Patents

Literature

53results about How to "Guaranteed temperature measurement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

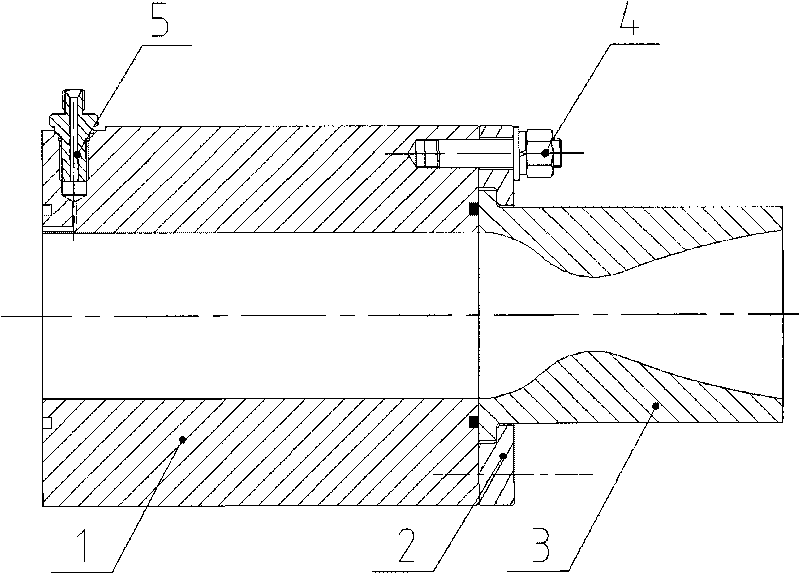

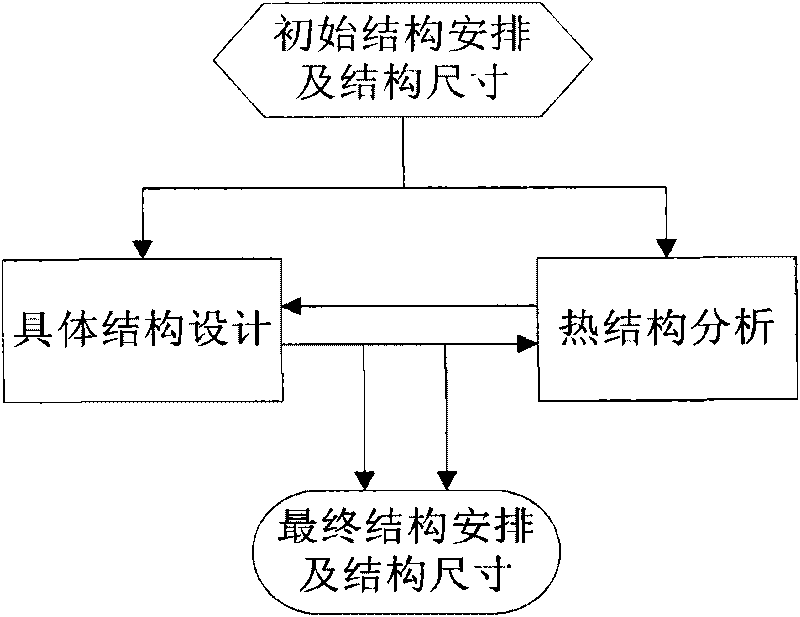

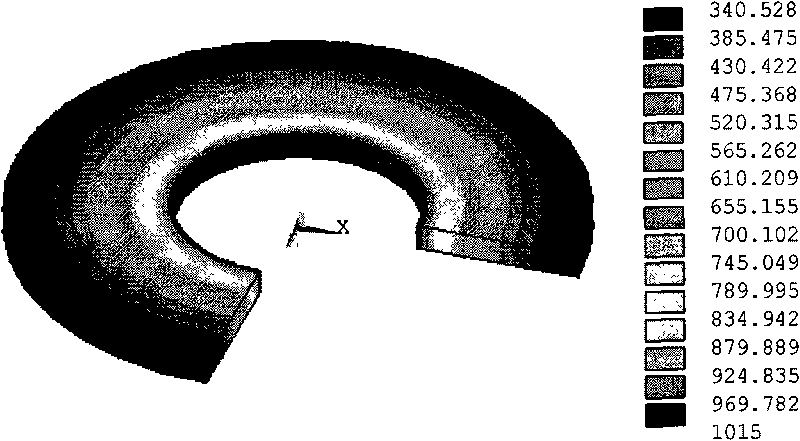

Method for designing structure of low-cost test combustion chamber with reliable thermal protection

InactiveCN101738316AGuaranteed temperature measurement accuracySmall volumeEngine testingRocket engine plantsCombustion chamberHeat conducting

The invention discloses a method for designing a structure of a low-cost test combustion chamber with reliable thermal protection. The combustion chamber comprises a body barrel segment, a connecting flange, a nozzle part, a connecting bolt and a measuring filler neck part. The combustion chamber adopts a capacitive type structure; the body barrel segment is made of a pure copper material with a high thermal conductivity; and the nozzle part is made from a copper-infiltrated tungsten material. In the invention, a thermal analysis aided design method is required to be used firstly, which needs to establish a computation mode and a computing method at first and then perform an iterative design process of the structural design and the thermal analysis. The computation mode adopts an unsteady thermal-dimensional heat conducting differential equation and the computed heat exchange mainly comprises heat convection from the gas to the chamber wall and the radiant heat exchange, the heat conduction in the chamber wall, the convection from the chamber wall to the outside and the radiant heat exchange. The thermal analysis aided design method comprises a global computing analysis and a local correcting and computing analysis. The method can minimize the materials used under the condition that the combustion chamber has the reliable thermal protection and greatly reduce the cost.

Owner:BEIHANG UNIV

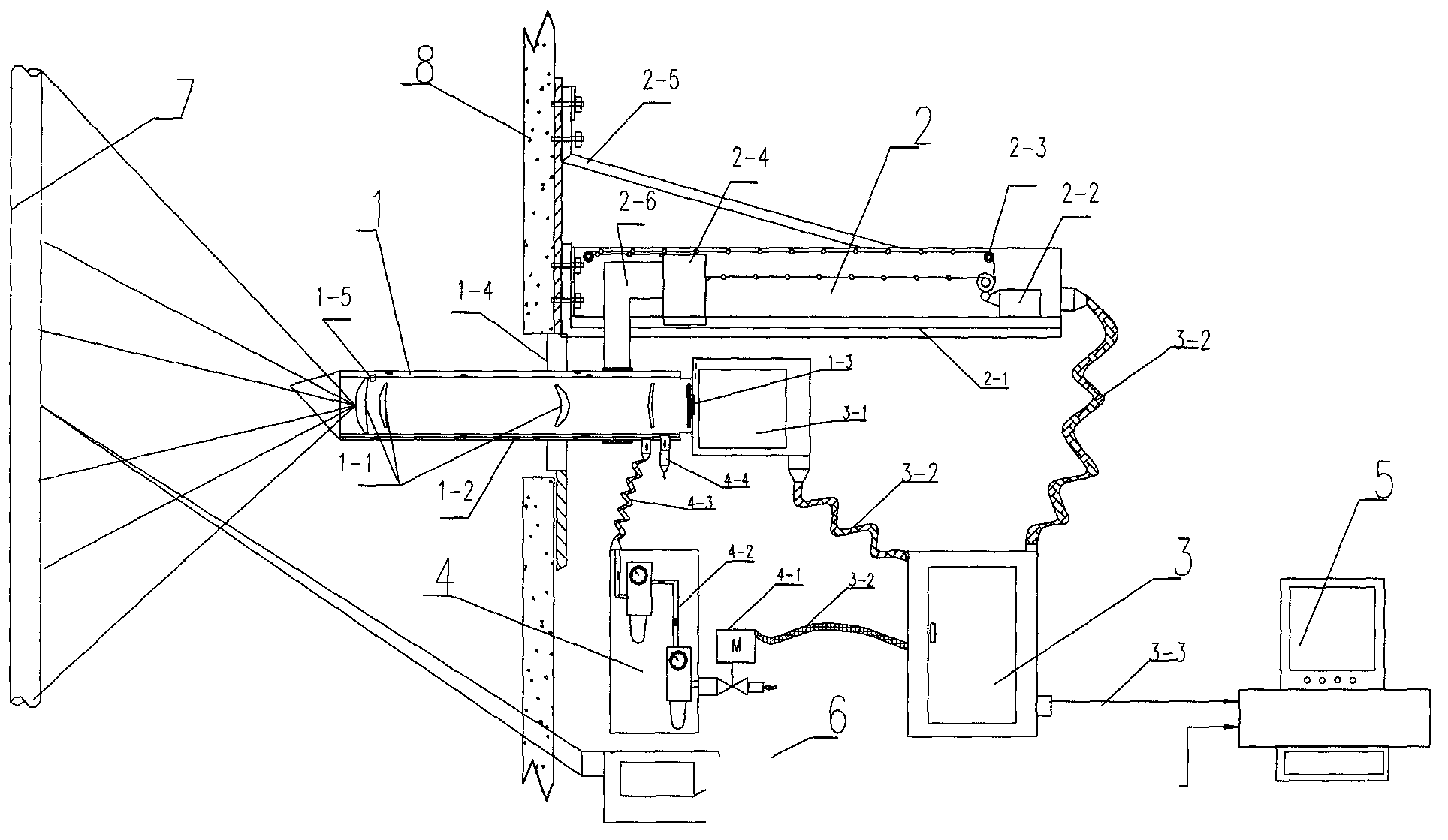

Hearth workpiece temperature measuring device and method

ActiveCN103808412AAccurate measurementHigh precision of contact temperature measurementRadiation pyrometryCorrection algorithmFlue gas

The invention discloses a hearth workpiece temperature measuring device and a method and mainly aims to realize on-line measurement on an industrial furnace hearth workpiece surface temperature field in the hot working field. The hearth workpiece temperature measuring device comprises an infrared endoscope lens group having a cooling protection sleeve, a high temperature flue gas filter, an infrared heat imaging probe, an automatic lens group rotation driving and reversing mechanism, an infrared heat imaging temperature measurement host, monitoring display equipment and a contact type workpiece surface temperature thermodetector. The hearth workpiece surface temperature field infrared heat imaging temperature measurement system device and the temperature measurement method are realized. According to the device, the infrared heat imaging lens group has the high temperature flue gas filter, so a temperature shielding effect for workpieces in the hearth can be realized through effectively filtering high temperature flue gas. Through a heat pixel temperature system error correction algorithm, a system error can be effectively eliminated, and temperature measurement precision is improved.

Owner:CHINA PETROCHEMICAL CORP +1

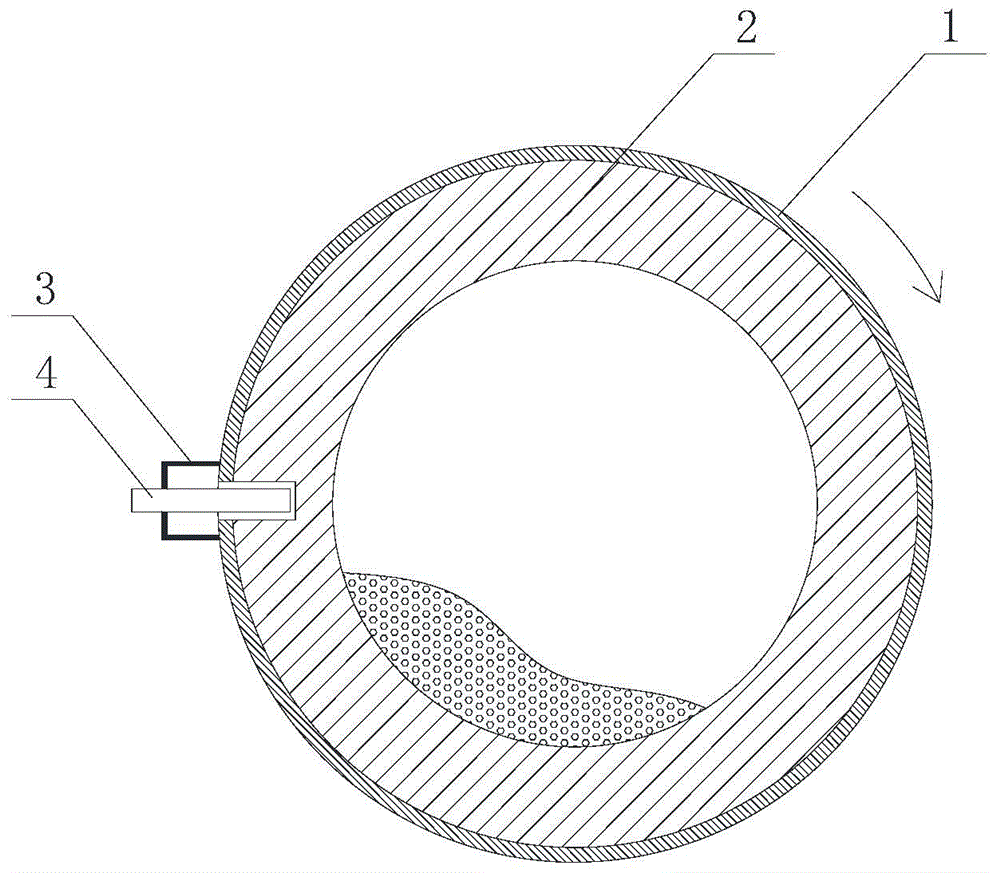

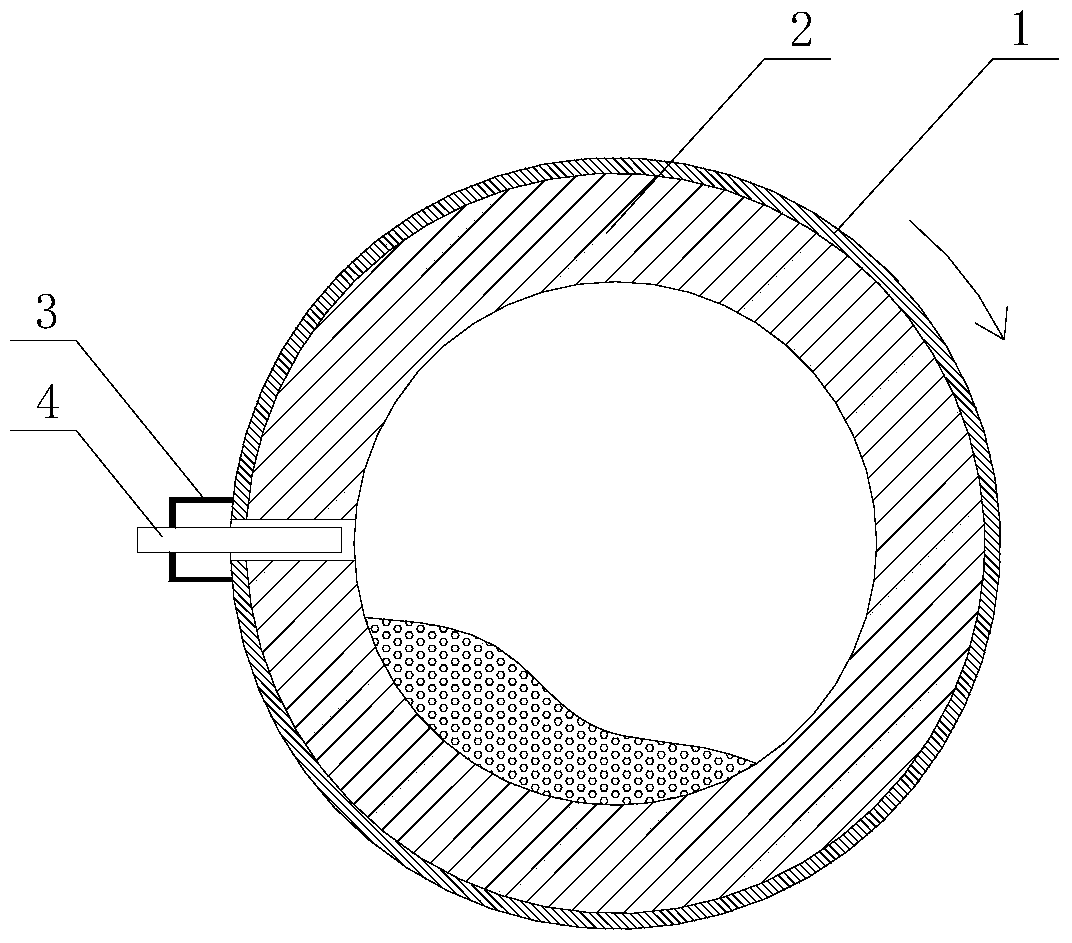

Motor-driven type rotary kiln direct temperature measuring device

ActiveCN104931147AGuaranteed service lifeGuaranteed temperature measurement accuracyThermometers using electric/magnetic elementsUsing electrical meansMotor driveReciprocating motion

The invention relates to the rotary kiln temperature measurement technical field, and provides a motor-driven type rotary kiln direct temperature measuring device comprising a linear motor, a thermocouple and a sleeve pipe arranged outside the thermocouple; the linear motor is connected with a first end of the thermocouple, and a second end of the thermocouple extends into a temperature measurement through hole arranged in a side wall of the rotary kiln; the thermocouple and the sleeve pipe are driven by the linear motor so as to make reciprocating motions along an axial direction of the temperature measurement through hole; the sleeve pipe is provided with a temperature measurement thin hole used for realizing thermocouple temperature measurement. The motor-driven type rotary kiln direct temperature measuring device uses the linear motor to drive the sleeve pipe and the thermocouple, so the sleeve pile and the thermocouple can make moves in the temperature measurement through hole at certain period in a radial direction of the rotary kiln in a rotary process of the rotary kiln, thus automatically removing material entering the temperature measurement through hole, preventing material pieces from blocking the temperature measurement through hole, and ensuring life and temperature measurement precision of the thermocouple.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

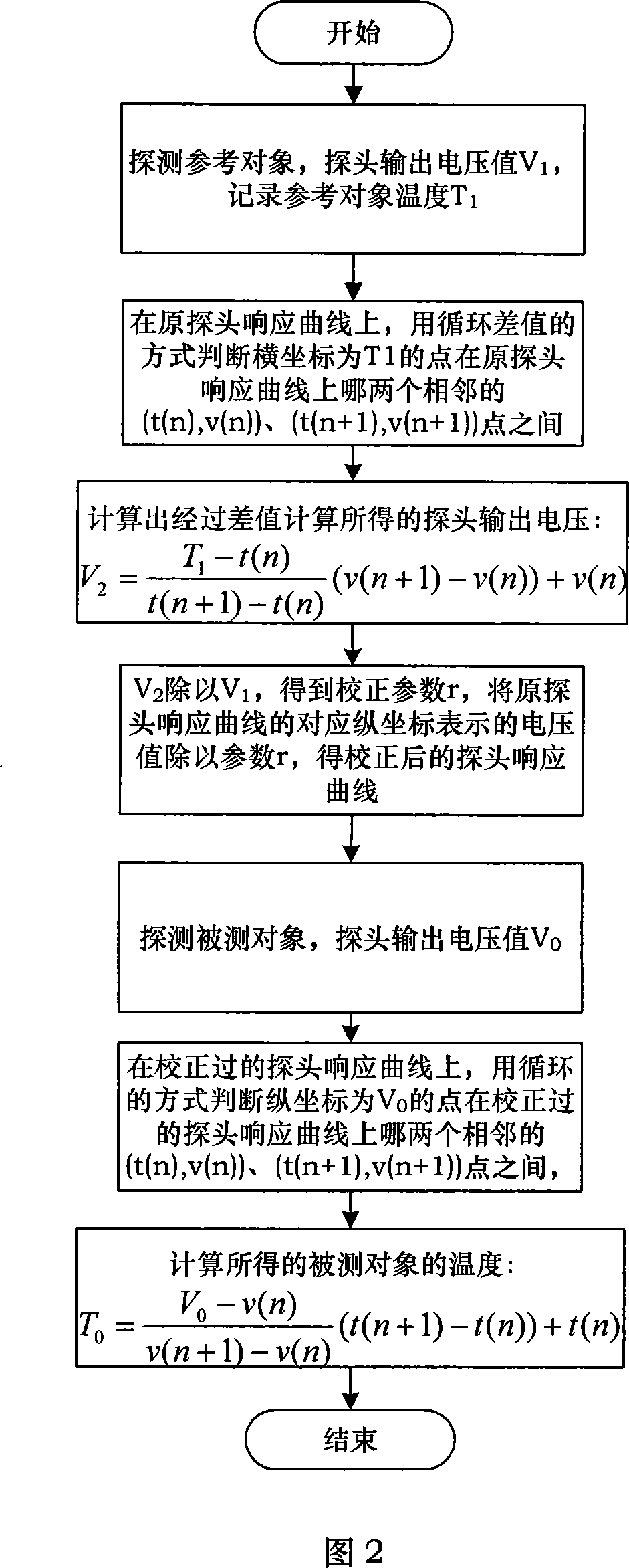

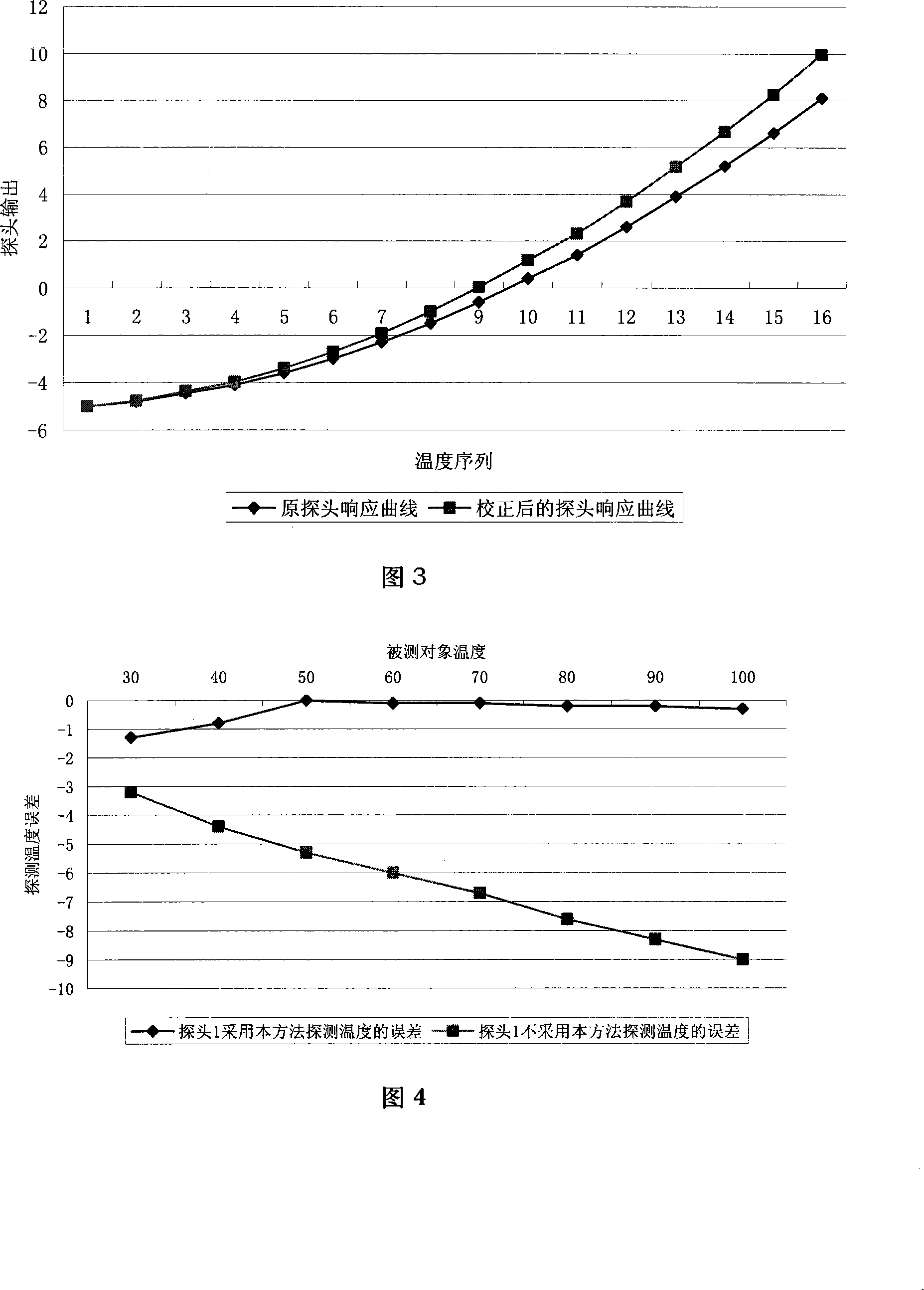

System calibrating method for improving measurement accuracy

InactiveCN101229813AEnsure system temperature measurement accuracyEliminate the influence of temperature measurement accuracyRailway auxillary equipmentRailway profile gaugesPhysicsTemperature measurement

The invention discloses a system calibration method for improving the measurement precision, which avoids the effect on temperature measurement precision due to different probe performance. After the probe is installed or replaced, a probe respond curve corresponding to the probe can be obtained by carrying out calibration once with blackbody and calculating by a computer system without inputting a respond curve of each probe or replacing any program manually, so as to avoid the effect on the temperature measurement precision due to different probe performance. When the change of probe performance is big, calibration is carried out once with the blackbody and the probe respond curve corresponding to the current performance of the probe can be obtained through the calculation of the computer system, thus guaranteeing the precision of temperature measurement of the system.

