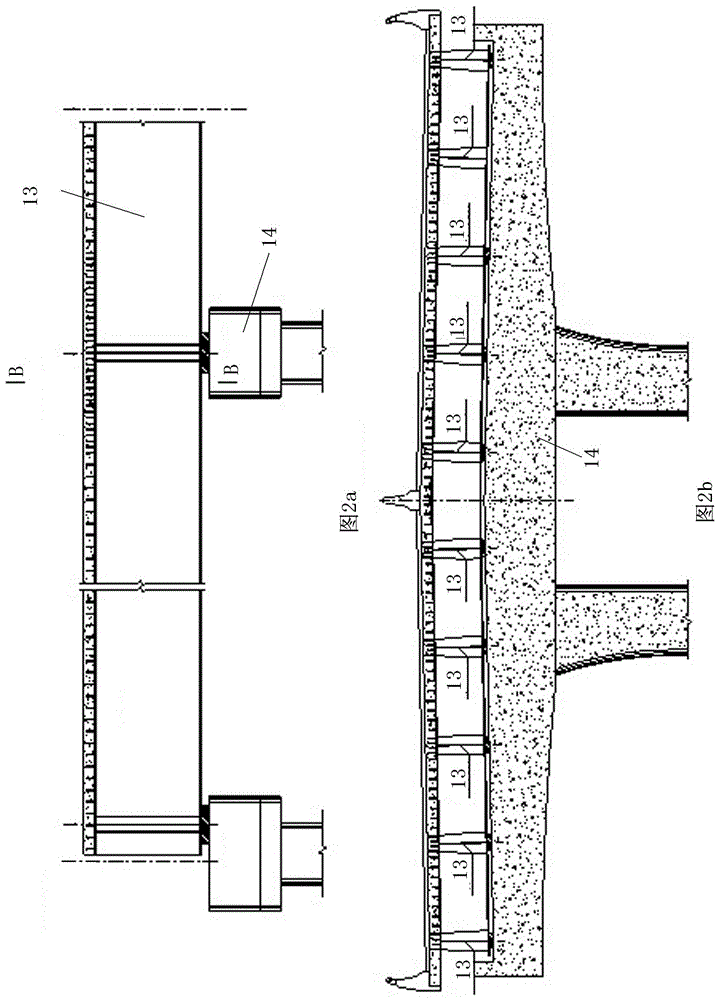

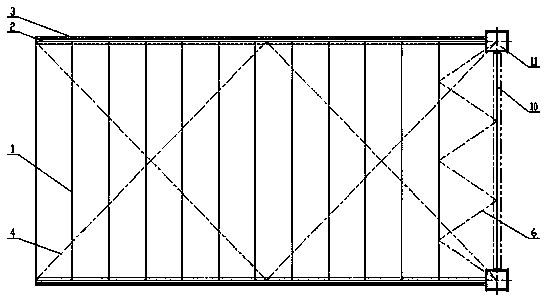

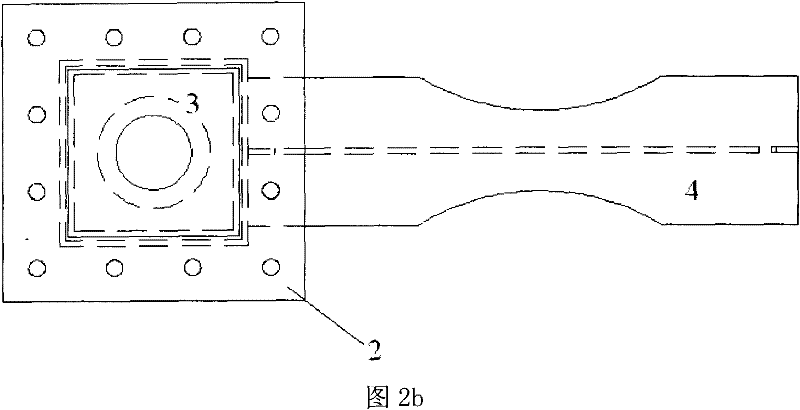

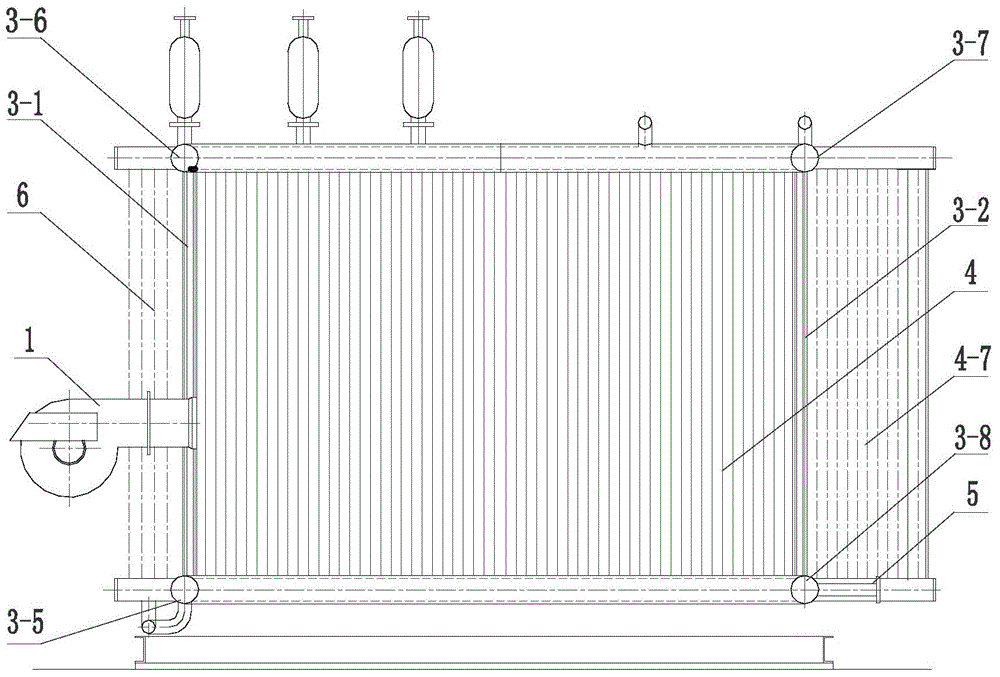

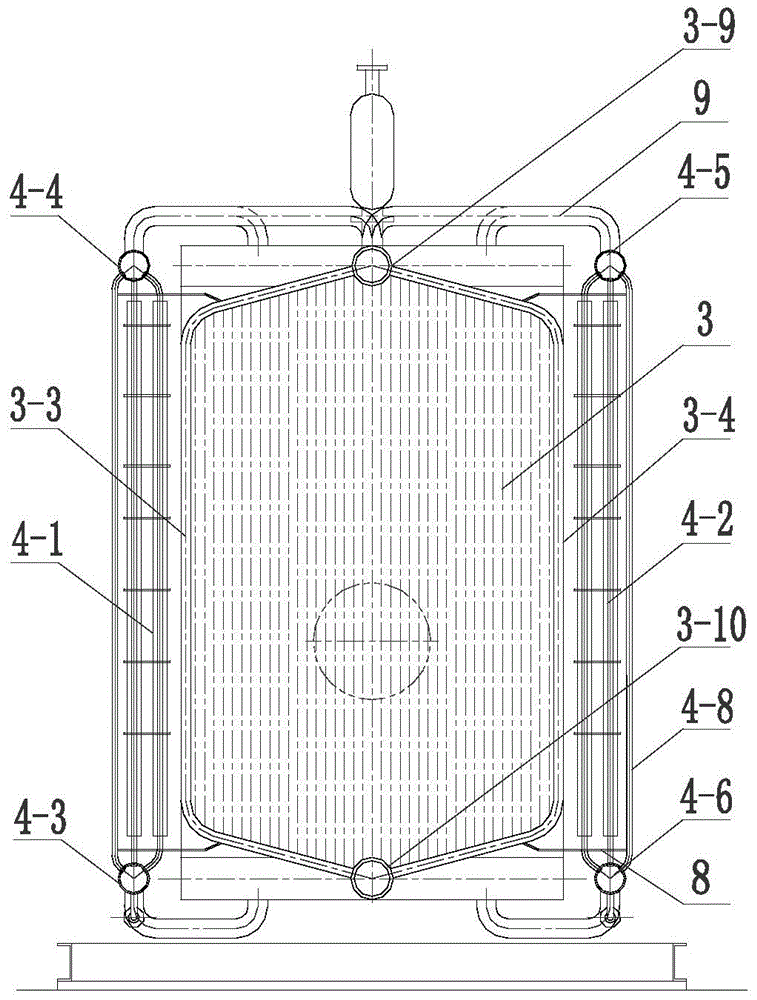

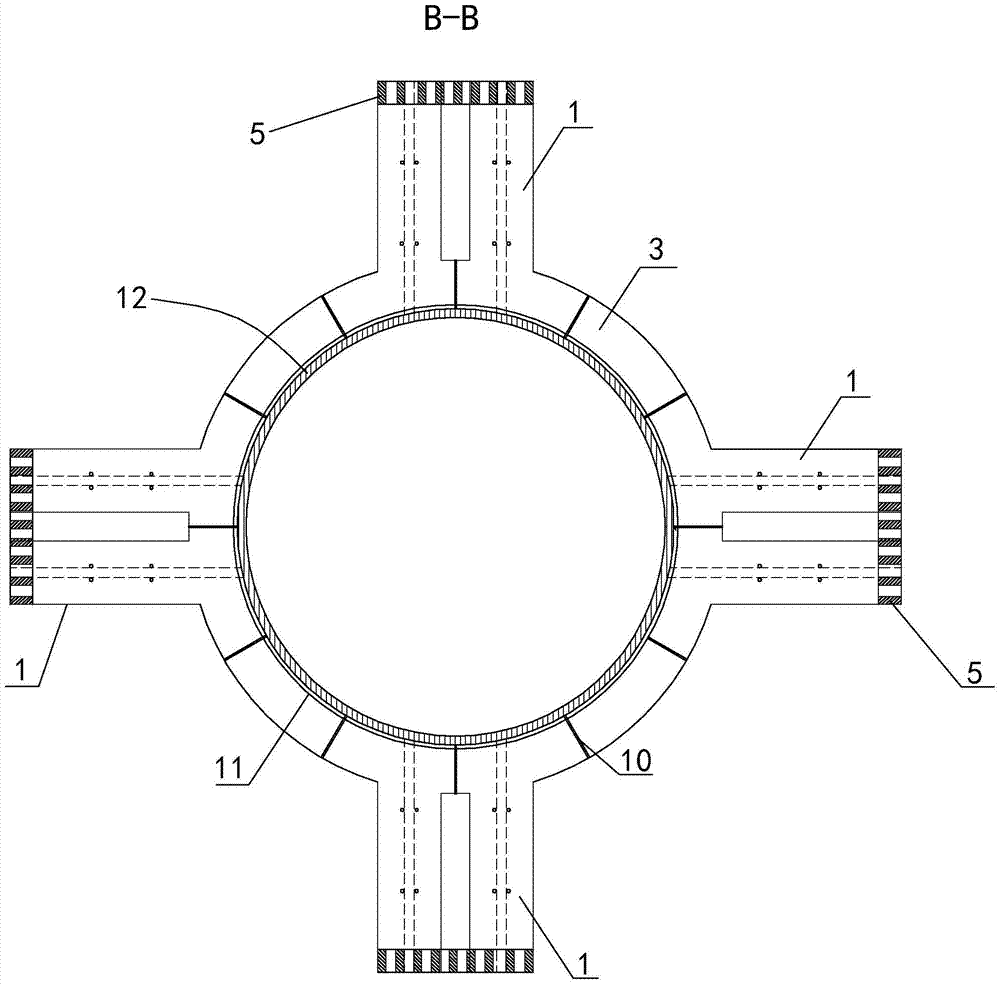

Connecting node for steel pipe concrete post and outside U-shaped steel and concrete composite beam

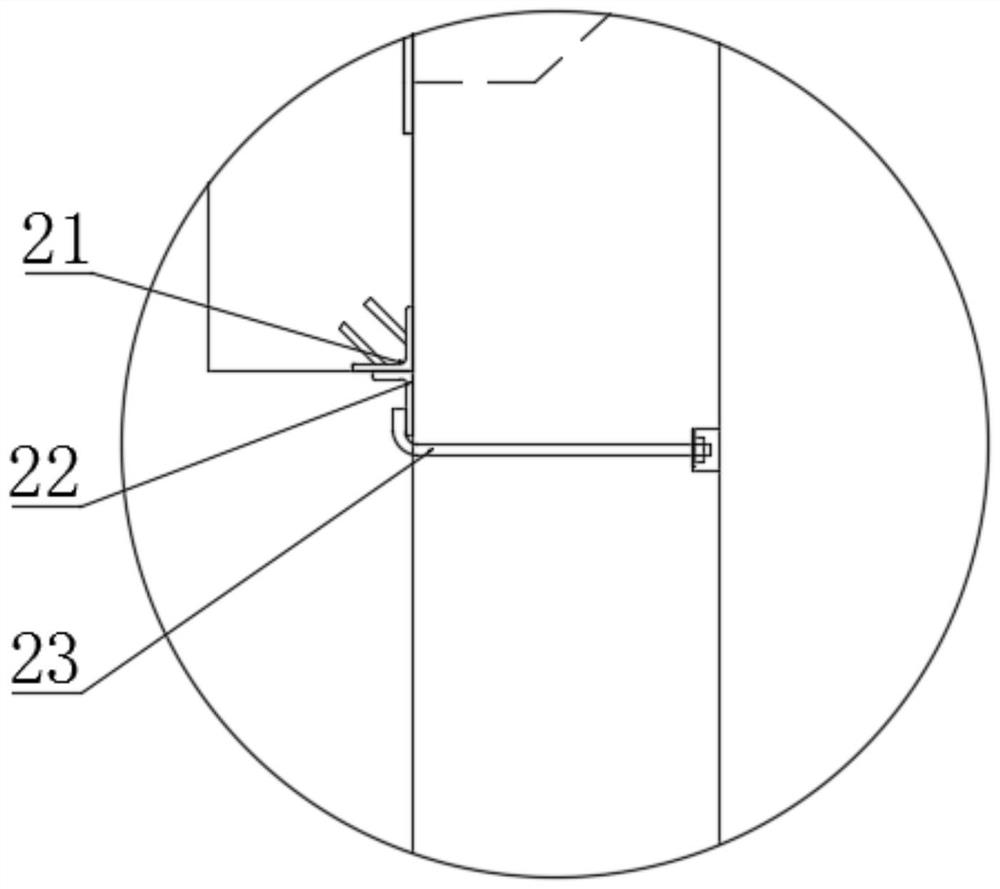

The invention provides a connecting node for a steel pipe concrete post and an outside U-shaped steel and concrete composite beam. In order to prevent the lamellar tearing of the steel pipe walls and the outer surface deformation of a post wall plate, a penetrating separation plate penetrating through steel pipes is arranged in the steel pipes arranged in a position of a composite beam bottom plate; the steel pipes are broken in a position of the penetrating separation plate; the upper steel pipe and the lower steel pipe are connected with the upper end surface and the lower end surface of the penetrating separation plate through butt-jointed welding seams with grooves; a U-shaped steel bottom plate is connected with the penetrating separation plate by the butt-jointed welding seams after the amputation; the welding seams cannot easily crack; the connection intensity is high; and the anti-seismic performance is good. The two opposite ends of the steel pipes in the length direction of the composite beam are correspondingly provided with sleeves capable of being movably connected with the end parts of negative reinforcement steel bars; and the sleeves are welded with the outer walls of the steel pipes. The structural form has the advantages that the weakening on the carrying force of the steel pipes due to the hole forming in the side walls of the steel pipes can be reduced; meanwhile, the welding workload is reduced; the construction is convenient; and the assemblage can be conveniently realized. In order to effectively transfer the load, a horizontal reinforcement plate is fixedly welded in a position, corresponding to the sleeves, of an inner cavity of the steel pipes.

Owner:SHANDONG JIANZHU UNIV

Solderless node connector for steel-concrete composite structure

InactiveCN101603330AReduce dosageEmission reductionBuilding constructionsReinforced concreteWhole body

The invention discloses a solderless node connector for a steel-concrete composite structure, which belongs to the field of connection of steel structures and reinforced concrete structures during the construction of building engineering. The prior connection mode of the steel structures and the reinforced concrete structures has the disadvantages of uneven global stress of beam bodies, piercing, large field welding workload and the like. The solderless node connector comprises a steel column, an annular plate and more than one corbel, the annular plate and the steel column are welded together, more than one corbel is welded with the annular plate respectively or is processed into a whole body, and a top plate and / or a bottom plate of each corbel is provided with a reinforcing steel bar connector for installing reinforcing steel bars; the reinforcing steel bar connector comprises a mounting plate and more than two stiffening plates which play a role in force transfer, and the mounting plate is provided with more than one through hole for the reinforcing steel bars to pass through. The solderless node connector for the steel-concrete composite structure can realize the aims of reasonable connection of a plurality of connection nodes, the guarantee of reasonable stress of structures thereof, convenient processing, convenient and quick field installation, quick construction, and the reduction of field welding workload.

Owner:中国建筑第五工程局有限公司东莞分公司

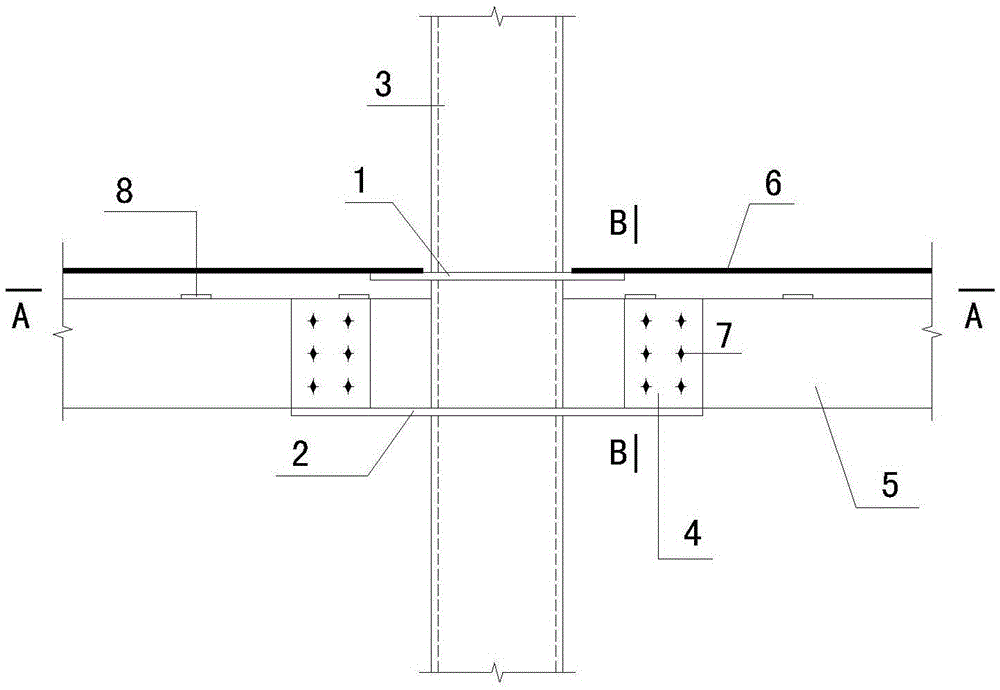

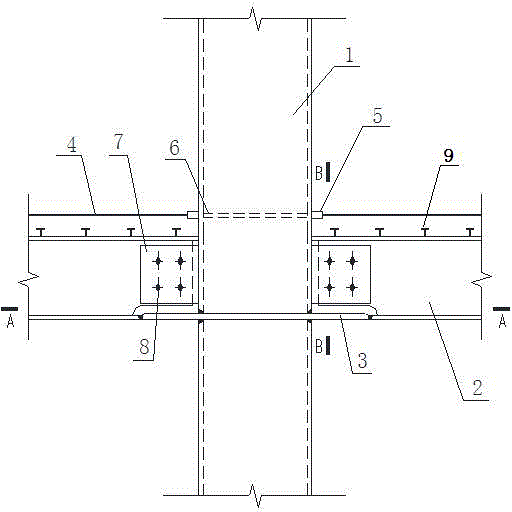

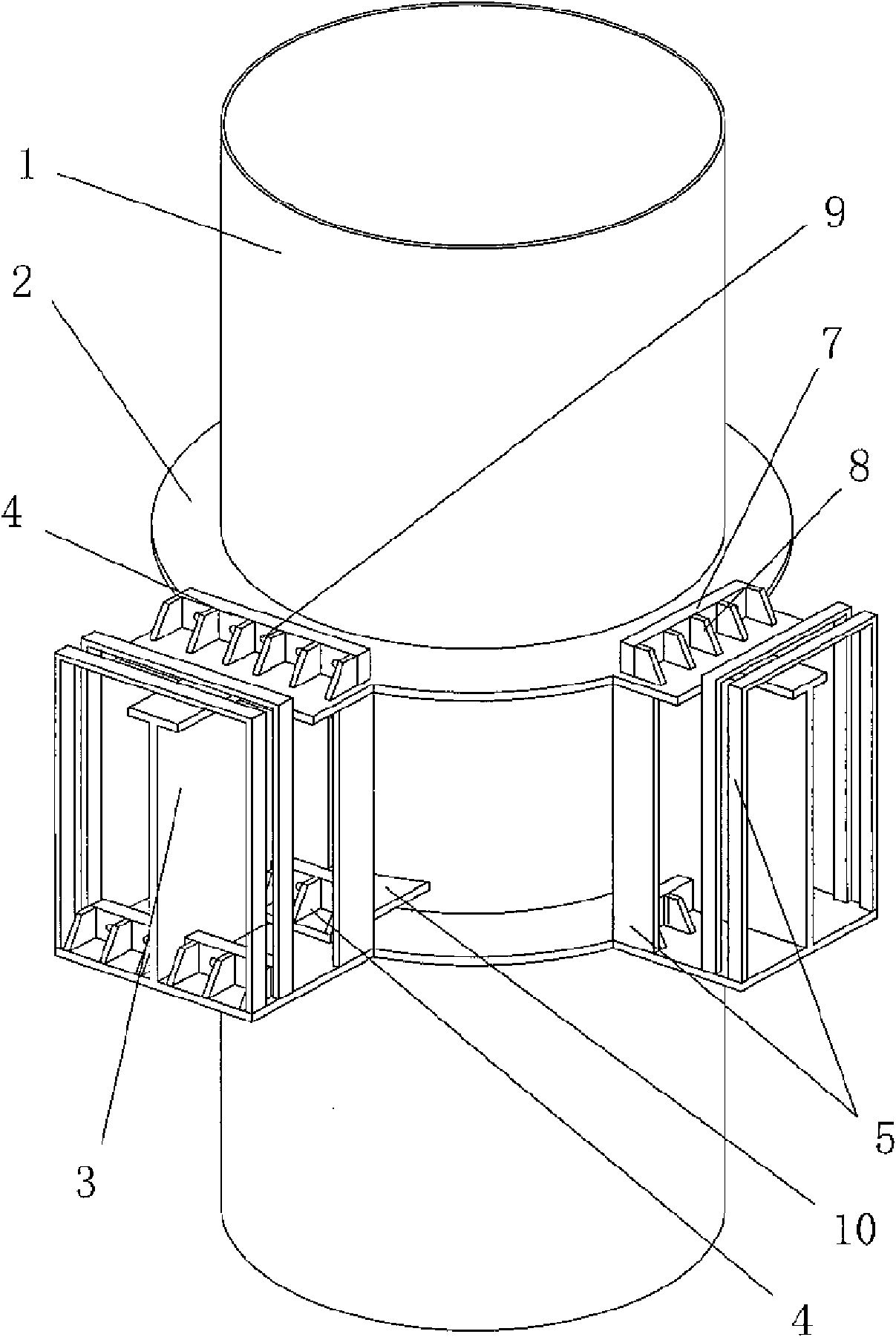

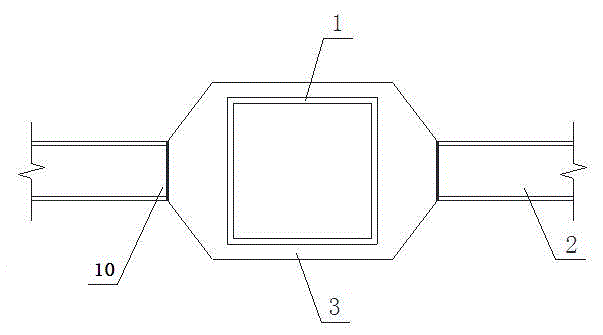

Node for connecting concrete-filled steel tube column and external wrapping U-shaped steel concrete composite beam

