Patents

Literature

377results about How to "Won't collide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

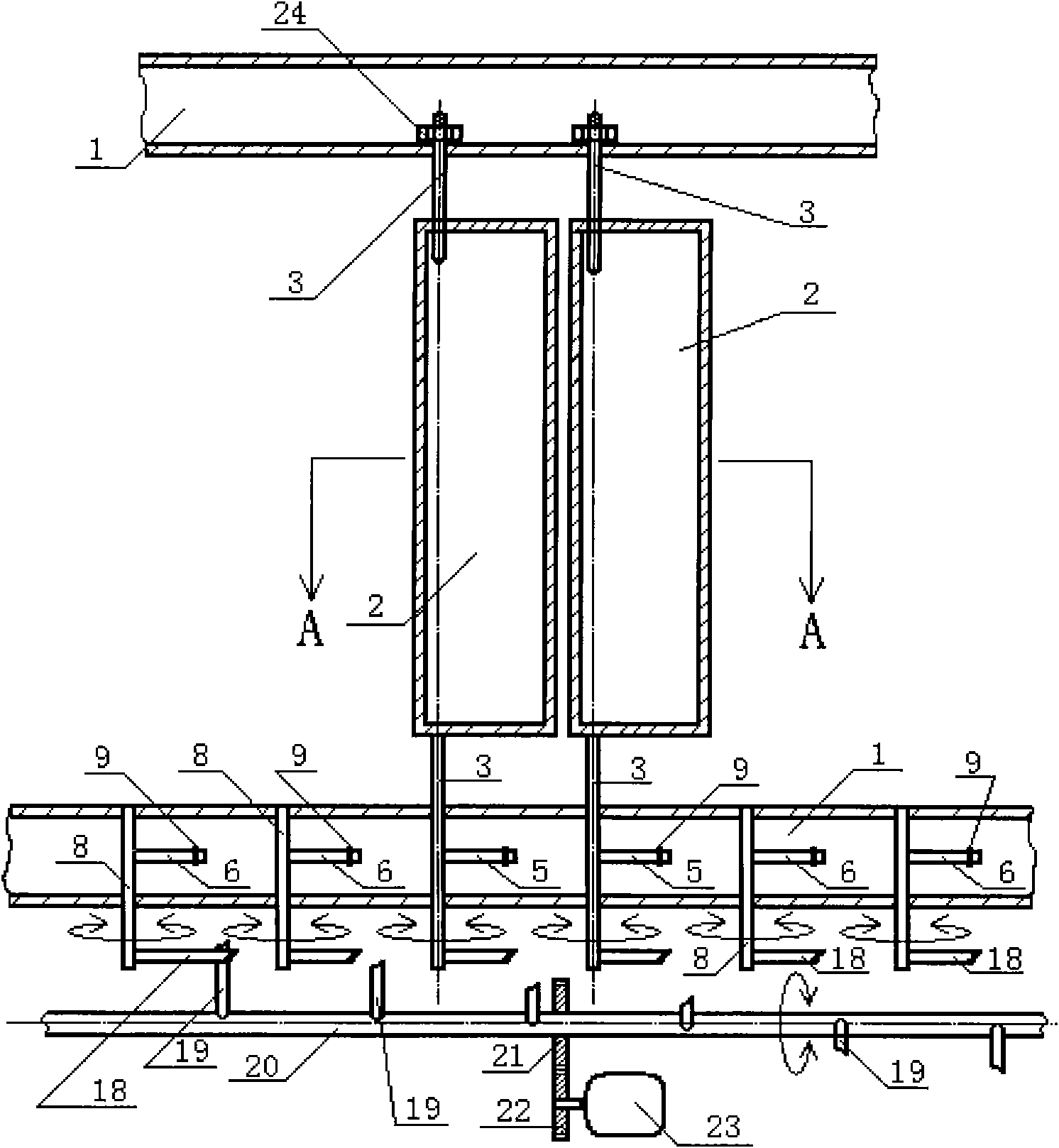

Indoor inspection robot for transformer substation

ActiveCN105945900AEasy to installReliable communicationProgramme-controlled manipulatorPower substationOmni directional

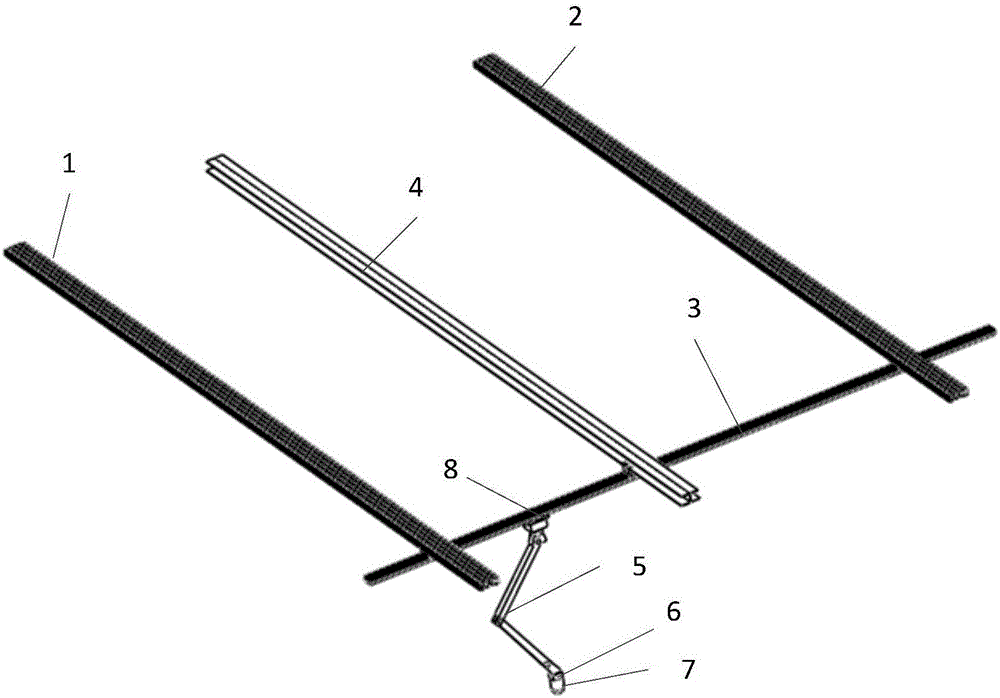

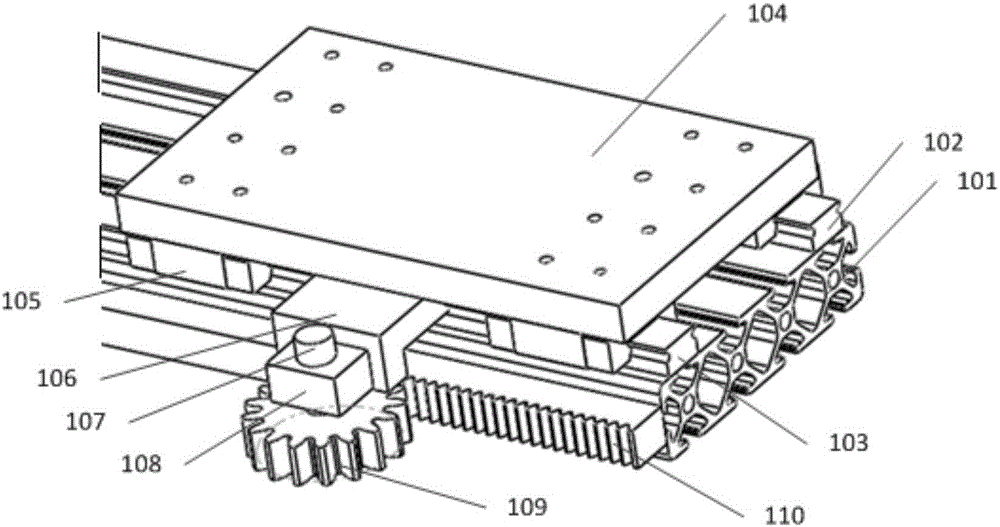

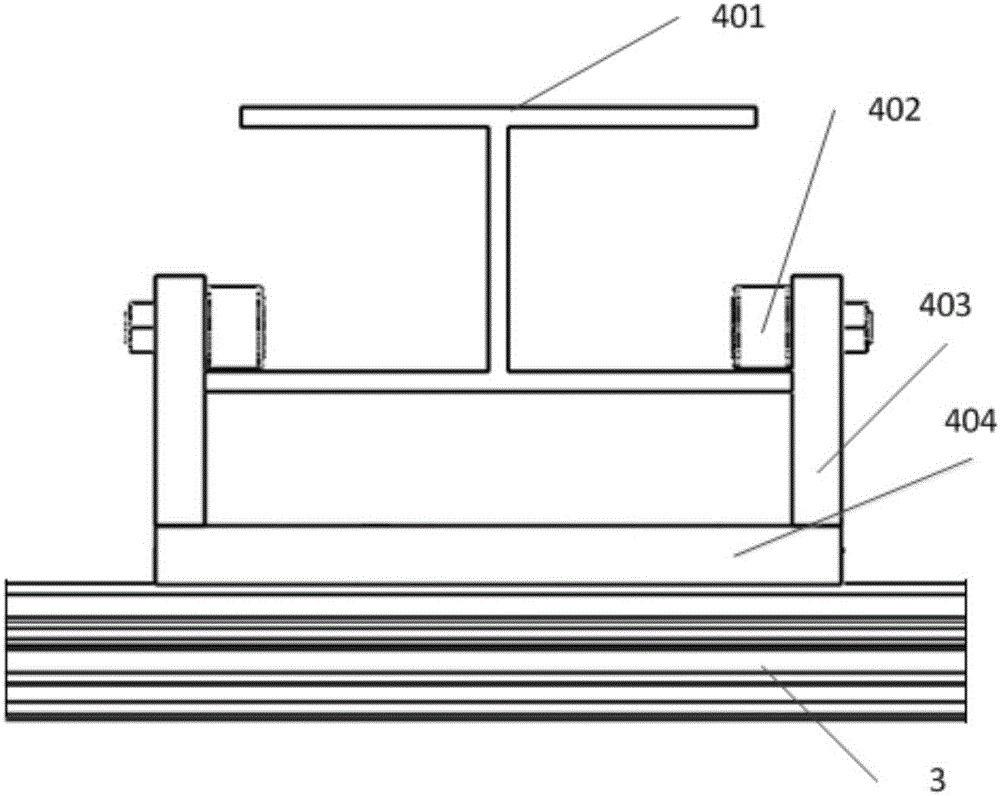

The invention discloses an indoor inspection robot for a transformer substation. The indoor inspection robot comprises an X-direction track, a Y-direction track, a mechanical arm and a detecting component, wherein the Y-direction track is arranged on the X-direction track and can move back and forth along the X-direction track; the mechanical arm is arranged on the Y-direction track through a mobile platform and the mobile platform can move back and forth along the Y-direction track; the detecting component is arranged on the mechanical arms; and omni-directional inspection for indoor equipment is realized by combined motion of the X-direction track, the Y-direction track and the mechanical arm.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

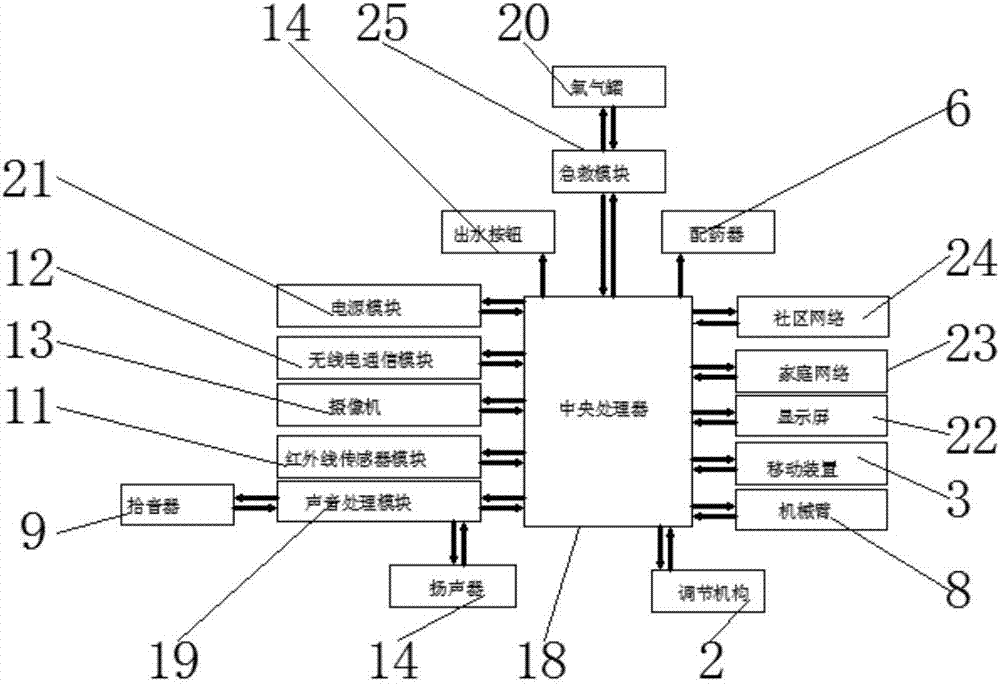

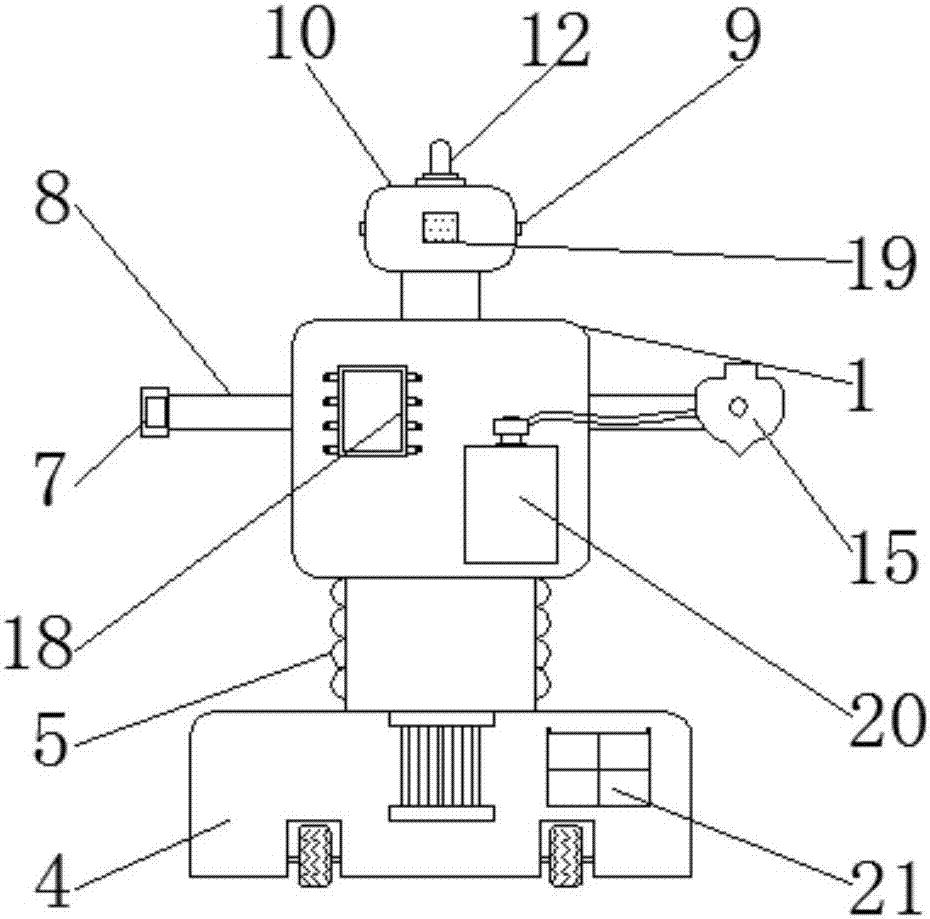

Home care robot

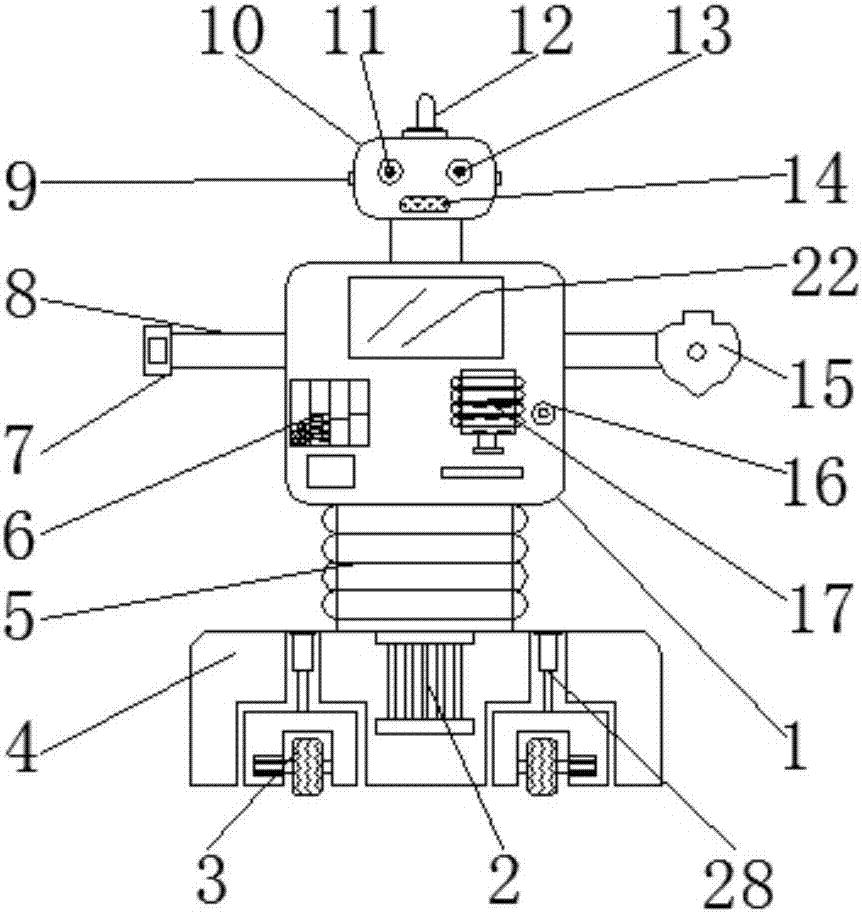

The invention discloses a home care robot. The home care robot comprises an outer shell, a head part, a door body and an intelligent bracelet. The lower end of the outer shell is connected with a base through an adjusting mechanism. Moving devices are arranged on the left side and the right side of the lower end of the base. The outer side of the upper end of the base is connected with the outer shell through a fence. A dispensing apparatus is installed on the left side of the exterior of the outer shell. The right side of the dispensing apparatus is provided with a heating pipe. A water-out button is installed on the right side of the heating pipe. Mechanical arms are installed at the left end and the right end of the back side of the outer shell. An armrest is arranged on the left side of the outer shell. Pickups are connected with the left side and the right side of the head part. The head part is located above the outer shell. An infrared sensor module and a camera are correspondingly arranged in the exterior of the head part. A radio communication module is arranged on the upper portion of the head part. According to the home care robot, the dispensing apparatus is arranged, timely and reasonable dose distribution according to the needed dose of the old can be achieved, and the condition of excessive medicine using or forgetting to take medicine cannot happen.

