Woodworking precise hammering auxiliary device and using method

An auxiliary device and precise technology, applied in distribution devices, packaging, manufacturing tools, etc., can solve problems affecting concrete forming, formwork deformation, personal safety, etc., and achieve convenient and fast operation and installation, shorten construction period, and improve construction quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

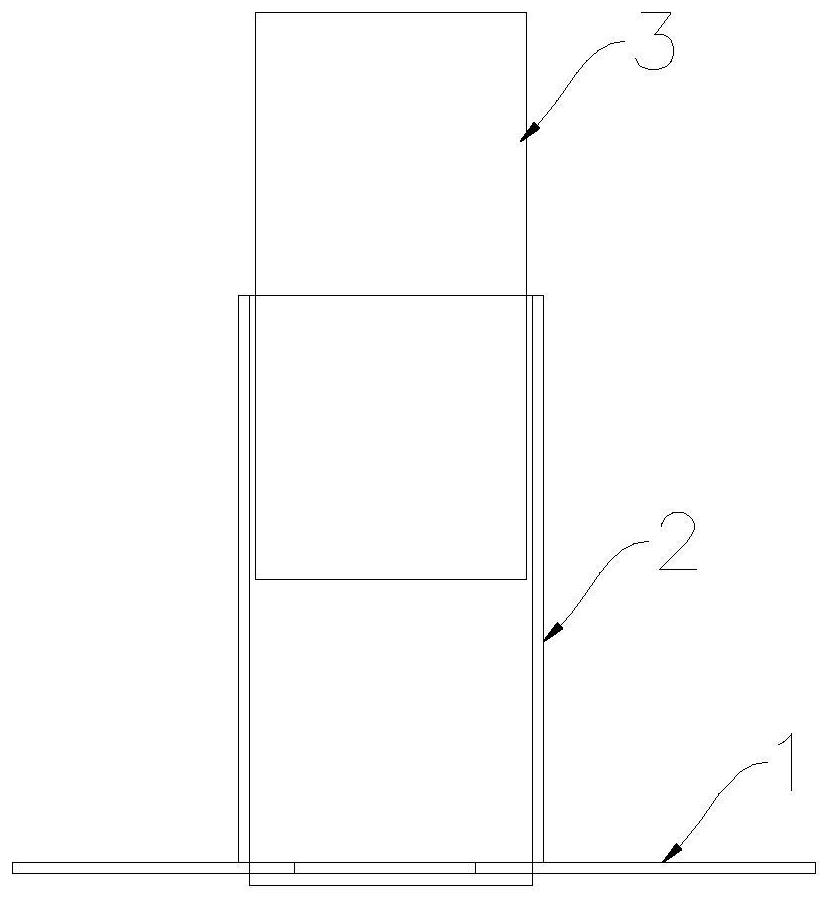

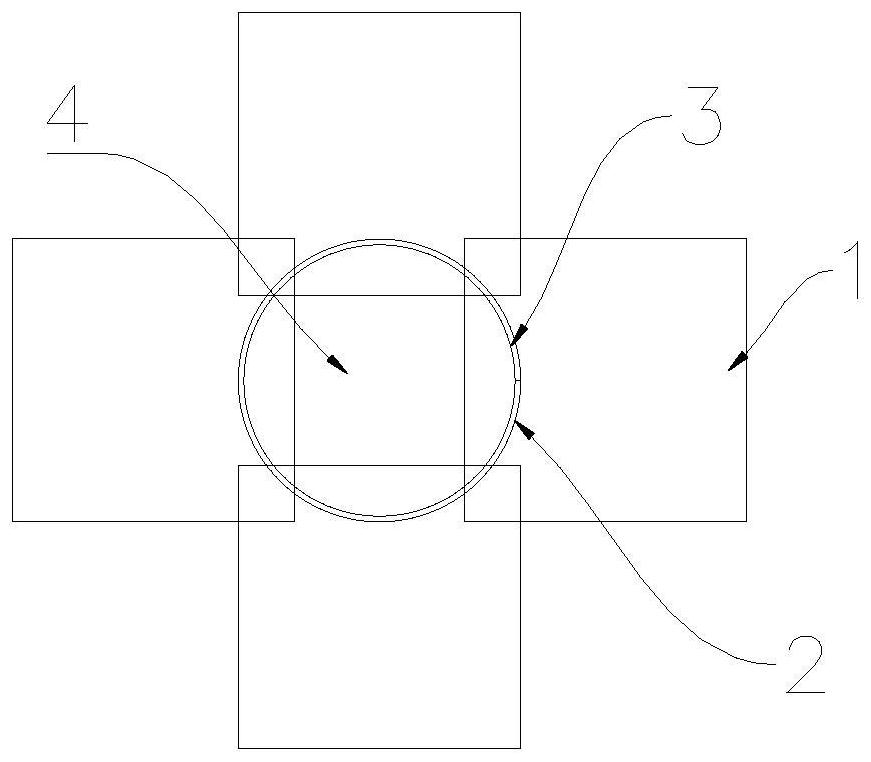

[0022] see figure 1 and figure 2 As shown, the present invention is a woodworking precision hammering auxiliary device, which includes a support plate 1, a guide tube 2 and an auxiliary hammer block 3, and a central through hole 4 is provided at the center of the support plate 1; the size of the guide tube 2 is larger than The size of the central through hole 4, the bottom of which is fixedly arranged on the support plate 1 outside the central through hole 4, and its central axis is on the same line as the center point of the central through hole 4; the auxiliary hammer block 3 and the guide tube 2 The inner side is adapted and the height is the same, and can be slidably arranged in the guiding circular tube 2 .

[0023] Preferably, the support plate 1 is formed by welding four square metal plates, the four metal plates are symmetrically arranged in four directions, and adjacent metal plates are overlapped at the corners and fixed by welding.

[0024] Preferably, the suppor...

Embodiment 2

[0034] The use method of a kind of woodworking precision hammering auxiliary device described in embodiment 1, the steps are as follows:

[0035] S1, take out the auxiliary hammer block 3 in the guide tube 2;

[0036] S2. Gently tap the nail on the template so that it can temporarily stand on the template without falling off, about 1cm can be nailed;

[0037] S3. Set the central through hole 4 of the support plate 1 and the guide tube 2 in the woodworking precision hammering auxiliary device to the nail, and move the nail to the center of the central through hole 4;

[0038] S4, put the auxiliary hammer block 3 into the guide tube 2;

[0039] S5. Use an ordinary hammer to strike from light to heavy until the auxiliary hammer block 3 is completely submerged into the guide tube 2. At this time, the four 50×50mm steel plates that form the support plate (1) are used to disperse the impact force, so that the template does not The effect of damage, but also to ensure the safety of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com