InactiveCN104947802APouring quality is easy to guaranteeEasy constructionShock proofingSteel tubeRebar

The invention provides a node for connecting a concrete-filled steel tube column and an external wrapping U-shaped steel concrete composite beam. The node facilitates the pouring of concrete in a steel tube, easily guarantees pouring quality of concrete in a node area, is favorable for welding operation and easily guarantees weld seam quality. An outer annular plate is welded to the outer side of the steel tube at the position of a U-shaped steel base plate, the two opposite ends inside the outer annular plate in the length direction of the composite beam are connected with the U-shaped steel base plate having undergone limb cutting through butt joint weld seams, the weld seams do not crack easily, the connecting strength is high, and the vibration resistance is good. Sleeves capable of being movably connected with the ends of a hogging moment steel rib are arranged at the two opposite ends inside the steel tube in the length direction of the composite beam respectively; and the sleeves are welded to an outer wall of the steel tube. The structural type can reduce the weakening of steel tube bearing capacity caused by hole opening in a side wall of the steel pipe, the welding workload is reduced, and the construction and assembly are facilitated. To effectively transmit a load, horizontal reinforcing plates are fixedly welded to the positions of a steel tube inner cavity corresponding to the sleeves.

Owner:SHANDONG JIANZHU UNIV

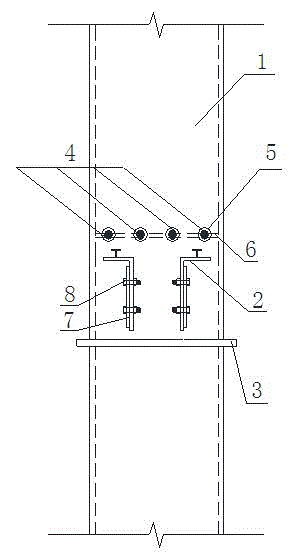

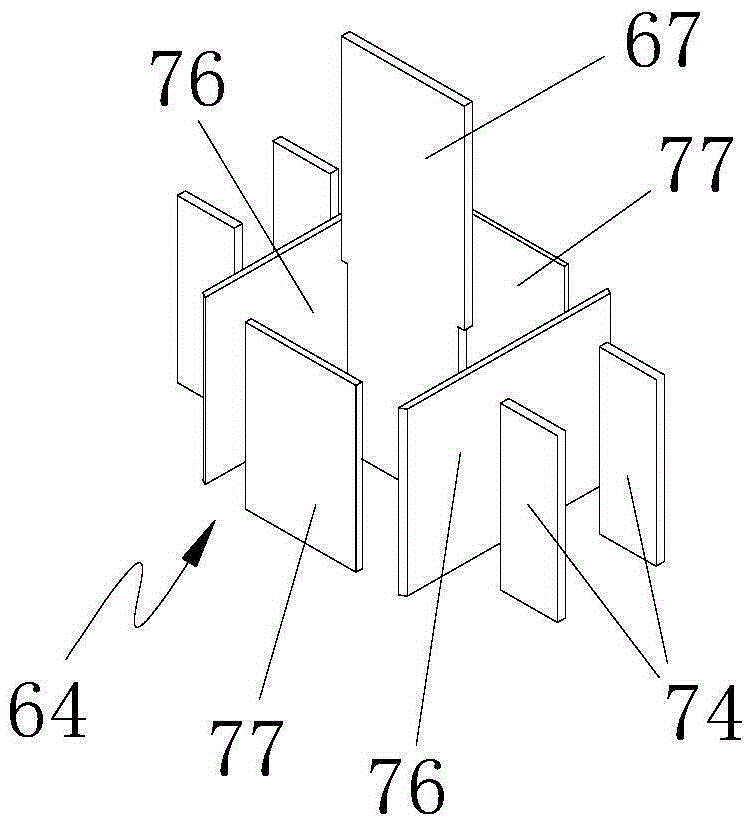

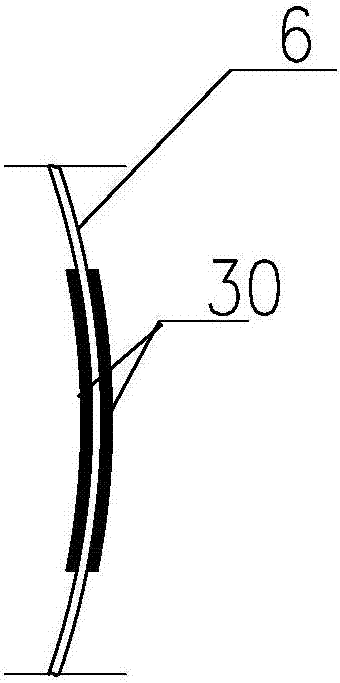

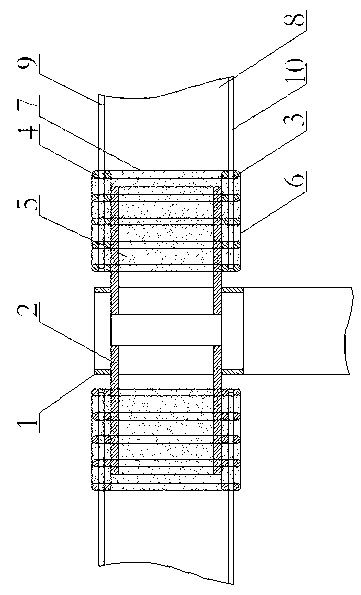

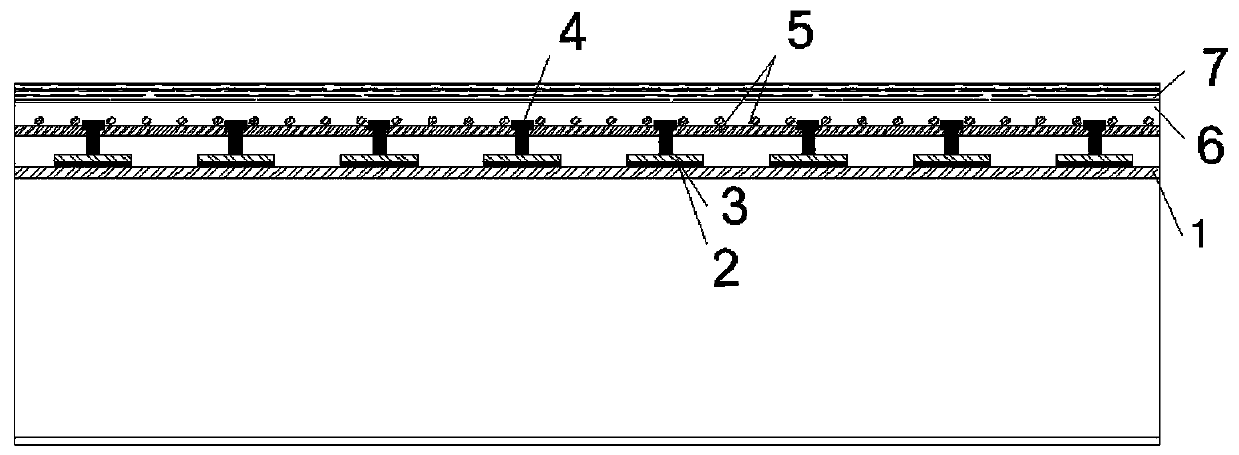

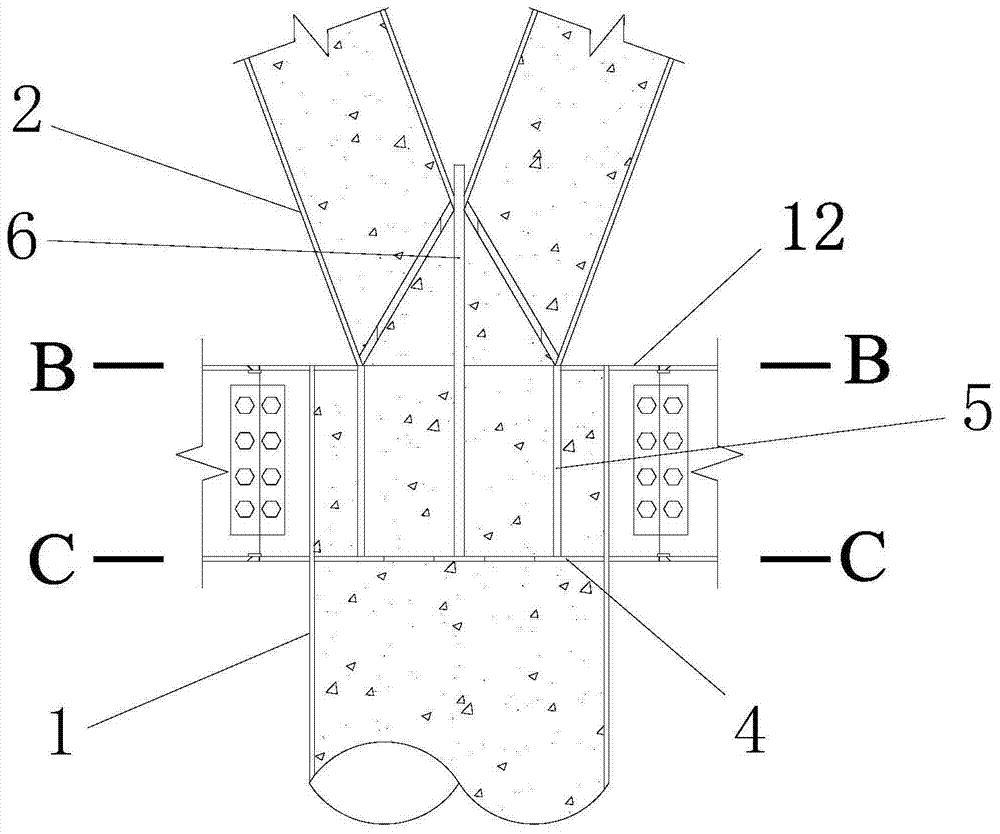

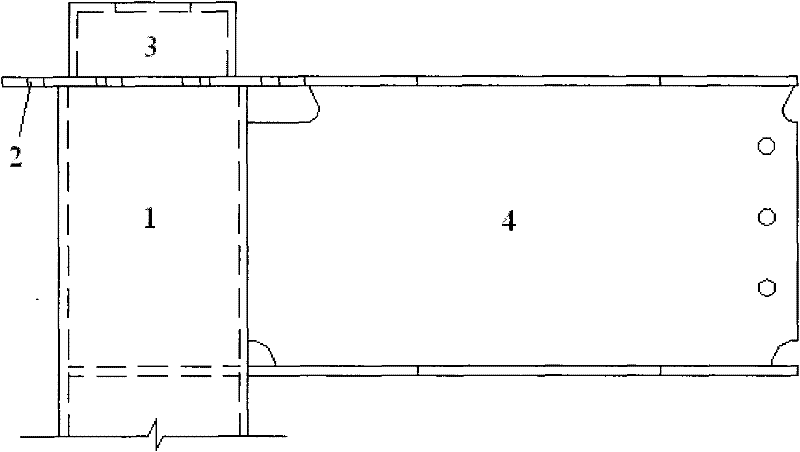

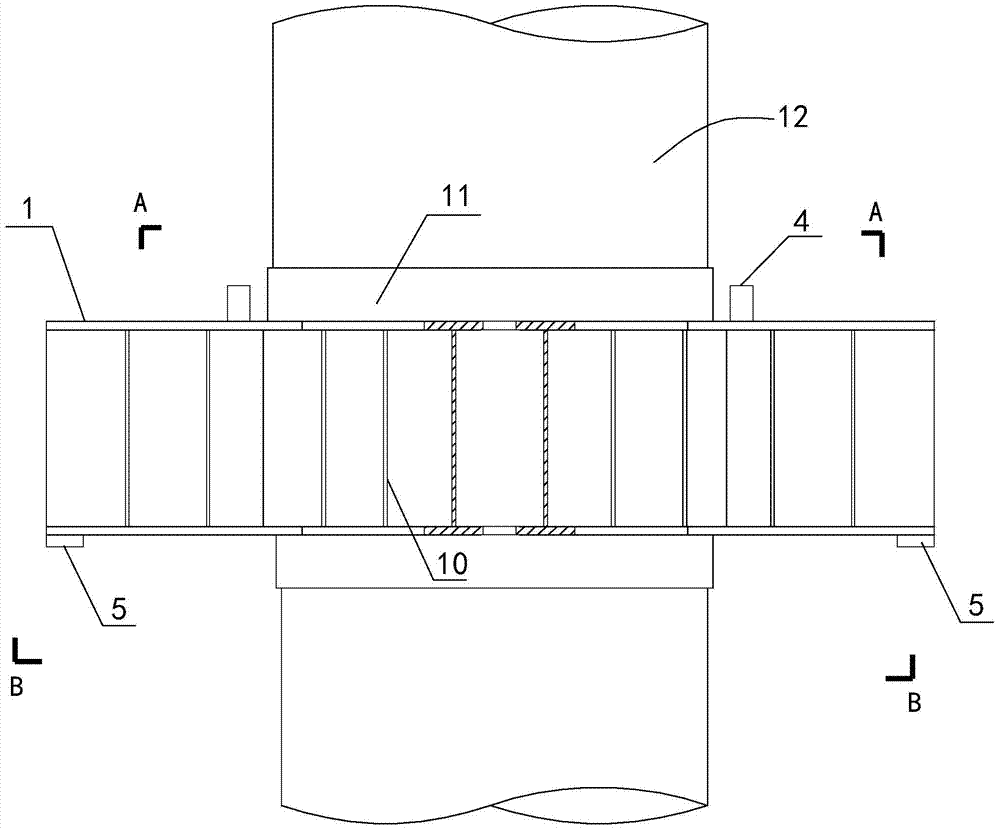

Concrete filled steel tube transfer joint structure and construction method thereof

The invention discloses a concrete filled steel tube transfer joint structure and a construction method thereof. The concrete filled steel tube transfer joint structure comprises a strut, a batter post and a socket frame; the batter post is fixedly connected to the socket frame; the socket frame is fixedly arranged inside the strut and located at a top end of the strut; the socket frame comprises a vertical inner ribbed plate; the batter post is provided with a section including a cross section; a shape of the vertical rib ribbed plate corresponds to a shape of the cross section and a connecting ribbed plate extends out of the vertical inner ribbed plate; the connecting ribbed plate extending out is fixedly connected to an inner wall of the strut; the batter post is fixed on the vertical inner ribbed plate through the section. The concrete filled steel tube transfer joint structure is integrated with the advantages of a concrete-filled steel tube and a battery post transfer structure, and has the advantages of direct force transfer, high bearing capacity, small sectional dimension of the component, good utilization of building space, no need for support formwork, small field welding workload, guaranteed construction quality and the like. Two batter posts and a beam system form a triangular force transfer mode, and meanwhile, excellent side force resisting capability is realized.