Owner:FUJIAN WANBAOLONG TECH DEV CO LTD

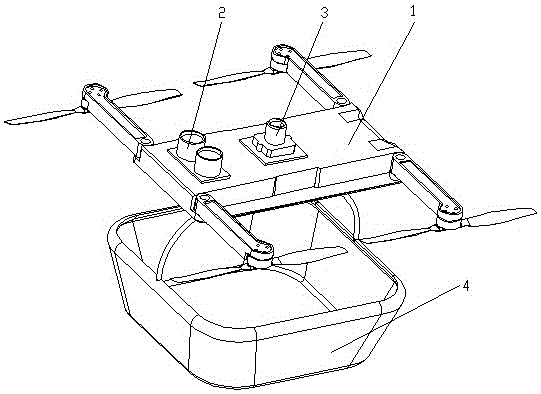

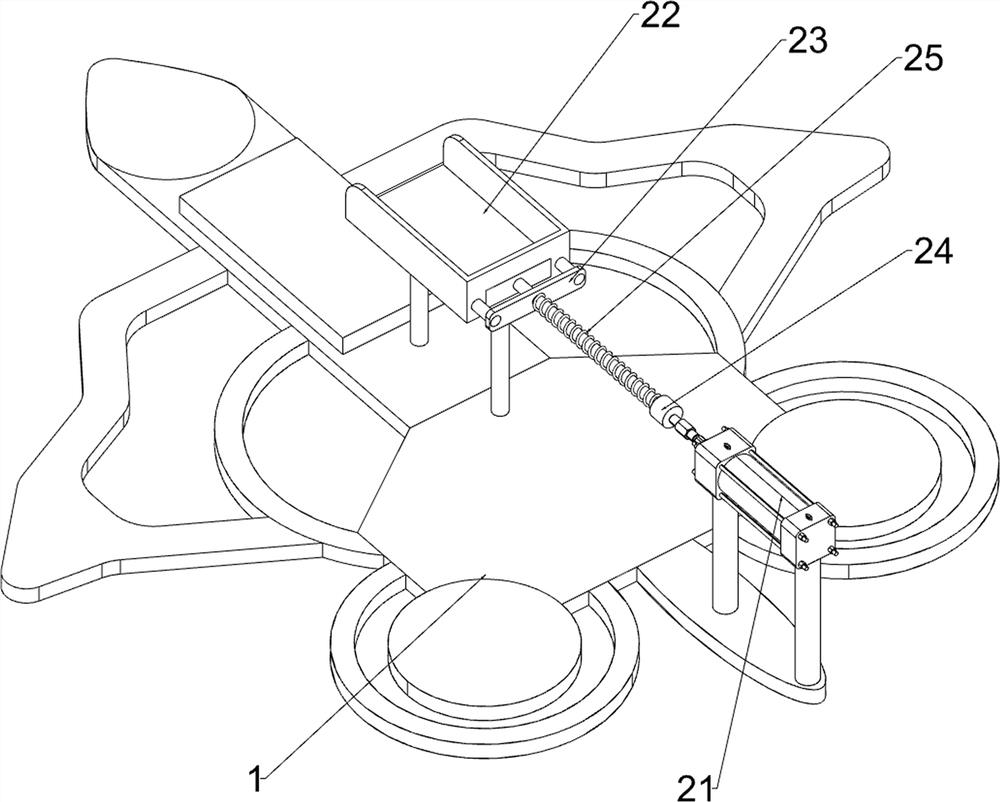

Multi-rotor indoor unmanned aerial vehicle

InactiveCN105667773APrecision flightWon't collideUsing optical meansRotocraftAutomotive engineeringDistance sensors

The invention discloses a multi-rotor indoor unmanned aerial vehicle. The multi-rotor indoor unmanned aerial vehicle comprises an unmanned aerial vehicle body, wherein an indoor ceiling of a room in which the unmanned aerial vehicle flies is provided with grains; the unmanned aerial vehicle body is provided with a light stream sensor and an ultrasonic distance sensor; the light stream sensor is arranged on one side of the ultrasonic distance sensor; the light stream sensor is used for identifying the indoor ceiling grains so that the unmanned aerial vehicle body can position the position of the unmanned aerial vehicle; and the ultrasonic distance sensor detects the distance from the unmanned aerial vehicle body to the indoor ceiling so as to control the height of the unmanned aerial vehicle and the flight track of the unmanned aerial vehicle. Through adoption of the mode, the multi-rotor indoor unmanned aerial vehicle disclosed by the invention can accurately fly according to a preset line in case of having no GPS signal indoors without collisions with other indoor objects.

Owner:WUXI MIRACLE SCI & TECH CO LTD

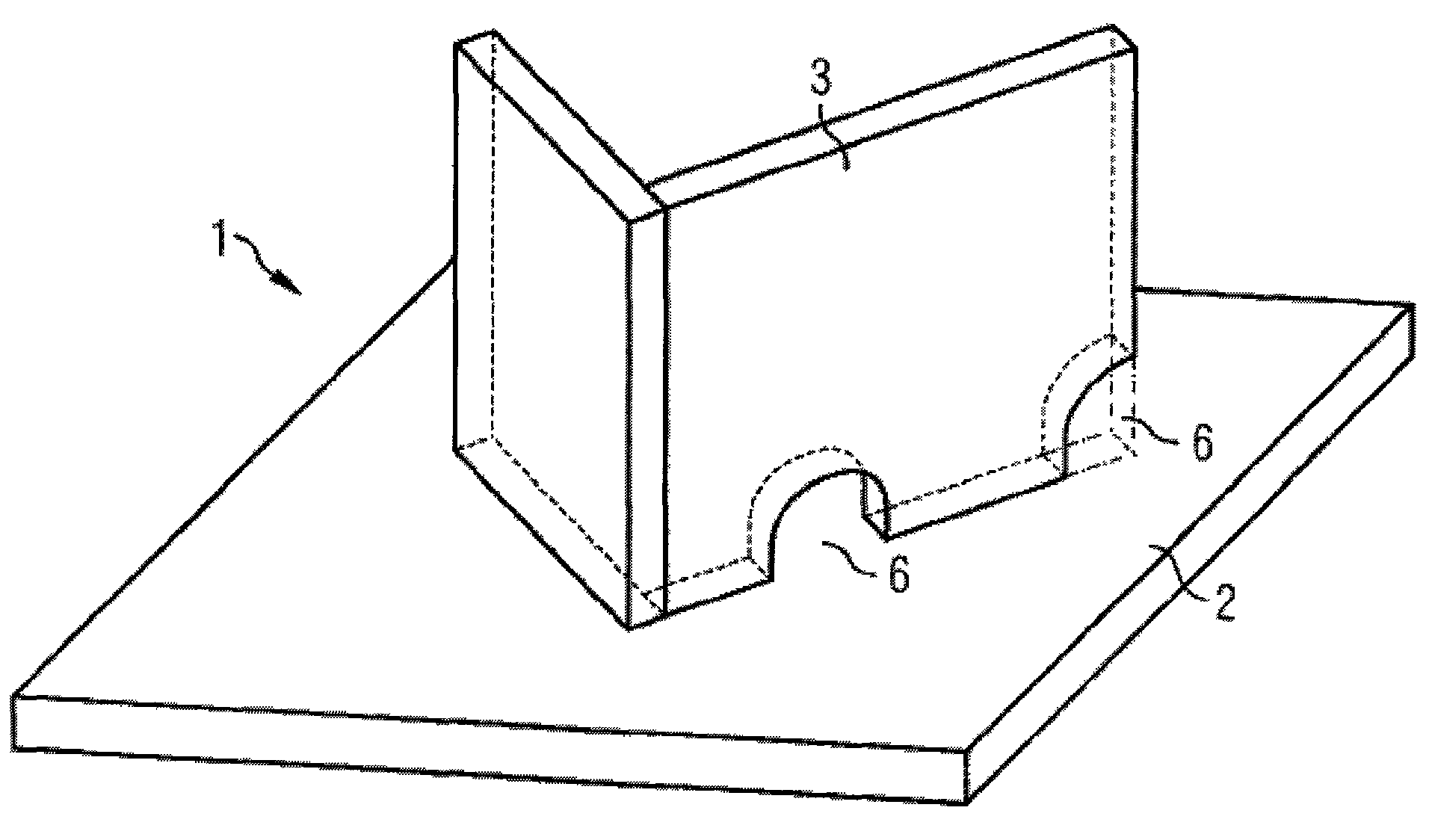

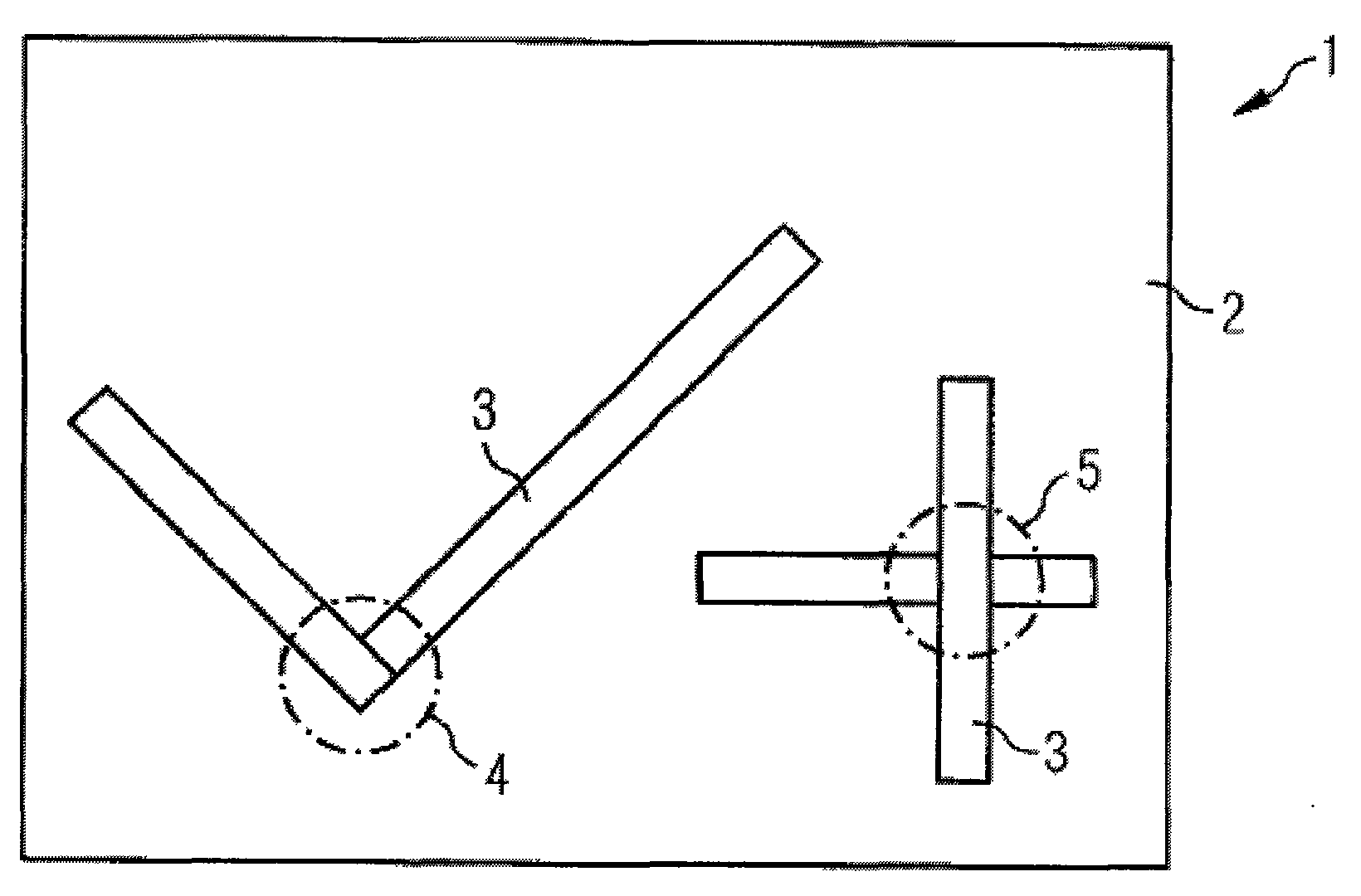

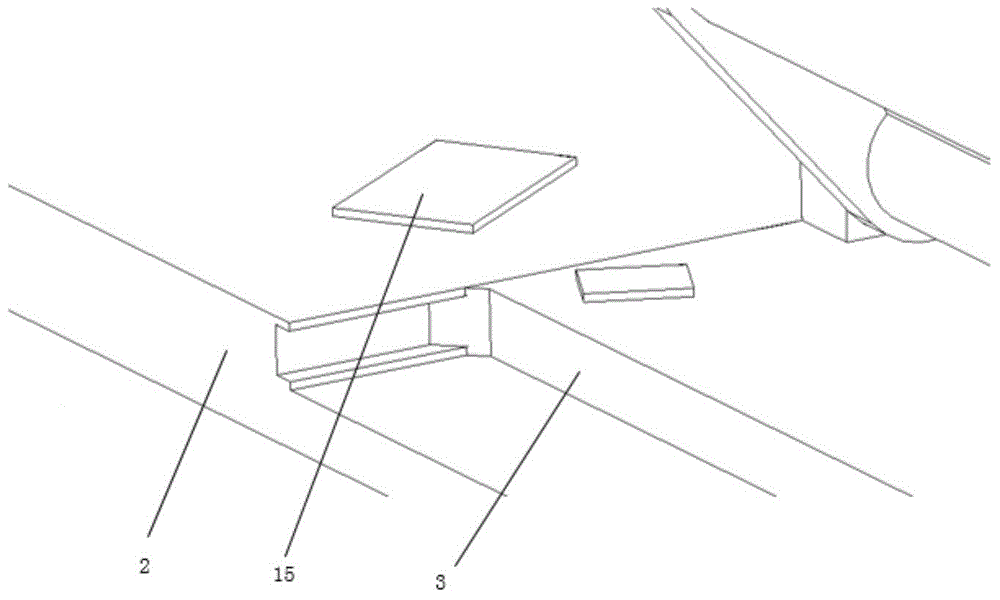

Method and device for controlling robots for welding workpieces

The invention relates to a method for controlling robots for welding three-dimensional workpieces, comprising the following steps: positioning and tacking profiles (3) to a plate (2) in order to formthe workpiece to be welded (1), depicting the workpiece by means of a three-dimensional imaging system in the form of three-dimensional pixels, determining the geometric data of the plate and profiles, including the allocation of cutouts and final cutting shapes from the three-dimensional pixels, determining the weld seam data from the geometric data while considering the profile placement lines and the contact lines of profiles, allocating the weld seam data to parameterizable specifications for the weld plan into stored predefined movement patterns of the robot, and into commands for the control of the welding process.

