Antioxidative tungsten-rhenium alloy for thermocouple and preparation method

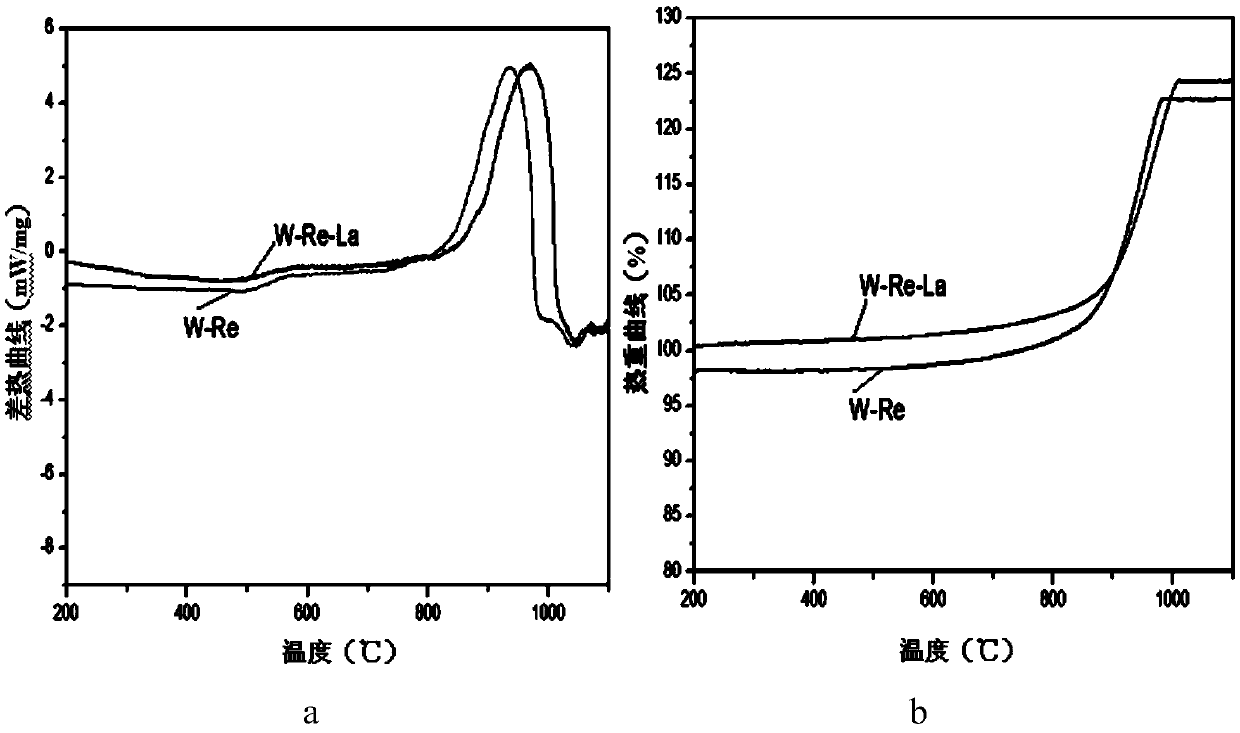

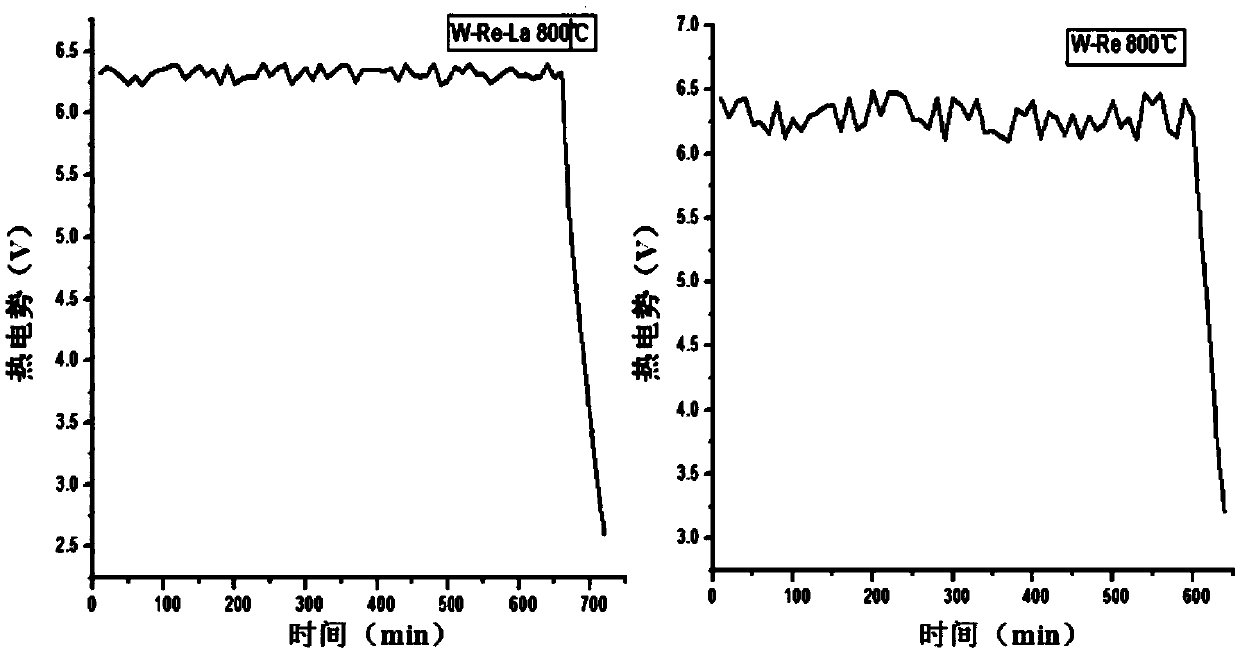

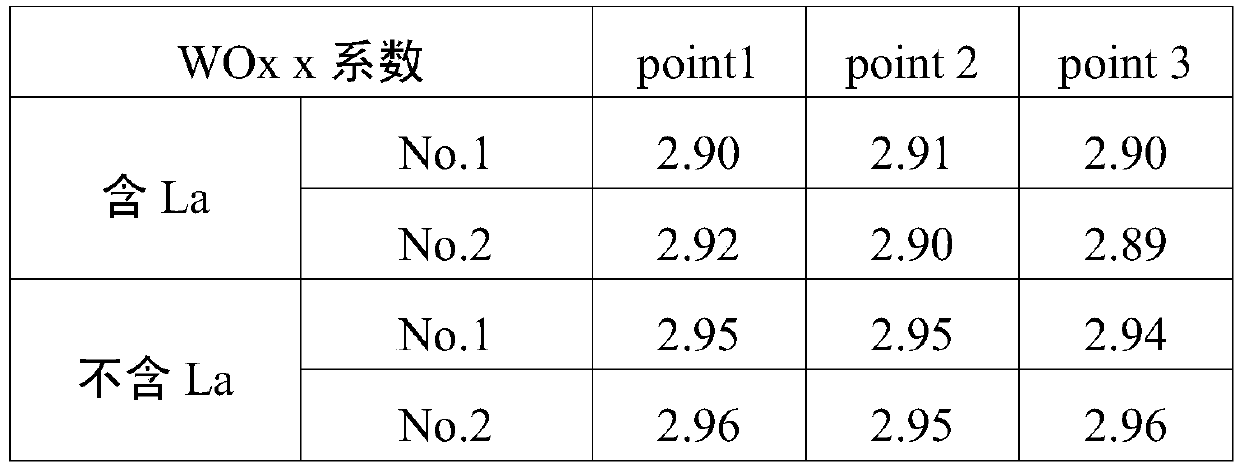

A rhenium alloy and tungsten oxide technology, applied in the field of alloys, can solve the problems of easy oxidation of the surface of the wire, affecting the temperature measurement accuracy and application, etc., to achieve the effect of improving the anti-oxidation performance and ensuring the temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 1000g of tungsten powder, 75.5g of ammonium rhenate, and 4g of lanthanum nitrate hexahydrate. The purity of the tungsten powder is ≥99.95%, the average particle size is 1.0-7.0μm, the particle size is in a normal mass distribution, and the shape is spherical or polygonal. Add lanthanum nitrate hexahydrate into 500ml of absolute ethanol to dissolve, then add tungsten powder and stir until it becomes a slurry, evaporate to dryness in a water-bath evaporator and keep stirring until it becomes a thick paste, stop stirring, and continue heating until the thick paste is completely Evaporate to dryness to obtain powder. The evaporated powder and ammonium rhenate were dispersed in a high-energy dispersing device at a speed of 120 r / min for 16 hours to obtain tungsten-rhenium pre-alloyed powder. After the tungsten-rhenium pre-alloy powder is molded, it is held in cold isostatic pressing with a pressure of 150MPa for 600s, then vertically melted and sintered, and kept at 19...

Embodiment 2