Owner:SOUTH CHINA UNIV OF TECH

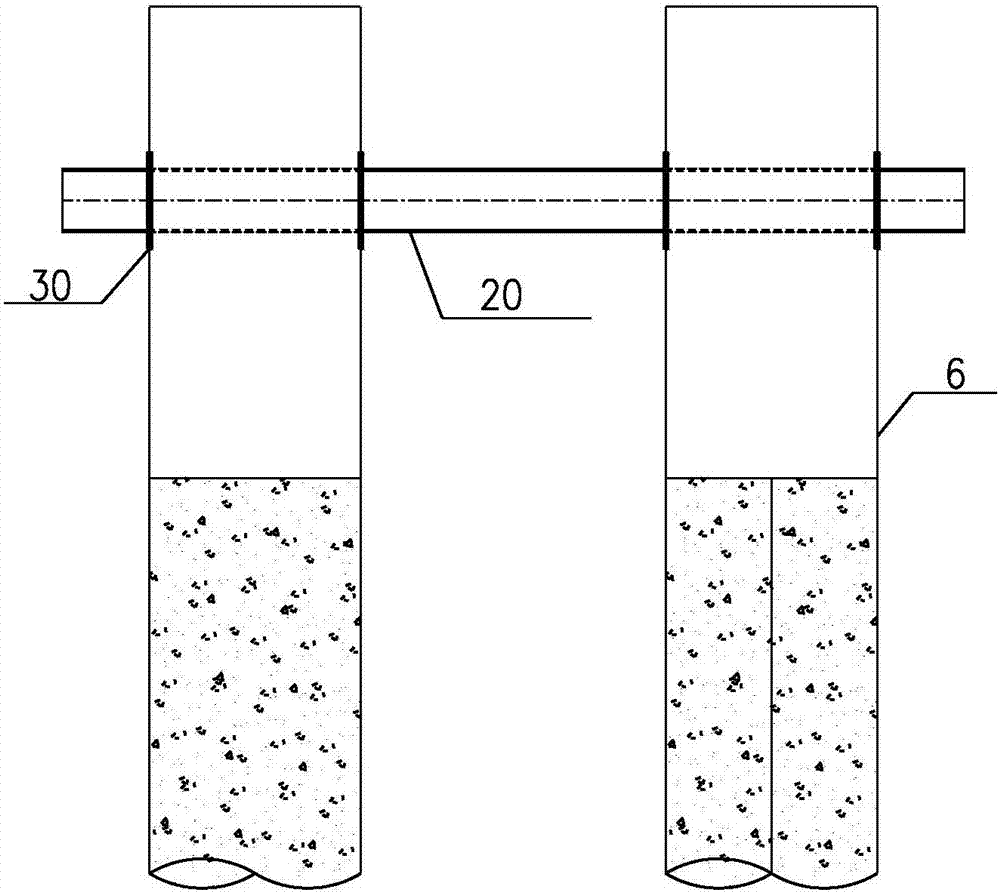

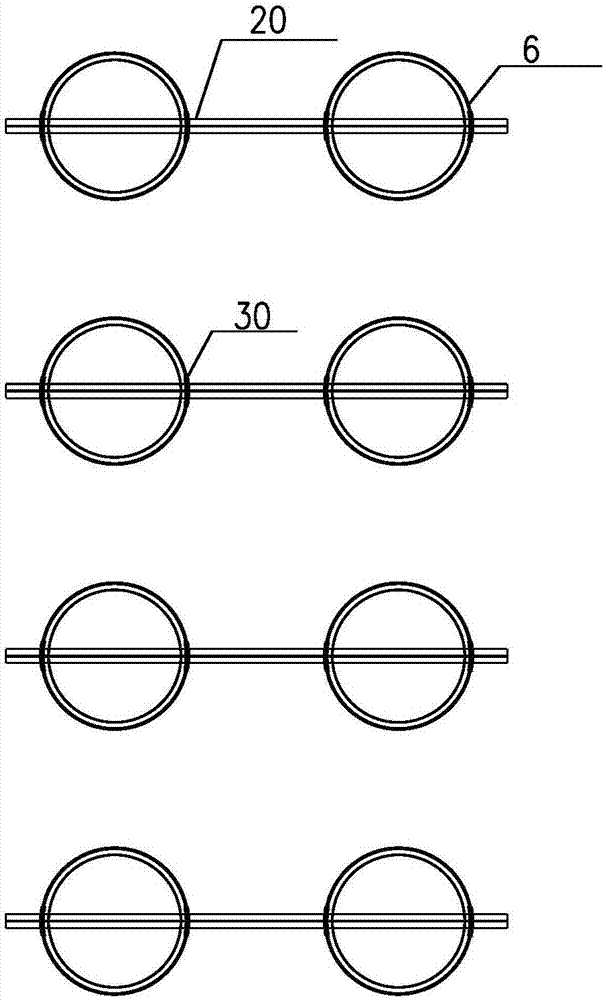

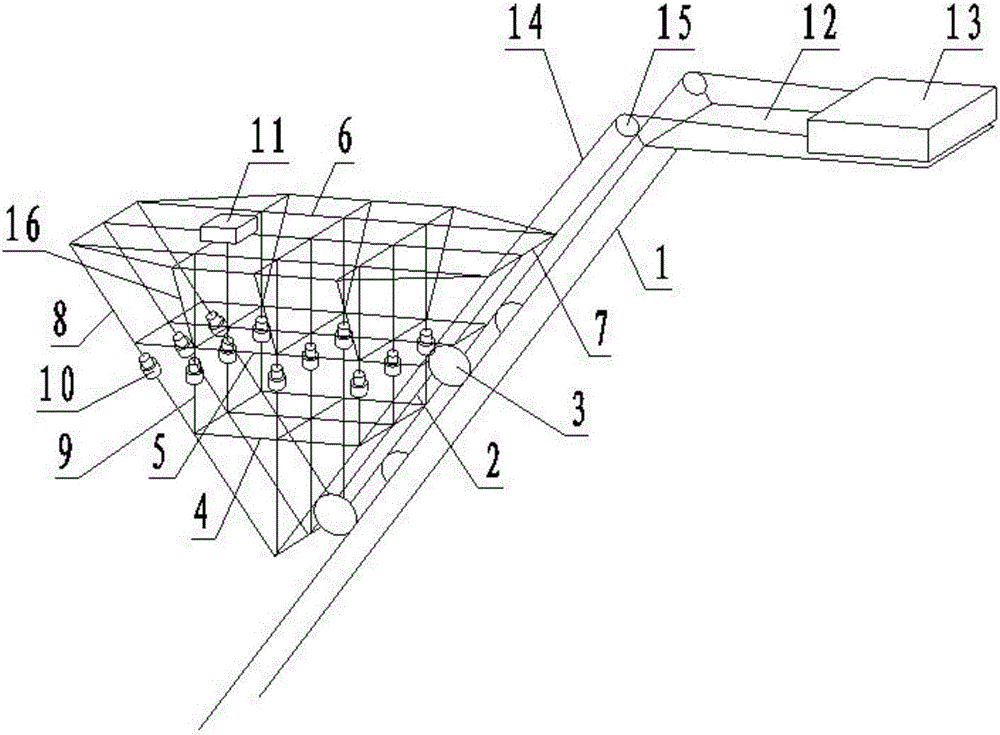

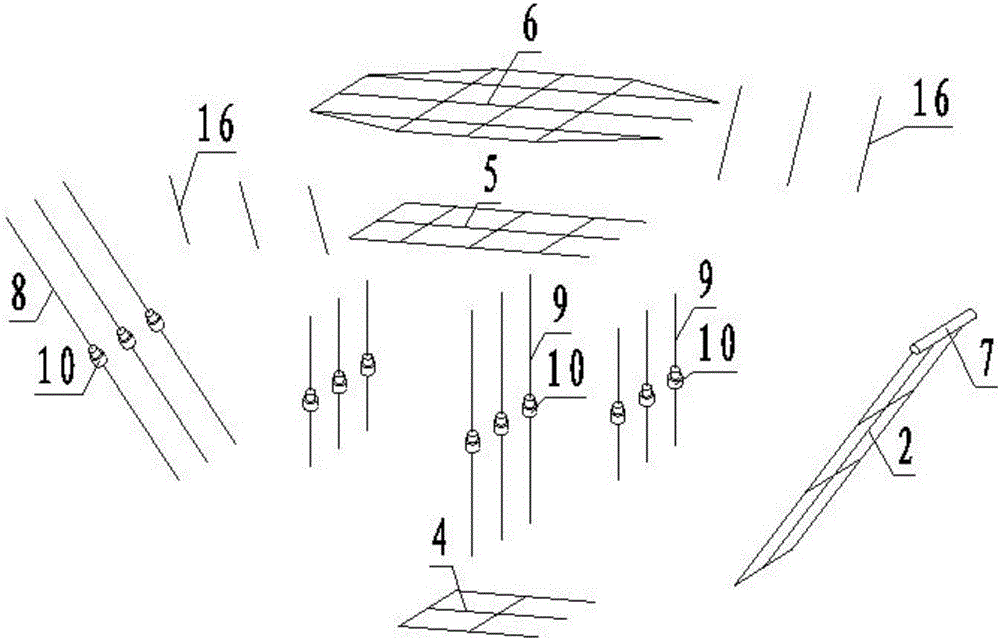

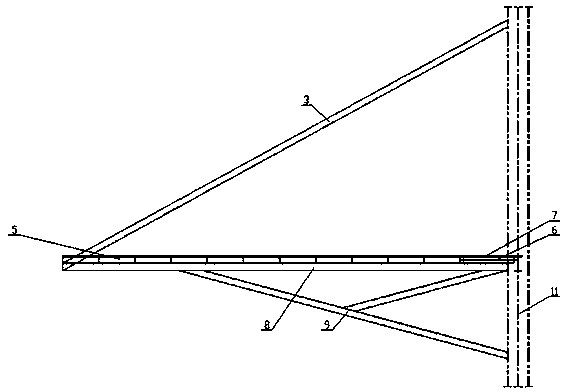

Steel suspension box hoisting system with integral hoisting function and hoisting method of steel suspension box hoisting system

ActiveCN107142954AReduce security risksReduce serious safety hazardsArtificial islandsUnderwater structuresCantileverMechanical engineering

The invention discloses a steel suspension box hoisting system with an integral hoisting function and a hoisting method of the steel suspension box hoisting system, and belongs to the field of sub-beam structure construction. The steel suspension box hoisting system comprises a steel suspension box and an assembly platform of the steel suspension box, wherein the assembly platform comprises a plurality of steel protective cylinders and a plurality of platform beams; penetrating open pores are prefabricated on the protective cylinder walls of all the steel protective cylinders; positioning-guiding mechanisms are arranged at the open pores of all the steel protective cylinders; a whole row of steel protective cylinders movably penetrate through each platform beam through the open pores of the steel protective cylinders; the two ends of each platform beam are exposed from the steel protective cylinders arranged at the two ends of the row; and the steel suspension box comprises the following four parts: a baseplate structure, a wall body structure, cantilever beams, as well as laterally stable supports and section steel suspension rods. By adoption of the steel suspension box hoisting system disclosed by the invention, the safety risk of detaching the assembly platform can be reduced; the time to establish and detach the assembly platform can be shortened to the greatest extent, the work efficiency can be improved, and the engineering progress can be accelerated; materials adopted for the assembly platform can be recycled to the greatest extent; and meanwhile, the difficulty in hoisting construction of the steel suspension box and the labor consumption can be reduced, the construction period can be shortened, and the mounting precision can be easier to control.

Owner:CCCC SHEC FOURTH ENG +1

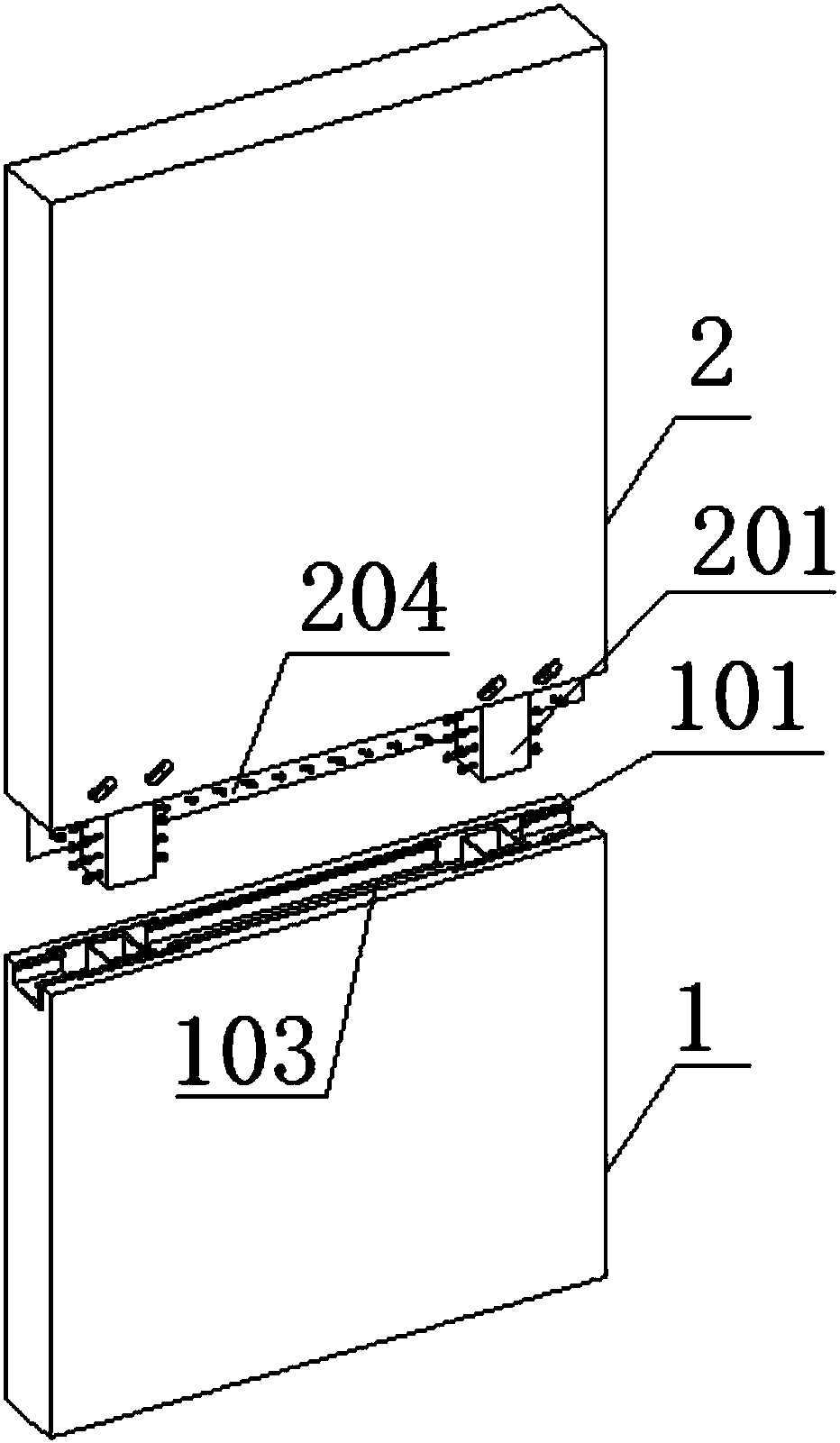

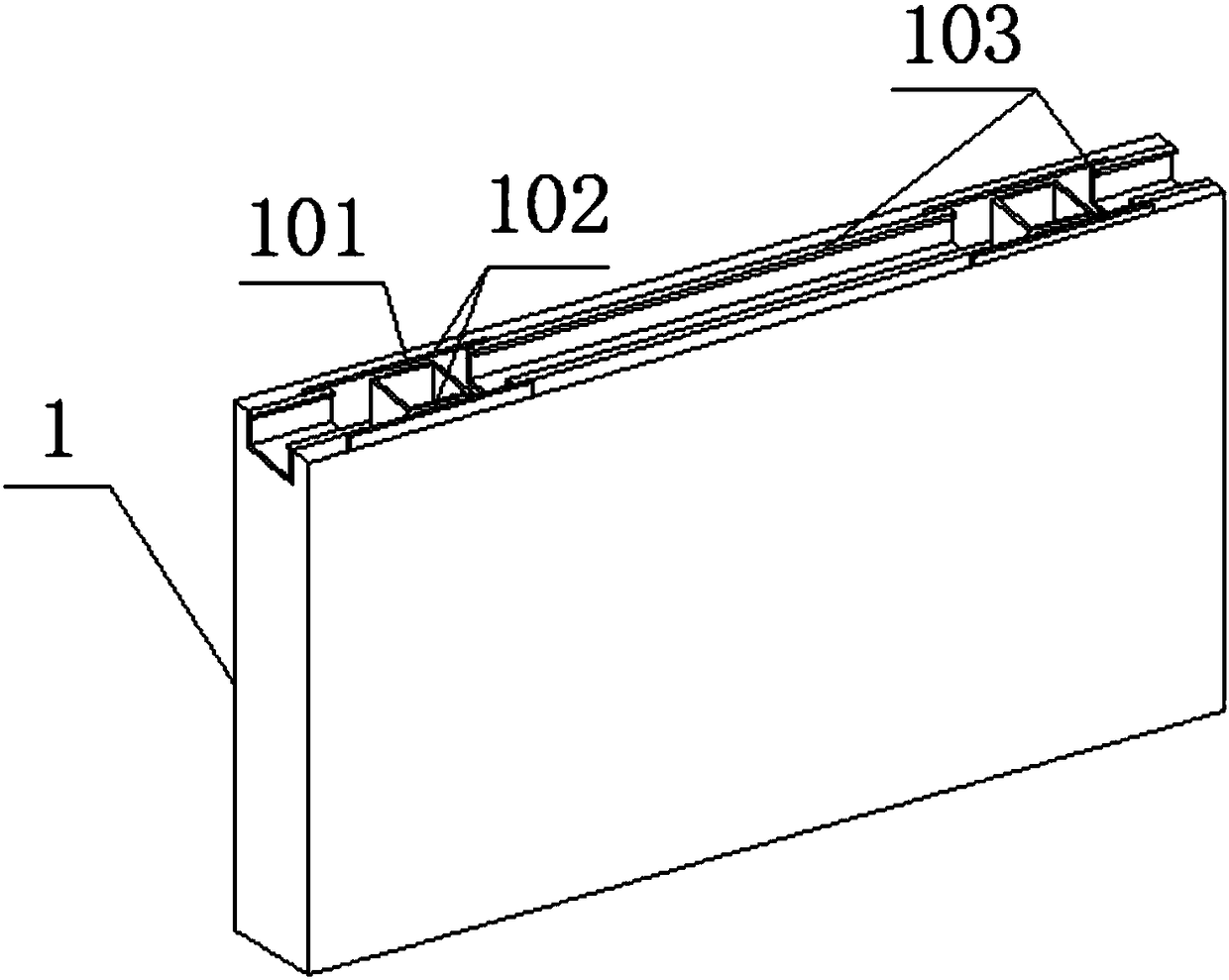

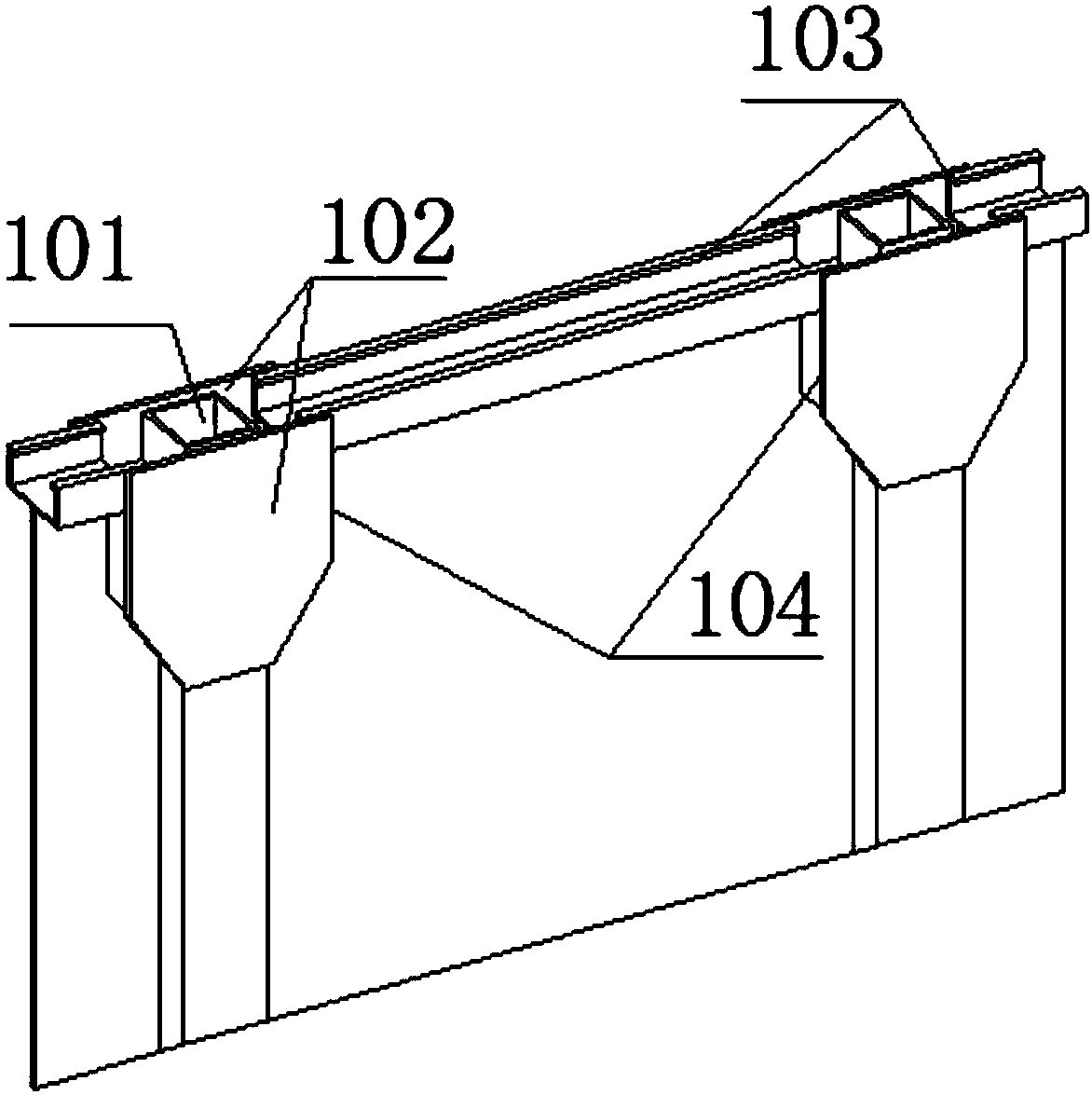

Prefabricated plate wall inter-layer transverse seam connecting joint

PendingCN108240037AQuick assemblyShorten the construction periodBuilding constructionsInter layerEngineering

The invention relates the technical field of connecting joints, in particular to a prefabricated plate wall inter-layer transverse seam connecting joint. The prefabricated plate wall inter-layer transverse seam connecting joint comprises a lower layer plate wall module upper end connecting joint body and an upper layer plate wall module lower end connecting joint body, connecting casing pipes matched with a cup mouth casing pipe are arranged on the two sides of the lower end of an upper layer plate wall module correspondingly, and the upper plate wall module is internally provided with the corresponding connecting joint body which is parallel to a transverse seam and comprises a connecting plate. The connecting plate and a second bolt are located in a C-shaped steel empty groove, and slurry injecting holes are formed in the two sides of the lower portion of the upper layer plate wall module correspondingly. The prefabricated modules can be multi-layer crossing modules, rapid assemblingof the prefabricated building modules can be achieved, and the construction period is shortened; the modules are connected through the anchoring effect of high-strength grouting materials, and a great amount of on-site welding workload is reduced; only a horizontal seam of 20 mm is reserved between the modules, and the on-site module support workload is reduced; and through the design of a cup mouth between the plate wall modules, the connecting strength and quality between the modules are ensured.