Owner:费劳恩霍弗应用技术研究院 +1

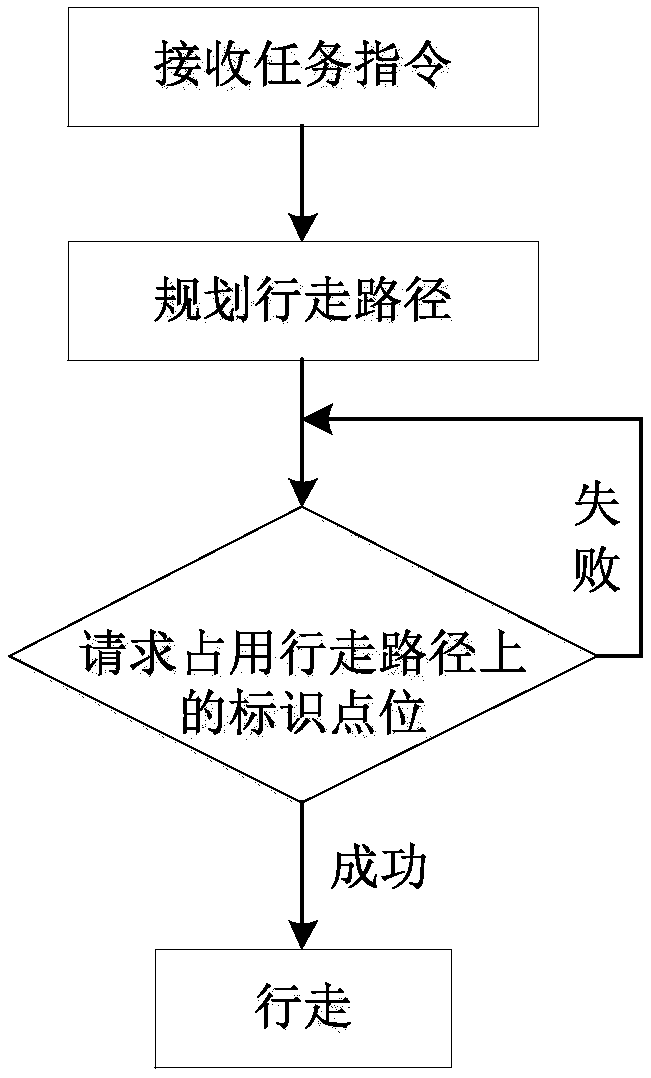

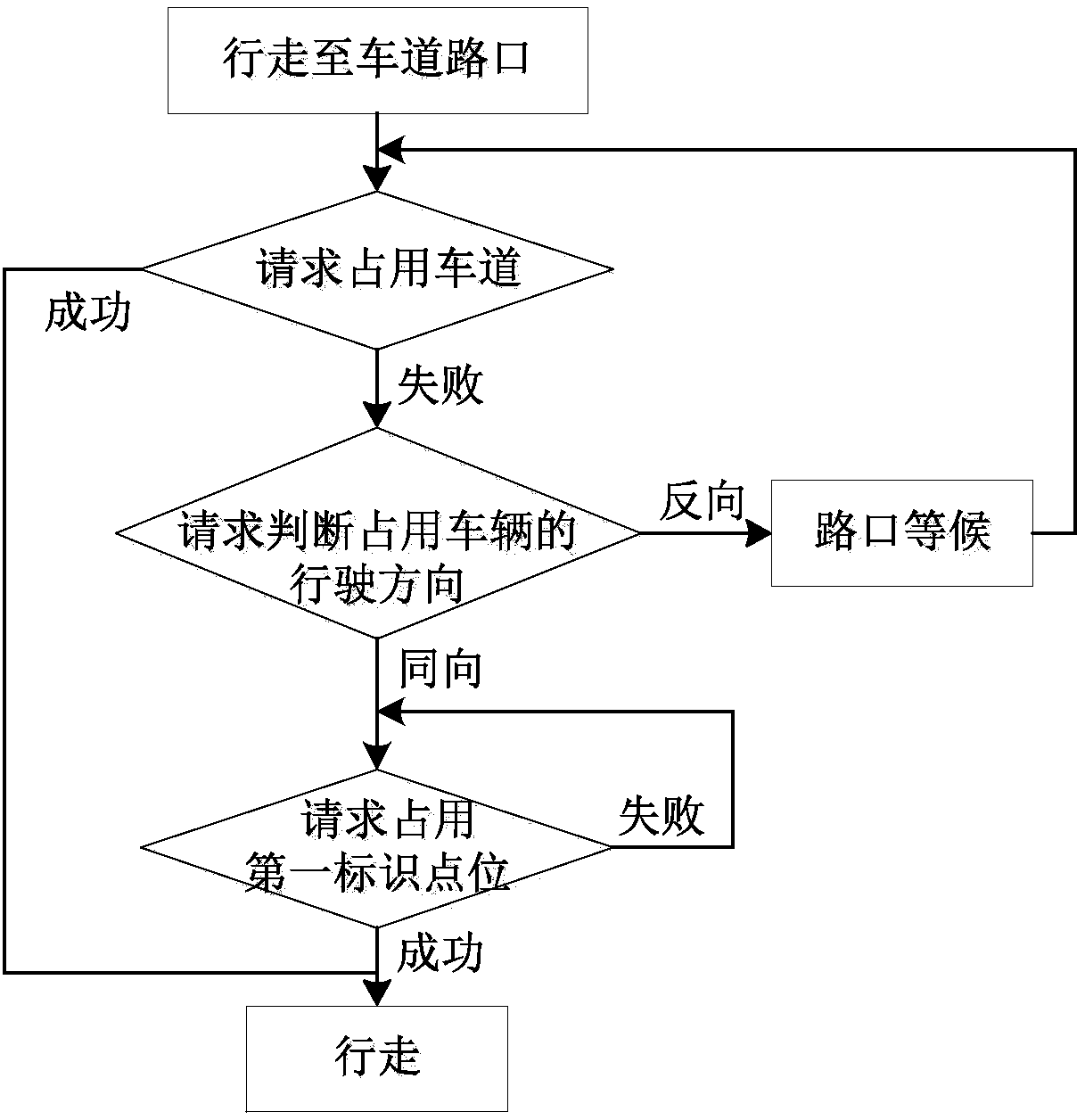

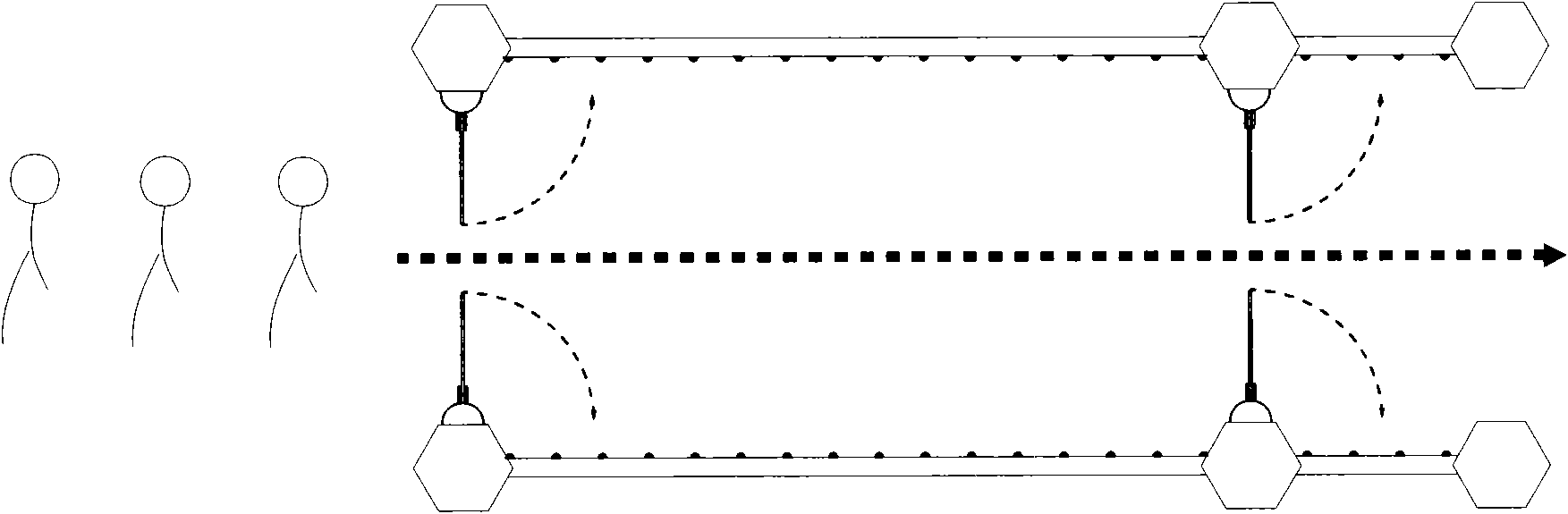

AGV-based traffic management method, electronic equipment, storage medium and AGV-based traffic management system

ActiveCN107807640AControl reachedWon't collidePosition/course control in two dimensionsAir traffic managementComputer science

The invention discloses an AGV-based traffic management method comprising the following steps that a task instruction is received and a walking path for performing the task instruction is planned; a request instruction is transmitted according to the walking path, wherein the request instruction requests for occupying the identification point on the walking path and the identification point only allows to be occupied by one AGV; if an occupation success instruction is received, walking to the identification point is performed; and if an occupation failure instruction is received, transmittingthe request instruction is continued. The invention also discloses electronic equipment, a computer readable storage medium and an AGV-based traffic management system. Walking of the AGV is controlledthrough the point position so that the passage efficiency of the road can be enhanced and traffic management for the AGV can be realized.

Owner:HANGZHOU JIAZHI TECH CO LTD

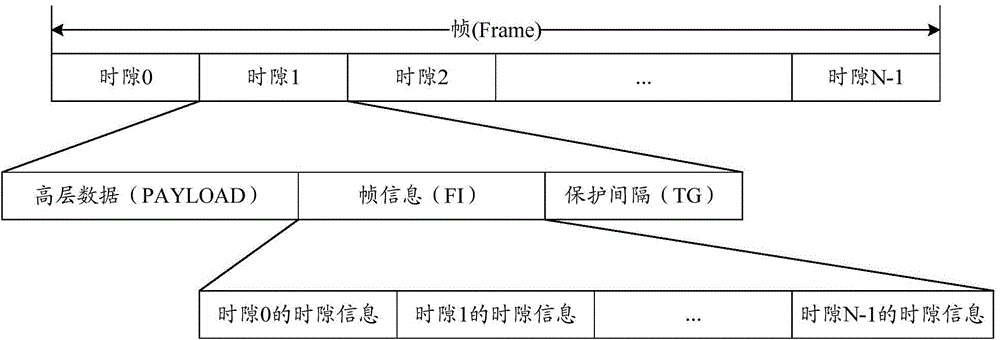

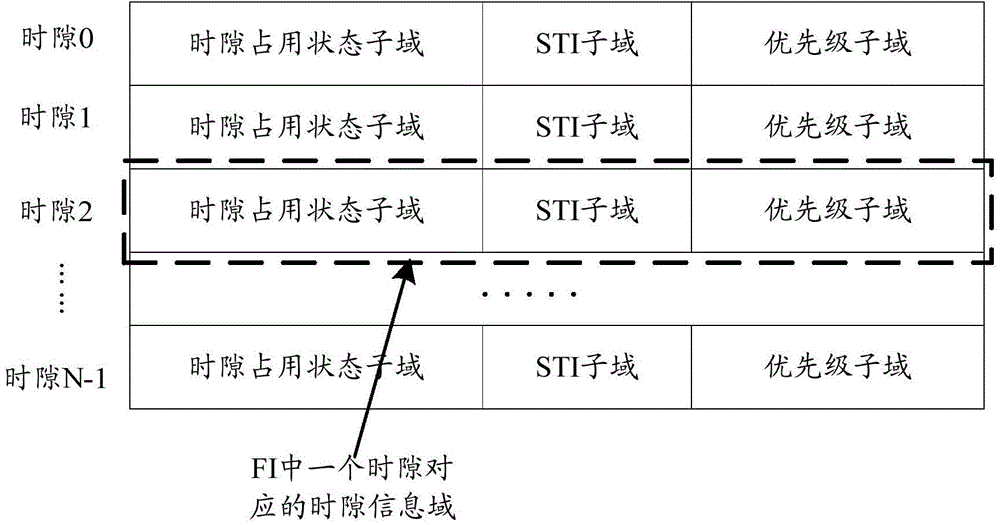

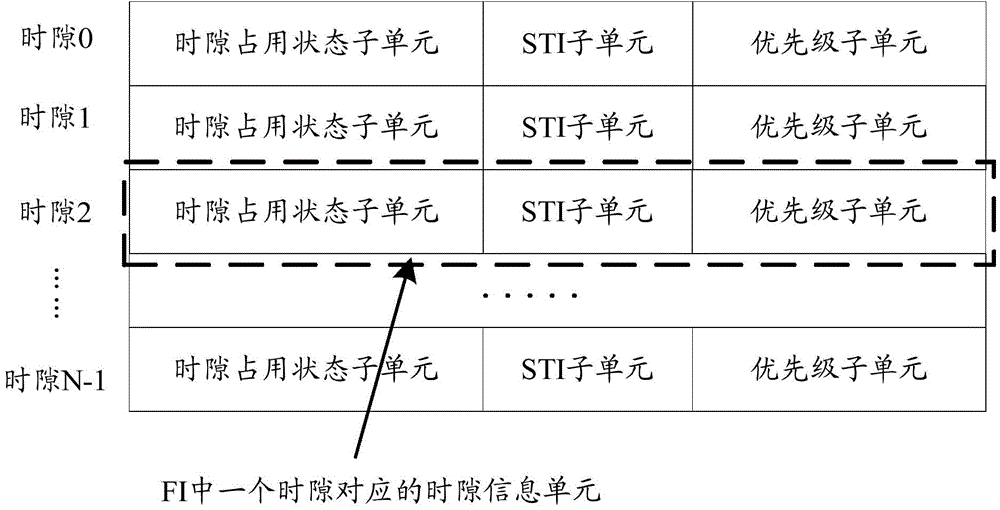

Time slot resource selecting method and device

ActiveCN105991207AReliable choiceFlexible sending rate changesTime-division multiplexWireless communicationRate changeReal-time computing

The invention discloses a method and device for selecting a time slot resource to satisfy the reliable time slot resource selection in different vehicle node densities, and a flexible message sending rate change is supported. The method comprises the steps that a first node receives frame information sent by other nodes besides the first node, the frame information carries indication information for representing the occupation times of time slots; according to the indication information for representing the occupation times of the time slots carried in the frame information, an available time slot resource is determined; and at least one time slot is selected from the determined available time slot resource as a sending time slot.

