Fuel-cell engine temperature collection circuit

A technology of engine temperature and fuel cell, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic components, etc., can solve the problems of high cost of circuit hardware, interference, malfunction, etc., and achieve simplification Temperature measurement circuit, improved anti-interference, and high measurement reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

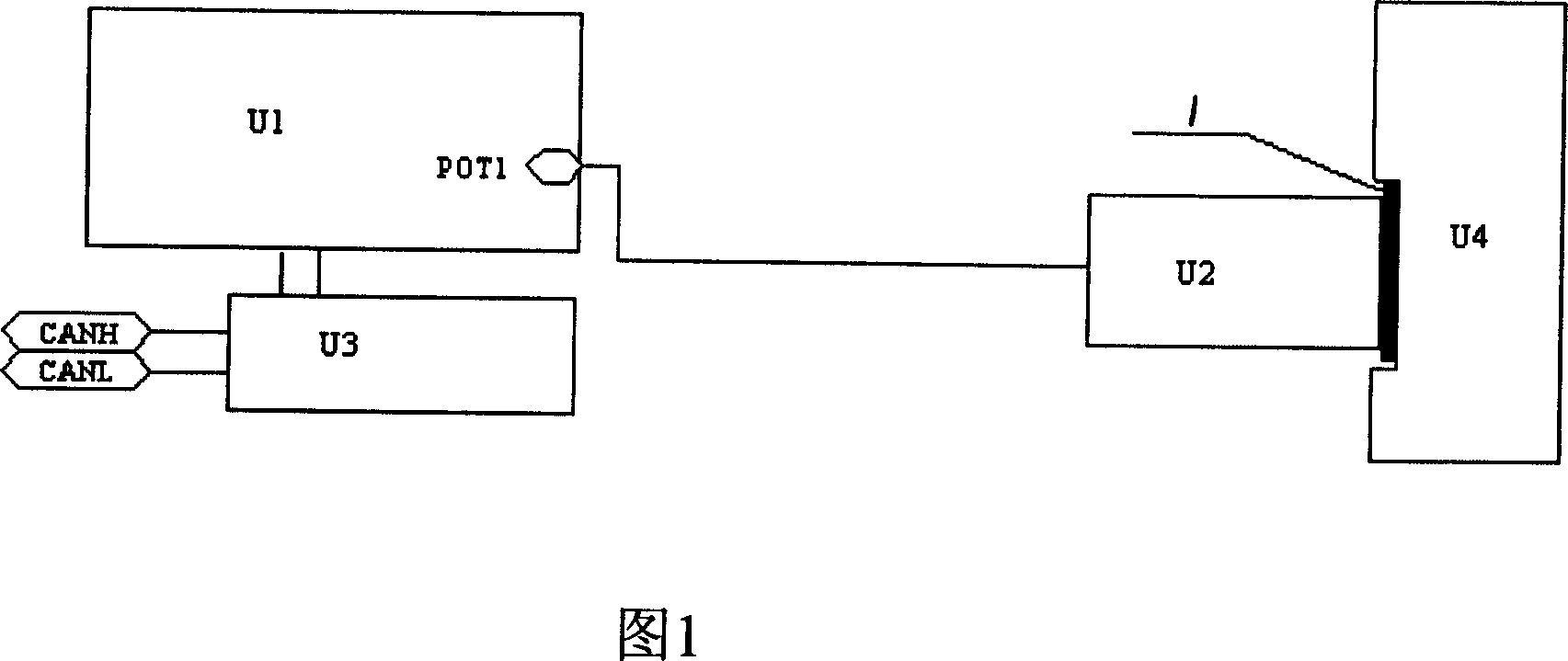

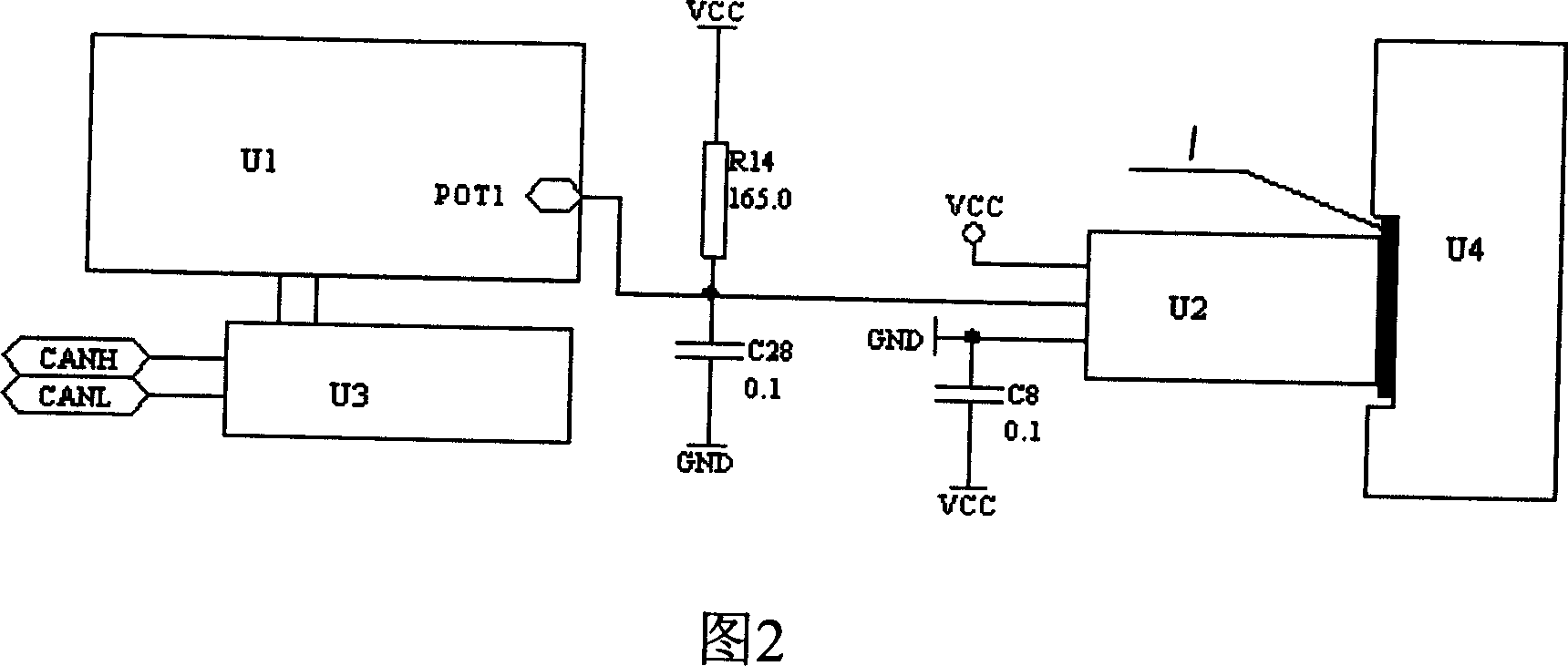

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] Referring to Fig. 2, Fig. 2 is an embodiment of temperature control in a 50 kW fuel cell power generation system of the present invention. The single-chip microcomputer chip used by the single-chip microcomputer U1 is Philips 87C591, and the semiconductor temperature sensor adopts DS18B20 product, and the temperature measurement range can meet the requirements of the current operating temperature range of the fuel cell engine -20°C-90°C. The single-chip microcomputer U1 is connected to the temperature sensor U2 through a switch input and output interface POT1. The single-chip microcomputer software reads the value of the temperature sensor strictly according to the timing requirements of DS18B20. The circuit branch composed of C28. On the branch, one end of the resistor R14 is connected to the power supply VCC, and the other end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com