Owner:BEIJING ZHIHUI YUNJIAN TECH CO LTD

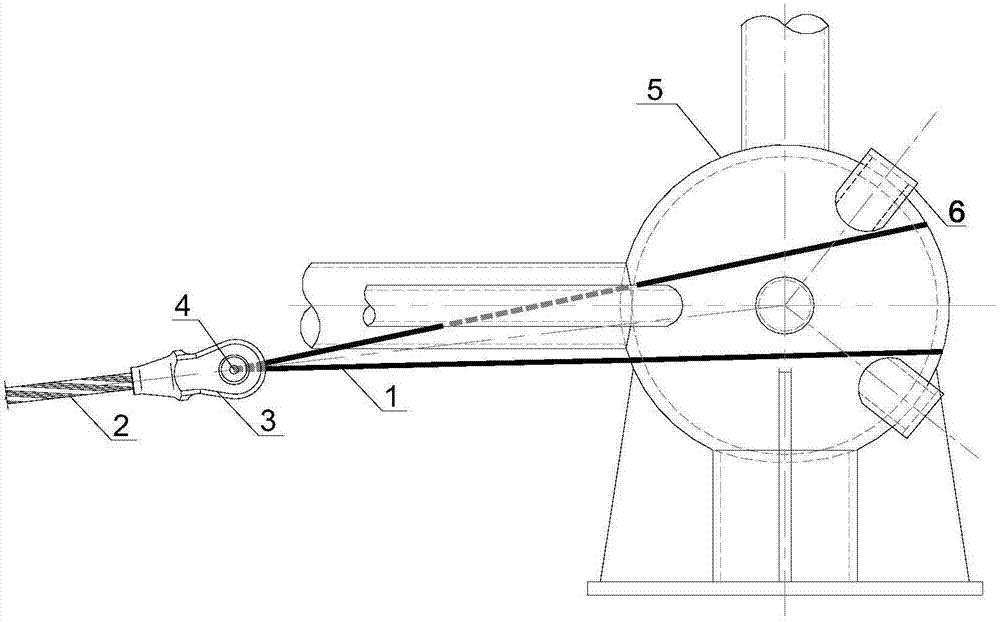

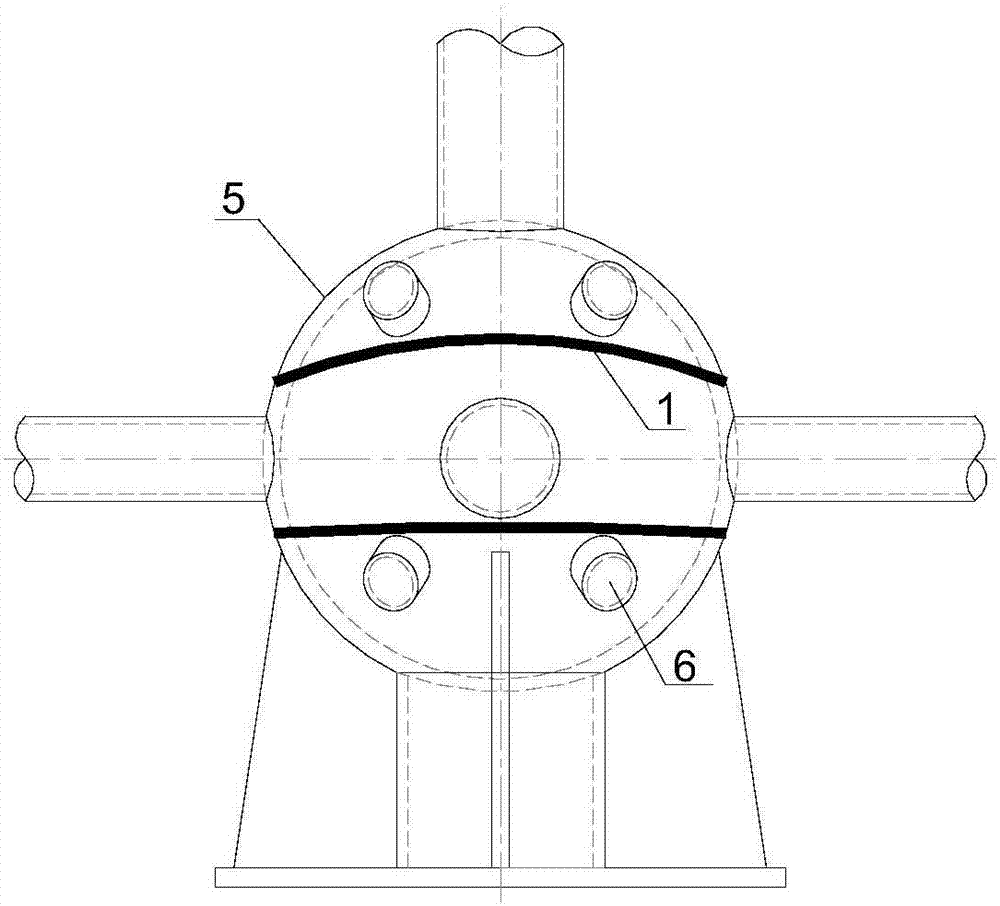

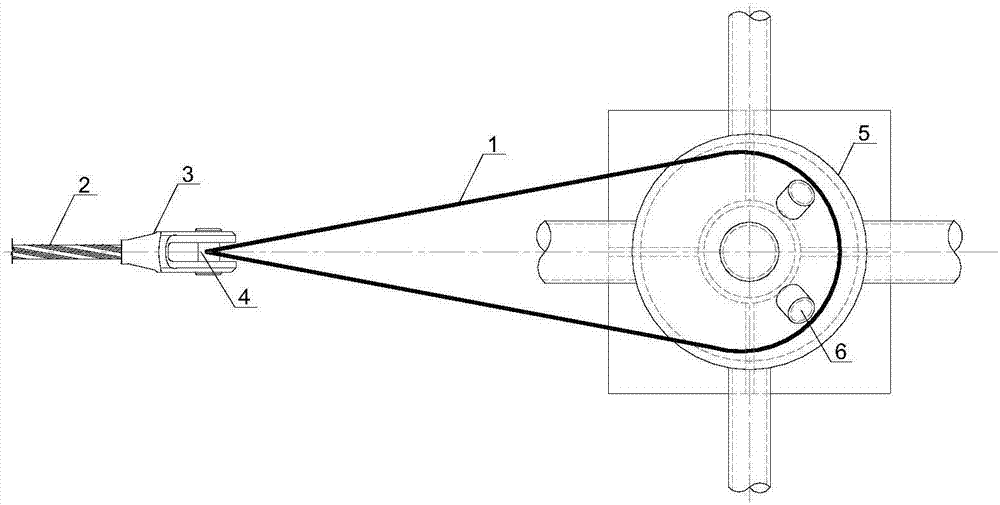

Stay cable joint for open chord strengthening of space structure

PendingCN107313604ASimple structureEasy to operate on siteBuilding repairsExtraordinary structuresClassical mechanicsSpherical joint

The invention relates to a stay cable joint for open chord strengthening of a space structure. Strengthening is achieved on an existing structure welded spherical joint (5). The stay cable joint comprises steel wire ropes (1), a stay cable (2), a dual-lug type cable head (3), a hinge pin (4) and limiting steel tubes (6), the hinge pin (4) penetrates through lug holes of the dual-lug type cable head (3), after the steel wire ropes wind across the welded spherical joint (5), the two ends of each steel wire rope are arranged on the hinge pin (4) in a sleeving mode, and the limiting steel tubes are fixed on the welded spherical joint (5), and used for limiting sliding of the steel wire ropes along a sphere.

Owner:TIANJIN UNIV

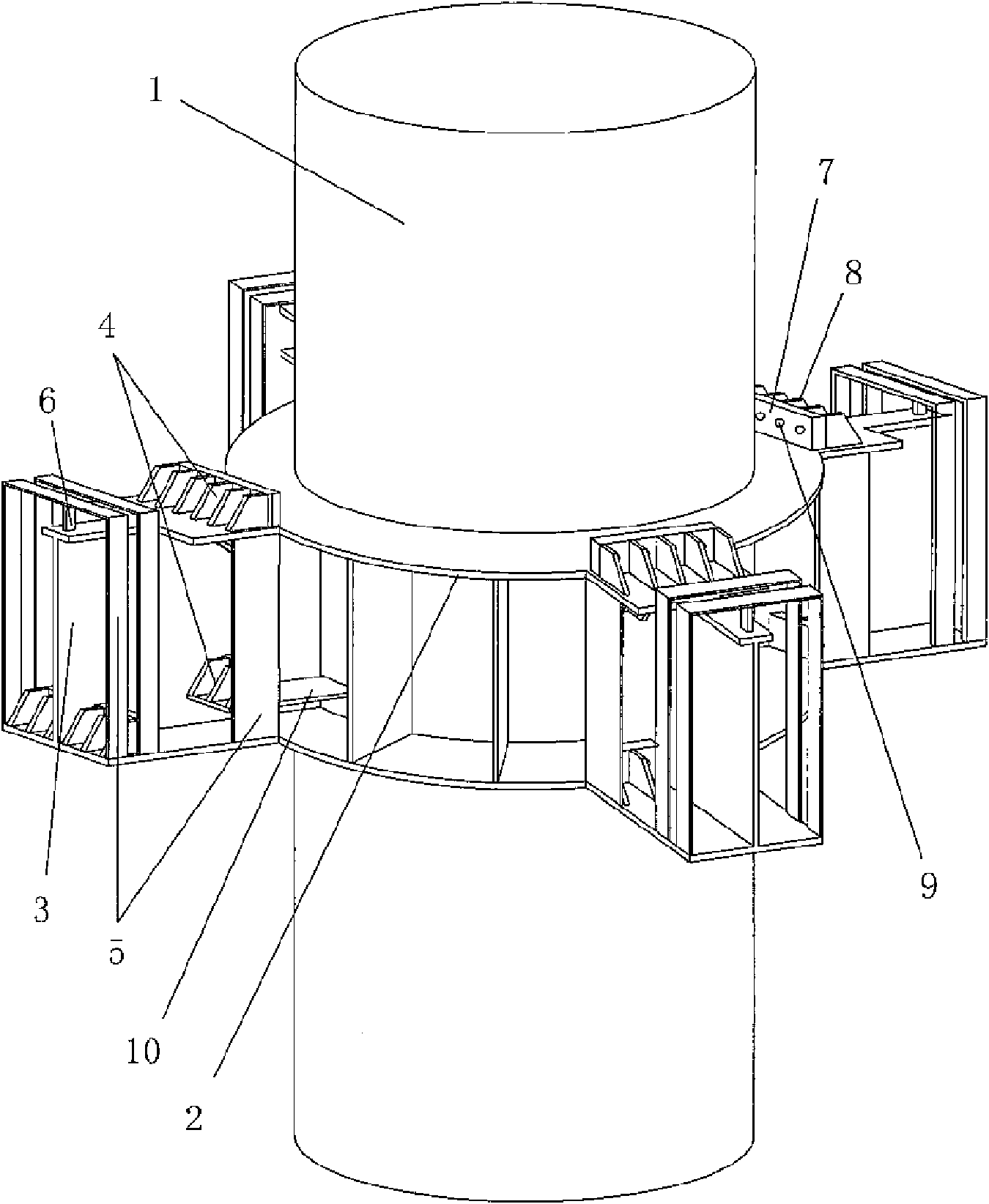

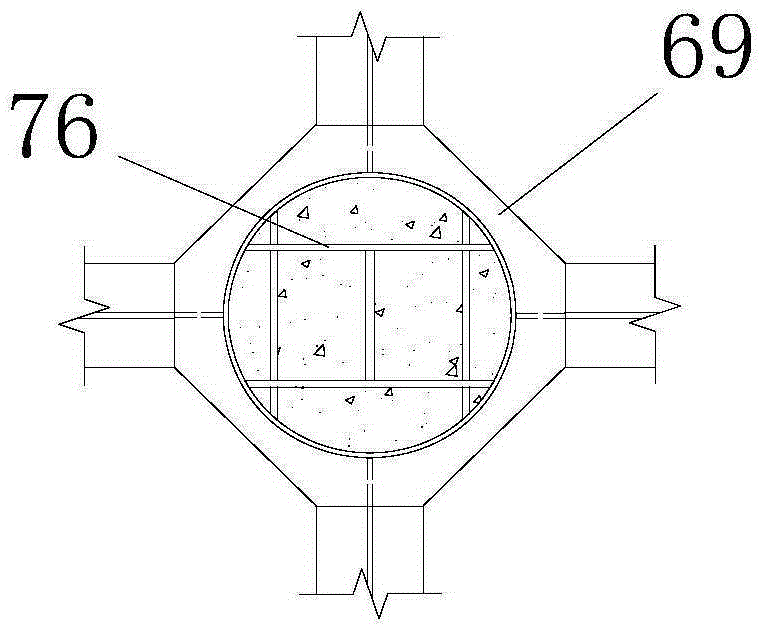

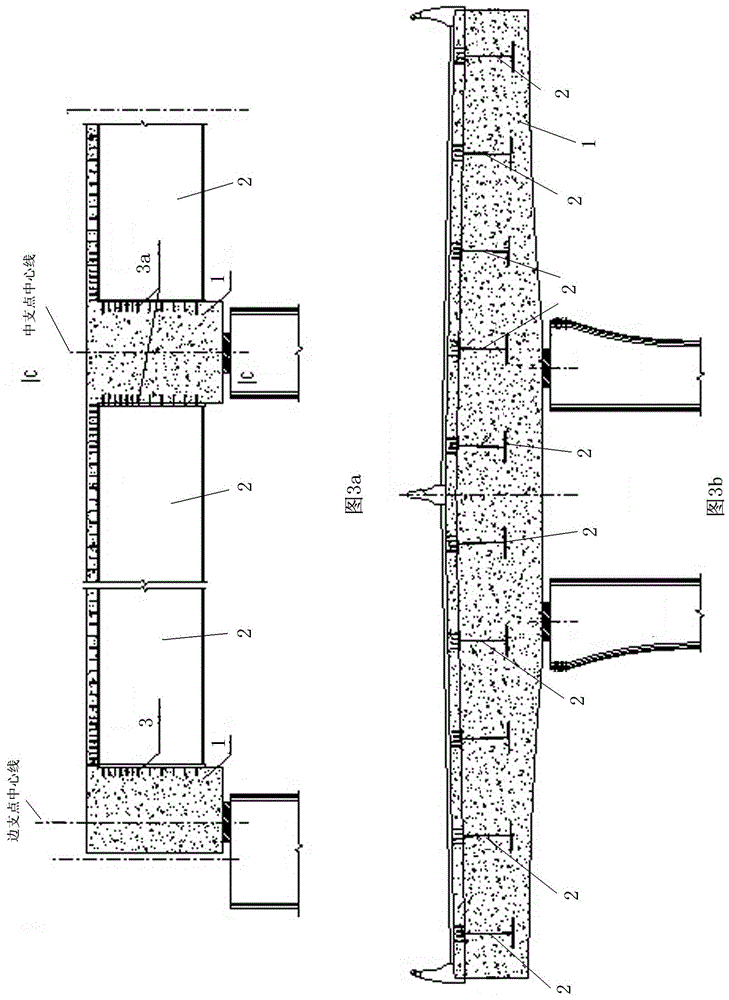

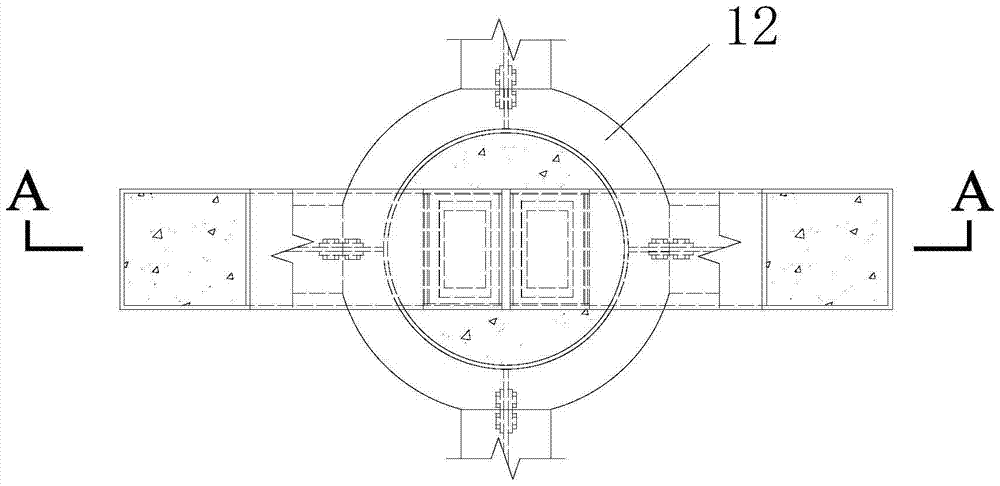

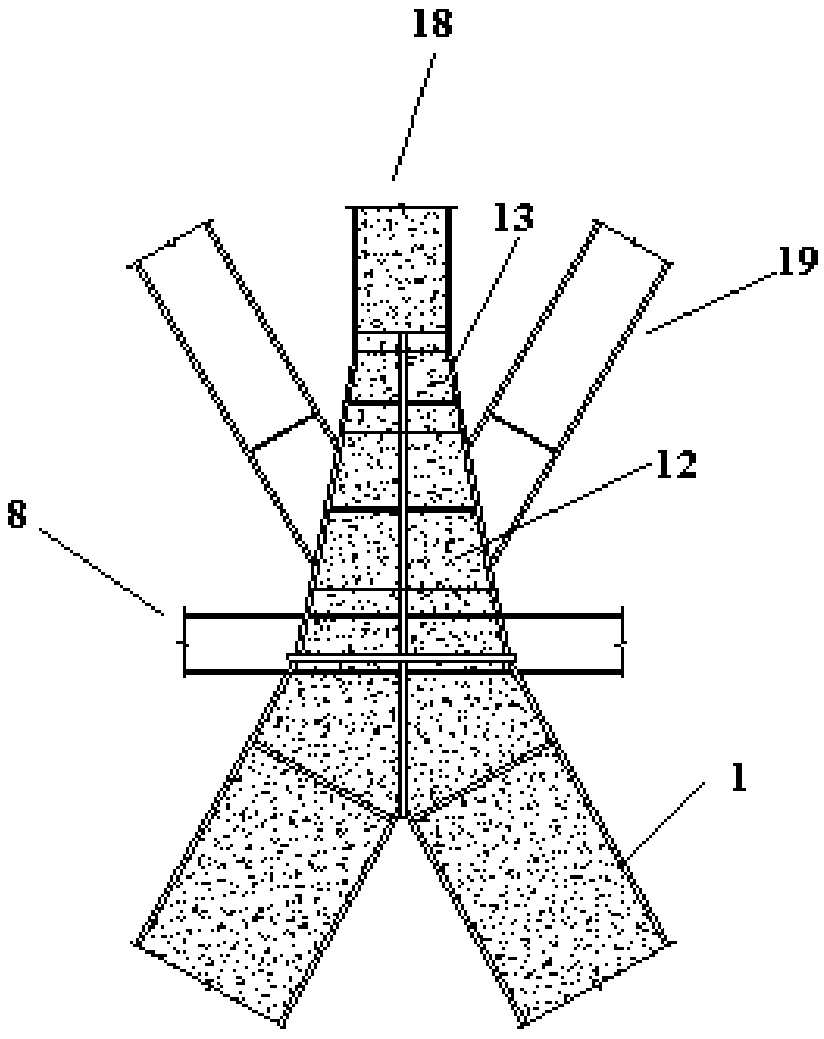

Construction method of multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and ring beam

The invention relates to a construction method of a multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and a ring beam. The joint comprises a plurality of steel corbels and the ring beam, wherein the steel corbels are radially connected to a steel tubular column; inner ends of the steel corbels penetrate through the steel tubular column and are mutually welded and connected in the steel tubular column, and outer ends of the plurality of steel corbels penetrate through the ring beam; the ring beam comprises a ring beam framework and inner concrete ring beam cores arranged in the ring beam framework; the ring beam framework comprises two layers of ring beam bottom ribs, two layers of ring beam top ribs and ring beam stirrups; a plurality of reinforcing steel bar rings of each layer of ring beam bottom ribs and each layer of ring beam top ribs are concentric, and are located on the same plane and bound by a plurality of stirrups; and the two layers of ring beam bottom ribs and the two layers of ring beam top ribs are bound by a plurality of the ring beam stirrups. The joint has the advantages that the joint is simple in structure, free of dense reinforcing steel bars and feeble fragile stress positions and stable in load transmitting, can safely and stably bear a frame beam, and is convenient to construct, short in period, low in cost and applicable to construction of high-rise and super high-rise buildings having multidirectional through concrete filled steel tubular column beam joints comprising steel corbels and ring beams.