Owner:DATANG MOBILE COMM EQUIP CO LTD

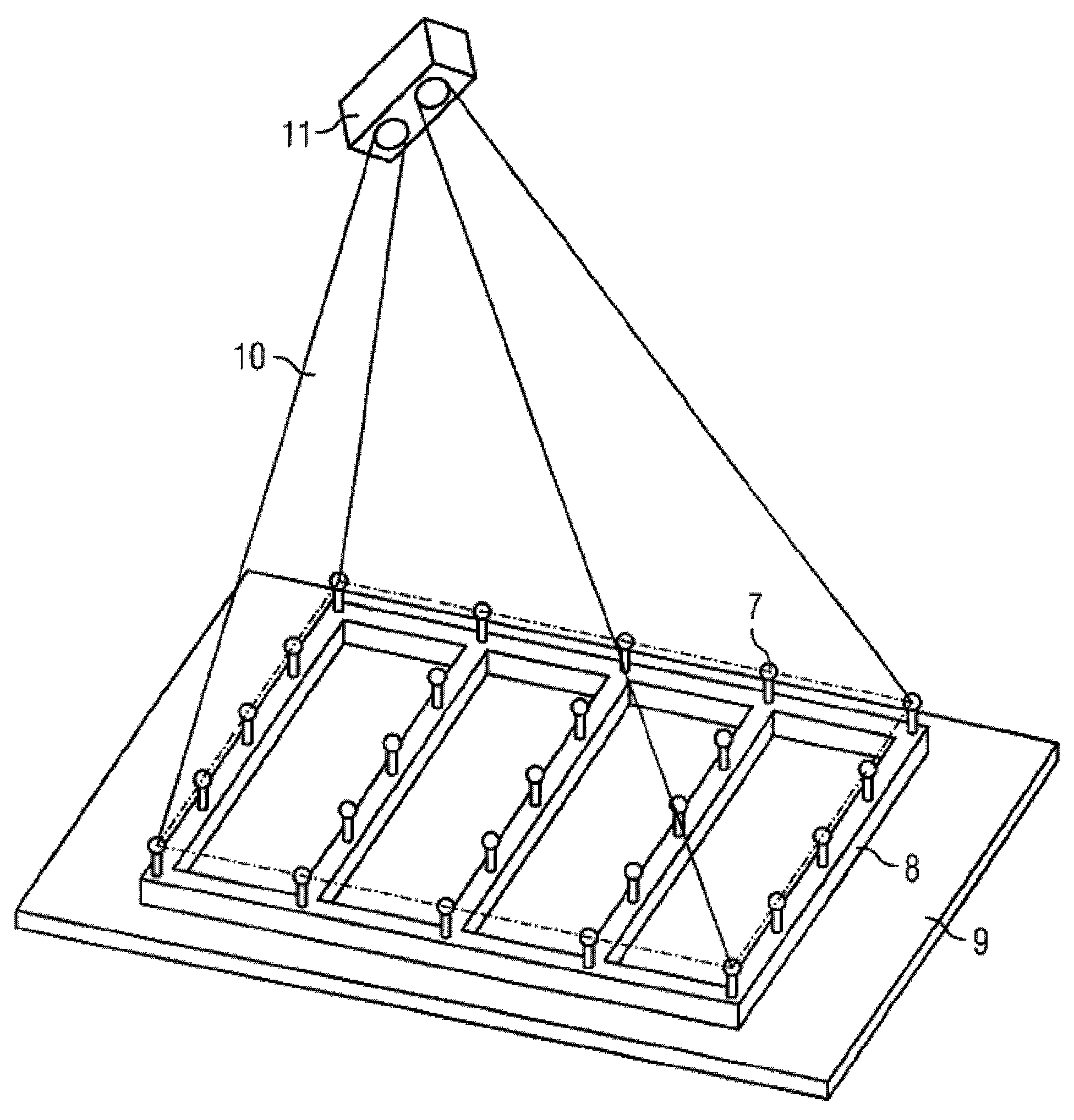

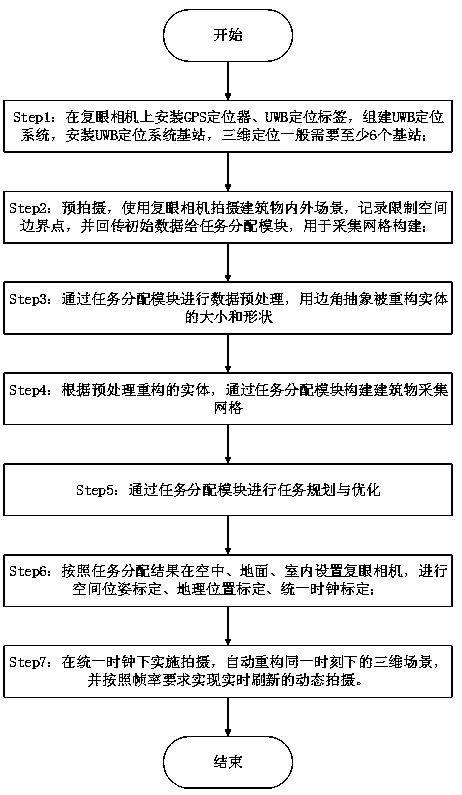

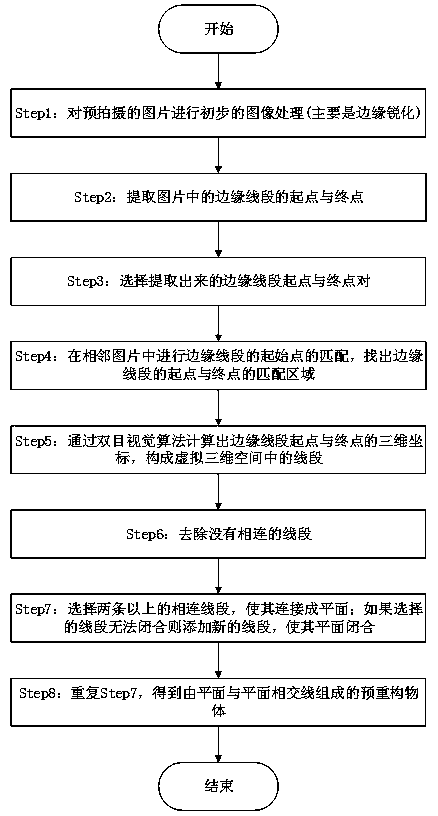

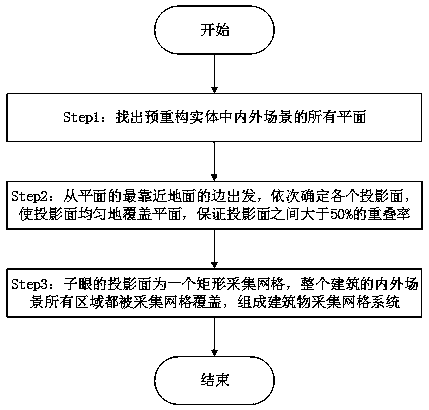

Virtual compound-eye camera system for acquiring three-dimensional scene of building satisfying time-space consistency and working method thereof

ActiveCN109118585ASpatiotemporal consistencyRealize dynamic 3D scene acquisitionTelevision system detailsImage enhancementComputer graphics (images)Data acquisition

The invention relates to the field of three-dimensional digital scene construction, provided are a virtual compound eye camera system for acquiring three-dimensional scene of a building satisfying spatio-temporal consistency and a working method thereof, the system includes a data acquisition module, positioning module and task assignment module, wherein the data acquisition module is composed ofall compound eye cameras facing the building object, and all compound eye cameras facing the building object are programmed according to a predetermined building acquisition grid, and the virtual group is formed into a complete and systematic compound eye system, which is called virtual compound eye; Virtual compound eye is composed of multiple compound eye cameras, which are programmed accordingto the acquisition grid of a given building, and are cooperated with each other to form a virtual compound eye. The virtual compound-eye camera system and the working method thereof can realize real-time shooting and real-time production with consistent time and space, and obtain more accurate and real dynamic three-dimensional virtual scene.

Owner:WUHAN UNIV OF TECH

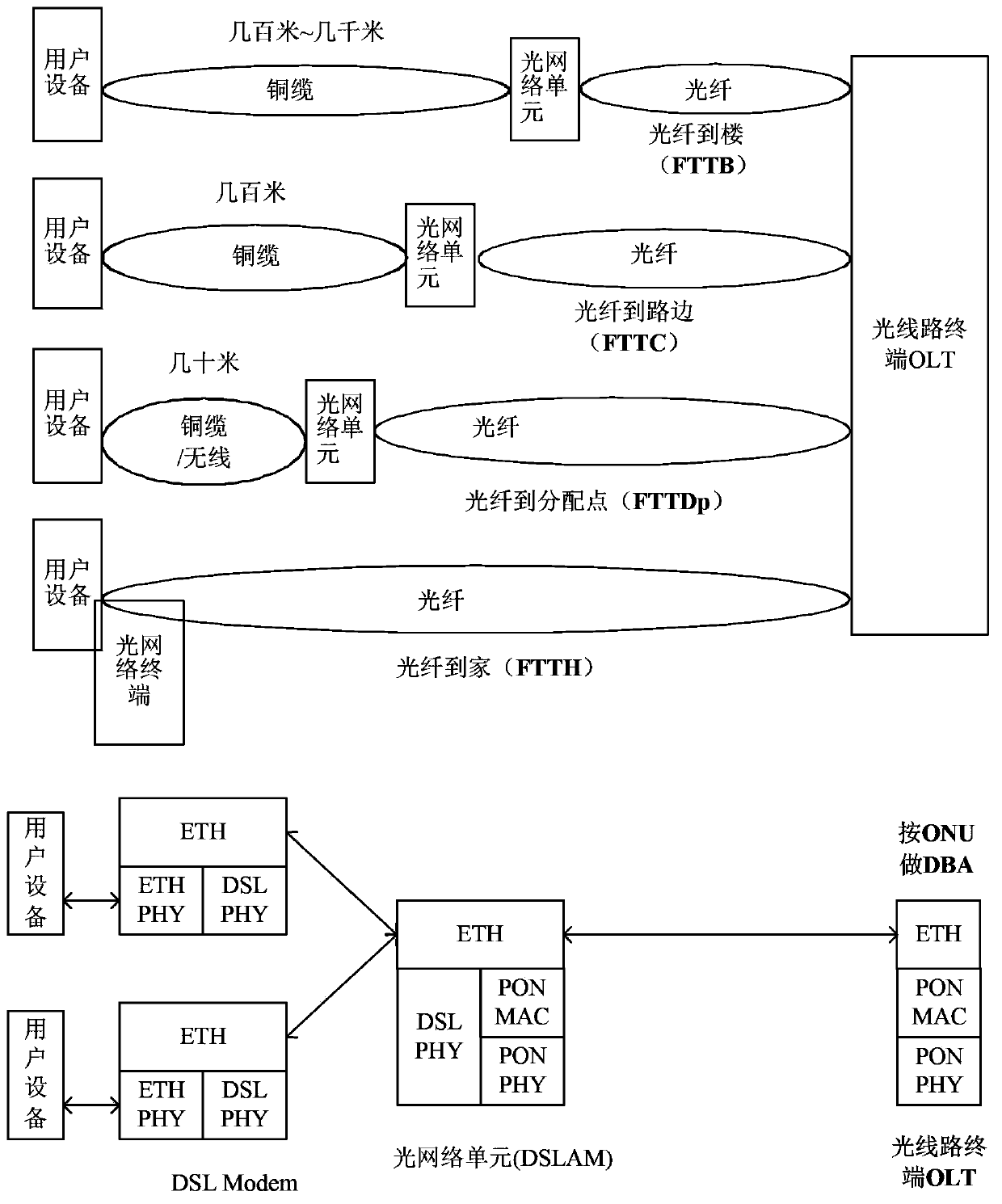

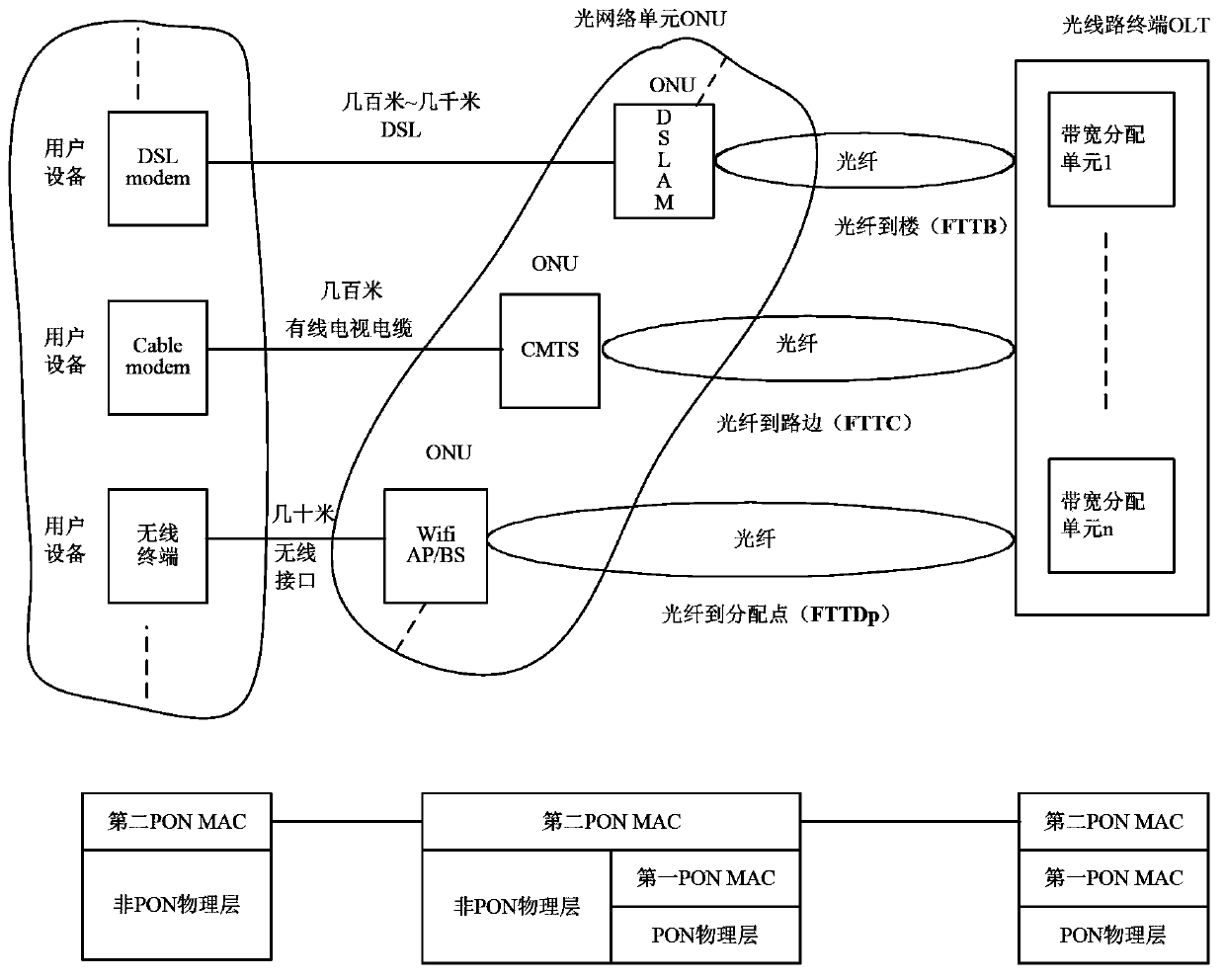

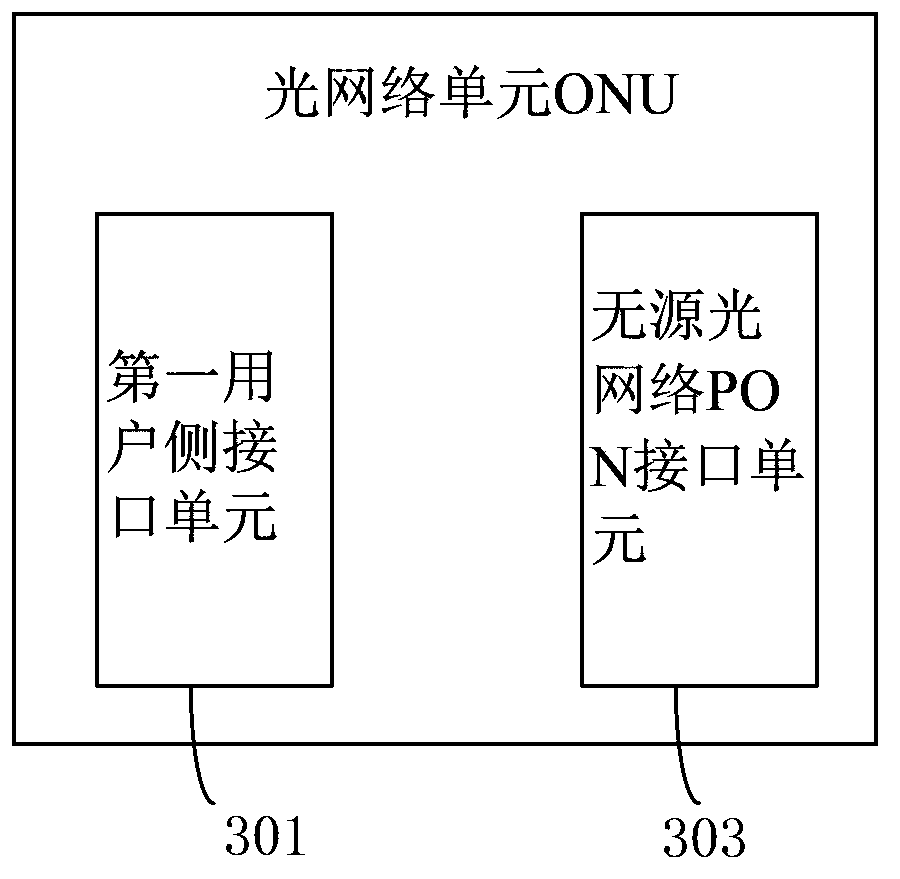

ONU, OLT and information transmission method

ActiveCN104243092AEnsure functionMake sure user devices are functionalMultiplex system selection arrangementsError preventionComputer hardwareInformation transmission

The invention discloses an ONU, an OLT and an information transmission method, and belongs to the field of network communication. The ONU comprises a user side interface unit and a PON interface unit. The PON interface unit is used for receiving a first PON physical layer frame from the OLT and removing a first PON physical layer frame header and a first PON MAC frame header in the first PON physical layer frame so as to obtain a first frame. The first user side interface unit is used for packaging a first non-PON physical layer frame header on a second frame obtained by the first user side interface unit so as to obtain a first non-PON physical layer frame and sending the first non-PON physical layer frame to user equipment, wherein the second frame is the first frame or a frame obtained based on the first frame. In the data transmission process, QoS scheduling is not needed, an expensive queue scheduling memorizer is omitted, and therefore cost is reduced.

