Reactor for sec.-butyl acetate

A technology of sec-butyl acetate and reaction kettle, which is applied in the direction of carboxylic acid ester preparation, feeding device, and organic compound preparation, etc. Uneven heat transfer and other problems, to achieve the effect of improving heat transfer effect and temperature measurement accuracy, ensuring stability, heat transfer effect and temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

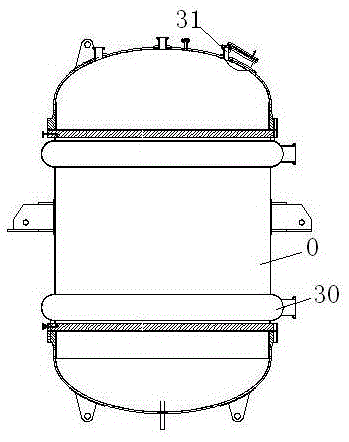

[0024] A sec-butyl acetate reactor as shown in the figure is characterized in that it includes a reactor body 0, and the reactor body 0 includes a liquid inlet device 30 arranged at the lower end of the reactor body 0 and a liquid inlet device arranged at the reactor body 0 The temperature measuring device 31 at the upper end;

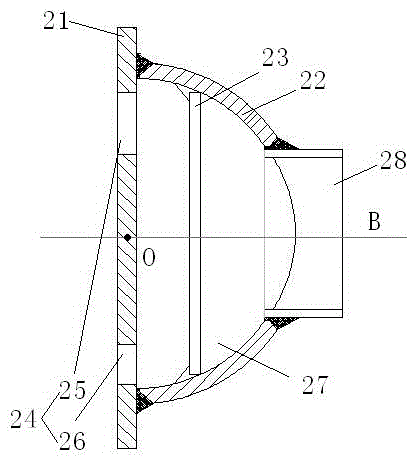

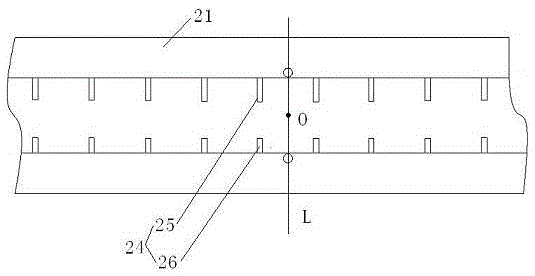

[0025] The liquid inlet device 30 includes a liquid inlet plate 21, an annular plate 22 and a deflector baffle 23. The liquid inlet plate 21 is connected end to end and is ring-shaped, and its center point is O. The liquid inlet plate 21 is provided with a liquid inlet Port 24, the liquid inlet 24 is rectangular, including the upper liquid inlet 25 located at the upper end of the liquid inlet plate 21 and the lower liquid inlet 26 located at the lower end of the liquid inlet plate 21, the number of the upper liquid inlet 25 is multiple, It is rectangular, and the width of the rectangle formed by all the upper liquid inlets 25 is the same. The upper liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com