Owner:BEIJING CTROWELL INFRARED TECHN

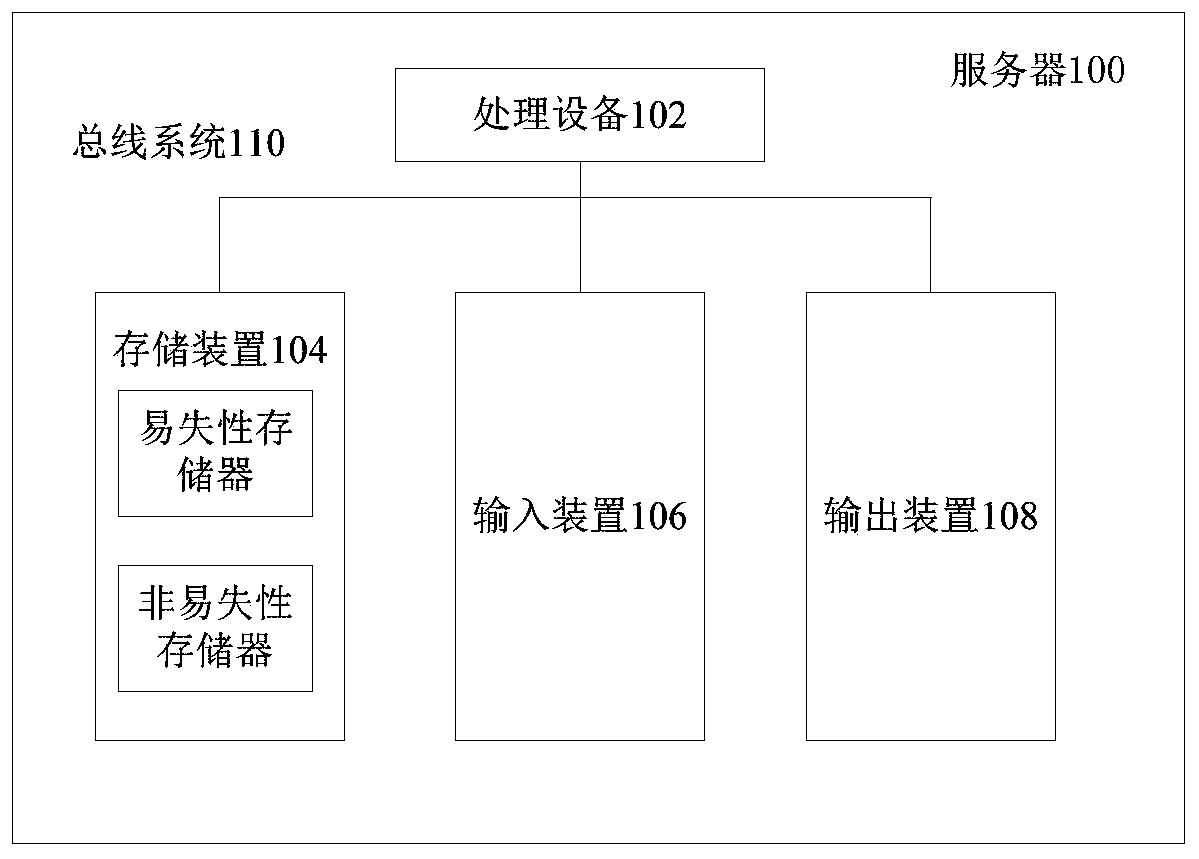

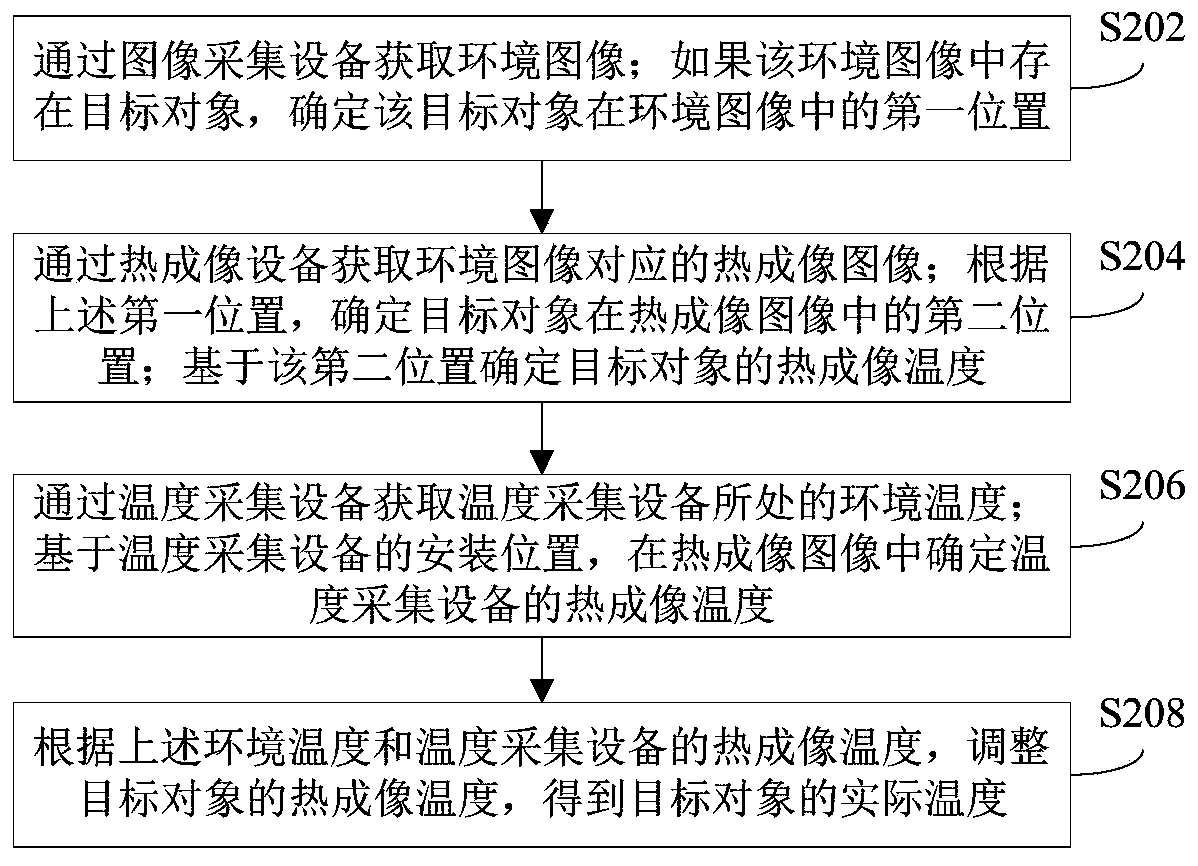

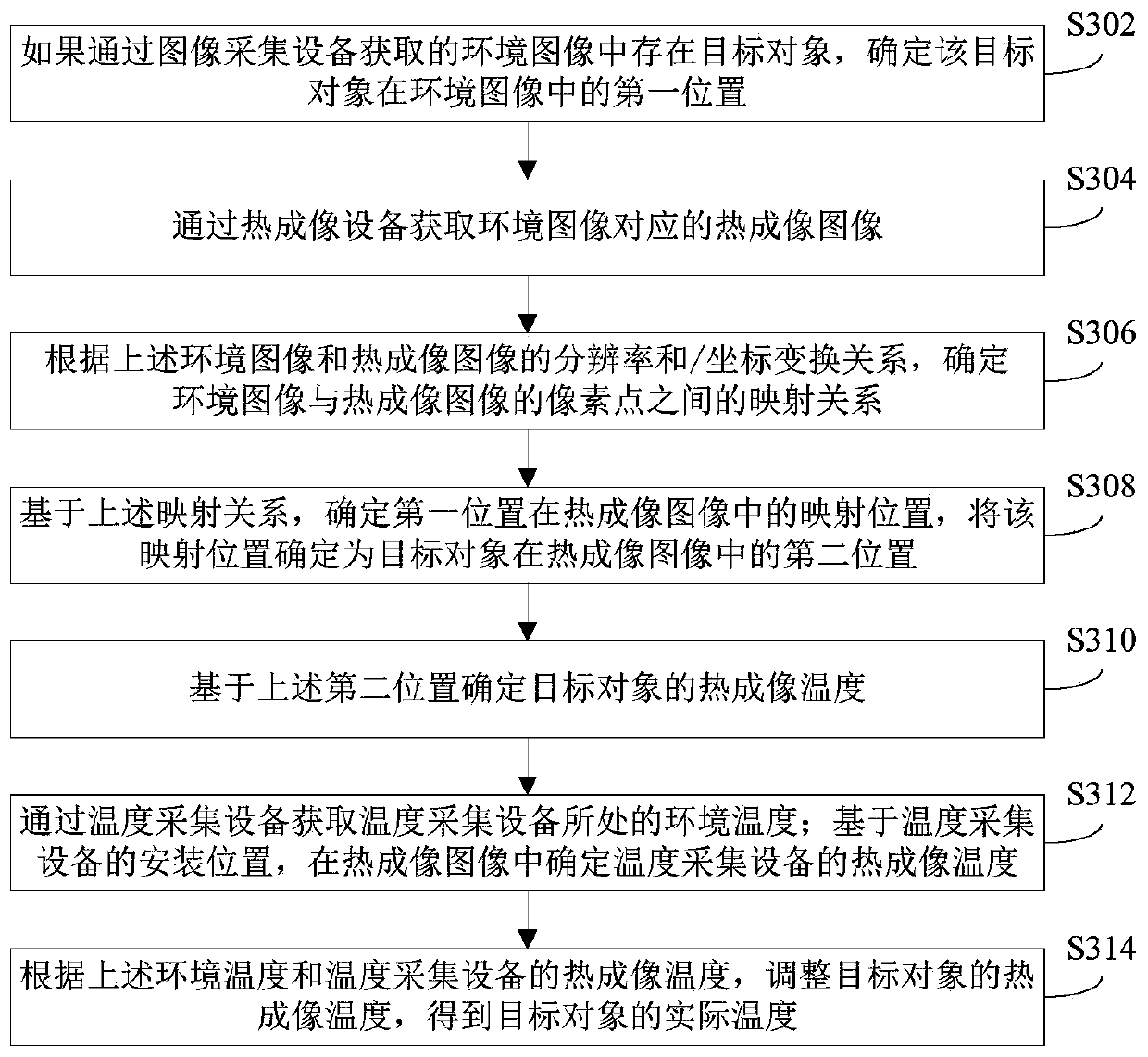

Temperature measurement method and device, server and temperature measurement system

PendingCN111157123AAvoid defectsGuaranteed temperature measurement accuracyRadiation pyrometryImage pairImaging equipment

The invention provides a temperature measurement method and device, a server and a temperature measurement system. The method comprises the steps of detecting a target object from an environment imageobtained by image acquisition equipment, and determining a first position of the target object; obtaining a thermal imaging image corresponding to the environment image through thermal imaging equipment, and determining a thermal imaging temperature of the target object based on the first position; acquiring an environment temperature through temperature acquisition equipment; and adjusting the thermal imaging temperature of the target object according to the environment temperature and the thermal imaging temperature of the temperature acquisition equipment in the thermal imaging image to obtain the actual temperature of the target object. According to the method, the temperature drift of the thermal imaging equipment is corrected through the environment temperature and the thermal imaging temperature of the temperature acquisition equipment, and the accurate actual temperature of the target object can be obtained based on the thermal imaging temperature of the target object. In addition, the method employs the temperature acquisition equipment to replace a conventional black body so as to avoid defects of the black body, so that the method improves the robustness and reduces thedeployment difficulty while guaranteeing the temperature measurement precision.

Owner:MEGVII BEIJINGTECH CO LTD

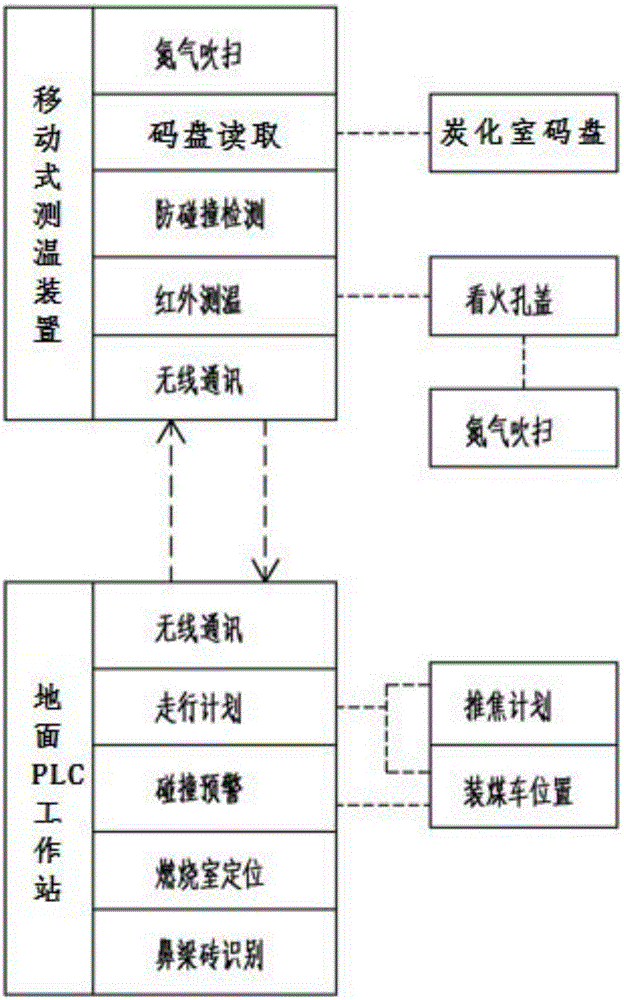

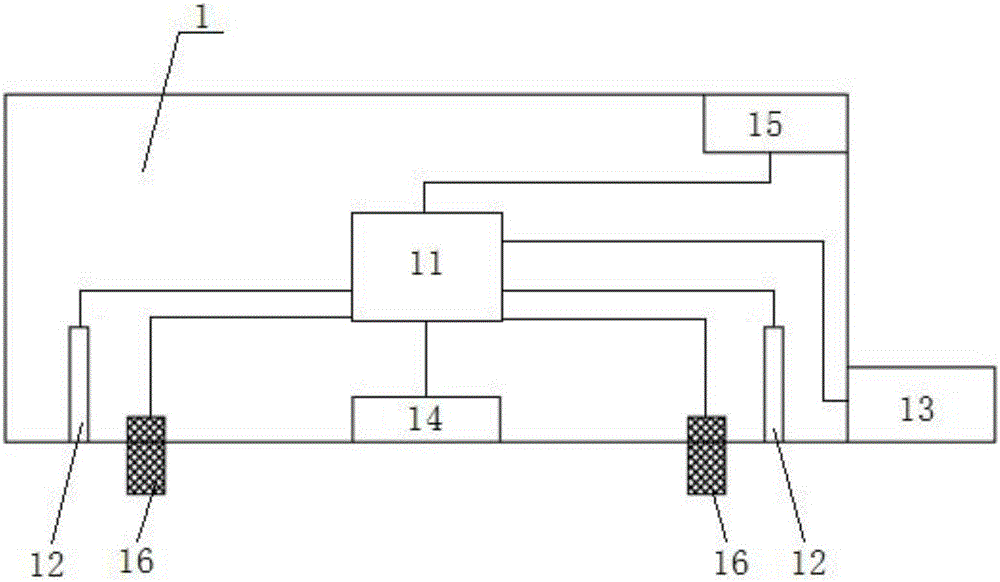

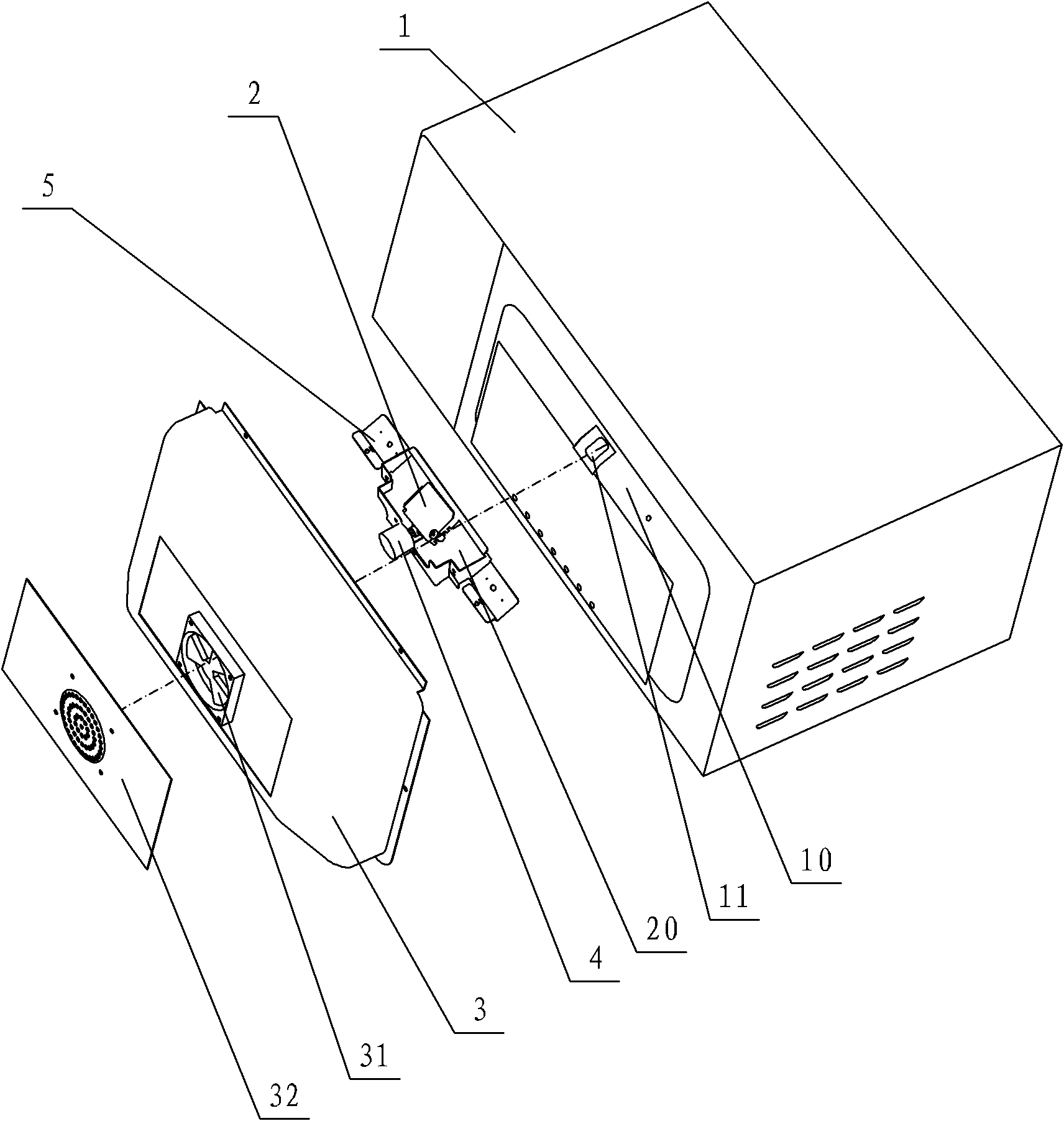

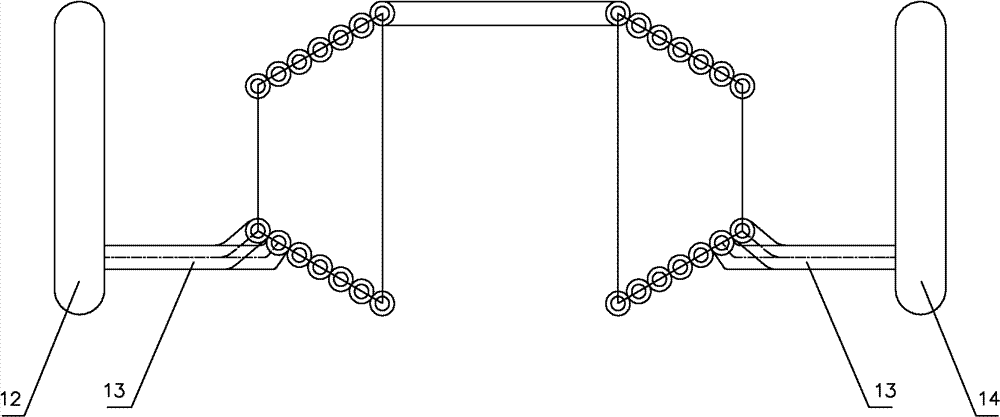

Automatic measuring method and automatic measuring system for temperature of vertical flue of coke oven

ActiveCN106382991ASimple compositionSmall footprintRadiation pyrometryEnergy inputBrickCombustion chamber

The invention relates to an automatic measuring method and an automatic measuring system for temperature of a vertical flue of a coke oven. Through a temperature measuring device walking track compiling process, a combustion chamber positioning process, a noise bridge brick identification process and a continuous temperature measuring process, the temperature of each vertical flue is determined according to a temperature curve which is measured in the continuous temperature measuring process, the number of the combustion chamber, a time stamp and nose bridge brick identification information. According to the automatic detecting method and the automatic detecting system, existing equipment in a coke oven production system is sufficiently utilized, such as a carbonizing chamber code disc and a coal charger track; three movable temperature measuring devices are utilized for simultaneously measuring the temperatures of the vertical flues in different areas; a ground PLC workstation compiles the temperature measuring device walking track and makes a walking plan according to a coke pushing plan; continuous temperature measurement is performed on the vertical flues periodically on the condition that normal operation of a coke oven coal charger is not affected; and furthermore opening or closing of a fire observing hole cover is not required in the temperature measuring process, thereby greatly improving temperature measuring efficiency and furthermore improving timeliness in performing tempering on the coke oven.

Owner:ACRE AUTOMATION CO LTD MCC

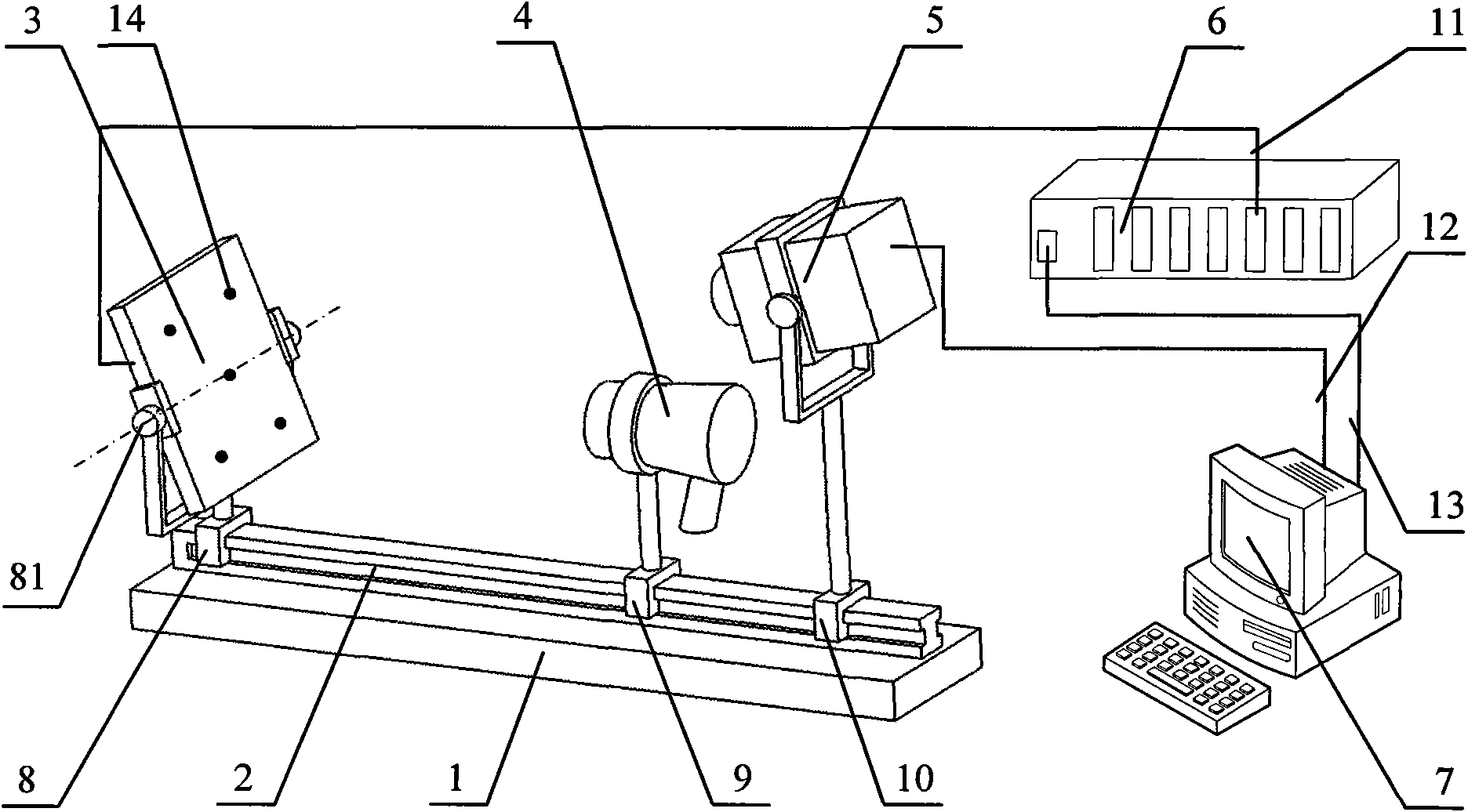

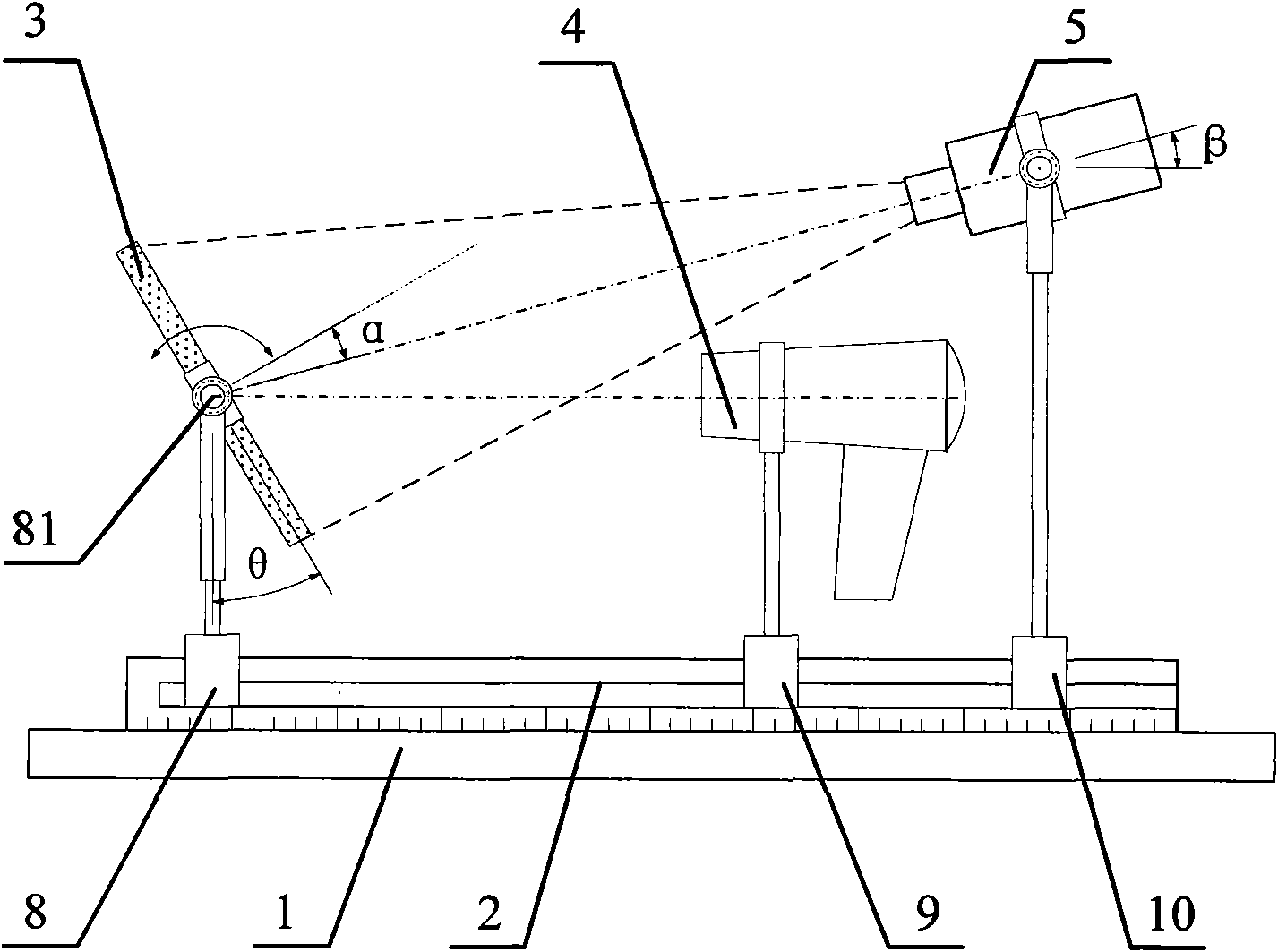

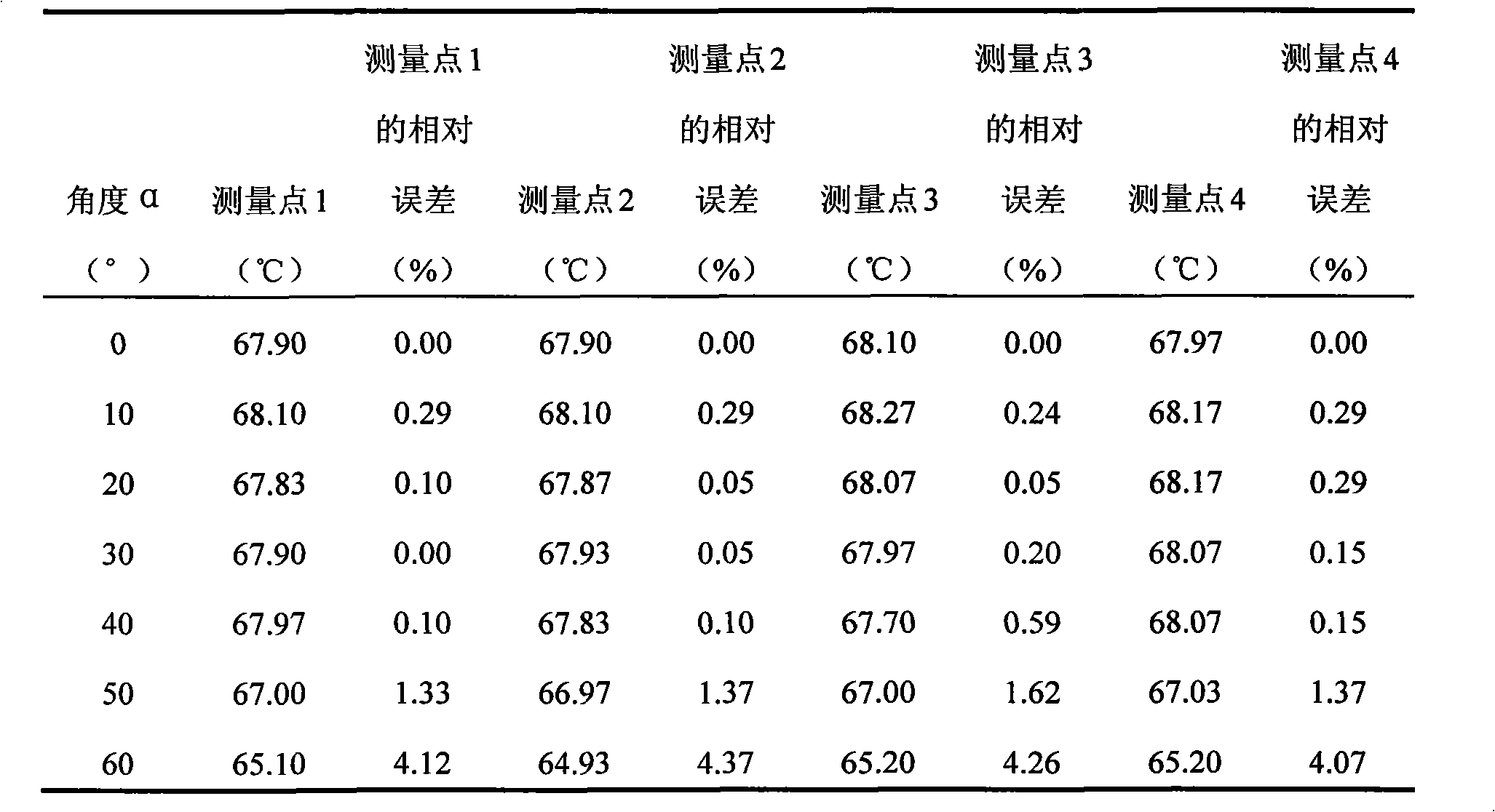

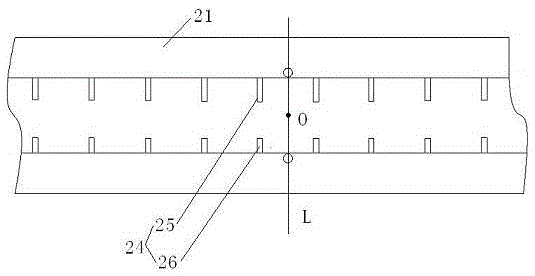

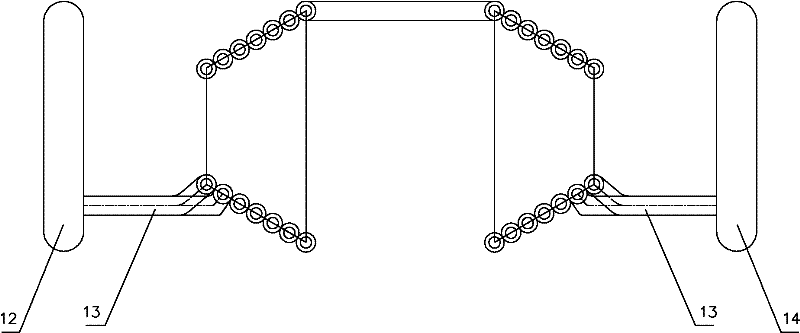

Combined measuring device and method for air outlet temperature filed of wind tube

InactiveCN101936775AOvercoming precise temperature distribution and temperature field characteristicsRealize combined measurementRadiation pyrometryThermometers using electric/magnetic elementsMeasurement deviceElectricity

The invention discloses a combined measuring device and method for the air outlet temperature field of a wind tube. A lead rail is fixed on a base, and a first bracket, a second bracket and a third bracket are mounted on the lead rail and matched with the lead rail in a sliding way. A wind target is mounted on a horizontal shaft of the first bracket and rotationally matched with the first bracket; and the horizontal shaft passes through the geometrical centre of the wind target and is vertical to the normal line of the wind target. The wind tube is mounted on the lead rail through the second bracket; an online infrared thermal imager is mounted on the lead rail through the third bracket; the wind tube is located between the wind target and the online infrared thermal imager; the centre line of the wind tube passes through the geometrical centre of the wind target; the air outlet of the wind tube and the lens of the online infrared thermal imager are opposite to the measuring end of a thermocouple on the wind target; and the optical shaft of the online infrared thermal imager passes through the geometrical centre of the wind target. The lens of the online infrared thermal imager is located above the air outlet of the wind tube. The thermocouple on the wind target is electrically connected with multiple paths of collectors; and the multiple paths of collectors and the online infrared thermal imager are respectively connected with an upper computer via data lines.