Owner:XFUSION DIGITAL TECH CO LTD

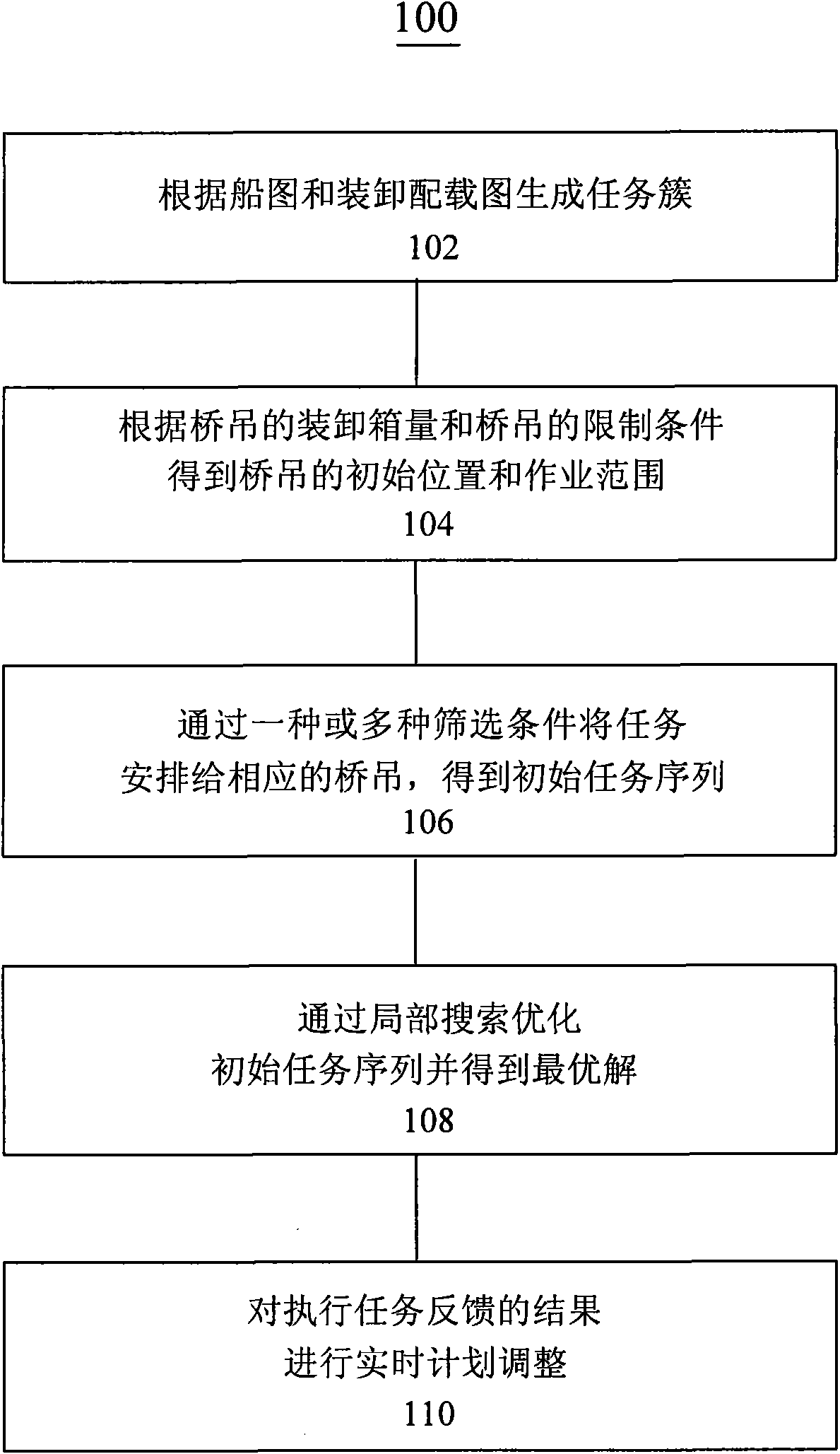

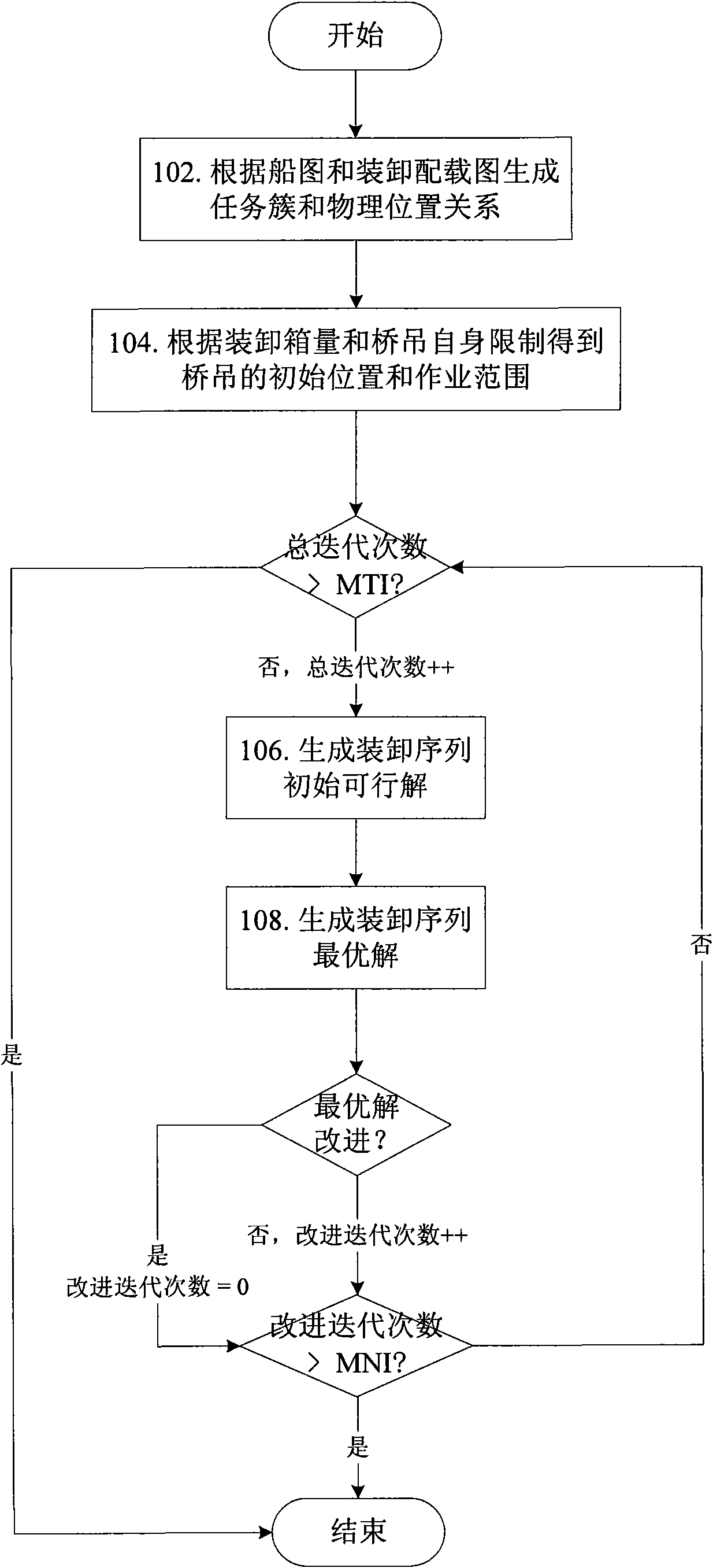

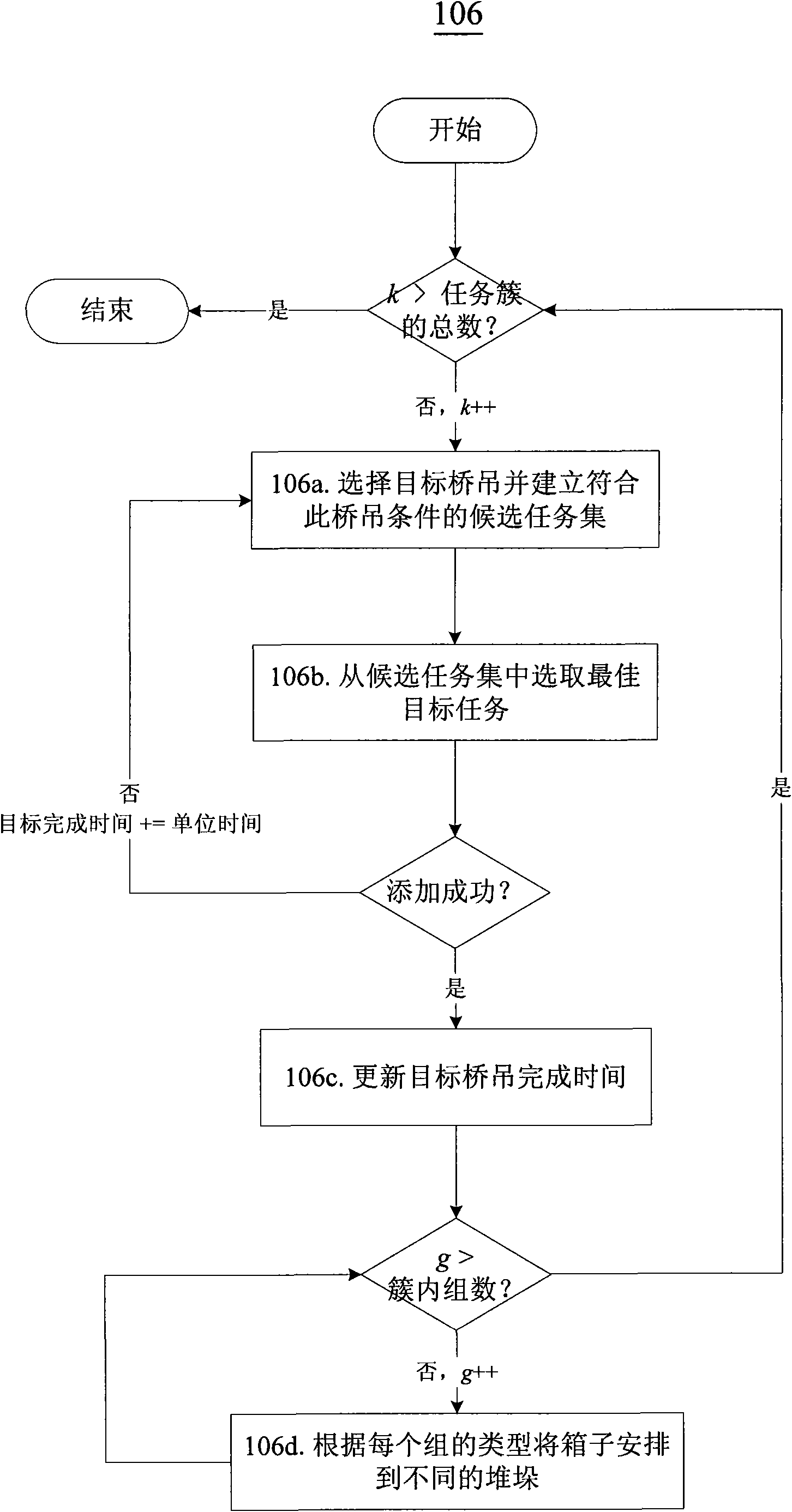

Method for planning and scheduling travelling bridge of automated dock

InactiveCN101930556AOptimize final completion timeOptimize completion timeResourcesLogisticsYardComputer science

The invention relates to a method for planning and scheduling a travelling bridge of an automated dock, which can optimize the loading and unloading flows of the automated dock and shorten the loading and unloading time of the dock. The method of the invention comprises the following steps of: generating a task cluster according to a ship drawing and a loading and unloading stowage plan, wherein the task cluster comprises containers having the same property; obtaining the initial position and operation range of the travelling bridge according to the number of loading and unloading containers and the limit condition of the travelling bridge; assigning the task to the travelling bridge through one or more screening conditions to obtain an initial task sequence; and obtaining an optimal result through local searching. The containers on a ship are divided into small tasks according to task types, so that the containers can be distributed effectively in a planning and arranging process of a container yard.

