Patents

Literature

102 results about "Radiant heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat exchanger

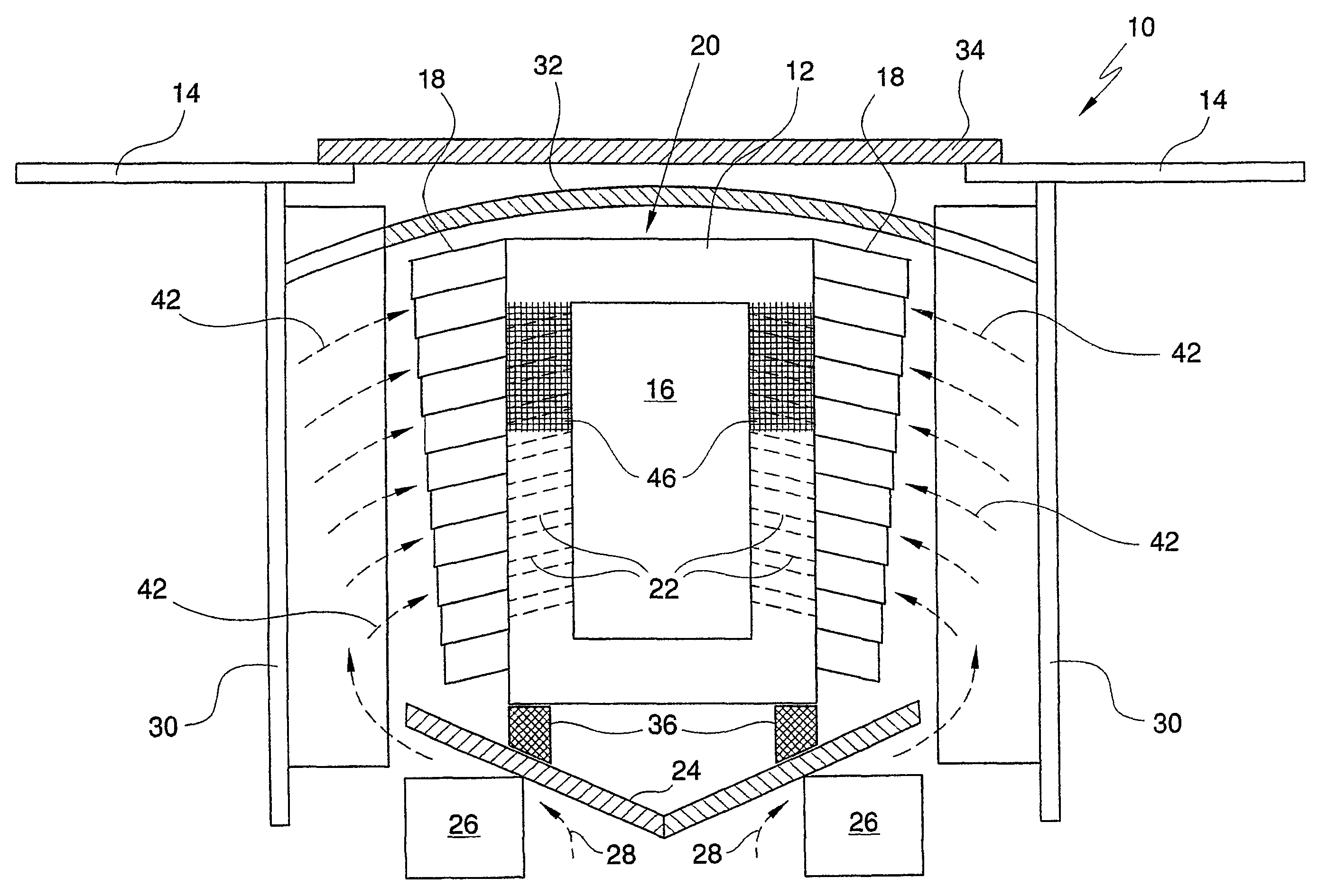

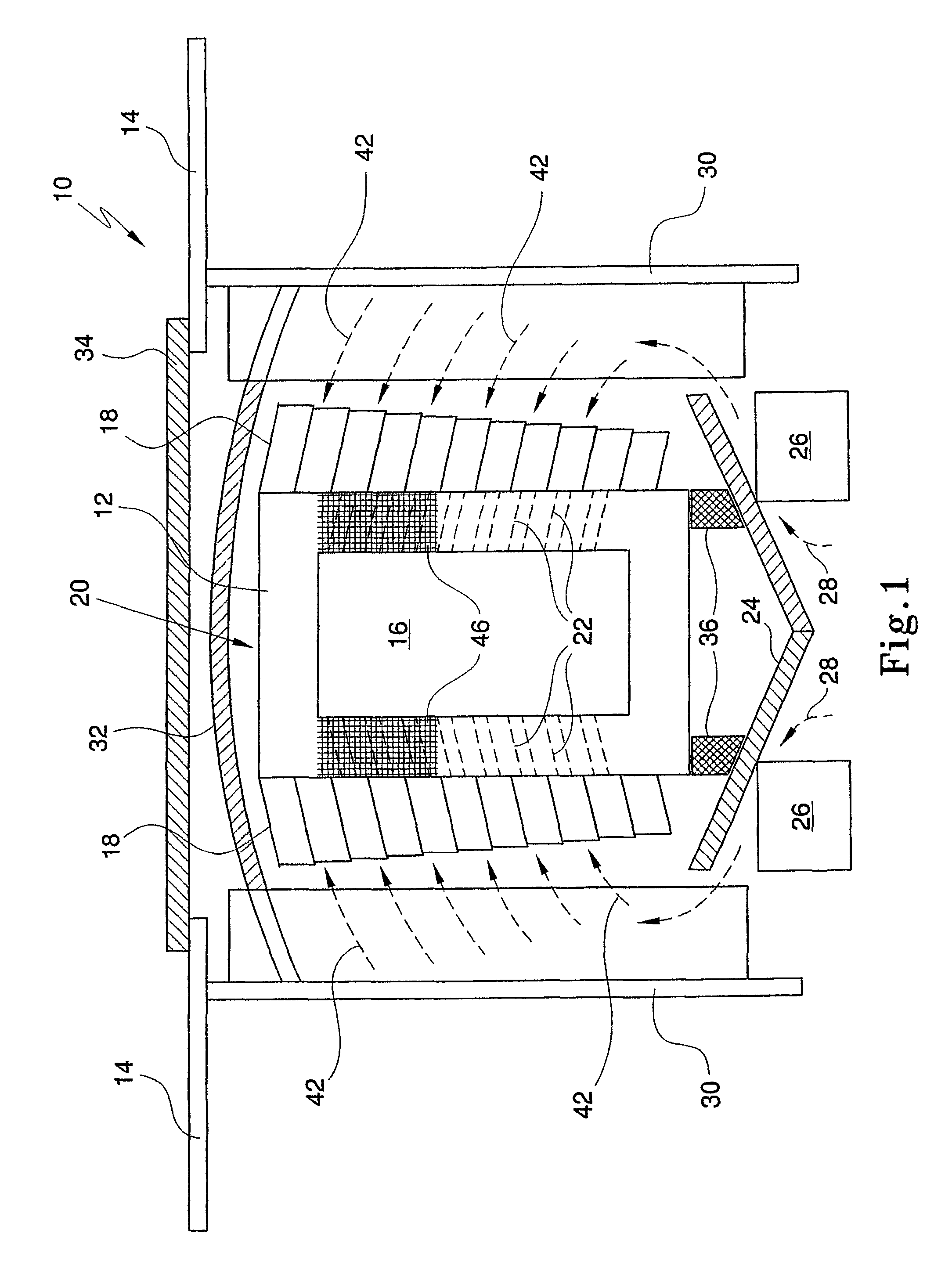

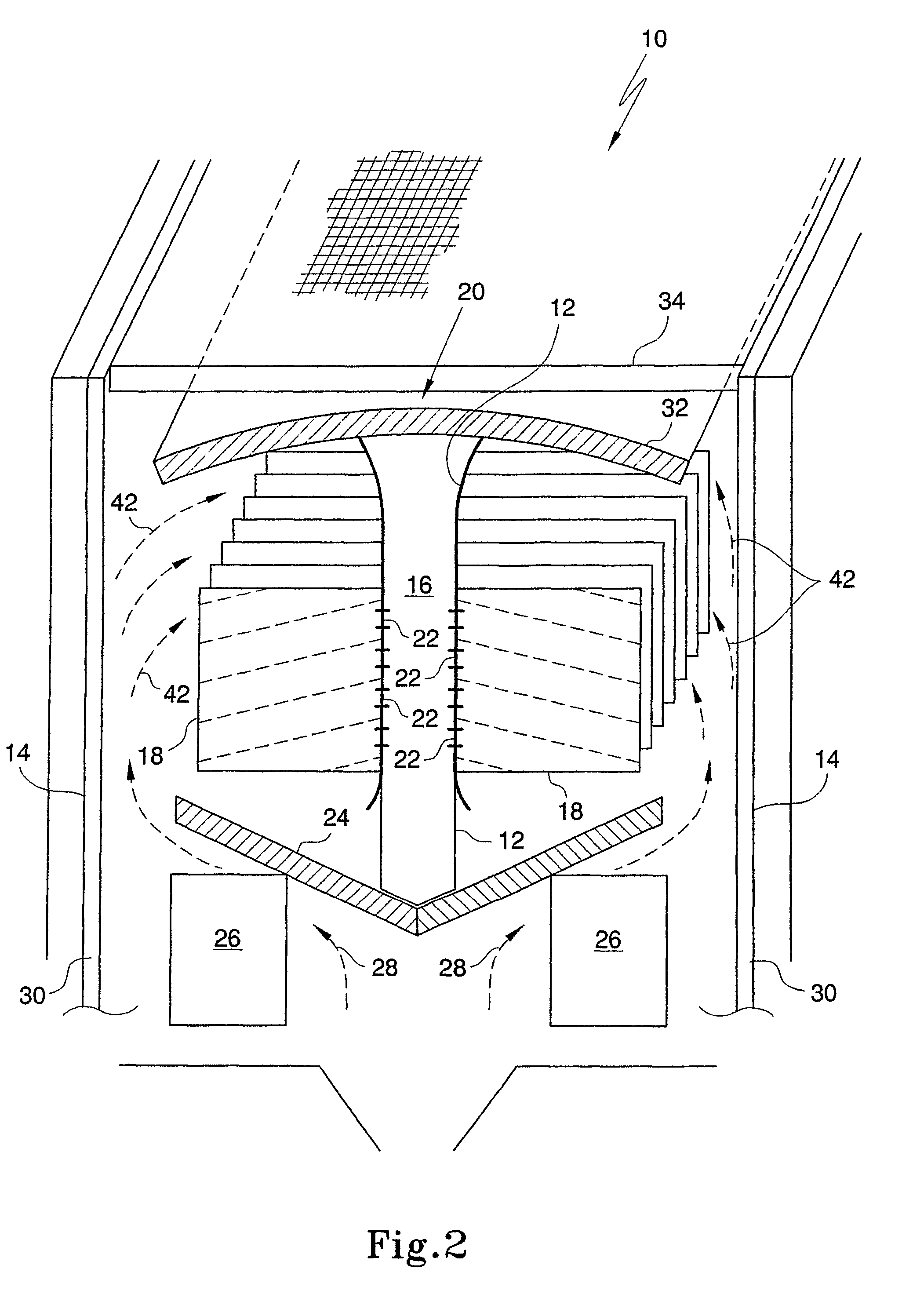

ActiveUS7901617B2Lower overall pressure dropImprove heat transfer performanceBlast furnace detailsManufacturing convertersEngineeringCooling fluid

A heat exchanger 10 includes a conduit 12 for conveying cooling fluid relative to a body to be cooled. A heat transfer arrangement 62 is arranged in communication with an interior of the conduit 12, the heat transfer arrangement 62 and the conduit 12 together defining an assembly that is mountable adjacent the body to be cooled, convective heat exchange occurring, in use, due to movement of the cooling fluid relative to the body and the heat transfer arrangement 62 of the assembly and radiant heat exchange occurring between the body and at least part of the heat transfer arrangement 62 of the assembly.

Owner:ENPOT HLDG LTD

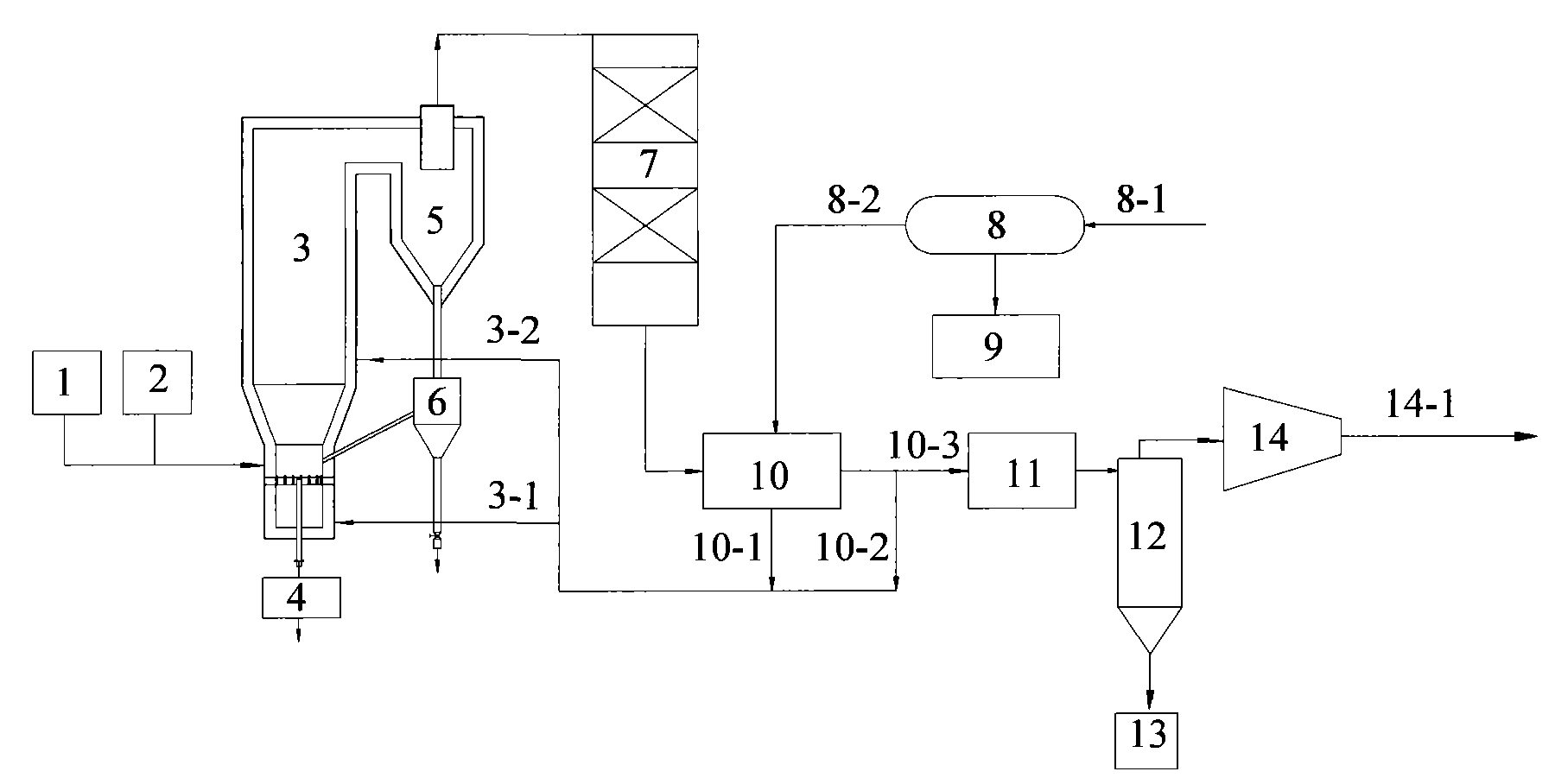

Method for reducing emission of carbon dioxide by circulating fluidized bed temperature flue gas circulation oxygen combustion

InactiveCN101634449ARealize rational utilizationHigh thermal efficiencyFluidized bed combustionDispersed particle separationResource utilizationWater vapor

The invention relates to a method for reducing emission of CO2 by circulating fluidized bed temperature flue gas circulation oxygen combustion, which is a method for realizing CO2 emission reduction applied in a circulating fluidized bed boiler based on the technology of temperature flue gas circulating oxygen combustion. The method comprises the following steps: feeding fuel and desulfurater into the circulating fluidized bed boiler, taking the gas mixture of O2 and circulating flue gas as combustion agent, passing through the heating surface at the tail by the flue gas generated by combustion, heating O2 (concentration is 96.5%-98.5%) from an air separation unit, generating temperature flue gas at the temperature of 140-150 DEG C, taking the gas mixture composed of 30%-70% of the temperature flue gas and O2 as oxidant to delivery to a furnace for combustion, carrying out dedusting by a deduster, multi-level condensation and dehydration and compression on the residual flue gas (volume concentration of CO2 is larger than 95%), and realizing resource utilization or storing in a sealing manner. The circulating glue gas is rich in vapor, entrainment unburned carbon and active desulfurater; the method enhances radiant heat exchange in the furnace, solves the problem of insufficient amount of convection heat transfer, improves combustion efficiency and desulfuration efficiency of the furnace, and can realize near-zero emission of gas pollutant; besides, the method can also lower comprehensive power consumption of space division and CO2 compression, and improve generating efficiency.

Owner:SOUTHEAST UNIV

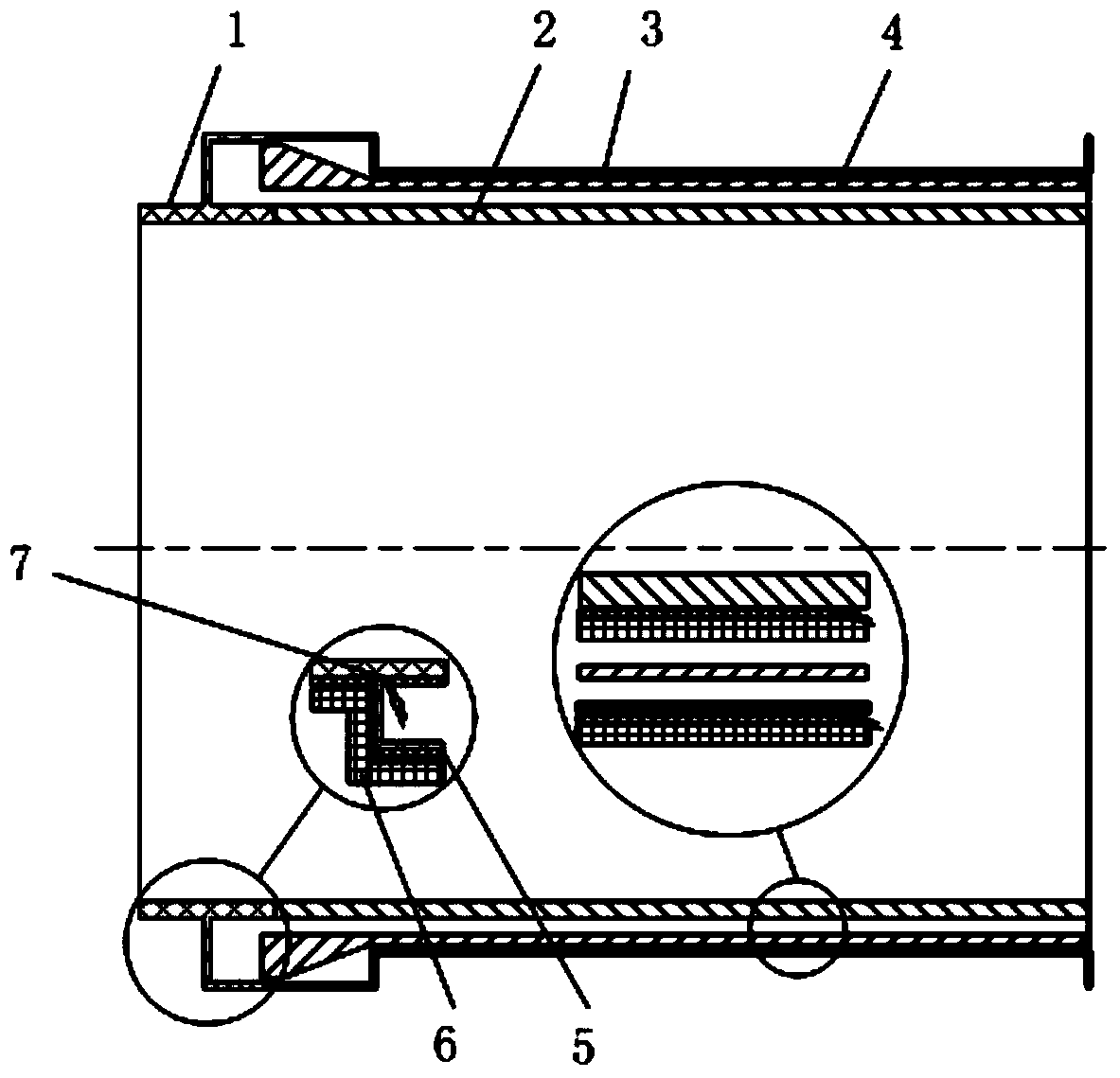

Indirect thermal control device for high resolution optical remote sensor precision temperature control

ActiveCN103863581AGuaranteed temperature levelSmall temperature fluctuationsCosmonautic environmental control arrangementTemperature controlThermal insulation

The invention discloses an indirect thermal control device for high resolution optical remote sensor precision temperature control. The indirect thermal control device comprises a thermal cover structure, a thin film electric heater, a temperature measuring element, a multi-layer thermal insulation assembly and a temperature control instrument circuit. The thermal cover structure is installed on the periphery of a controlled object in a thermal insulation mode, the thin film electric heater and the temperature measuring element are stuck on the thermal cover structure, the temperature reading number fed back by the temperature measuring element is read through a temperature control instrument, and active temperature control over the thermal cover structure is achieved through a control loop. The thermal cover structure is coated with the multi-layer thermal insulation assembly, and the influence of environmental temperature fluctuation on the temperature of the thermal cover structure is reduced. The temperature of the thermal cover structure is controlled to fluctuate within the temperature control threshold value range. By means of radiant heat exchange between the surface of the thermal cover structure and the controlled structure, temperature control over the controlled object is achieved. The indirect thermal control device for high resolution optical remote sensor precision temperature control controls the temperature of the controlled object through active temperature control over the thermal cover structure and radiant heat exchange between the thermal cover structure and the controlled object.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

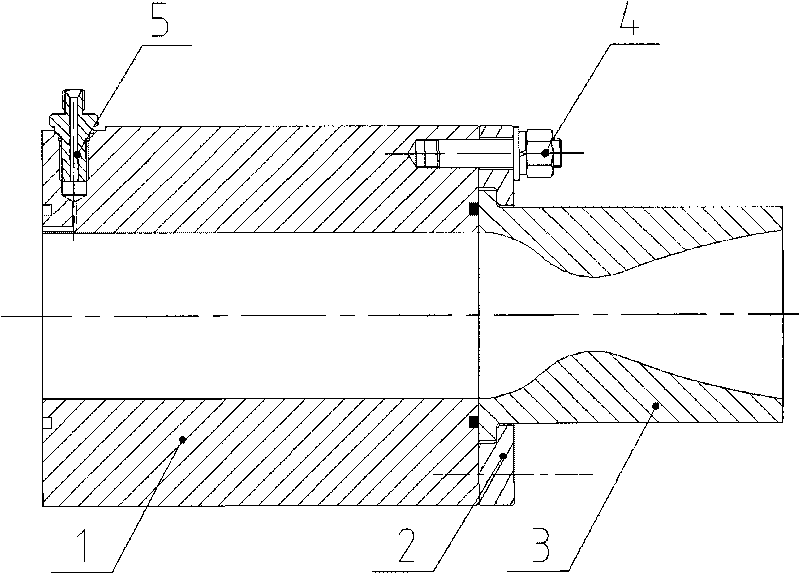

Method for designing structure of low-cost test combustion chamber with reliable thermal protection

InactiveCN101738316AGuaranteed temperature measurement accuracySmall volumeEngine testingRocket engine plantsCombustion chamberHeat conducting

The invention discloses a method for designing a structure of a low-cost test combustion chamber with reliable thermal protection. The combustion chamber comprises a body barrel segment, a connecting flange, a nozzle part, a connecting bolt and a measuring filler neck part. The combustion chamber adopts a capacitive type structure; the body barrel segment is made of a pure copper material with a high thermal conductivity; and the nozzle part is made from a copper-infiltrated tungsten material. In the invention, a thermal analysis aided design method is required to be used firstly, which needs to establish a computation mode and a computing method at first and then perform an iterative design process of the structural design and the thermal analysis. The computation mode adopts an unsteady thermal-dimensional heat conducting differential equation and the computed heat exchange mainly comprises heat convection from the gas to the chamber wall and the radiant heat exchange, the heat conduction in the chamber wall, the convection from the chamber wall to the outside and the radiant heat exchange. The thermal analysis aided design method comprises a global computing analysis and a local correcting and computing analysis. The method can minimize the materials used under the condition that the combustion chamber has the reliable thermal protection and greatly reduce the cost.

