Box type beam and column connecting assembly type node preparation technology and node thereof

A preparation process and technology of box beams, which are applied in construction, building structure, etc., can solve problems such as unsatisfactory welding quality, hidden safety hazards in the structure, affecting the construction progress of the project, etc., so as to optimize the processing technology and reduce labor costs. The effect of labor intensity and shortening of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

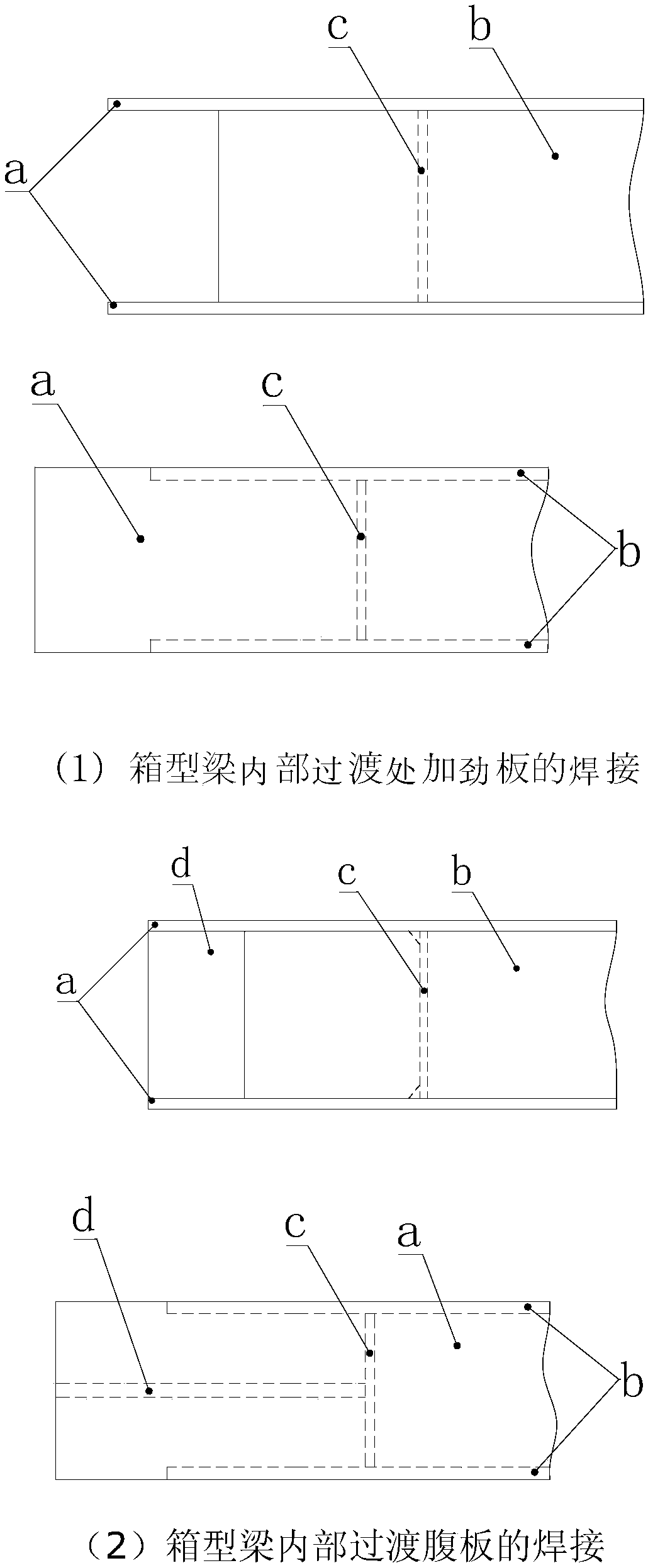

[0035] Such as Figure 5 What is shown is that the corbel 3 is connected to the column web 22, that is, the weak axis connection. The column web 22 and the corbel 3 are connected by welding in the workshop, and the transverse reinforcing rib 8 on the column 2 corresponds to the upper and lower flanges 31 and 32 of the corbel. The box girder 1 is welded and spliced in the workshop to form a box girder with an H-shaped end. The H-shaped end includes an upper flange 41 , a lower flange 42 and a web 43 . After the box girder 1 and column 2 are transported to the construction site, align the upper and lower flanges 41, 42 of the box girder end with the upper and lower flanges 31, 32 of the corbel, and align the web 43 of the end of the box girder with the corbel The leg web 33 is aligned, and after alignment, the connecting plate 5 is set on both sides of the flange and the web, and the H-shaped end flange and the corbel flange, the end web and the corbel web are fastened by bol...

Embodiment 2

[0037] Such as Figure 6What is shown is that the corbel 3 is connected to the column flange 21, that is, the strong axis connection. The column flange 21 and the corbel 3 are connected by welding in the workshop, and the transverse reinforcing ribs on the column 2 correspond to the upper and lower flanges 31 and 32 of the corbel. The box girder 1 is welded and spliced in the workshop to form a box girder with an H-shaped end. The H-shaped end includes an upper flange 41 , a lower flange 42 and a web 43 . After the box girder 1 and the column 2 are transported to the construction site, the upper and lower flanges 41, 42 of the box girder end are aligned with the upper and lower flanges 31, 32 of the corbel, and the web plate 43 of the end of the box girder is aligned with the corbel. The leg web 33 is aligned, and after alignment, the connecting plate 5 is set on both sides of the flange and the web, and the H-shaped end flange and the corbel flange, the end web and the cor...

Embodiment 3

[0039] In the above-mentioned prefabricated node connection between the box beam and the column, the column is an H-shaped structure. In practical applications, the column can also be a regular structure such as a box-shaped, circular, or other special-shaped structure. Combine now Figure 7 The connection between the box-shaped beam and the box-shaped column shown is explained. The box-shaped column 9 is assembled from box-shaped wall panels 91 . The box-shaped column 9 is provided with a transverse reinforcing rib 8 inside. The box-shaped column 9 and the corbel 3 are connected by welding in the workshop, and the transverse reinforcing rib 8 provided inside the box-shaped column 9 corresponds to the upper and lower flanges 31 and 32 of the corbel. The box girder 1 is spliced into a box girder with an H-shaped end by welding in the workshop, and the H-shaped end includes an upper flange 41 of the end, a lower flange 42 of the end and a web 43 of the end. After transporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com