Owner:CHINA JILIANG UNIV

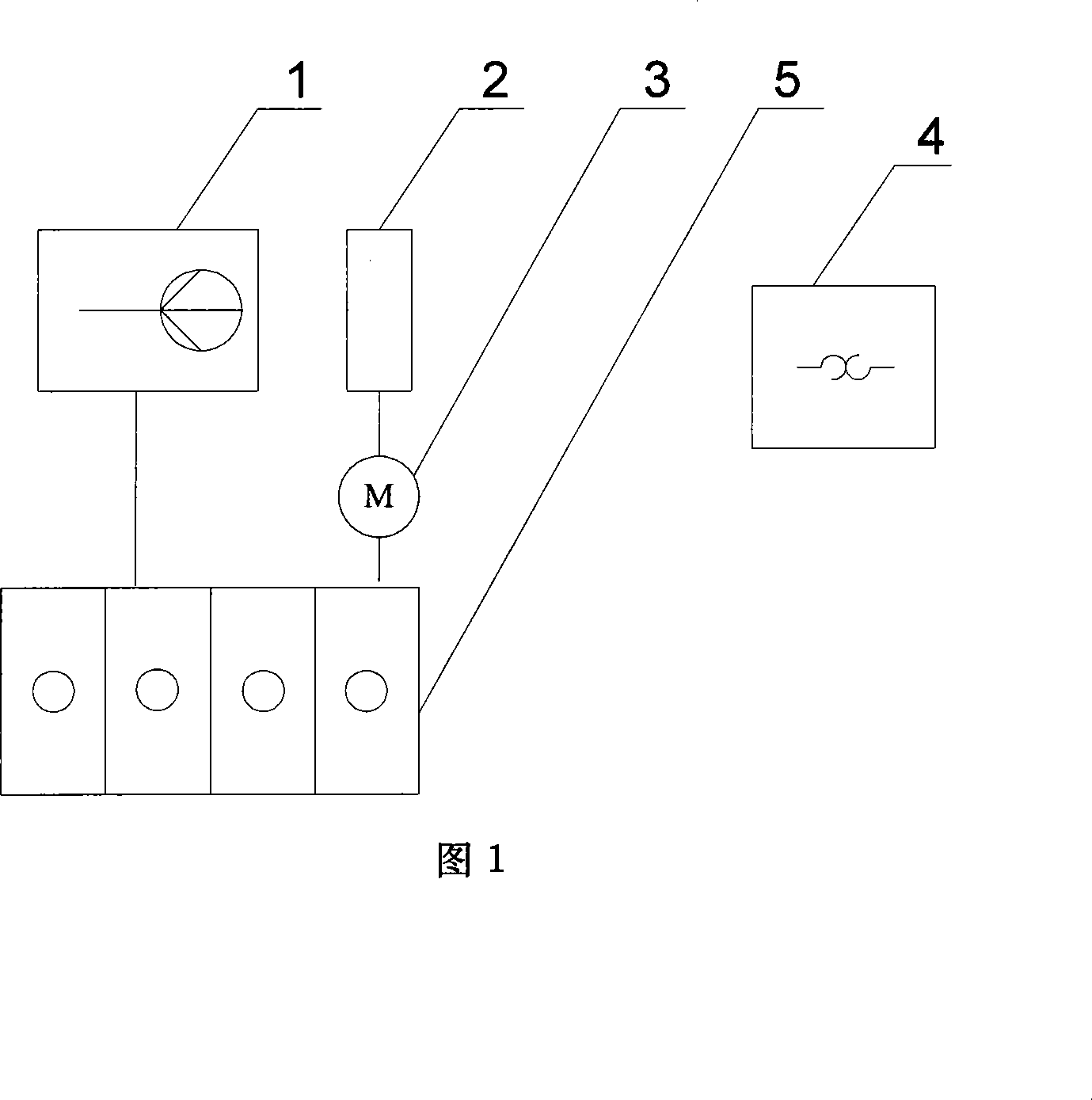

Microwave oven with intelligent induction function

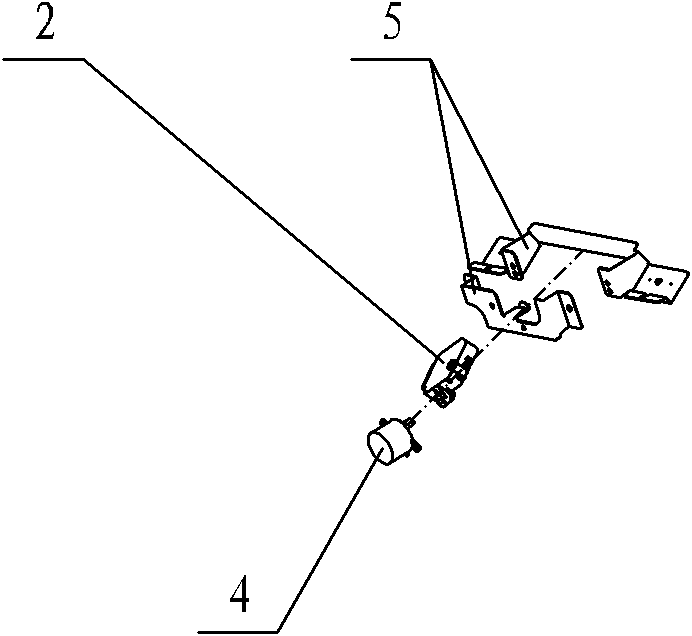

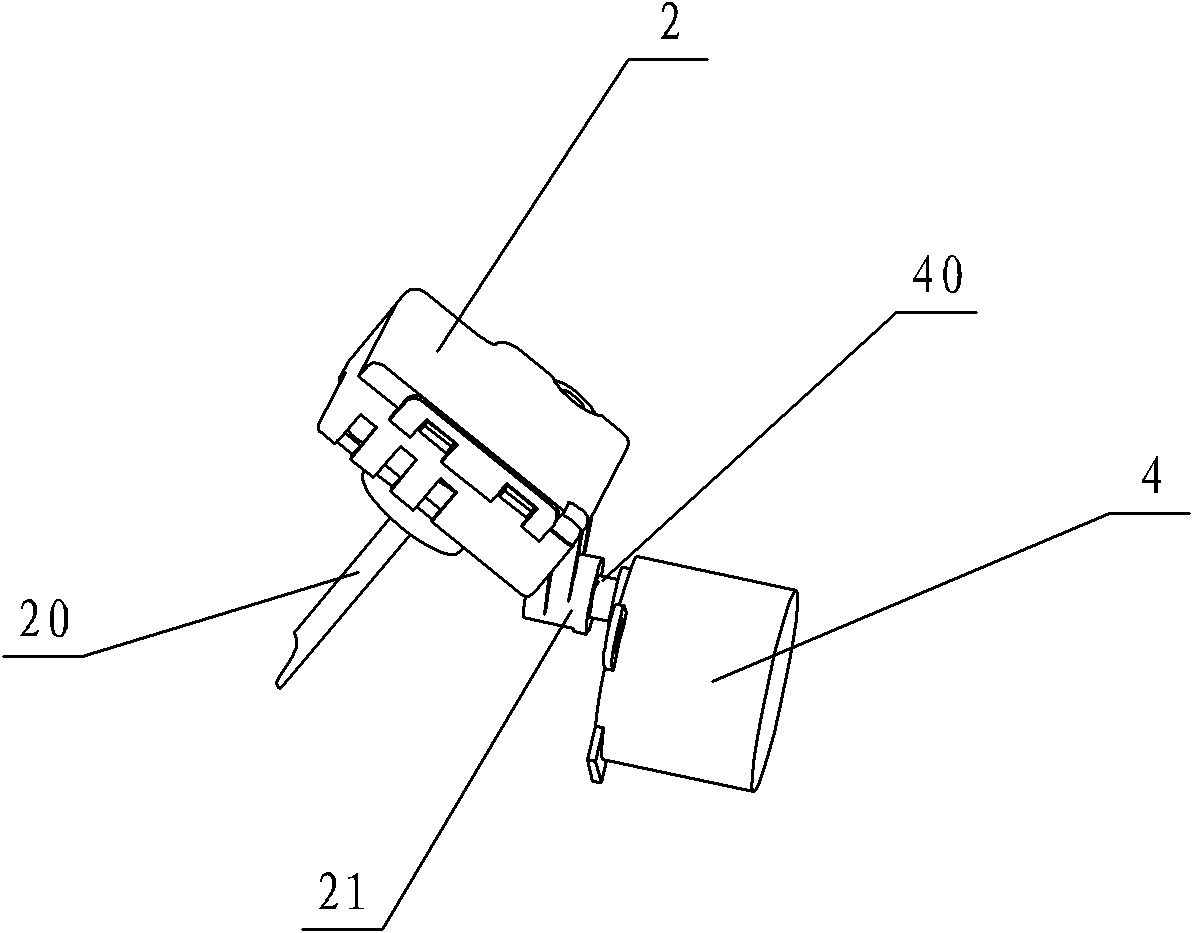

ActiveCN102012050AImprove sensing accuracyExpand coverageDomestic stoves or rangesLighting and heating apparatusRotational axisMotor drive

The invention discloses a microwave oven with intelligent induction function, which comprises a cavity, an intelligent sensing element, a rear cover and a control device, wherein the cavity is provided with an opening; an inductor of the intelligent sensing element is arranged at the opening; and rays emitted by the inductor can enter the cavity. The microwave oven also comprises a rotating motor, wherein the rotating motor is connected with the inductor of the intelligent sensing element; an included angle between a rotating shaft of the rotating motor and a central shaft of the inductor is less than 90 degrees; the central shaft of the inductor is inclined downwards and faces the interior of the cavity; and the rotating motor drives the inductor to rotate so as to make the central shaft of the inductor rotate from side to side. A mounting frame is also arranged on the microwave oven; and the rotating motor and the intelligent sensing element are fixed on the rear cover behind the cavity through the mounting frame. According to the invention, the coverage range of the rays emitted by the intelligent sensing element in the cavity is widened, the induction accuracy of the intelligent inductor is improved, the temperature in the cavity of the microwave oven can be accurately judged, and the cooking effect of the microwave oven is improved.

Owner:MIDEA GRP CO LTD

Low-temperature contact type surface temperature sensor

PendingCN109253817AEasy to useGuaranteed accuracyThermometer detailsThermometers using electric/magnetic elementsEngineeringContact type

The invention relates to a low-temperature contact type surface temperature sensor, comprising a housing, an upper cover, a temperature sensor, a magnetic ring and a uniform temperature medium, wherein an annular clamping groove is formed in the lower end of the housing; the magnetic ring is mounted in the annular clamping groove; a uniform temperature tank is arranged in the housing; the upper cover is arranged on the upper end of the housing and seals the uniform temperature tank in the housing; the temperature sensor is arranged in the upper cover in a penetrating manner; the lower portionof the temperature sensor is inserted into the uniform temperature tank; the uniform temperature medium is accommodated in the uniform temperature tank, which is an antifreezing solution; a liquid injecting hole is formed in the upper cover and corresponds to the uniform temperature tank on the housing; and a plug is arranged in the liquid injecting hole. According to the invention, the low-temperature contact type surface temperature sensor is attached to the surface of an object to be detected in a magnetic attraction manner, and no damage to the object to be detected is caused, thus ensuring the normal safe use of the object to be detected; the liquid uniform temperature medium is arranged in the housing of the surface temperature sensor, and the temperature sensor is immersed in the uniform temperature medium, so that the influence of external environment temperature and humidity on the temperature sensor can be avoided, ensuring the accuracy of temperature measurement.

Owner:HENAN PROVINCE INST OF METROLOGY

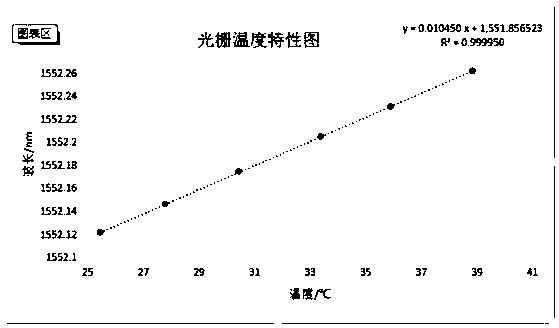

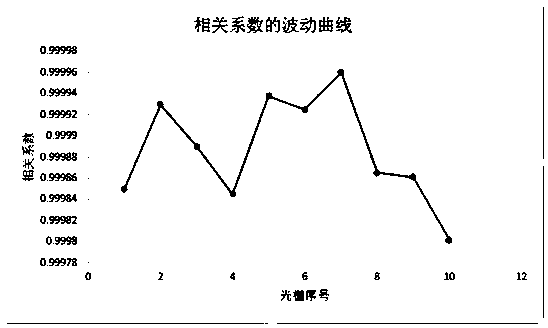

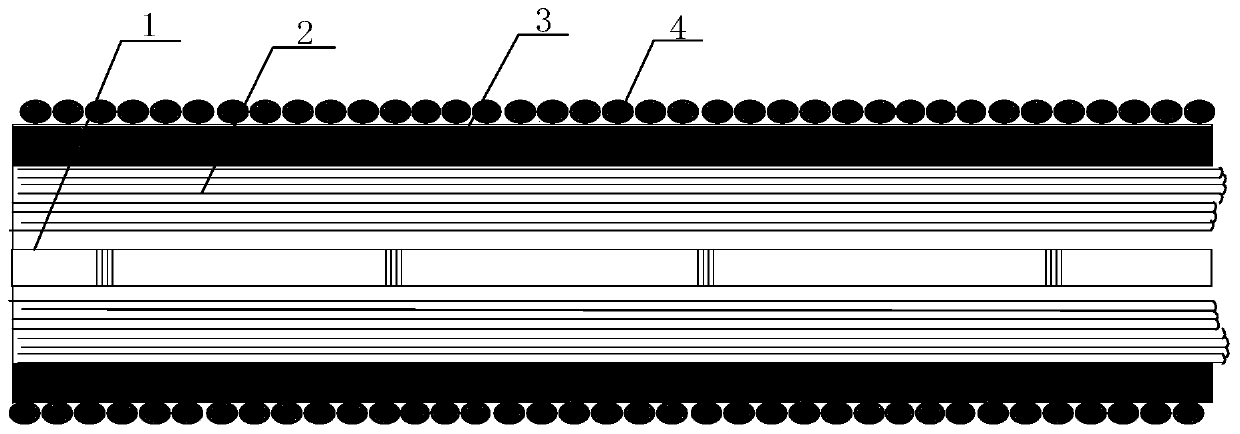

Stress-packaging-free temperature-sensing optical fiber cable and preparation method thereof

PendingCN110596837AEliminate the effects ofImprove temperature sensing accuracyThermometers using physical/chemical changesFibre mechanical structuresGratingLinear correlation

A stress-packaging-free temperature-sensing optical fiber cable and a preparation method thereof are provided, wherein the stress-packaging-free temperature-sensing optical fiber cable comprises: an ultra-weak optical fiber grating array positioned in the center; fiber bundles uniformly distributed around the ultra-weak optical fiber grating array in parallel, wherein the ultra-weak optical fibergrating array and the fiber bundles are freely combined; a metal tube wrapping the peripheries of the ultra-weak optical fiber grating array and the fiber bundles along the axial direction; and a reinforcement which is twisted and surrounded in a spiral form around the metal tube. According to the stress-packaging-free temperature-sensing optical fiber cable of the invention, the ultra-weak optical fiber grating array and the multiple fiber bundles are freely combined, then the metal tube is adopted for direct packaging, the extra length of the optical fiber is absorbed by adoption of a beam expanding effect after the optical fiber rebounds, the friction between the optical fiber and the tube wall of the metal tube is reduced, accumulated distribution of the extra length is inhibited, batch calibration is facilitated, the linear correlation degree of a temperature curve of the optical fiber is up to more than 0.999, the temperature sensitivity fluctuation is less than 0.3pm / DEG C, andthe temperature measurement precision of the optical cable is improved.

Owner:宜昌睿传光电技术有限公司

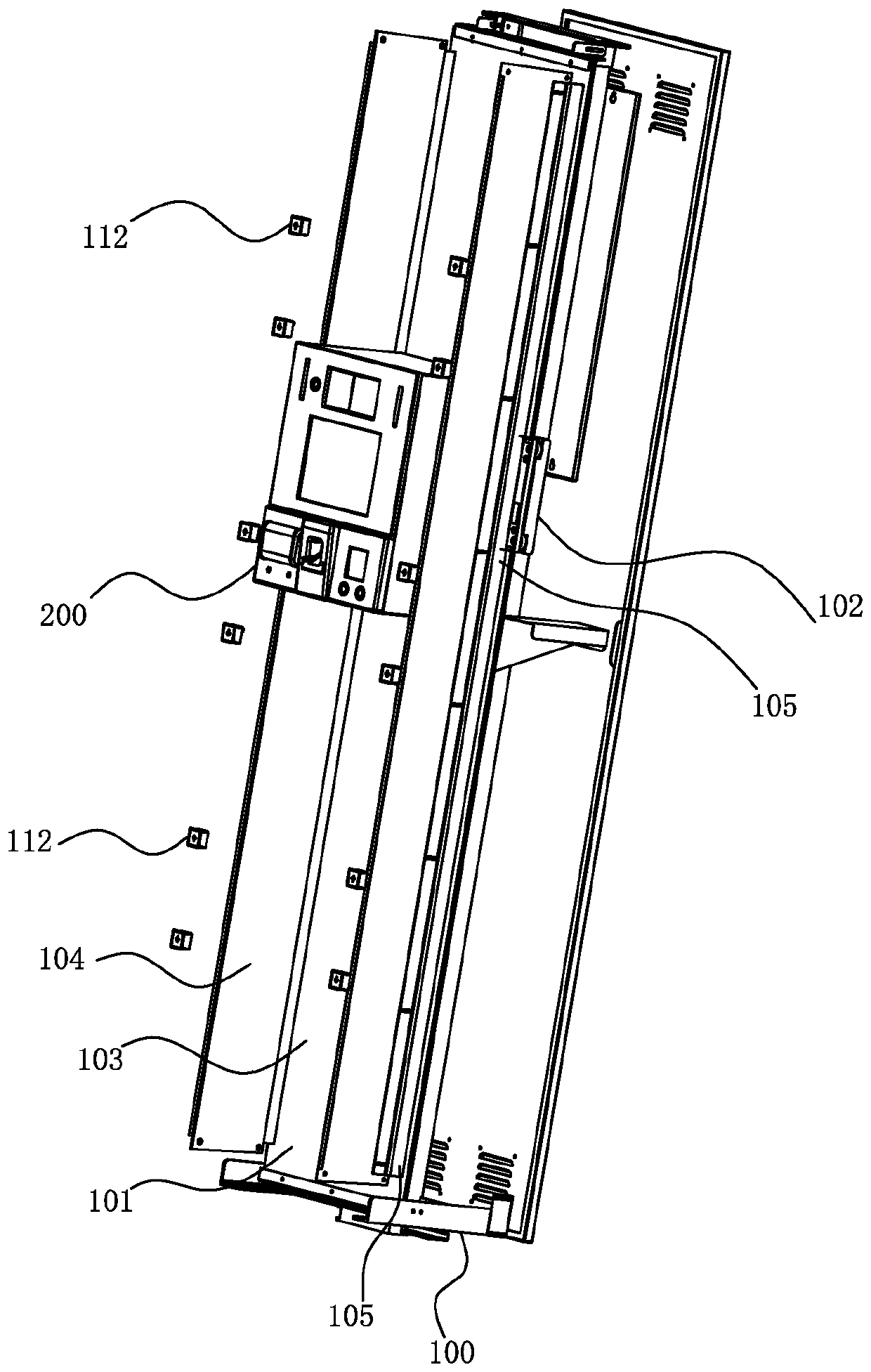

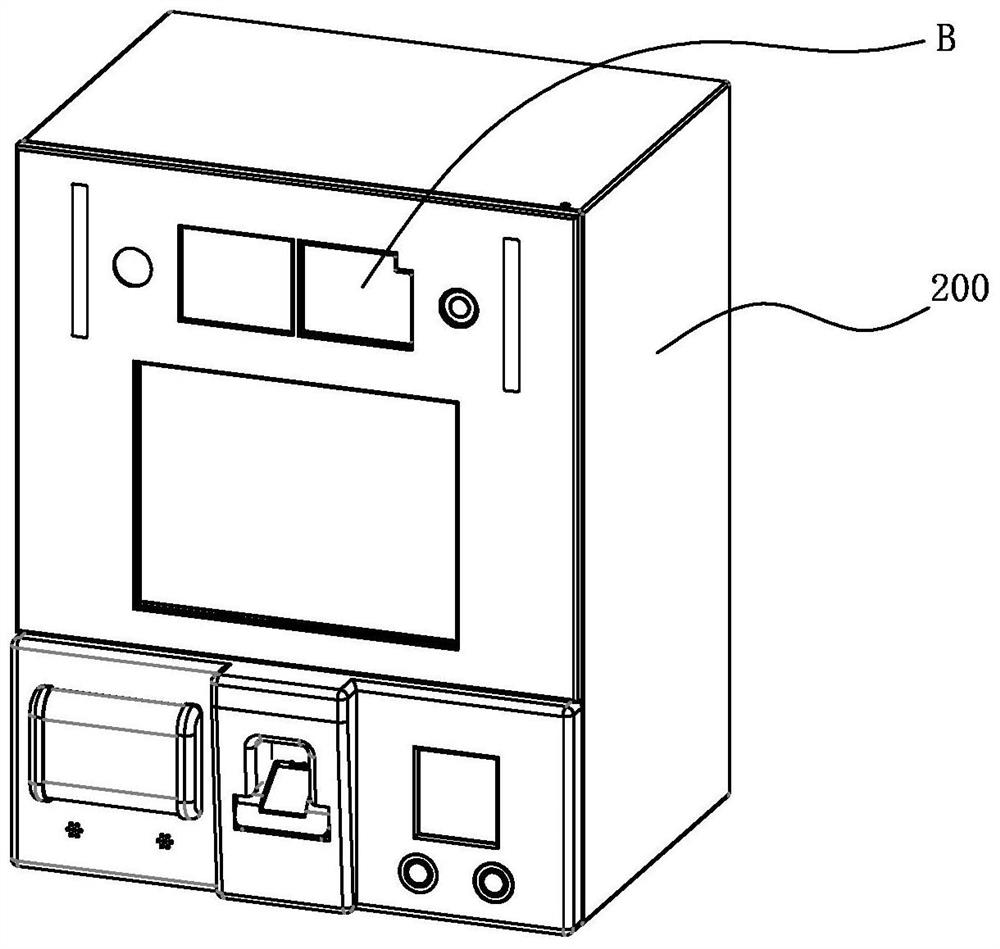

Embedded intelligent telescopic integrated cabinet

PendingCN110864813AImprove the level of informatizationAchieve positioningRadiation pyrometryIndividual entry/exit registersStructural engineeringMechanical engineering

The invention discloses an embedded intelligent telescopic integrated cabinet, and the cabinet comprises a cabinet frame, a first function module installed on the cabinet frame and a second function module installed on the cabinet frame. The first function module comprises a first panel fixedly connected with the cabinet frame, a certificate reader installed on the first panel, a fingerprint instrument installed on the first panel, and a scanning reader-writer installed on the first panel and located on the side edge of the fingerprint instrument. The second function module comprises a secondpanel which is fixedly connected with the cabinet frame and is connected with the cabinet frame through an elastic hinge, a point touch screen which is arranged on the second panel, a glass structurewhich is arranged on the second panel and is positioned above the point touch screen, a rotary door which is installed on the second panel and located on the right side of the glass structure, a roundglass structure which is installed on the second panel and located on the left side of the glass structure, and an ultrasonic probe which is installed on the second panel and located on the right side of the rotary door, so the labor intensity and personal injury risks of inspection and quarantine personnel are greatly reduced.