Owner:TAIXING FIRST CONSTR INSTALLATION

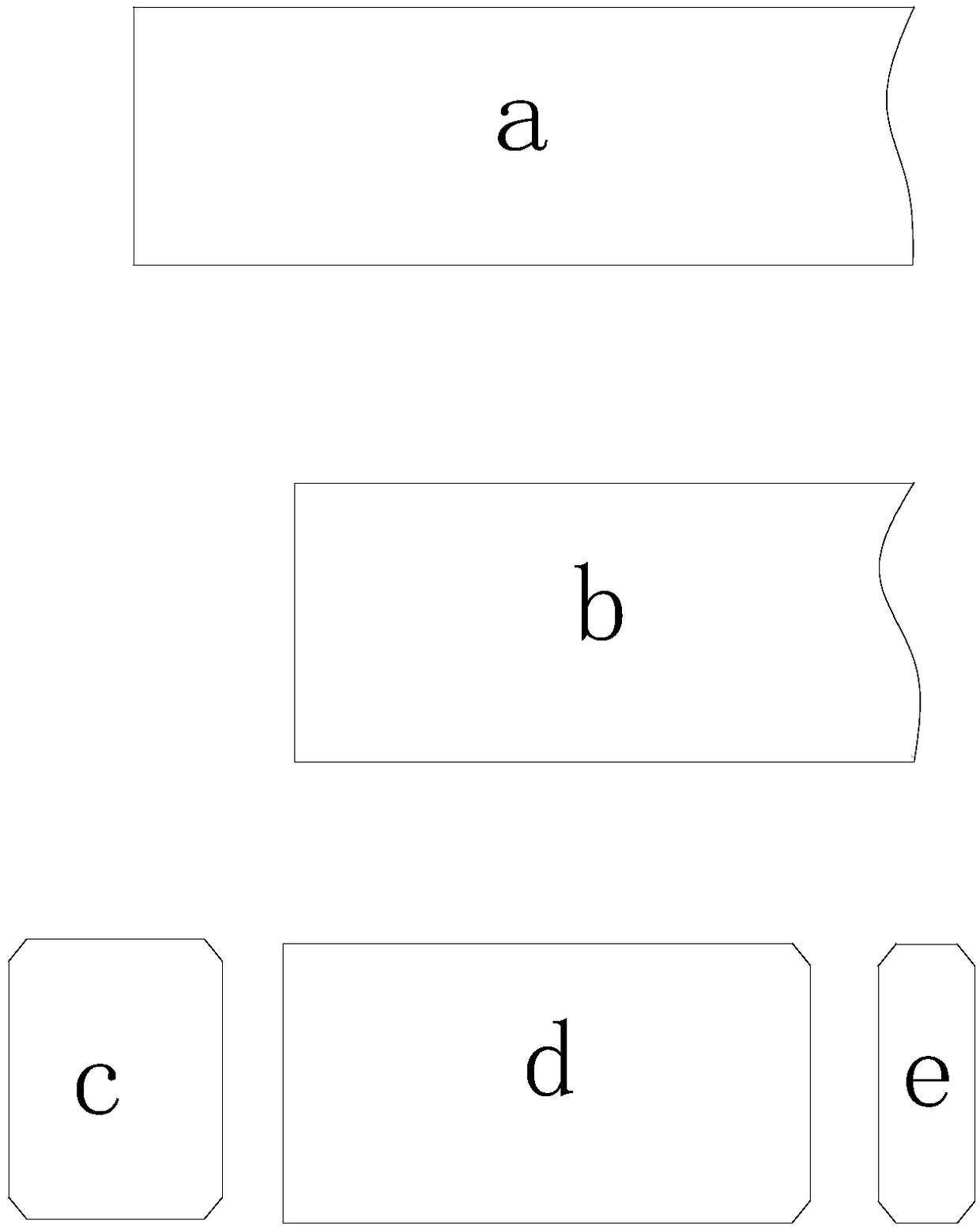

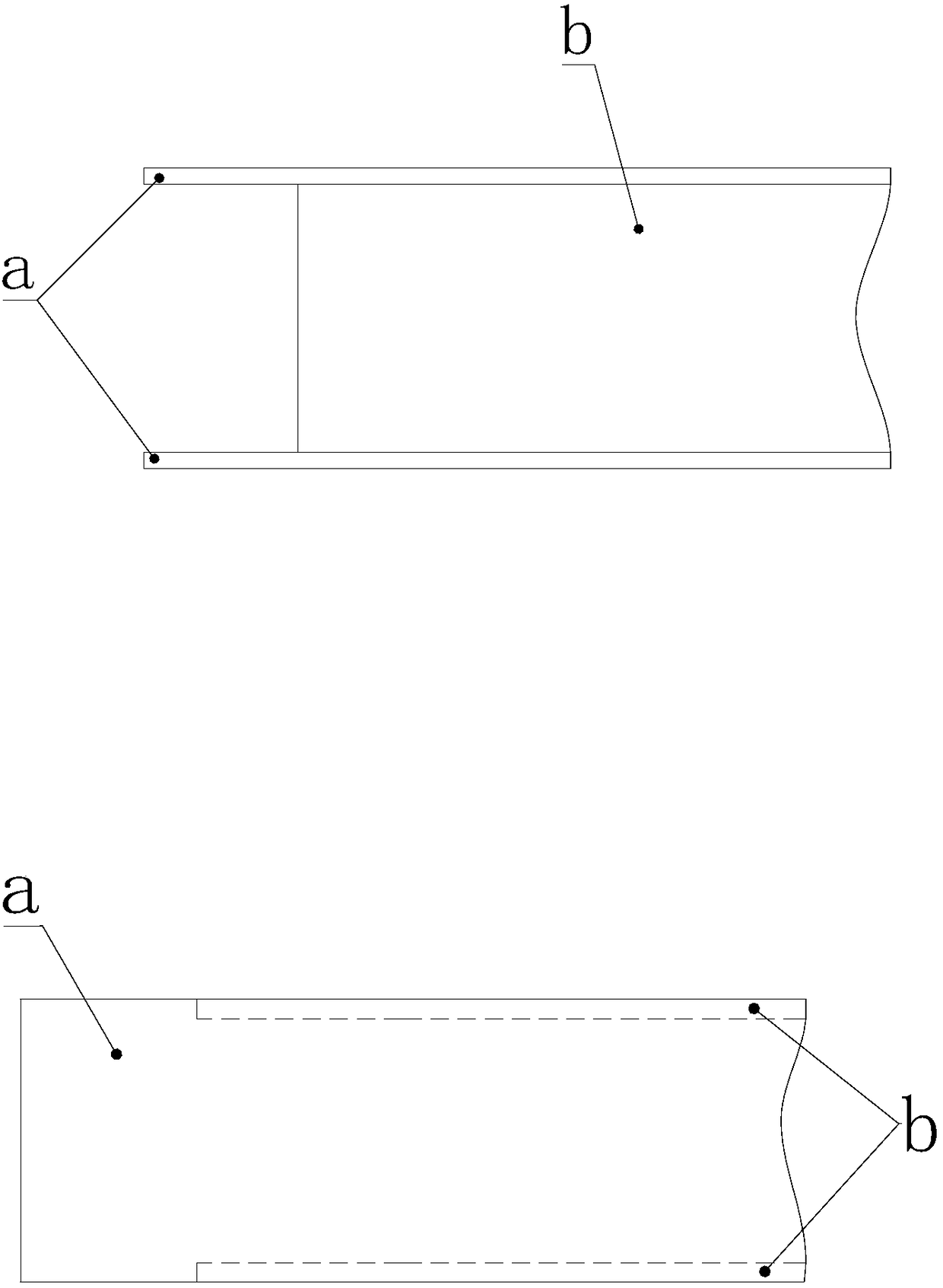

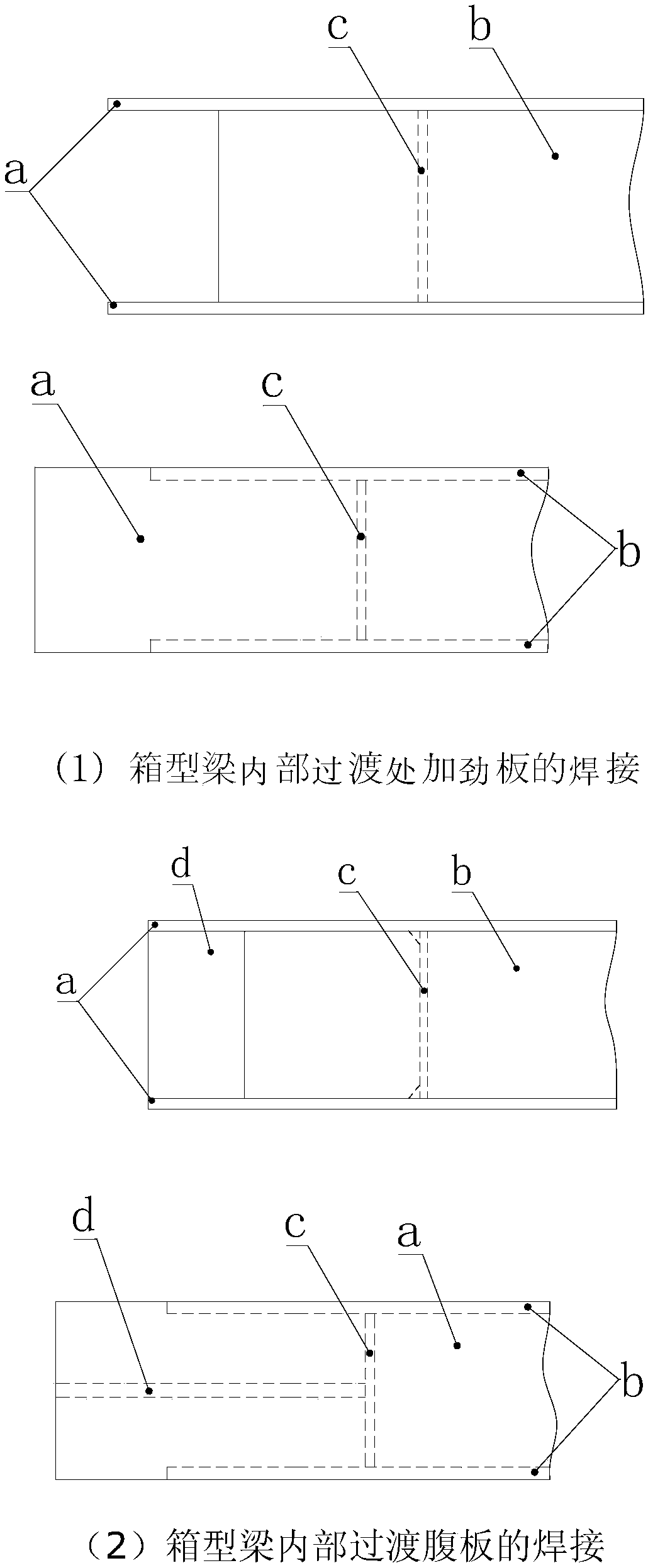

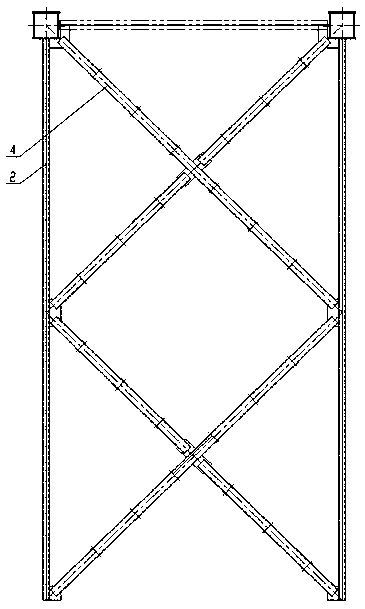

Box type beam and column connecting assembly type node preparation technology and node thereof

PendingCN108457374AEasy to operate and installReduce welding workloadBuilding constructionsButt jointFlange

The invention relates to a box type beam and column connecting assembly type node preparation technology and a node thereof. The node comprises a box type beam, a vertical column and a bracket, the end of the box type beam forms an H-type end through transition, the H-type end comprises an end upper flange, an end lower flange and an end web plate; the vertical column is connected with the bracketthrough welding, and the bracket is an H-type bracket which comprises a bracket upper flange, a bracket lower flange and a bracket web plate; the H-type end is in butt joint with the flanges and theweb plate of the H-type bracket, connecting plates are arranged on the two sides of the flanges and the web plate and firmly connected through bolts, and then the box type beam and column connecting assembly type node is formed. Accordingly, the manufacturing cost is greatly lowered, on-site construction is more convenient, the labor intensity is lowered, box type beam node complete assembly connection is achieved, the box type beam and column connecting mounting speed is increased, and the project construction period is shortened.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

