High-temperature coal slag classification screening and waste heat recovery device

A waste heat recovery device and grading and screening technology, which is applied in the direction of filter screen, solid separation, water heater, etc., can solve the problems of occupying land resources, waste of resources, increase of production cost, etc., and achieve the effect of simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

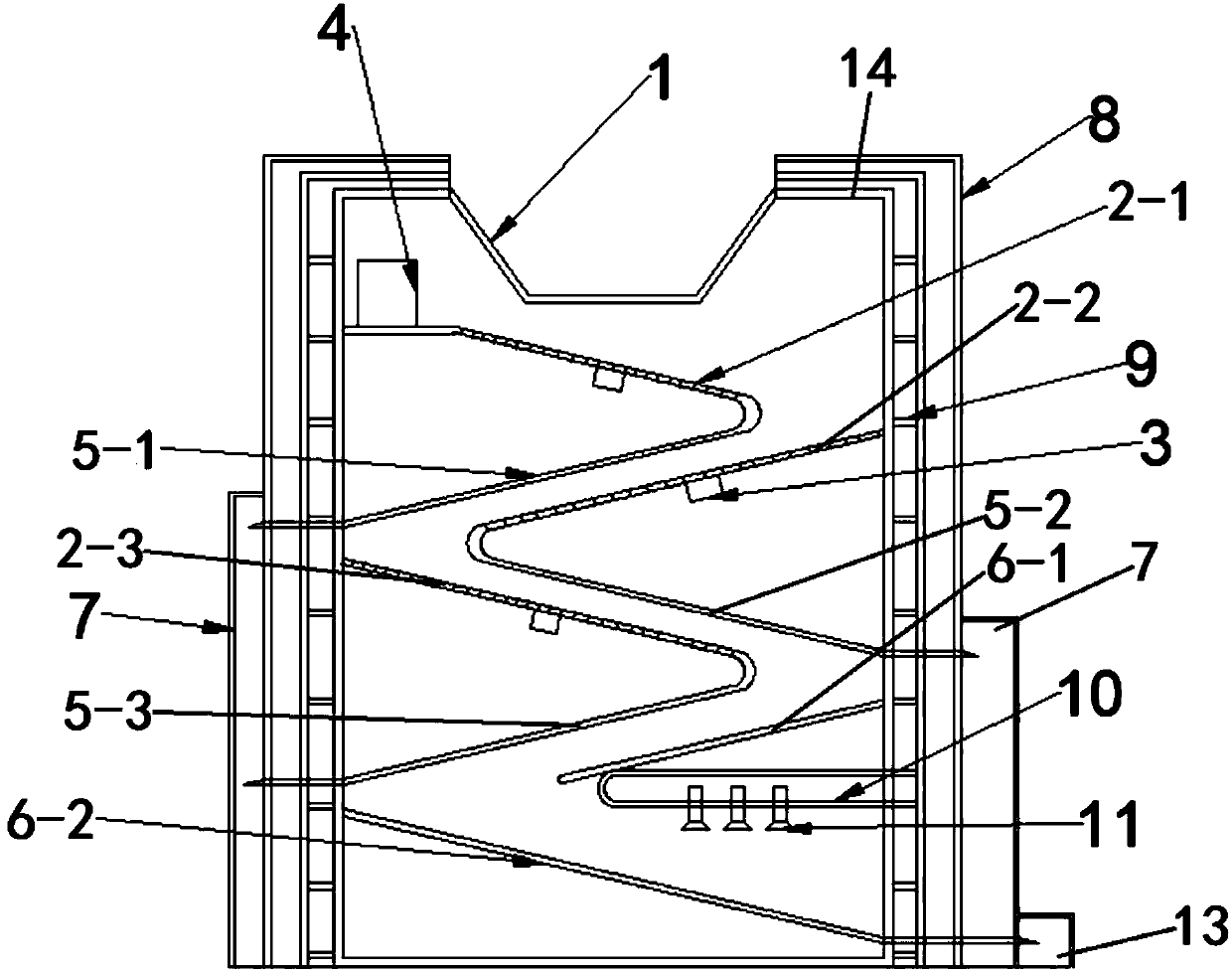

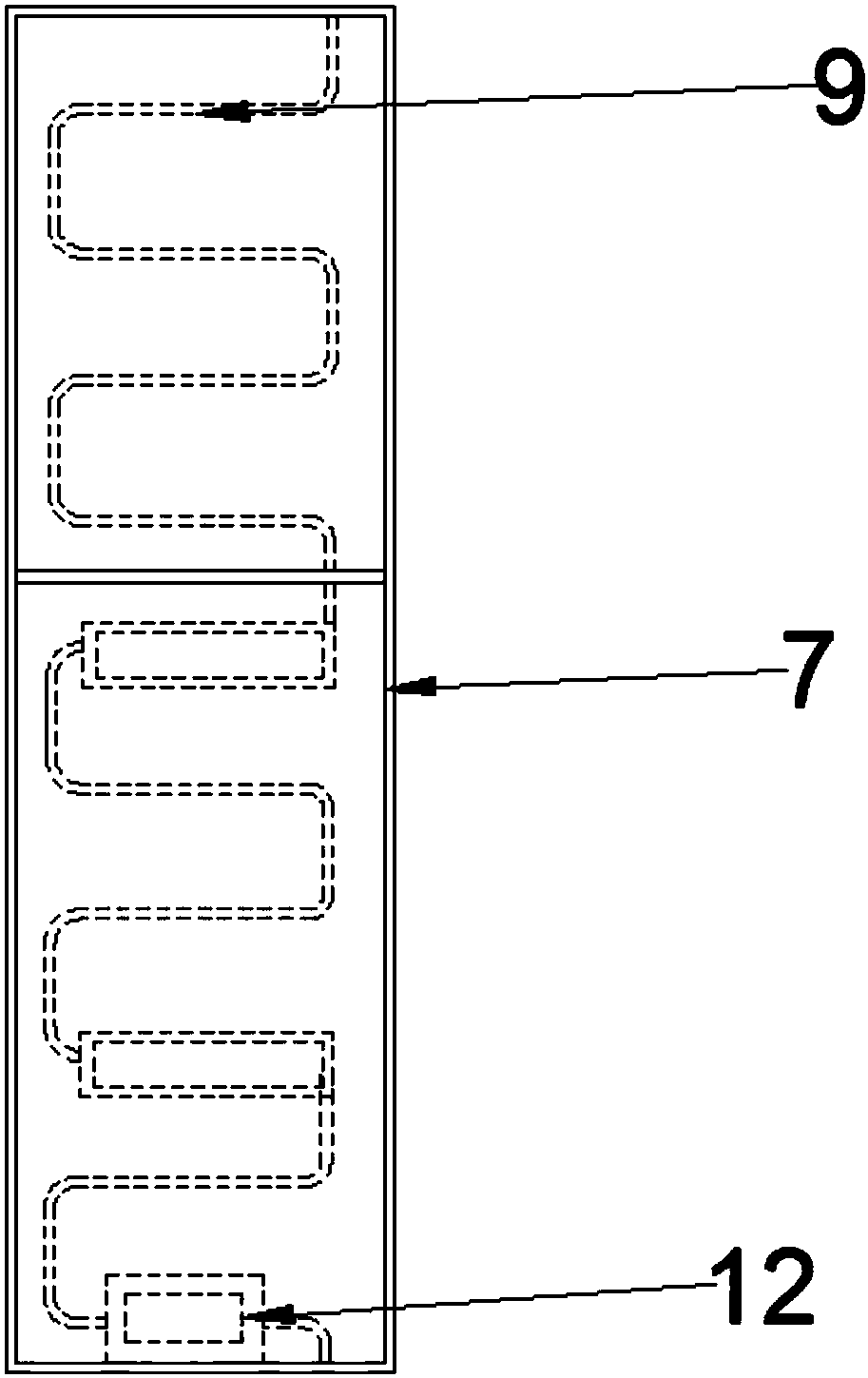

[0034] see figure 1 , figure 1 It is a front view of the high-temperature coal slag classification and screening and waste heat recovery device. Embodiment 1 includes: a coal slag classification and screening mechanism and a coal slag waste heat recovery mechanism; Feed bin 1, filter screen ramp 2, fine cinder recovery ramp, coarse cinder recovery ramp 6, fine cinder collection chamber 7 and coarse cinder collection chamber 13; feed bin 1 is arranged on the top of coal cinder classification and screening shell 14; The net ramp 2 is connected with the connection port of the fine coal slag recovery ramp, and the fine coal slag collection chamber 7 is connected with the recovery port of the fine coal slag recovery ramp, so that the fine coal slag passes through the filter screen of the filter screen ramp 2 under the action of gravity and falls to After the fine coal cinder recovery ramp, it rolls into the fine coal cinder collection chamber 7; the recovery port of the coarse coa...

Embodiment 2

