Hearth workpiece temperature measuring device and method

A technology of temperature measuring device and furnace, which is applied in the direction of measuring device, radiation pyrometry, optical radiation measurement, etc., can solve the real situation that cannot reflect the surface temperature distribution, can not rule out the heat shielding effect of flue gas on the furnace tube, and measurement error Large and other problems, to achieve the effect of eliminating system errors, high field of view, temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

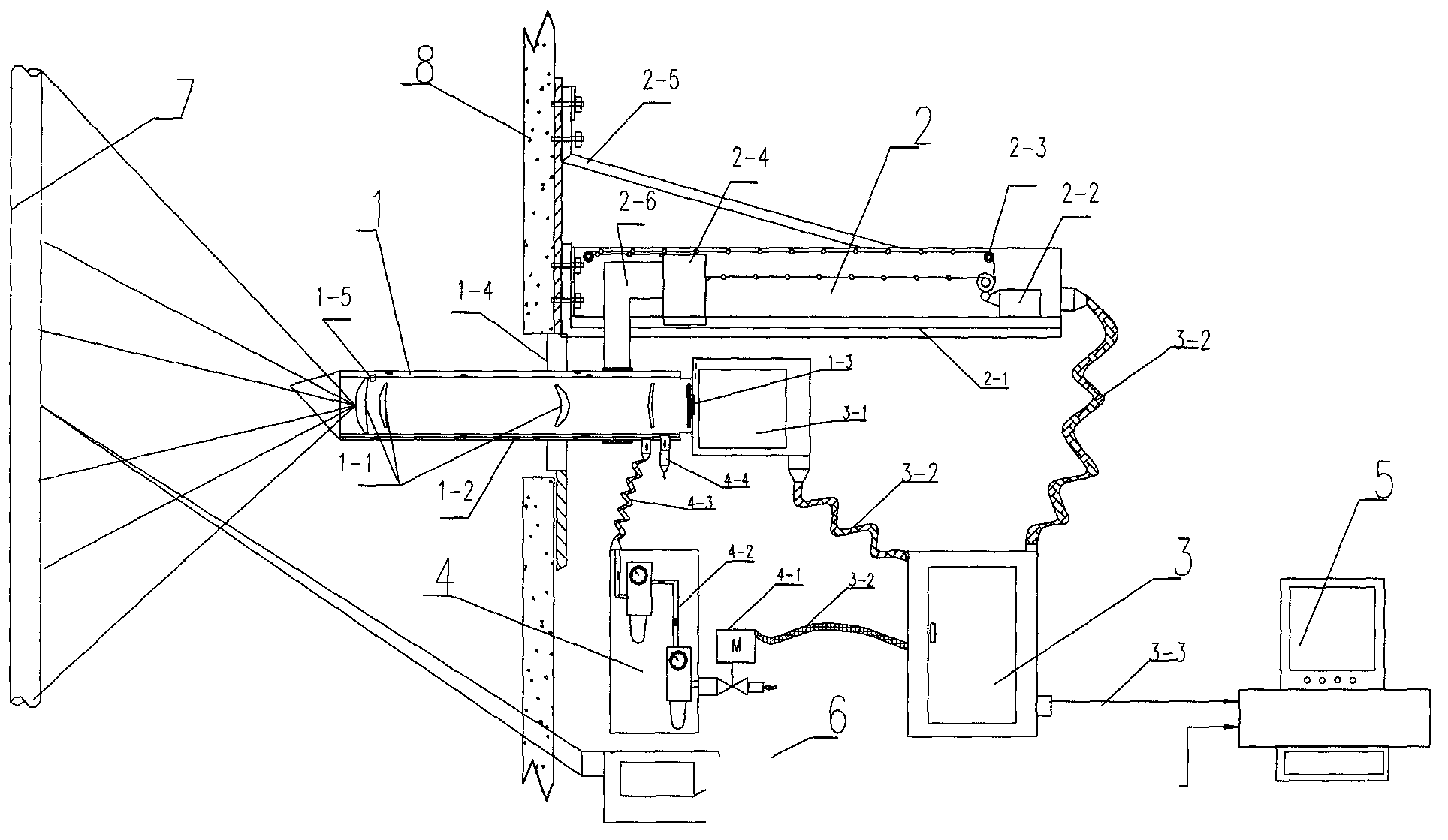

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings. The drawings and specific embodiments do not limit the scope of protection claimed by the present invention.

[0024] The furnace workpiece infrared temperature measurement system device is constituted in this way. The infrared lens group 1-1 is installed inside the cooling protective sleeve 1-2, the sleeve 1-2 is a three-layer jacket structure, and the innermost layer is equipped with multiple infrared lenses and a temperature sensor 1-5 is installed in the front lens; Cooling air flows in from the middle casing and flows out from the outer casing. The automatic advancing and retreating mechanism is fixed on the housing of the furnace outer wall 8 by the supporting connector 2-5. The sleeve tube 1-2 of the infrared endoscope lens group is connected with the automatic advance and retreat mechanism through the device 2-6. The heat insulation sealing plate 1-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com