Owner:BEIHANG UNIV

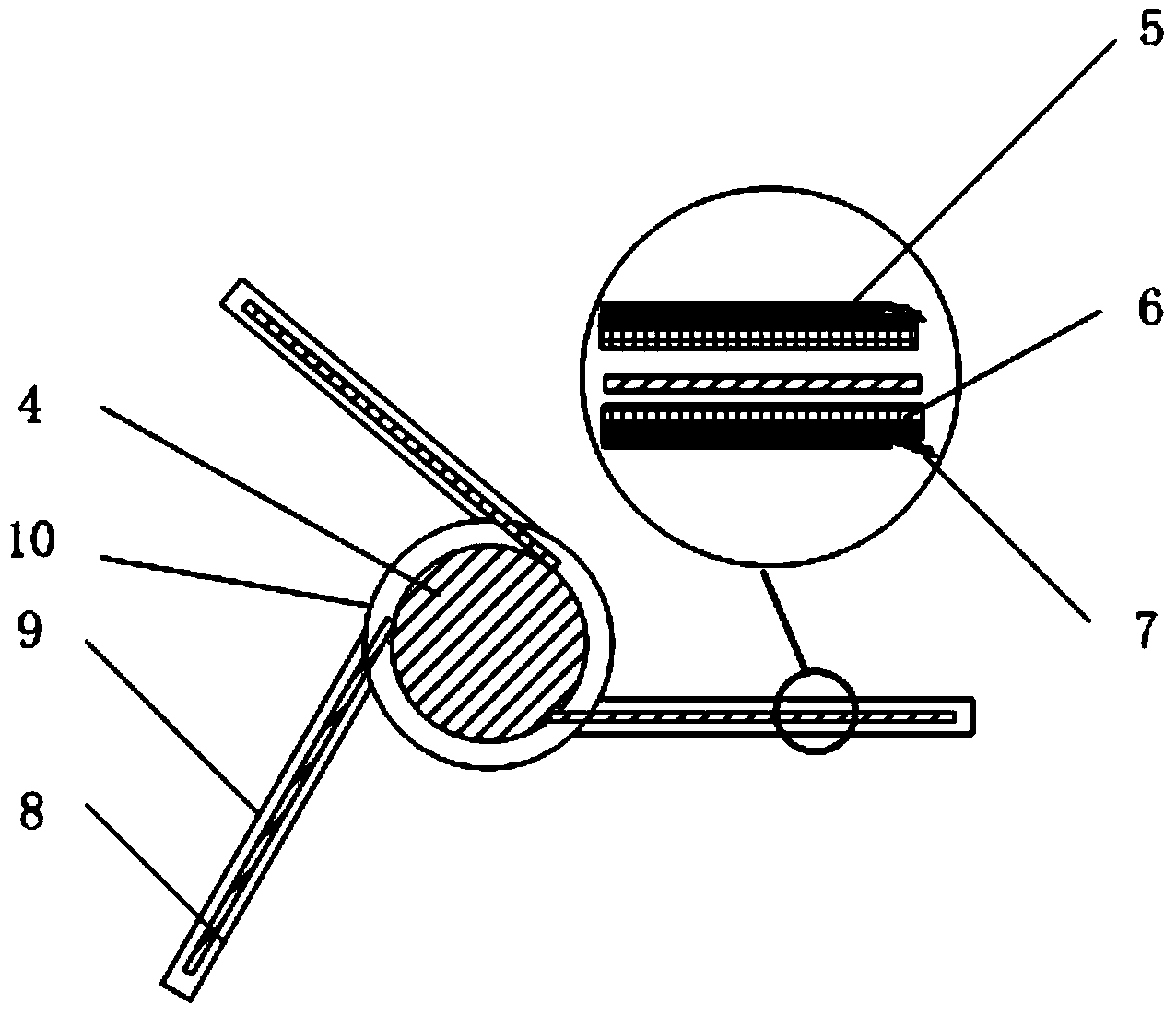

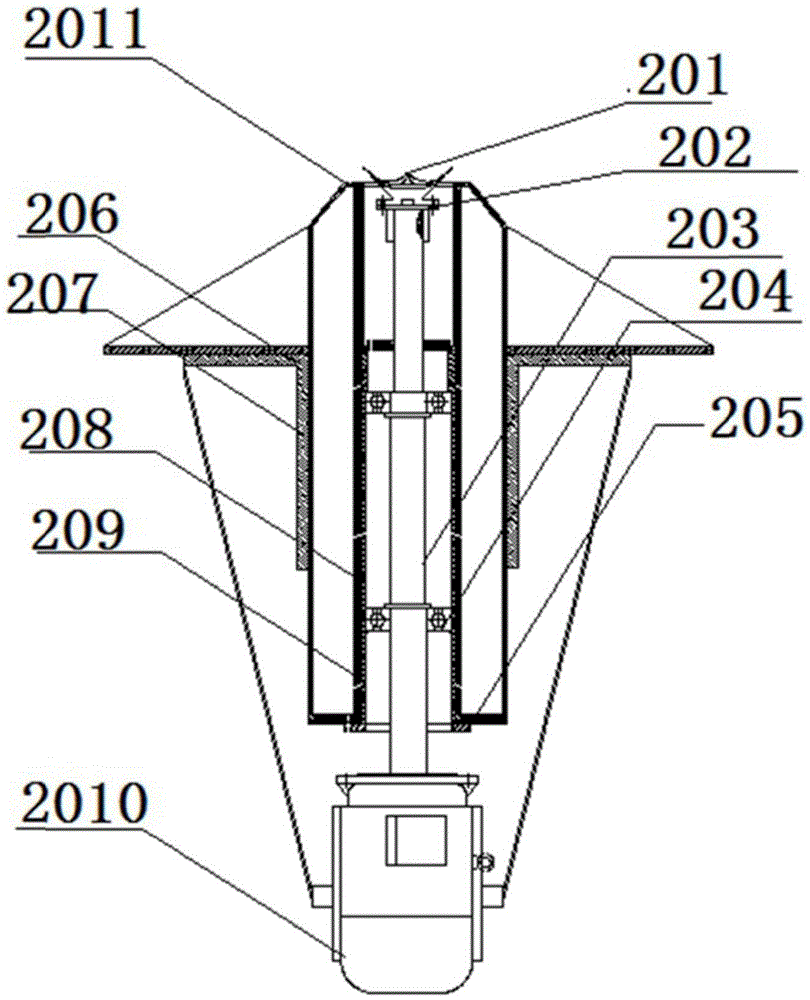

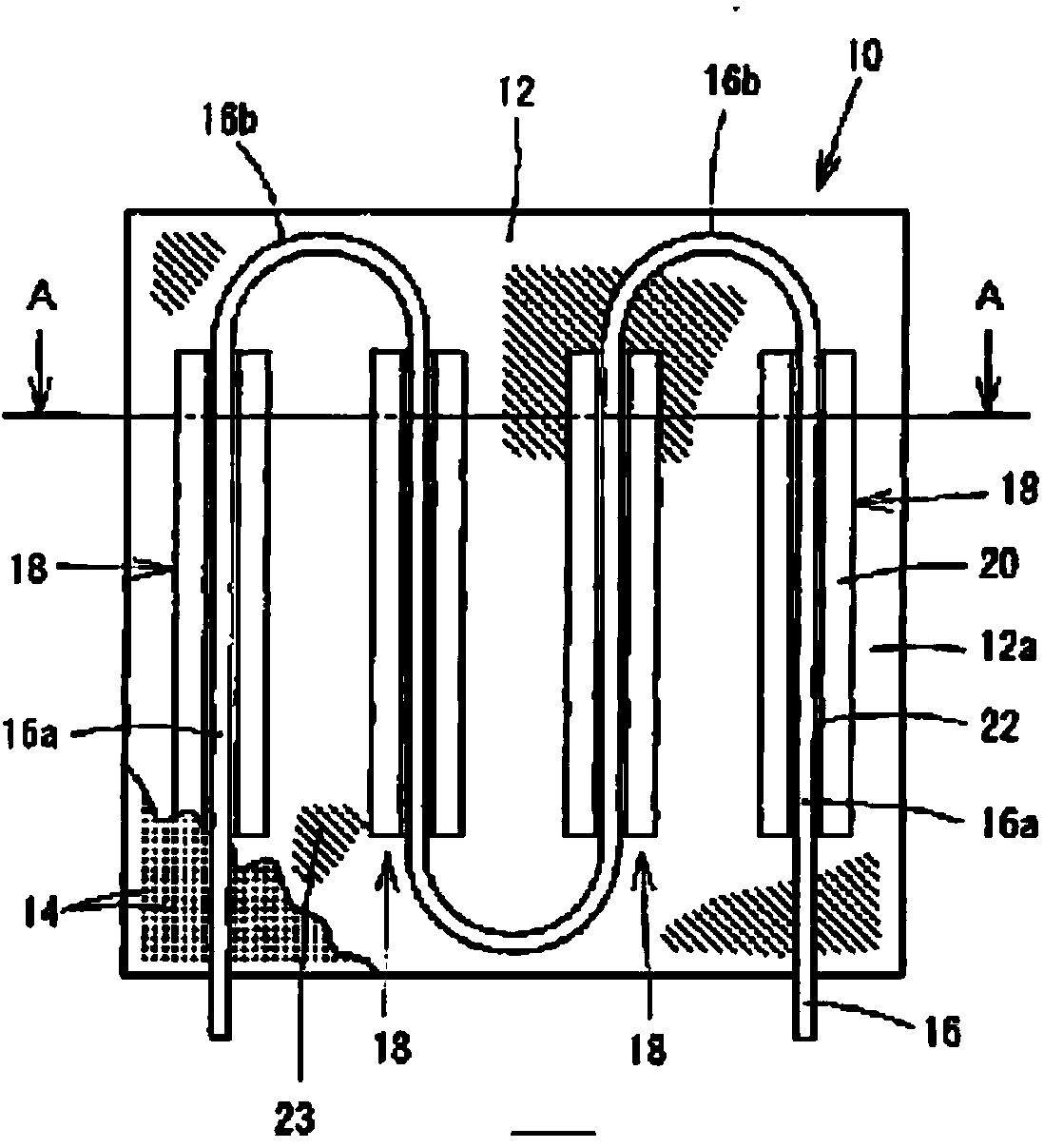

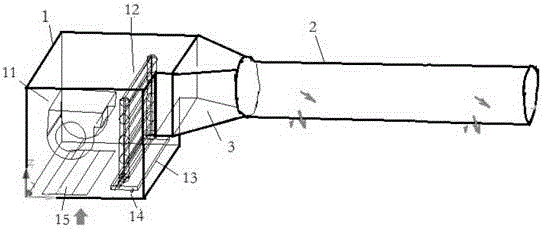

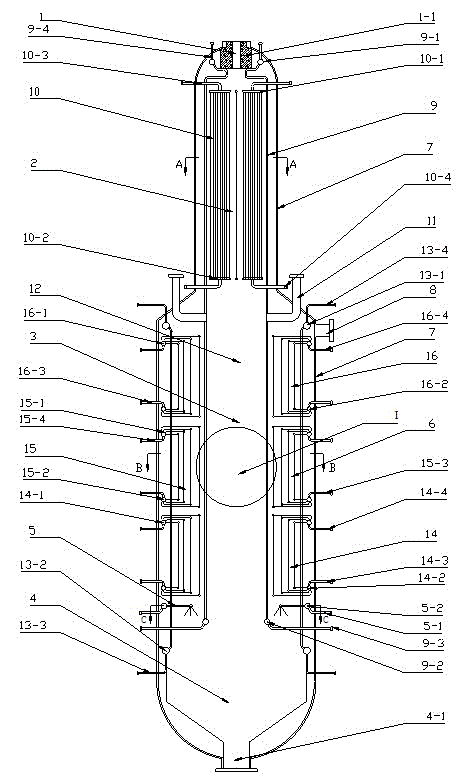

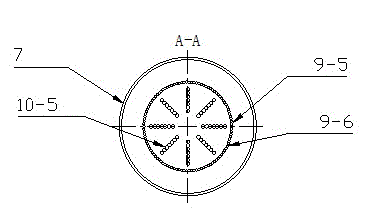

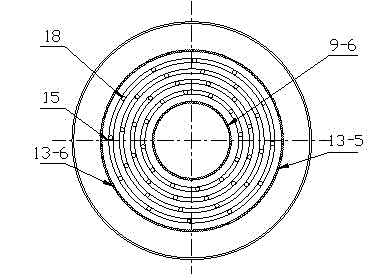

Exhaust gas processing system and method for rotary hearth type reducing furnace

InactiveUS20100186644A1Rapid coolingEasy to disassembleRotary drum furnacesCorrosion preventionCombustorRefractory

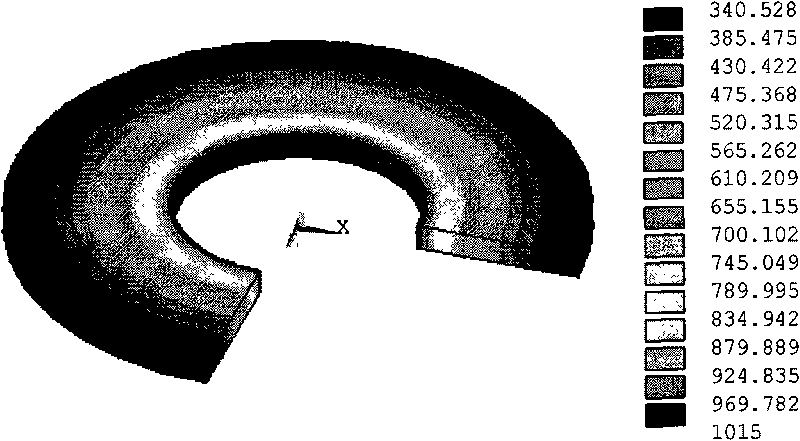

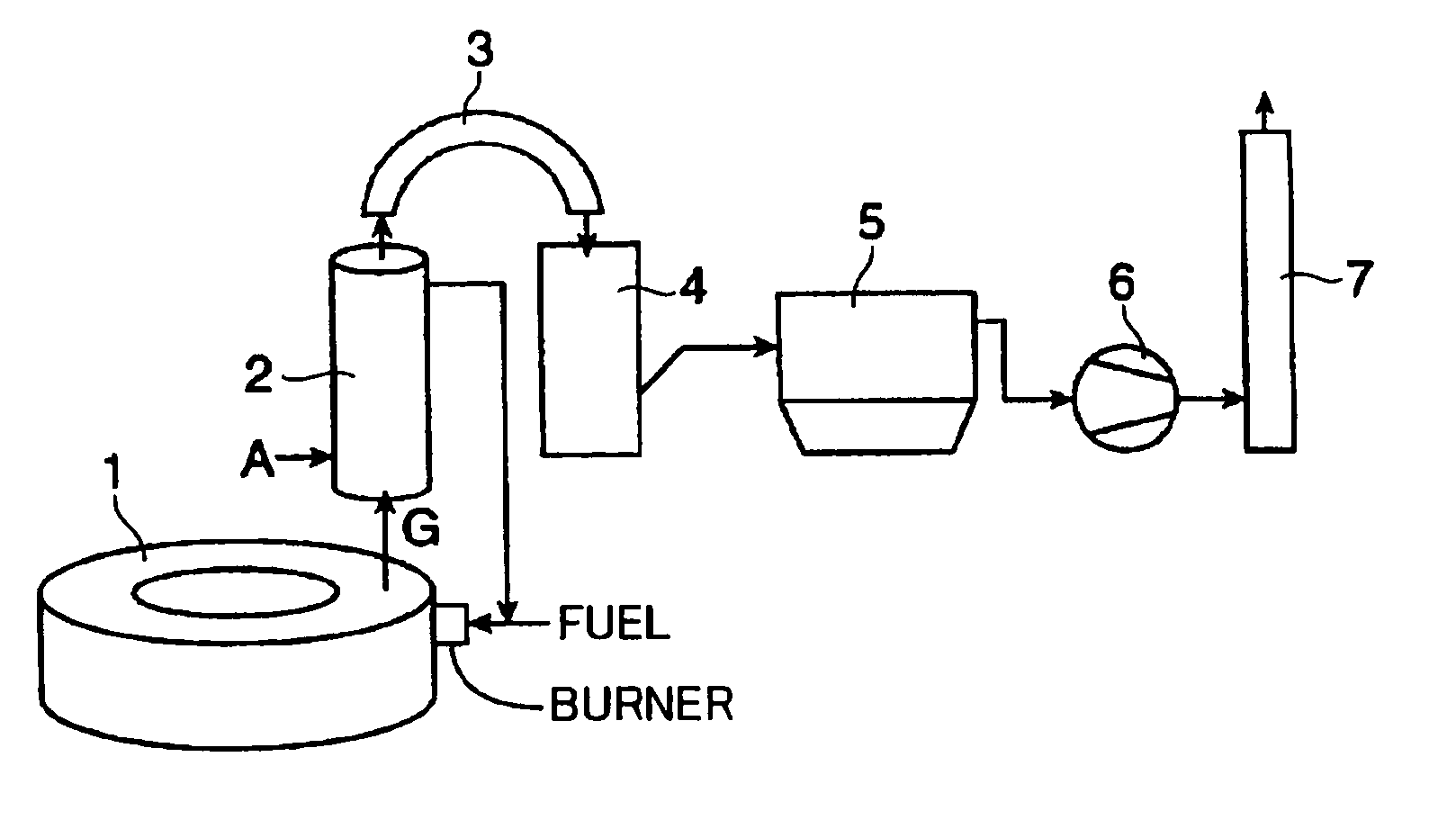

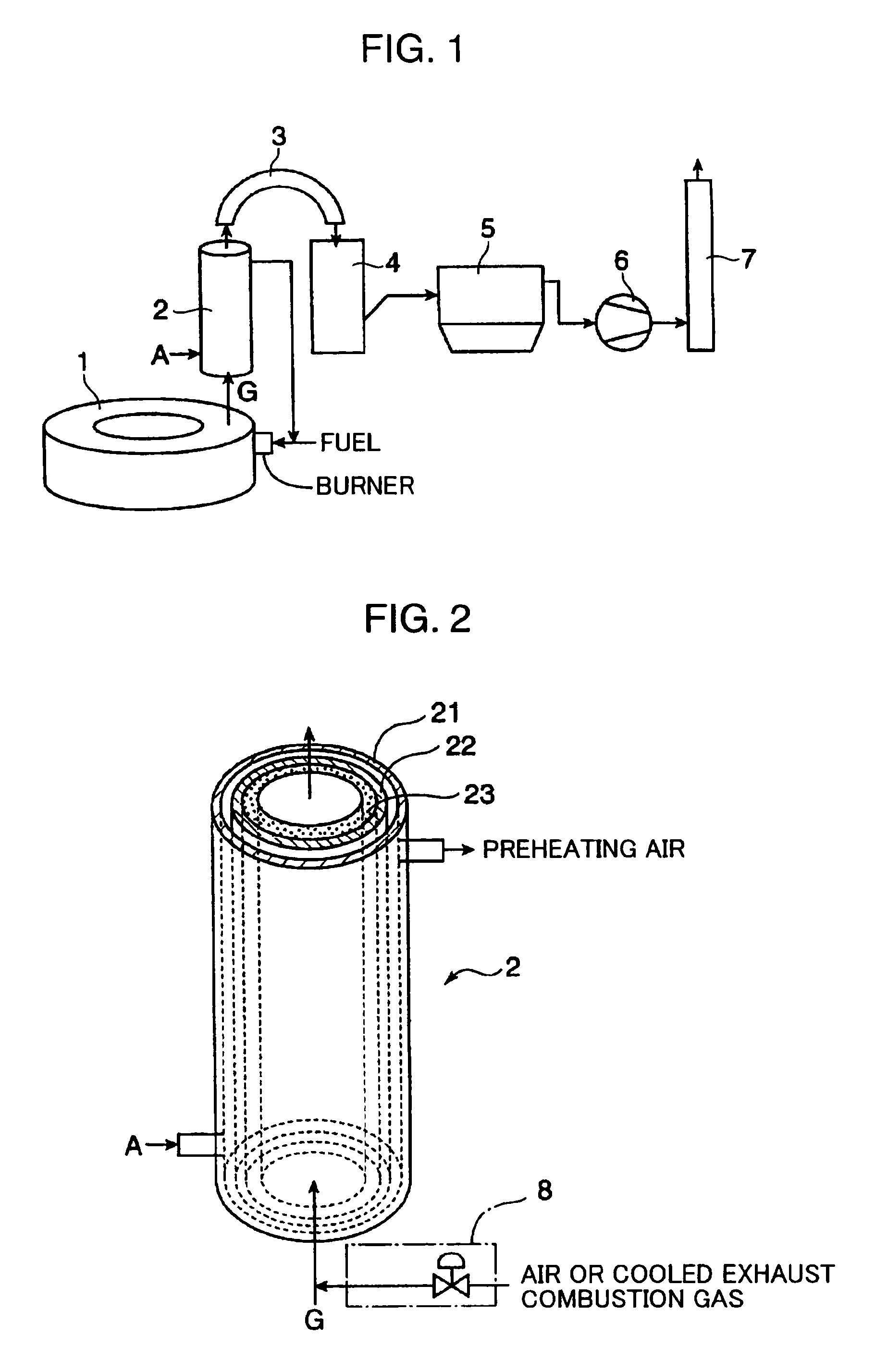

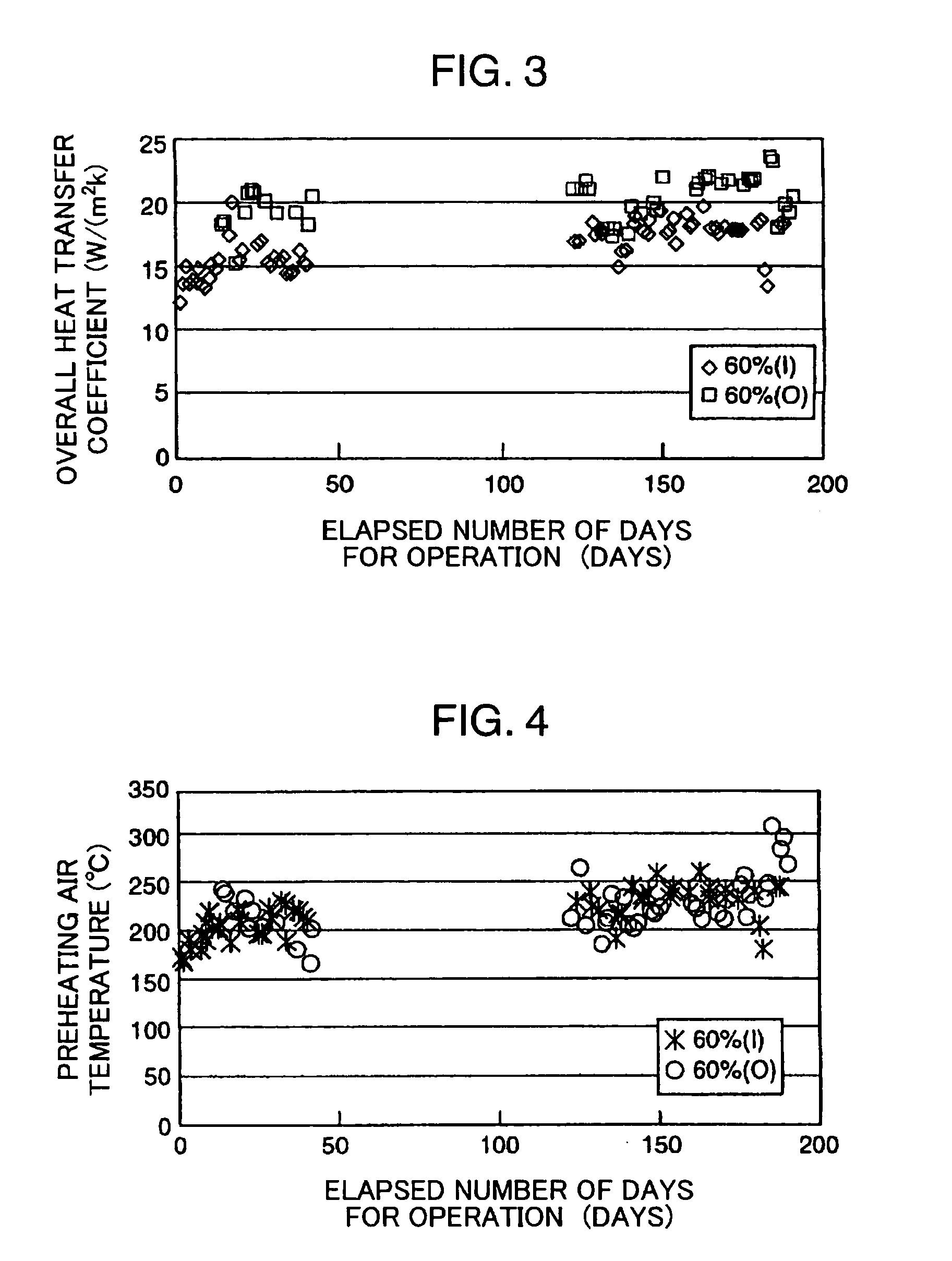

Provided are an exhaust gas processing system and method capable of effectively utilizing the sensible heat of an exhaust gas for preheating air for burner combustion in a rotary hearth type reducing furnace while preventing troubles caused by adhesion of dust such as blockage in an exhaust gas processing facility for a rotary hearth type reducing furnace and corrosive deterioration in the facility without increasing the facility costs excessively. The system comprises a radiant heat exchanger 2 for heat exchange between an exhaust gas exhausted from the rotary hearth type reducing furnace and air. The radiant heat exchanger 2 includes an inner cylinder 22 made of metal surrounding a space through which the exhaust gas flows; an outer cylinder 21 disposed on an outer side in a radial direction of the inner cylinder to define a flow channel between the inner cylinder and the outer cylinder 21 for allowing the air to flow so as to exchange heat with the exhaust gas; and a highly thermal conductive refractory 23 applied to an inner side of the inner cylinder 22 so as to cover an inner surface thereof.

Owner:KOBE STEEL LTD

Harvest drying method and apparatus

InactiveUS20100088920A1Drying solid materials with heatHeat recovery systemsProcess engineeringRadiant heat transfer

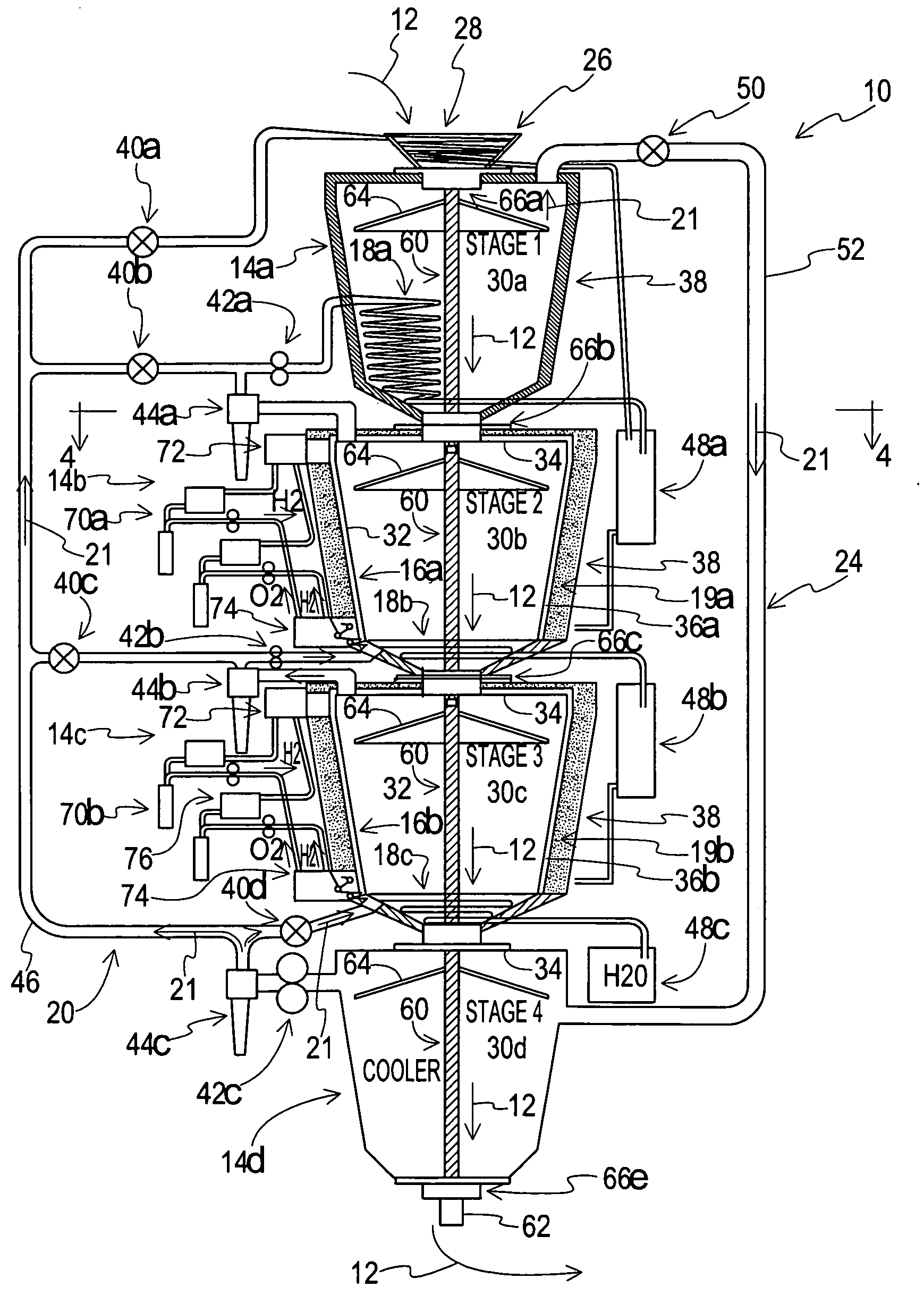

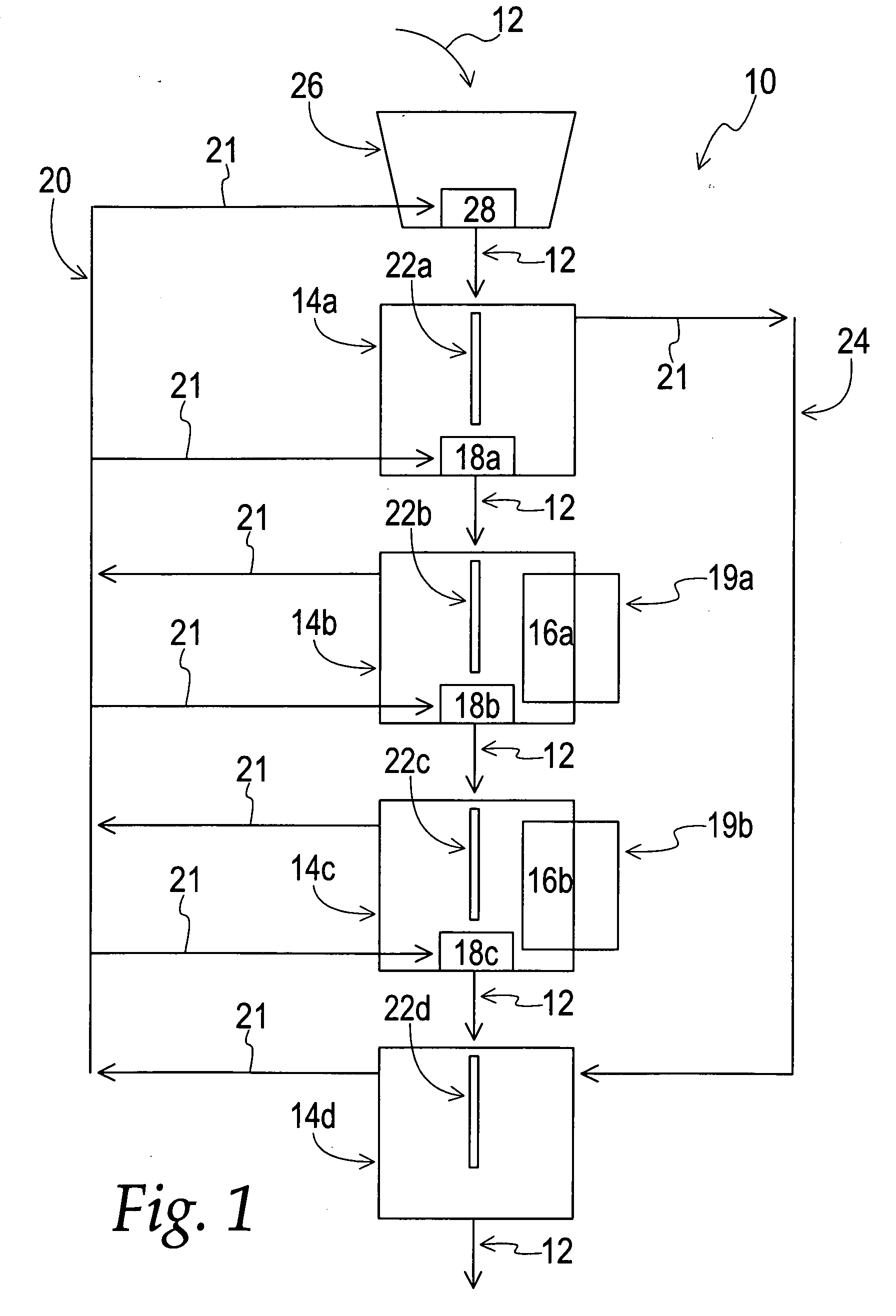

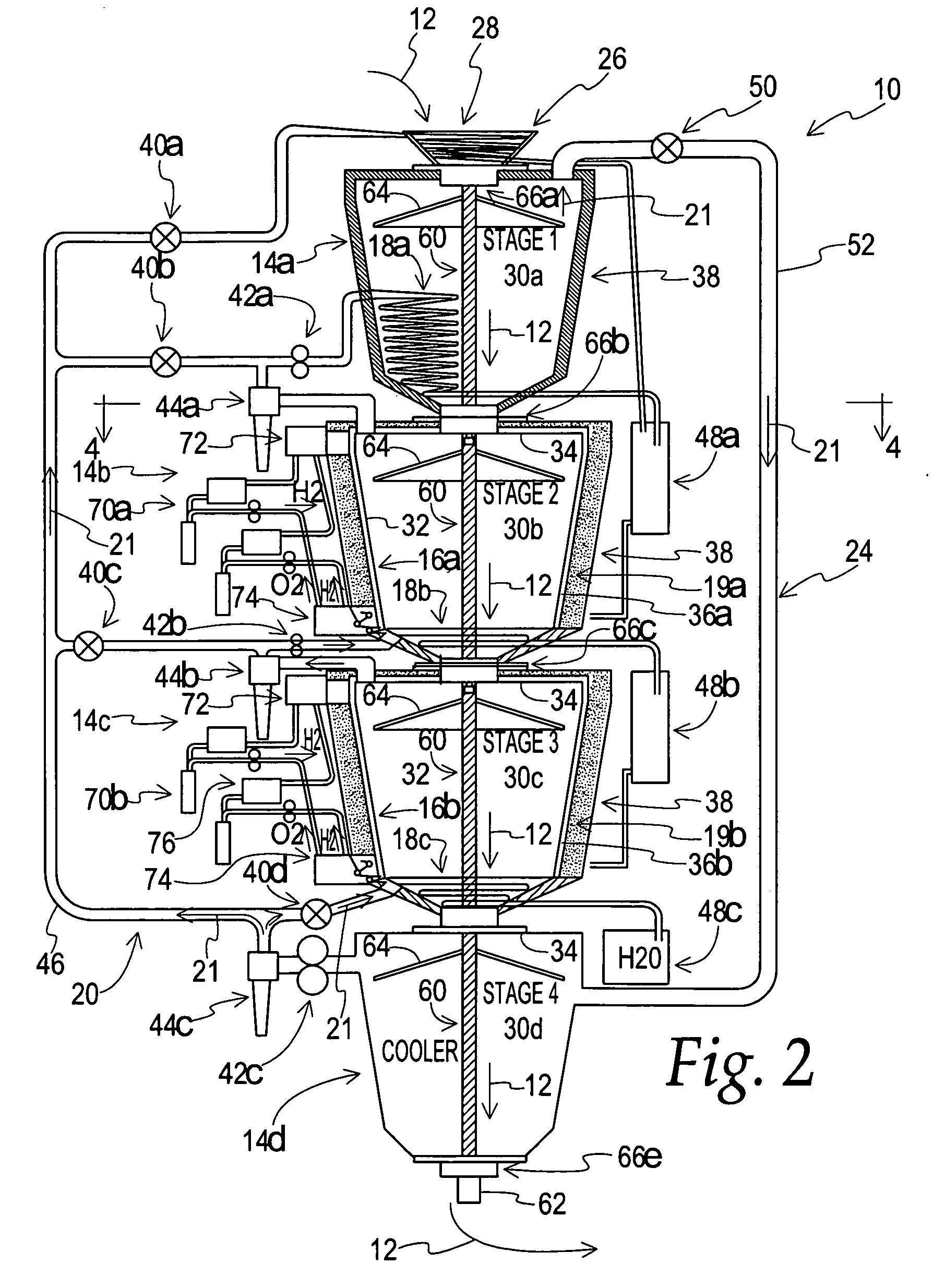

A multi-stage harvest dryer (10) is provided for drying an agricultural harvest product (12), such as, for example, corn, sunflowers, beans, seeds, etc. The dryer (10) includes multiple drying stages (14a-14d) connected in sequence to dry a volume of harvest product (12) passed from one drying stage (14) to the next. Heat exchangers (16a, 16b, 18a, 18b, 18c) are located in the stages (14a-14c) to transfer heat to the harvest product (12) in each of the corresponding stages (14a-14d). The heat exchangers (16a and 16b) are radiant heat exchangers that efficiently heat the harvest product (12) via radiant heat transfer, with heaters (19a, 19b) being provided to maintain the heat exchangers (16a, 16b) within a desired temperature range. The heat exchangers (18a-18c) are condensers that efficiently recycle the heat within the dryer (10) by transferring heat back to the harvest product (12) by condensing water that has been evaporated from the harvest product (12) elsewhere in the dryer (10).

