Impregnating furnace electric thermo-couple protector

A protection device, thermocouple technology, applied in the direction of using electrical devices, measuring devices, thermometers with electrical/magnetic components directly sensitive to heat, etc., can solve the problems of short service life of thermocouples, inaccurate measurement, etc. The effect of prolonging life, improving quality and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

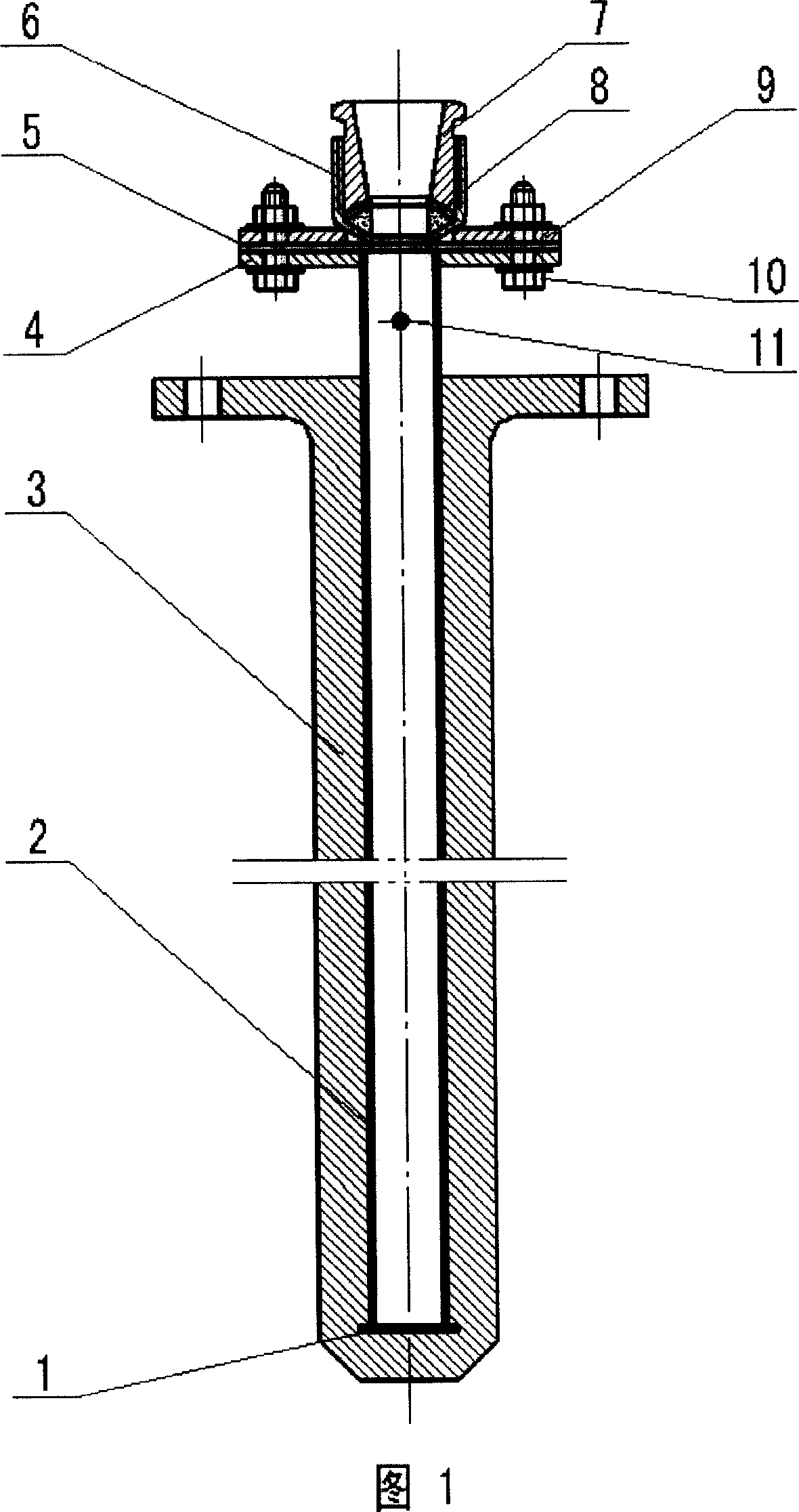

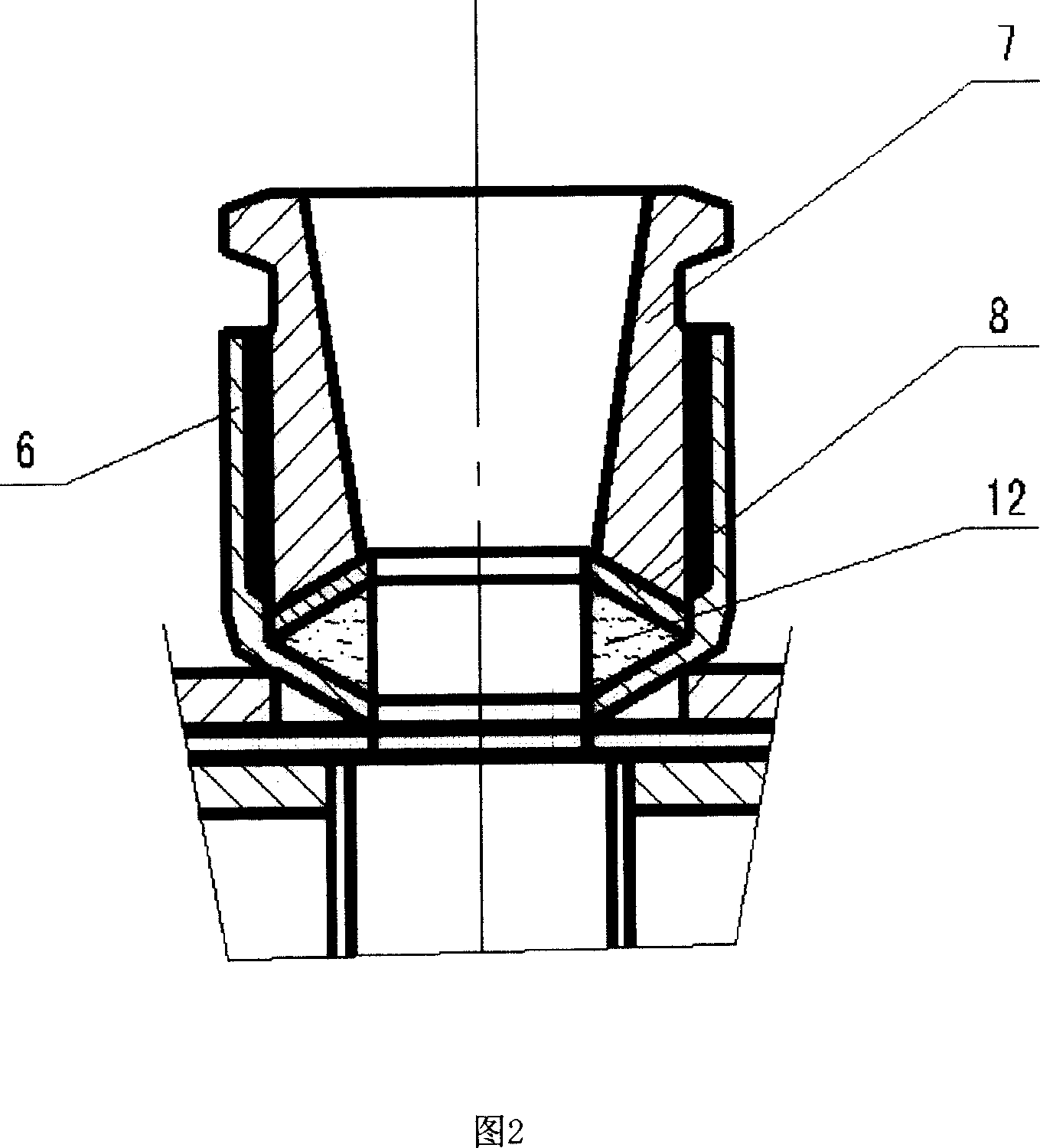

[0023] The embodiment of the present invention: the bottom plate 1, the protection tube 2 and their parts are made, the heat-resistant steel material is used to cast the reinforced protective layer 3 on the outside of the bottom plate 1, the protective tube 2, and the flanges and holes are processed in the reinforced protective layer 3 according to the attached Install as shown in the figure.

[0024] The specific process is as follows: first weld the bottom plate 1 and the protective tube 2 to each other to form a casing, which becomes the casing for inserting the thermocouple later; the outside of the casing is cast with heat-resistant steel castings, namely the reinforced protective layer 3, as a whole, heat-resistant cast steel The parts are resistant to high temperature and corrosion, and can protect the inserted thermocouple from corrosion; flange 4 is welded on the upper end of the casing, which is convenient to connect and fix with the flange 9 through the bolt assembly 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com