Stress-packaging-free temperature-sensing optical fiber cable and preparation method thereof

A temperature-sensing optical fiber and weak fiber grating technology, which is applied in the field of stress-free encapsulated temperature-sensing optical fiber and cable and its preparation, can solve the problems of poor temperature measurement accuracy, complex structure of temperature measurement cable, difficulty in automatic production, etc., and achieve high production efficiency. , easy to automate batch, easy to machine batch preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

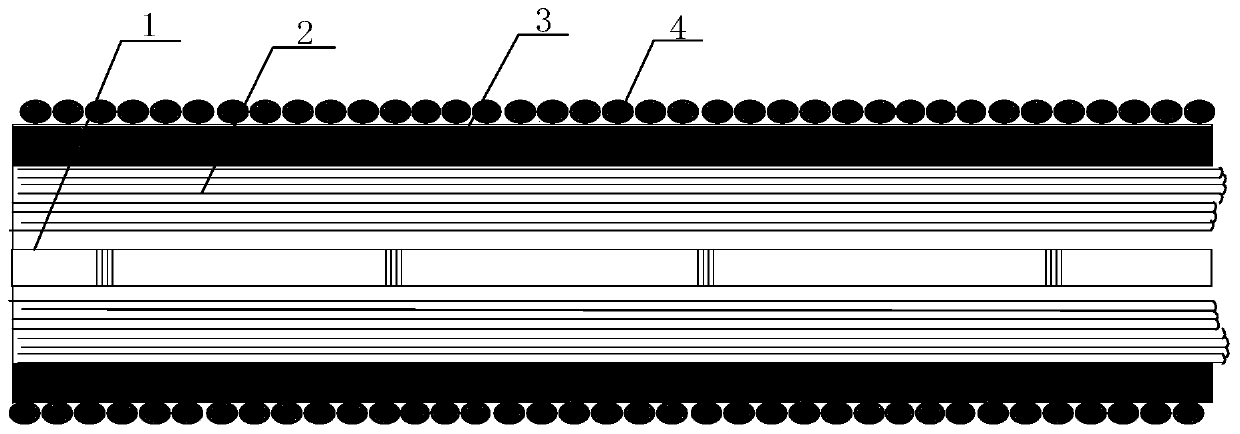

[0043] A stress-free packaged temperature-sensing optical fiber cable, comprising:

[0044] An ultra-weak fiber grating array 1 located in the center;

[0045] Fiber bundles 2 uniformly distributed in parallel around the ultra-weak fiber grating array 1, the ultra-weak fiber grating array 1 and the fiber bundle 2 are freely bundled;

[0046] A metal tube 3 wrapped axially around the ultra-weak fiber grating array 1 and the fiber bundle 2;

[0047] The surrounding reinforcement 4 is twisted helically around said metal tube 3 .

[0048]The fiber bundle 2 is a multi-strand Kevlar fiber, which is used to generate free beam expansion after the winding tension is released, and is evenly distributed in the metal tube 3, so that the ultra-weak fiber grating array 1 is separated from the inner tube wall of the metal tube 3 s contact. This greatly reduces the friction between the optical fiber and the wall of the metal tube 3, effectively avoiding the additional stress generated by l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

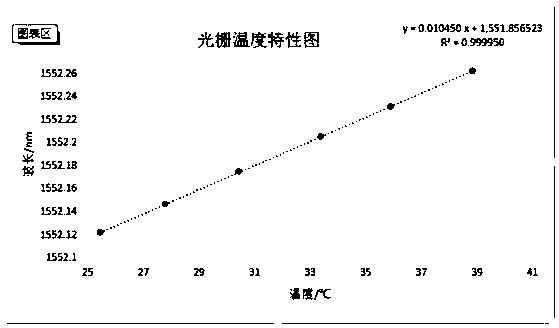

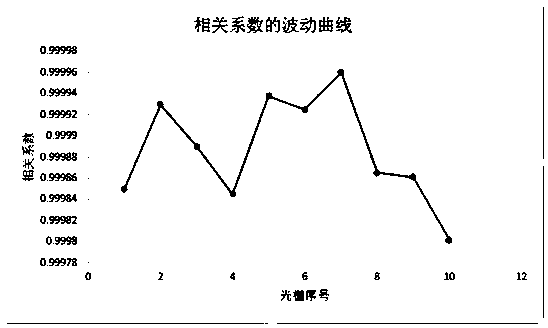

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com