[0036] see figure 1 , figure 1 It is a front view of the high-temperature coal slag classification and screening and waste heat recovery device. Embodiment 2 includes: a coal slag classification and screening mechanism and a coal slag waste heat recovery mechanism; Feed bin 1, filter screen ramp 2, fine cinder recovery ramp, coarse cinder recovery ramp 6, fine cinder collection chamber 7 and coarse cinder collection chamber 13; feed bin 1 is arranged on the top of coal cinder classification screening shell 14; The net ramp 2 is connected with the connection port of the fine coal slag recovery ramp, and the fine coal slag collection chamber 7 is connected with the recovery port of the fine coal slag recovery ramp, so that the fine coal slag passes through the filter screen of the filter screen ramp 2 under the action of gravity and falls to After the fine coal cinder recovery ramp, it rolls down into the fine coal cinder collection chamber 7; the recovery port of the coarse co...

Embodiment 3

[0043] see figure 1 , figure 1 It is a front view of the high-temperature coal slag classification and screening and waste heat recovery device. Embodiment 3 includes: a coal slag classification and screening mechanism and a coal slag waste heat recovery mechanism; Stock bin 1, filter screen ramp 2 include filter screen first sub-ramp 2-1, filter screen second sub-ramp 2-2 and filter screen third sub-ramp 2-3, fine coal fine cinder recovery ramp Including the first sub-ramp 5-1 of fine cinder recovery, the second sub-ramp 5-2 of fine cinder recovery and the third sub-ramp 5-3 of fine cinder recovery, the coarse cinder recovery ramp 6 includes the first sub-ramp of coarse cinder recovery The ramp 6-1 and the second sub-ramp 6-2 for coarse cinder recovery, the fine cinder collection chamber 7 and the coarse cinder collection chamber 13;

[0044] The feed bin 1 is arranged on the top of the coal slag grading and screening shell 14; the first sub-ramp 2-1 of the filter screen is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com