Automatic measuring method and automatic measuring system for temperature of vertical flue of coke oven

A technology of automatic detection and fire path, which is applied in the field of coking production, can solve the problems of long auxiliary time in the temperature measurement process, low measurement efficiency, and affecting the normal production rhythm of the coke oven, so as to achieve less space occupation, improve automation level, and improve actual efficiency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

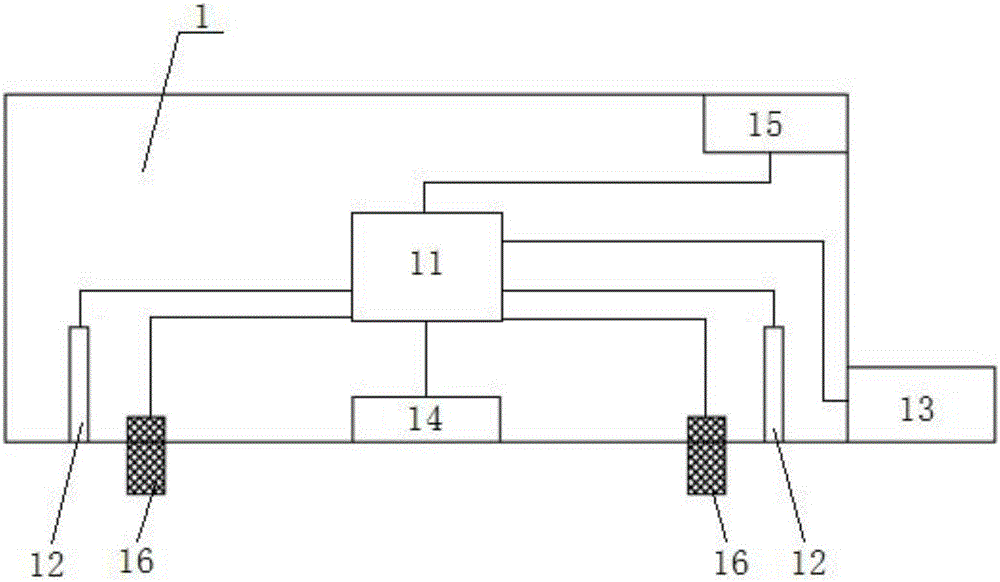

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

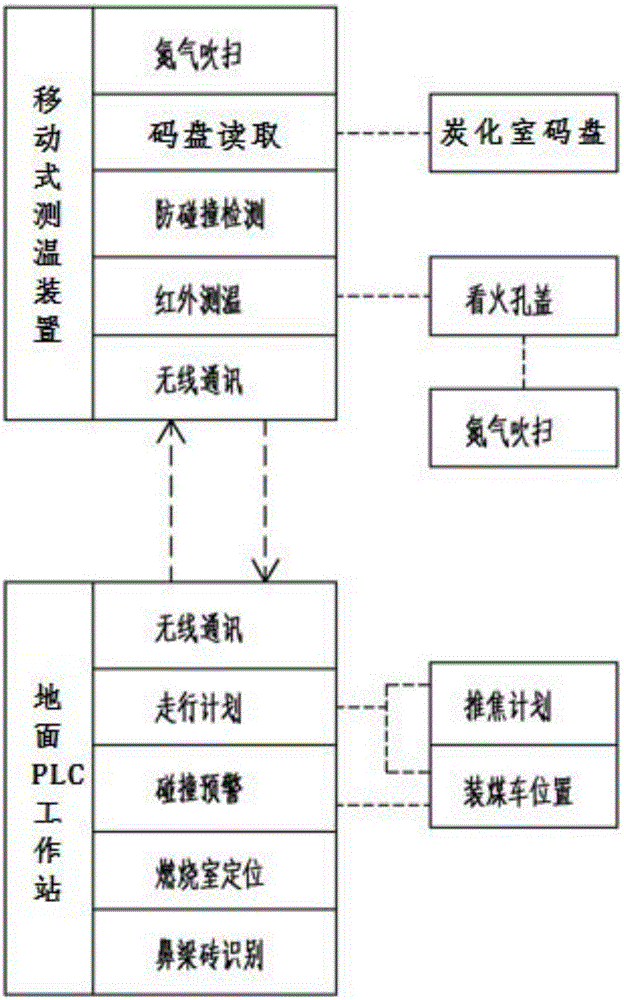

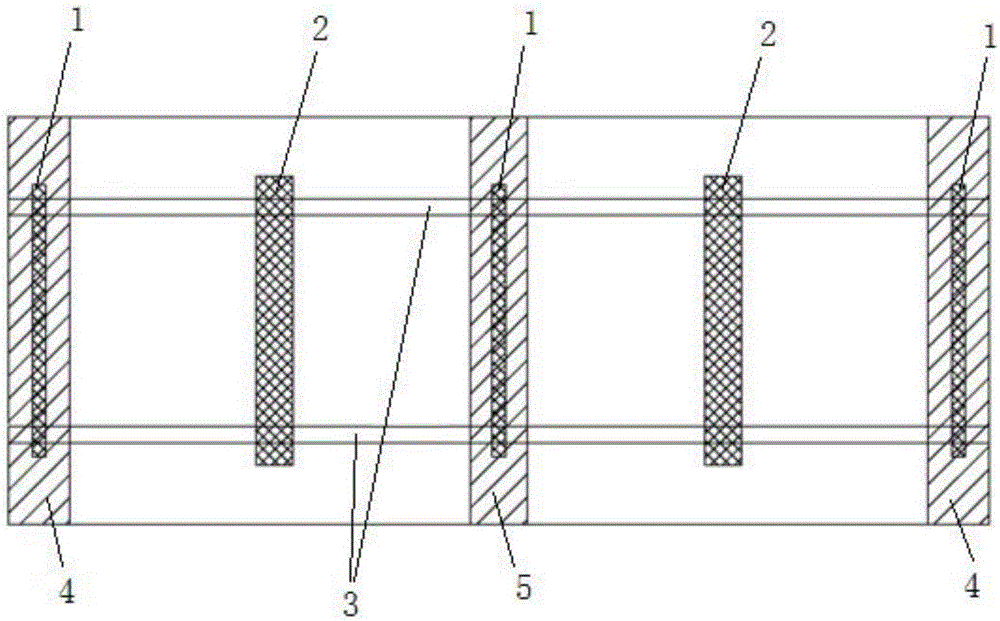

[0035] The method for automatically detecting the temperature of the coke oven vertical flue of the present invention includes the process of preparing the trajectory of the temperature measuring device, the positioning process of the combustion chamber, the identification process of the bridge brick and the continuous temperature measurement process; the process of preparing the trajectory of the temperature measuring device is used to On the basis of considering the focus push plan, the temperature of the standard flue is detected periodically by the mobile temperature measuring device 1; the combustion chamber positioning process is used to determine the combustion chamber number and the corresponding time stamp; Identify the corresponding temperature of the nose brick in the temperature measurement; the mobile temperature measurement device 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com