Owner:LAROU ALBERT M & LAROU MILDRED R FAMILY TRUST

Satellite temperature control method allowing rapid responding and multi-orbit adaption

InactiveCN105035365AReduce working conditionsSave research and development costsCosmonautic environmental control arrangementThermal insulationLacquer

The invention provides a satellite temperature control method allowing rapid responding and multi-orbit adaption, wherein by adopting a heat pipe network, reinforcing contact thermal conduction, and spraying a high-emissivity thermal control coating inside a satellite to reinforce in-cabin thermal conduction and radiation heat exchange, a temperature field is distributed uniformly in a cabin; a whole satellite temperature level is adjusted by a compensative electric heater; a nightside of a side plate of the satellite is taken as a major heat dissipation face, the outer surface of the nightside is sprayed with a white paint, and all the other outer surfaces of the satellite body, except for the major heat dissipation face, are covered by multiple layers of thermal insulation assemblies; and components outside the satellite are sprayed with a white paint thermal control coating. A propelling cabin has independent design, wherein the entire outside of the cabin is covered by the multiple layers of the thermal insulation assemblies, a baseplate inside the cabin is covered by the multiple layers of the thermal insulation assemblies, and the propelling cabin is finally integrated with a platform cabin. By integral design of machinery, heat and electricity, the satellite temperature control method allowing the rapid responding and the multi-orbit adaption provided by the invention realizes thermal control requirements of the whole satellite under conditions of a sun-synchronous orbit and an inclined track by the temperature control method.

Owner:SHANGHAI SATELLITE ENG INST

Fused salt energy storage heating heat-exchange system

InactiveCN104266358ALow energy storage medium priceEasy to implementStorage heatersSteam generation using hot heat carriersThermal energyThermal insulation

Disclosed is a fused salt energy storage heating heat-exchange system. An integrated device with a large-capacity and good thermal insulation fused salt tank, an electric heating tube for heating in a fused salt liquid and a radiation heat exchange tube which is mounted in the fused salt liquid and used for heat exchange is applied, thereby, the complicated process of fused salt energy storage and heat exchange application is simplified, and a technology of fused salt energy storage is easy to implement and extremely low in costs; direct heating is performed in the fused salt liquid so that the heating efficiency is high, radiant heat exchange is performed in the fused salt liquid so that the heat exchange efficiency is high, energy is controllable, safety and reliability are achieved, and off-peak electric energy is stored as required; the energy is used for heat supply of residential quarters in winter, the ultra-large fused salt tank is used, and heat energy is stored by the off-peak electric energy at night; high-pressure steam is generated through the heat exchange tube to push a steam turbine to generate electricity during on-peak power utilization, and insufficient power can be supplemented; compared with other energy storing methods, the method of electricity generation by the fused salt energy storage has the advantages that the investment is small, the method can rapidly take effect, the price of energy storing media is low, the source is wide, materials are easy to obtain, and the heat conversion efficiency is high.

Owner:山东省汶上重力机械厂

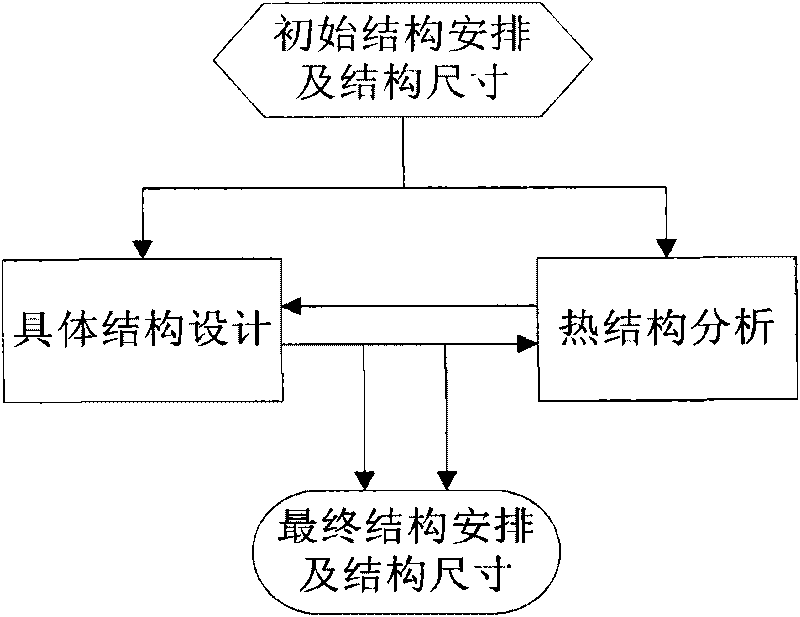

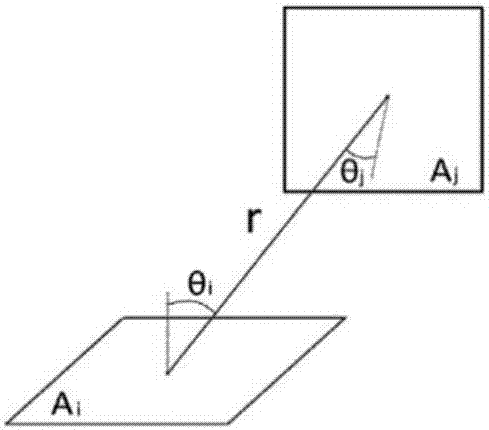

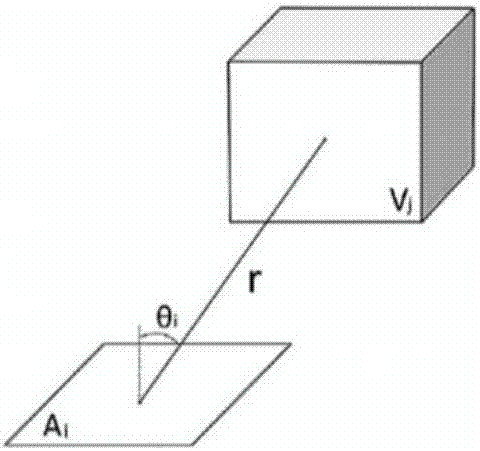

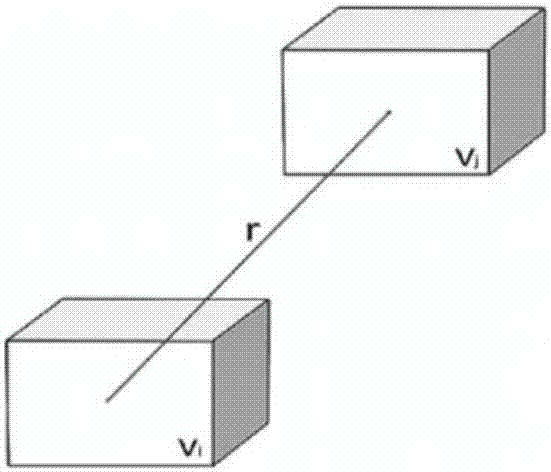

Complex structure radiant heat exchange calculation method

ActiveCN107391894ASolve the problem of self-radiationSmall amount of calculationDesign optimisation/simulationSpecial data processing applicationsEnergy balancingEnergy balance equation

The invention discloses a complex structure radiant heat exchange calculation method, and provides an improved Monte Carlo zone ray tracing method combining a Monte Carlo method, a zone method and a ray tracing method. The improved Monte Carlo zone ray tracing method solves the problem of possible self-zone radiation of a gas zone and is suitable for complex structure radiant heat exchange angle coefficient calculation. Besides, probability simulation statistics and temperature field iterative solution are separated, so that probability simulation of energy beams is omitted and only energy-balance equations need to be solved again when temperature fields change, and calculation amount is decreased.

Owner:CENT SOUTH UNIV

Liquid high-temperature slag granulation and waste heat recovery device

ActiveCN105624347AAchieve recyclingAvoid stickingIncreasing energy efficiencyRecycling and recovery technologiesSlagEnergy recovery

The invention discloses a liquid high-temperature slag granulation and waste heat recovery device. The device comprises a slag falling pipe, a granulation bin and a granulation device body. The granulation bin is in an inverted box shape, and the lower portion of the granulation bin is open. An opening is formed in the top of the granulation bin and used for allowing the slag falling pipe to stretch in. The inner wall of the granulation bin is a heat exchange surface used for absorbing heat dissipated by liquid high-temperature slag during granulation. The granulation device body is arranged under the slag falling pipe. The high-temperature slag flows into the granulation bin through the slag falling pipe, falls onto the granulation device body, is granulated by the granulation device body rotating at a high speed and meanwhile conducts radiant heat exchange on the heat exchange surface laid on the granulation bin under the action of ring air surrounding the granulation device body, so that granulation and partial energy recovery of the liquid high-temperature slag are realized.

Owner:SUZHOU HAILU HEAVY IND

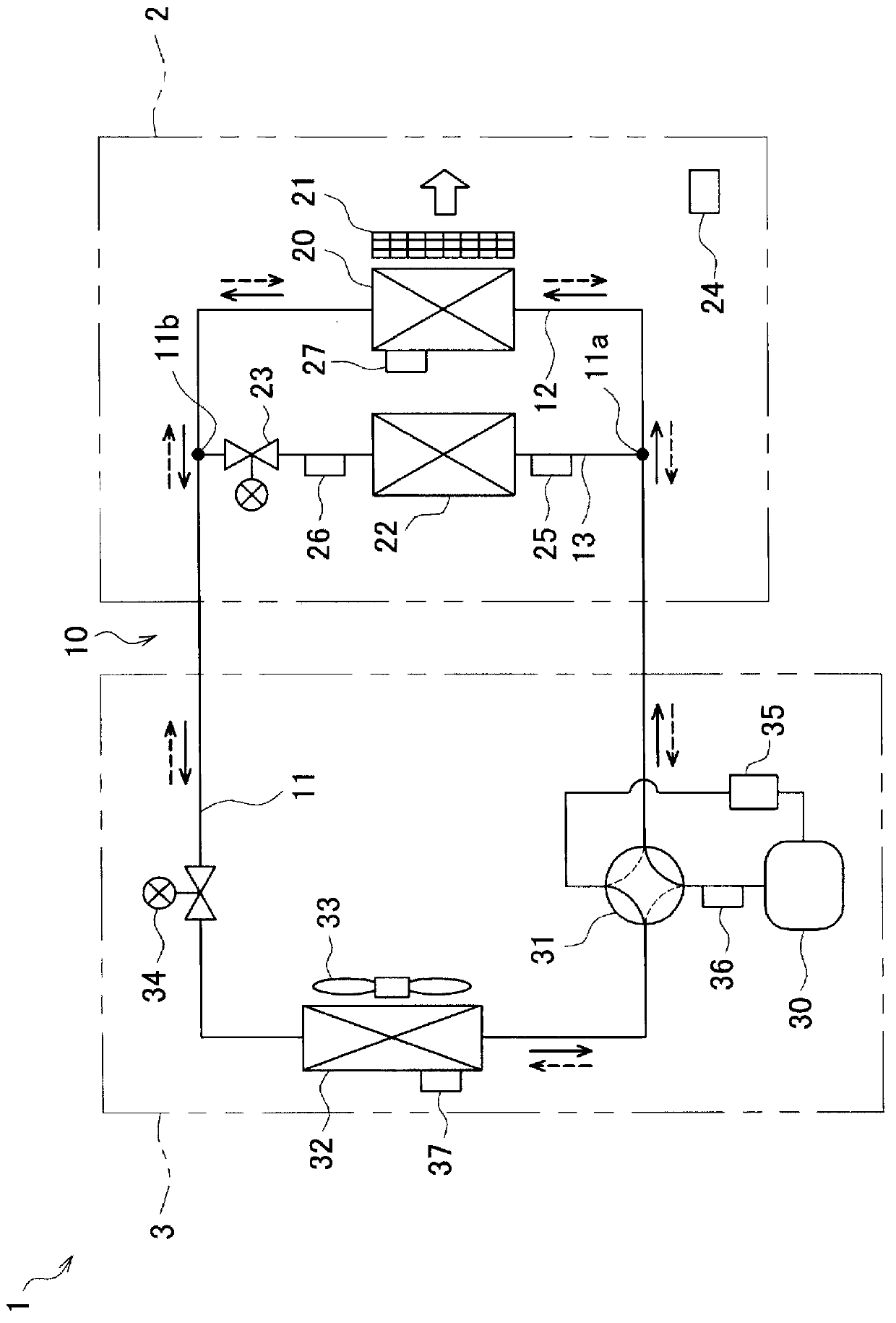

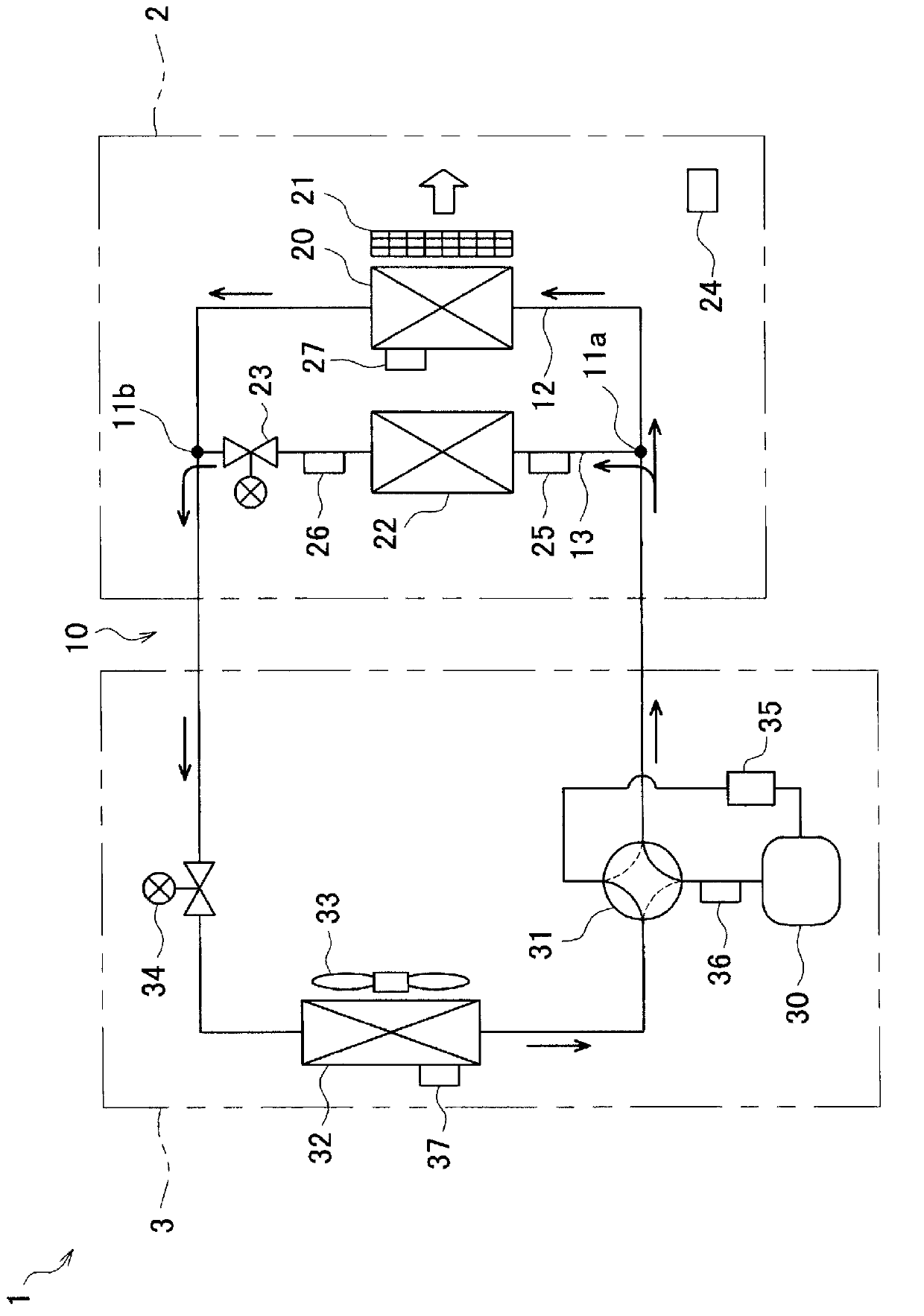

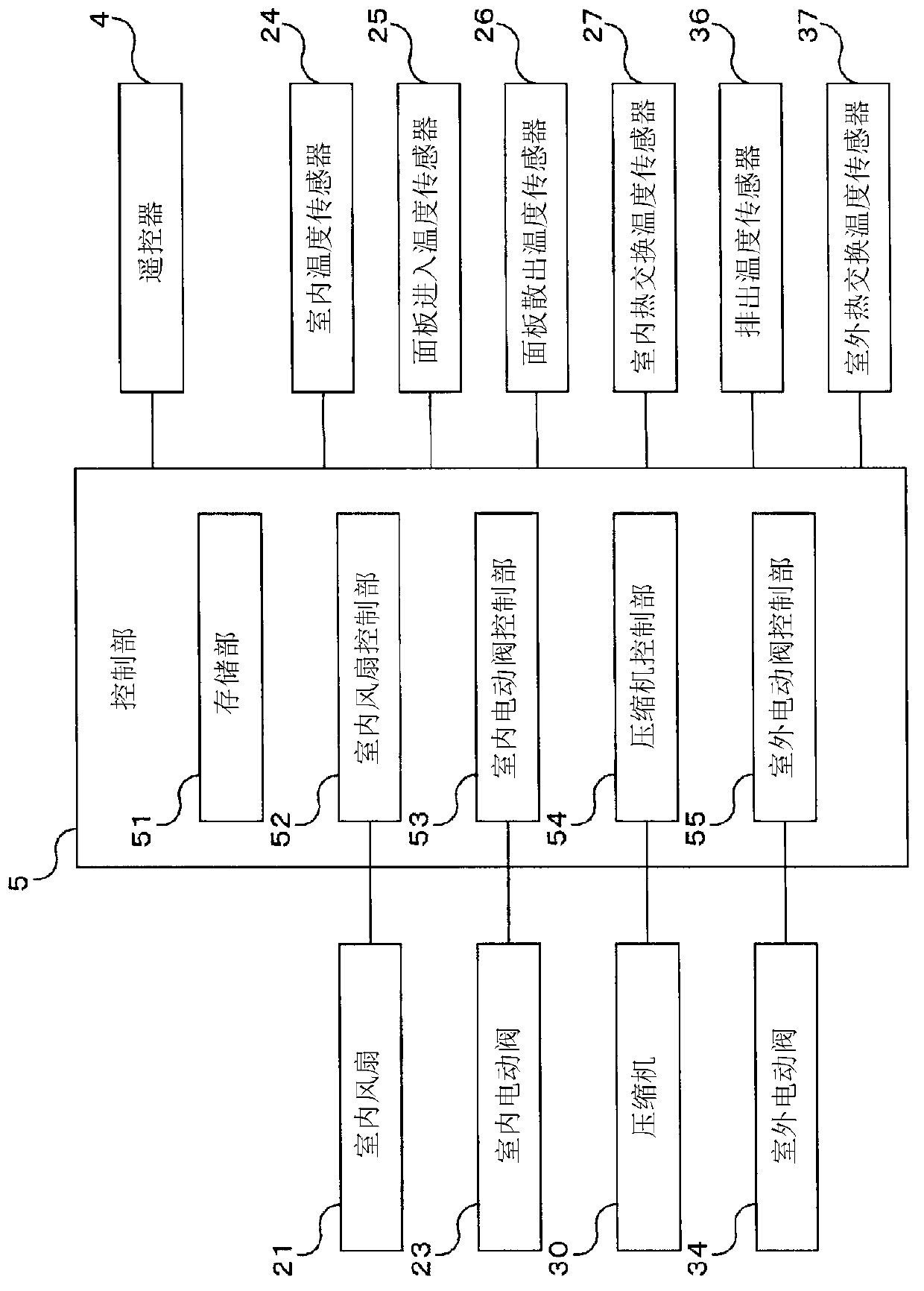

Air conditioner

ActiveCN103328895AReduce the temperatureReduce temperature differenceMechanical apparatusSpace heating and ventilation safety systemsEngineeringRadiant heat

In order to improve comfort, this air conditioner is provided with a refrigerant circuit having a compressor, an indoor heat exchanger, a radiant heat exchanger, a pressure reduction mechanism, and an outdoor heat exchanger. The indoor heat exchanger is disposed inside an indoor unit in such a manner as to face an indoor fan, and the radiant heat exchanger is disposed on the outer surface of the indoor unit. In addition, the air conditioner has an indoor electrically-operated valve for adjusting the amount of refrigerant supplied to the radiant heat exchanger. The air conditioner is controlled in such a manner that, when a refrigerant is flushed through the indoor heat exchanger to carry out warm-air heating, and the refrigerant is flushed through the radiant heat exchanger to carry out radiant heating, the opening of the indoor electrically-operated valve becomes larger after the frequency of the compressor drops.