Owner:深圳市软筑信息技术有限公司

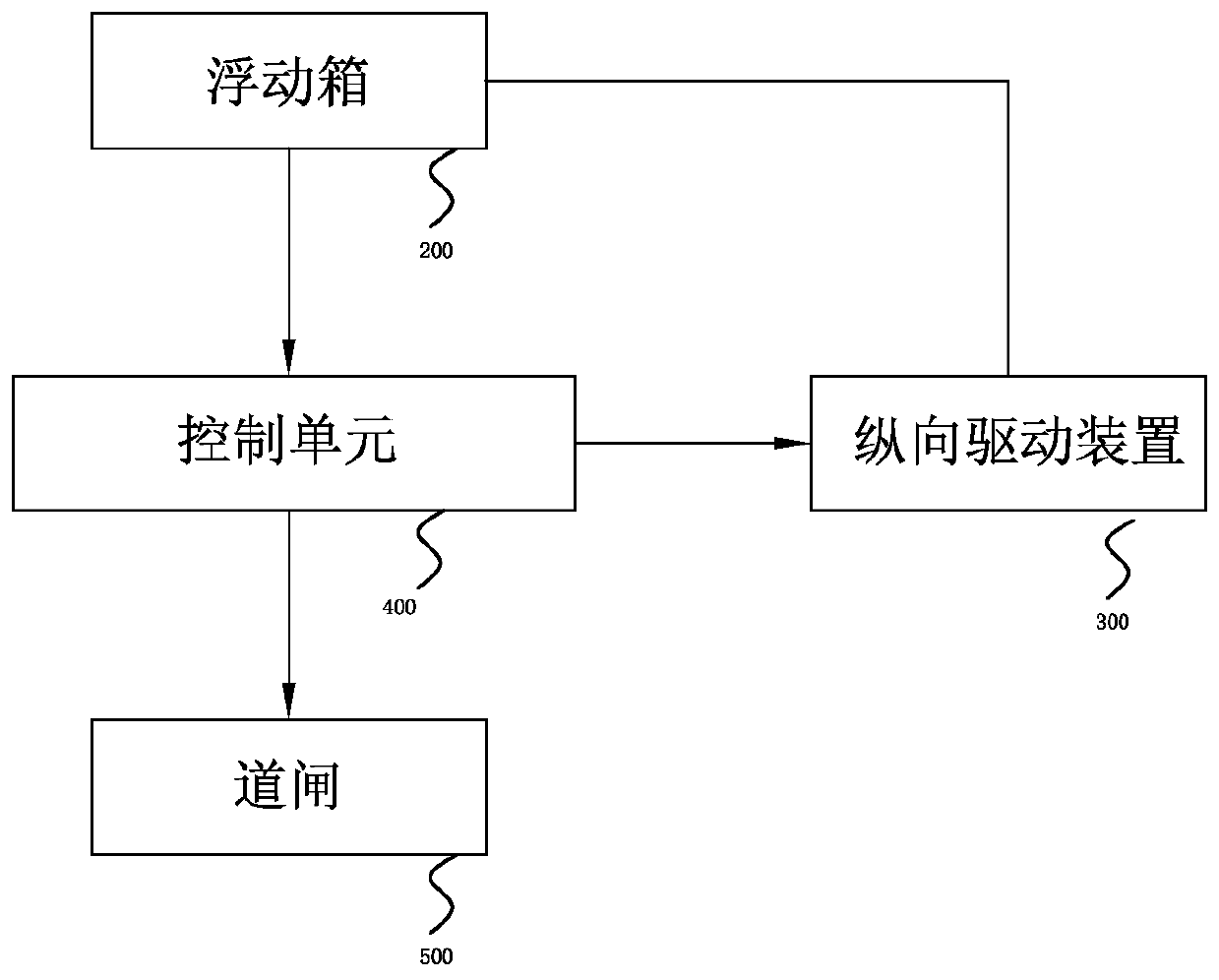

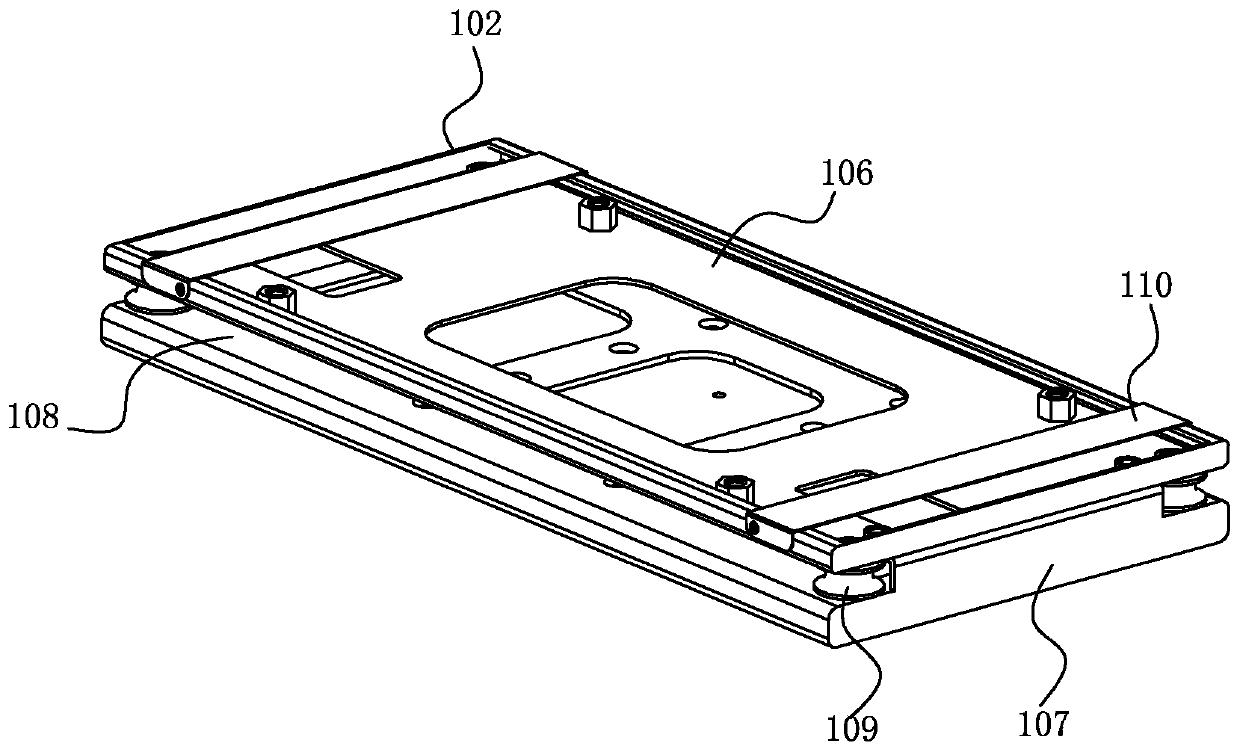

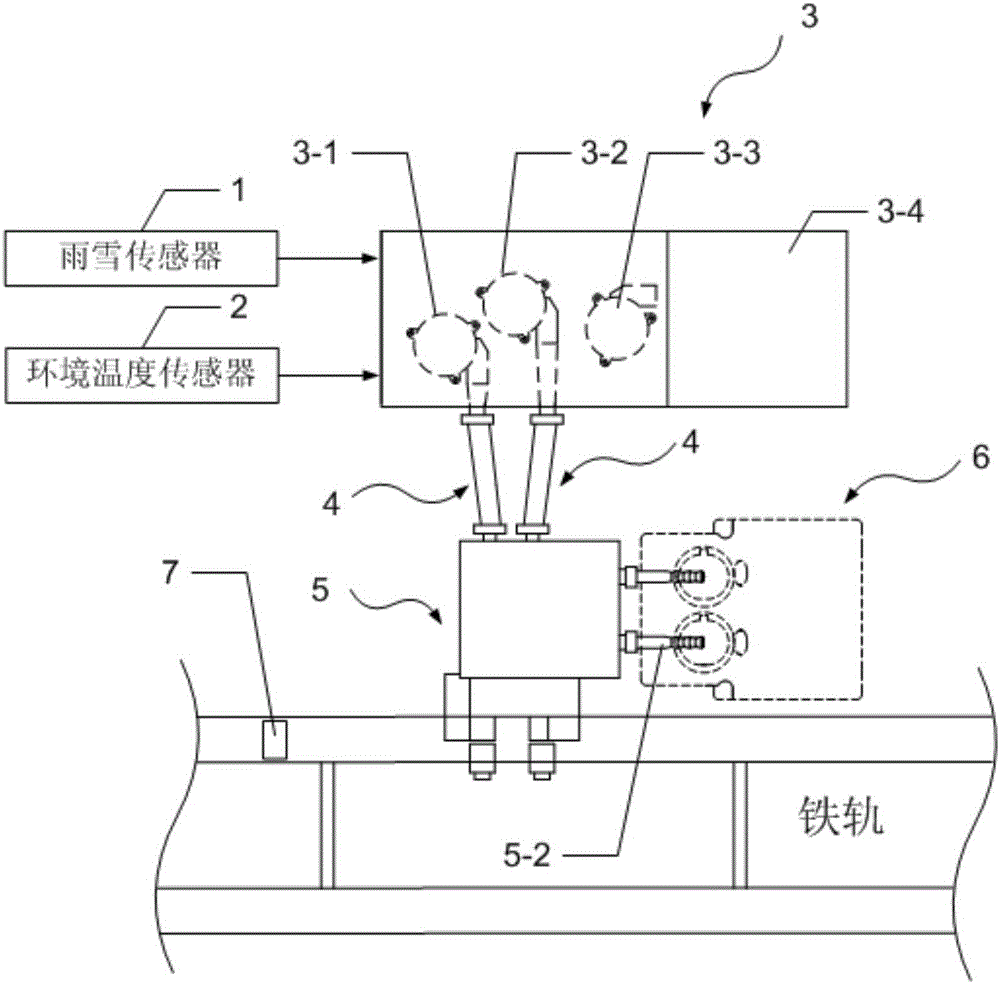

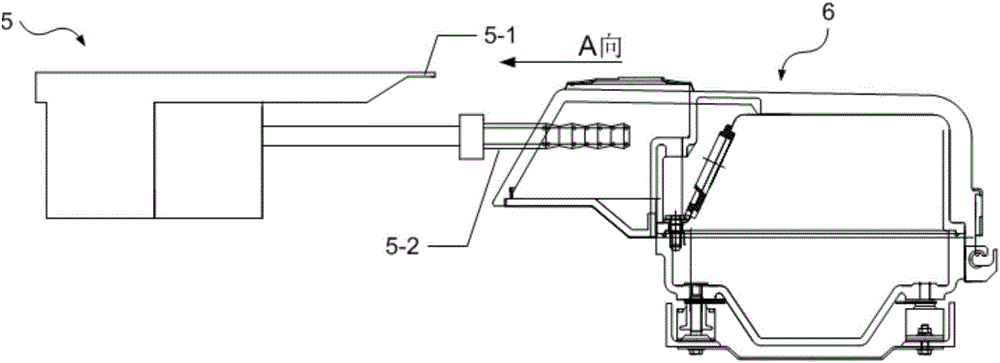

System and method for removing accumulated snow or sundries for train infrared axle temperature detecting equipment

ActiveCN106080654APrevent secondary occlusionAccurate judgmentCleaning using gasesRailway auxillary equipmentSnowpackMeasurement device

The invention provides a system and method for removing accumulated snow or sundries for train infrared axle temperature detecting equipment, and belongs to the field of railway assisted control systems. The problem that in severe snowing weather, due to the fact that snow and sundries enter a detection window, an infrared detection light path of the infrared axle temperature detecting equipment for measuring the train axle temperature is affected, and the measuring precision is affected accordingly can be solved. The system comprises a rain and snow sensor, an ambient temperature sensor, an air source mechanism, two air pipes and a bellows. The air source mechanism comprises a box, and an external air blower, an internal air blower and a controller are arranged in the box. Whether it snows can be accurately judged according to signals of the ambient temperature sensor and signals of the rain and snow sensor, and the air pipes are controlled to directly stretch into a train axle temperature measuring device to sweep the edge of a temperature measuring probe. The upper surface of the train axle temperature measuring device is swept again after delaying, the temperature measuring probe is prevented from being shielded by ice, snow and sundries on the surface again, and the temperature measuring precision is guaranteed.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

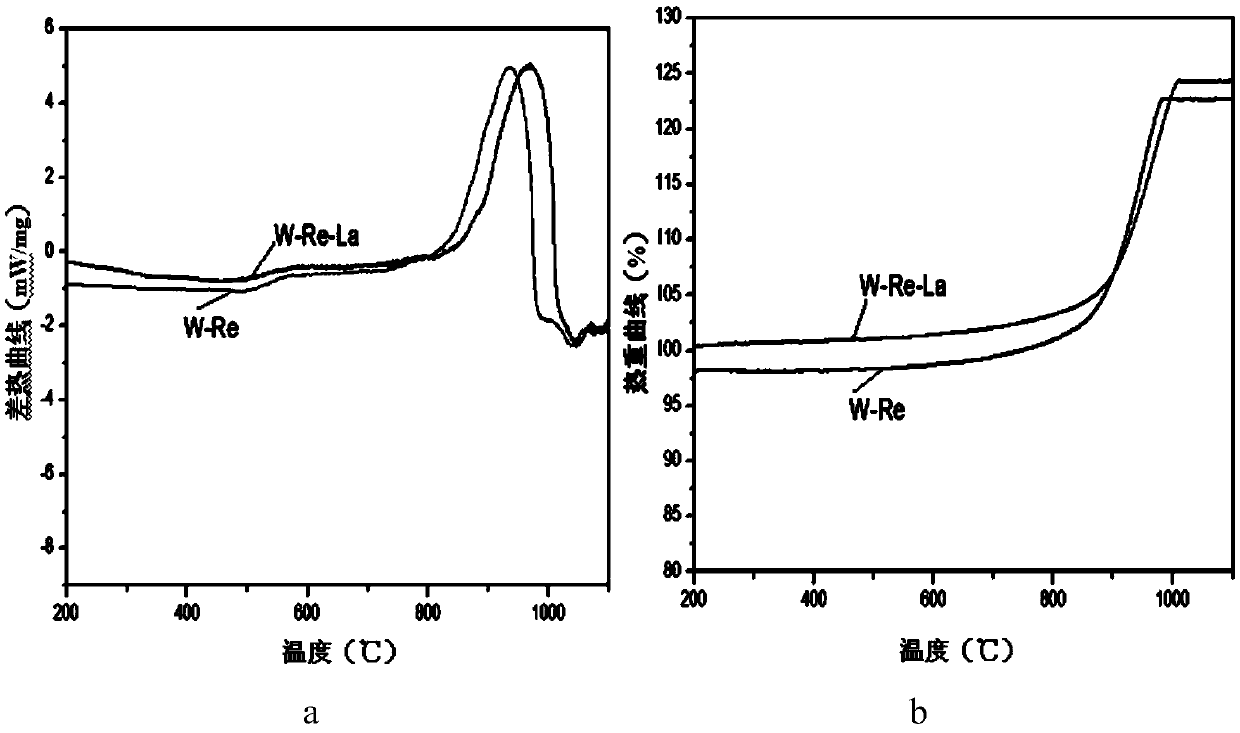

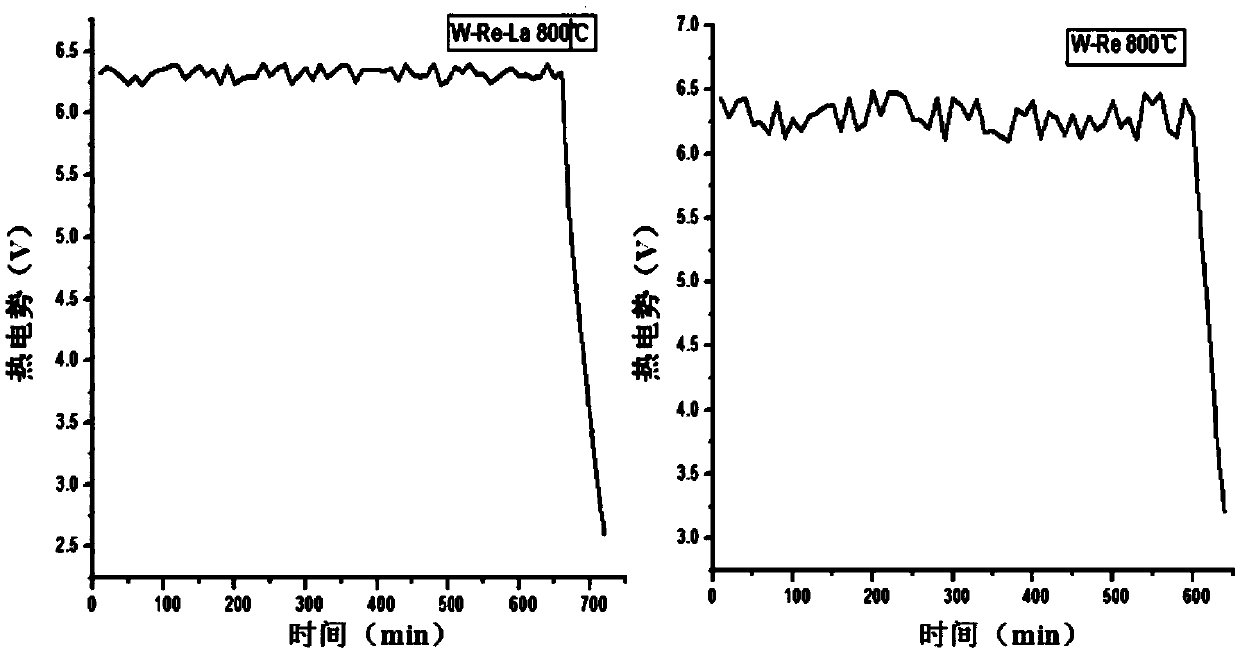

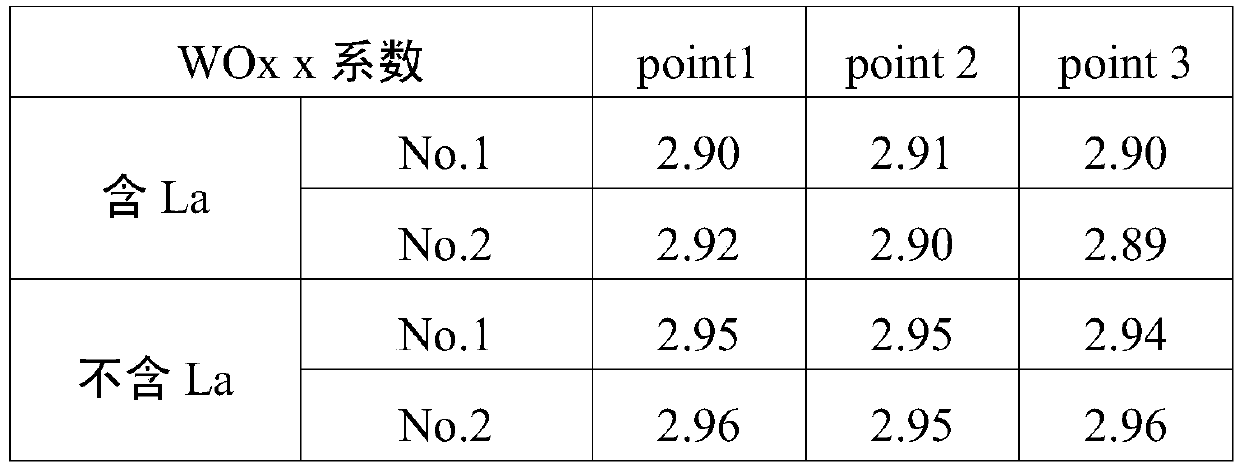

Antioxidative tungsten-rhenium alloy for thermocouple and preparation method

ActiveCN105506429AExtend your lifeLow coefficient of oxygenThermometers using electric/magnetic elementsUsing electrical meansRheniumPlatinum

The invention relates to an antioxidative tungsten-rhenium alloy for a thermocouple and a preparation method. The alloy comprises the following components in percentage by weight: 1%-26% of Re, 0.05-0.8% of an antioxidative element and the balance of W, and is prepared by prealloy powder preparation, molding, vertical sintering, drawing, white wire forming, annealing and the like, the temperature measurement precision of a thermocouple material reaches the level of wires of a platinum-rhodium noble-metal thermocouple, compared with the oxidation resistance of a conventional thermocouple wire, the oxidation resistance of the alloy is remarkably improved, particularly in a medium-temperature section and a low-temperature section, wire oxidation speed can be reduced or wire oxidation can be delayed effectively, obvious oxidation onset temperature can be reduced effectively, and temperature measuring precision of the alloy is guaranteed.

Owner:CHONGQING MATERIALS RES INST

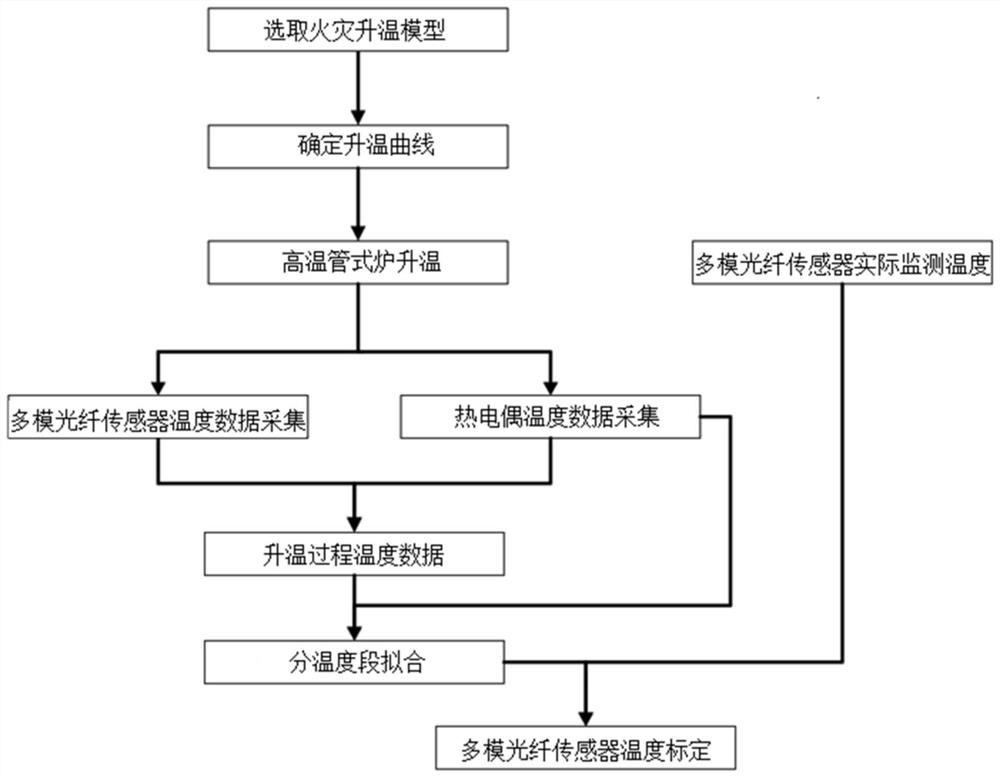

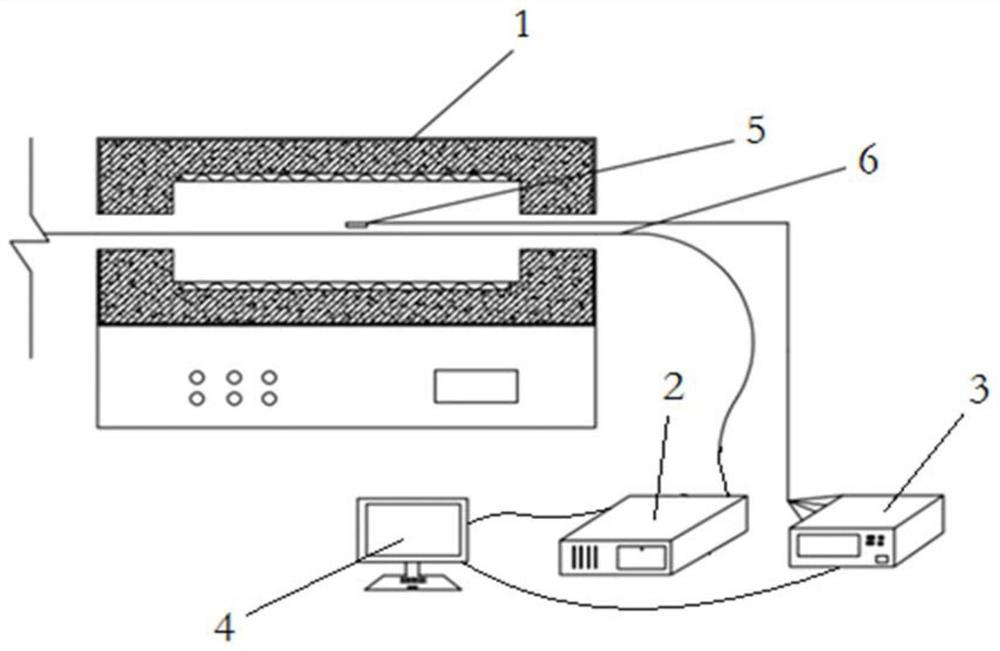

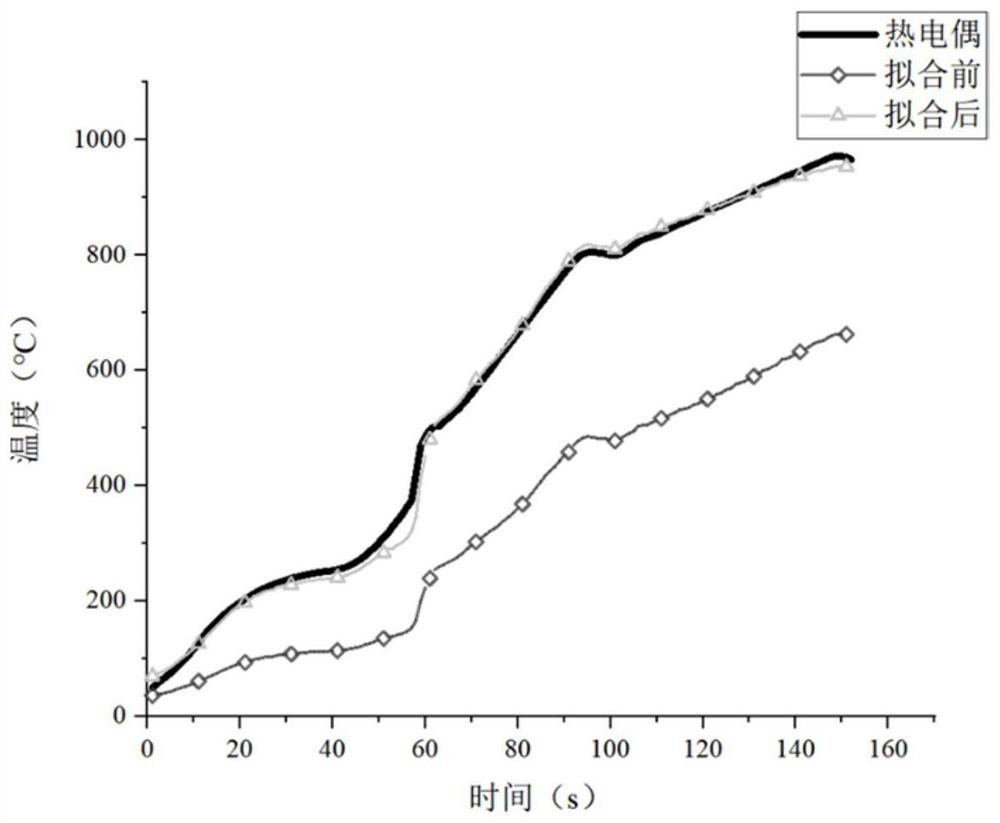

Distributed optical fiber sensor high-temperature dynamic calibration system and method

PendingCN114279594ALow costGuaranteed temperature measurement accuracyThermometer testing/calibrationMulti-mode optical fiberTube furnace

The invention discloses a distributed optical fiber sensor high-temperature dynamic calibration system and method.The calibration system comprises a high-temperature tube furnace, a temperature demodulator, a DTS Raman optical fiber demodulator and a computer, a thermocouple and a multimode optical fiber sensor are placed in the high-temperature tube furnace, the thermocouple is connected with the temperature demodulator, and the temperature demodulator is connected with the DTS Raman optical fiber demodulator; the multimode optical fiber sensor is connected with the DTS Raman optical fiber demodulator; the temperature demodulator and the DTS Raman optical fiber demodulator are connected with the computer; the multi-mode optical fiber sensors penetrate through the high-temperature tube furnace in a reciprocating mode in an S-shaped mode, the turning positions of the multi-mode optical fiber sensors are arranged outside the high-temperature tube furnace, at least four sections of the multi-mode optical fiber sensors are arranged in the high-temperature tube furnace, and the mechanical tension state of each section of the multi-mode optical fiber sensors in the high-temperature tube furnace is zero; and a thermocouple is correspondingly arranged on one side of each section of multimode optical fiber sensor in the high-temperature tube furnace.