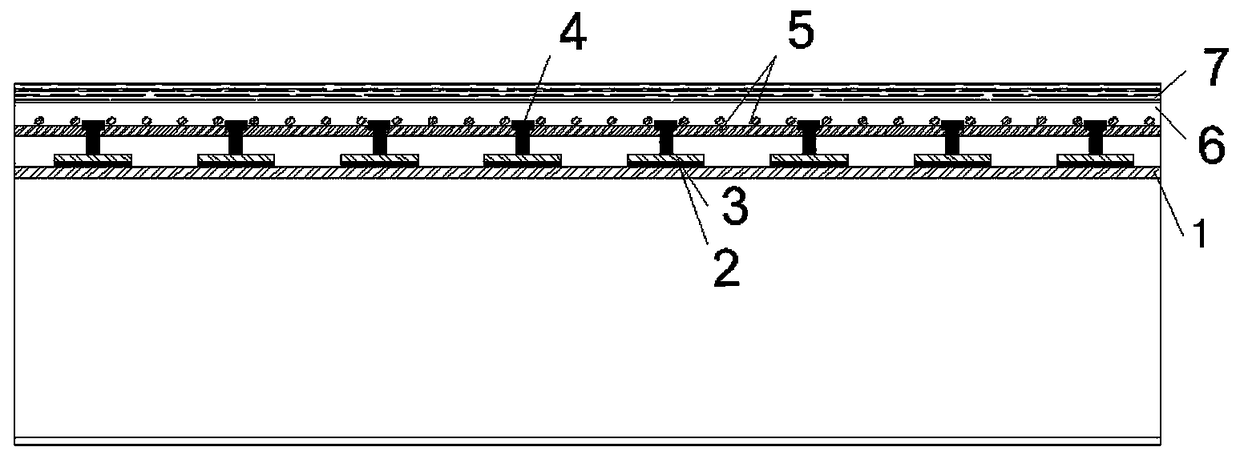

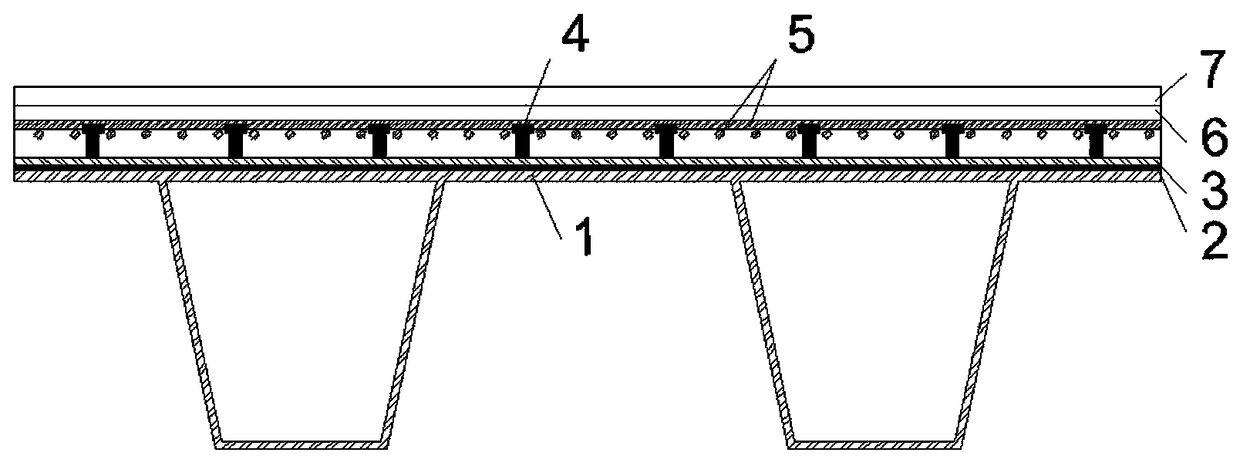

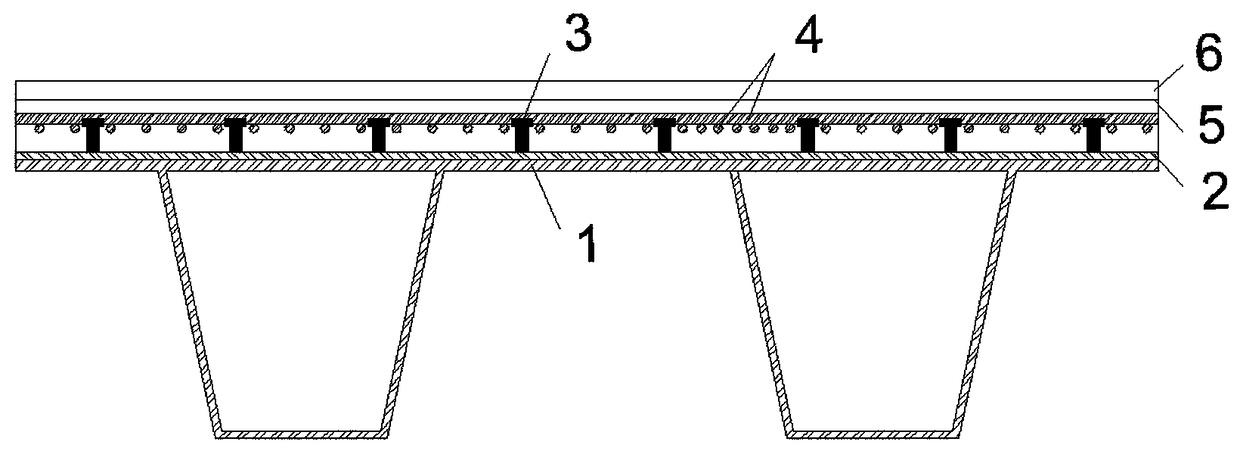

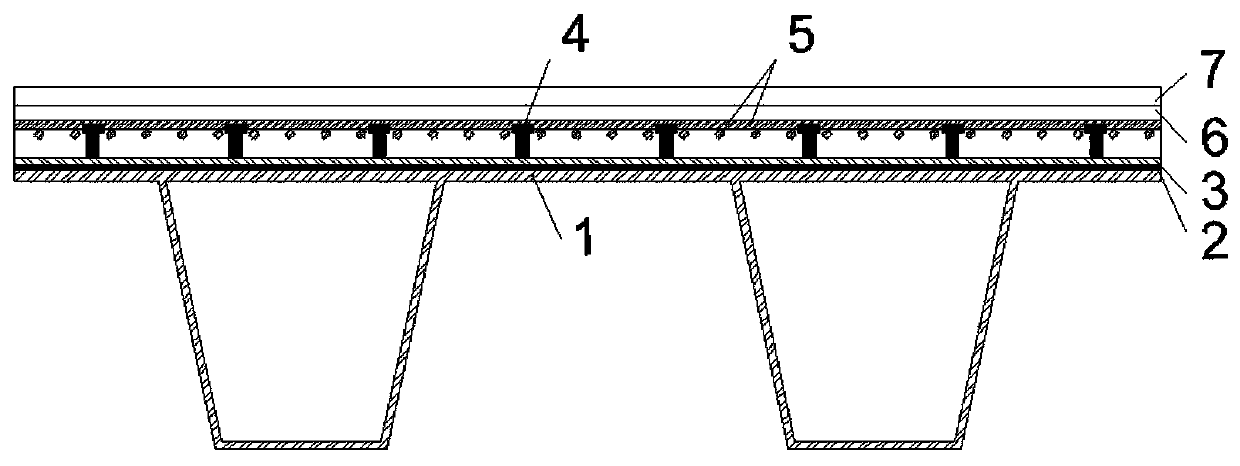

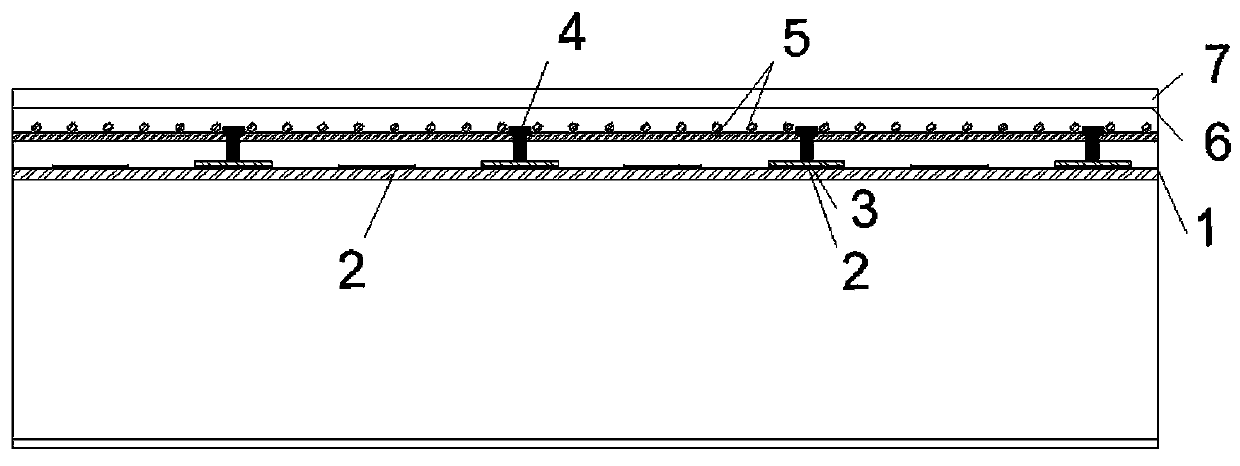

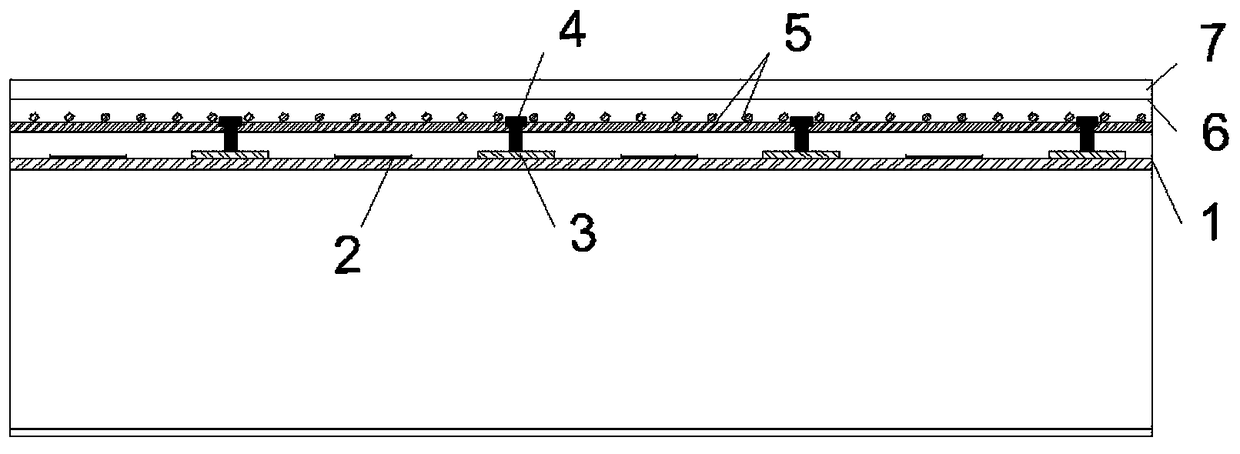

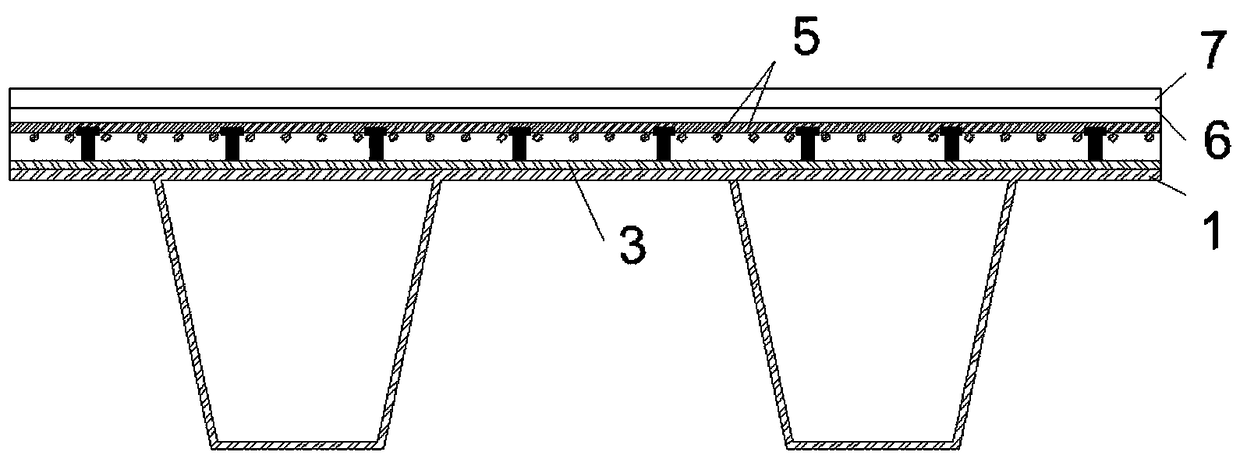

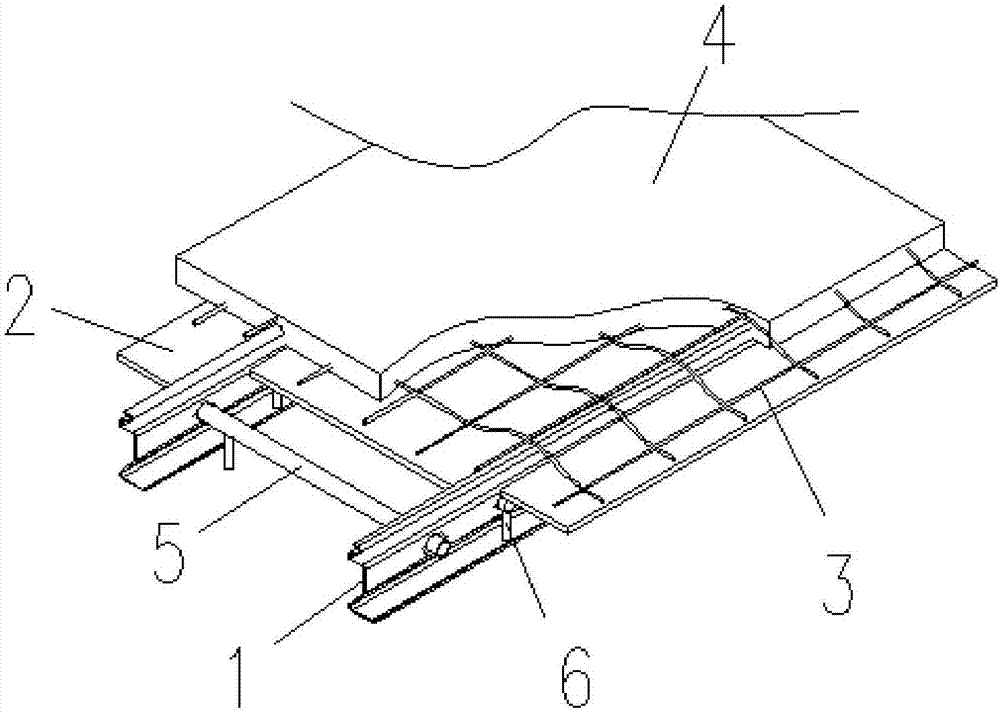

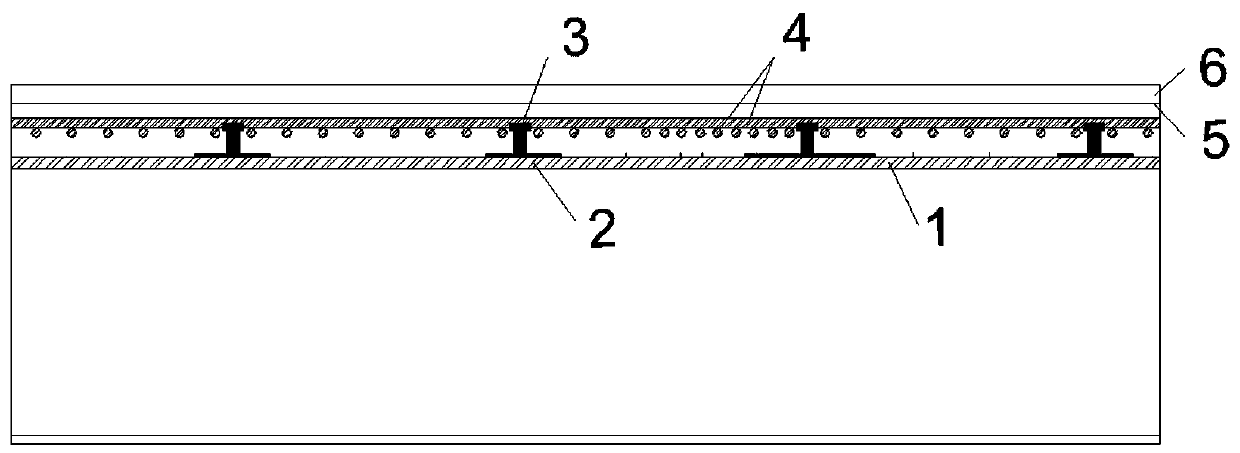

Reinforcing structure for fatigue cracked steel bridge panel

InactiveCN109338905AReduce transverse tensile stressAvoid crackingBridge structural detailsBridge erection/assemblyFiberCarbon fibers

The invention relate to a reinforcing structure for a fatigue cracked steel bridge panel. According to the technical scheme, the reinforcing structure for the fatigue cracked steel bridge panel comprises the cracked steel bridge panel, carbon fiber reinforcing battens, metal reinforcing battens, shear connecting parts, steel fabrics, an ultra-high performance concrete layer and a wearing layer, wherein the carbon fiber reinforcing battens are bonded to the cracked steel panel through organic structural adhesives; the shear connecting parts are welded to the metal reinforcing battens; and the metal reinforcing battens with the shear connecting parts are bonded above the carbon fiber reinforcing battens through organic structural adhesives, the steel fabrics are placed on the cracked steel bridge panel, the steel fabrics are composed of longitudinal steel bars and transverse steel bars, the longitudinal steel bars and the transverse steel bars are crisscrossed, the ultra-high performanceconcrete layer is arranged on the cracked steel bridge panel in a pouring mode, the carbon fiber reinforcing battens, the metal reinforcing battens, the shear connecting parts and the steel fabrics are covered with the ultra-high performance concrete layer, the ultra-high performance concrete layer is connected with the cracked steel bridge panel, and the ultra-high performance concrete layer iscovered with the wearing layer.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

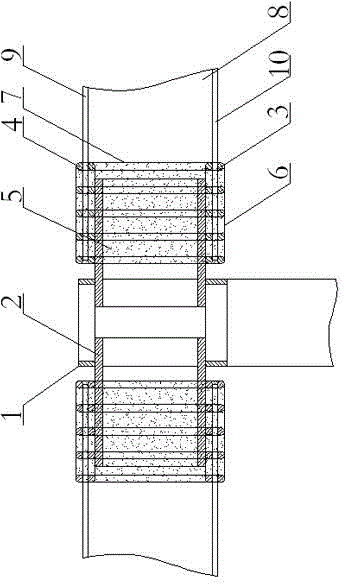

Pumped storage power station inclined shaft construction variable-angle expanding excavation trolley

The invention discloses a pumped storage power station inclined shaft construction variable-angle expanding excavation trolley which comprises a trolley bottom plate (2) parallel to an inclined shaft rail (1). The side, corresponding to the inclined shaft rail (1), of the trolley bottom plate (2) is connected with trolley wheels (3), and the other side of the trolley bottom plate (2) is connected with a horizontal main platform (6). A roll shaft (7) rotationally connected with one end of the main platform (6) is arranged at the top of the trolley bottom plate (2), the other end of the main platform (6) is connected with inclined trolley columns (8), and the lower portion of the middle of the main platform (6) is connected with vertical trolley columns (9). The middles of the inclined trolley columns (8) and the middles of the vertical trolley columns (9) are connected with jacks (10). The pumped storage power station inclined shaft construction variable-angle expanding excavation trolley has the advantages of being convenient to demount and mount and wide in application range, the expanding excavation construction cost of a power station can be reduced, the field welding workload is reduced, and the structural stability and safety are improved.

Owner:STATE GRID CORP OF CHINA +2

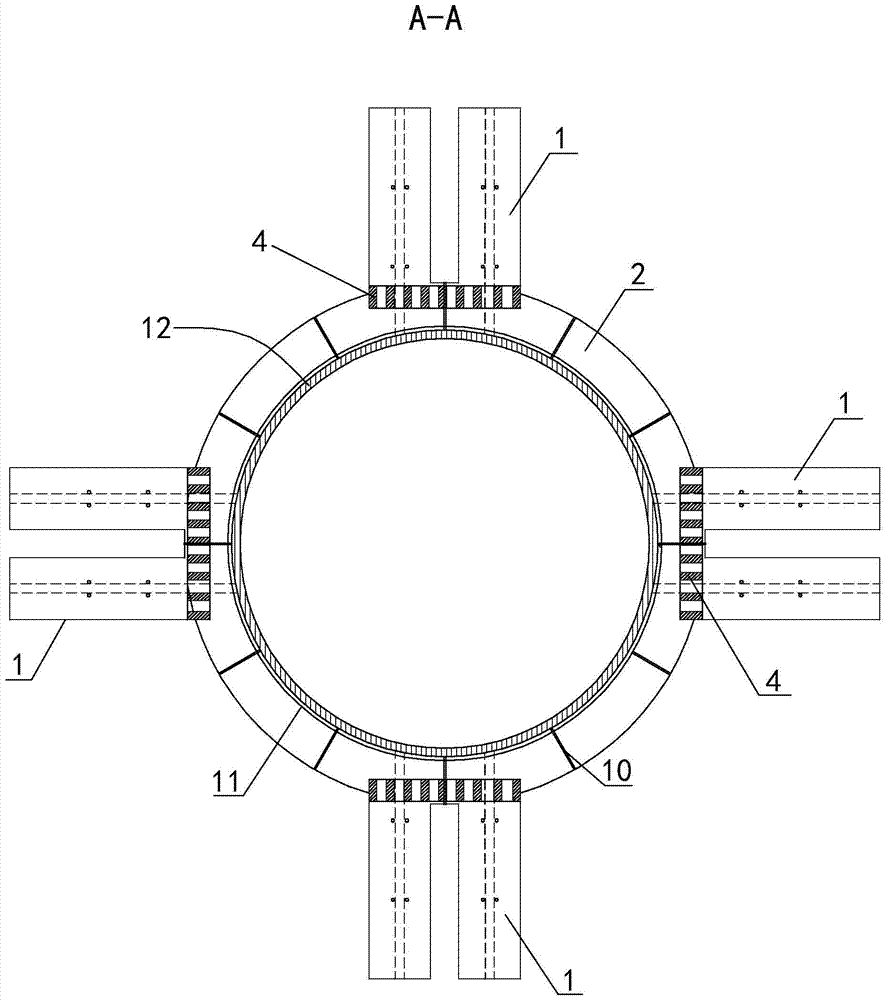

Multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and ring beam

The invention relates to a multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and a ring beam. The multidirectional through concrete filled steel tubular column beam joint comprises a plurality of steel corbels and the ring beam, wherein the steel corbels are radially connected to a steel tubular column; inner ends of the plurality of the steel corbels penetrate through the steel tubular column and are mutually welded and connected in the steel tubular column, and outer ends of the plurality of the steel corbels penetrate through the ring beam; the ring beam comprises a ring beam framework and inner concrete ring beam cores arranged in the ring beam framework; the ring beam framework comprises two layers of ring beam bottom ribs, two layers of ring beam top ribs and ring beam stirrups; a plurality of reinforcing steel bar rings of each layer of ring beam bottom ribs and each layer of ring beam top ribs are concentric, and are located on the same plane and bound by a plurality of stirrups; and the two layers of ring beam bottom ribs and the two layers of ring beam top ribs are bound by a plurality of the ring beam stirrups. The joint has the advantages that the joint is simple in structure, free of dense reinforcing steel bars and feeble fragile stress positions and stable in load transmitting, can safely and stably bear a frame beam, and is convenient to construct, short in period, low in cost and applicable to construction of high-rise and super high-rise buildings having multidirectional through concrete filled steel tubular column beam joints comprising steel corbels and ring beams.

Owner:TAIXING FIRST CONSTR INSTALLATION

Combined reinforcement structure for solving cracked steel bridge deck by additionally arranging fiber-reinforced layer

InactiveCN109338903AMake up for the lack of fatigue crackingFit tightlyBridge structural detailsBridge erection/assemblyBridge deckFiber-reinforced composite

The invention relates to a combined reinforcement structure for solving a cracked steel bridge deck by additionally arranging a fiber-reinforced layer. The combined reinforcement structure for solvingthe cracked steel bridge deck by additionally arranging the fiber-reinforced layer is characterized in that the combined reinforcement structure for solving the cracked steel bridge deck by additionally arranging the fiber-reinforced layer comprises the fatigue cracked steel bridge deck, a fiber-reinforced composite material layer, shear connecting parts, steel fabrics and a concrete layer, wherein the shear connecting parts are arranged on the fiber-reinforced composite material layer, the fiber-reinforced composite material layer is laid to a cracked part of the fatigue cracked steel bridgedeck, the steel fabrics are placed on the fatigue cracked steel bridge deck, the concrete layer is arranged on the fatigue cracked steel bridge deck in a pouring mode, the shear connecting parts andthe steel fabrics are covered with the concrete layer, and the concrete layer is connected with the fatigue cracked steel bridge deck.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Strengthening structure for fatigue cracked steel bridge deck

PendingCN110499717AReduce transverse tensile stressAvoid crackingBridge structural detailsBridge erection/assemblyFiberCarbon fibers

The invention discloses a strengthening structure for a fatigue cracked steel bridge deck. According to the technical scheme, the strengthening structure is characterized by comprising the cracked steel bridge deck, carbon fiber reinforced battens, metal reinforced battens, shear connecting pieces, reinforcing meshes, an ultrahigh-performance concrete layer and a wearing layer. The carbon fiber reinforced battens are arranged on the cracked steel bridge deck; the shear force connecting pieces are welded to the metal reinforced battens; the metal reinforced battens with the shear force connecting pieces are arranged above the carbon fiber reinforced battens; the reinforcement meshes are placed on the cracked steel deck; the ultrahigh-performance concrete layer is poured on the cracked steelbridge deck; the carbon fiber reinforced battens, the metal reinforced battens, the shear force connecting pieces and the reinforcing meshes are arranged in a covering manner to be connected with thecracked steel bridge deck; and the wearing layer is arranged on the top face of the ultrahigh-performance concrete layer in a covering manner.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Reinforcing structure for cracked steel bridge panel

InactiveCN109338904AImprove fatigue lifeIncreased durabilityBridge structural detailsBridge erection/assemblyAdhesiveSurface plate

The invention relate to a reinforcing structure for a cracked steel bridge panel. According to the technical scheme, the reinforcing structure for the cracked steel bridge panel comprises the crackedsteel bridge panel, carbon fiber reinforcing battens, metal reinforcing battens, shear connecting parts, steel fabrics, an ultra-high performance concrete layer and a wearing layer, wherein the carbonfiber reinforcing battens are bonded to the cracked steel panel through organic structural adhesives; the shear connecting parts are welded to the metal reinforcing battens; the metal reinforcing battens with the shear connecting parts are directly welded or cemented on the cracked steel bridge panel, and alternately arranged with the carbon fiber reinforcing battens in parallel; and the steel fabrics are placed on the cracked steel bridge panel, the steel fabrics are composed of longitudinal steel bars and transverse steel bars, the longitudinal steel bars and the transverse steel bars are crisscrossed, the ultra-high performance concrete layer is arranged on the cracked steel bridge panel in a pouring mode, the carbon fiber reinforcing battens, the metal reinforcing battens, the shear connecting parts and the steel fabrics are covered with the ultra-high performance concrete layer, the ultra-high performance concrete layer is connected with the cracked steel bridge panel, and the ultra-high performance concrete layer is covered with the wearing layer.

Owner:湖南中路华程桥梁科技股份有限公司

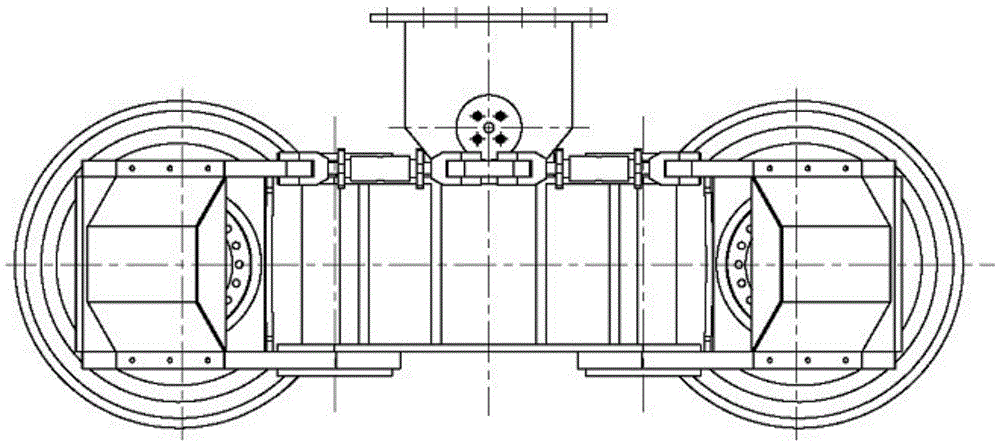

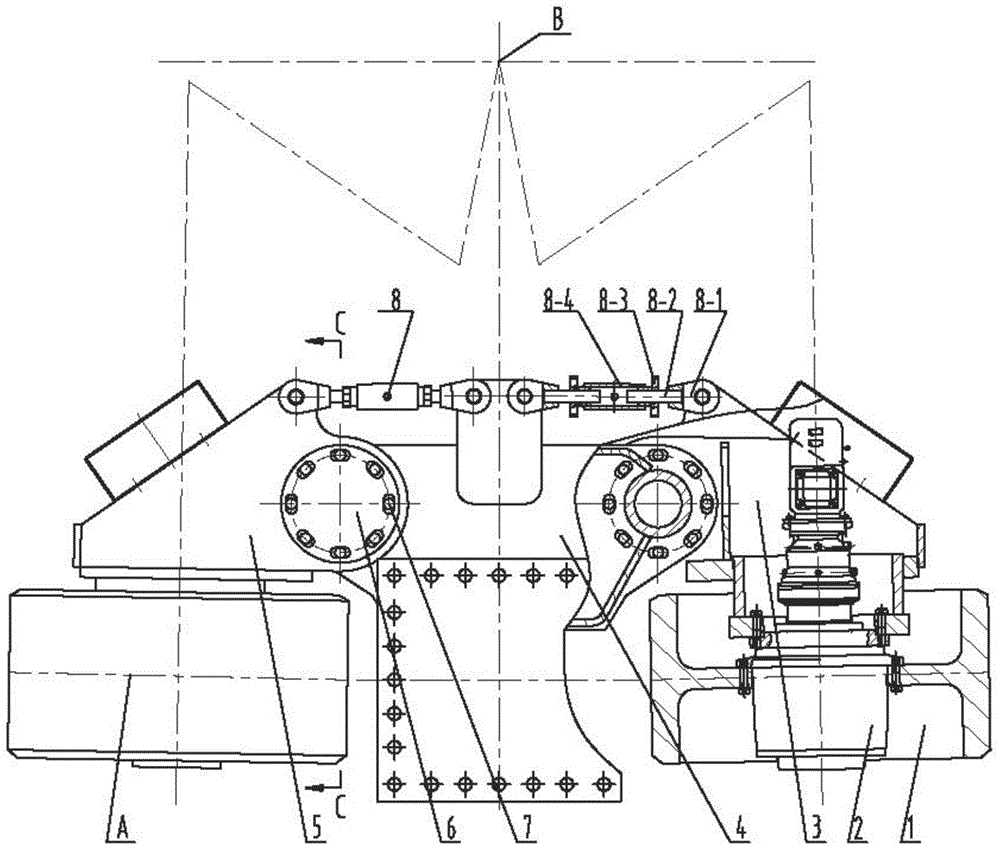

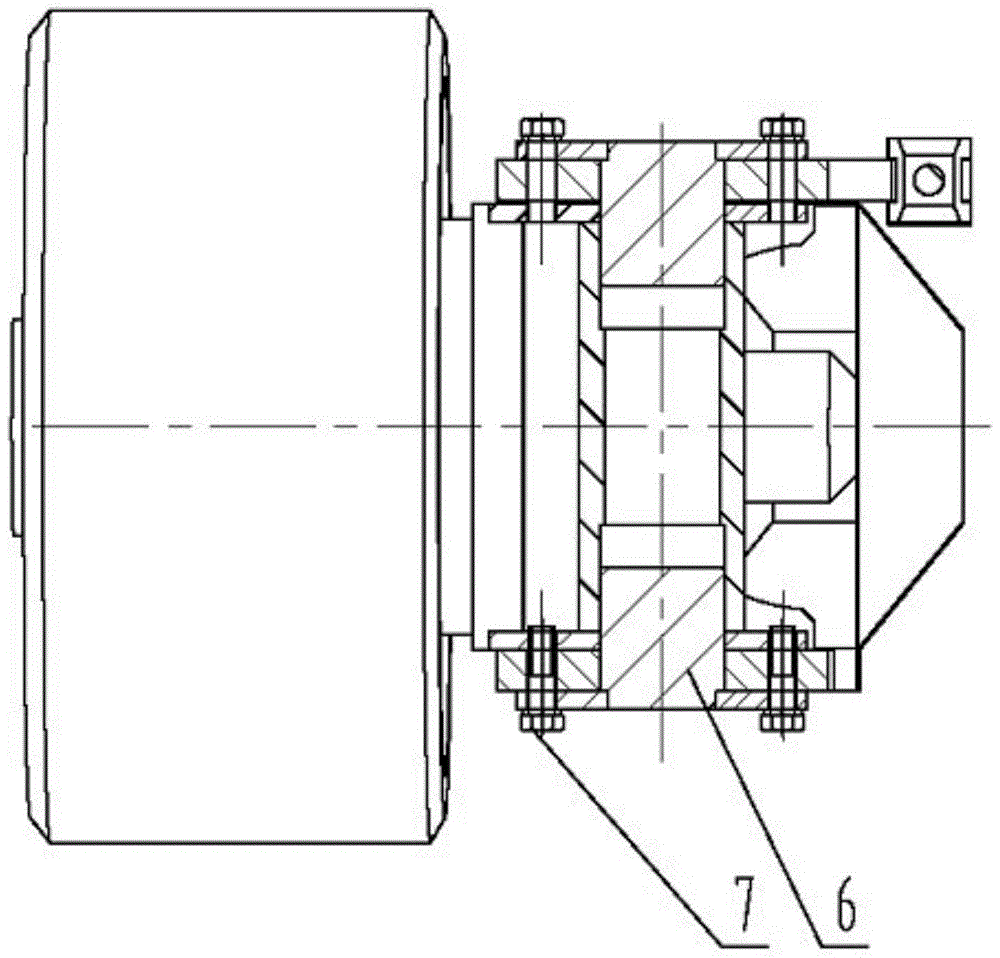

A Device for Adjusting the Axial Angle of an End Beam Traveling Wheel

The invention discloses an axial angle adjusting device of an end beam walking wheel, which is applied to circular storage homogenization stockyards in such fields as papermaking, water conservancy, metallurgy, electric power, port docks, coals, building materials and chemical engineering. The device comprises wheels, driving units, a left wheel frame, a bogie frame, a right wheel frame, pin shafts, connecting bolts and an adjusting device combination, wherein the bogie frame is connected with the left wheel frame and the right wheel frame by hinge shafts; the bogie frame is connected with the left wheel frame and the right wheel frame through the pin shafts in the hinged points by the connecting bolts; the wheels are mounted on the driving units, and are connected with the left wheel frame and the right wheel frame; the two sets of wheels and the two sets of driving units are respectively connected with the left wheel frame and the right wheel frame; and one side of the adjusting device combination is connected with the left wheel frame and the right wheel frame. The device is convenient to operate, so that the scene installation and debugging period is largely shortened; an end beam body is wholly welded in a factory, so that the strength is enhanced, and the scene welding workload is reduced; and the structural part quality is controlled.