Owner:DAIKIN IND LTD

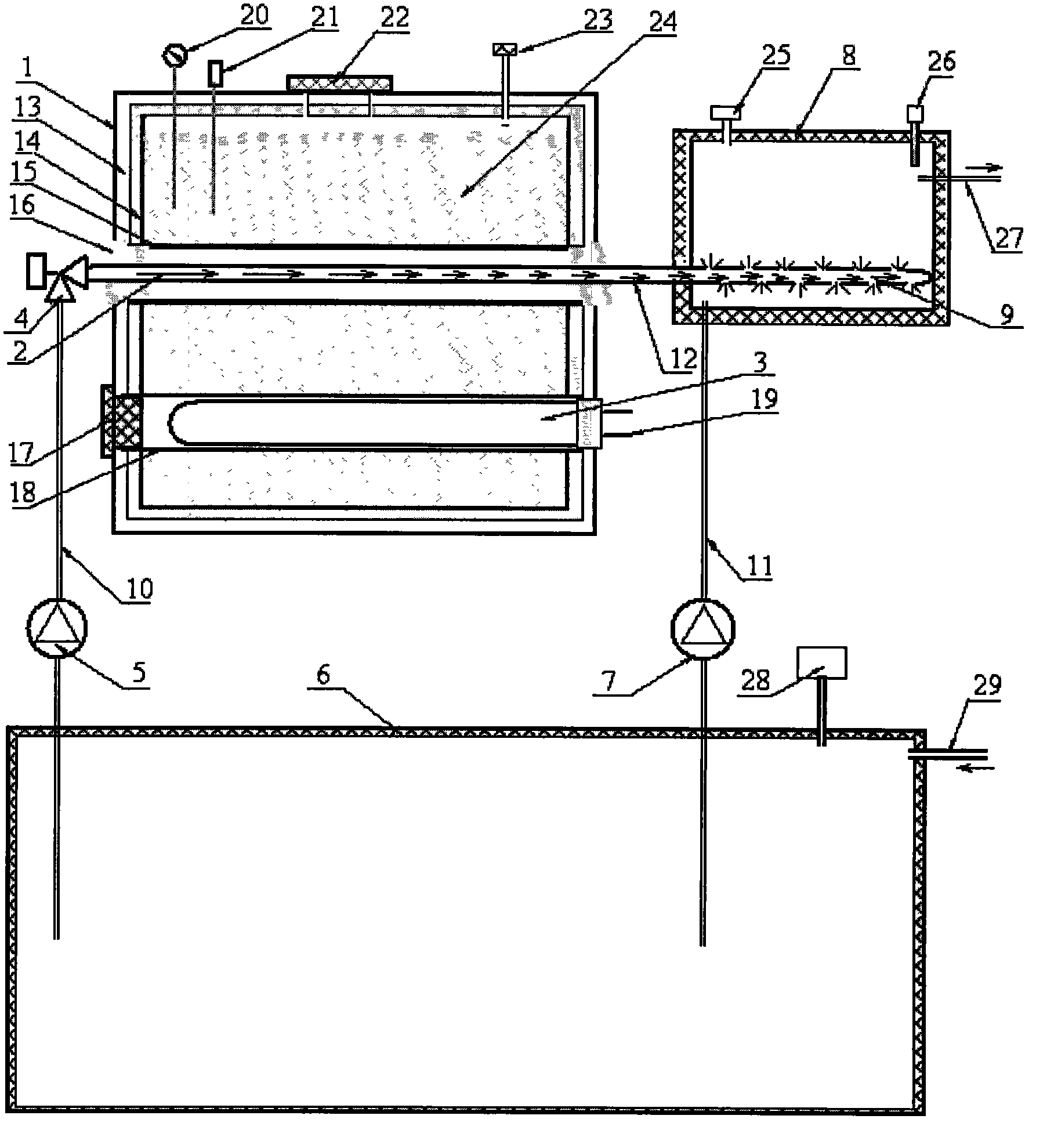

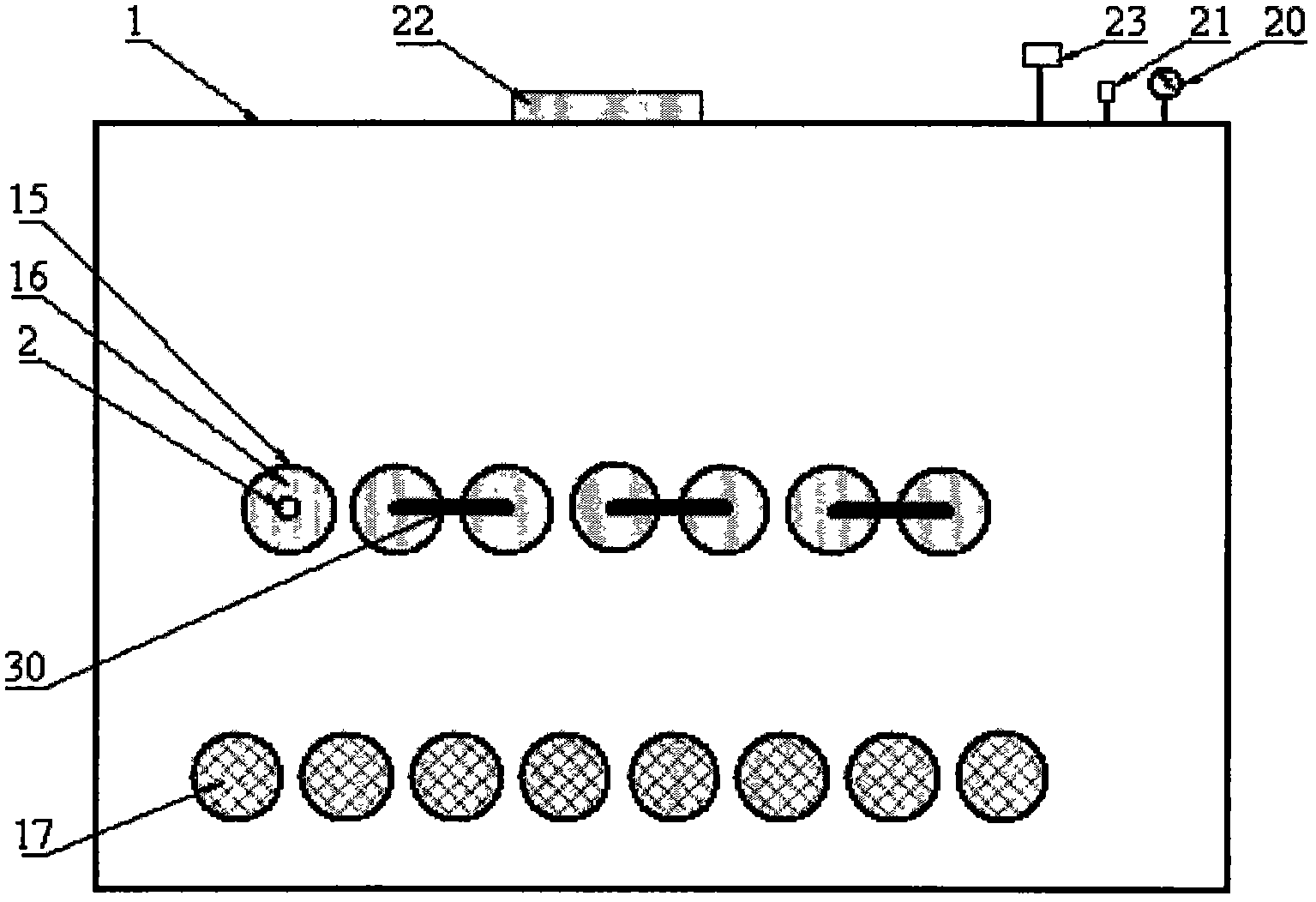

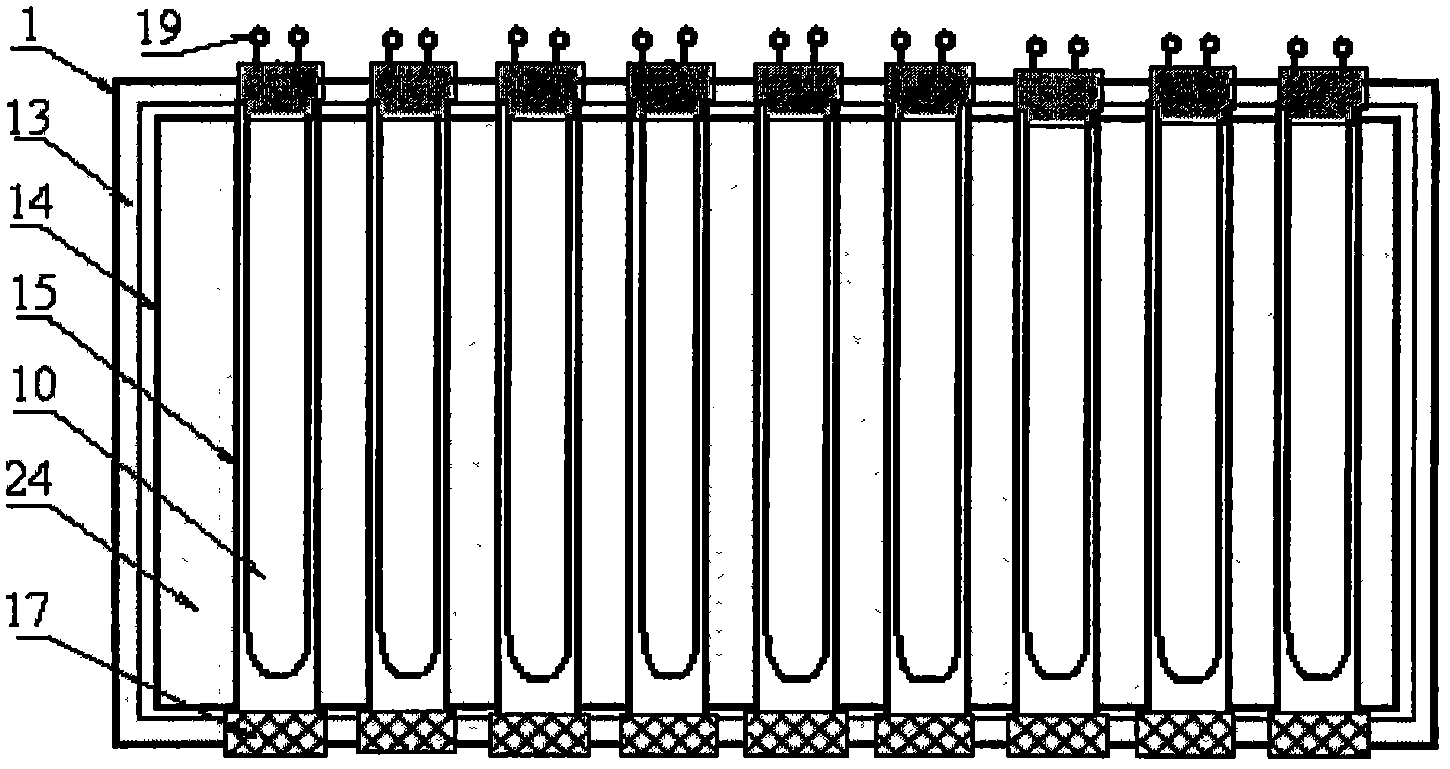

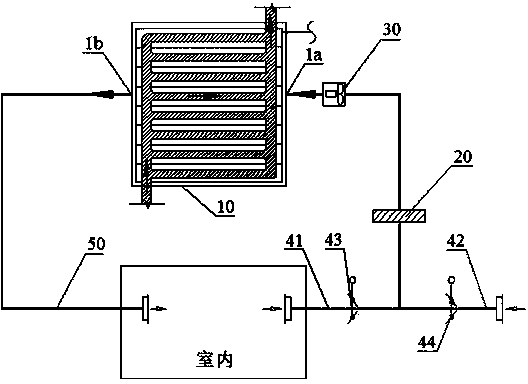

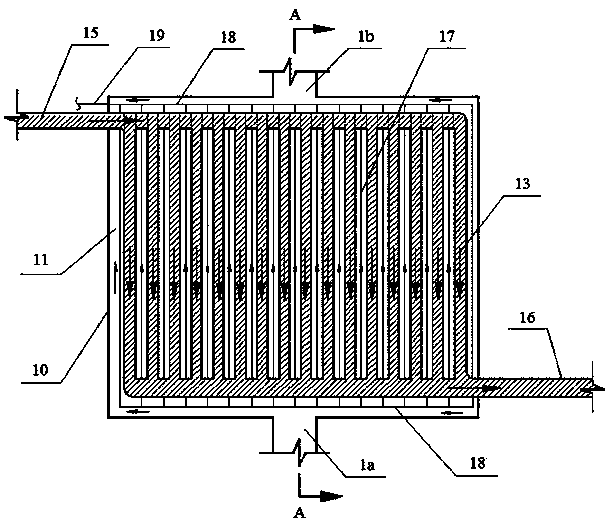

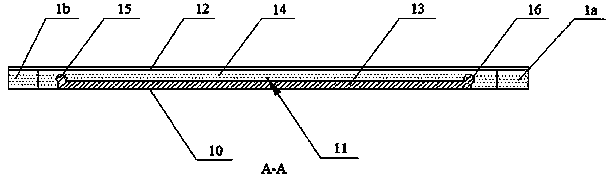

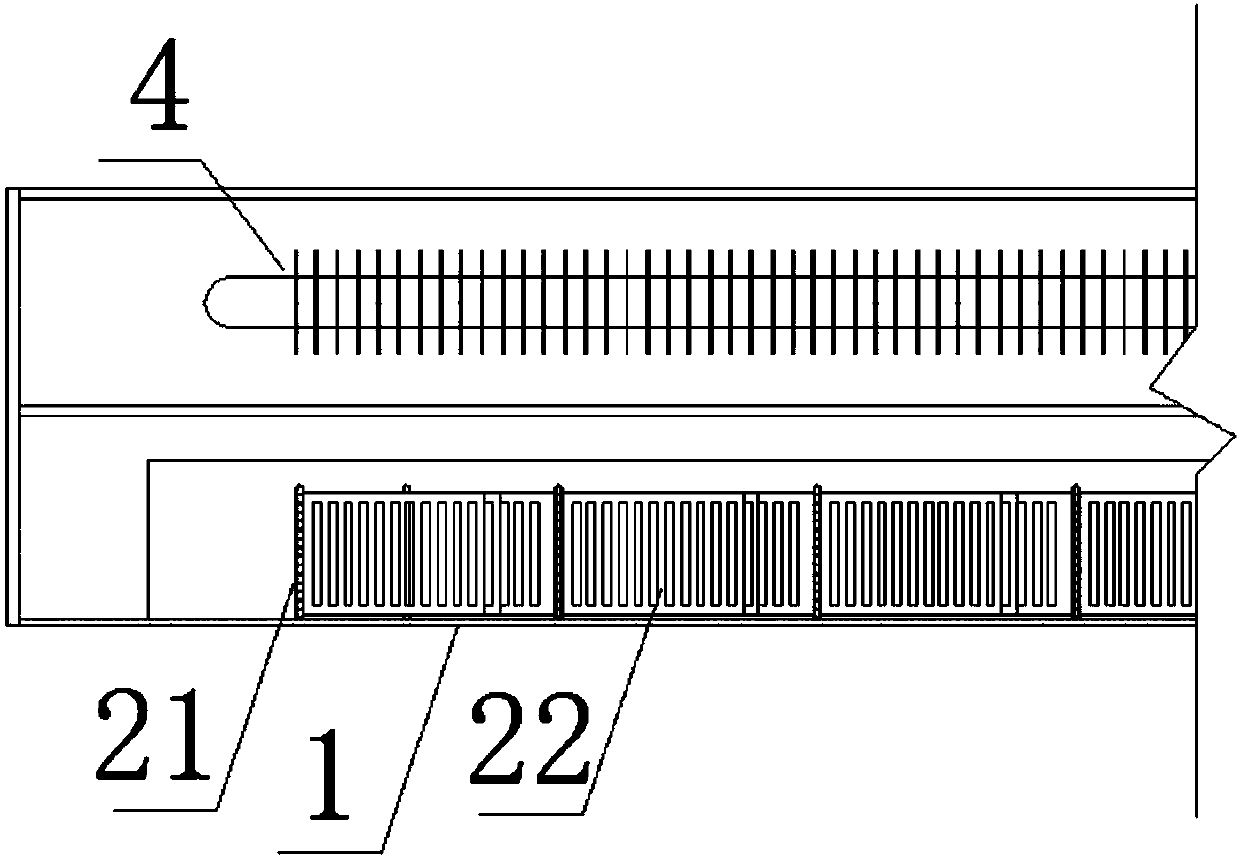

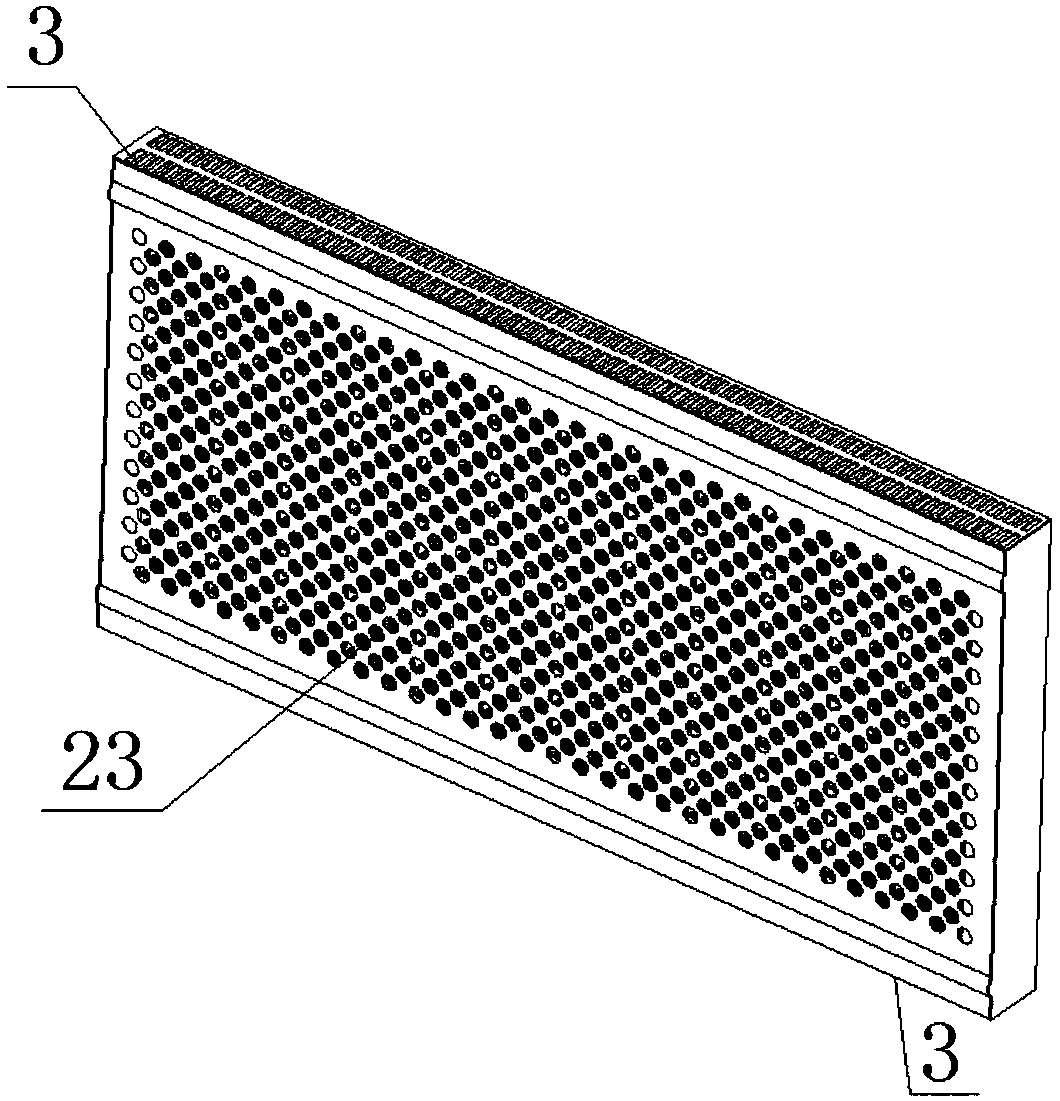

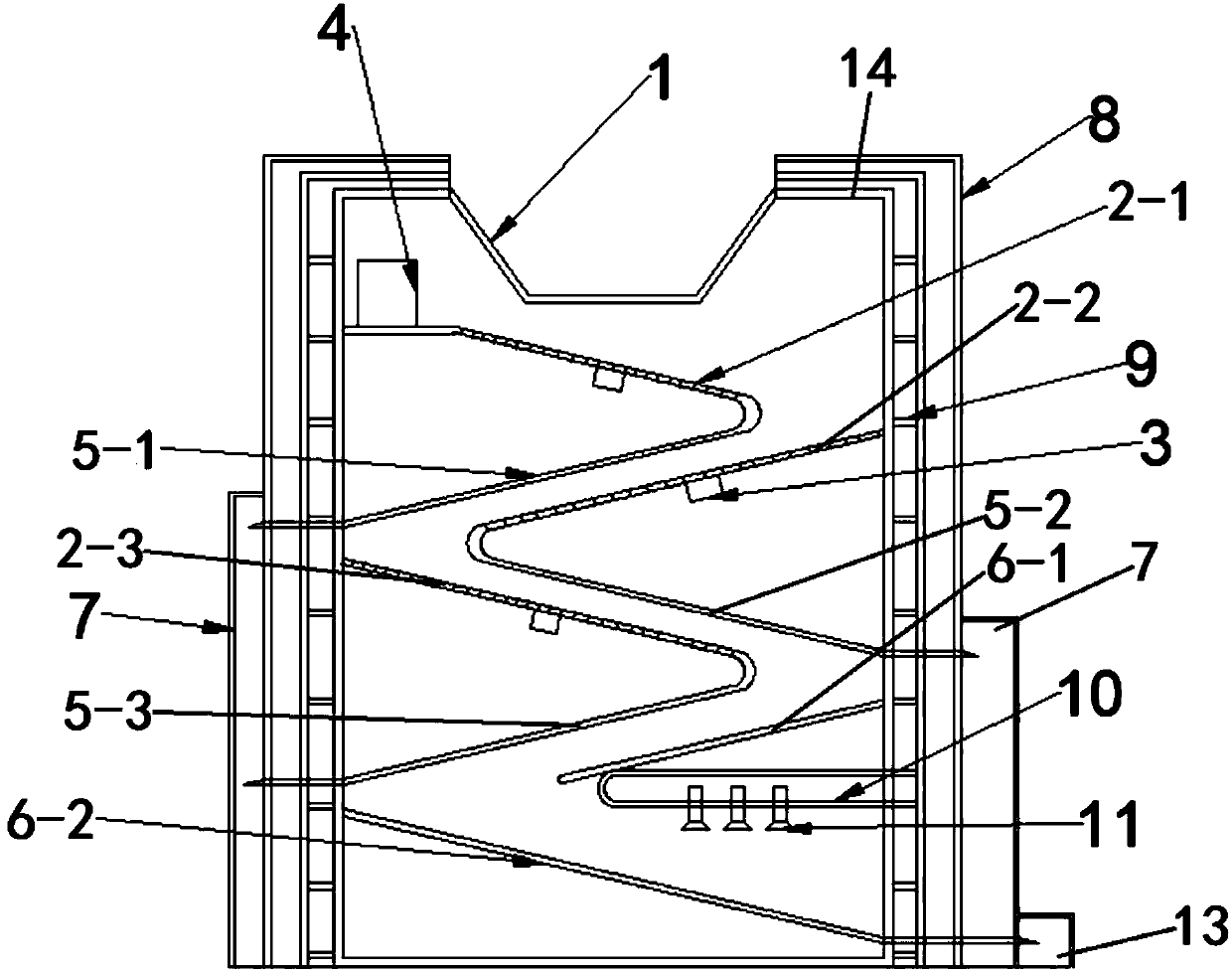

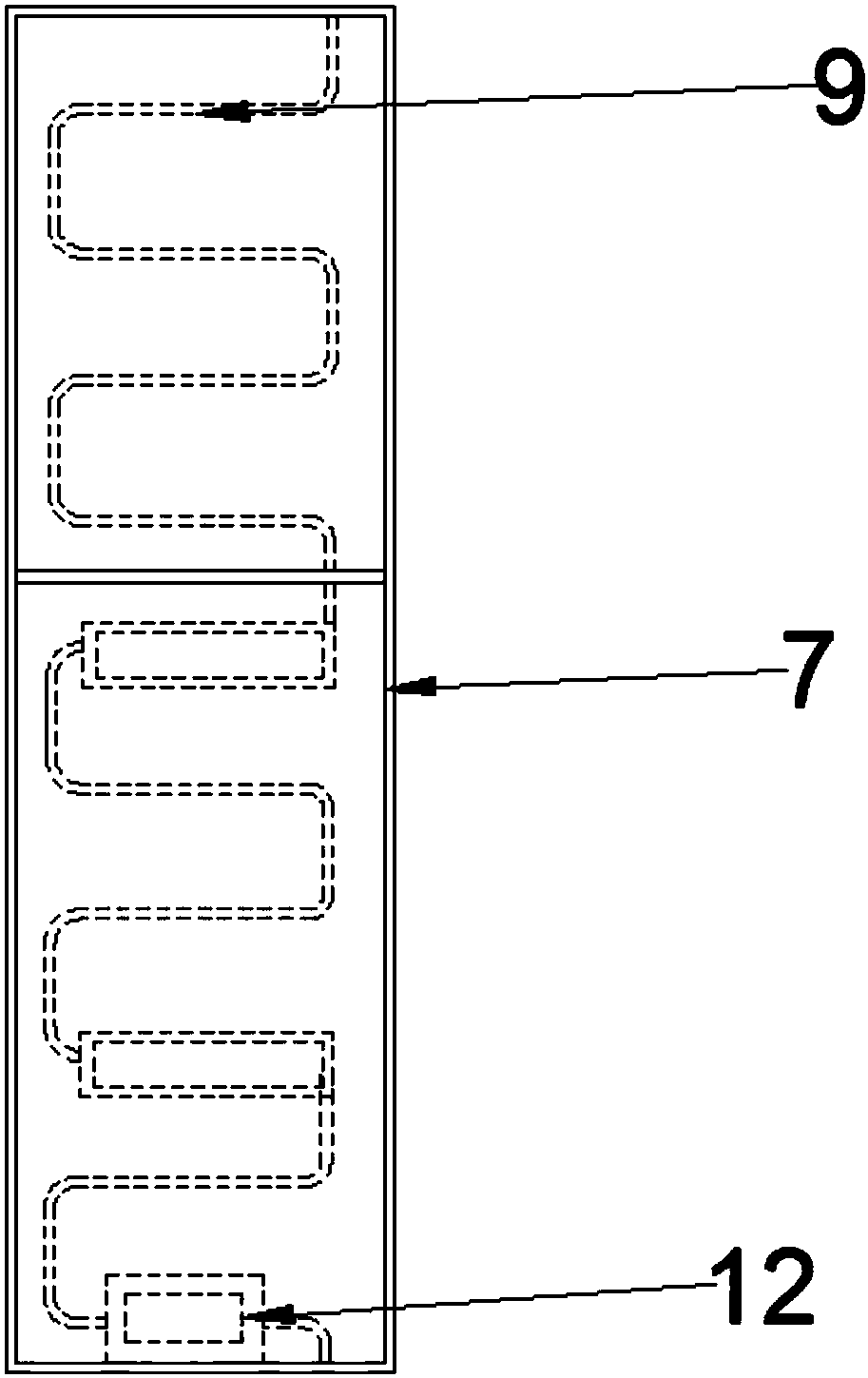

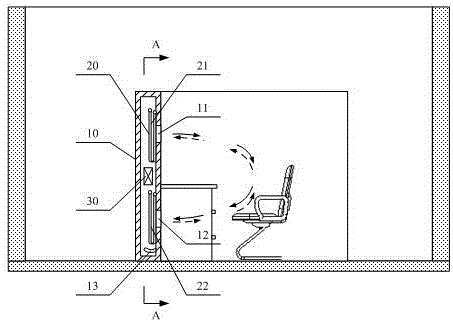

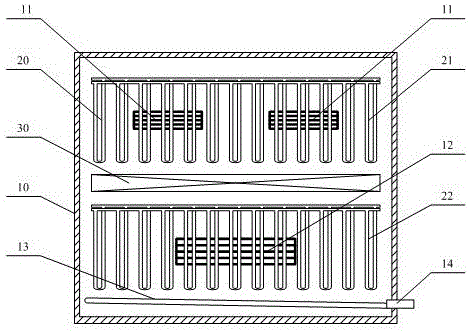

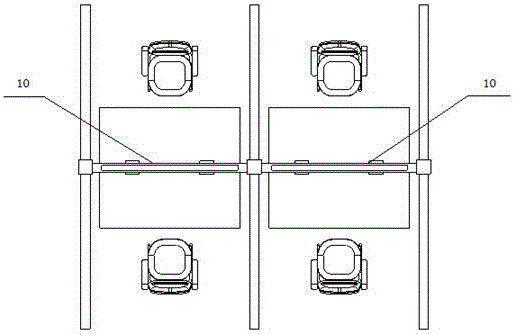

Active radiant panel heat exchange system and heat exchange processing method thereof

ActiveCN103982968AReduce initial investmentMultifunctionalDucting arrangementsCondensate preventionThermodynamicsFresh air

The invention provides an active radiant panel heat exchange system and a heat exchange processing method thereof. The active radiant panel heat exchange system integrates radiant heat exchange and active heat convection. In the process of implementing the heat exchange processing method, heat exchange can be performed via radiation and environment, and a fan can be utilized to actively force the active radiant panel heat exchange system to perform heat convection, so that air can be heated / cooled, temperature difference between supplying water and returning water of a radiant panel can be enlarged, heating efficiency of the active radiant panel heat exchange system is improved, cool and heat supplying capability of the radiant panel are enhanced, the problems that the radiant panel system in the prior art is limited in cool and heat supplying capability and difficult to popularize in use are solved, certain humidity load can be eliminated when fresh air and return air are processed, and the defect that traditional radiant systems cannot dehumidify is overcome. The active radiant panel heat exchange system and the heat exchange processing method thereof have the advantages that a novel resolution is provided for a radiant panel air-conditioning system, and a broad marketing application prospect is realized.