Owner:应急管理部天津消防研究所 +1

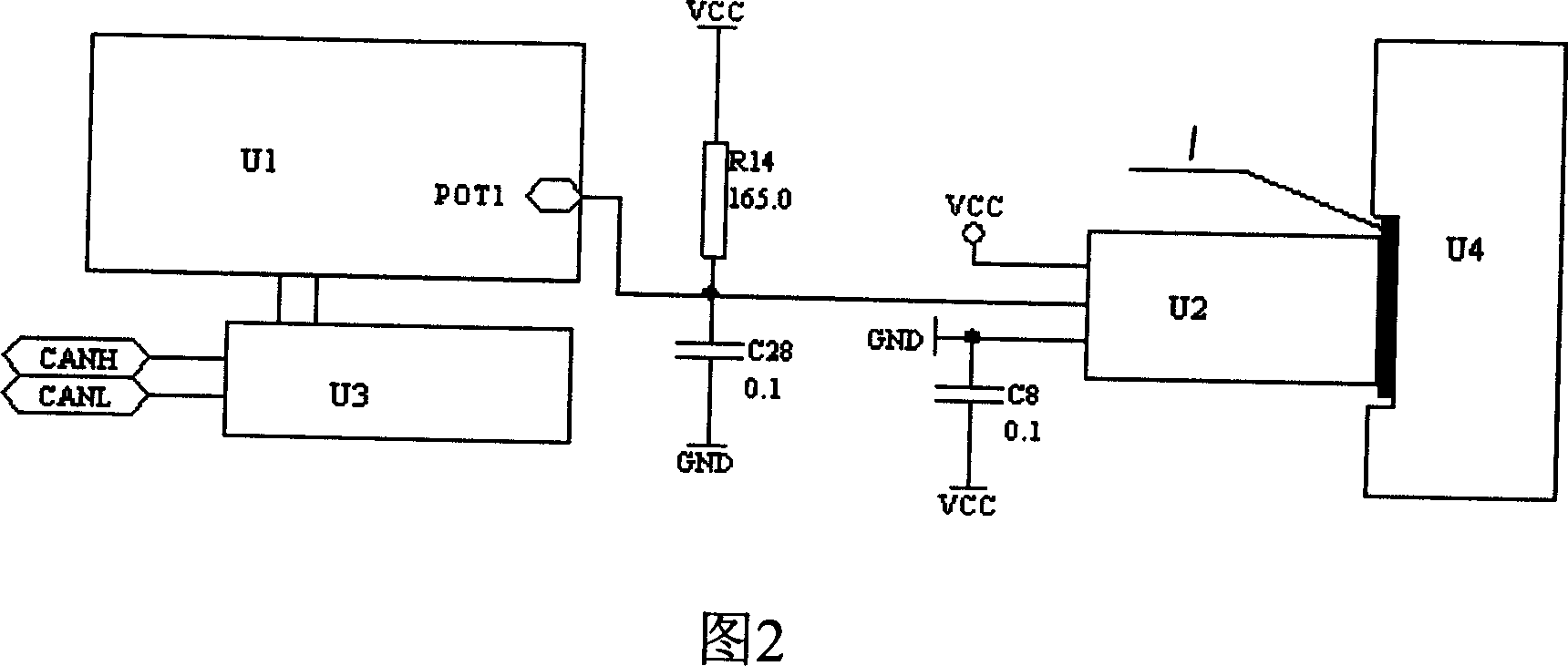

Fuel-cell engine temperature collection circuit

ActiveCN1979105ALow costImprove anti-interference abilityThermometer detailsThermometers using electric/magnetic elementsMicrocontrollerCommunication interface

The invention relates to a fuel cell engine temperature gathering IC that includes MCU, temperature sensor, and communication interface circuit. The temperature sensor could be semiconductor temperature sensor or thermocouple temperature sensor, which is installed in fuel cell water tank to gather temperature signal. The temperature sensor connects to MCU, and MCU connects to communication circuit. Comparing to existing technology, it has the advantages of strong system interference immunity, high measuring reliability, simple temperature measuring circuit, low cost of hardware, and it needs not to adjust in locale.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

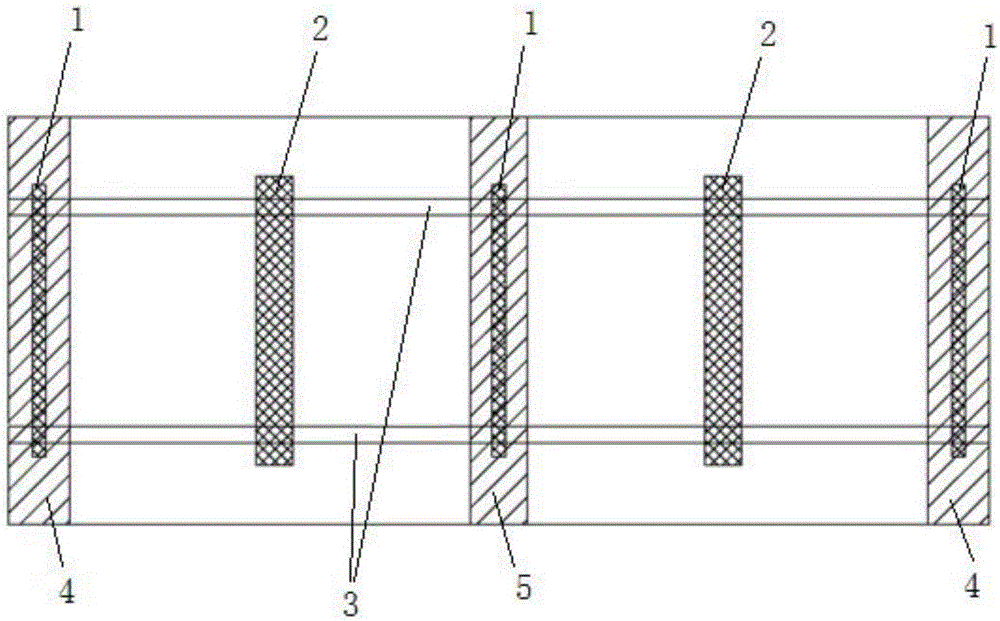

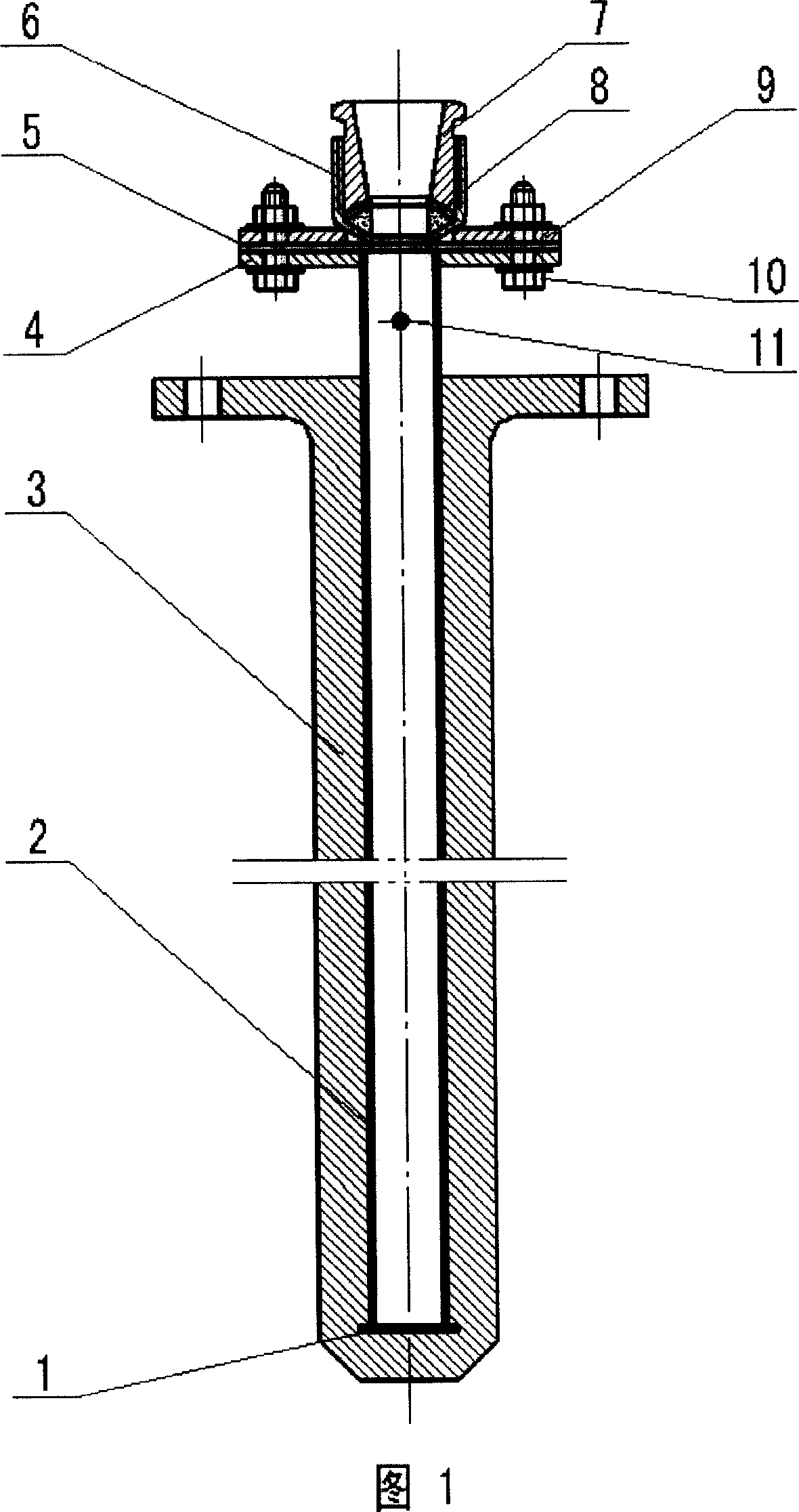

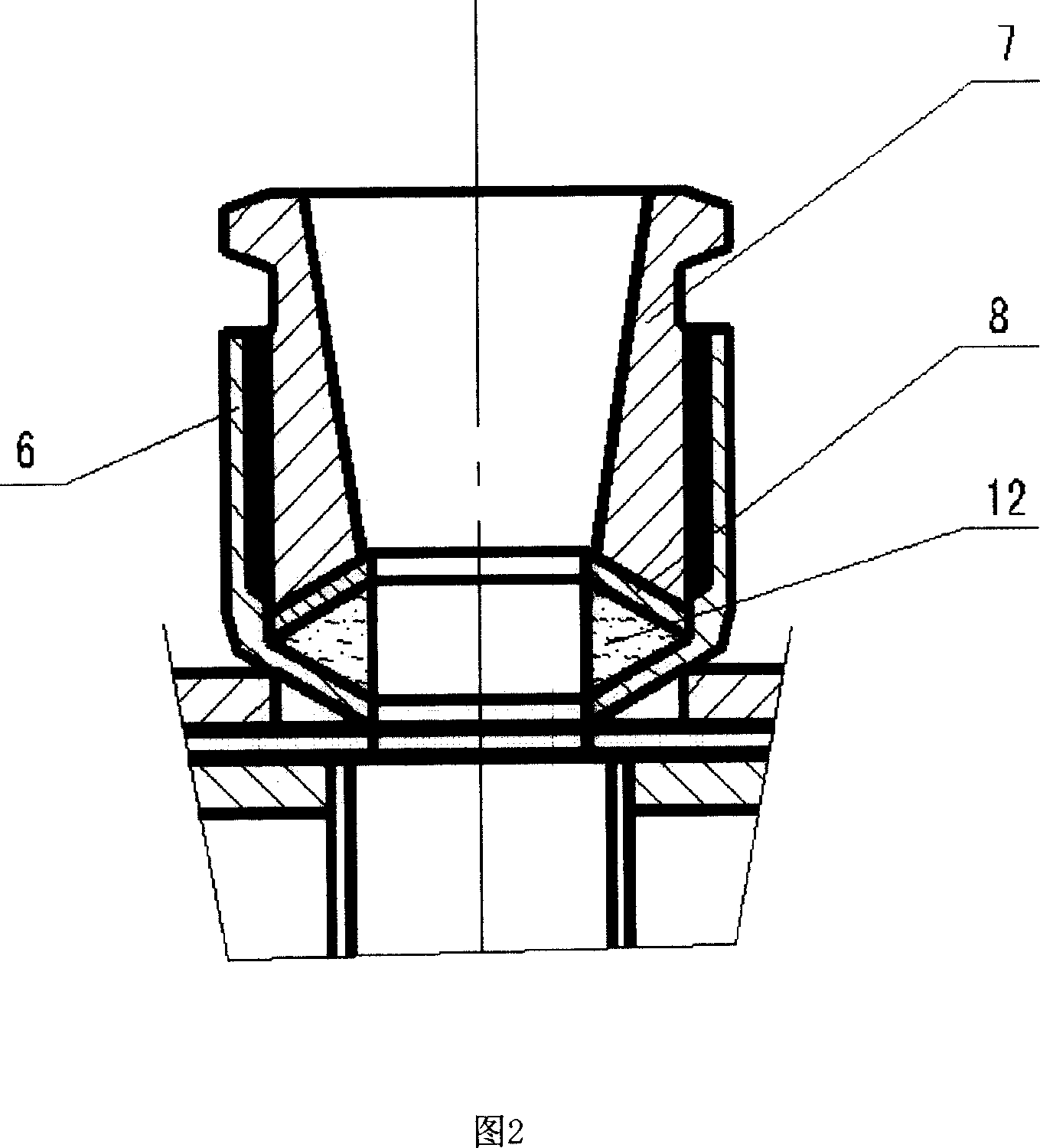

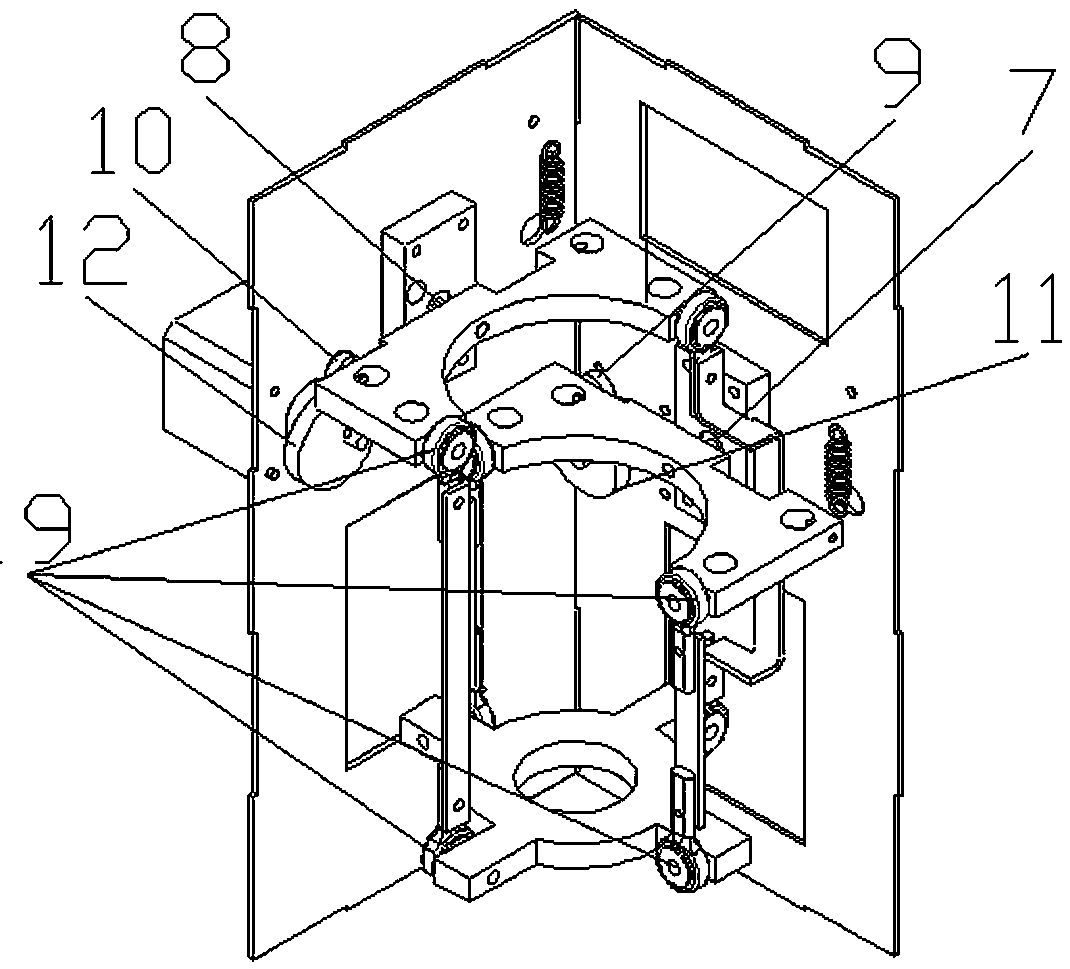

Impregnating furnace electric thermo-couple protector

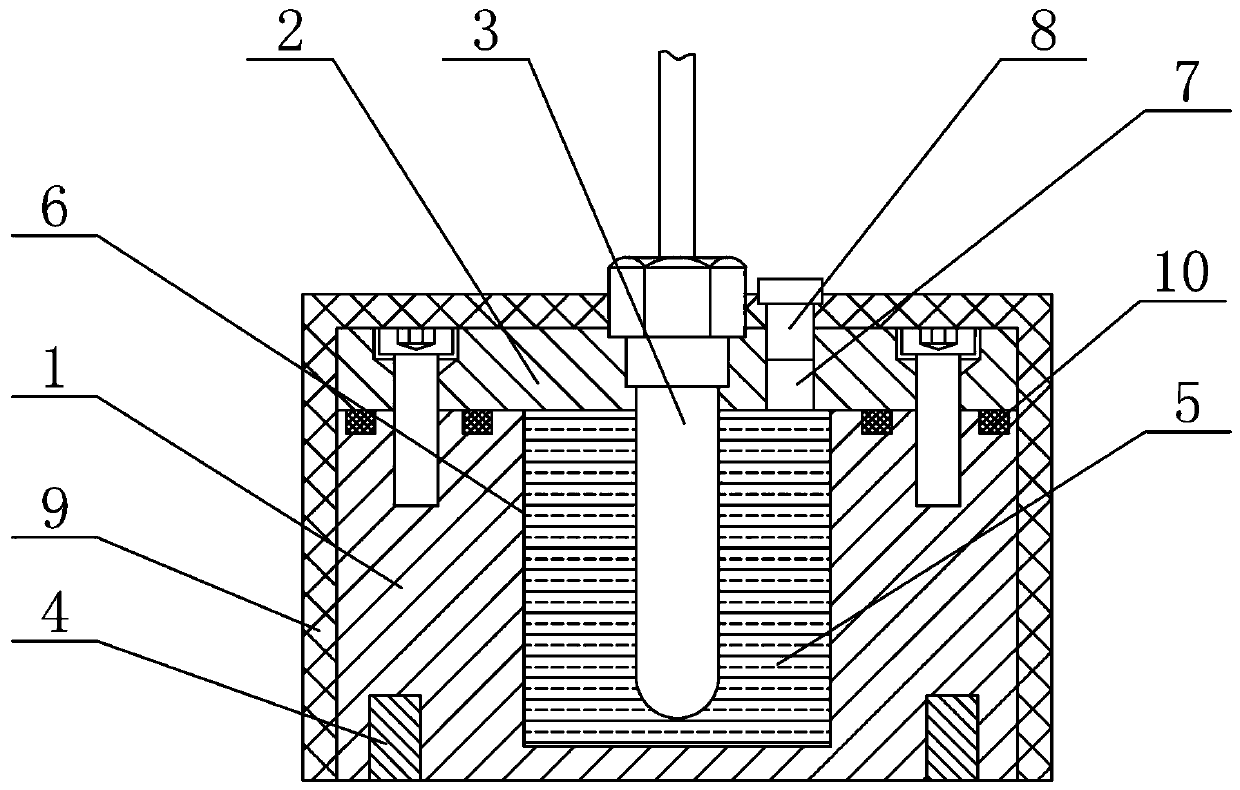

InactiveCN1932459AThickness is easy to controlImprove thermal conductivityThermometer detailsThermometers using electric/magnetic elementsWaddingEngineering

The invention discloses a thermo element protector for the impregnating furnace. The motherboard (1) is in the bottom of the protector tube (2) which the outside is the reinforced covering layer (3) founded by the heat-resistant steel material. The flange (4) is on the top of the protector tube which is connected by the bolt units (10); also it has the rubber blanket (5) between the flanges; the outside of the connecting groove (6) is connected with the flange and the inside is connected with the connecting cap (7) by the screw thread; the junk ring (8) and the asbestos-cement filler (12) are between the underside of the connecting cap and the connecting groove; the constant hole (11) is in the protector tube; the upper end of the reinforced protecting layer has the flange and hole. The invention can prolong the life of the use in the high temperature and the corrosive liquid and ensure the temperature measuring precision.