Owner:SHANGHAI ZHENHUA HEAVY IND

Communication connection structure and LED unit box

Owner:SHENZHEN LIGHTLINK DISPLAY TECH

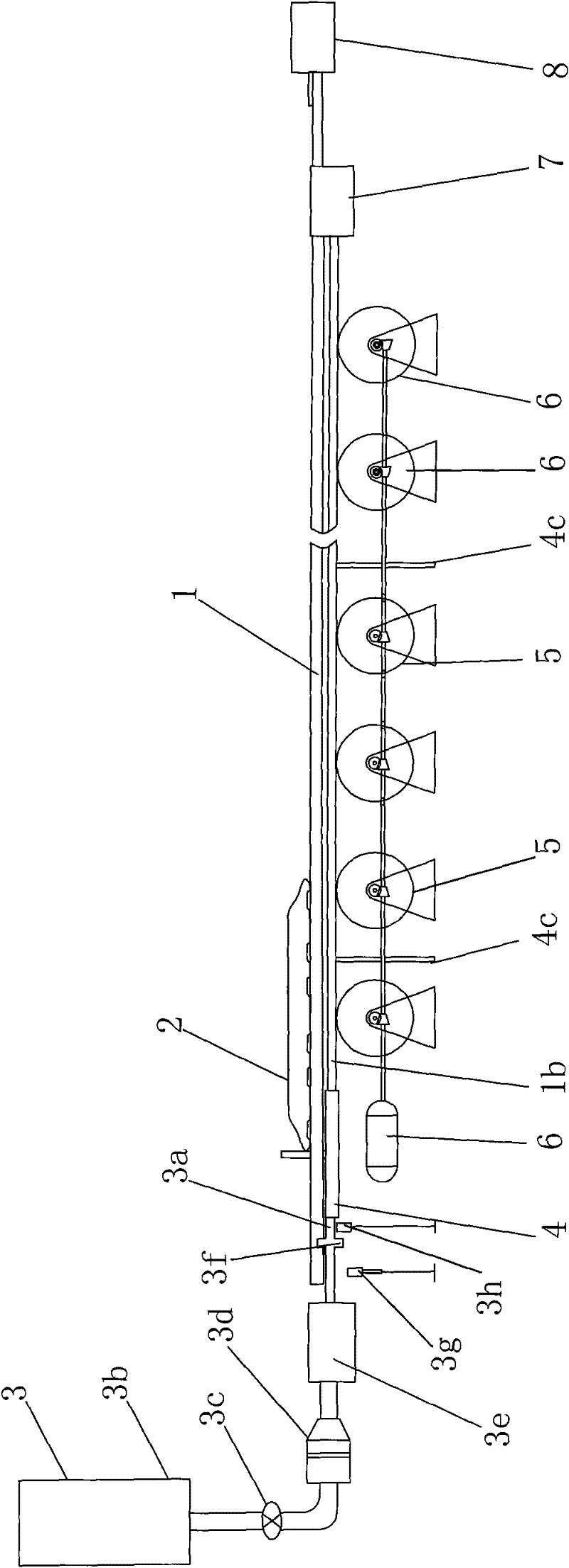

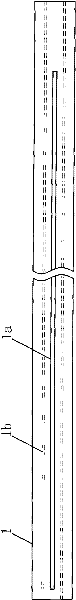

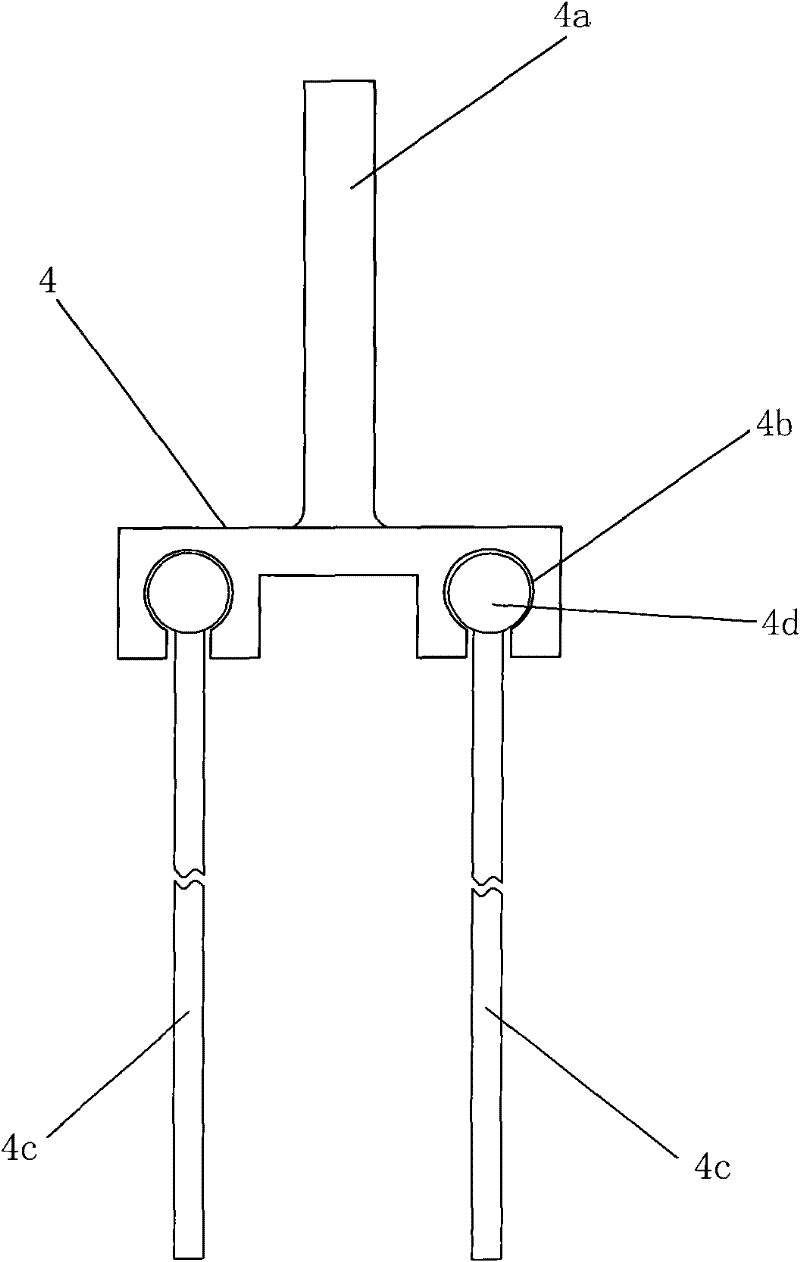

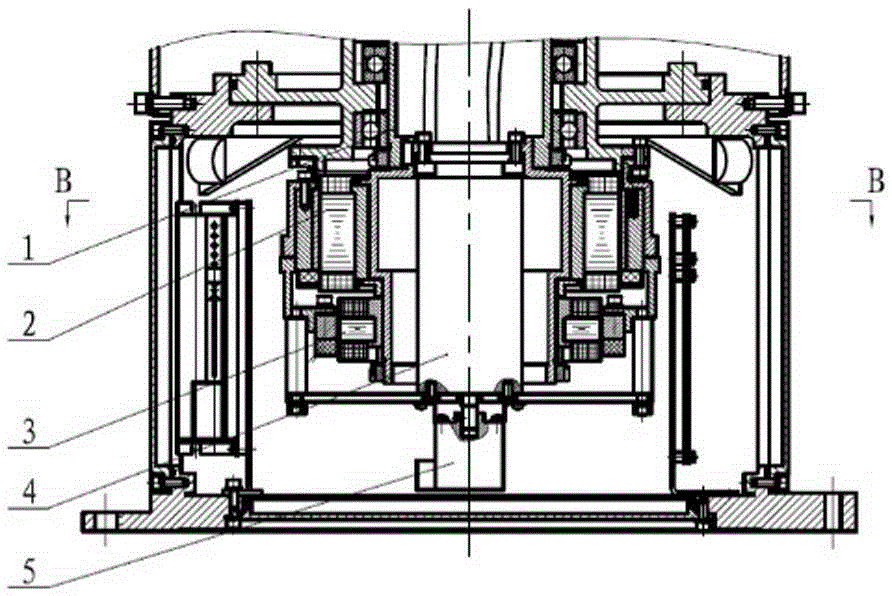

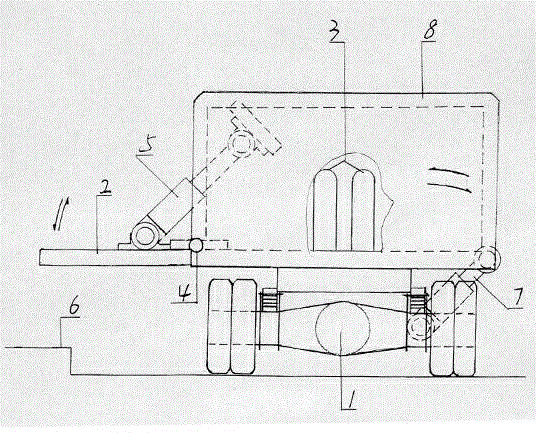

Train moving die experiment system

InactiveCN101750219AIncreased acceleration powerIncreased size and weightAerodynamic testingRailway vehicle testingElectric machineryFlywheel

The invention provides a train moving die experiment system, wherein the power device is constituted by a compression air ejection mechanism, a barrow and a flywheel accelerating mechanism; the flywheel accelerating mechanism is constituted by a plurality of flywheels driven by a motor below the line support rear area; the vertical position of the barrow is arranged between the flywheel accelerating mechanism and the line support; the horizontal position thereof is arranged between a testing car and the compression air ejection mechanism; the catch bar on the upper surface of the barrow penetrates through a guiding groove of the line support upwards and aligns with the tail part of the testing car; the line support in front of the flywheel accelerating mechanism is provided with a hydraulic barrow interceptor which has the same vertical position with the barrow; and the ejection rod of the compression air ejection mechanism is aligned with the tail part of the barrow. The system has strong power, the testing car has great shape and heavy weight, the testing car can reach a higher speed in a shorter time, the experiment environment is more close to the real conditions and the experiment results are more reliable.

Owner:SOUTHWEST JIAOTONG UNIV

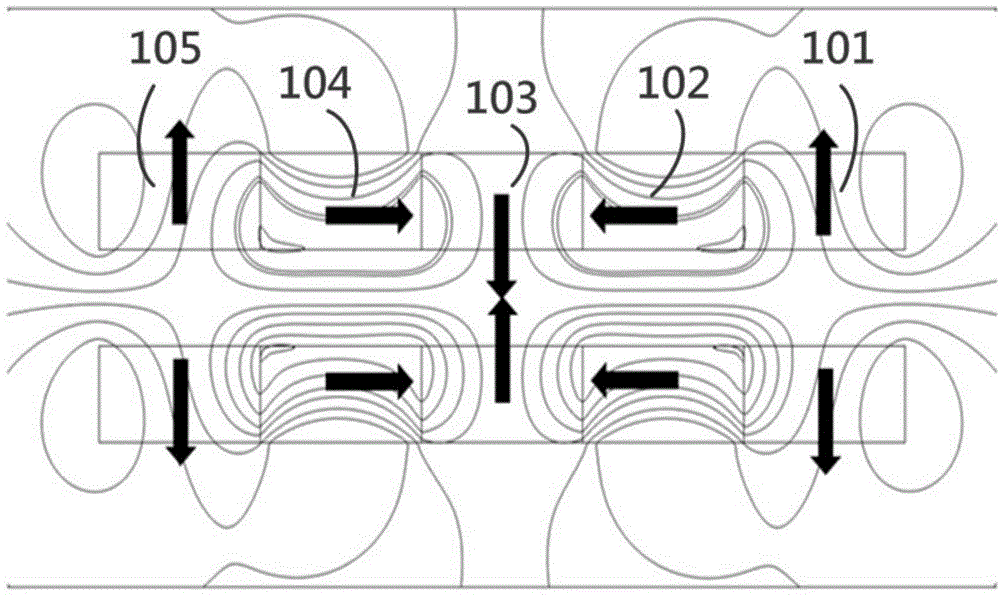

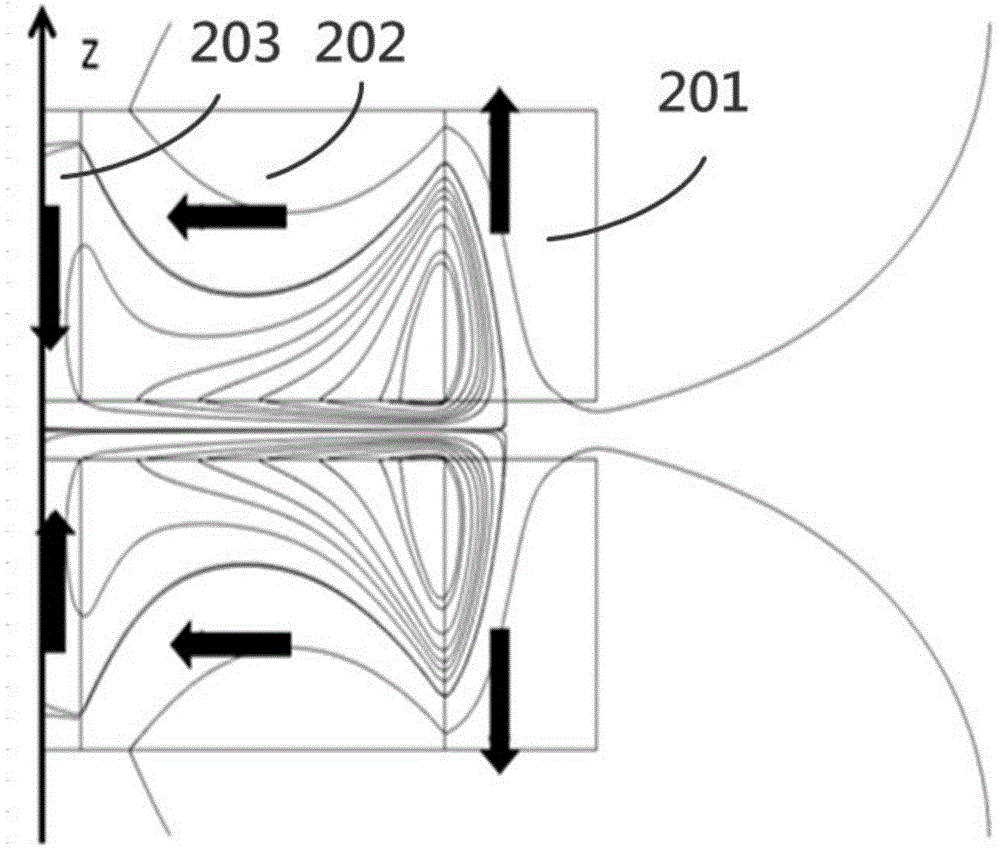

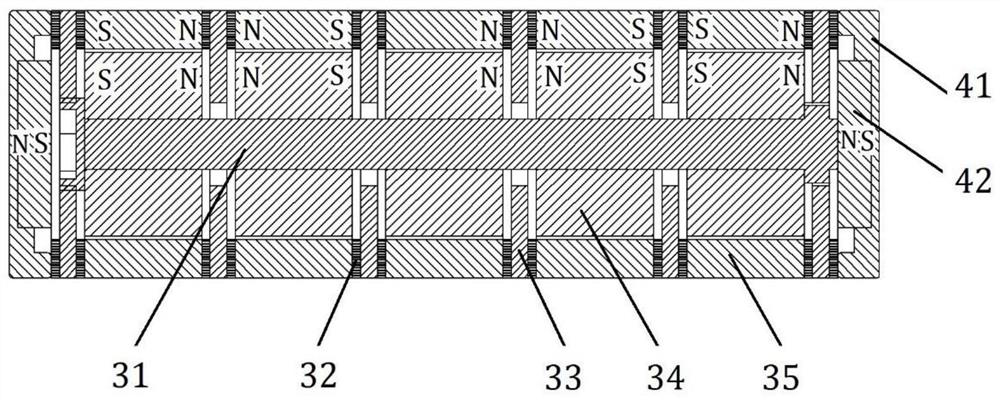

Plane voice coil loudspeaker and plane voice coil loudspeaker module

A plane voice coil loudspeaker comprises a circuit board matrix, one or more voice coils arranged on the two corresponding surfaces of the circuit board matrix, and one or more magnet sets. Each magnet set comprises one or more magnets. A first magnet field direction set, a second magnet field direction set and a third magnet field direction set are formed in the first direction of each magnet set in sequence, wherein the magnet field direction of the first magnet field direction set is perpendicular to the first direction and the third direction and is far away from voice coils, the magnet field direction of the second magnet field direction set is perpendicular to the second direction and the third direction and faces the third magnet field direction set, the magnet field direction of the third magnet field direction set is perpendicular to a plane formed by the first direction and the third direction, an included angle of 180 degrees is formed between the magnet field direction of the third magnet field direction set and the magnet field direction of the first magnet field direction set, and the first direction, the second direction and the third direction are perpendicular to one another. The invention further provides a plane voice coil loudspeaker module. The magnet fields can be evenly distributed on the plane voice coils through the plane voice coil loudspeaker structure.