Owner:CHONGQING UNIV

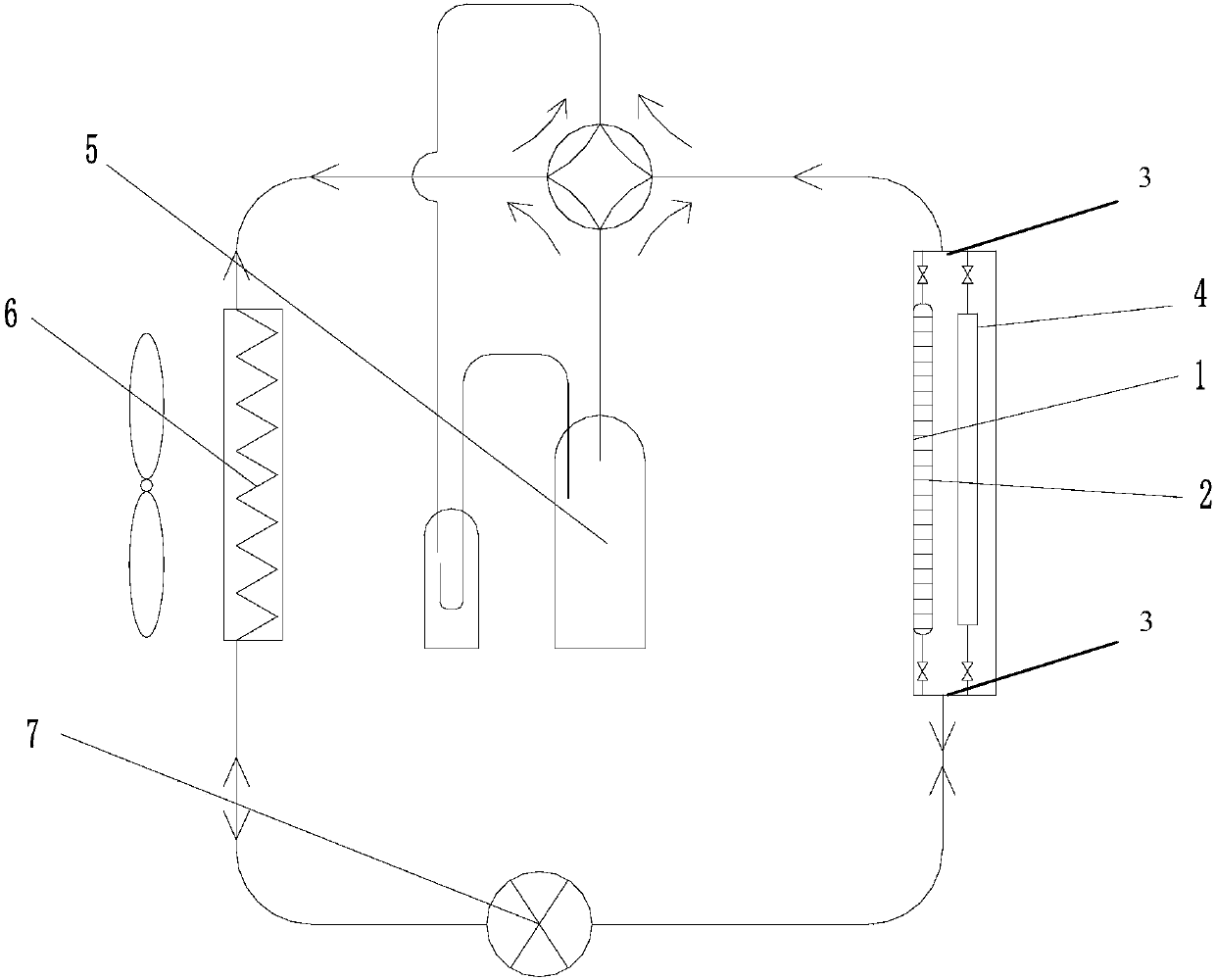

Radiant air conditioner indoor unit, air conditioning system and control method

PendingCN107763732AImprove comfortRealize the appearance beautificationMechanical apparatusSpace heating and ventilation safety systemsNatural convectionNatural convection heat transfer

The invention provides a radiant air conditioner indoor unit, an air conditioning system and a control method. The radiant air conditioner indoor unit comprises a radiant panel and a microchannel heatexchanger. The radiant panel is attached to the side face, facing indoors, of the microchannel heat exchanger. According to the radiant air conditioner indoor unit, the air conditioning system and the control method provided by the invention, by arranging the microchannel heat exchanger and the radiant panel, radiant heat exchange and natural convection heat exchange can be achieved, the user comfort is improved, in addition, by arranging the radiant panel, the radiation efficiency and comfort can be improved, the appearance of the microchannel heat exchanger is beautified, the mounting and later maintaining difficulty is lowered, due to the fact that a coolant is directly introduced into a room, the temperature range for heat exchange is enlarged, by arranging a thermal infrared imager and an image collecting device, the frequency of a compressor and / or the opening degree of an adjusting valve can be intelligently adjusted according to the detected indoor temperature, body temperature of a user and physical state of the user, the purpose of intelligent control is achieved, and by arranging a second heat exchanger, the radiant heat exchange efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

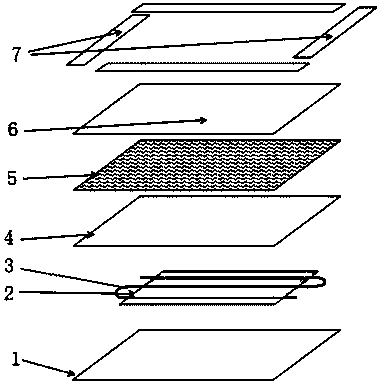

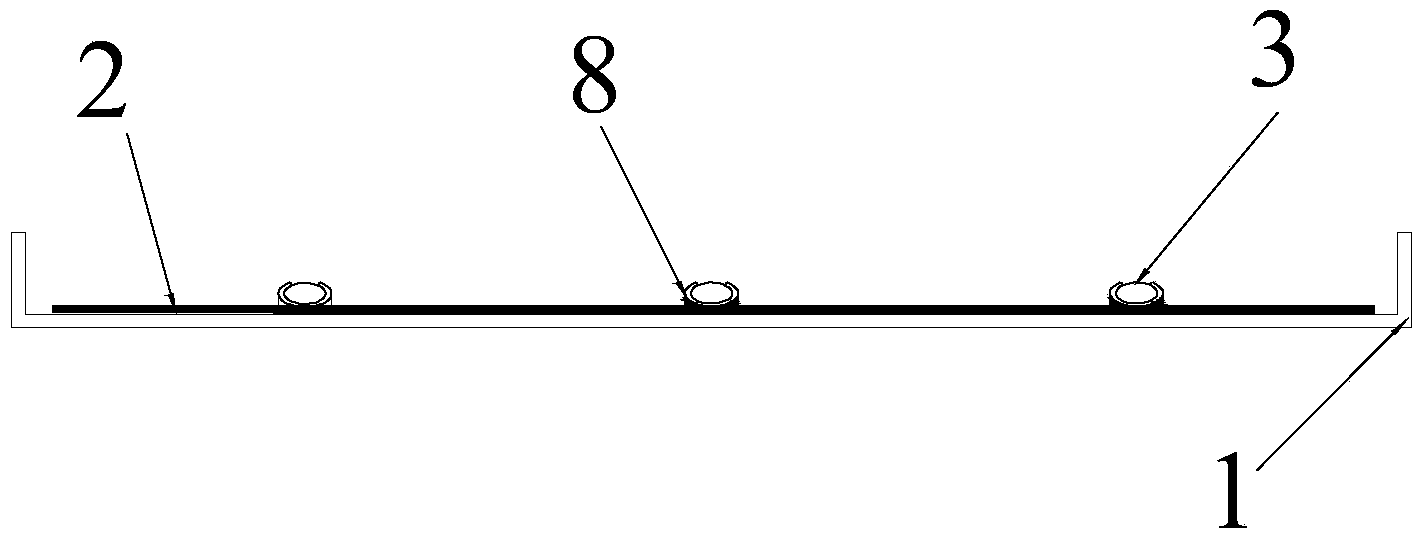

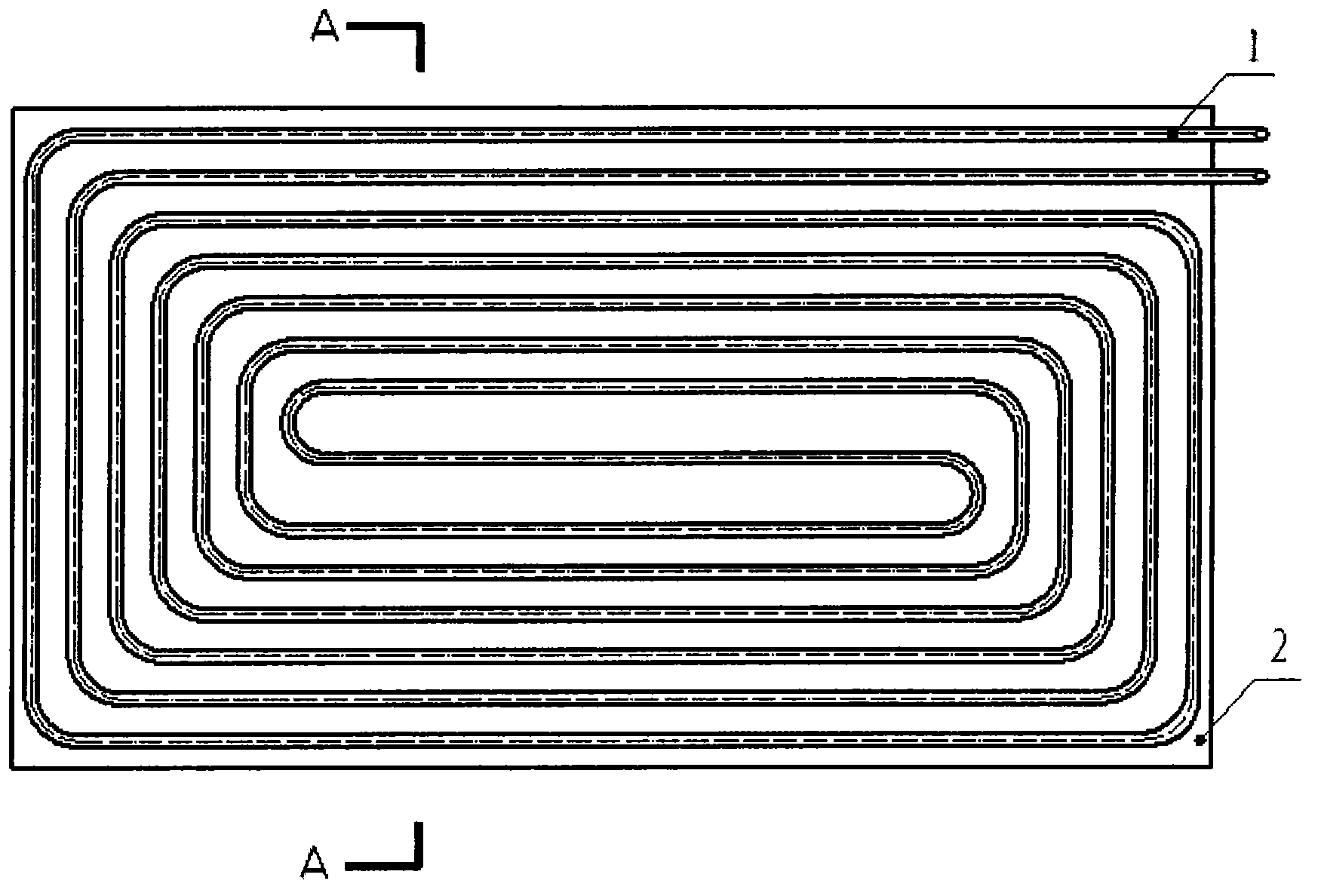

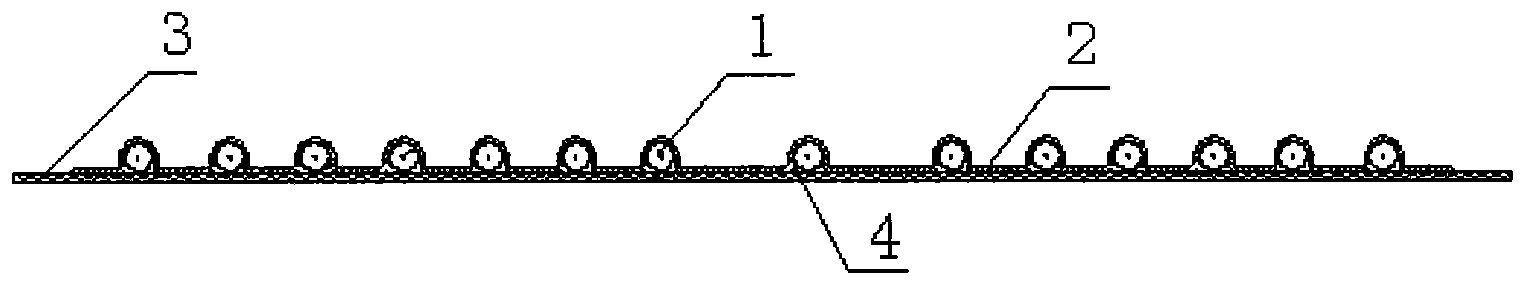

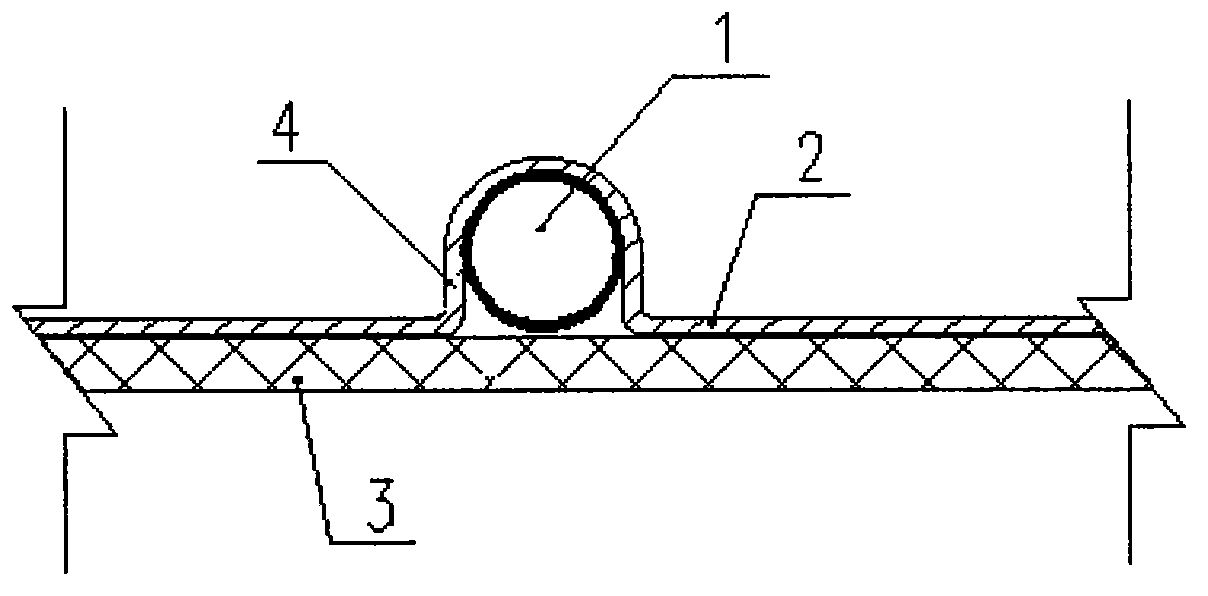

Radiant heat exchange plate and central air conditioning system

InactiveCN104390263AImprove heat transfer effectNot easy to condensationCondensate preventionLighting and heating apparatusEngineeringHeat transfer efficiency

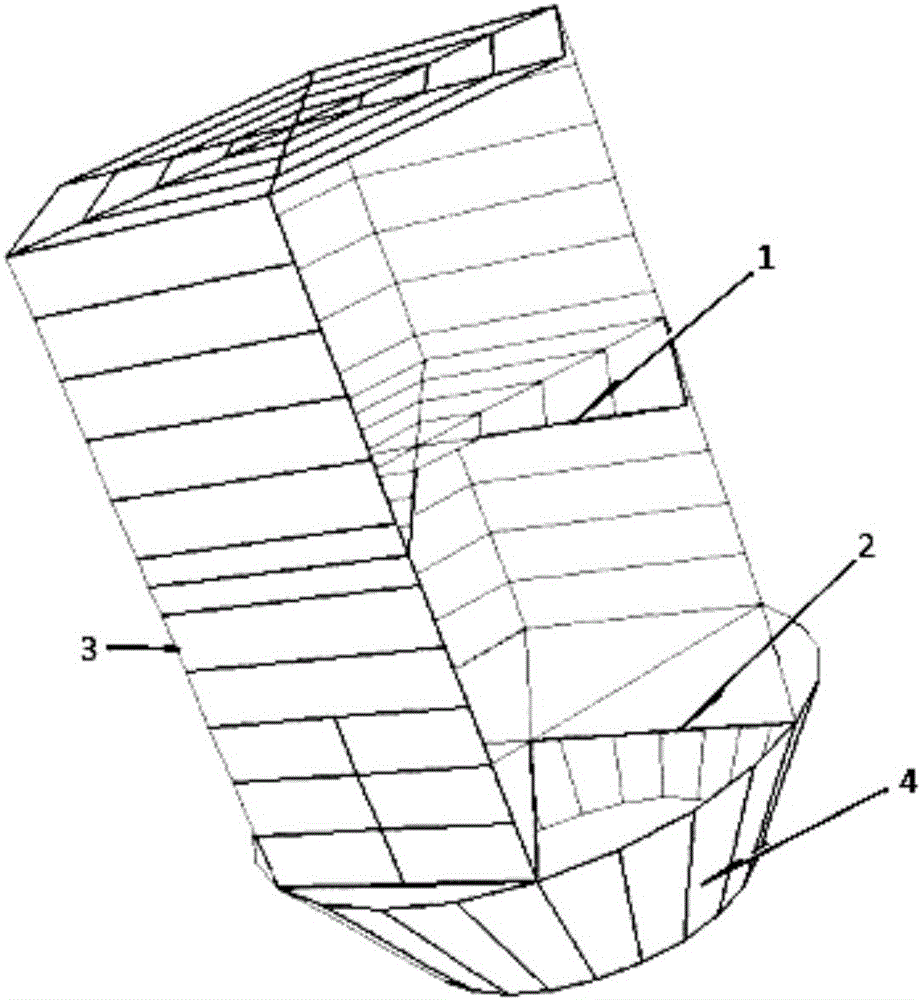

The invention discloses a radiant heat exchange plate and a central air conditioning system. The radiant heat exchange plate comprises a radiation panel (1), a heat exchange part and a heat preserving layer, wherein the radiation panel is a gypsum panel or a stone panel; the heat exchange part is arranged on the radiation panel (1), and comprises integral heat transfer fins (2) attached onto the radiation panel (1) and heat exchange tubes (3) which are arranged on the heat transfer fins (2) and are in close contact with the heat transfer fins (2); the heat preserving layer covers the heat exchange part. The radiant heat exchange plate according to the invention has the advantages that the surface temperature field is uniform, condensation does not easily occur and the radiant heat transfer amount is great.

Owner:GREE ELECTRIC APPLIANCES INC

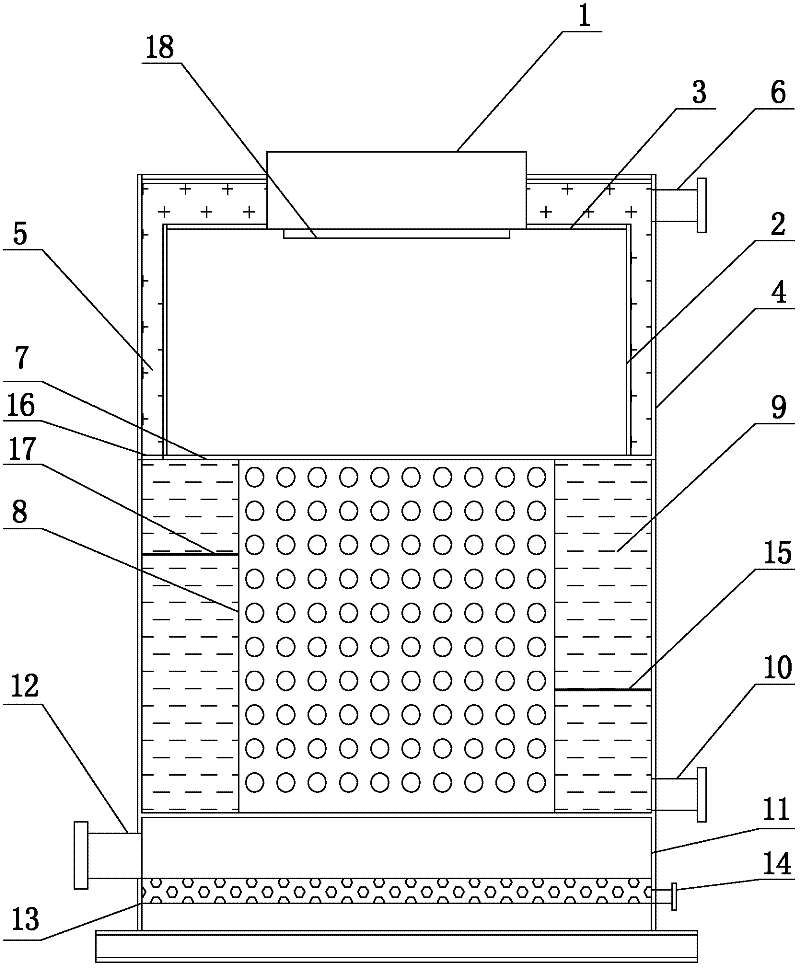

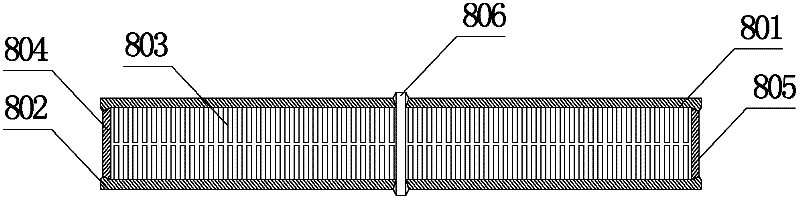

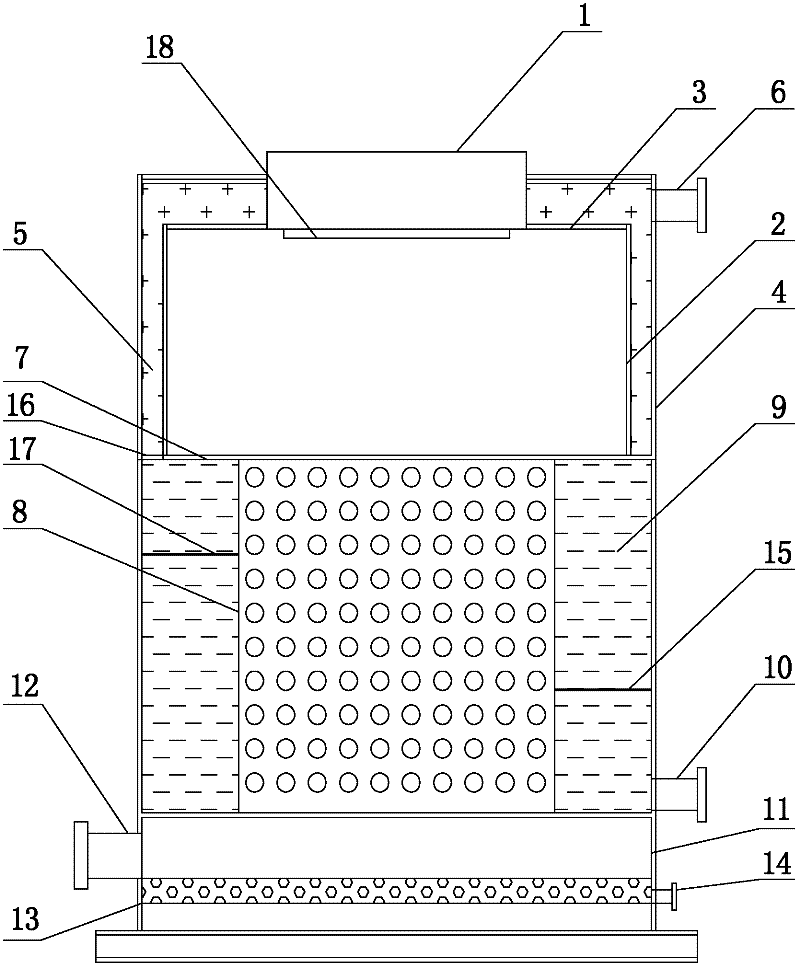

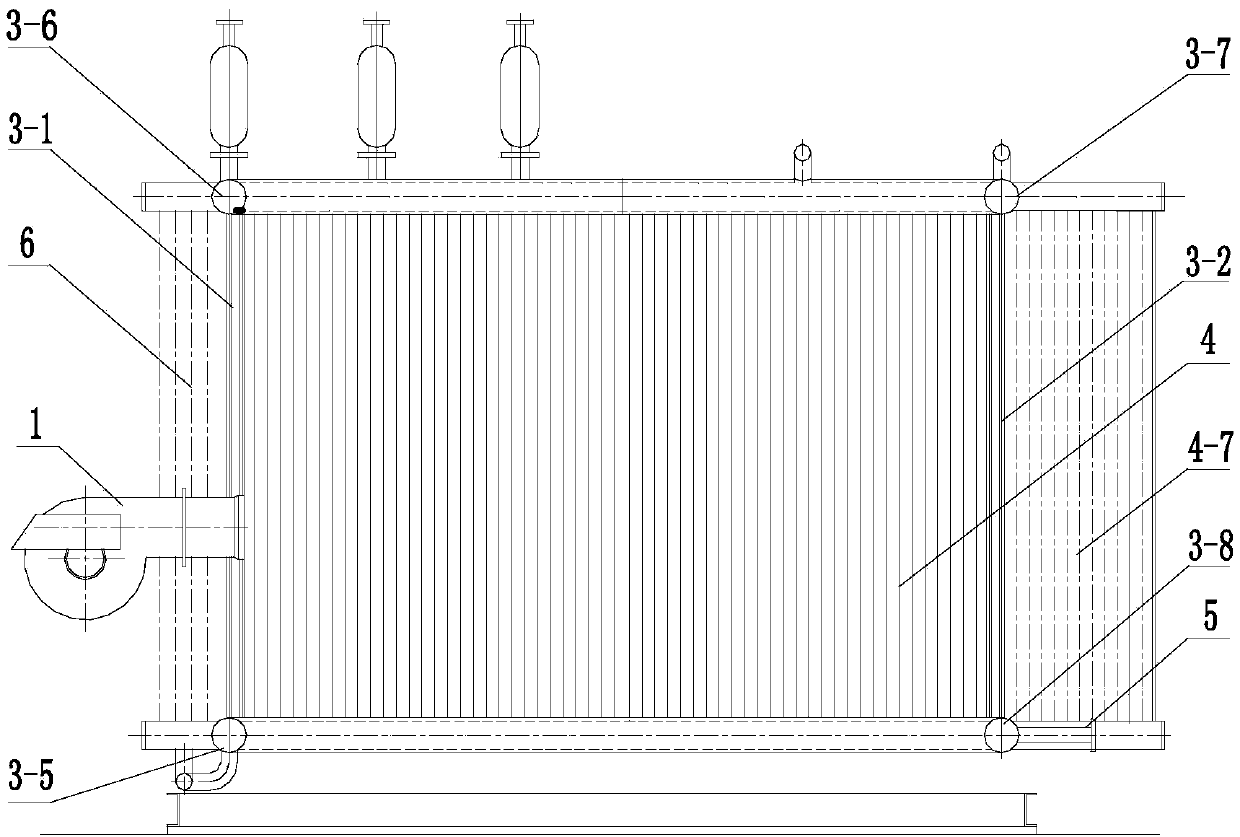

High-temperature coal slag classification screening and waste heat recovery device

The invention belongs to the technical field of waste slag treatment, and provides a high-temperature coal slag classification screening and waste heat recovery device. The device comprises a coal slag classification screening mechanism and a coal slag waste heat recovery mechanism. The coal slag waste heat recovery mechanism wraps the periphery of a coal slag classification screening shell. The coal slag classification screening mechanism automatically carries out classification screening on coal slag through the gravity settling action. Small-particle fine coal slag is screened to slide downto a fine coal slag collection chamber from a fine coal slag recovery ramp, and large-particle coarse coal slag rolls to a coarse coal slag collection chamber from a filter screen ramp and a coarse coal slag recovery ramp. The coal slag classification screening mechanism can screen the coal slag into the coarse coal slag and the fine coal slag; and meanwhile, after the coal slag enters the devicefrom a feeding bin, heat of high-temperature furnace slag is transmitted to a heat exchange pipeline in a radiant heat exchange manner, and the waste heat utilization efficiency can be improved. Thedevice can effectively overcome the technical defect of lacking a device capable of achieving efficient and environment-friendly recovery treatment of the coal slag at present.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