Owner:GUIYANG AL-MG DESIGN & RES INST

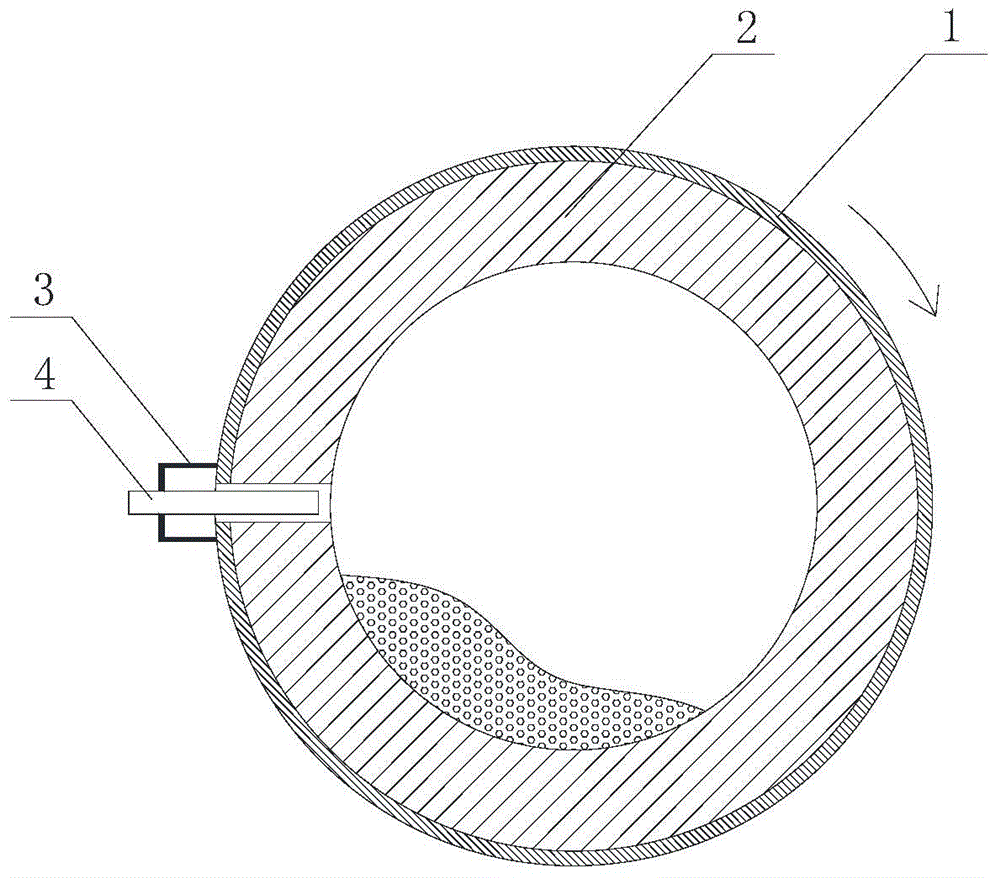

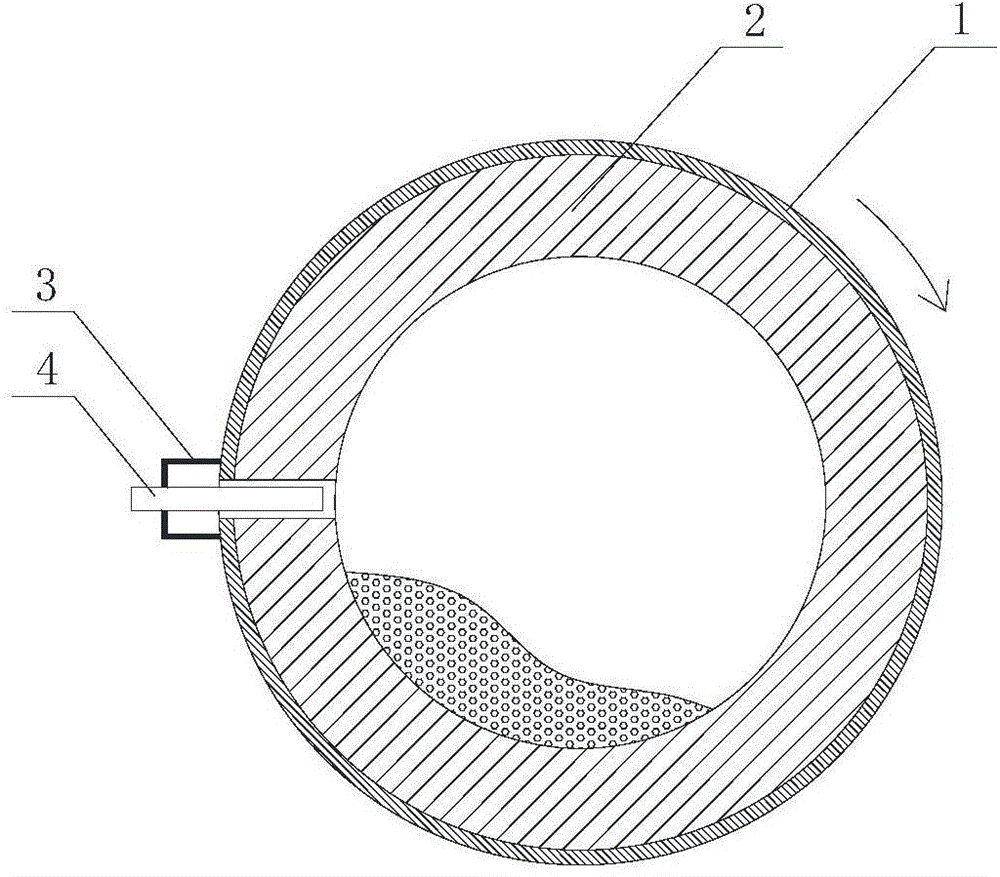

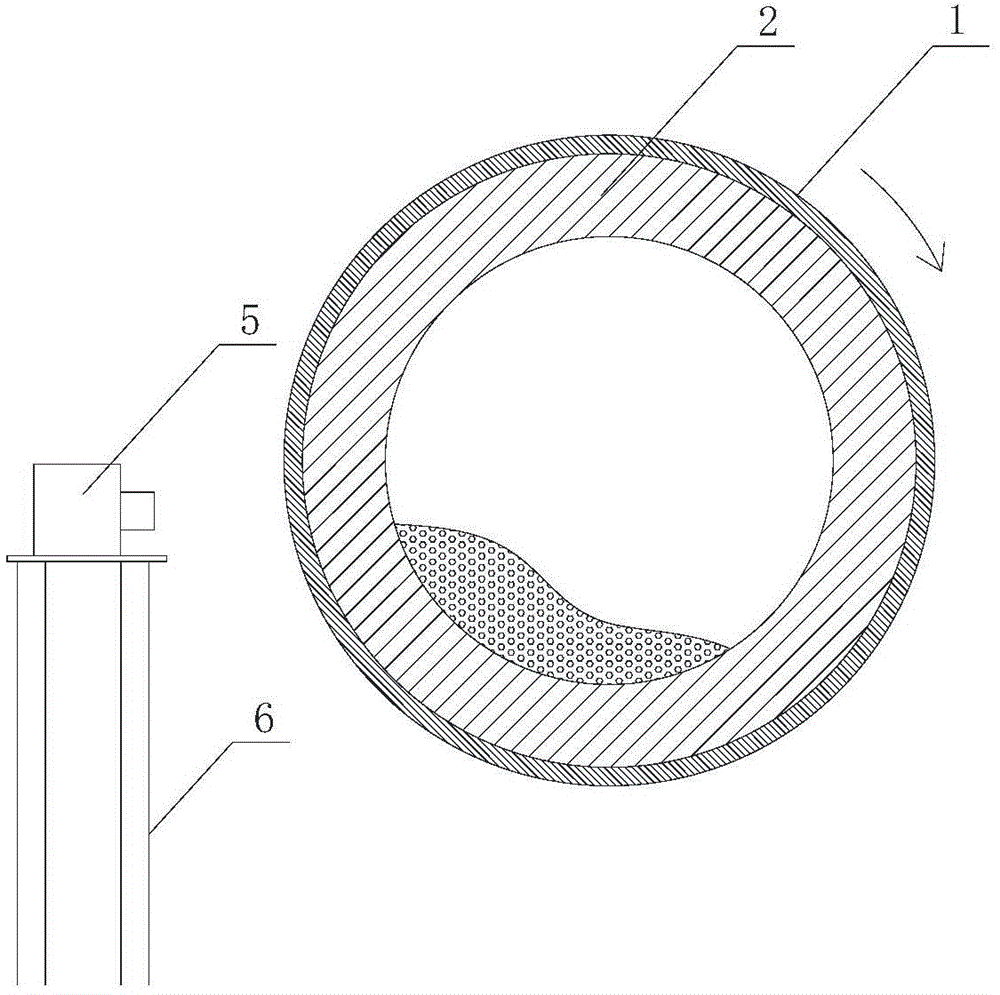

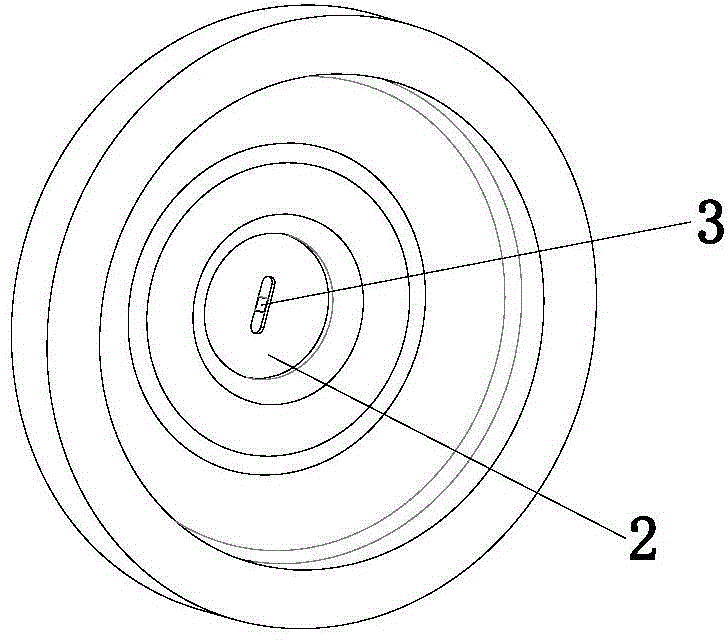

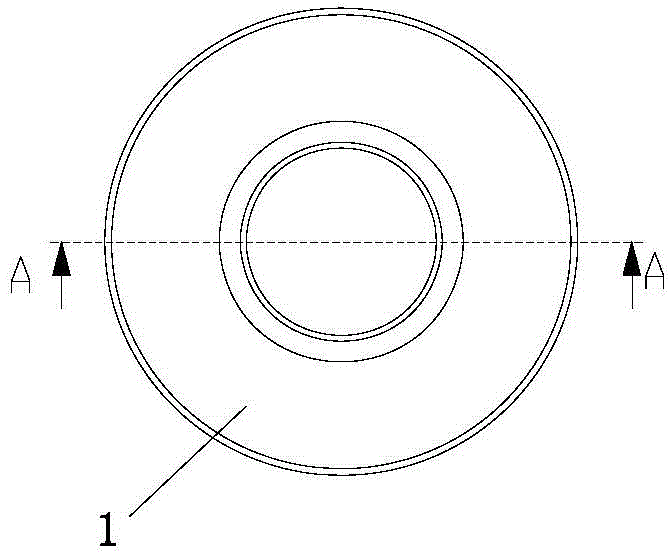

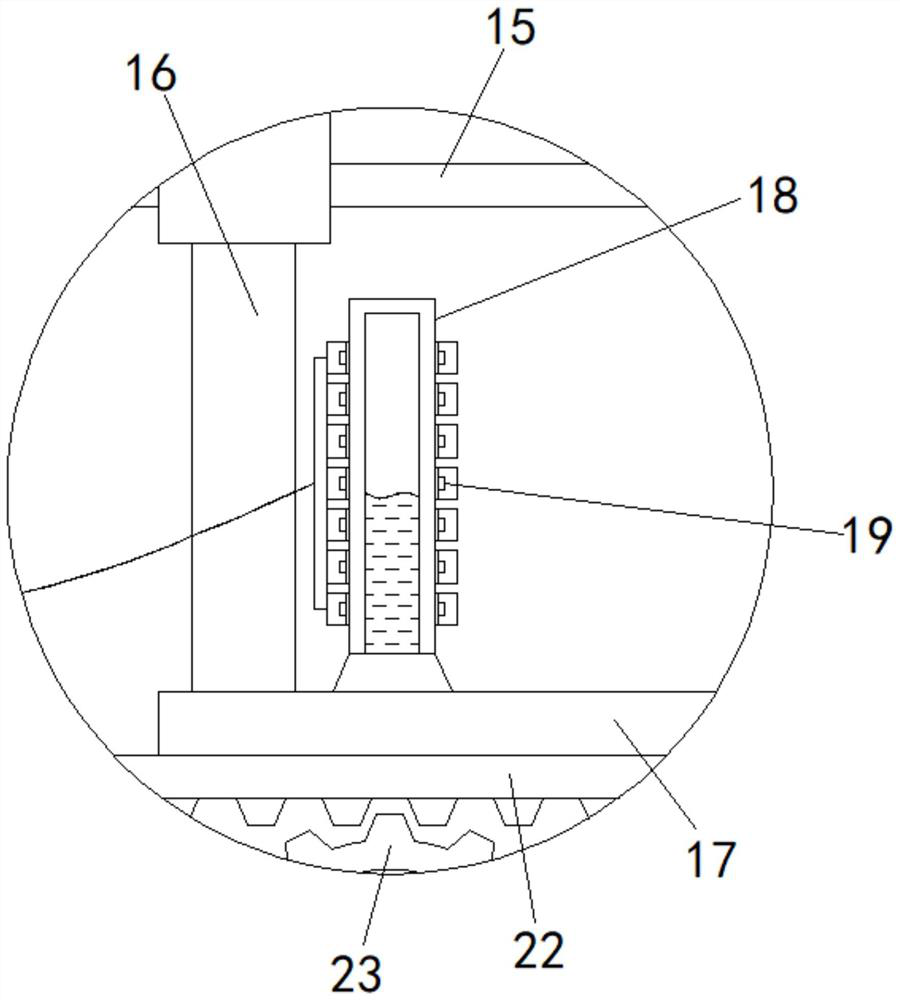

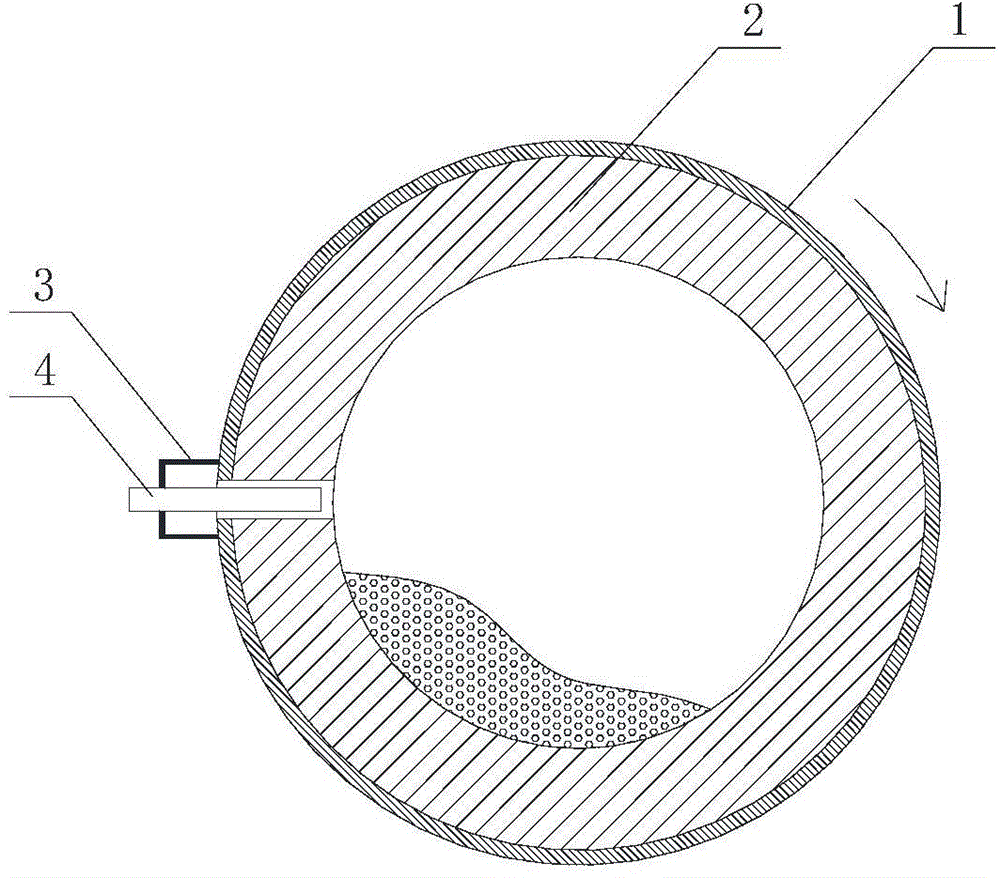

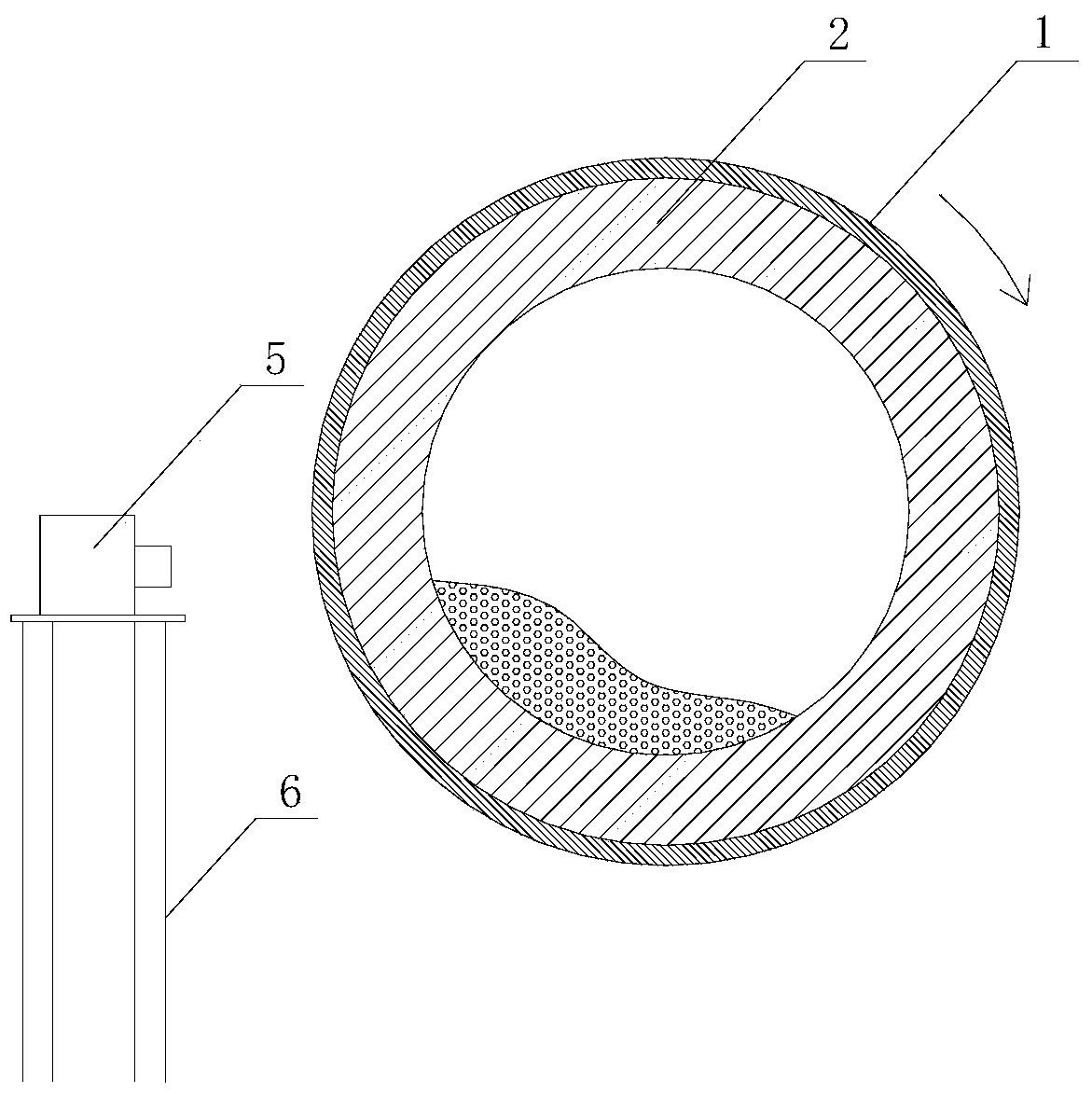

Self-weight rotary kiln direct temperature measurement device

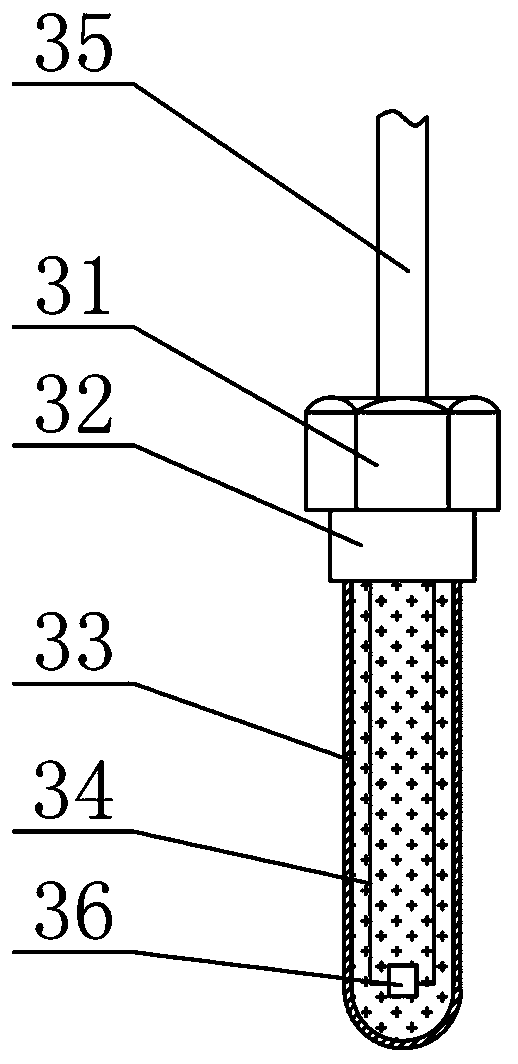

ActiveCN104833206AGuaranteed service lifeGuaranteed temperature measurement accuracyRotary drum furnacesThermocoupleSelf weight

The invention relates to the technical field of rotary kiln temperature measurement, and provides a self-weight rotary kiln direct temperature measurement device. The self-weight rotary kiln direct temperature measurement device comprises a counterweight box, a thermocouple, restraint rods of which the first ends are fixedly mounted on the side wall of a rotary kiln, and a sleeve tube which is arranged on the outer side of the thermocouple; a plurality of restraint pipelines are arranged in the counterweight box; the second ends of the restraint rods are limited in the restraint pipelines; the counterweight box is connected with the first end of the thermocouple; the second end of the thermocouple extends into a temperature measuring through hole which is formed in the side wall of the rotary kiln; the sleeve tube is connected with the counterweight box or the thermocouple and can move axially along the temperature measuring through hole; thin temperature measuring slim holes used for realizing thermocouple temperature measuring are formed in the sleeve tube. According to the device, the counterweight box drives the thermocouple and the sleeve tube to move in the temperature measuring through hole along the radial direction of the rotary kiln during the rotating process of the rotary kiln under the automatic action of the counterweight box, so that the sleeve tube can clean the materials in the temperature measuring through hole automatically, and the temperature measuring through hole is prevented from being blocked by a material tumor; therefore, the service life and the temperature measurement accuracy of the thermocouple are ensured.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

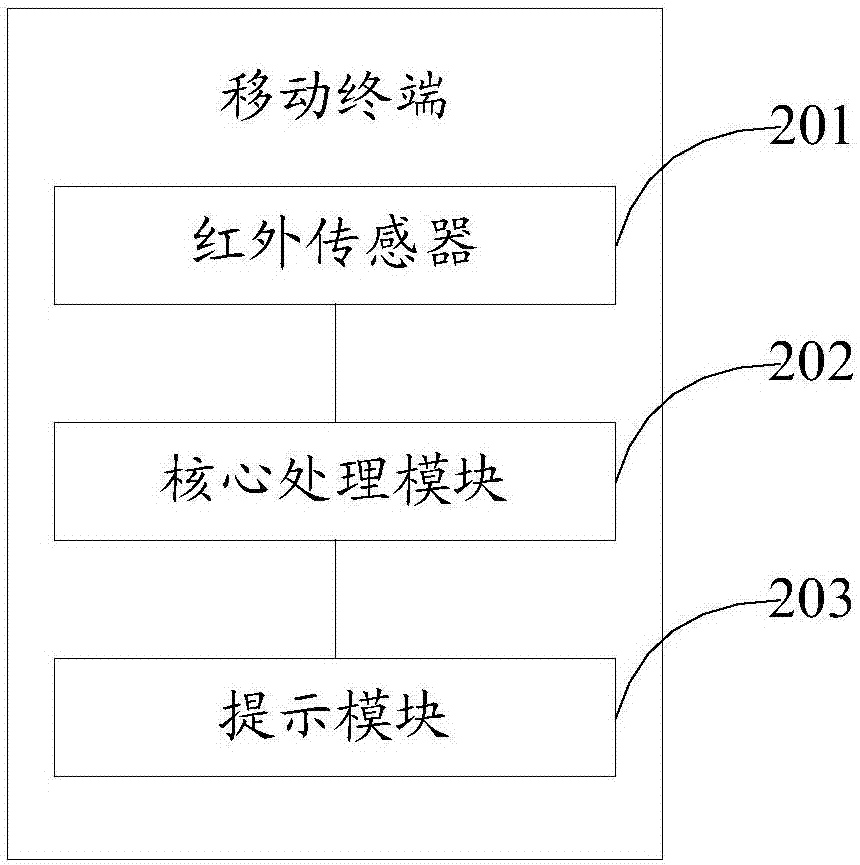

Headphone, mobile terminal having functions of ear thermometer and ear temperature detection method

InactiveCN107960987AImprove usabilityVersatileEarpiece/earphone attachmentsDiagnostic recording/measuringBody temperature measurementComputer terminal

The invention discloses a headphone, a mobile terminal having functions of an ear thermometer and an ear temperature detection method. The method comprises the following steps: receiving temperature data of a human body eardrum detected and transmitted by virtue of an ear temperature probe of the headphone; converting the temperature data from a light signal into an electric signal, and conductingamplifying and corresponding treatment on the electric signal, so that a processed human body temperature value is obtained; and transmitting alarm information when the human body temperature value reaches a preset threshold. According to the headphone, the mobile terminal and the ear temperature detection method provided by the invention, the precision of body temperature measurement is guaranteed and the cost of body temperature measurement is reduced; and moreover, operations are simplified and facilitated, and functions of such mobile terminals as a mobile phone and the like are greatly enriched; therefore, the availability of the mobile terminal is enhanced.

Owner:ZTE CORP

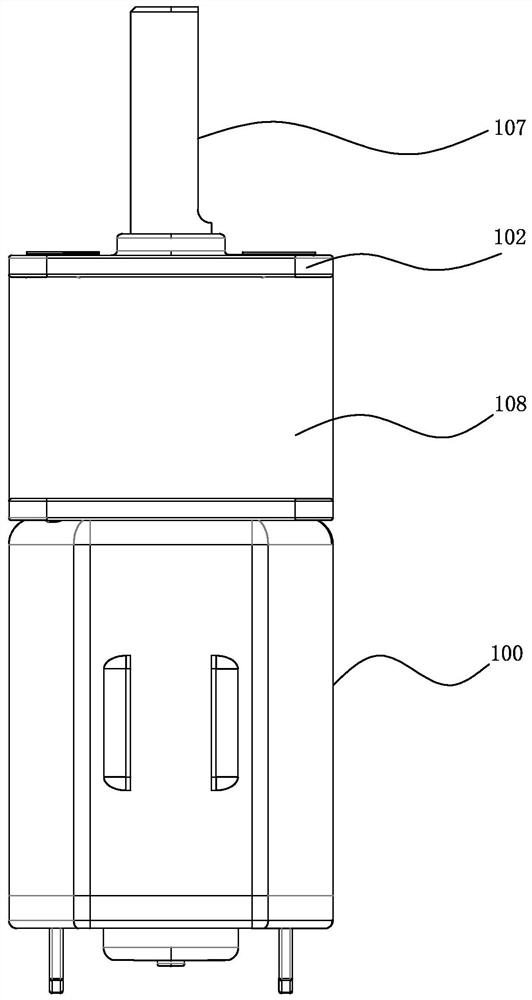

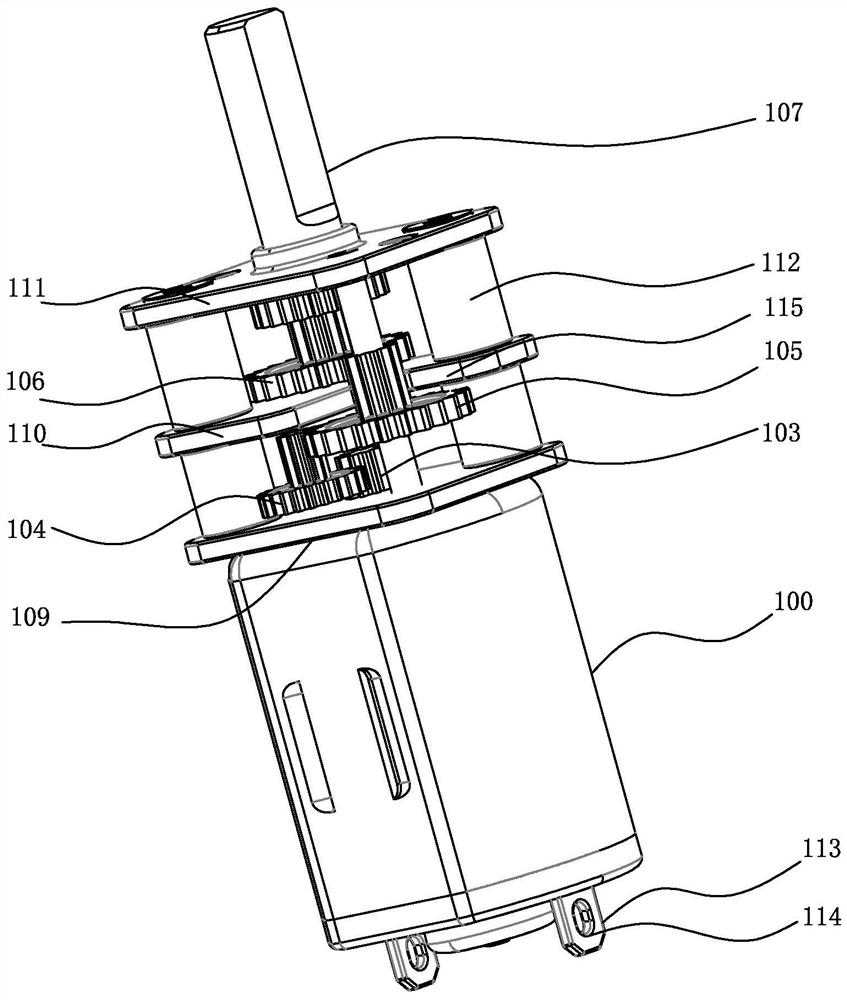

Dustproof miniature gear motor and black box integrated system

PendingCN111835143AStable temperature measurementHigh precisionGearboxesMechanical energy handlingGear wheelElectric machinery

The invention discloses a dustproof miniature gear motor and black box integrated system, and the dustproof miniature gear motor is applied to a customs or frontier inspection and release detector, and comprises a micromotor main body, a transmission mechanism connected with the micromotor main body, and a supporting structure for supporting the transmission mechanism. The micromotor main body comprises a structure base frame, and a controlled body, an actuator, a sensor and a controller which are arranged on the structure base frame; the transmission mechanism comprises a first gear connectedwith the controlled body, a second gear connected with the first gear, a third gear installed on the supporting structure and connected with the second gear, and an output shaft comprising gear teethconnected with the third gear. By adopting the scheme, the dustproof miniature gear motor can meet the power driving requirement of the intelligent checking and releasing all-in-one machine proposedby the applicant, can meet the requirements of the size and the rotating speed, can enable the temperature measurement of the checking and releasing machine to be stable and high in precision, betterachieves dust prevention, and guarantees the stable operation.

Owner:深圳市软筑信息技术有限公司

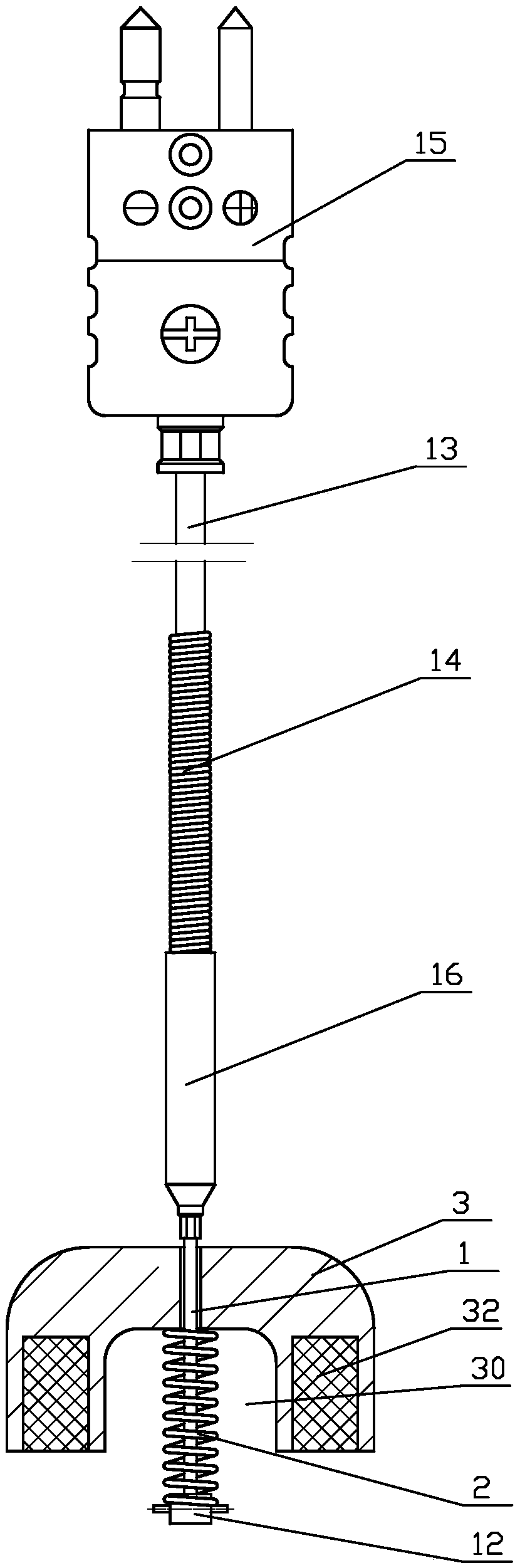

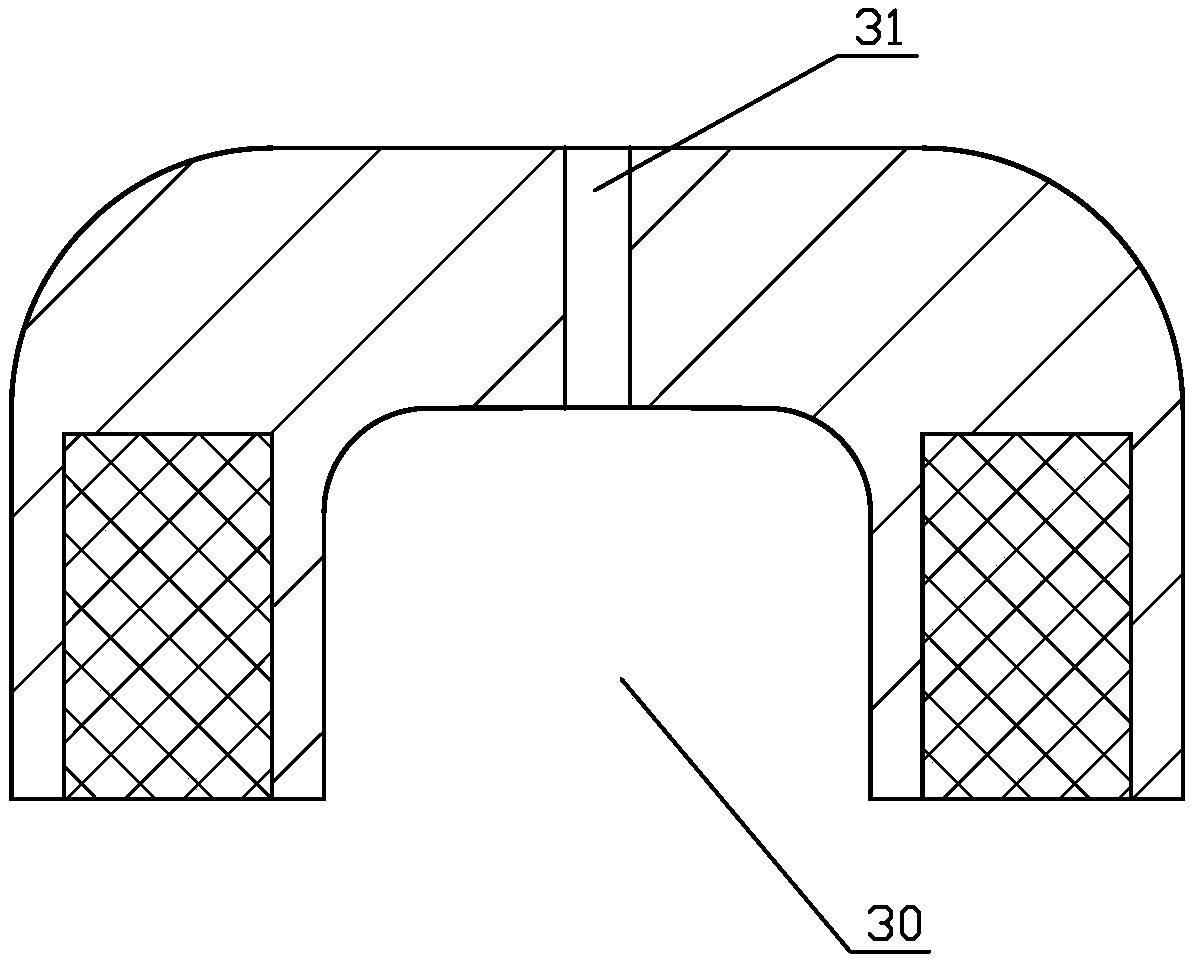

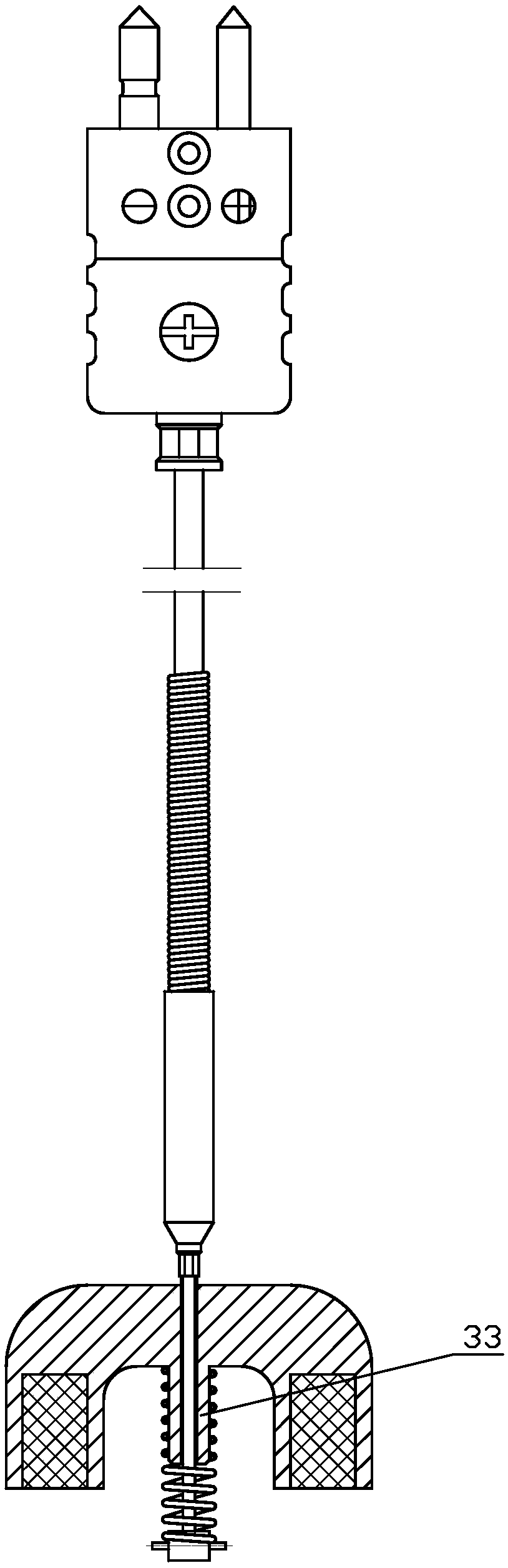

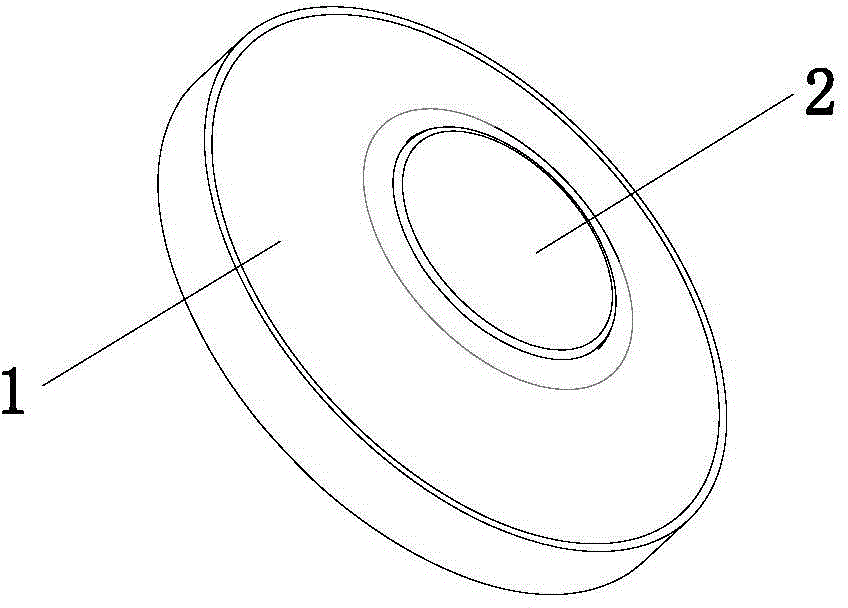

Temperature measuring device for bottom surface of tin bath of floating glass manufacturing line

ActiveCN108680270AIncrease contact areaGuarantee the accuracy of temperature measurementThermometer detailsThermometers using electric/magnetic elementsGlass manufacturingManufacturing line

The invention discloses a temperature measuring device for a bottom surface of a tin bath of a floating glass manufacturing line. The temperature measuring device comprises an armored thermocouple, amounting seat and a spring, wherein one end surface of the mounting seat has an accommodation groove, the mounting seat has a first through hole penetrating the accommodation groove and the other endsurface of the mounting seat, the armored thermocouple is arranged in the first through hole, a temperature measuring end of the armored thermocouple penetrates out from one end of the accommodation groove, the spring sleeves on the armored thermocouple and is limited between the accommodation groove and the temperature measuring end of the armored thermocouple, one end surface of the mounting seat having the accommodation groove has a magnetic body, when the magnetic body is absorbed on a to-be-measured device, and the temperature measuring end of the armored thermocouple is pushed to contactwith the to-be-measured device through the restoring force generated by the compressed spring. The temperature measuring device is advantaged in that the structure is simple, the temperature measuring end closely contacts with the to-be-measured device, and mounting and dismounting are convenient.