Owner:蔡旭钦

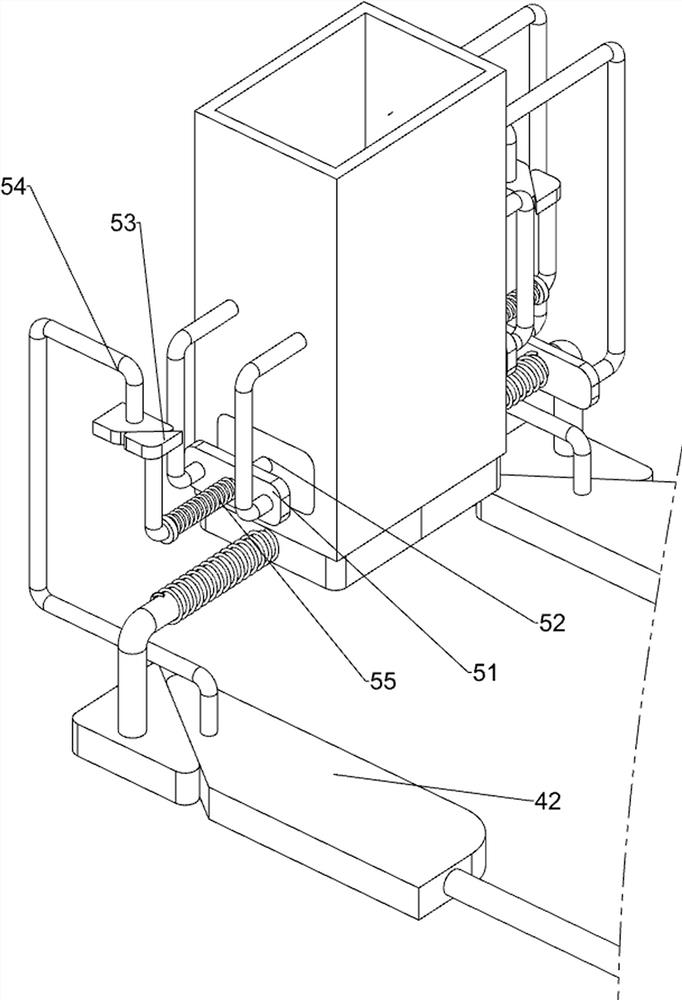

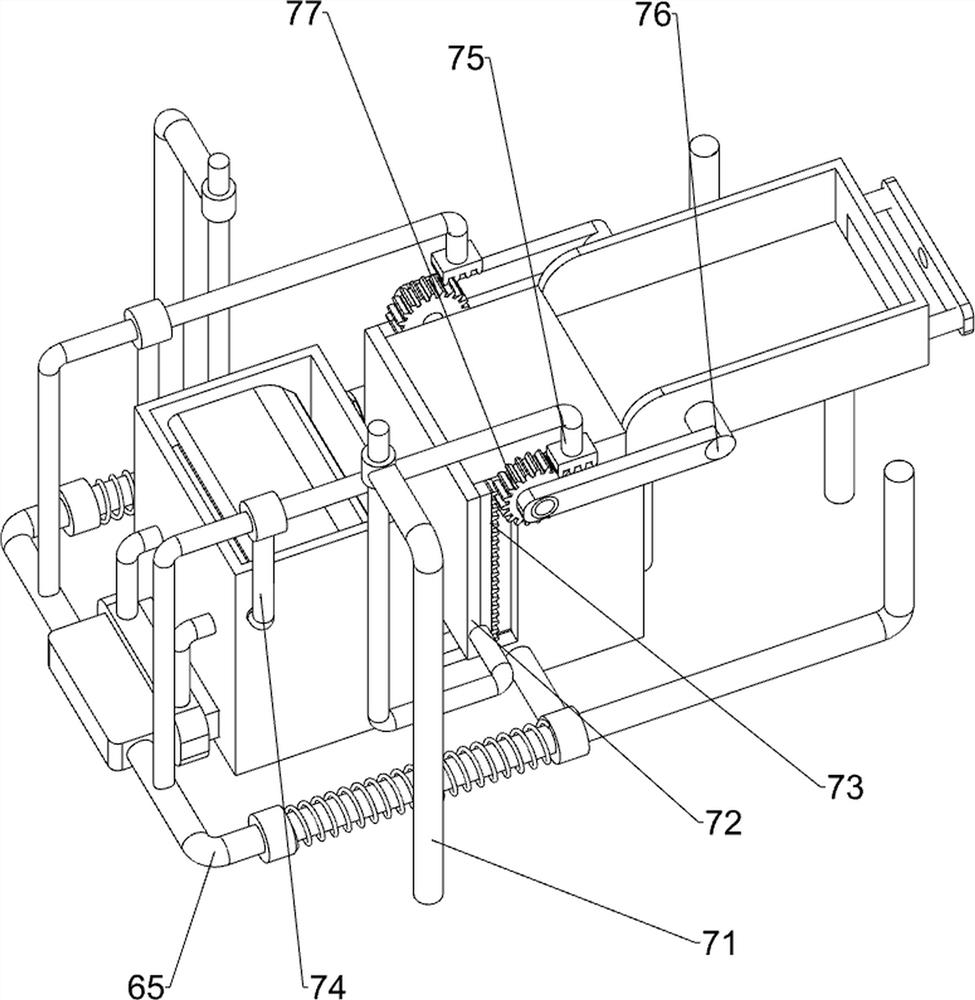

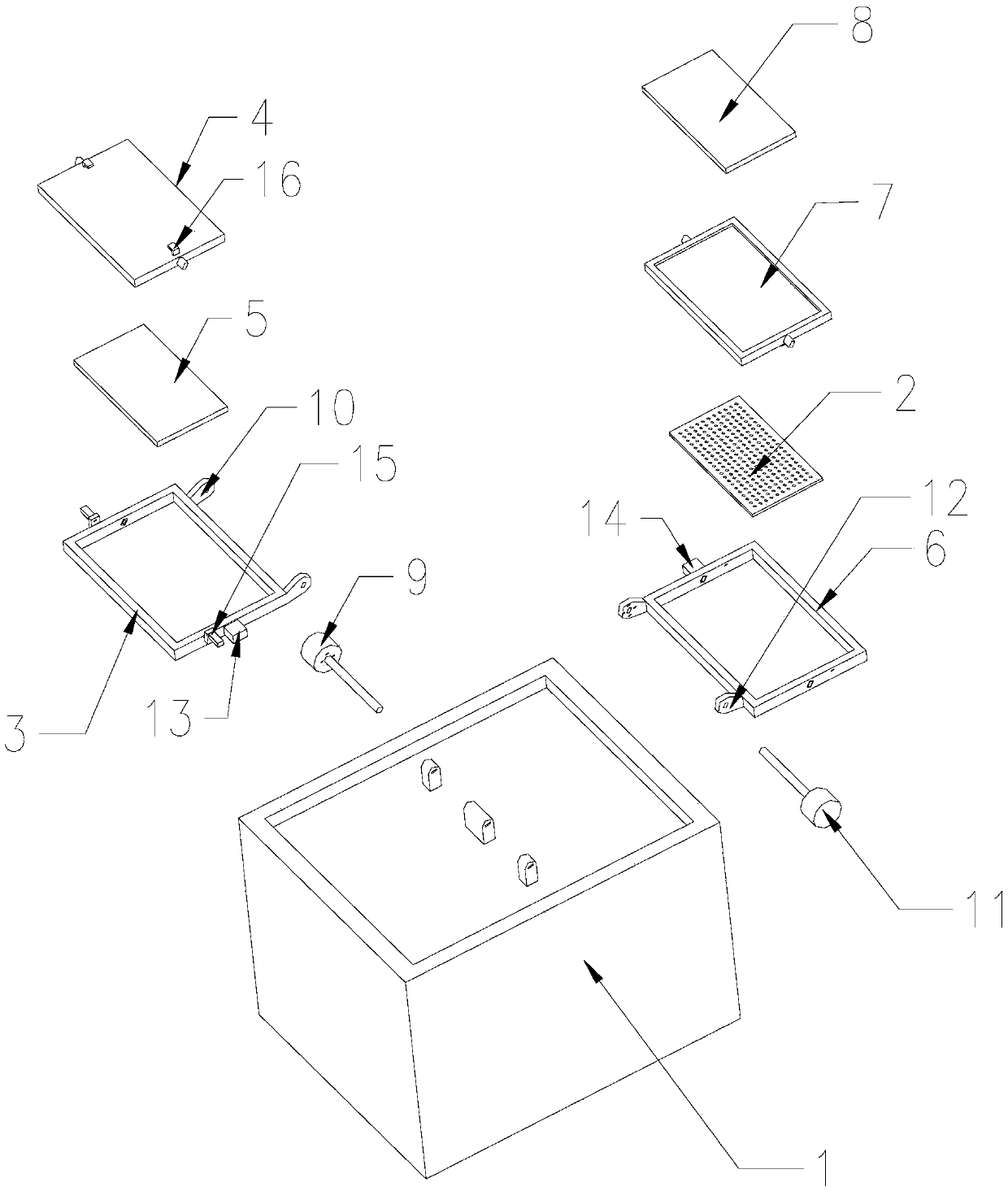

Boxing packaging machine for machined and formed boards

ActiveCN112340083ASave energyImprove work efficiencyBundling machine detailsIndividual articlesWood plankIndustrial engineering

The invention relates to a boxing packaging machine, in particular to a boxing packaging machine for machined and formed boards. The boxing packaging machine for the machined and formed boards is provided, wherein the boxing packaging machine automatically packages the boards, and can relatively protect the boards. The boxing packaging machine for the machined and formed boards comprises a bottomplate, a pushing mechanism, a cutting mechanism, an automatic intermittent discharging mechanism, and an intermittent clamping mechanism, wherein the pushing mechanism is arranged in the middle of thebottom plate, the cutting mechanism is arranged on the bottom plate, the automatic intermittent discharging mechanism is arranged in the middle of the bottom plate, and the intermittent clamping mechanism is arranged among the intermittent clamping mechanism, the cutting mechanism and the automatic intermittent discharging mechanism. According to the boxing packaging machine for the machined andformed boards, the pushing mechanism and the cutting mechanism are matched with each other, so that a storage frame is used for discharging the boards, the boards fall into a conveying frame, the boards are pushed through a first pushing plate, and the effects that when people package the boards, the labor is saved, and the working efficiency is relatively improved are achieved.

Owner:杭州卓良包装制品有限公司

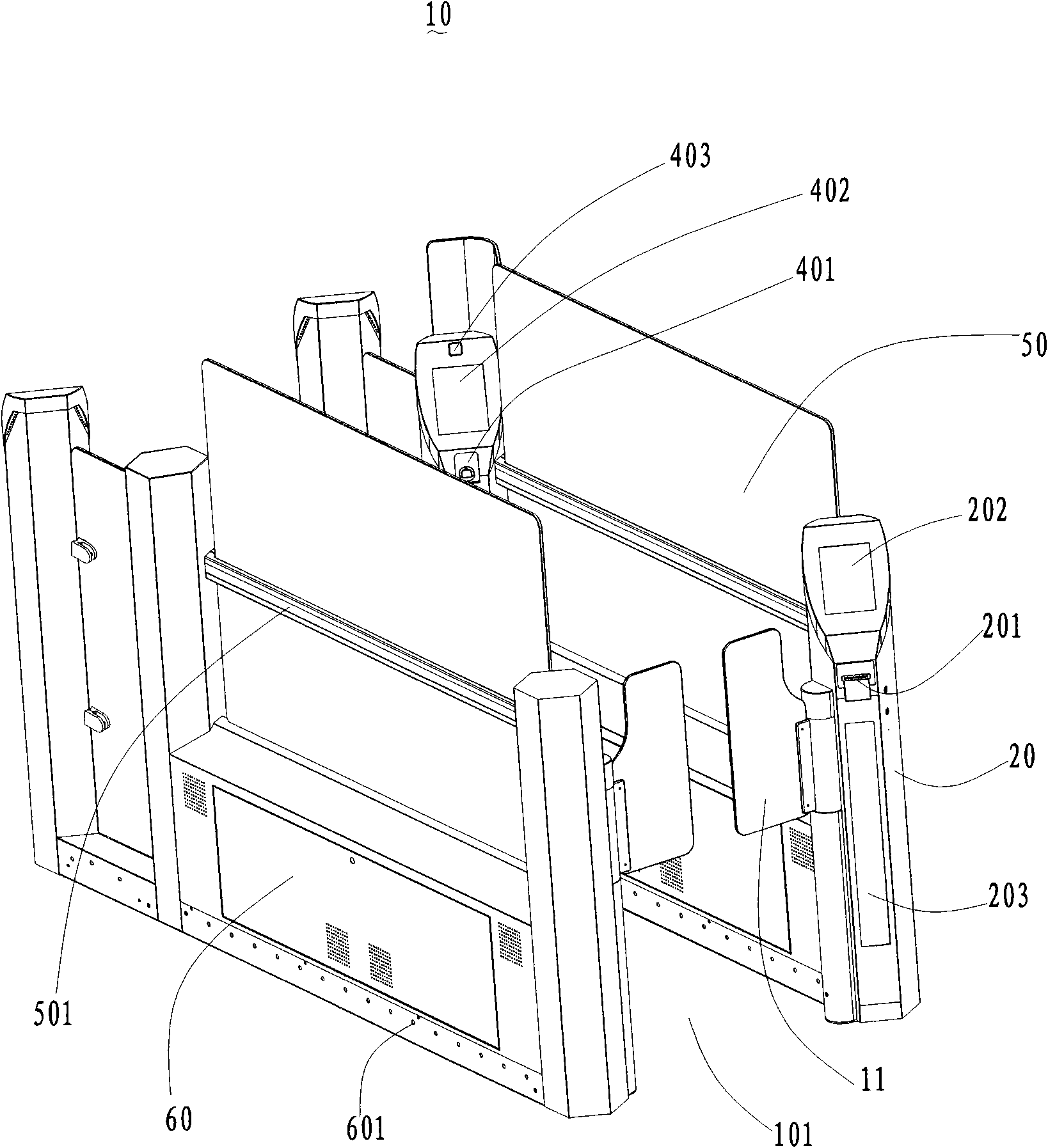

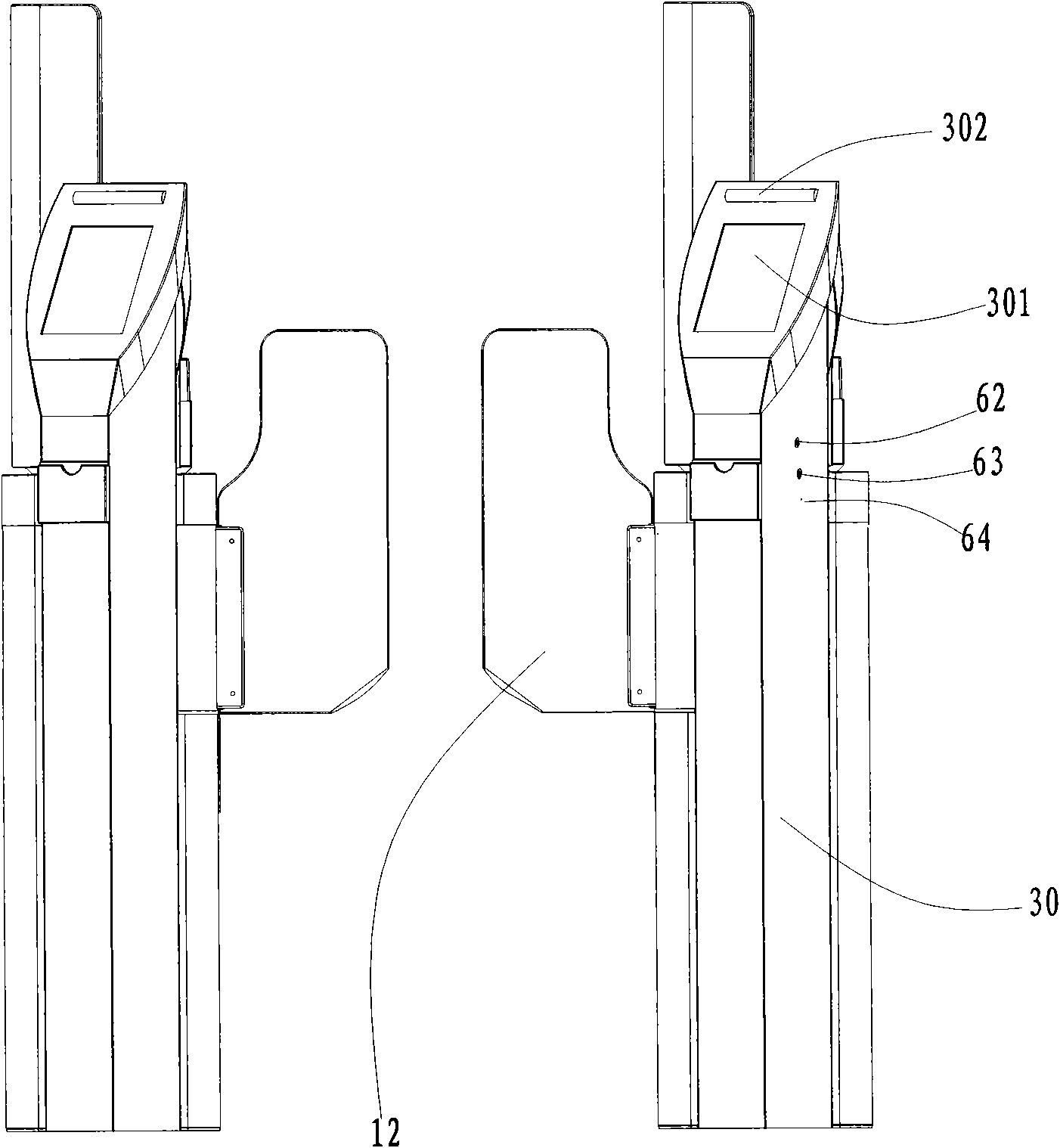

Traveler self-help transit control system

InactiveCN101599186ANo manual manipulationSave human resourcesOptical detectionCharacter and pattern recognitionControl systemFingerprint

The invention discloses a traveler self-help transit control system comprising at least one self-help border channel, wherein each self-help border channel is provided with two transparent doors, and an inlet of each self-help border channel is at least provided with a first multifunctional intelligent processing upright post which can be used for initially identifying an identity of a traveler; an outlet area of the self-help border channel is at least provided with a second multifunctional intelligent processing upright post which is used for a customs officer assisting the traveler to transit and processing sudden events, a third multifunctional intelligent processing upright post which is used for checking fingerprint information of the traveler is arranged between the first multifunctional intelligent processing upright post and the second multifunctional intelligent processing upright post, and the self-help border channel is also provided with a sensor in order to ensure safety, high efficiency, and the like of the traveler self-help transit control system.