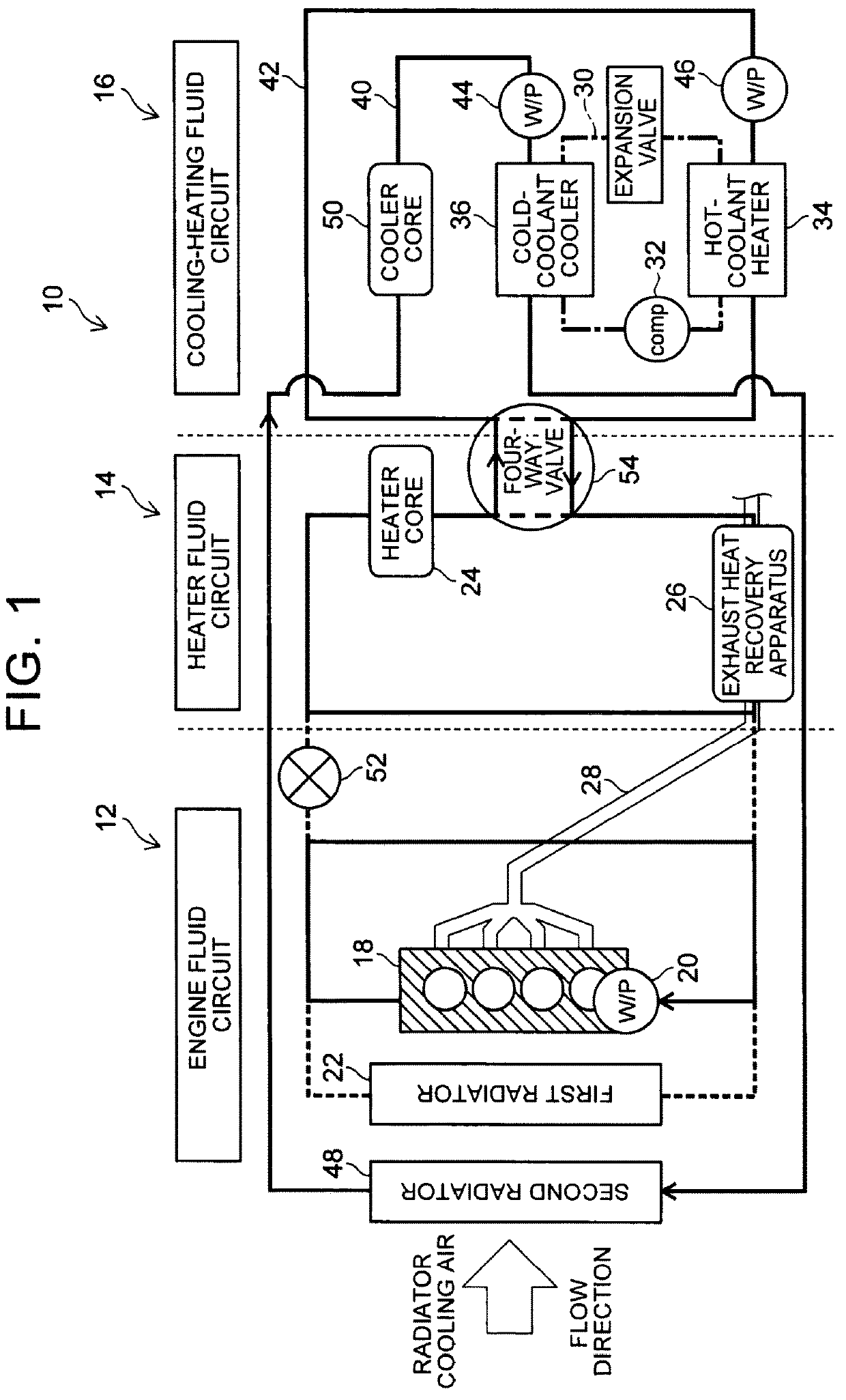

Vehicle-mounted heat utilization device

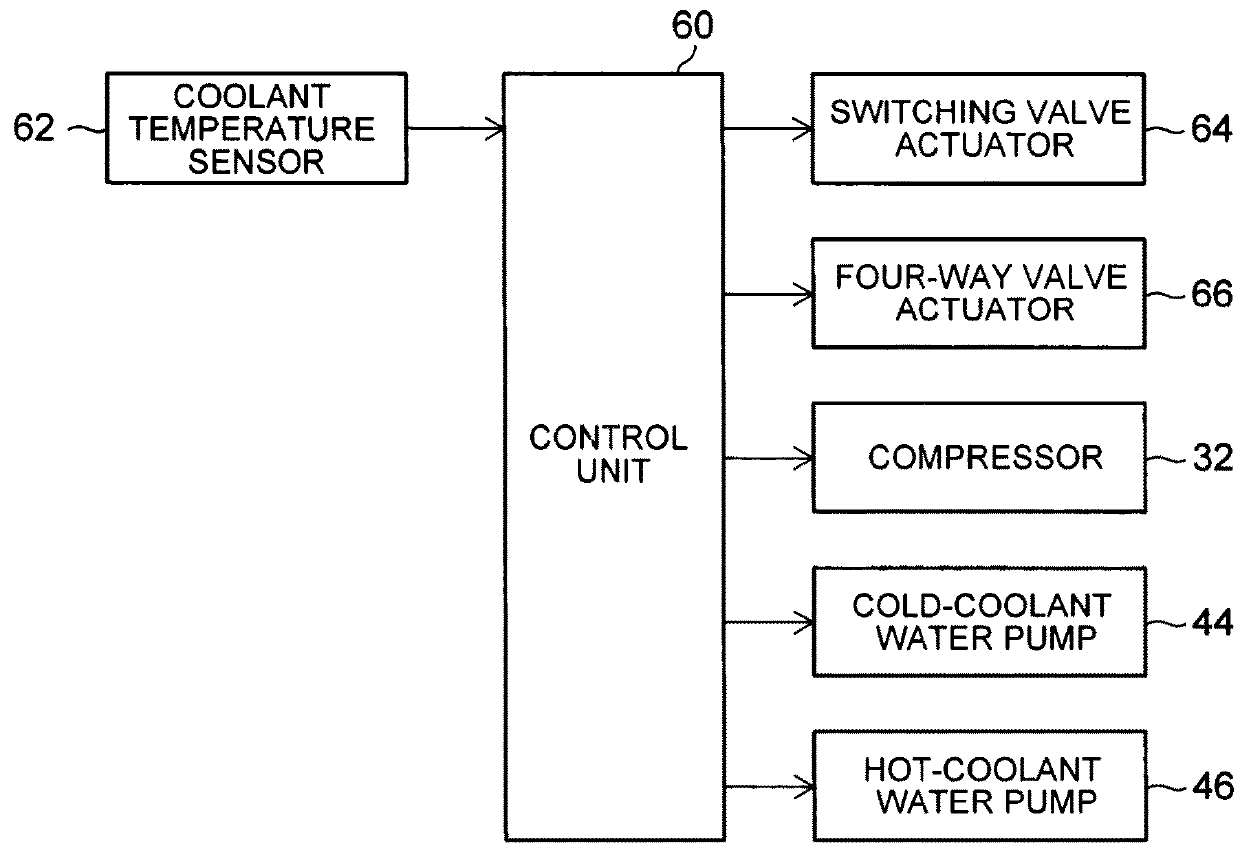

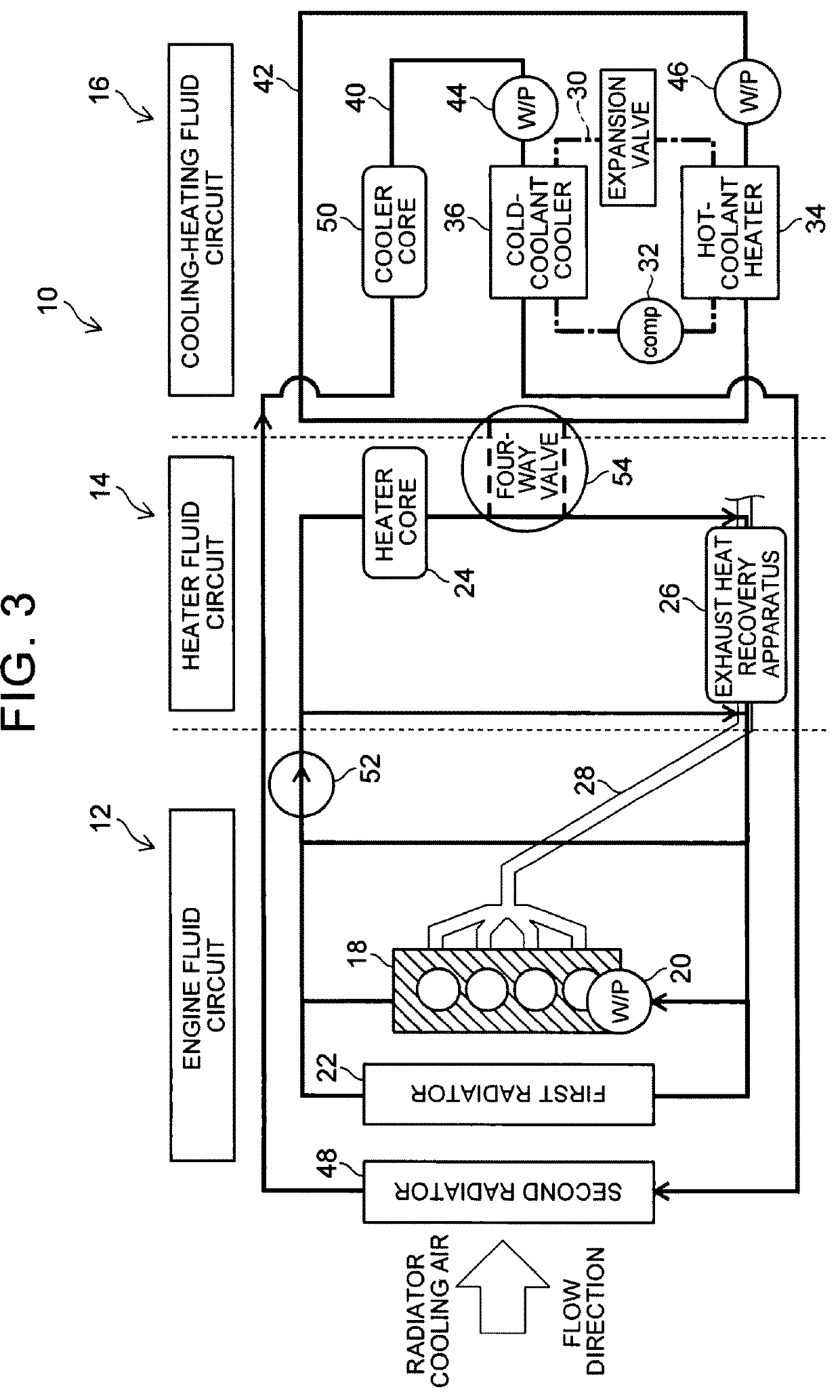

InactiveUS20180272840A1Without increasing warmup operation timeHeating fastAir-treating devicesVehicle heating/cooling devicesEngineeringRefrigeration

A vehicle-mounted heat utilization device (10) includes: an engine fluid circuit (12) in which fluid circulates to cool an engine (18); a heater fluid circuit (14) that passes through an exhaust heat recovery apparatus (26) that recovers a heat of exhaust gas (28) and a vehicle-interior heat exchanger (24) for radiating a heat of the fluid into a vehicle interior; a cooling-heating fluid circuit (16) that passes through a radiating heat exchanger (34), the radiating heat exchanger being included in a refrigeration cycle (30) in which refrigerant is compressed by a compressor (32) and the compressed refrigerant is expanded; a first switching unit (52) that is configured to selectively switch a state of the engine fluid circuit (12) and the heater fluid circuit (14) between a connected and a disconnected state; a second switching unit (54) that is configured to selectively switch a state of the heater fluid circuit (14) and the cooling-heating fluid circuit (16) between a connected state and a disconnected state.

Owner:TOYOTA JIDOSHA KK +1

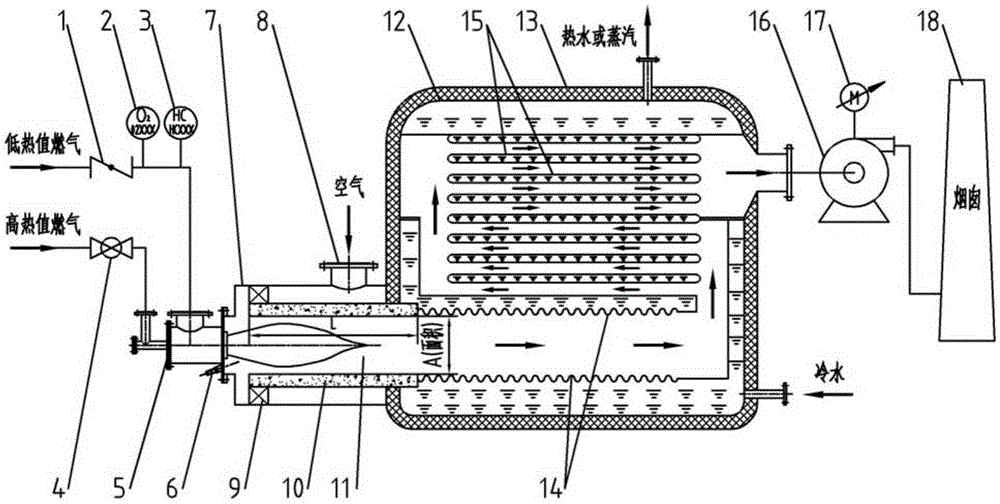

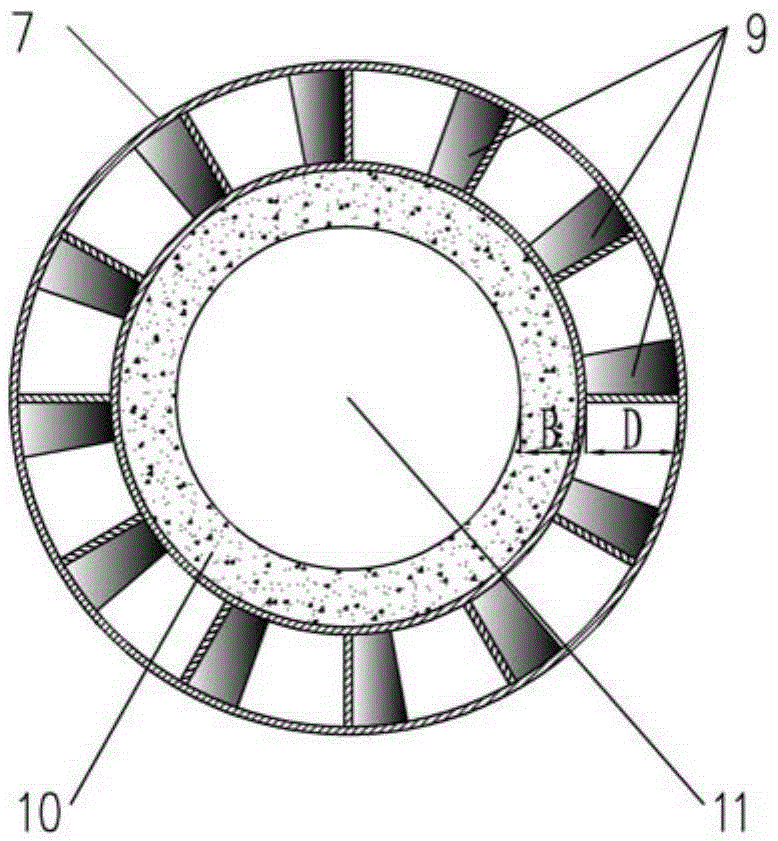

Boiler system adopting burning low-heating-value fuel gas and operation method for boiler system

InactiveCN105258110AReduce heat dissipationReduce heat lossGaseous fuel burnerCombustion chambersCombustion chamberRetention time

The invention belongs to the technical field of combustion and boilers, relates to a boiler system adopting burning low-heating-value fuel gas and an operation method for the boiler system, and the low-heating-value fuel gas with a heating value of 600Kcal / m<3>-1000Kcal / m<3> is adopted as a fuel. The boiler system is characterized in that a heat-insulation combustion chamber is arranged, wherein a boiler heating surface is arranged at the periphery of the heat-insulation combustion chamber; heat dissipation of the heat-insulation combustion chamber is reduced by adopting refractory castable, so that conditions such as space, temperature and retention time are provided for stable and complete combustion of the low-heating-value fuel; a ring-shaped seam between a combustion chamber housing and the refractory castable is a combustion-supporting air channel; a little heat dispersed by the refractory castable is absorbed by combustion-supporting air, so that temperature of the combustion-supporting air is increased, and heat dissipation loss is reduced; area of a heat exchange surface is set according to a combustion product of the low-heating-value fuel gas, a radiant heat exchange surface is reduced by 40%-40% in comparison with that of a common boiler, and convection heat exchange surface is increased by 10%-30% in comparison with that of the common boiler. The boiler system effectively solves the emission-reduction and utilization problem of the low-heating-value process tail gas, and has the advantages of high heat recycling efficiency, low operation cost and the like.

Owner:北京矿大节能科技有限公司

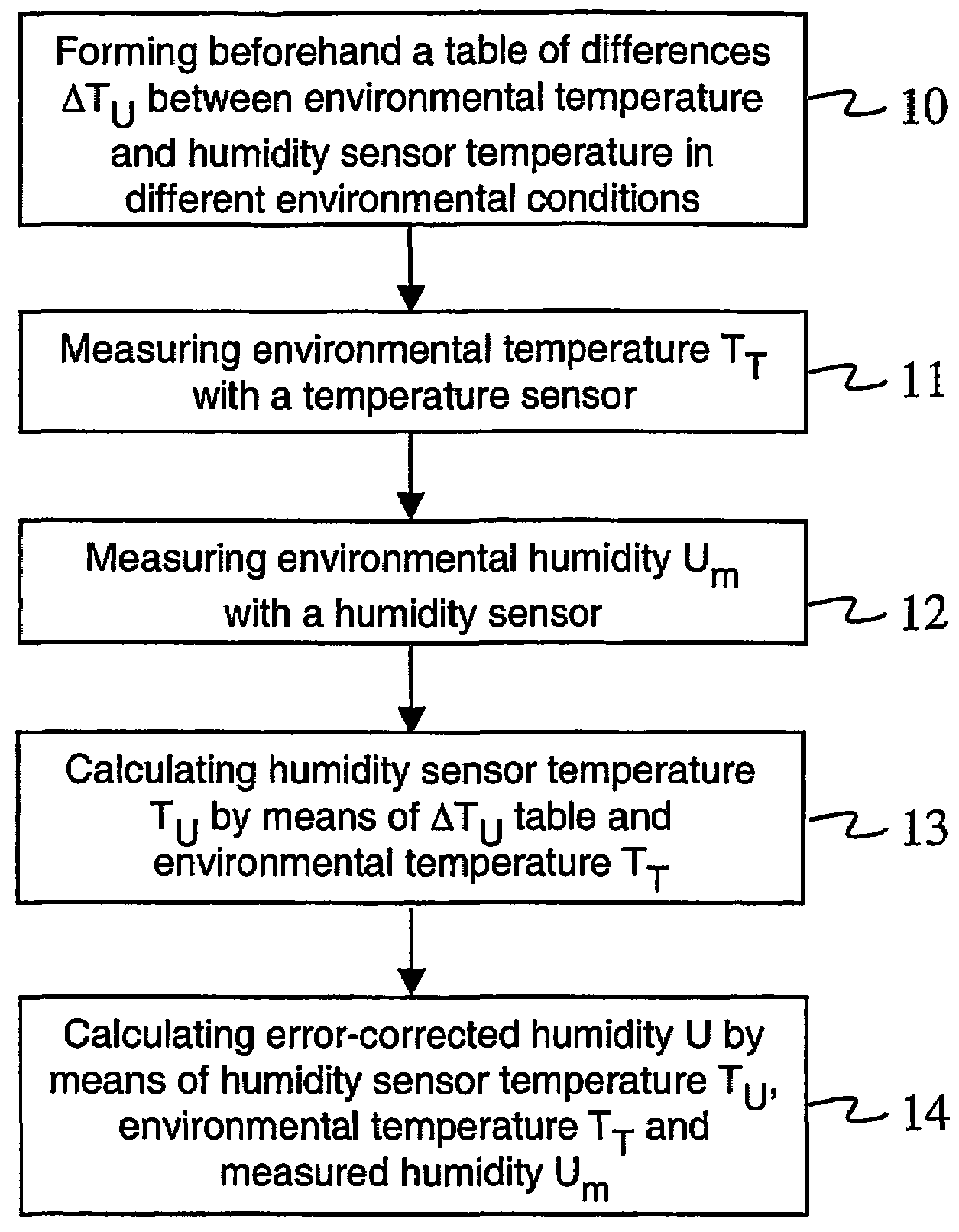

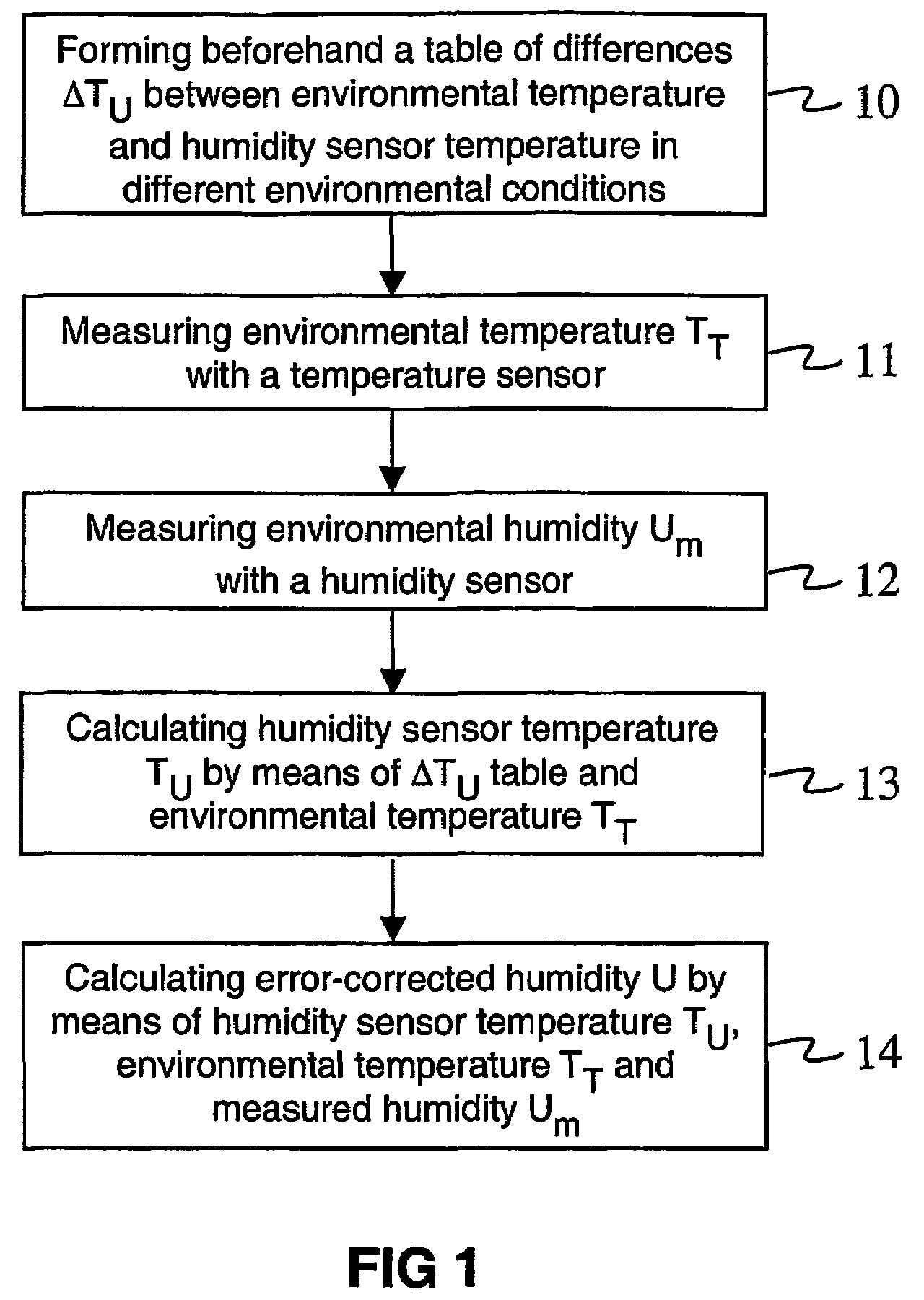

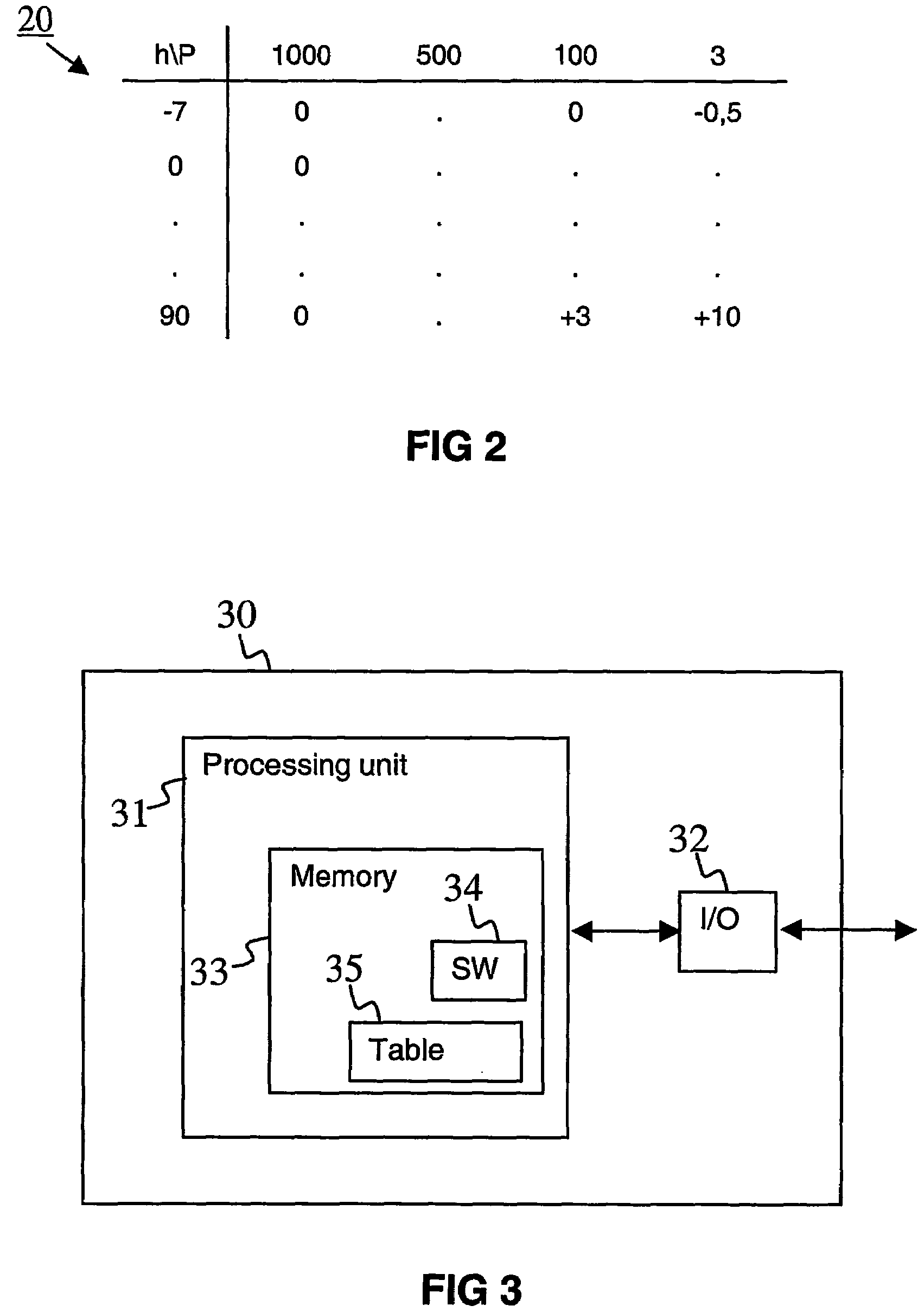

Correction of humidity measurement results of a radiosonde

InactiveUS7509838B2Testing/calibration apparatusSpeed measurement using gyroscopic effectsRadiosondeMoisture sensor

A method for correcting humidity measurement results of a radiosonde, especially for errors resulting from radiative heat exchange. Environmental humidity Um is measured with a humidity sensor in the radiosonde, a current value of at least one environmental condition parameter is determined, and error-corrected humidity U is calculated directly or indirectly utilizing the measured environmental humidity Um and a correction value corresponding to the at least one current environmental condition parameter value.

Owner:VAISALA

Working position separated type radiant heat exchange air conditioner terminal device and heat exchange treating method

InactiveCN106288096AReduce heat and humidity loadEfficient damp heat load handlingMechanical apparatusSpace heating and ventilation safety systemsTerminal equipmentEngineering

The invention provides a working position separated type radiant heat exchange air conditioner terminal device. According to the radiant heat exchange air conditioner terminal, separation radiant plates are used as components for indoor working position separation and simultaneously used as radiant heat transferair conditioning terminals for carrying out refrigerating / heating on different working positions in working position separation, radiant heat exchange and air supply airflow heat exchange are conducted on working position local area space directly through the separation radiant plates, the wet and heat power can be more centrally and more efficiently used for wet and heat load treatment for the working position local area space, the energy consumption utilization rate of an air conditioner system is improved in an assisted mode, the overall energy consumption caused by the office building air conditioner system is lowered, the requirements of different workers for the comfort and difference of working position local area environment can be better met, and unnecessary energy consumption waste is reduced; meanwhile, the invention further provides a heat exchange treating method of the working position separated type radiant heat exchange air conditioner terminal device. Balance and comfort of refrigerating and heating for the working position local area space can be better guaranteed.