Owner:NORTHERN HEAVY IND GRP CO LTD

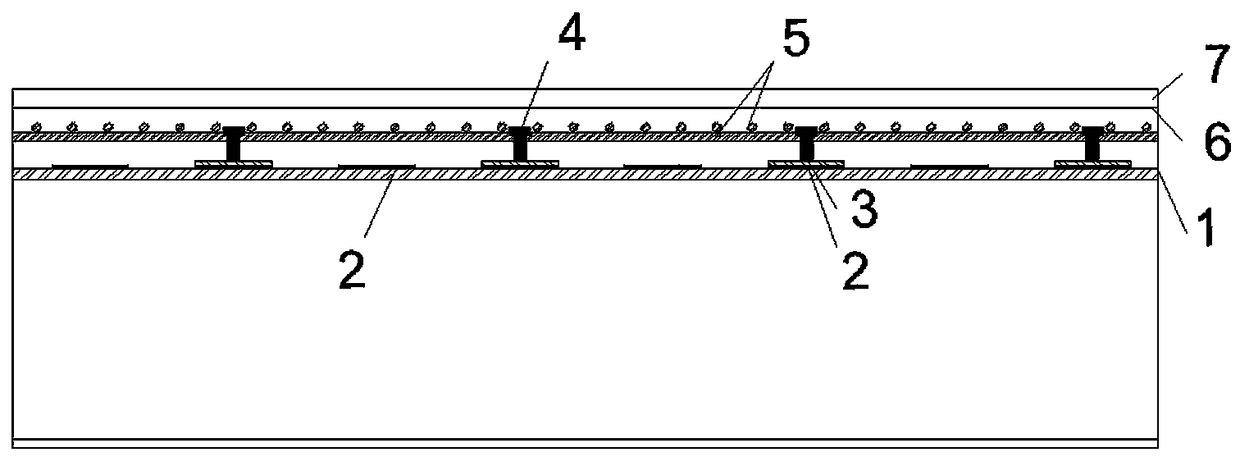

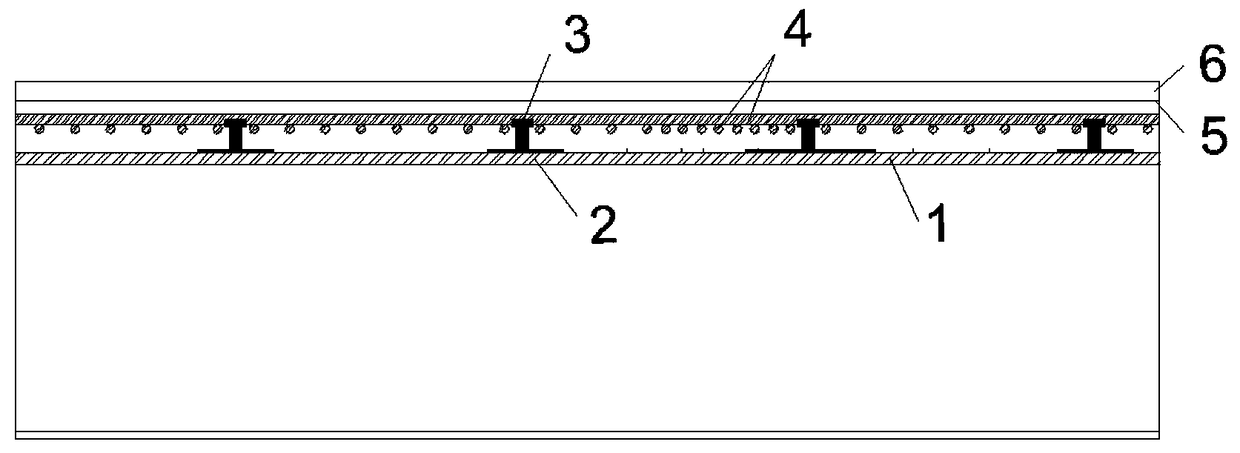

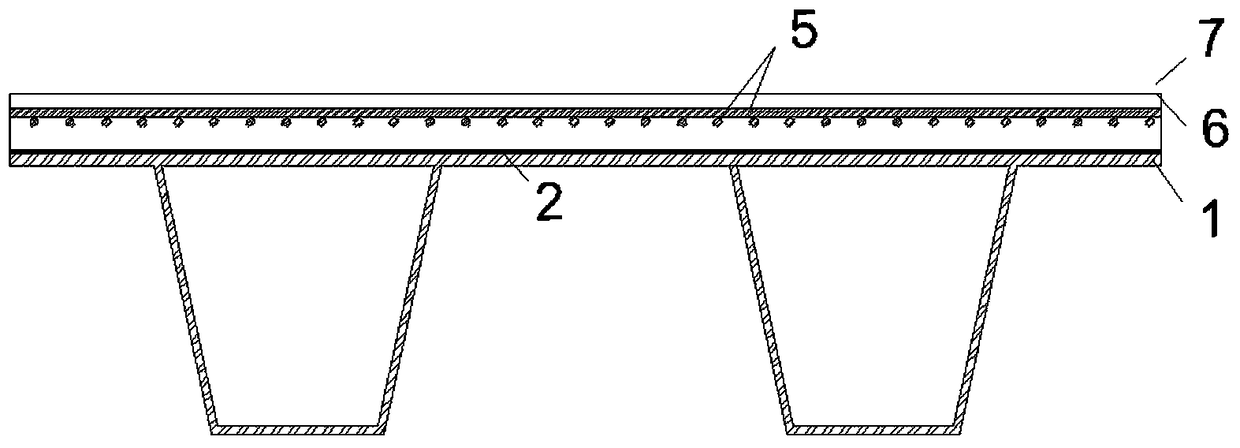

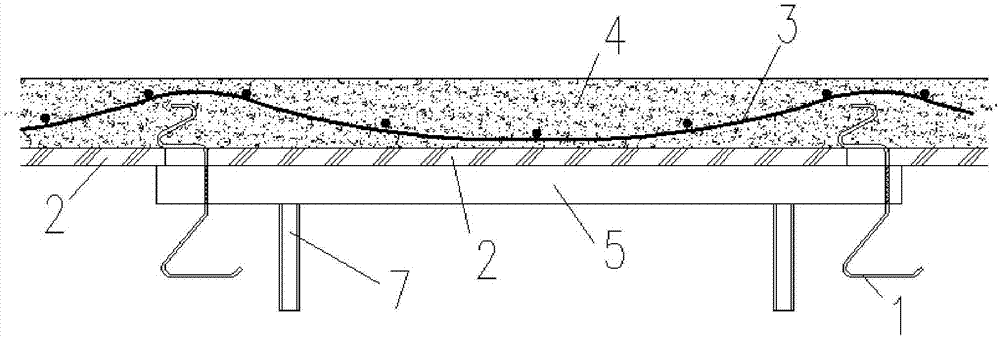

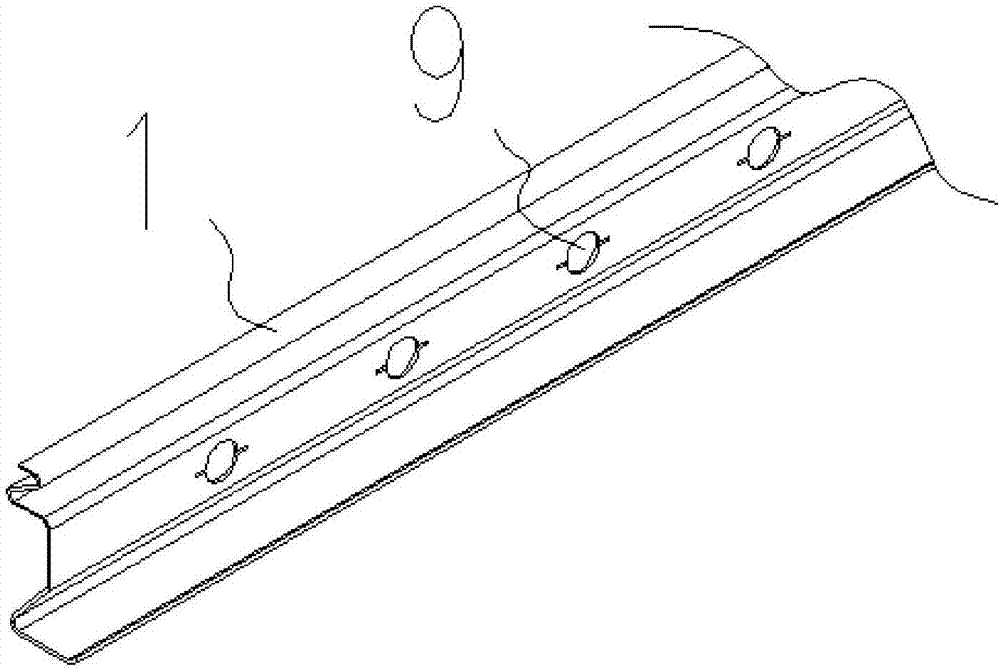

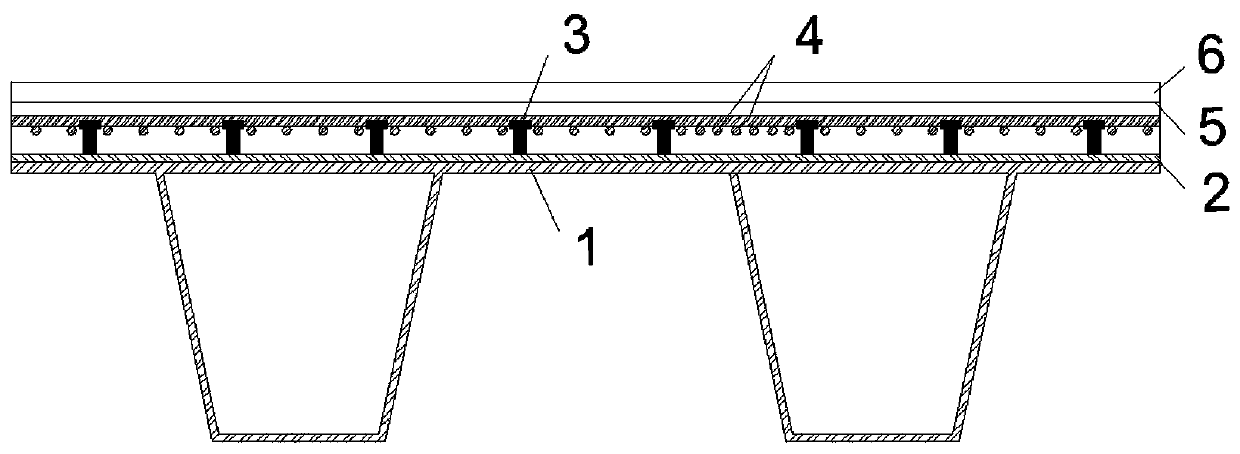

Floor system formed by cold bending type steel combination beam

ActiveCN106894556ALarge operating spaceLow steel contentFloorsSustainable buildingsMesh reinforcementRebar

The invention provides a floor system formed by cold bending type steel combination beam, comprising cold bending type profile steels, a floor template and a floor concrete layer; two cold bending type profile steels are arranged in parallel, and the inside between the cold bending type profile steels is provided with a long holding rod, and the outside is provided with a short holding rod, thus a group of cold bending type profile steels is formed; the upsides of the cold bending type profile steels are crossed trough the floor template and fixed with the floor concrete layer on the floor template; a floor reinforcement mesh piece is arranged in the floor concrete layer and the floor concrete layer is located above a group of cold bending type profile steels; the cross section of each cold bending type profile steel is multi-curve structure, and the cold bending type profile steels are provided with multiple groups of connecting holes along the length direction; the long holding rod crosses through the connecting holes and is arranged at both ends of a group of cold bending type profile steels, and the short holding rod is arranged on the connecting holes at the inner parts of the cold bending type profile steels. The floor system adopts the cold bending type profile steels and combines with the long and short holding rods and the floor reinforcement mesh pieces; the steel content of the floor is greatly reduced; the component processing is simple, the site construction speed is fast, a lot of construction times are saved, and the cost is reduced.

Owner:SHANGHAI OPEN STEEL JOIST

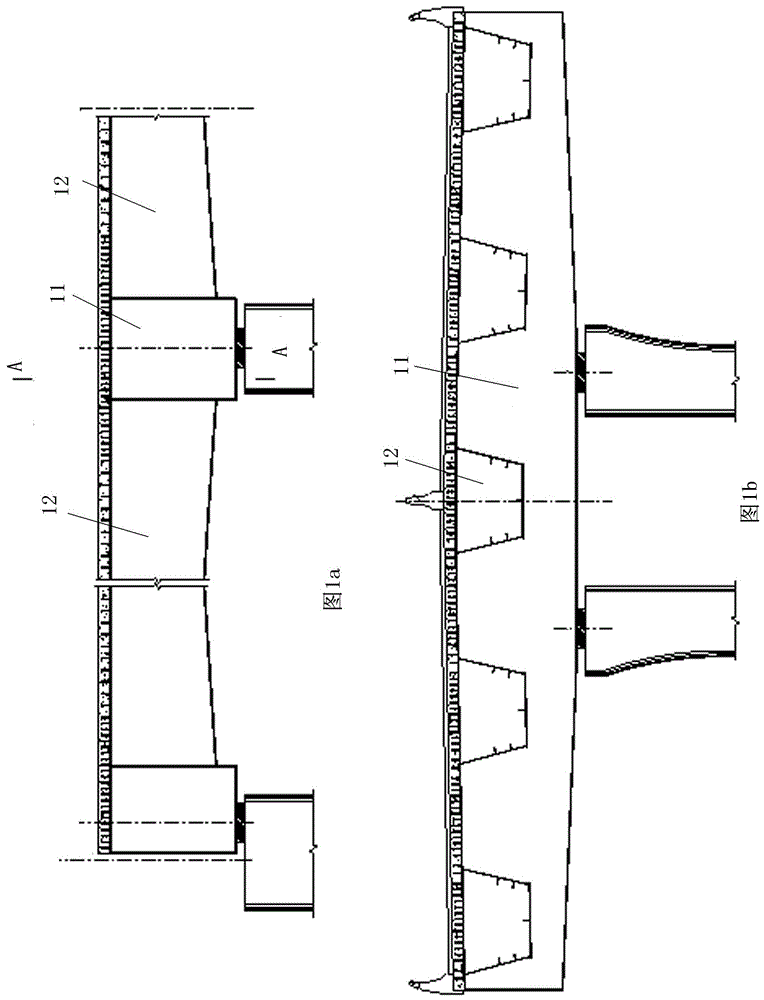

A multi-piece composite girder bridge upper and lower integral structure and its construction method

The invention discloses an upper and lower integral structure of a multi-piece type combined beam bridge and a construction method thereof. The upper and lower integral structure mainly comprises a beam, a span main beam and a connection structure which is arranged between the beam and the span main beam. The upper and lower integral structure is characterized in that the span main beam is a multi-piece type steel and concrete combined steel plate beam or a multi-piece type steel and concrete combined steel box beam; the beam is formed by concrete materials; the steel structure portion of the span main beam is connected with the beam through the connection structure; the concrete portion of the span main beam and the beam are directly connected together. According to the upper and lower integral structure of the multi-piece type combined beam bridge and the construction method thereof, the beam is changed into the concrete beam from the conventional steel structure beam and accordingly the cost is reduced; the site welding work is reduced, the construction method is conventional, simple and convenient, the construction difficulty is reduced, and the construction quality is easy to control; the beam and the span main beam are located in the same elevation plane to form the integral structure and accordingly the occupied clearance under the bridge is not too much, the structural height is small, and the bridge landscape is good; the maintenance work in the later period is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

An inner diaphragm type concrete filled steel pipe transfer node structure and its construction method

ActiveCN105239668BReduce section sizeEfficient use ofBuilding constructionsQuality assurancePlate column

The invention discloses an inner diaphragm type concrete-filled steel pipe transfer node structure and a construction method thereof, wherein an inner diaphragm type steel pipe concrete transfer node structure includes a pillar, a slanted column and a socket for connecting the slanted column to the pillar There is a section on the inclined column, and the section includes a cross section. The receiving frame is fixedly arranged inside the pillar and is located at the top of the pillar. The receiving frame includes a lower inner partition and a vertical inner rib, and the vertical inner rib is fixed on the On the lower inner partition, the shape of the vertical inner rib corresponds to the cross-sectional shape of the oblique column, and the oblique column is fixed to the vertical inner rib through the section. The invention combines the advantages of the steel pipe concrete and inclined column conversion structure, and has the advantages of direct force transmission, high bearing capacity, small component cross-sectional size, favorable use of building space, no need for formwork, less on-site welding workload, and guaranteed construction quality, etc. advantage. The two slanted columns and the beam system constitute a triangular force transmission mode, and have good resistance to lateral forces.

Owner:SOUTH CHINA UNIV OF TECH

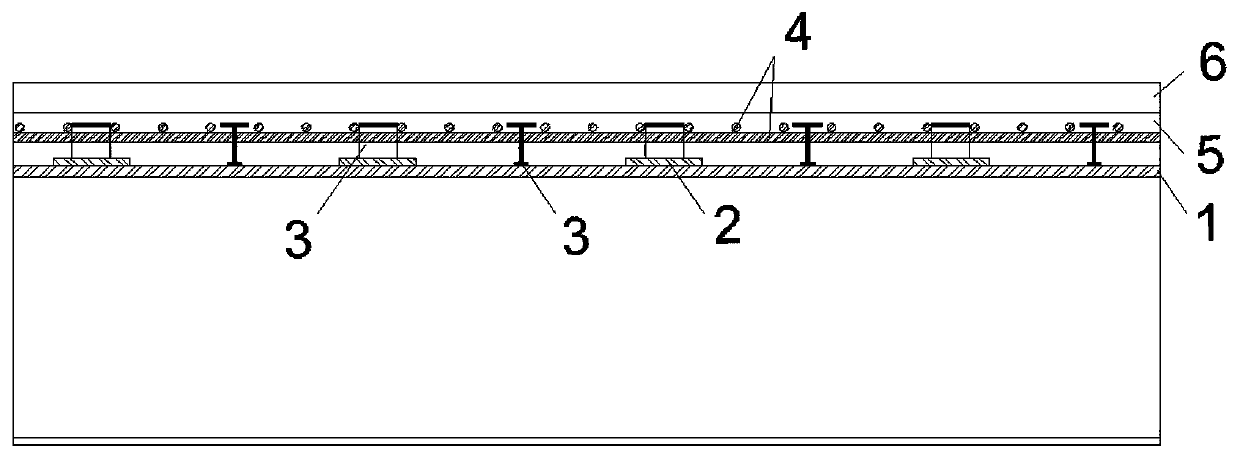

Outer hanging connecting structure of ALC batten

PendingCN114753526AReduce on-site welding workloadReduced risk of weld quality defectsWallsClassical mechanicsBatten

The invention relates to the technical field of ALC board installation, and particularly discloses an ALC batten external hanging connection structure which comprises an external hanging structure I installed on the outer side of a current-layer structural beam and used for fixing the bottom of an ALC batten, and an external hanging structure II installed on the outer side of an upper-layer structural beam and used for fixing the upper portion of the ALC batten. The first external hanging structure comprises a pre-embedded steel plate installed on the outer side of a structural beam of the layer, a supporting bracket connected with the outer side of the pre-embedded steel plate and two sets of supporting angle steel installed on the supporting bracket and transversely arranged. The two groups of supporting angle steel supports form a mounting groove for mounting the ALC batten; according to the connecting joint, the force transmission path is clear, the welding workload is effectively reduced, the construction speed is higher, and the quality is easier to control.