[0040] Weigh 1000g of tungsten powder, 480g of ammonium rhenate, 10g of cobalt nitrate hexahydrate, and 3g of lanthanum nitrate hexahydrate. Add cobalt nitrate hexahydrate and lanthanum nitrate hexahydrate into 500ml of absolute ethanol to dissolve, then add tungsten powder and stir until it becomes a slurry, evaporate to dryness in a water-bath evaporator and keep stirring until it becomes a thick paste, then stop stirring and continue heating until The thick paste was completely evaporated to dryness to obtain a powder. Disperse the evaporated powder and ammonium rhenate in a high-energy dispersing device at a speed of 130 r / min for 18 hours to obtain tungsten-rhenium pre-alloyed powder. After the tungsten-rhenium pre-alloy powder is molded, it is held in cold isostatic pressing with a pressure of 200MPa for 700s, then vertically melted and sintered, and kept at 2200A for 20min. After cooling, it is kept at 3300A for 40min to obtain a sintered billet. The sintered billet is...

Embodiment 3

[0042] Weigh 1000g of tungsten powder, 44.5g of ammonium rhenate, and 3g of cerium nitrate hexahydrate. Add cerium nitrate hexahydrate to 500ml of absolute ethanol to dissolve, then add tungsten powder and stir until it becomes a slurry, evaporate to dryness in a water-bath evaporator and keep stirring until it becomes a thick paste, stop stirring, and continue heating until the thick paste is completely Evaporate to dryness to obtain powder. Disperse the evaporated powder and ammonium rhenate in a high-energy dispersing device at a speed of 100 r / min for 15 hours to obtain tungsten-rhenium pre-alloyed powder. After the tungsten-rhenium pre-alloy powder is molded, it is held in cold isostatic pressing with a pressure of 150MPa for 400s, then vertically melted and sintered, and kept at 2100A for 20min. After cooling, it is kept at 3050A for 30min to obtain a sintered billet. The sintered billet is opened according to the processing rate of 15%, and the heating temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com