T-shaped supporting structure on assembly type concrete shear wall

A technology of concrete shear wall and support structure, which is applied to supporting machines, mechanical equipment, etc., can solve problems such as troublesome operation and unscientific application, and achieve the effect of functional improvement, neat threading method, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

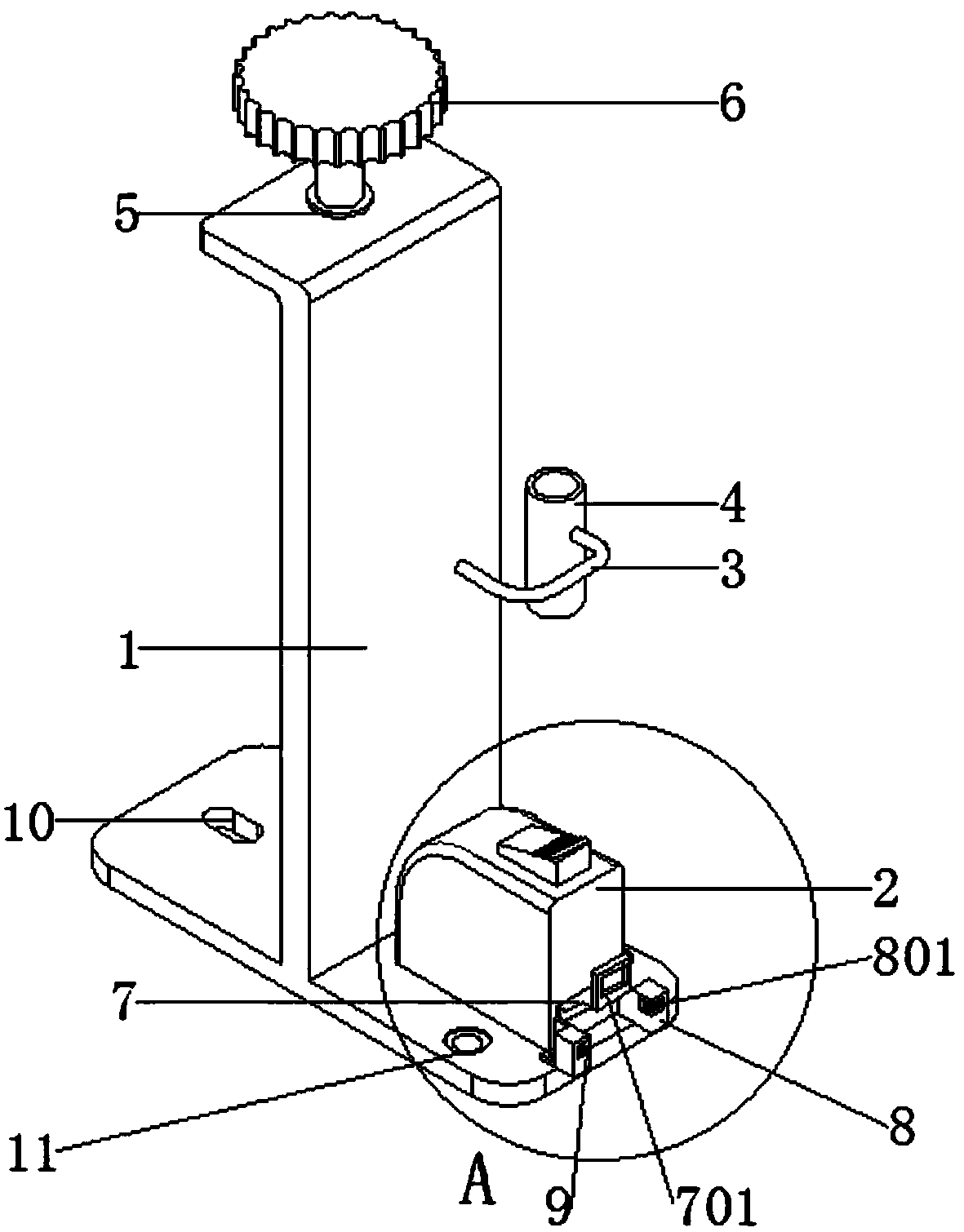

[0023] as attached figure 1 to attach Figure 4 Shown:

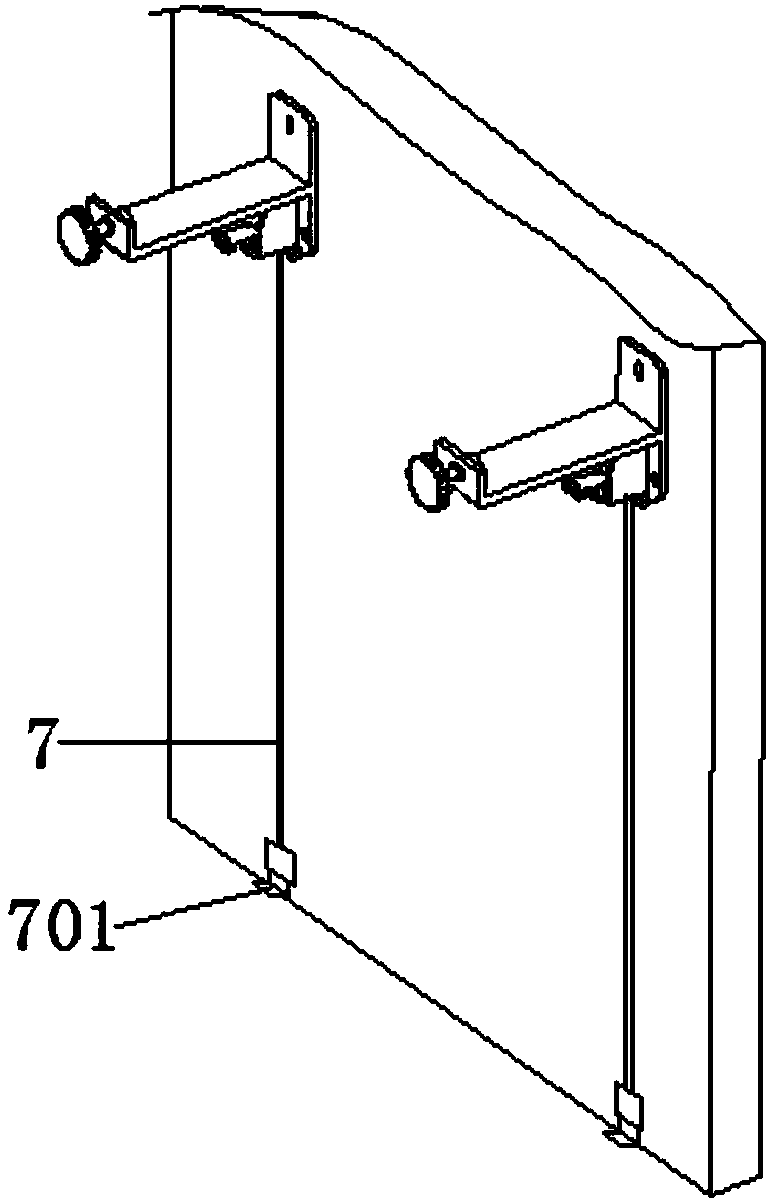

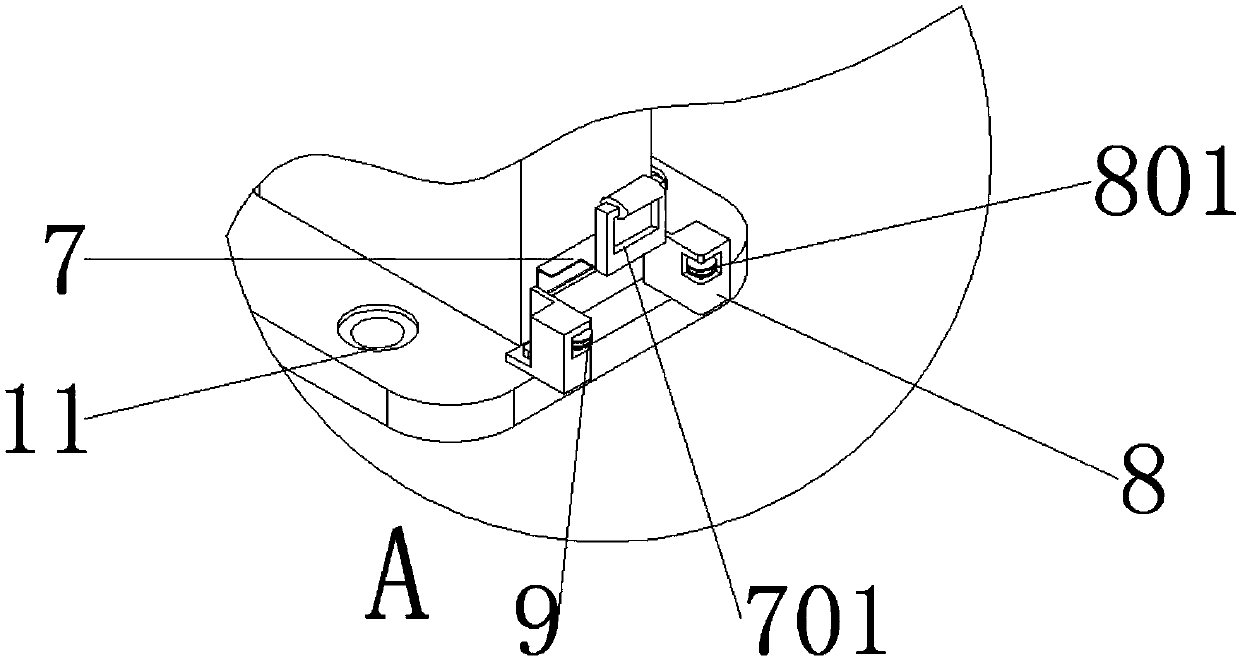

[0024] The present invention provides a T-shaped support structure on a prefabricated concrete shear wall, including a main body 1, a meter base 2, a crutch 3, a pipe 4, a slot 401, a threaded sleeve 5, a lock nut 6, a ruler 7, Draw groove 701, guide seat 8, guide wheel 801, installation groove 9, first installation hole 10 and second installation hole 11; There is a through pipe 4 welded; the main body 1 is a T-shaped structure, wherein the front end plate of the T-shaped structure is curved, and a lock nut 6 is penetrated by a threaded sleeve 5 at this curved structure, and a lock nut 6 is inserted in the T-shaped structure. The rear end plate of the structural main body 1 is respectively provided with a first installation hole 10 and two second installation holes 11 from top to bottom; Place meter ruler seat 2, and a guide seat 8 is respectively installed by screws on the left and right sides of the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com