Automatic aiming device of coke oven vertical flame path temperature measuring gun

A technology of automatic aiming and temperature measuring guns, which is applied in the direction of measuring devices, furnace safety devices, coke ovens, etc., can solve the problems of inaccurate temperature, low investment, and inability to directly measure the actual temperature, so as to ensure the accuracy of temperature measurement , Ensure high precision and high resolution, avoid the application effect of limit switches and safety control circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

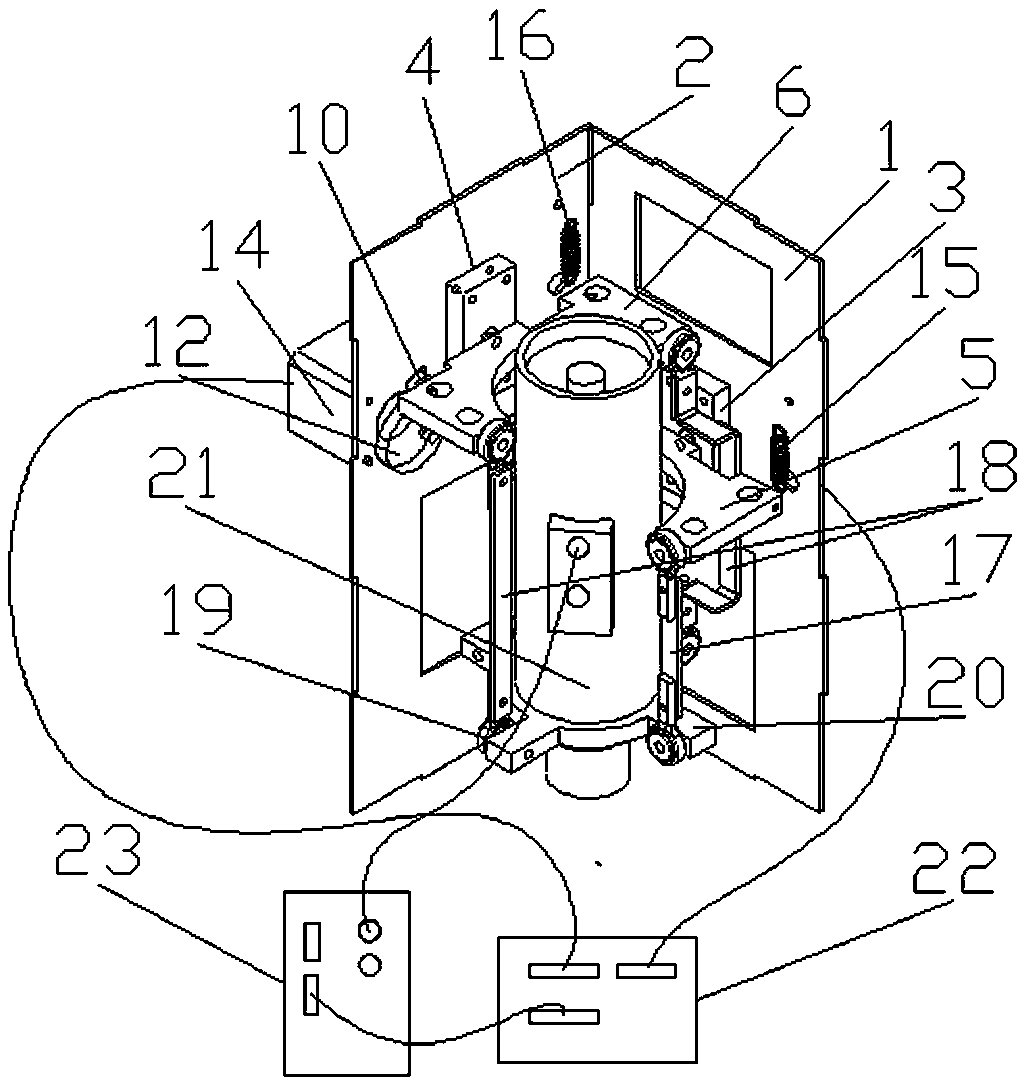

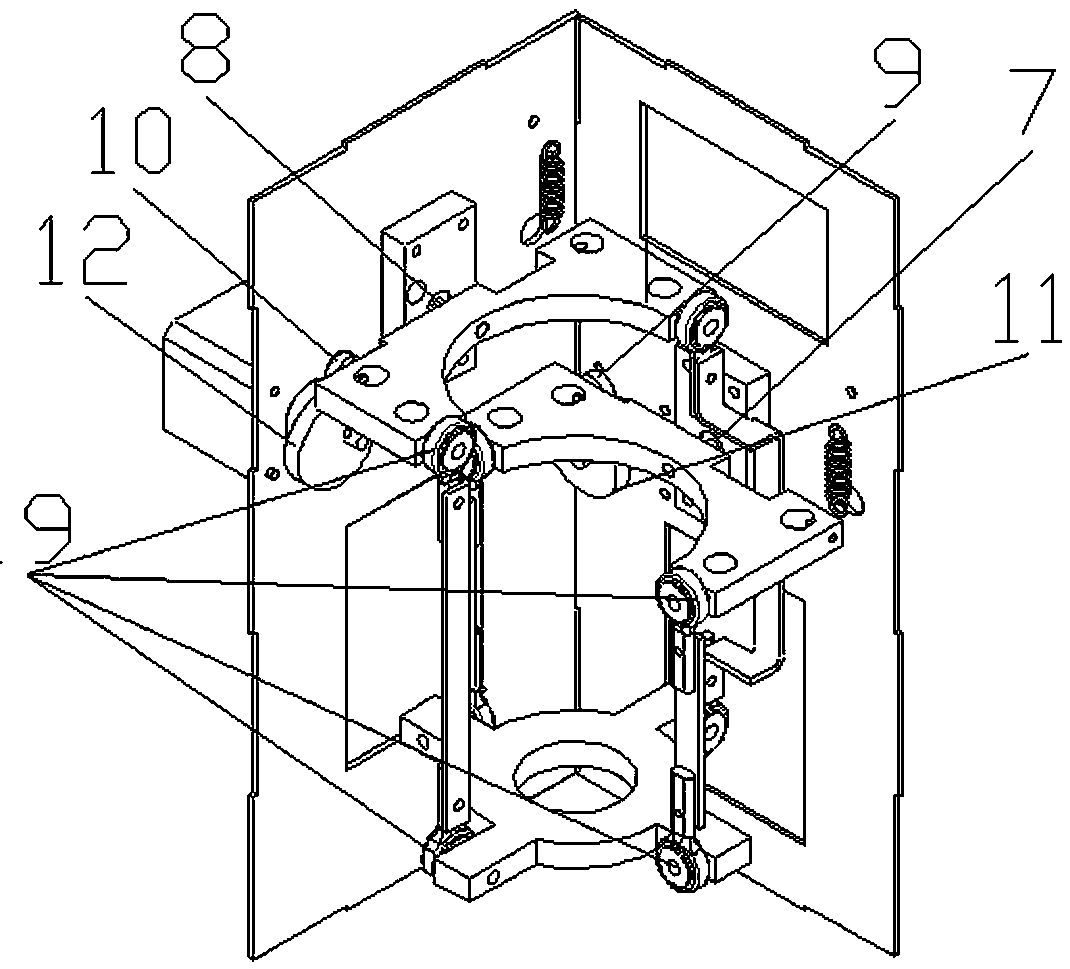

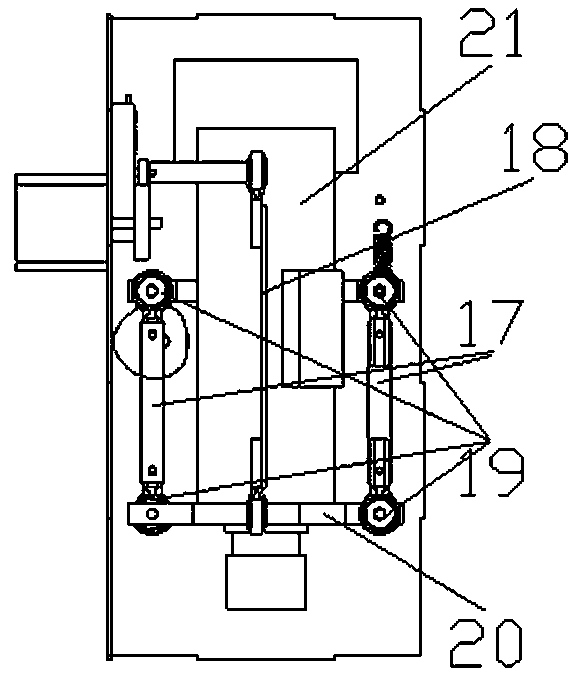

[0022] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0023] Such as Figure 1-4 As shown, the present invention provides an automatic aiming device for a temperature measuring gun of a coke oven vertical flue. Bearing seat; the left rocker arm shaft is fixed between the left rocker arm bearing seat and the left side plate, and the other end of the left rocker arm shaft is connected to the central part of the left rocker arm, so that the left rocker arm can rotate around the axis; The plane of the arm is close to the side of the left side plate, the left top bolt bearing is installed on the end surface of the left rocker arm, the left top bolt bearing is parallel to the left rocker shaft, and the cam parallel to the left side plate is installed under the left top bolt bearing, The cam is connected with the stepper motor shaft fixed on the left plate and drives it to rotate; the other end of the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com