Multidirectional through concrete filled steel tubular column beam joint provided with steel corbels and ring beam

A technology of steel corbels and steel pipe columns, which is applied in construction and building construction, can solve problems such as poor seismic performance, and achieve the effects of improving the strength of ring beams, reducing welding workload, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

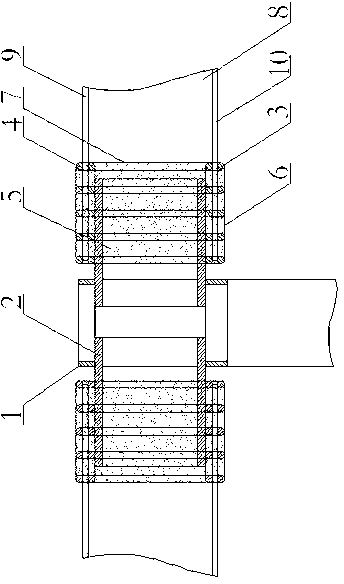

[0023] figure 1 As shown, a multi-directional steel corbel, ring beam, steel pipe concrete column beam joint includes a plurality of steel corbels 2 and ring beams radially connected to the steel pipe column 1, the steel corbel 2 is I-shaped, and the The inner end of a steel corbel 2 penetrates into the steel pipe column 1 and is welded to each other in the steel pipe column, and the outer ends of a plurality of steel corbels 2 are pierced into the ring beam, and the ring beam includes a ring beam skeleton and a concrete ring beam inner core 5 , the ring beam skeleton is composed of two layers of ring beam bottom bars 3, two layers of ring beam top bars 4 and ring beam stirrups 7, the multiple steel rings of each layer of ring beam bottom bars 3 are concentric and in the same plane, and each layer of ring beams The multiple reinforcement circles of the bottom reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com