Owner:CHINA MCC5 GROUP CORP

Combined strengthening structure for repairing cracked steel bridge deck by additionally arranging fiber reinforced layer

PendingCN110499716AIncrease stiffnessExtended service lifeBridge structural detailsBridge erection/assemblyBridge deckFiber-reinforced composite

The invention discloses a combined strengthening structure for repairing a cracked steel bridge deck by additionally arranging a fiber reinforced layer. The combined strengthening structure is characterized by comprising the fatigue cracked steel bridge deck, the fiber reinforced composite material layer, shear force connecting pieces, reinforcing meshes and a concrete layer; the shear force connecting pieces are arranged on the fiber reinforced composite material layer; the fiber reinforced composite material layer is laid on the cracked part of the fatigue cracked steel bridge deck; the reinforcing meshes are placed on the fatigue cracked steel bridge deck; the concrete layer is poured on the fatigue cracked steel bridge deck; and the shear force connecting pieces and the reinforcing meshes are arranged in a covering manner and are connected with the fatigue cracked steel bridge deck.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

Large-span suspended soot blowing platform

PendingCN108980869AMeet layout requirementsSimple supporting structureSolid removalMarine engineeringSoot

The invention belongs to the technical field of boiler component structures, and particularly relates to a large-span suspended soot blowing platform structure which comprises a platform, two supporting frames, a hanging frame and a truss, wherein the lower part of the platform is supported by the supporting frames, and the truss is arranged between the supporting frames; one end of each supporting frame is fixed onto one corresponding vertical column, and the suspended end of the supporting frame is connected with the vertical column through the hanging frame, so that an upper-hanging and lower-bracket structure can be formed; the platform is composed of a plurality of platform frameworks, a horizontal support and a grid; the horizontal support is arranged on the side, close to a beam andthe vertical columns, of the platform; the platform frameworks are arranged side by side on the outer side of the platform; and the grid is laid above the platform frameworks and the horizontal support. According to the large-span suspended soot blowing platform structure provided by the invention, the brand-new supporting-hanging mode is adopted, no outer columns need to be arranged, the platform supporting structure is simplified, the large-span soot blowing platform layout demand is met, and the steel consumption and the civil engineering cost are reduced.

Owner:温州伟明环保能源有限公司

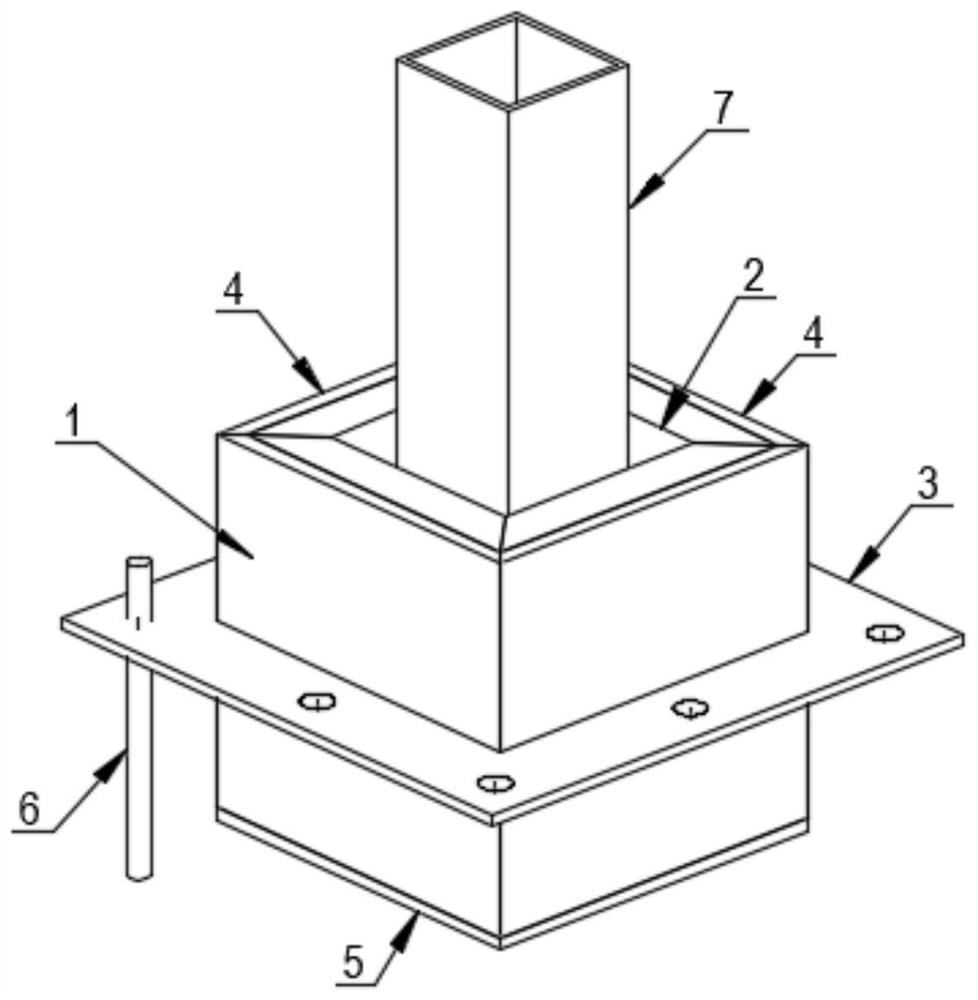

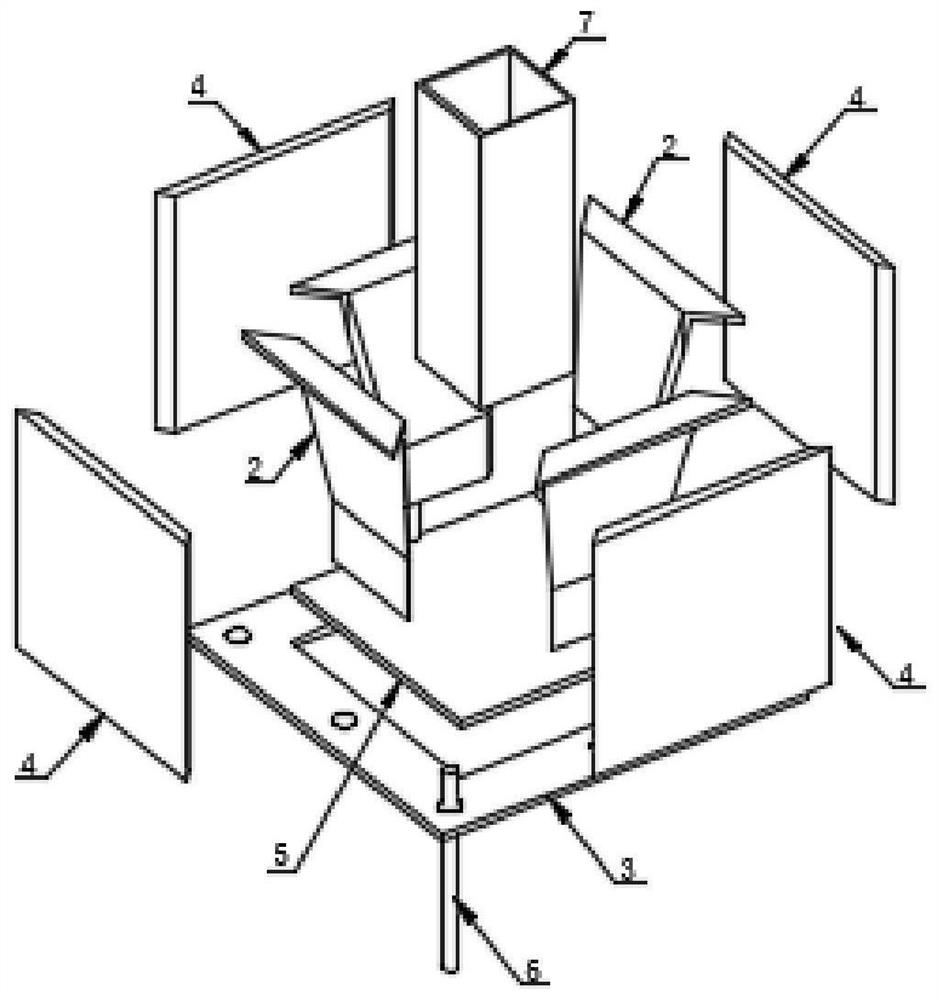

Beam-to-column connections for square steel tube columns

InactiveCN101775840BSimplify on-site construction processImprove node ductilityBuilding constructionsEngineeringCantilever

The invention discloses a beam-column joint suitable for a square steel pipe column, comprising: a lower square steel pipe column and an upper square steel pipe column, a dog-bone short I-steel cantilever is arranged on the lower square steel pipe column, The end is connected with a lower flange, and the end of the upper square steel pipe column is connected with an upper flange that can match the lower flange. The inner section of the rib, and the upper square steel pipe column is sleeved on the inner section, and the lower flange and the upper flange are fastened and connected by bolts. The invention effectively realizes the outward shift of the plastic angle of the node domain, improves the secondary seismic performance of the node domain, and simplifies the construction technology of the beam-column connection of the steel frame.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST CO LTD +1

Construction method of multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and ring beam

The invention relates to a construction method of a multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and a ring beam. The joint comprises a plurality of steel corbels and the ring beam, wherein the steel corbels are radially connected to a steel tubular column; inner ends of the steel corbels penetrate through the steel tubular column and are mutually welded and connected in the steel tubular column, and outer ends of the plurality of steel corbels penetrate through the ring beam; the ring beam comprises a ring beam framework and inner concrete ring beam cores arranged in the ring beam framework; the ring beam framework comprises two layers of ring beam bottom ribs, two layers of ring beam top ribs and ring beam stirrups; a plurality of reinforcing steel bar rings of each layer of ring beam bottom ribs and each layer of ring beam top ribs are concentric, and are located on the same plane and bound by a plurality of stirrups; and the two layers of ring beam bottom ribs and the two layers of ring beam top ribs are bound by a plurality of the ring beam stirrups. The joint has the advantages that the joint is simple in structure, free of dense reinforcing steel bars and feeble fragile stress positions and stable in load transmitting, can safely and stably bear a frame beam, and is convenient to construct, short in period, low in cost and applicable to construction of high-rise and super high-rise buildings having multidirectional through concrete filled steel tubular column beam joints comprising steel corbels and ring beams.

Owner:TAIXING FIRST CONSTR INSTALLATION

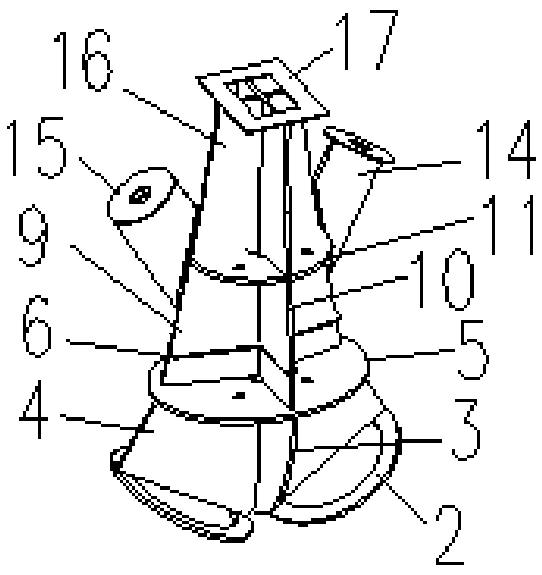

Slot device based on self-similar curtain wall structure system and construction method

ActiveCN114059690AEnhance sensory effectAchieve standardized designWallsMechanical engineeringStructure system

The invention discloses a slot device based on a self-similar curtain wall structure system and a construction method. The slot device comprises side plates, a slot body with an opening in the upper end is defined by the multiple side plates, a bottom plate is fixed to the bottom of the slot body, and a spring plate is arranged in the slot body; the plurality of spring plates are mutually enclosed to form a slot; the problems that in a traditional curtain wall structure column fixing structure and a construction method, precision is difficult to control, construction operation is difficult, and a reserved gap of a curtain wall column inserting core is difficult to control are solved.

Owner:WUHAN CONSTR ENG

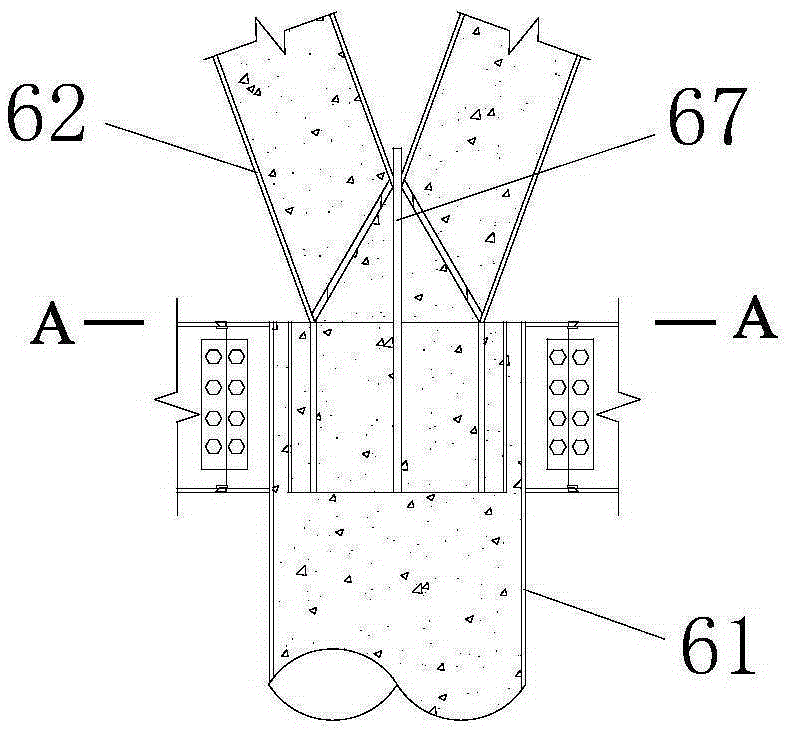

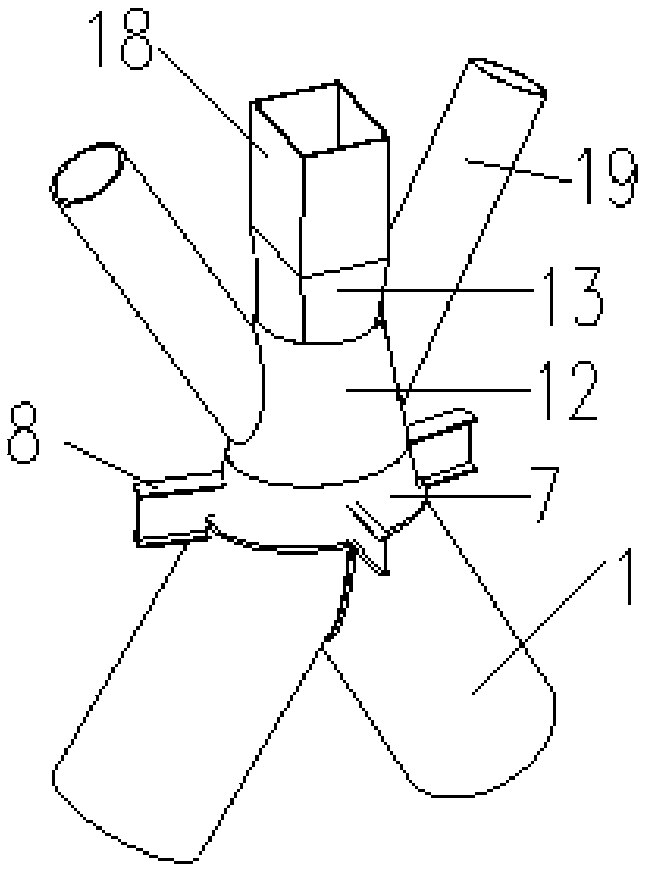

Giant concrete-filled steel tubular inclined column and inclined strut transferring joint structure

PendingCN109322406ADirect forceImprove bearing capacityBuilding constructionsSteel tubeWaste management

The invention provides a giant concrete-filled steel tubular inclined column and inclined strut transferring joint structure. The giant concrete-filled steel tubular inclined column and inclined struttransferring joint structure comprises inclined supporting columns (1), a frame column (18), inclined struts (19), a transferring element and a frame beam (8), the inclined struts (19) are fixedly connected to the transferring element, the frame column is fixedly connected to the transferring element, the transferring component is fixedly arranged at the top ends of the inclined supporting columns, and the frame beam is fixedly connected or hinged to the transferring element. The transferring element comprises an elliptical transferring piece, a great circle-to-small circle transferring pieceand a circle-to-square transferring piece, wherein the elliptical transferring piece, the great circle-to-small circle transferring piece and the circle-to-square transferring piece are sequentiallyand fixedly connected. The elliptical transferring piece is connected with the inclined supporting columns, the great circle-to-small circle transferring piece is connected with the inclined struts, and the circle-to-square transferring piece is connected with the frame column. Annular stiffening rib plates and longitudinal stiffening rib plates are arranged in the inclined supporting columns, theframe column and the inclined struts, vertical internal rib plates parallel to the surfaces of the inclined struts, vertical internal rib plates perpendicular to the surfaces of the inclined strut and annular stiffening rib plates are arranged in the transferring element, and the inclined supporting columns are connected with the transferring element through a horizontal circular transferring ribplate and a vertical arc-shaped transferring rib plate.

Owner:CHINA IPPR INT ENG

A new type of full-tube panel high-efficiency fuel-fired gas-fired boiler

InactiveCN103791479BAvoid crackingReduce welding workloadSteam boilersConvection heatPetroleum engineering

A novel full tube panel type efficient oil and gas fired boiler comprises a radiant heat exchange membrane type water-cooled wall tube panel structure and a convection heat exchange tube bundle type tube panel structure, wherein the radiant heat exchange membrane type water-cooled wall tube panel structure comprises a front wall membrane type water-cooled wall, a rear wall membrane type water-cooled wall, a left side wall membrane type water-cooled wall and a right side wall membrane type water-cooled wall, and an O-shaped section structure is formed by the left side wall membrane type water-cooled wall, the right side wall membrane type water-cooled wall, a side wall lower header and a side wall upper header; the convection heat exchange tube bundle type tube panel structure comprises convection heat exchange tube bundles, a convection tube panel outside wall membrane type wall and a tail smoke chamber, the radiant heat exchange side wall membrane type water-cooled walls serve as inside wall membrane type walls of the convection heat exchange tube bundle type tube panel structure, and a convection flue with two sides being sealed is formed by the radiant heat exchange side wall membrane type water-cooled walls, the outside wall membrane type wall, an upper welding steel board and a lower welding steel board. The novel full tube panel type efficient oil and gas fired boiler is high in safety margin and good in heat transfer performance, makes use of modular design, and is capable of being rapidly installed and integrally assembled, short in installation period, easy and convenient to operate and maintain, and convenient to repair; the overall sealing performance of the whole boiler is good, heat loss due to radiation is reduced obviously, and heat efficiency is improved effectively.

Owner:XI AN JIAOTONG UNIV +1

Mechanically anchored connection node structure between concrete filled steel tube columns and reinforced concrete beams

ActiveCN105113640BSolve delivery problemsForce relationship is clearBuilding constructionsReinforced concreteRebar

The invention discloses a mechanical anchoring connection joint structure of a steel pipe concrete column and a reinforced concrete beam in a building structure. The joint structure comprises a steel pipe column, a beam surface rib, a beam bottom rib, a steel corbel, an upper horizontal ring plate, a lower horizontal ring plate and a connection anchoring machine, wherein the steel corbel is joist steel; the upper and lower wing edges, near the steel pipe column, of the steel corbel are respectively welded with the steel pipe column through the upper horizontal ring plate and the lower horizontal ring plate; the connection anchoring machine consists of an upper anchoring machine and a lower anchoring machine; the upper anchoring machine and the lower anchoring machine both have joint grooves; the upper anchoring machine is vertically welded on the upper horizontal ring plate; the end part, near the steel pipe column, of the beam surface rib is inserted into the joint groove of the upper anchoring machine after being provided with a nut and a washer; the lower anchoring machine is vertically and reversely welded at the bottom end of the steel corbel, and the welding position is far from the steel pipe column; and the end part, near the steel pipe column, of the beam bottom rib is inserted into the joint groove of the lower anchoring machine after being provided with a nut and a washer. The joint structure is simple in structure, stable in stress, quick in construction period, simple in construction and few in scene welding procedures, and can save steel materials.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Dirt discharging device for package boiler lower boiler barrel

The invention relates to the technical field of dirt discharging devices, in particular to the dirt discharging device for a package boiler lower boiler barrel. The dirt discharging device comprises adirt discharging pipe seat and a dirt discharging pipe, wherein the dirt discharging pipe seat is fixed right below a lower boiler barrel, and the dirt discharging pipe is fixed on the side surface of the dirt discharging pipe seat; and the boiler dirt is discharged from the dirt discharging opening of the lower boiler barrel, passes through the dirt discharging pipe seat, then passes through thedirt discharging pipe and is smoothly discharged out of a boiler. Through the production of the dirt discharging pipe seat forge piece, the height of the pipe seat can be effectively controlled, so that lower level of the dirt discharging pipe seat does not exceed a transportation base plane, and the transportation safety of pressure-bearing parts of the boiler is ensured; the dirt discharging opening is located right below the lower boiler barrel so that the dirt in the boiler barrel can be smoothly discharged; and dirt discharging opening of the boiler is larger than the zero square meter,so that the arrangement of the integral dirt discharging system of a boiler room is facilitated.

Owner:WUXI HUAGUANG IND BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com