Owner:JUMO AUTOMATION DALIAN CO LTD

Pot body temperature measuring device for electromagnetic oven

InactiveCN104791860AAvoid severe agingGuaranteed reliabilityDomestic stoves or rangesLighting and heating apparatusEngineeringSilica gel

The invention provides a pot body temperature measuring device for an electromagnetic oven. The device comprises a base, a heat conductor and a temperature sensor, wherein the heat conductor is fixedly connected to the top of the base, and the temperature sensor is fixedly mounted on the heat conductor. The base is made from an elastic material, so that a bulge portion of the base can downwards deform under the pressure of a load and bounces upwards after the load leaves, the bottom of a pot can be in full contact with the heat conductor, and thus the temperature of a pot body is accurately measured. According to the pot body temperature measuring device for the electromagnetic oven, the top of an existing temperature measuring structure adopts a heat-conducting and non-conductive ceramic material as the heat conductor, so that the reliability of long-term use is guaranteed, and the phenomenon of severe aging of the existing silica gel materials after long-term use is avoided.

Owner:SUZHOU WESTON HOME AUTOMATION

Self-adaptive feed cooling equipment

ActiveCN113587542AImprove cooling effectReduce the amount of feedDomestic cooling apparatusFeeding-stuffEngineeringStructural engineering

The invention relates to the technical field of feed production equipment, and discloses self-adaptive feed cooling equipment which comprises an equipment shell, wherein the top of the equipment shell is communicated with a feeding hopper extending into the equipment shell, the bottom of the feeding hopper is communicated with a cut-off pipe, the bottom of the cut-off pipe is hinged to a first cooling square pipe, a communicating square pipe is hinged to the bottom of the first cooling square pipe, a second cooling square pipe is hinged to the bottom of the communicating square pipe, a discharging square pipe is hinged to the bottom of the second cooling square pipe, and a limiting ring with two sides fixedly connected with the left side wall and the right side wall of an inner cavity of the equipment shell correspondingly is slidably connected to the outer side of the discharging square pipe. The self-adaptive feed cooling equipment has the advantages that the cooling time and the cooling speed of feed can be adaptively adjusted according to the temperature of the feed when the feed enters the equipment, and meanwhile, the feed can be prevented from being adhered to the pipeline when falling into the pipeline.

Owner:郴州九鼎饲料有限公司

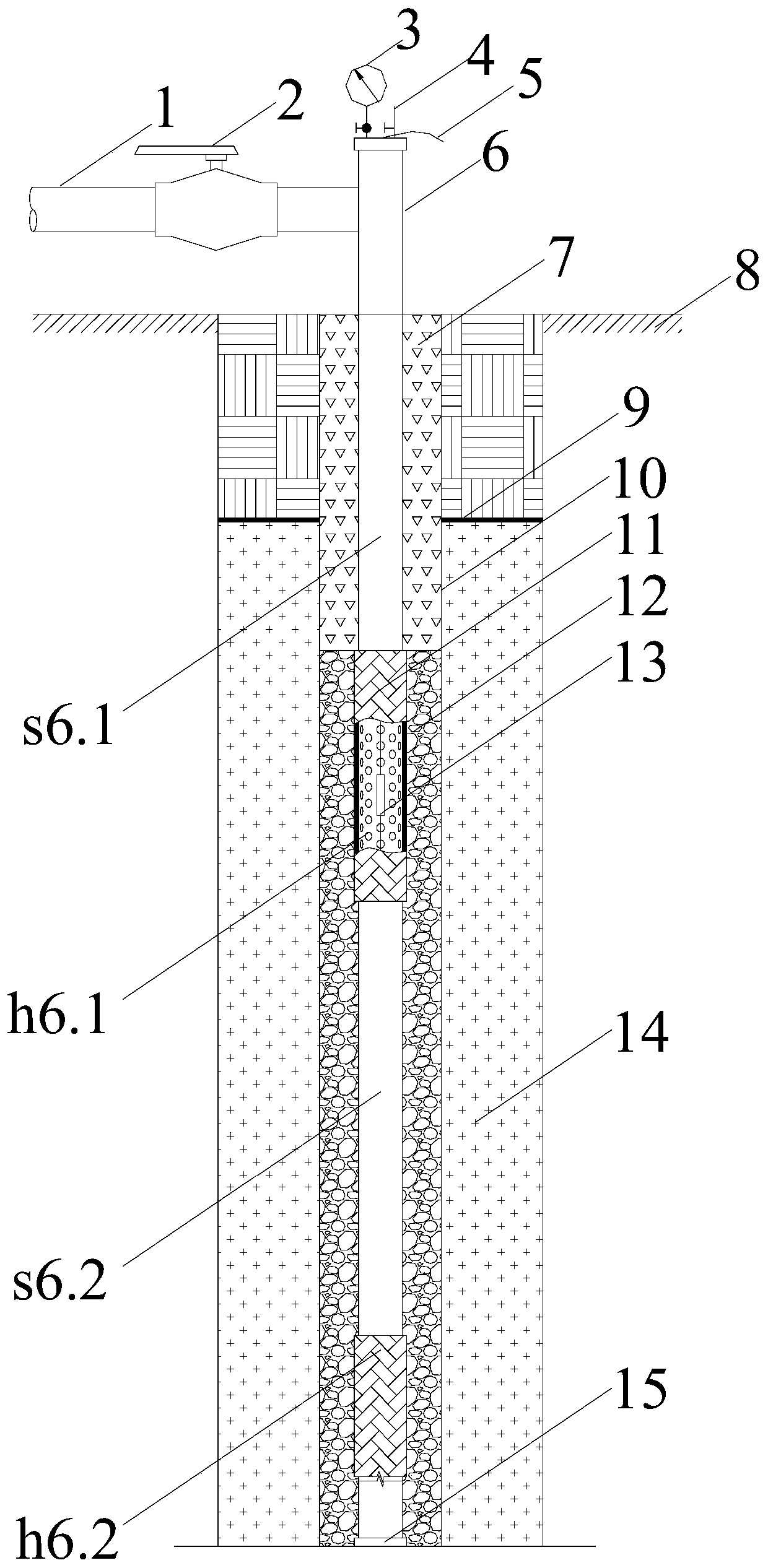

Gas exhausting and injecting well device for aerobic bioreactor process

PendingCN111014225AImprove uniformityImprove liquidityLandfill technologiesSolid waste disposalTube wellReal time analysis

The invention provides a gas exhausting and injecting well device for an aerobic bioreactor process. The gas exhausting and injecting well device is characterized in that the surface of a garbage heapis drilled downwards to form a gas well, a well pipe is inserted into the gas well, the top of the well pipe stretches out of the ground by 0.5 m to 1.0 m and is connected with a horizontal branch pipe through a manifold branch, a bidirectional pressure gauge capable of displaying positive and negative pressure and a gas sampling valve are mounted at the top end of the well pipe, and pressure andgas ingredients in the well can be analyzed in real time; and the well pipe is a PE or HDPE pipe of De 75 mm to 150 mm. According to the gas exhausting and injecting well device, by designing the structure of the well pipe, the ubiquitous problems that gas exchange at different depths of the garbage heap is uneven, a temperature sensor cannot fast and sensitively reflect the real-time temperature, and a sleeve needs to be additionally arranged are solved; and the effects that gas exhausting and injecting wells are tightly closed, gas exchange is smooth, construction is simple, control is easy, and the temperature, the pressure, the gas ingredients and the like can be monitored in real time are achieved, and the aerobic treatment technology is more mature and efficient.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

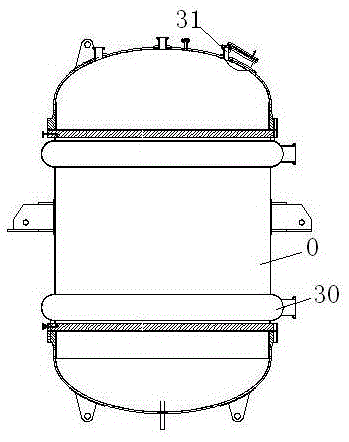

Reactor for sec.-butyl acetate

InactiveCN105521748AImprove sealingImprove pressure resistanceProductsOrganic compound preparationEngineeringInlet flow

The invention provides a reactor for sec.-butyl acetate. The reactor comprises a reactor main body, wherein the reactor main body comprises a liquid inlet device and a temperature measuring device, the liquid inlet device comprises a liquid inlet plate, an annular plate and a flow guiding baffle, liquid inlets are formed in the liquid inlet plate and comprise upper liquid inlets and lower liquid inlets, the upper liquid inlets decrease gradually towards the two sides of the liquid inlet plate, the lower liquid inlets increase gradually towards the two sides of the liquid inlet plate, flow guiding holes are formed in the flow guiding baffle, the temperature measuring device comprises a connecting tube, a flange, a blind flange, a top cover and a temperature measuring tube, a tetrafluoro coating pad is arranged between the blind flange and a protection plate and serves as a sealing element, and the top cover and the blind flange are filled with asbestos packing. According to the reactor, the structure is simple, and the design is reasonable; by adopting disc-ring-shaped annular liquid inlet, the balance of liquid inlet flow velocity and heat exchange efficiency are guaranteed, and the energy consumption is lowered; the flow guiding baffle plays a role in guiding flow, and thus the stability of liquid inlet is guaranteed; and the temperature measuring device is excellent in sealing performance and pressure resistance and is not prone to leakage, so that the heat exchange effect and temperature measurement accuracy are improved and guaranteed.

Owner:YANGZHONG SHENYANG HEAT EXCHANGE EQUIP

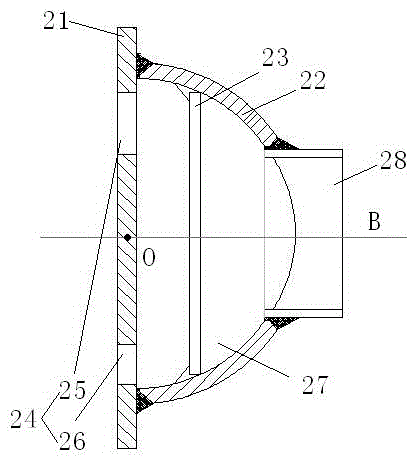

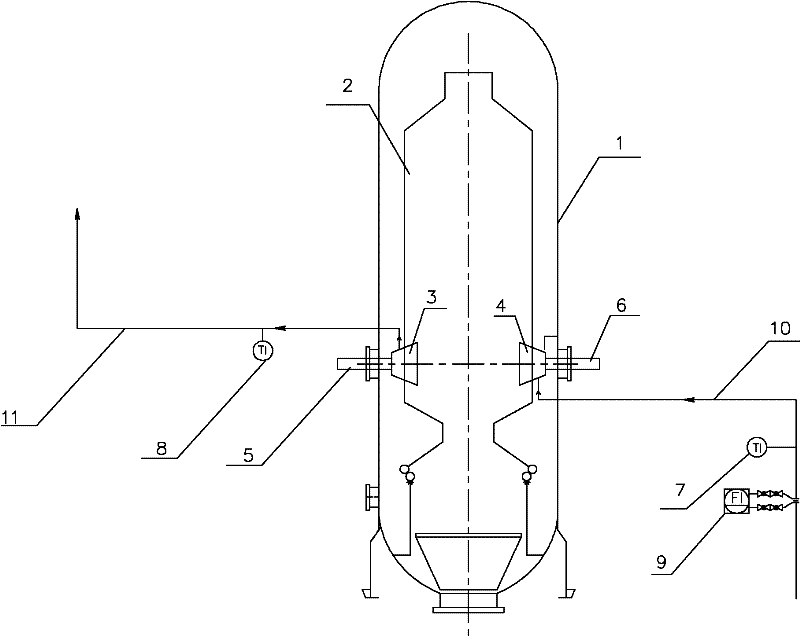

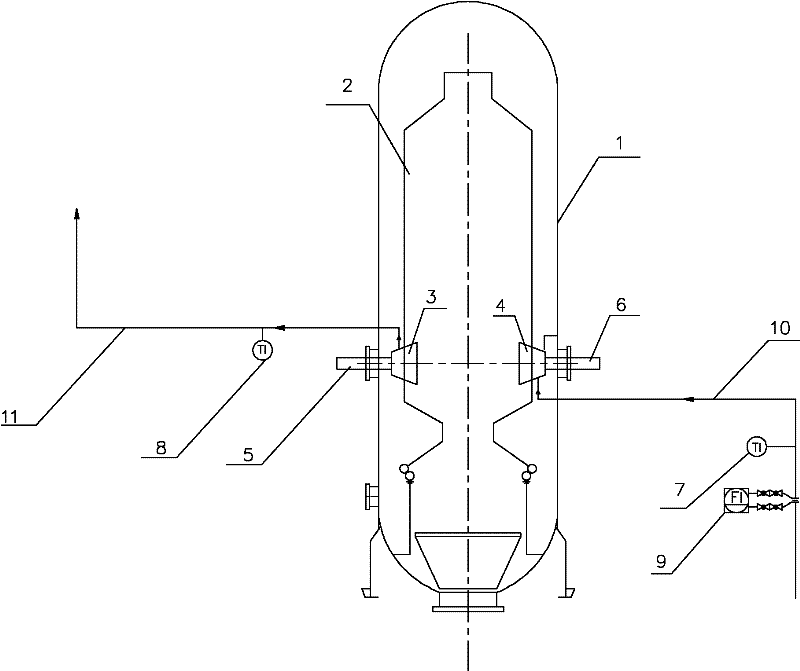

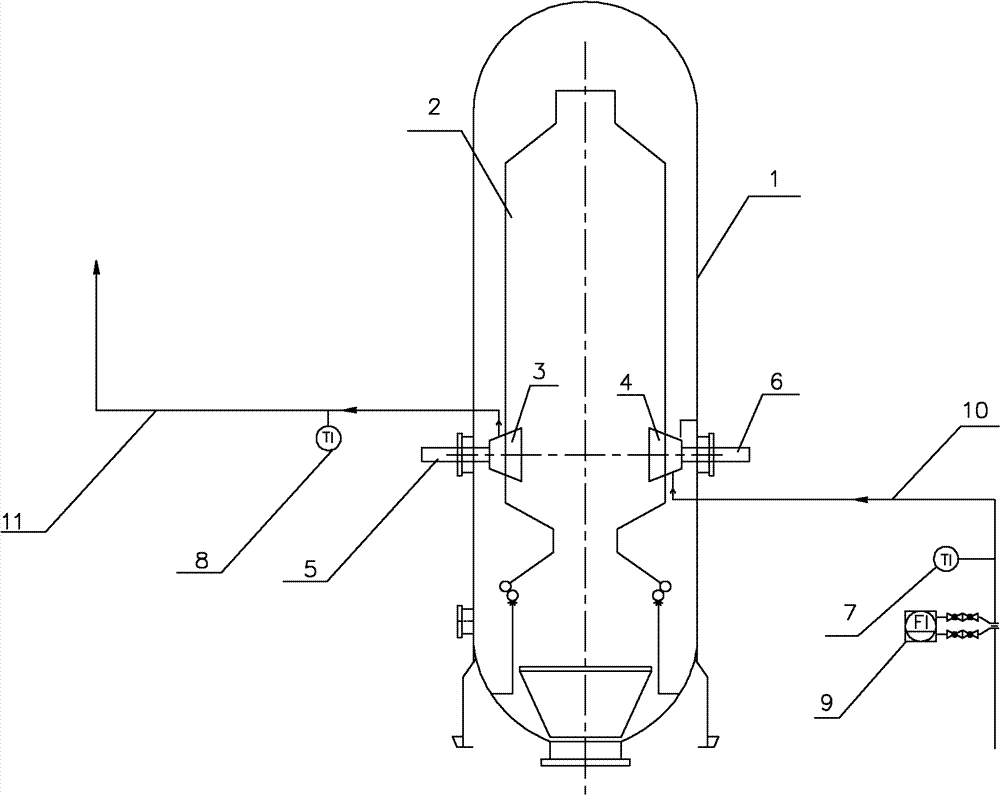

Indirect temperature measuring device in entrained flow gasifying furnace

ActiveCN102305675AReasonable structureAccurate calculationTemperature measurement of flowing materialsCombustible gas productionSpray nozzleEngineering

The invention belongs to the field of measurement and control of boilers and discloses an indirect temperature measuring device in an entrained flow gasifying furnace. The indirect temperature measuring device in the entrained flow gasifying furnace comprises a first spray nozzle and a second spray nozzle which are horizontally distributed in a furnace body and have the same structure, wherein the first spray nozzle and the second spray nozzle penetrate through the furnace body; one end, which is positioned inside the inner cavity of the furnace body, of the first spray nozzle is connected with a first water cooling hood; one end, which is positioned inside the inner cavity of the furnace body, of the second spray nozzle is connected with a second water cooling hood; the first water cooling hood and the second water cooling hood are trumpet-shaped and ends with bigger trumpet openings face the center of the furnace body; the horizontal central axial lines of the first water cooling hood and the second water cooling hood are the same line; a water inlet pipe is coiled on the second water cooling hood; a water outlet pipe is coiled on the first water cooling hood; a flow meter and a water inlet temperature meter are arranged on the water inlet pipe; and a water outlet temperature meter is arranged on the water outlet pipe. The indirect temperature measuring device in the entrained flow gasifying furnace has the characteristics of reasonable structure, and capacities of protecting equipment in the furnace and ensuring the temperature measuring precision, and can measure the temperature accurately in real time; and simple and convenient computation is guaranteed.