Owner:CHONGQING UNIV

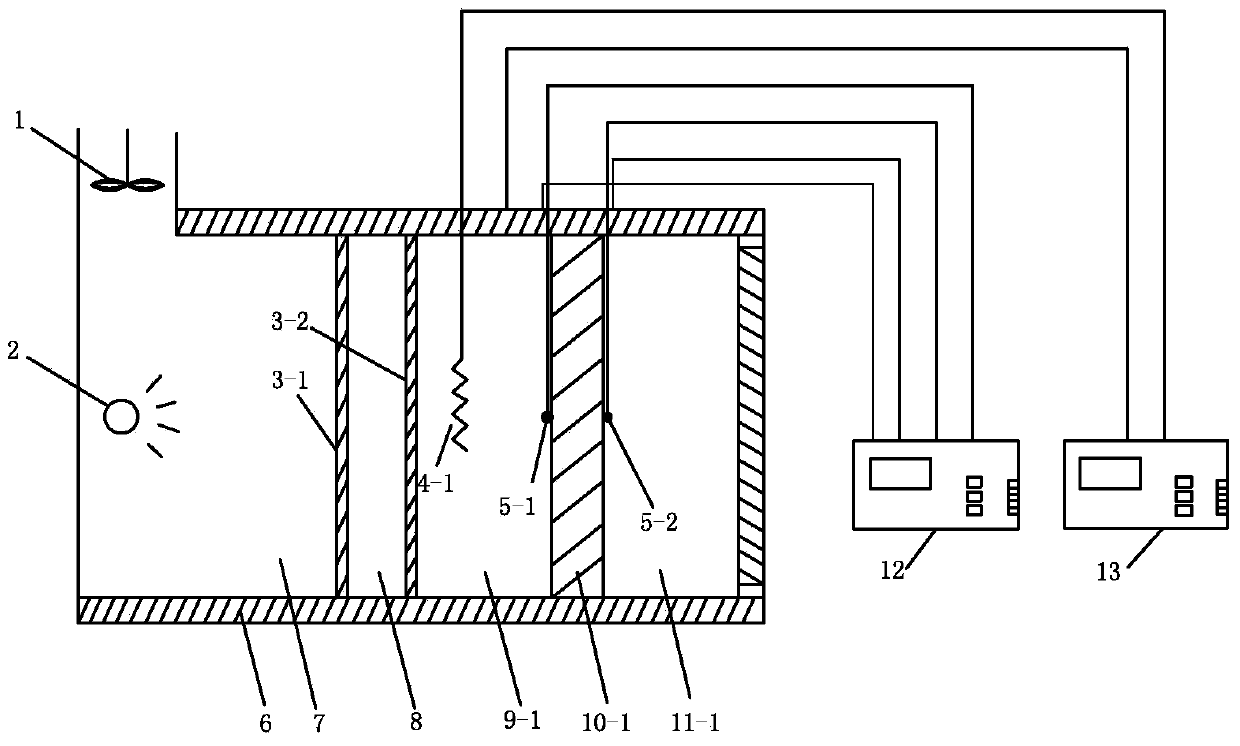

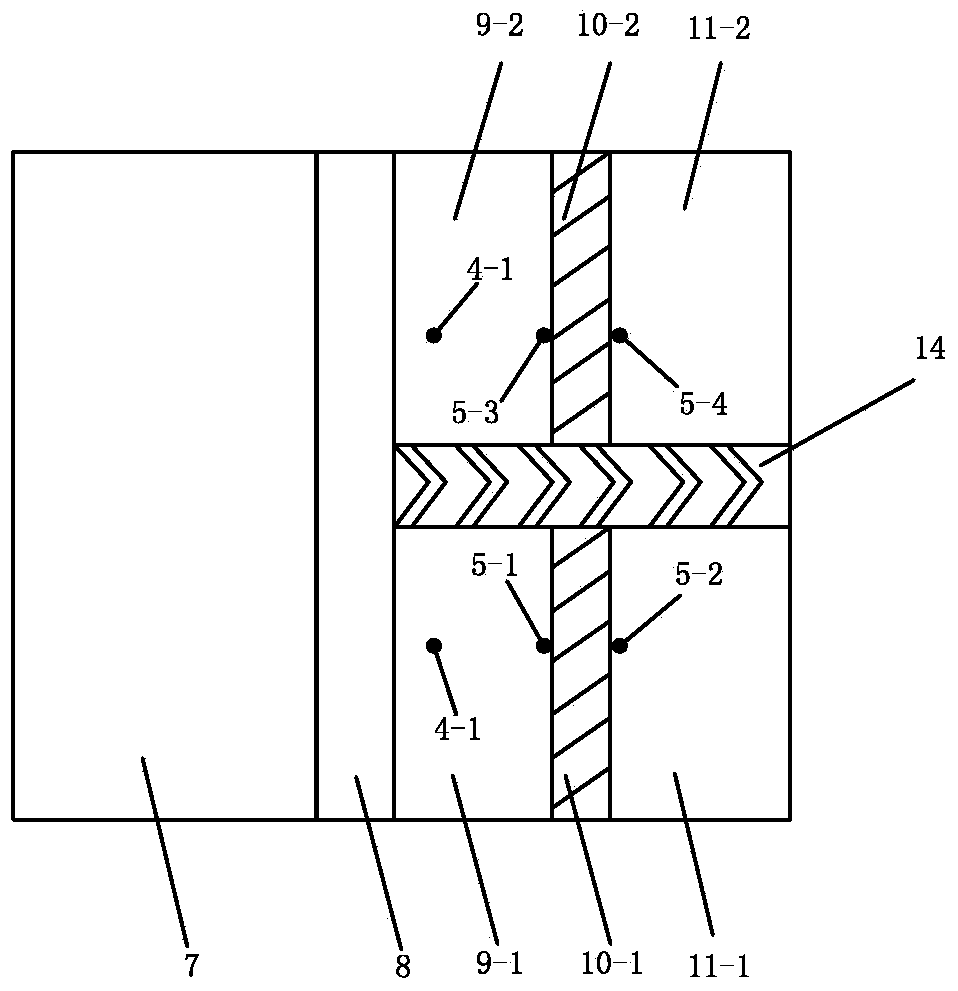

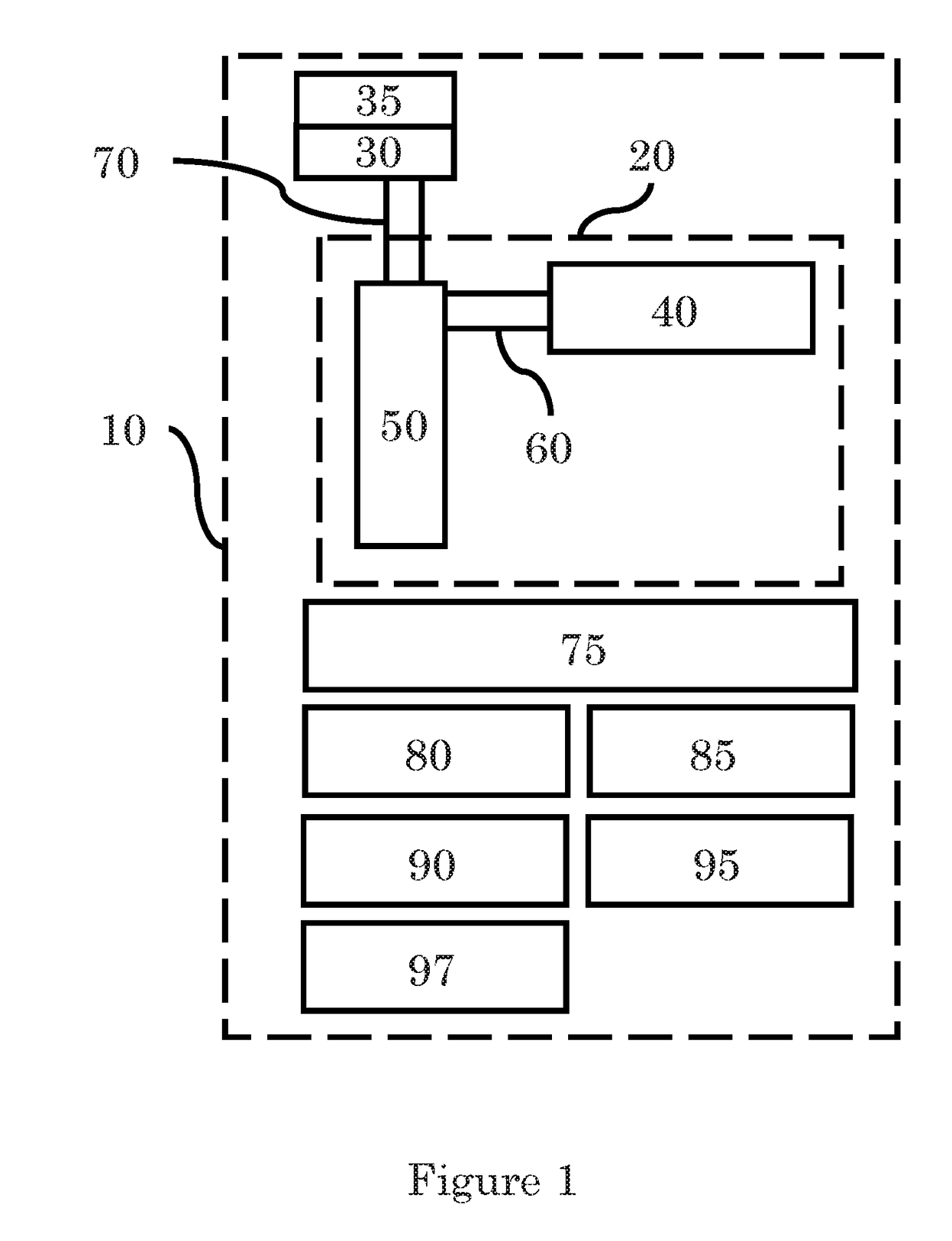

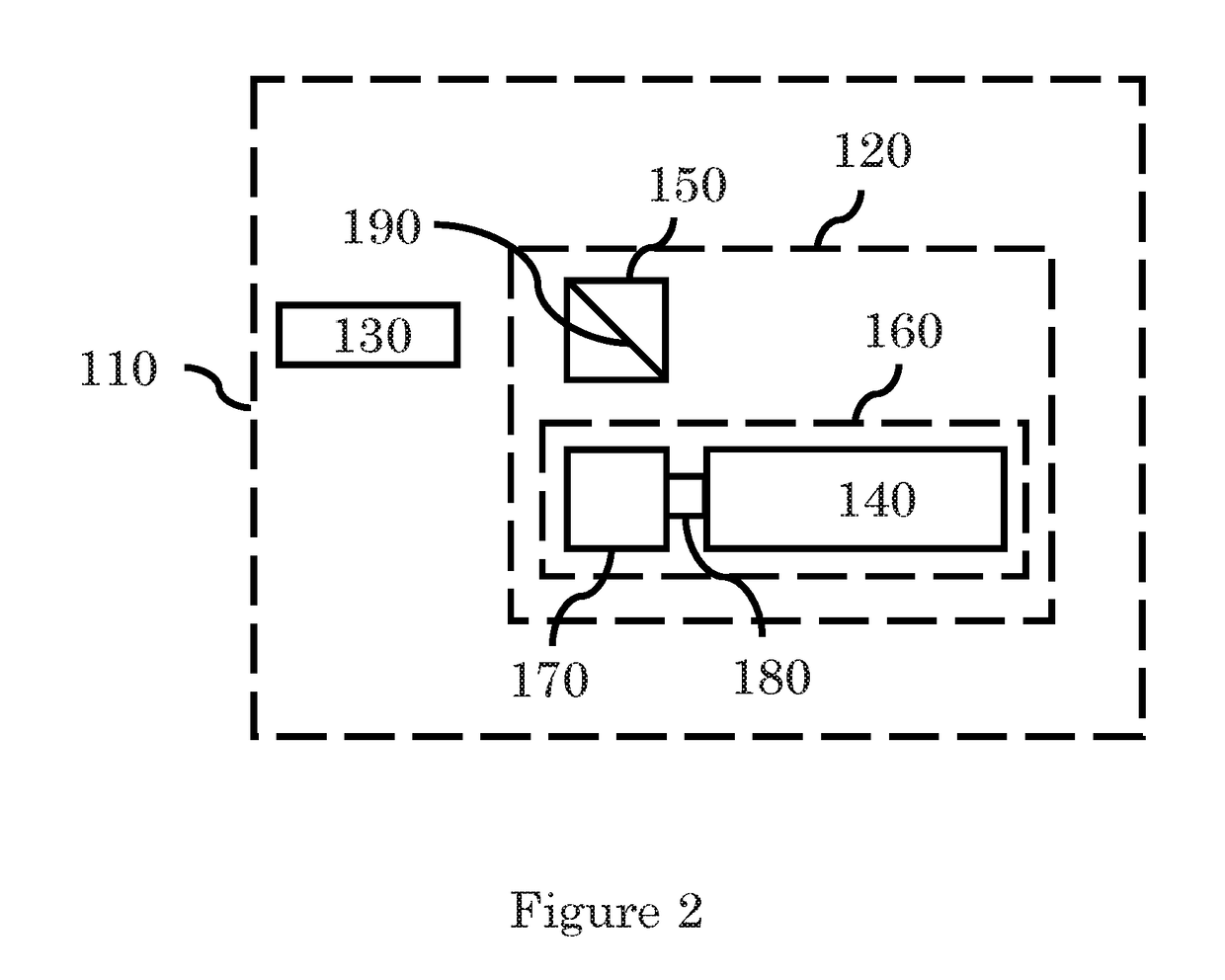

Device and method for measuring relative heat conductivity coefficient of phase change member by radiant heat exchange method

The invention provides a device for measuring a relative heat conductivity coefficient of a phase change member by a radiant heat exchange method. The device comprises a test box, a multi-path temperature inspection instrument and a temperature control instrument, wherein the test box comprises a light source chamber, a heat insulation chamber, a first temperature control chamber, a first temperature measuring chamber, a second temperature control chamber and a second temperature measuring chamber; the light source chamber is internally provided with a light source; the first temperature control chamber is internally provided with a first electric heating wire and a first thermoelectric couple; the first temperature measuring chamber is internally provided with a second thermoelectric couple; the second temperature control chamber is internally provided with a second electric heating wire and a third thermoelectric couple; the second temperature measuring chamber is internally provided with a fourth thermoelectric couple; a first test box end wall is arranged at the right side of a standard member; a second test box end wall is arranged at the right side of the phase change member; the first test box end wall and the second test box end wall are detachable. A method and the device for measuring the relative heat conductivity coefficient of the phase change member take radiant heat storage as a main heat storage manner.

Owner:BEIJING UNIV OF TECH

Convection radiation air conditioner indoor unit adopting fiber wind distributor

InactiveCN106091110AImprove thermal comfortReduce capacityDucting arrangementsLighting and heating apparatusFiberTerminal equipment

The invention provides a convection radiation air conditioner indoor unit adopting a fiber wind distributor. The convection radiation air conditioner indoor unit comprises a machine enclosure and the fiber wind distributor, wherein the fiber wind distributor is a convection radiation terminal device of the convection radiation air conditioner indoor unit, and is made of osmosis fiber, so that on one hand, air is diffused outwards from fiber pores at extremely low flow speed, and temperature and humidity of indoor air are regulated in a connective mode, and on the other hand, the fiber wind distributor which is filled with a certain amount of air becomes a potential cold / thermal radiator, carries out heat exchange with an indoor solid wall surface in a radiative mode to regulate comfort of indoor staff; the machine enclosure is connected to the fiber wind distributor through a direction-adjustable flexible connecting hose; the machine enclosure internally comprises a centrifugal fan, a heat exchanger, a water condensing plate and a water draining pipe, wherein the heat exchanger is located in front of an air outlet of the fan; the water condensing plate is located below the heat exchanger and is equipped with the water draining pipe; and a return air inlet with a filter device is further arranged below the machine enclosure. The convection radiation air conditioner indoor unit adopting the fiber wind distributor provided by the invention has the convective heat exchange function of an existing air conditioner indoor unit and also has a radiant heat exchange function, and further has the characteristics of being low in outlet air flow velocity, capable of filtering and purifying air, high in comfort of a human body and more energy-saving.

Owner:CHANGZHOU UNIV

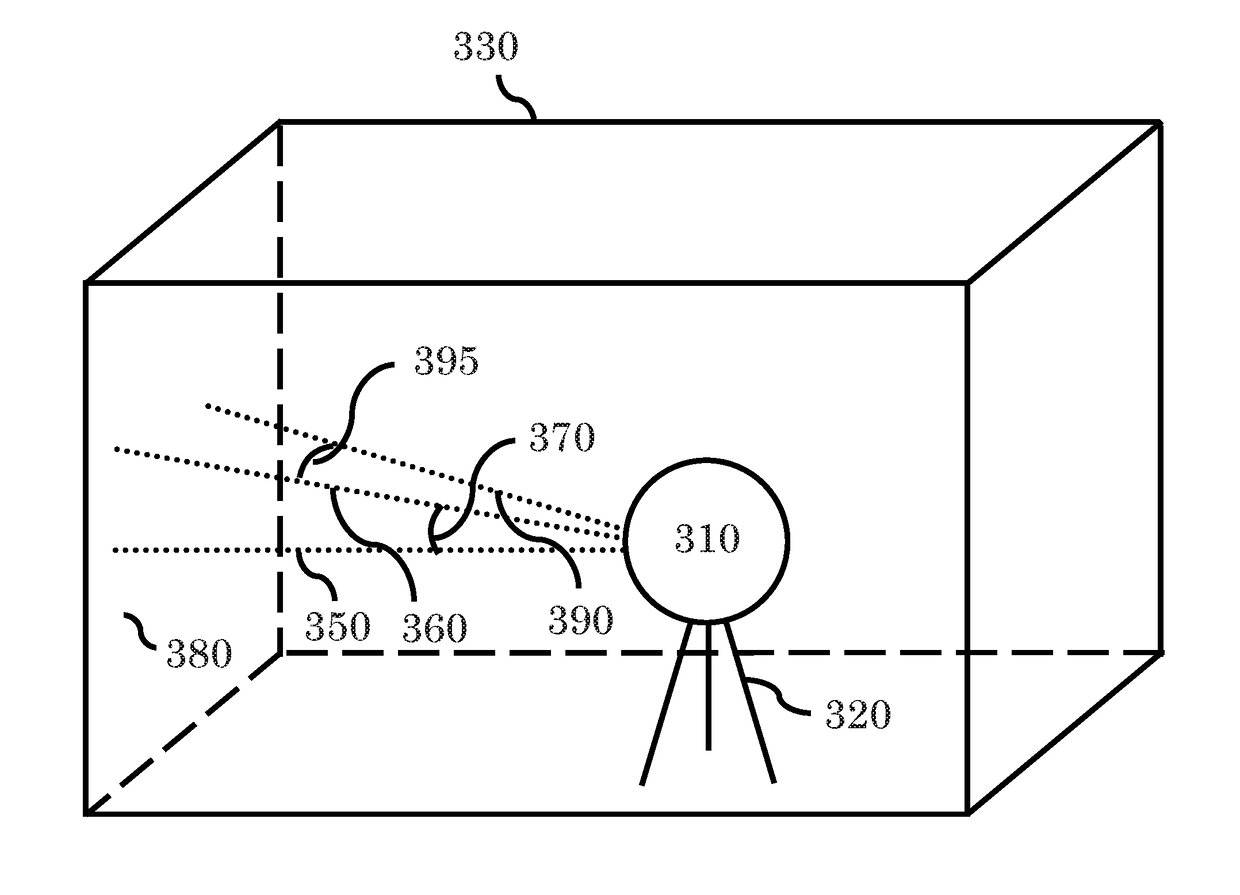

Spherical-motion average radiant temperature sensor

ActiveUS20180073930A1Thermometer detailsThermometers using mean/integrated valuesMean radiant temperatureComputer science

A mean radiant temperature sensor is used to measure radiant heat exchange to determine comfort. Disclosed herein are a spherical-motion average radiant temperature sensor (SMART Sensor) device or system, and an associated method, for taking an average overall global reading while also being able to record weighting for different directions easily in spherical coordinates.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Integral condensing boiler

ActiveCN102331085ACompact structureEfficient and environmentally friendly structureEnergy efficient heating/coolingAir heatersThermal energyBoiler furnace

The invention provides an integral condensing boiler. In the integral condensing boiler, a fully-premixed flameless burner fueled by oil gas fuels is used for radiant heat exchange in a boiler furnace, a platefin type heat transfer component is used for entire convection and condensation heat transfer and a flue gas mainstream temperature zone is directly inserted by welding a pin or a cast boss, thus effectively reducing the temperature gradient from the glue gas mainstream to a wall surface, continuously damaging a flowing boundary layer of the wall surface and a flue gas center and strengthening the heat convection; furthermore, condensation heat transfer can expand from the wall surface to the whole surface of the pin or the cast boss so that the condensation heat transfer area can be effectively enlarged; meanwhile, condensation heat transfer of water vapor in the flue gas can be strengthened, thus the whole convection and condensation heat transfer coefficients of the condensing boiler can be greatly improved; the condensation liquid can absorb partial harmful gases in the flue gas, such as CO2, NOx, SOx, and the like, thus pollutant emission can be effectively reduced. The boiler has a simple structure and high entire convection and condensation heat transfer coefficients and can be used for improving the conversion efficiency of thermal energy to the greatest extent.

Owner:XI AN JIAOTONG UNIV

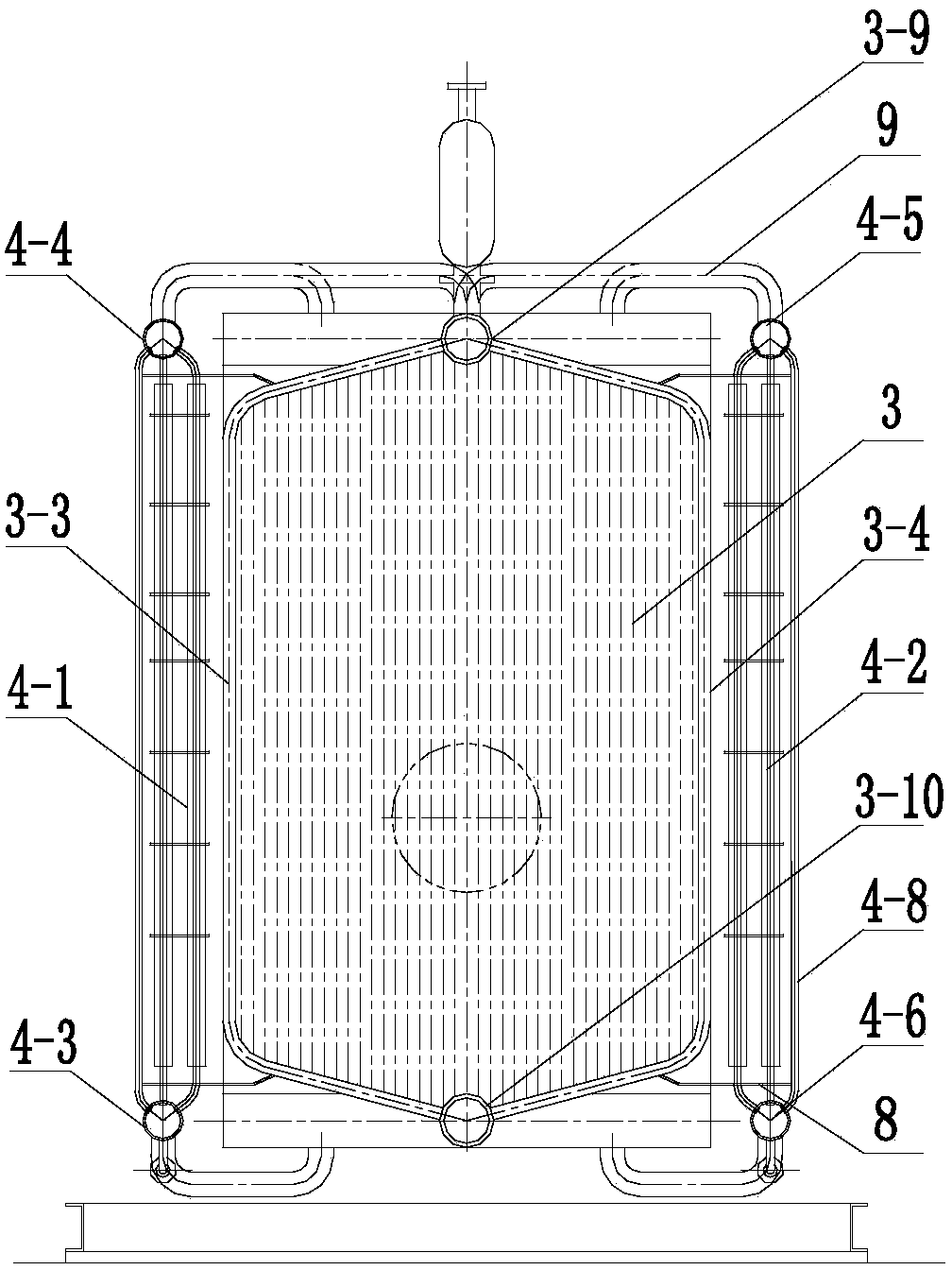

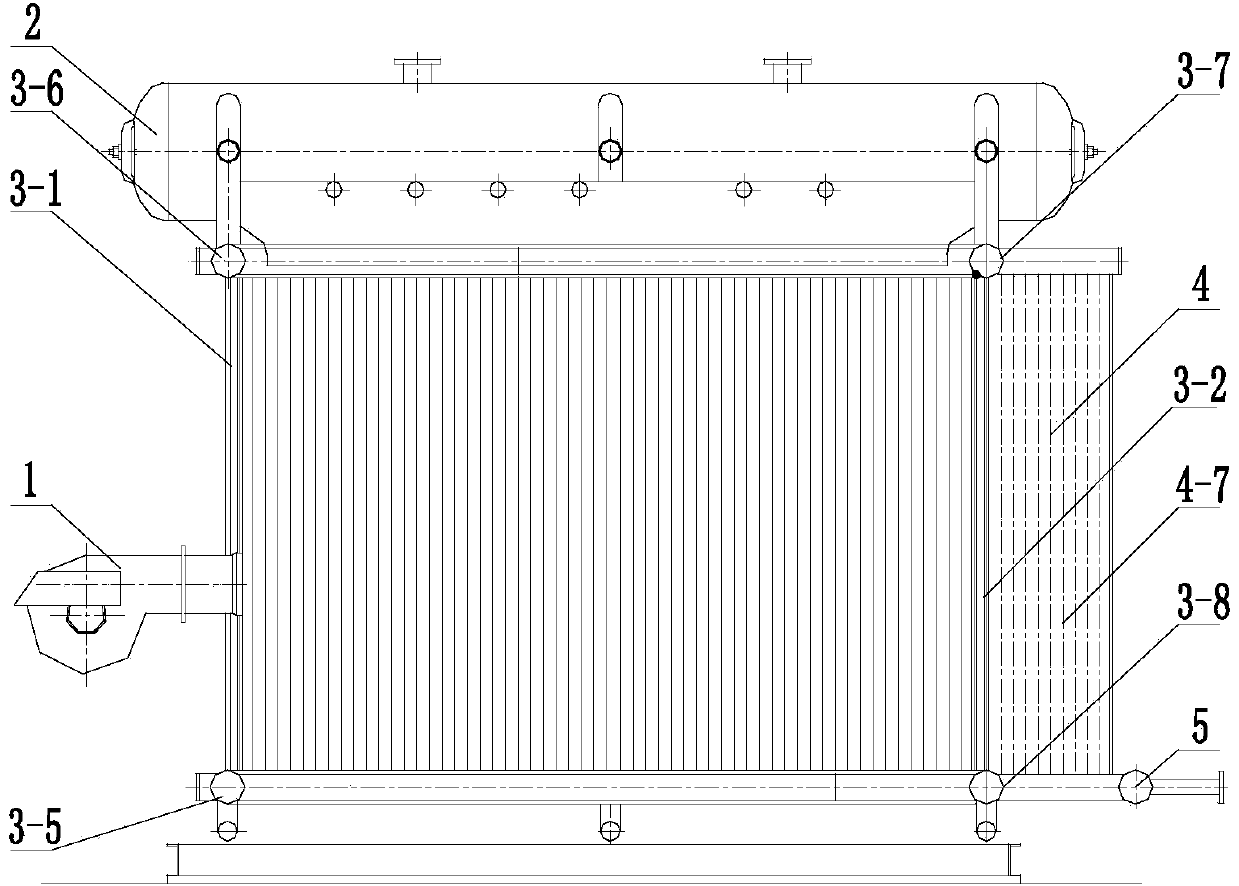

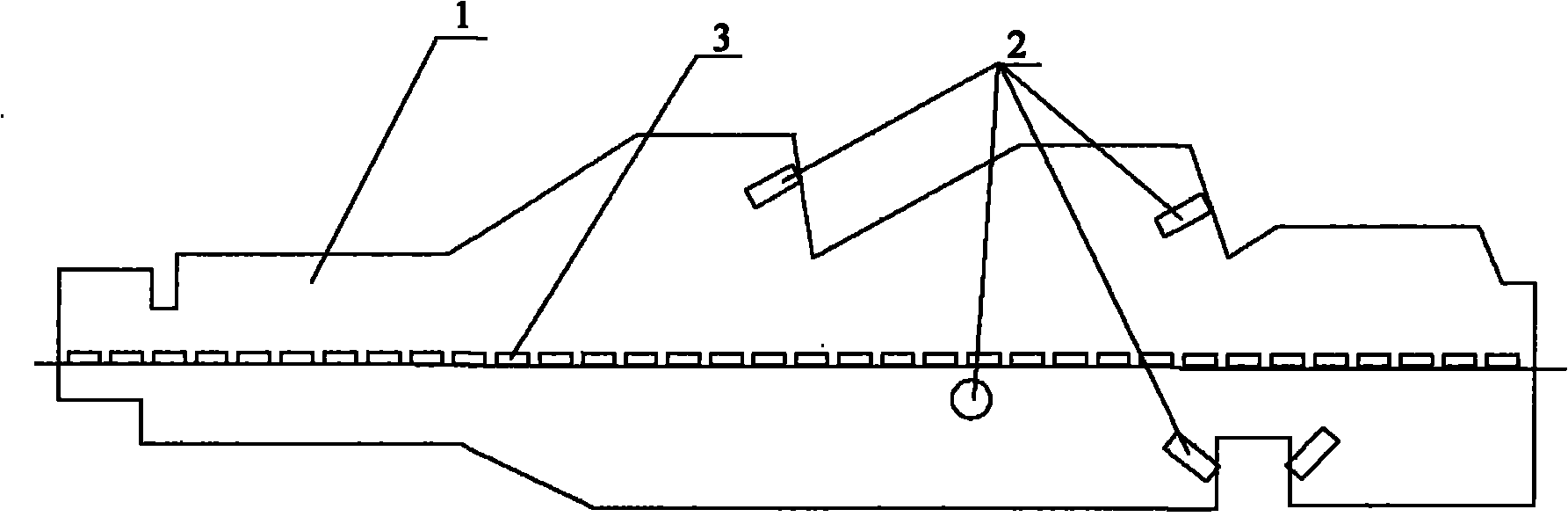

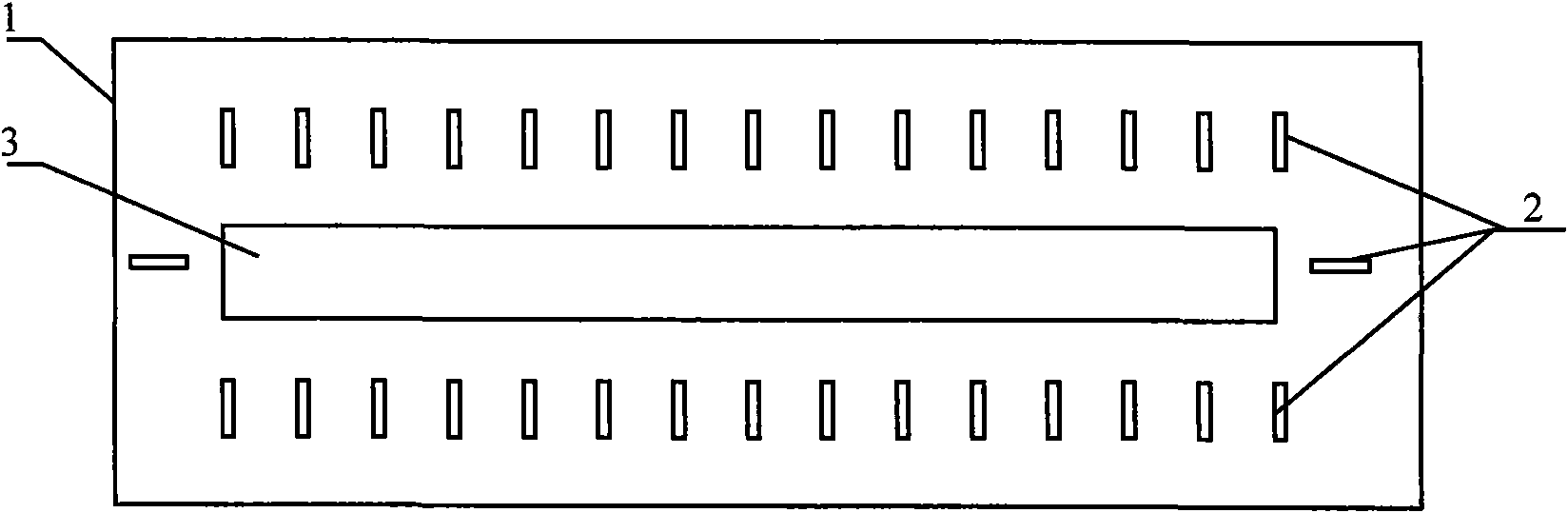

Novel full tube panel type efficient oil and gas fired boiler

InactiveCN103791479AAvoid crackingReduce welding workloadSteam boilersConvection heatPetroleum engineering

A novel full tube panel type efficient oil and gas fired boiler comprises a radiant heat exchange membrane type water-cooled wall tube panel structure and a convection heat exchange tube bundle type tube panel structure, wherein the radiant heat exchange membrane type water-cooled wall tube panel structure comprises a front wall membrane type water-cooled wall, a rear wall membrane type water-cooled wall, a left side wall membrane type water-cooled wall and a right side wall membrane type water-cooled wall, and an O-shaped section structure is formed by the left side wall membrane type water-cooled wall, the right side wall membrane type water-cooled wall, a side wall lower header and a side wall upper header; the convection heat exchange tube bundle type tube panel structure comprises convection heat exchange tube bundles, a convection tube panel outside wall membrane type wall and a tail smoke chamber, the radiant heat exchange side wall membrane type water-cooled walls serve as inside wall membrane type walls of the convection heat exchange tube bundle type tube panel structure, and a convection flue with two sides being sealed is formed by the radiant heat exchange side wall membrane type water-cooled walls, the outside wall membrane type wall, an upper welding steel board and a lower welding steel board. The novel full tube panel type efficient oil and gas fired boiler is high in safety margin and good in heat transfer performance, makes use of modular design, and is capable of being rapidly installed and integrally assembled, short in installation period, easy and convenient to operate and maintain, and convenient to repair; the overall sealing performance of the whole boiler is good, heat loss due to radiation is reduced obviously, and heat efficiency is improved effectively.

