Fell ball aspirator of ball bed high-temperature air cooled reactor

A technology for a high temperature gas-cooled reactor and a suction device, which is applied in the field of reactor engineering, can solve the problems of complicated and difficult recharging, and achieve the effects of less equipment, low cost, and simple principle and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

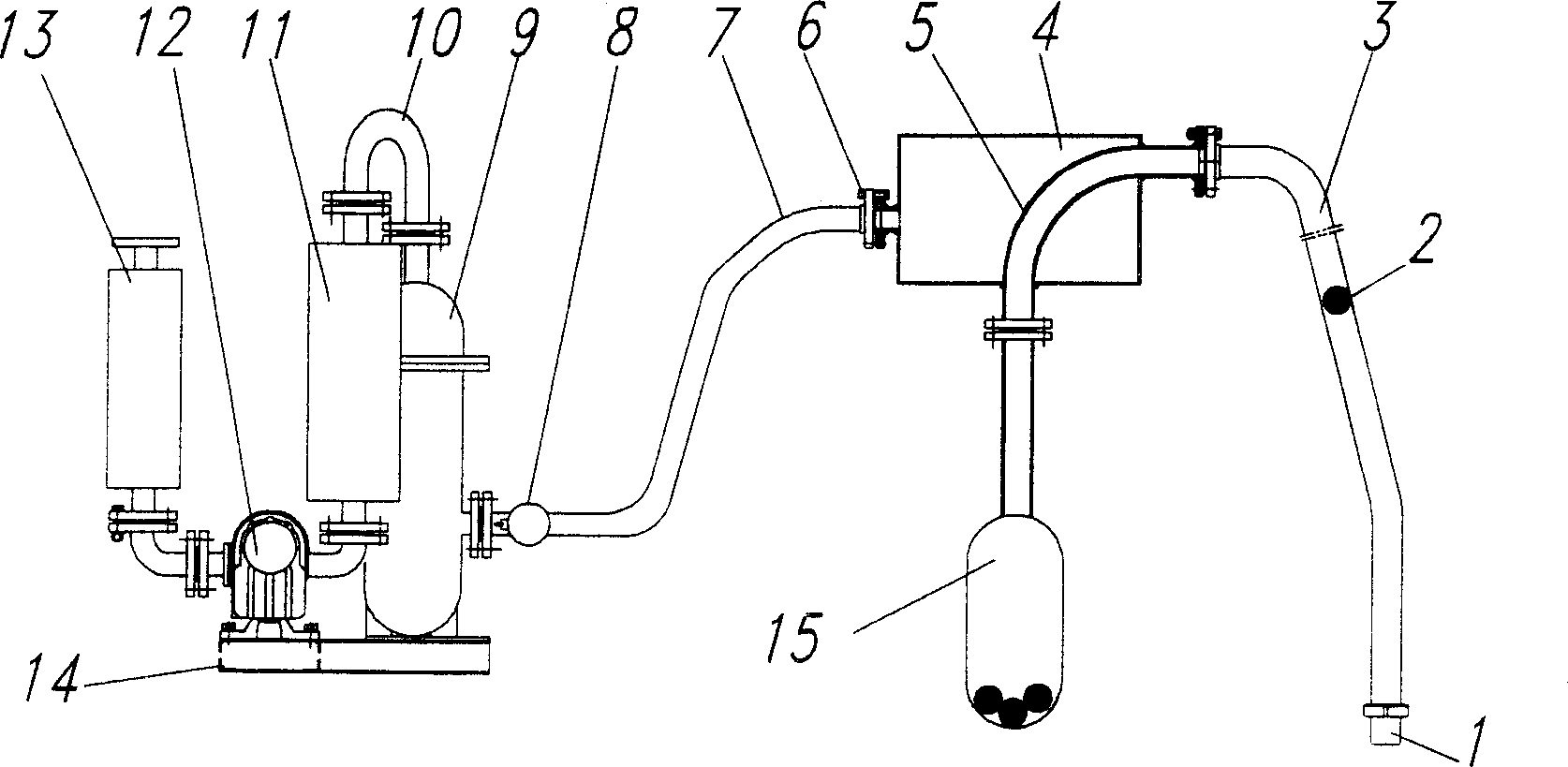

[0008] The pebble bed high temperature gas-cooled reactor fuel sphere pumping device that the present invention proposes, its structure is as follows figure 1 As shown, it includes a suction nozzle 1 , a porous pipe 5 , a suction chamber 4 , a filter 9 , an inlet muffler 11 , an outlet muffler 13 and a fan 12 . The porous connecting pipe 5 is placed in the suction chamber 4, one end of the porous connecting pipe 5 is connected with the suction nozzle 1 through a flange and a hose, and the other end is connected with the storage container 15 through a flange. The fan 12 is fixed on the base 14 , the air outlet of the fan 12 is connected with the outlet muffler 13 , and the air inlet of the fan 12 is connected with the inlet muffler 11 . The inlet of the intake muffler 11 is connected with the outlet of the filter 9 , and the inlet of the filter 9 is connected with the suction chamber 4 through a flange, a hose 7 and a ball valve 8 .

[0009] The fuel sphere suction device prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com