Owner:HUANENG CLEAN ENERGY RES INST +1

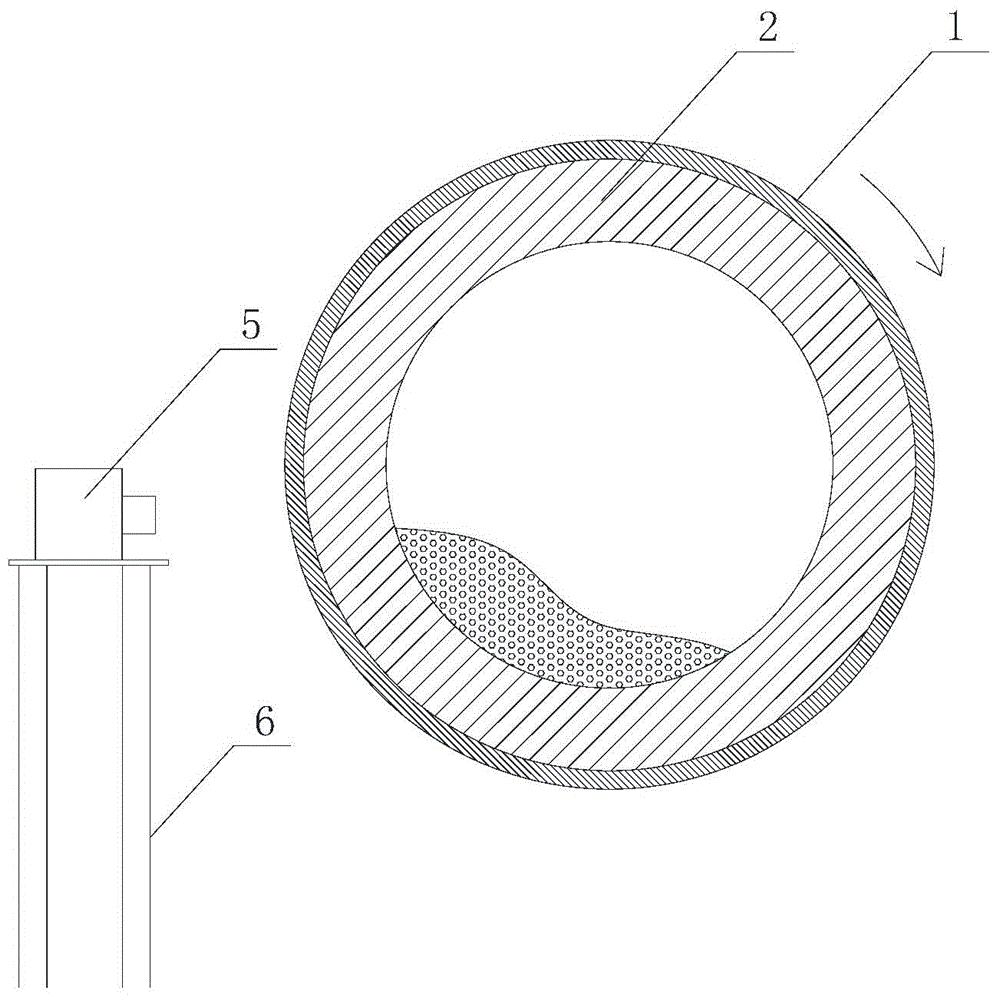

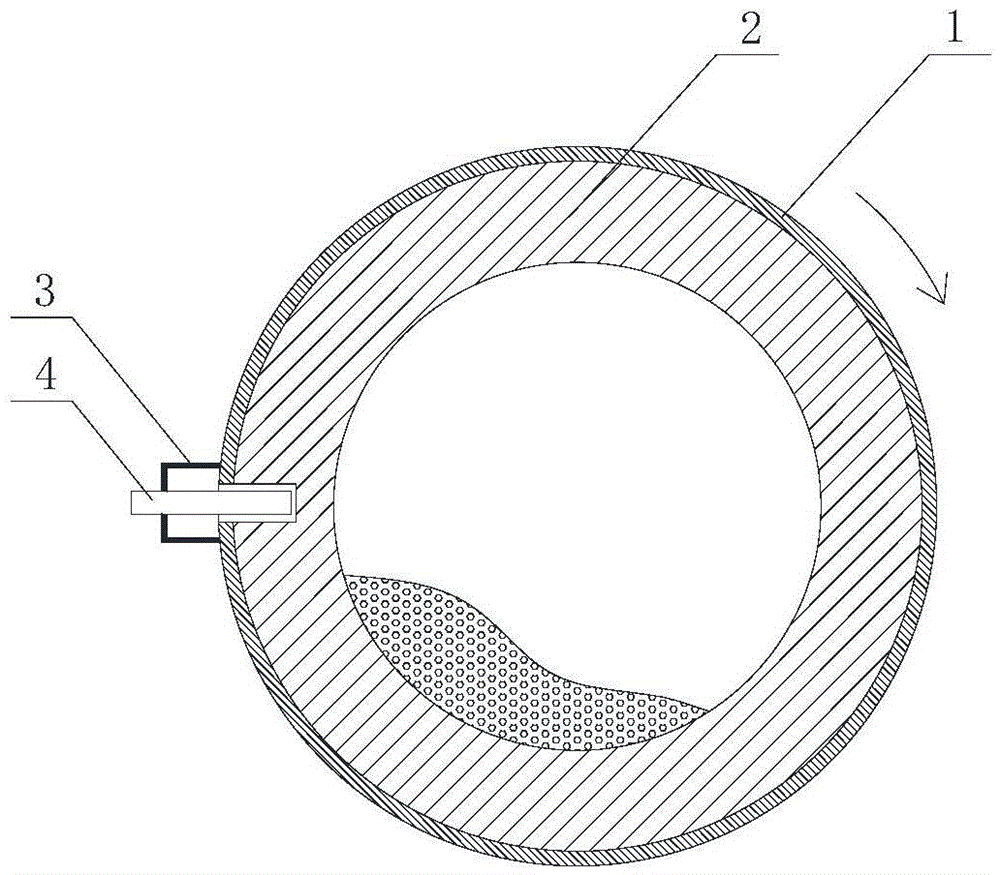

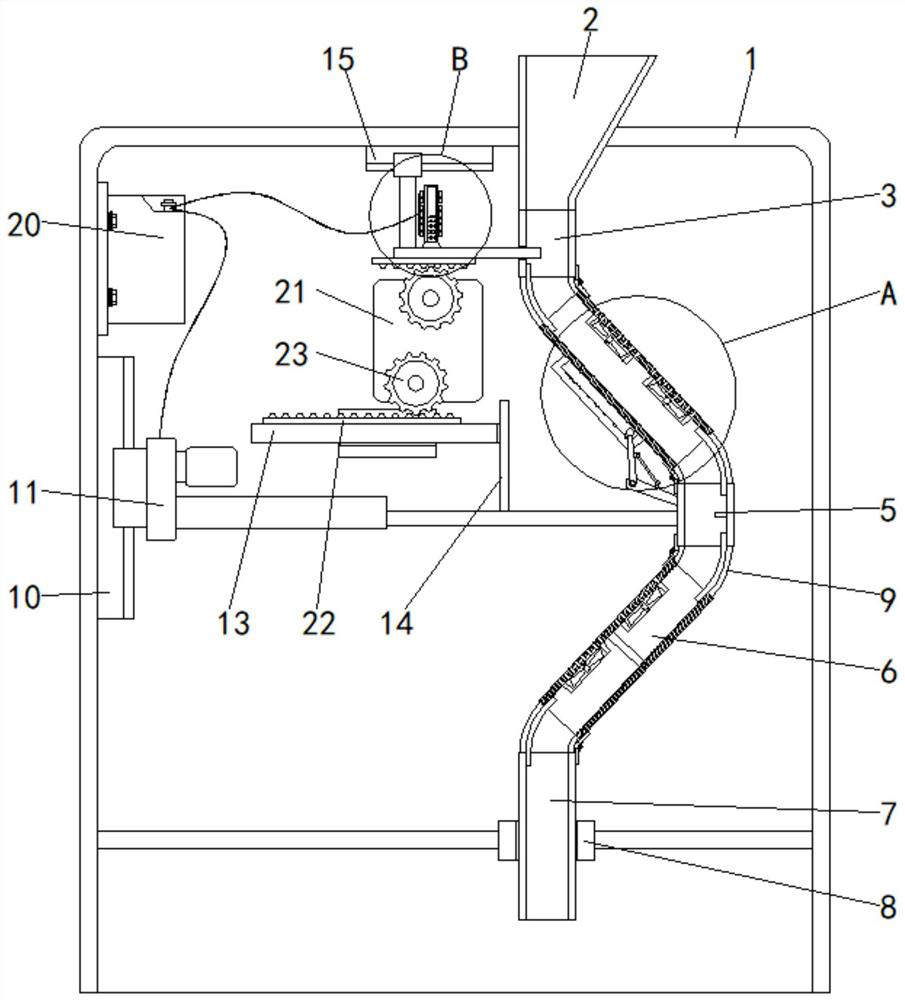

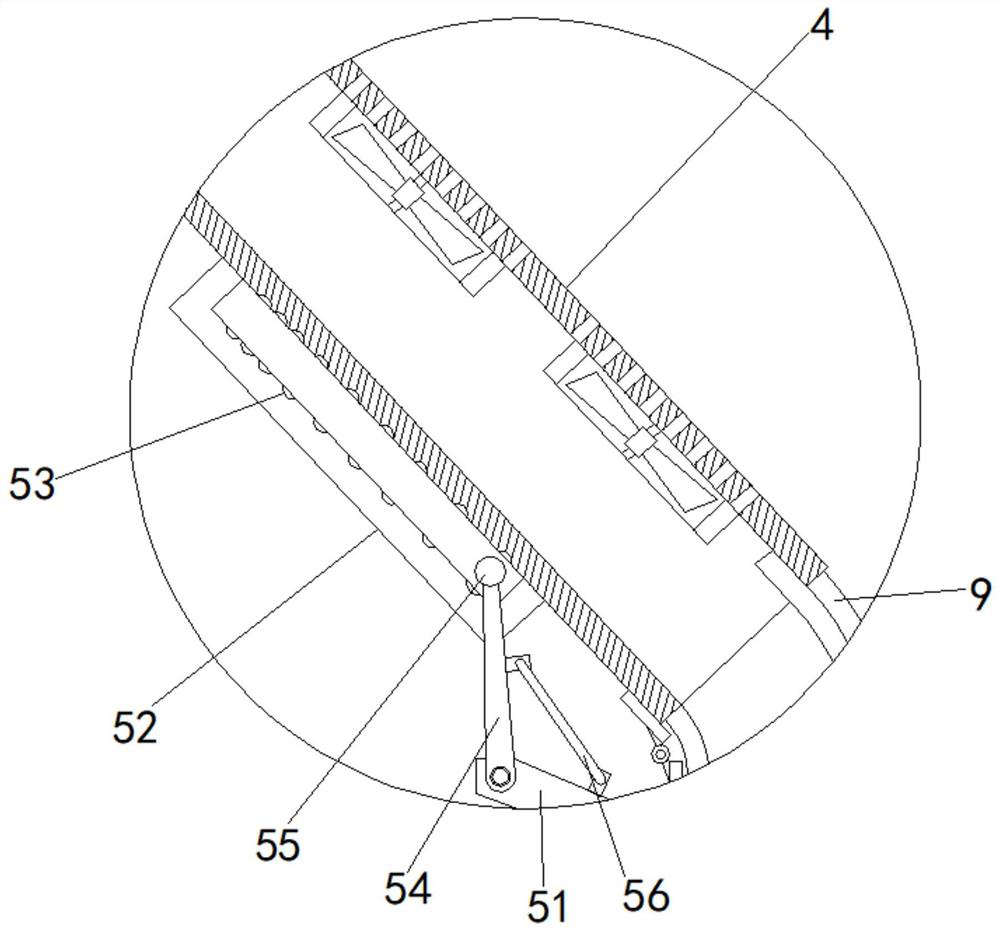

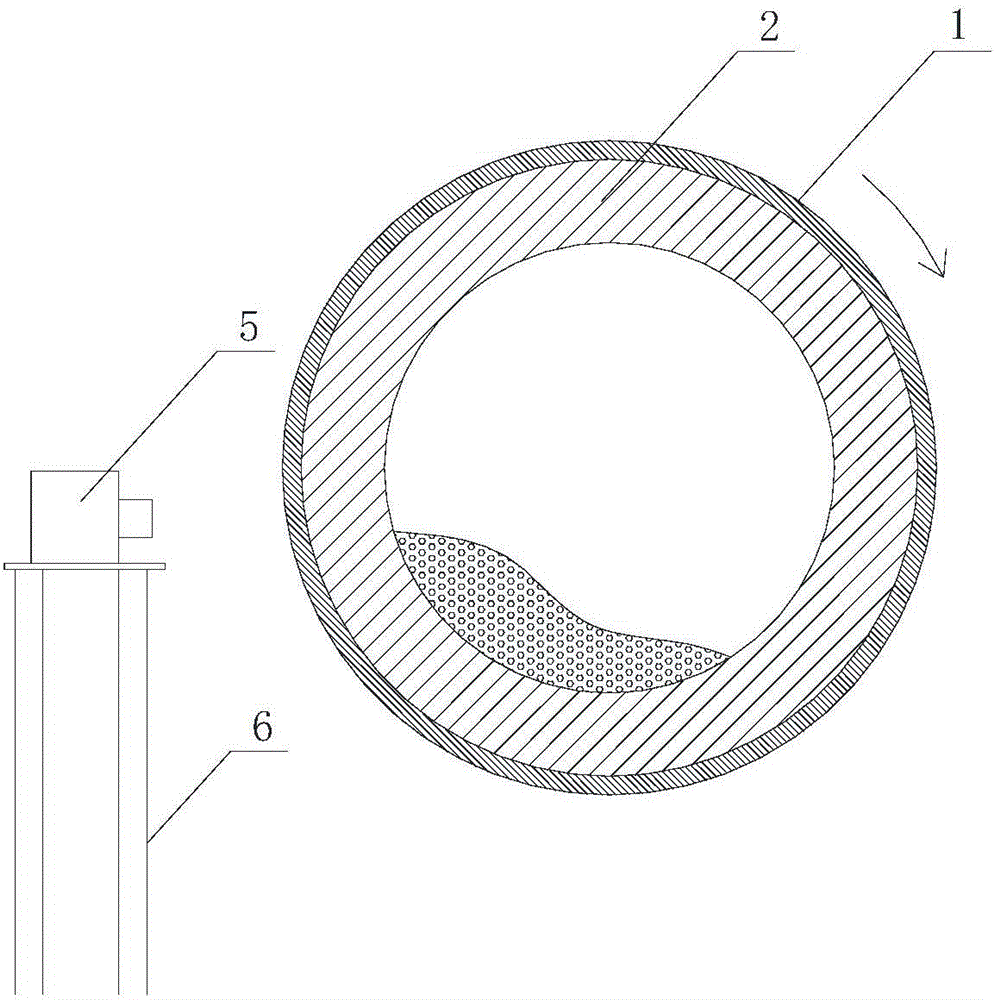

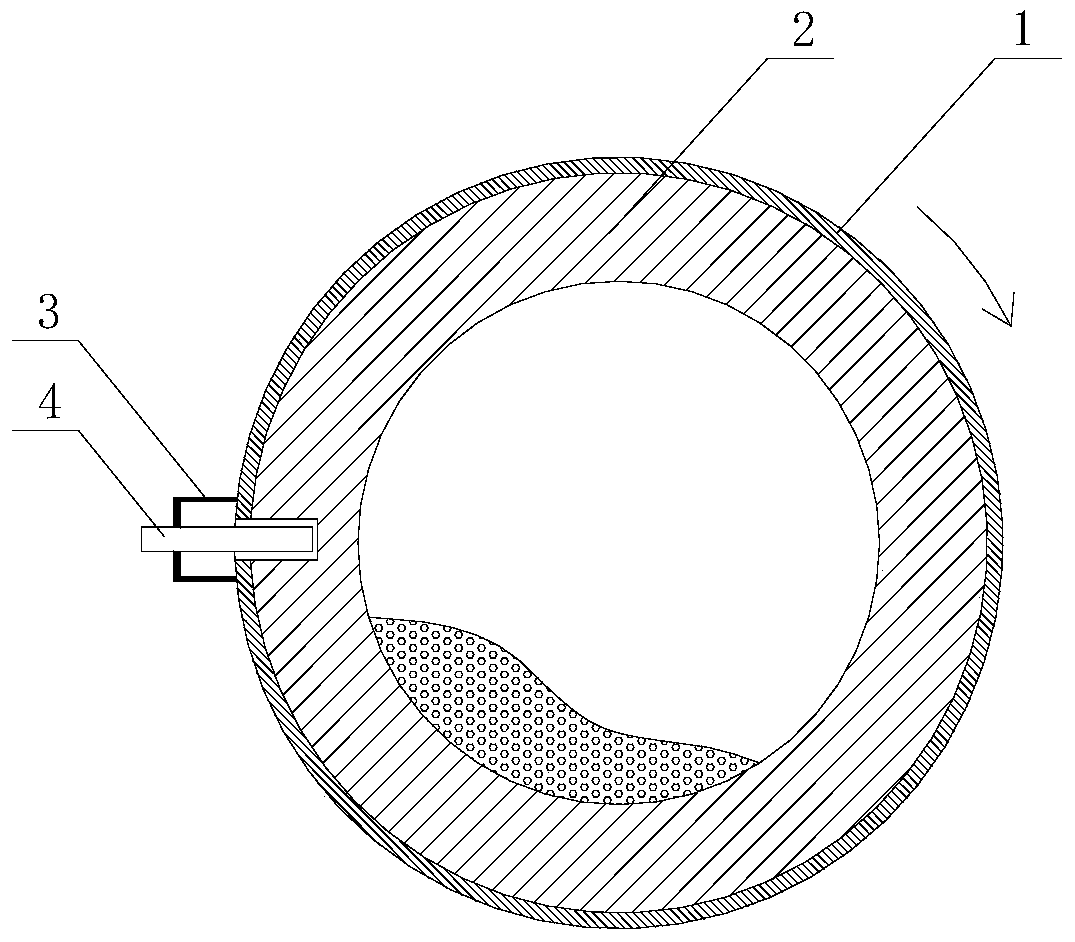

Self-driven type direct temperature measurement device for rotary kiln

ActiveCN106288770AGuaranteed service lifeGuaranteed temperature measurement accuracyRotary drum furnacesThermometer applicationsMotor driveEngineering

The invention relates to the technical field of temperature measurement of rotary kilns and provides a self-driven type direct temperature measurement device for a rotary kiln. The device comprises a rotating driving motor, screw rods, a thermocouple and a sleeve pipe, wherein the rotating driving motor drives the screw rods to rotate; the sleeve pipe is fixedly arranged on the outer side of the thermocouple in a sleeving manner and extends into a temperature measurement through hole formed in the side wall of the rotary kiln; screw grooves matched with threads of the screw rods are formed in the outer surface of the sleeve pipe; and the sleeve pipe is driven by the screw rods to drive the thermocouple to reciprocate periodically in the axial direction of the temperature measurement through hole. According to the device, the thermocouple is driven by the sleeve pipe to move, so that materials entering the temperature measurement through hole are cleared automatically, the temperature measurement through hole is prevented from being blocked by material beads, and the service life and the temperature measurement precision of the thermocouple are guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

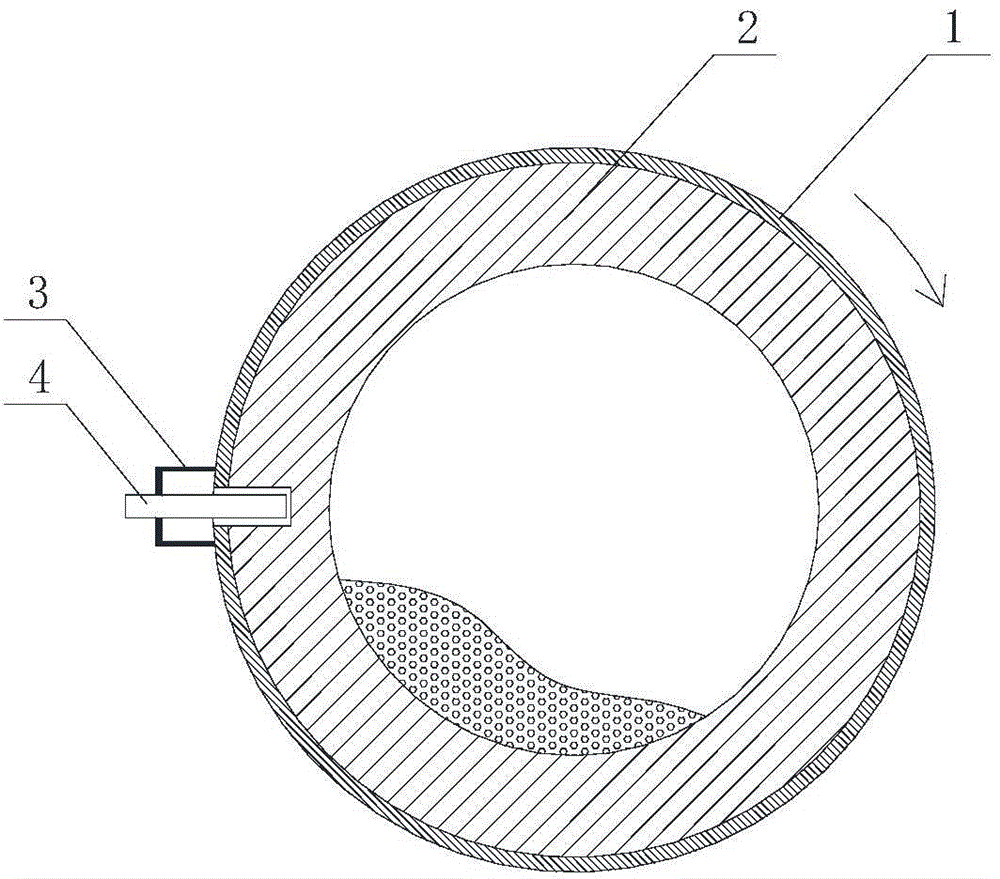

A self-driven direct temperature measuring device for a rotary kiln

ActiveCN106288771BAvoid cloggingGuaranteed service lifeRotary drum furnacesTemperature measurement of flowing materialsReciprocating motionElectric machine

The invention relates to the technical field of temperature measurement of a rotary kiln, and provides a self-driven direct temperature measurement device for a rotary kiln. The device includes a rotary drive motor, a screw rod, a fixed mount, a thermocouple and a sleeve tube; the rotary drive motor, the screw rod and the thermocouple are mounted on the fixed mount, and the fixed mount is fixed on a rotary On the side wall of the kiln; the rotary drive motor drives the screw rod to rotate; the sleeve tube is sleeved on the outside of the thermocouple and extends into the temperature measuring through hole opened on the side wall of the rotary kiln; the The outer surface of the sleeve tube is provided with a spiral groove that matches the thread of the screw rod. Driven by the screw rod, the sleeve tube performs periodic reciprocating motion along the axial direction of the temperature measuring through hole . The invention automatically removes the material entering the temperature measuring through hole through the movement of the sleeve tube, avoiding the blockage of the temperature measuring through hole by material lumps, thereby ensuring the service life and temperature measuring accuracy of the thermocouple.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Indirect temperature measuring device in entrained flow gasifying furnace

ActiveCN102305675BReasonable structureAccurate calculationTemperature measurement of flowing materialsCombustible gas productionSpray nozzleEngineering

The invention belongs to the field of measurement and control of boilers and discloses an indirect temperature measuring device in an entrained flow gasifying furnace. The indirect temperature measuring device in the entrained flow gasifying furnace comprises a first spray nozzle and a second spray nozzle which are horizontally distributed in a furnace body and have the same structure, wherein the first spray nozzle and the second spray nozzle penetrate through the furnace body; one end, which is positioned inside the inner cavity of the furnace body, of the first spray nozzle is connected with a first water cooling hood; one end, which is positioned inside the inner cavity of the furnace body, of the second spray nozzle is connected with a second water cooling hood; the first water cooling hood and the second water cooling hood are trumpet-shaped and ends with bigger trumpet openings face the center of the furnace body; the horizontal central axial lines of the first water cooling hood and the second water cooling hood are the same line; a water inlet pipe is coiled on the second water cooling hood; a water outlet pipe is coiled on the first water cooling hood; a flow meter and awater inlet temperature meter are arranged on the water inlet pipe; and a water outlet temperature meter is arranged on the water outlet pipe. The indirect temperature measuring device in the entrained flow gasifying furnace has the characteristics of reasonable structure, and capacities of protecting equipment in the furnace and ensuring the temperature measuring precision, and can measure the temperature accurately in real time; and simple and convenient computation is guaranteed.

Owner:HUANENG CLEAN ENERGY RES INST +1

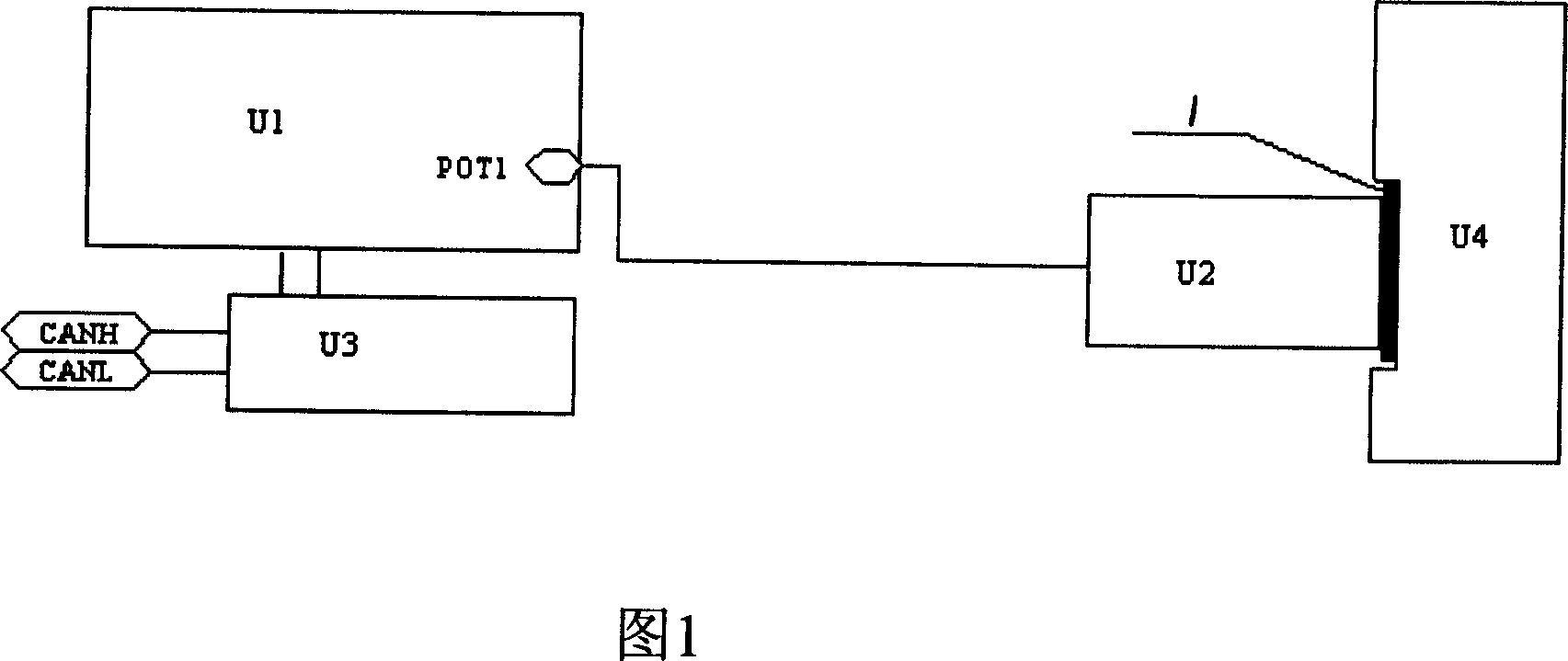

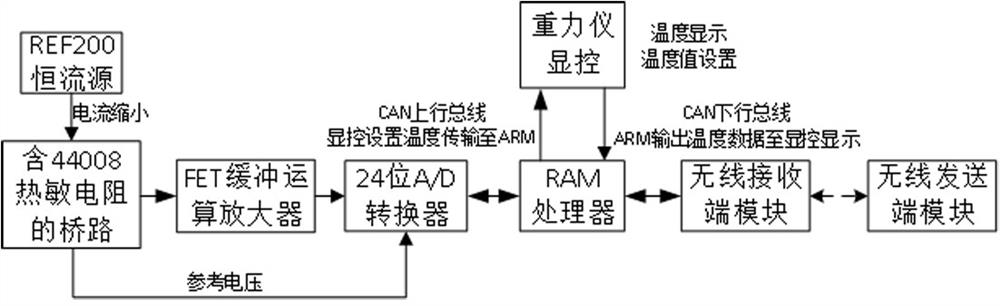

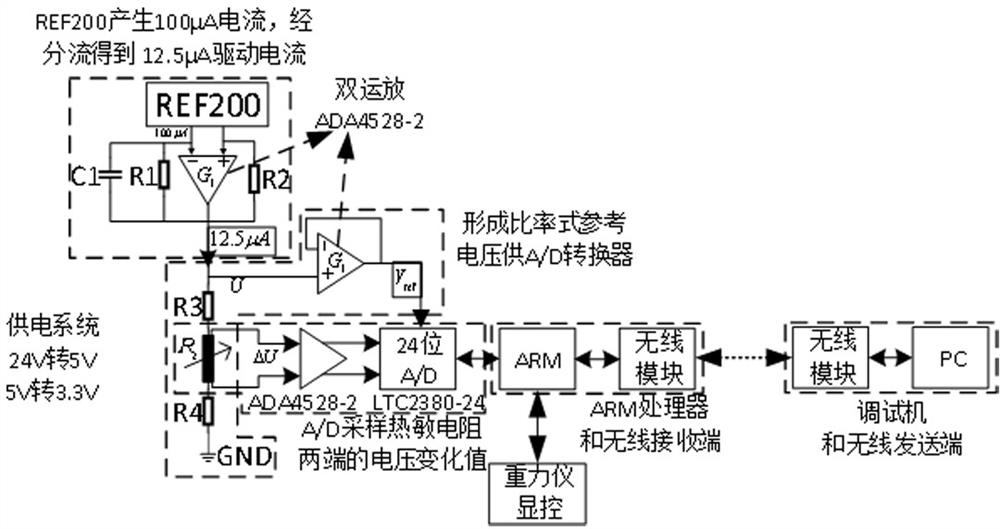

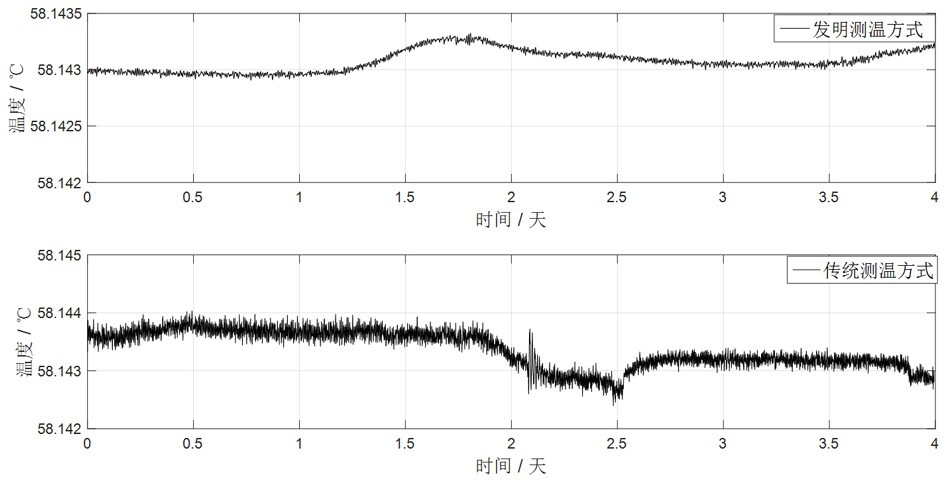

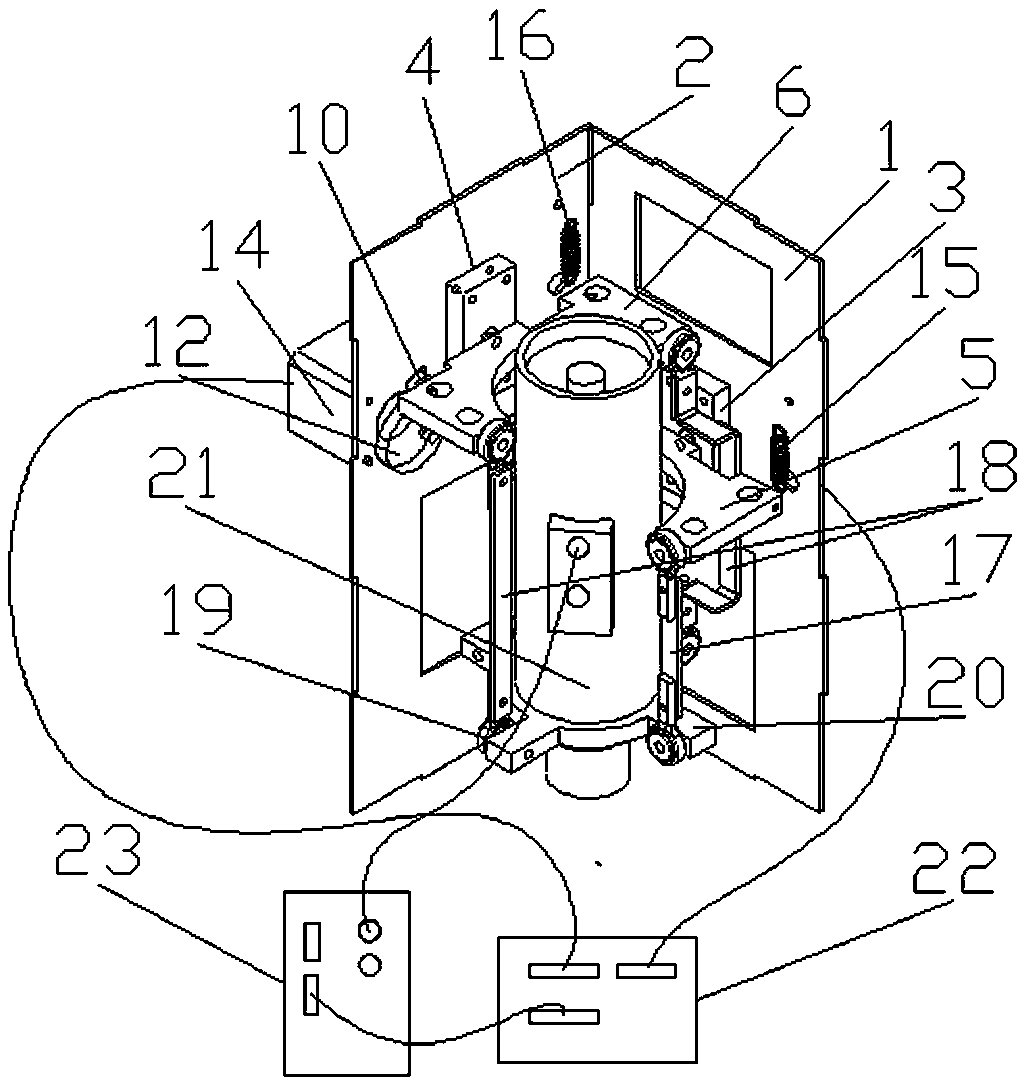

Digital high-precision temperature measurement system and method of relative gravimeter

ActiveCN114720009AHigh precisionConducive to state solidificationThermometers using electric/magnetic elementsUsing electrical meansConvertersHemt circuits

The invention relates to a digital high-precision temperature measurement system and method for a relative gravimeter, and the method comprises the steps: constructing a bridge circuit comprising a 44008 thermistor, providing a constant current for the bridge circuit through an REF constant current source circuit, carrying out the gain buffering of the voltage of the 44008 thermistor, carrying out the analog-to-digital conversion of the voltage through an A / D converter, and finally inputting the voltage into an RAM processor for the fitting of the voltage and temperature. Through a bidirectional CAN bus, the RAM processor transmits the temperature data to the gravimeter display controller, and the display controller transmits a temperature control value of a gravimeter temperature control system to the RAM processor. Meanwhile, the wireless transmitting end module is added to the RAM processor, and program updating or upgrading can be achieved through the wireless receiving end module. According to the invention, the linearity and precision of measurement can be improved, digitization is used for control, the debugging convenience is improved, the state solidification of a gravimeter constant temperature system is facilitated, and the method can be widely applied to various gravimeters.

Owner:TIANJIN NAVIGATION INSTR RES INST

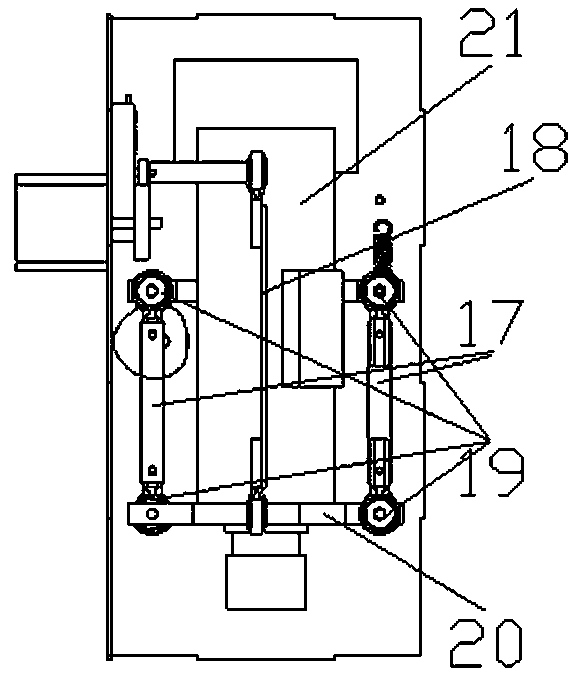

Automatic aiming device of coke oven vertical flame path temperature measuring gun

PendingCN111238686AGuaranteed temperature measurement accuracyAvoid the application of limit switches and safety control circuitsThermometer detailsCoke oven safety devicesPhysicsRocker arm

The invention belongs to the technical field of coke production and provides an automatic aiming device of a coke oven vertical flame path temperature measuring gun. A temperature measuring gun with video output is used; image recognition is carried out on temperature measuring points in the vertical flame path; the relative position of the measured temperature point and the current aiming point of the temperature measuring gun is determined; motion control data of an x axis and a y axis is calculated; an x-axis motor and a y-axis motor are driven; the motor drives the corresponding cam to rotate; under the action of rocker arm pull-up springs, the cam is in close contact with bolt bearings at one ends of the corresponding rocker arms to rotate at small angles; small-angle rotation of therocker arms is transmitted to the four rocker arms of the cradle through the combination of the fisheye bearings at the ends of the pull rods and the pull rods, so that the temperature measuring gun fixed to the cradle moves at a small angle in a high-precision mode, a measured point can be rapidly and accurately aimed, and the temperature measuring precision is guaranteed.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com