Owner:XI AN JIAOTONG UNIV +1

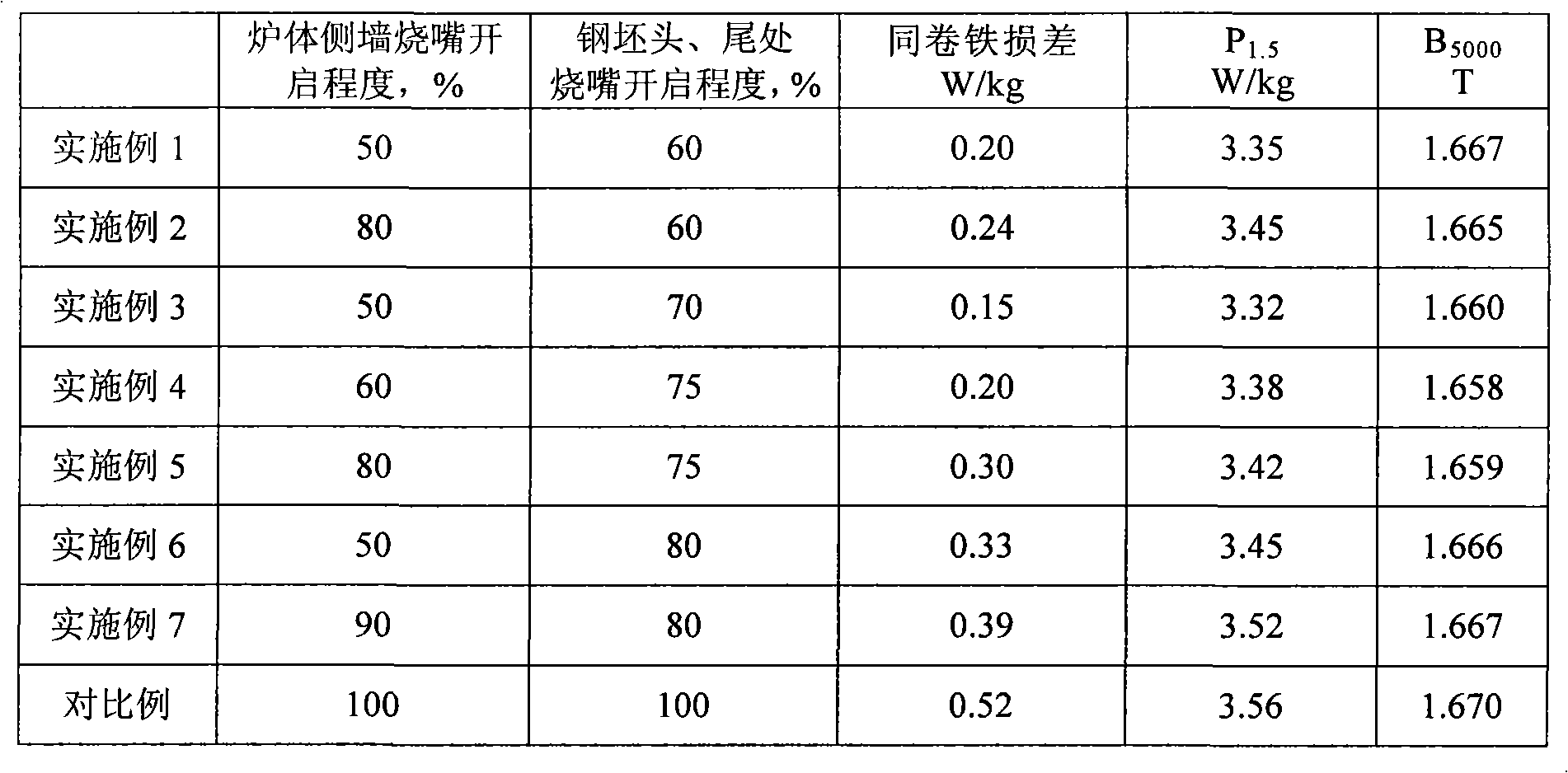

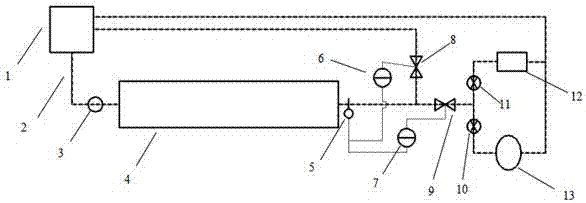

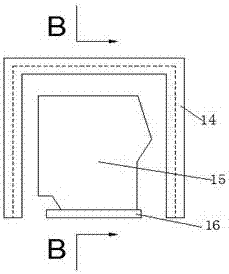

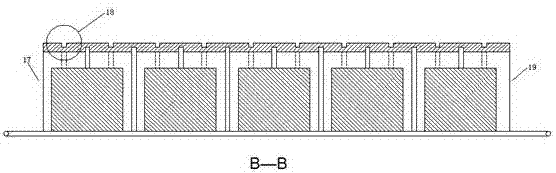

Hot rolling heating method capable of improving head and tail performance of non-oriented silicon steel

InactiveCN101879529AReduce radiative heat transferReduce electromagnetic performance fluctuationsTemperature control deviceHeating timeHeating furnace

The invention provides a hot rolling heating method capable of improving the head and tail performance of non-oriented silicon steel. In the method, a billet to be heated for hot rolling is of a fixed size, a stepwise heating furnace is used for heating, and the opening rate of a burner on the inner side of the heating furnace and burners which are less than one meter away from the head and tail parts of the billet are controlled to be 50 to 90 percent. In the invention, the thickness of the billet is 150 to 300 millimeters, the charging temperature of the billet is above 400 DEG C, the heating time is 120 to 280 DEG C, the heating temperature is 1,200 to 1,400 DEG C, and the discharging temperature is 1,100 to 1,240 DEG C. In the invention, the opening rate of the burners in the heating furnace is controlled to reduce the temperatures of the heating furnace close to the head and tail parts of the billet, and thus, the radiant heat exchange between the furnace body and the head and tail parts of the billet is reduced. When the technical scheme of the invention is adopted, the fluctuation in the electromagnetic performance of the cold-rolled non-oriented silicon steel product can be reduced effectively by using the conventional equipment without influencing output and the performance of other products produced in the same furnace; and therefore, the head and tail performance of the cold-rolled non-oriented silicon steel product is improved.

Owner:ANGANG STEEL CO LTD

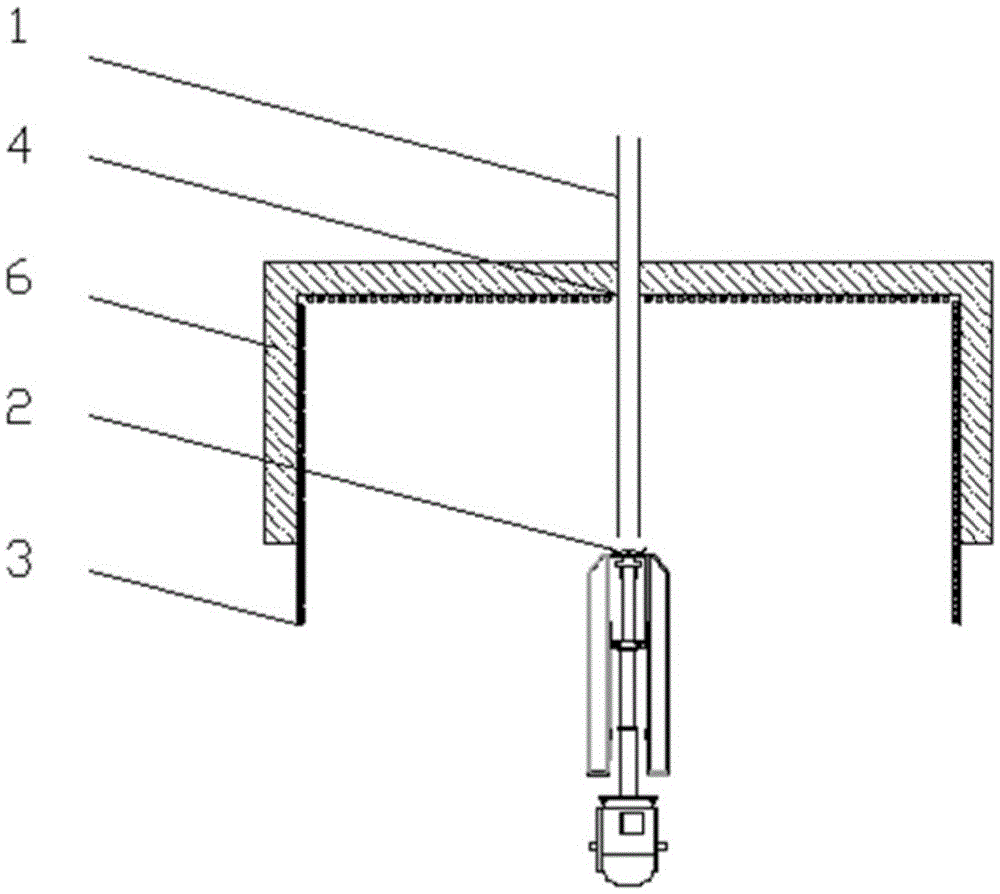

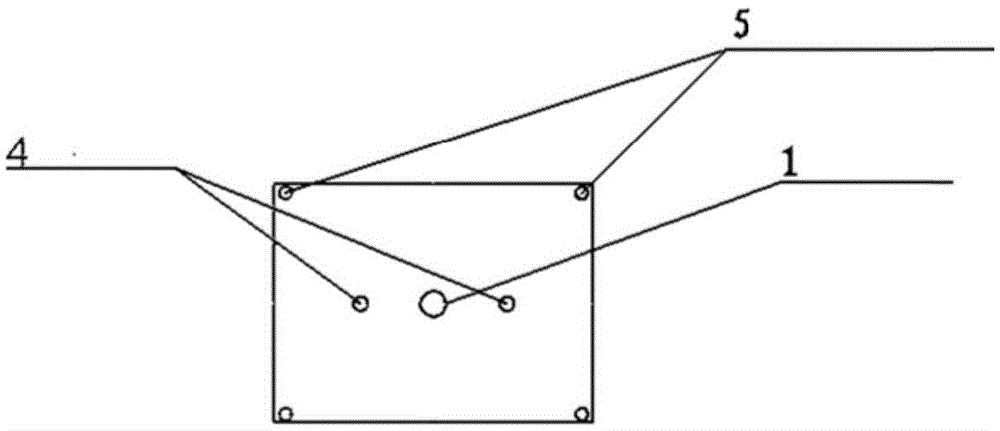

Casting waste heat recycling device based on radiant heat exchange

ActiveCN106925765ADoes not affect internal structural propertiesAchieve continuous recyclingIncreasing energy efficiencyWaste heat treatmentTemperature controlSolenoid valve

Owner:HEBEI UNIV OF TECH

Integrated rotary radiation preheating mixing type heat recovery device with smoke chilling function

ActiveCN102977931AImprove recycling ratesIncrease profitEnergy inputCombined combustion mitigationSlagSuperheater

Owner:DONGFANG ELECTRIC CORP LTD

Combined type ceiling radiant plate

InactiveCN103791555ASimple structureEasy to useLighting and heating apparatusAir conditioning systemsTerminal equipmentEngineering

The invention relates to a combined type ceiling radiant plate, belongs to terminal devices of independent temperature and humidity control central air conditioners and can be used in an air conditioning system for refrigeration and heating. A radiant ceiling is composed of a radiant coiler, a heat conduction plate good in heat conduction performance, a decoration ceiling panel and the like. The inflection type radiant coiler is clamped in a pipe groove of the heat conduction plate to increase the downward radiant quantity of the radiant ceiling. The heat conduction plate can be machined into different specifications according to the onsite building structure condition. The decoration panel with or without micro holes clings to the lower surface of the heat conduction plate to serve as a ceiling face, convection heat exchange of the radiant plate and indoor air is improved while radiant heat exchange is conducted, and the refrigeration / heating capability is improved.

Owner:CHINA ACAD OF BUILDING RES

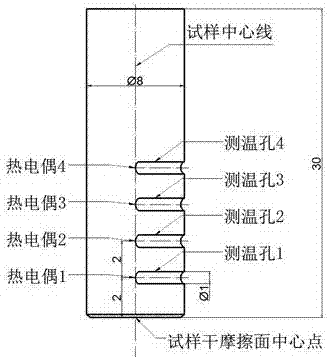

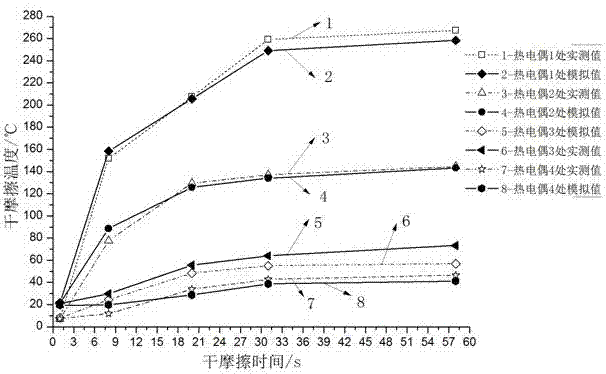

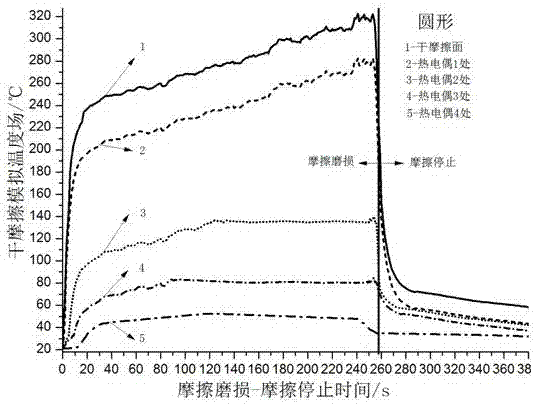

Method for determining specimen dry friction surface temperature field

ActiveCN107016247AAvoid failureLow input costInformaticsSpecial data processing applicationsGrinding wheelThermocouple device

The invention belongs to a method for determining a specimen dry friction surface temperature field. According to the technical scheme, 1-5 temperature measurement holes are chosen on the surface of a specimen to fix thermocouples, and the thermocouples are connected to a temperature measurement instrument to conduct actual measurement on dry friction temperatures; using a finite element to simulate temperature values at the thermocouples on different warm boundary conditions, and establishing an error quadratic sum model between the temperature simulation values and actual temperature measurement values at all the thermocouples; with the purpose that quadratic sum between the temperature simulation values and the actual temperature measurement values is the smallest, using an optimal constraint function to optimize and determine a radiation heat transfer efficient of a specimen dry friction surface to environment, a contact heat transfer coefficient of a grinding wheel, a contact heat transfer coefficient of a grinding disc, a specimen dry friction surface, and a heat source density of a specimen dry friction surface, and in this way, determining a material dry friction surface and a dry friction temperature field near the material dry friction surface. The method for determining the specimen dry friction surface temperature field is simple, reliable in result and low in cost; the determined temperature is close to reality, the critical temperature can be predicted when a material generates abrasion, and basic data is provided for design of the material and optimization.

Owner:WUHAN UNIV OF SCI & TECH

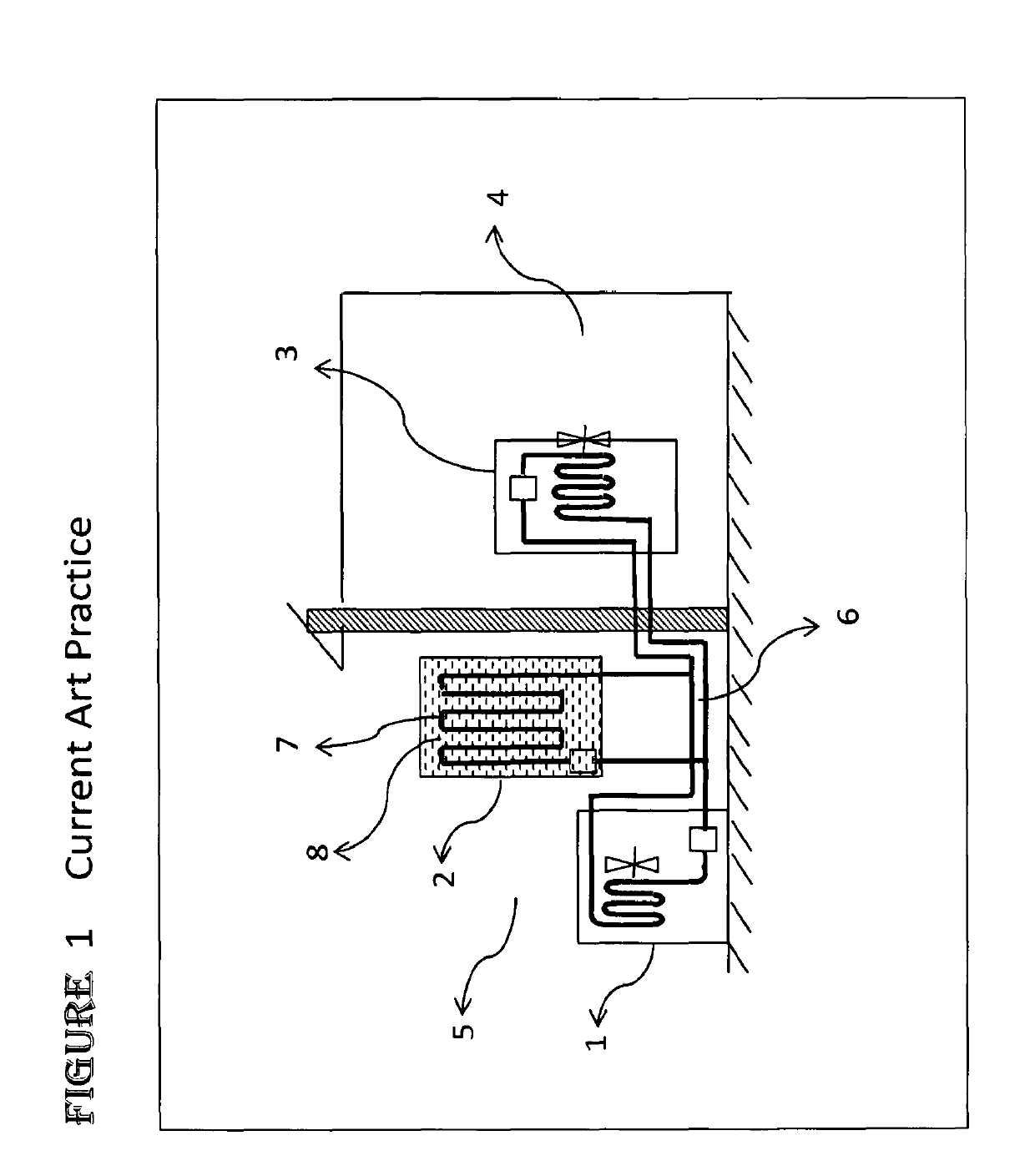

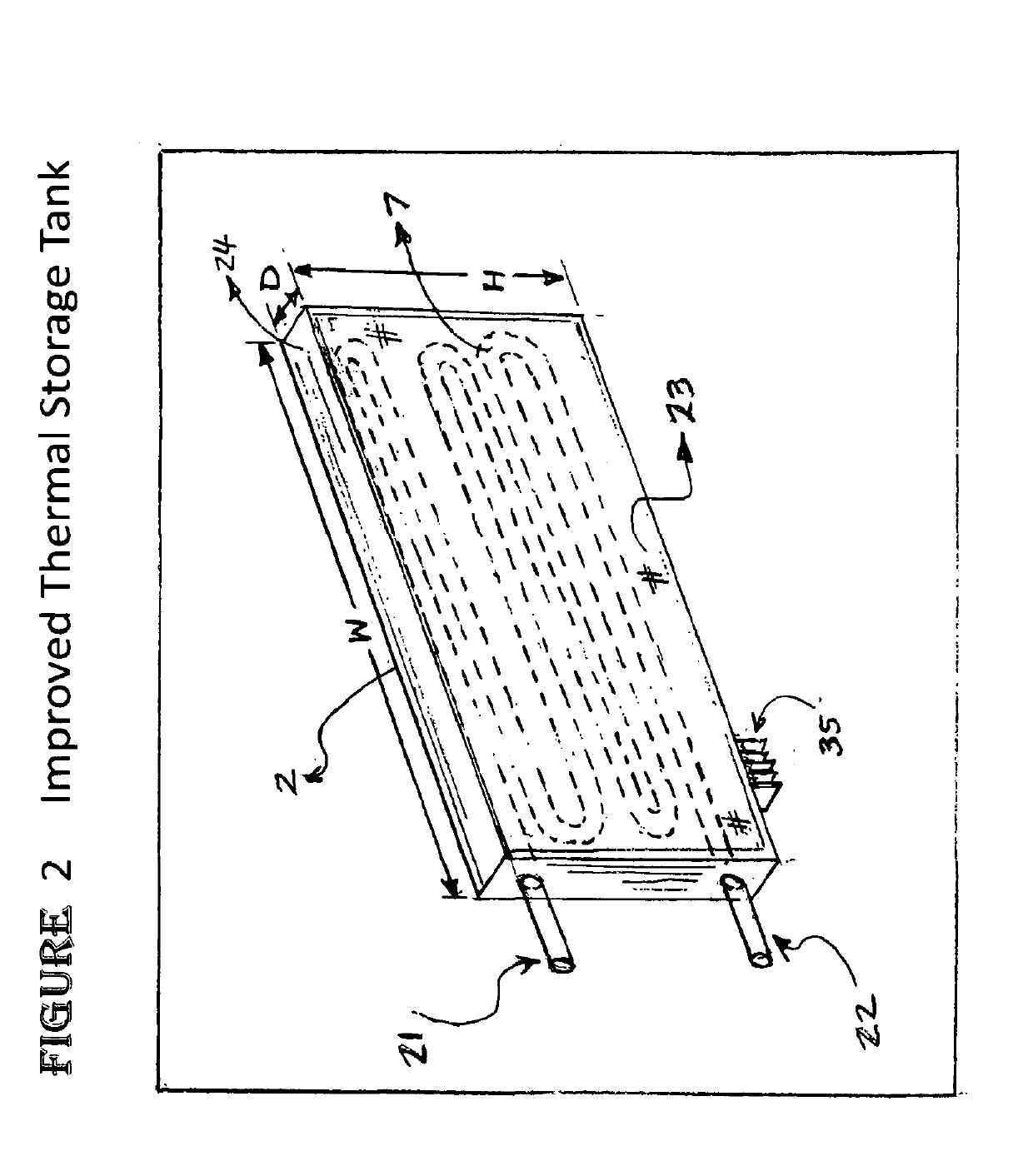

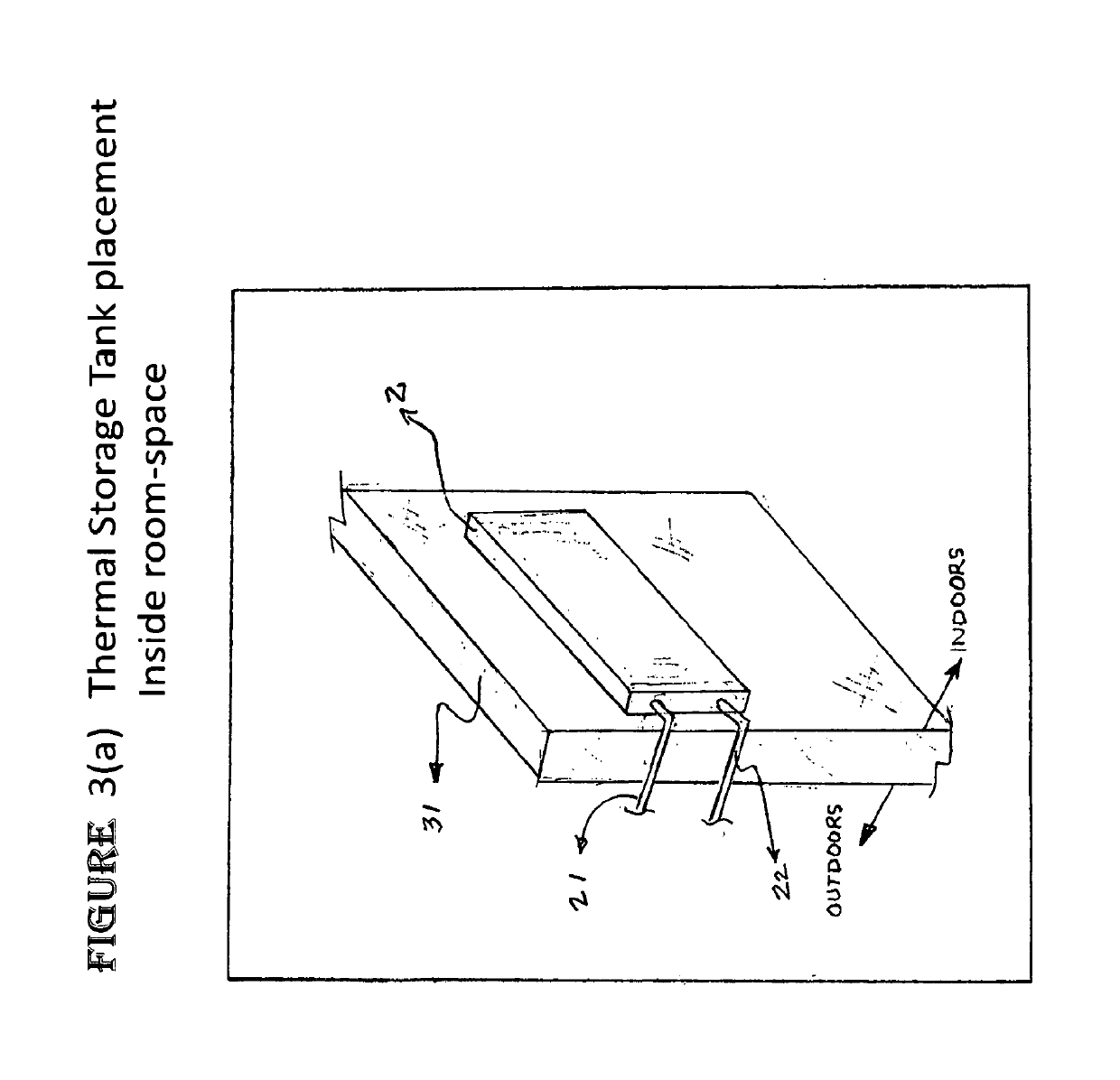

Room space Cooling with Improved Thermal Storage

ActiveUS20190195519A1Low costReduce usageEvaporators/condensersRefrigeration devicesThermal energyThermal energy storage

A thermal storage system, capable of storing and releasing thermal energy, with a radiative heat exchange outer surface and a method of operating the device to cool a room-space without using a circulating refrigerant in the room cooling step

Owner:TWYCE ENERGY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com