Owner:INT SECURITY TECH SHENZHEN

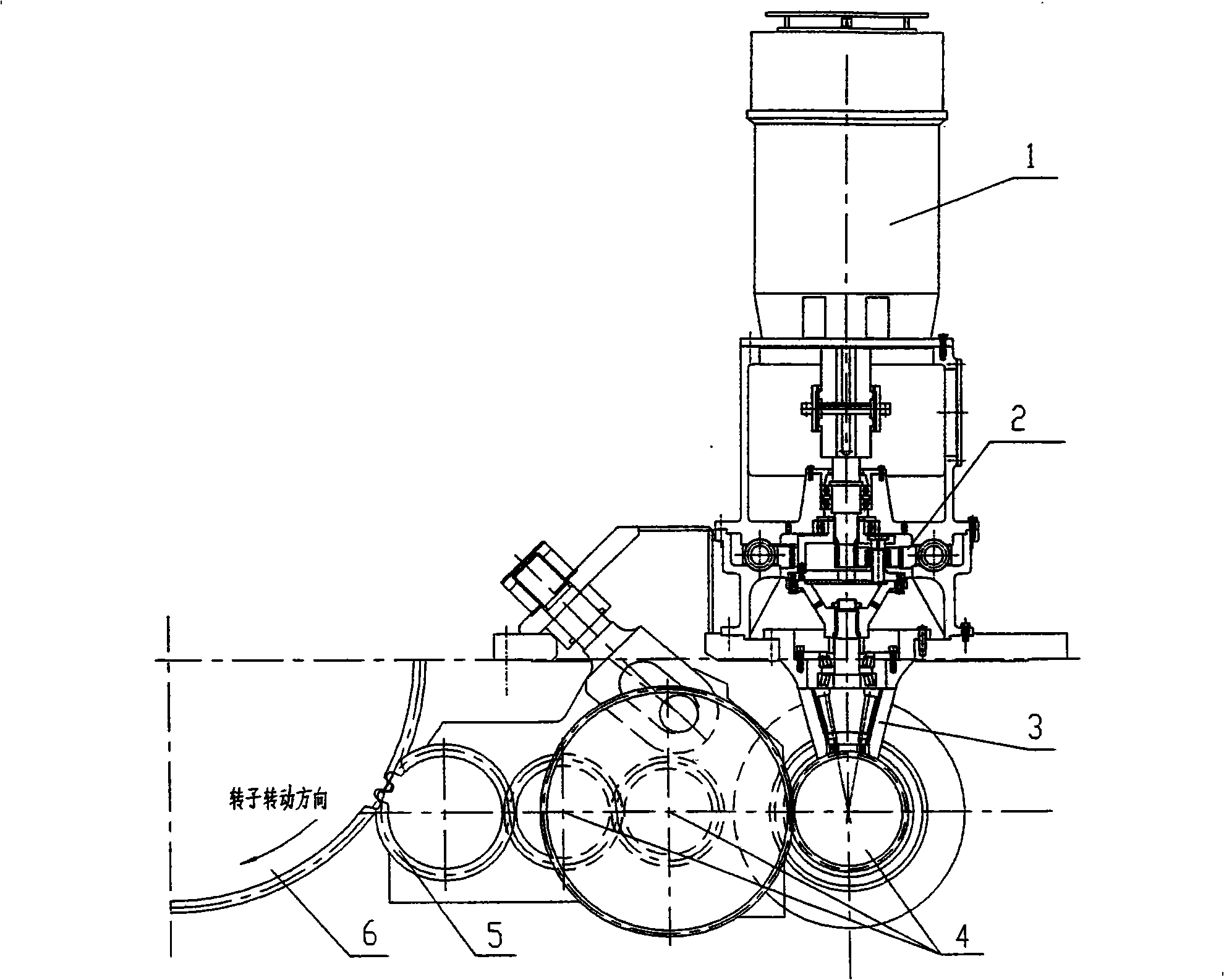

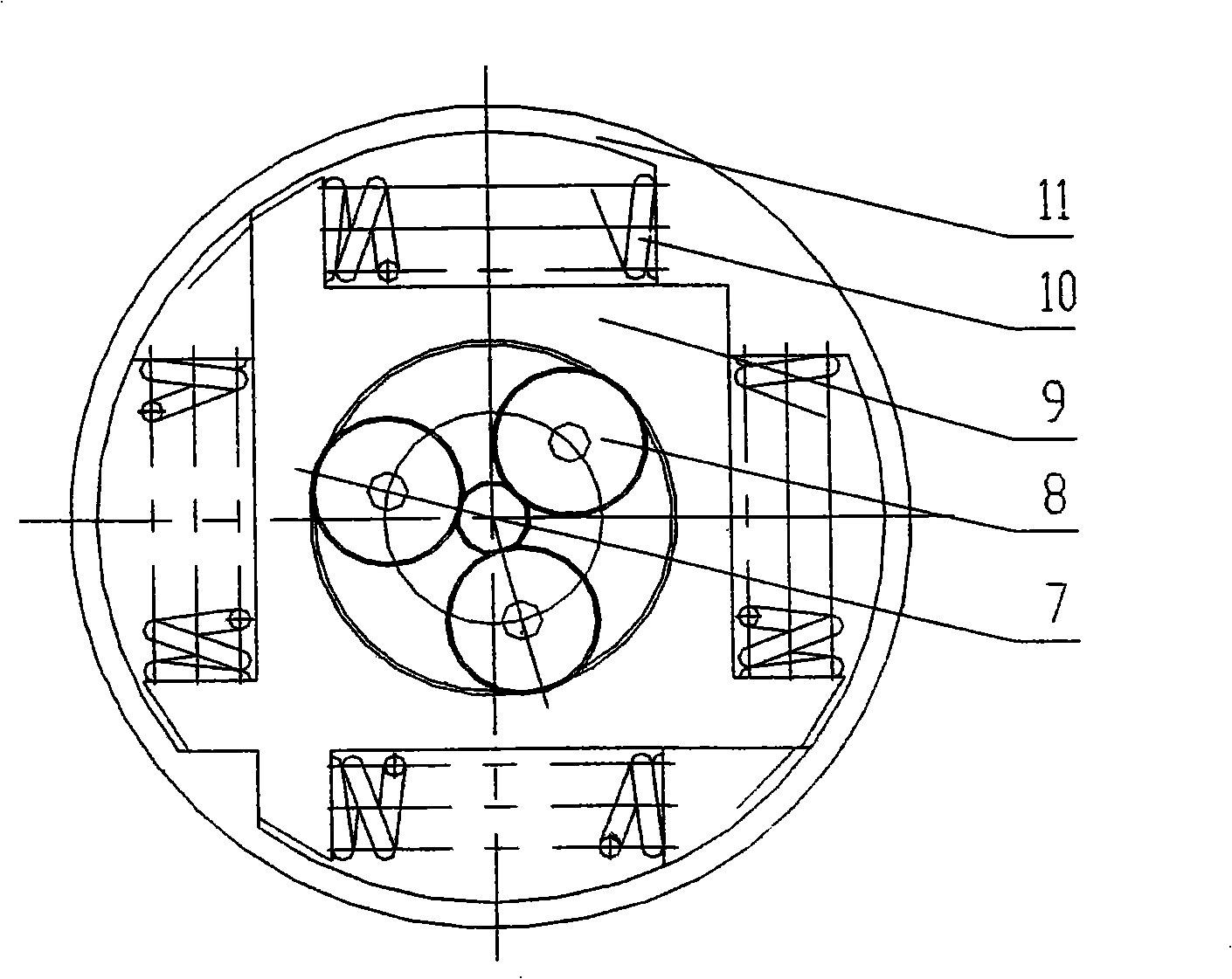

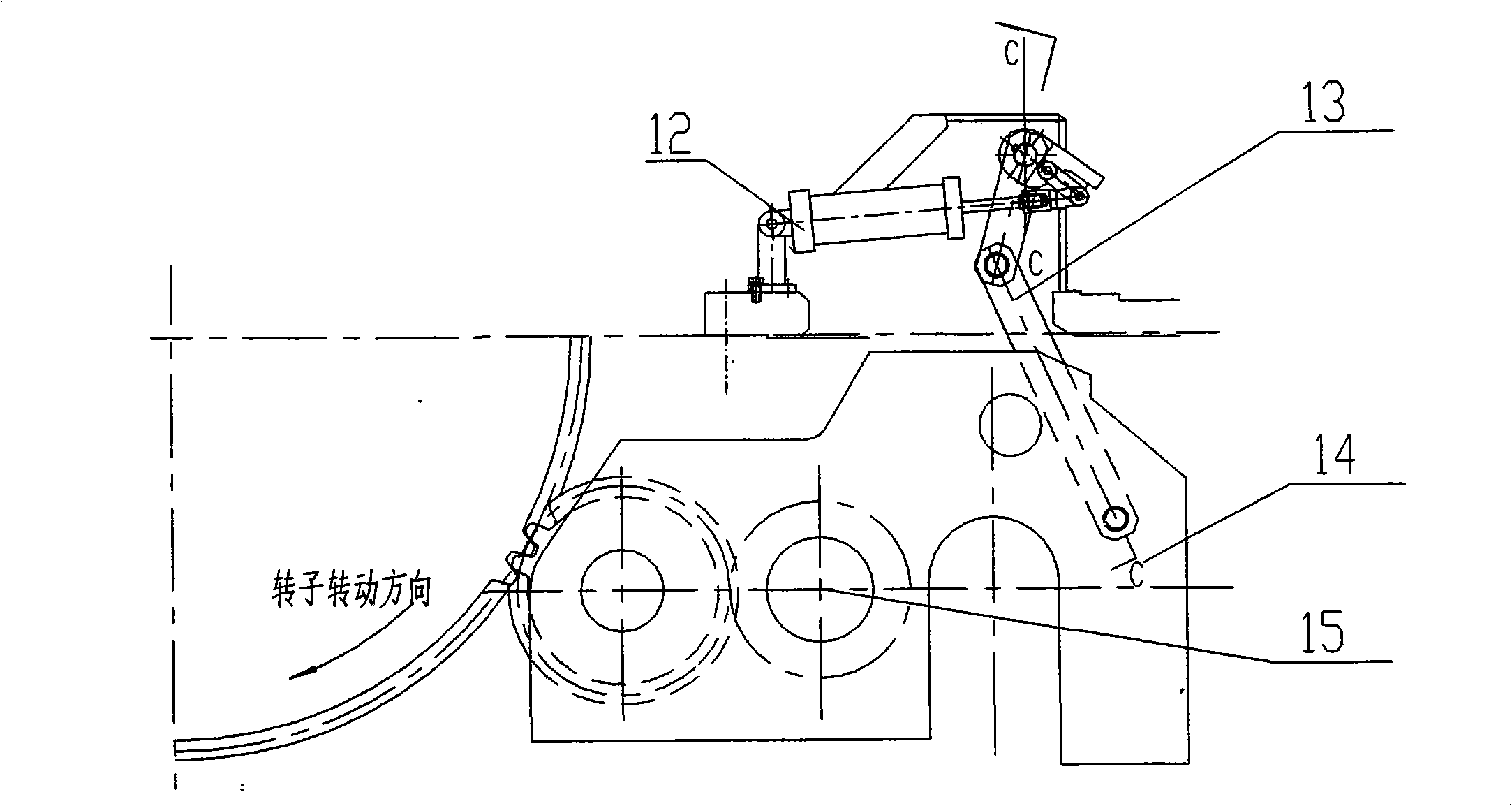

Rolling gear of turbine

InactiveCN101344018ADecrease the number of stages of decelerationMeet the requirements of 2r/min low speed crankingMachines/enginesEngine componentsMiscarriageReduction drive

The invention discloses a turning gear of a steam turbine, comprising a driving motor, a reducer, a swinging gear, a large tooth ring and a clutch mechanism of the swinging gear which are connected in sequence; the large tooth ring is arranged on a rotor of the steam turbine and the reducer is provided with a multilevel speed-reducing transmission pair; the first-level speed-reducing transmission pair of the reducer is a planetary gear transmission box, a second-level speed-reducing transmission pair is an umbrella gear transmission pair and the rest is a planar gear speed-reducing transmission pair; a buffering spring is arranged between an inner tooth ring of the planetary gear transmission box and the box; the bearings of the swinging gear and the planar gear are rolling bearings; the swinging gear is positioned below the middle section of the rotor of the steam turbine and is corresponding to the large tooth ring in a tangential mode. The invention has the advantages of compact structure and small occupied area and has the buffering function with safety and reliability and without miscarriage when in use.

Owner:DONGFANG TURBINE CO LTD

Automatic turnover device of magnetic steel product and turnover method thereof

The invention discloses an automatic turnover device of a magnetic steel product and a turnover method thereof. The automatic turnover device of the magnetic steel product comprises a frame, a first plate turning mechanism, a second plate turning mechanism, a first rotating mechanism for driving the first plate turning mechanism to overturn, a second rotating mechanism for driving the second plate turning mechanism to overturn, a third rotating mechanism, a fourth rotating mechanism, a turnover net plate and a plate turning locking mechanism; the turnover of the magnetic steel product on the net plate can be realized through controlling the first rotating mechanism, the second rotating mechanism, the third rotating mechanism and the fourth rotating mechanism; because of effects of a first sponge plate in the first plate turning mechanism and a second sponge plate in the second plate turning mechanism, the magnetic steel product cannot be deviated in multiple turnover process, and cannot generate collision; and the automatic turnover device of the magnetic steel product has the advantages of realization of turnover automation of the magnetic steel product, high turnover efficiency, capability of preventing staff from working under bad environments for a long time and guarantee of health of the staff.

Owner:NINGBO YUNSHENG +2

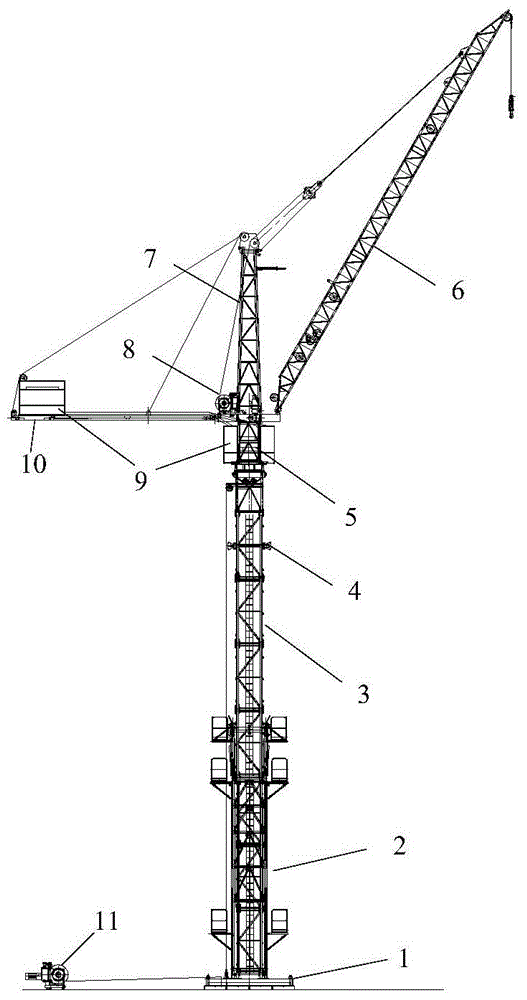

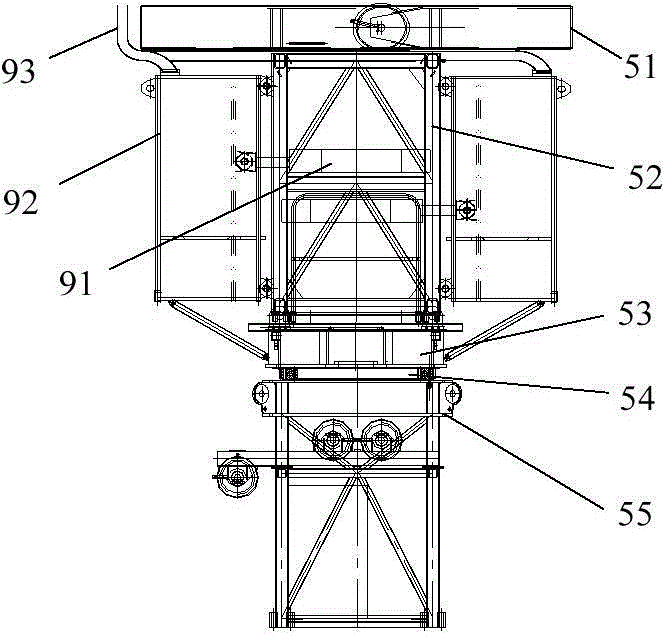

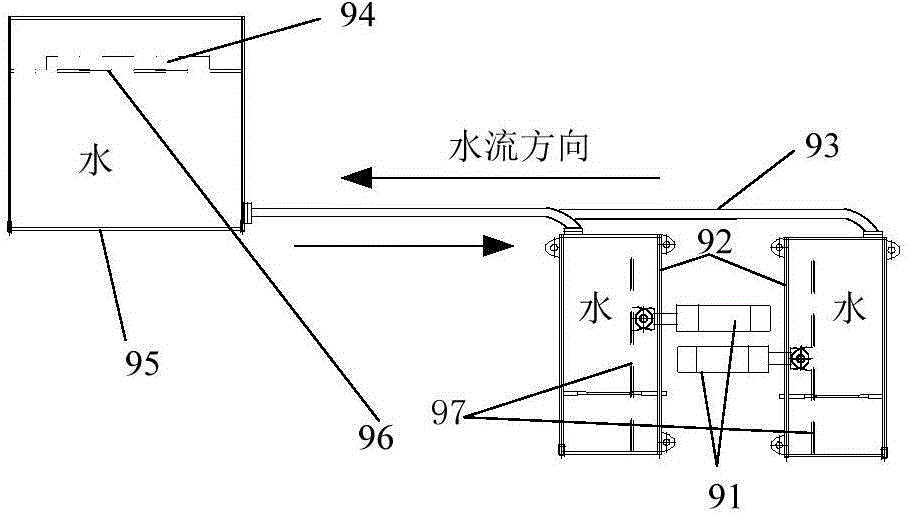

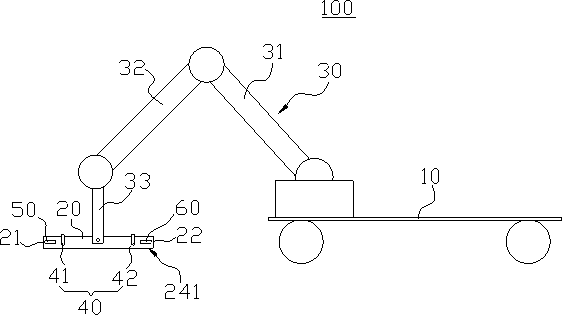

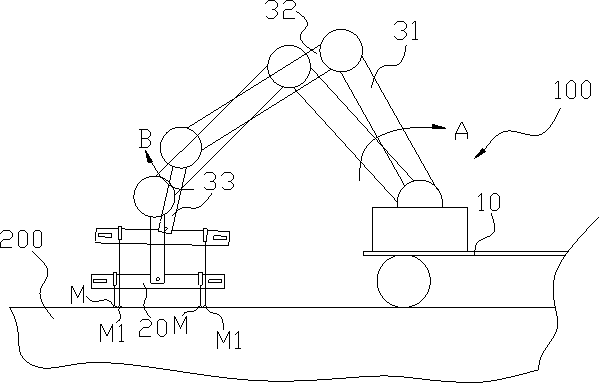

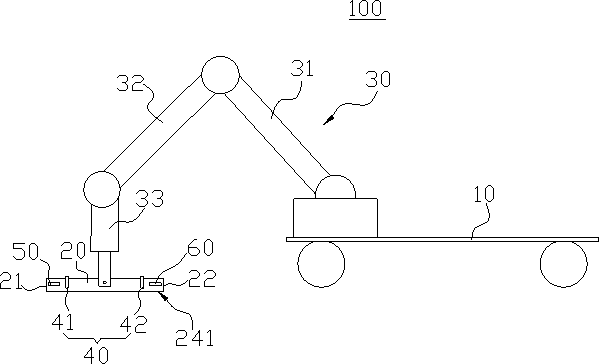

Single-action arm ground lifting pole with flowing water counterweight system

ActiveCN104787690AReduce volumeFlexible counterweight change controlCranesStress conditionsLifting capacity

The invention provides a single-action arm ground lifting pole with a flowing water counterweight system, which comprises a lifting pole foundation, a jacking sleeve frame, a tower body, a rotary assembly and a lifting pole head that are arranged sequentially from the bottom up, wherein the rotary assembly is provided with a lifting arm and a balance arm. The lifting pole is characterized in that the rotary assembly and the balance arm are provided with the flowing water counterweight system; the flowing water counterweight system comprises hydraulic pushers, small water tanks and a counterweight water tank; the hydraulic pushers and the small water tanks are arranged on the rotary assembly; the counterweight water tank is arranged at the tail of the balance arm; and the small water tanks are connected with the counterweight water tank via water pipes. Compared with the prior art, the stress condition of the single-action arm ground lifting pole with the flowing water counterweight system can be improved, the lifting capacity of the lifting pole is improved, or the sectional dimension and weight of a pole body are decreased under the same lifting capacity, and the single-action arm ground lifting pole better meets erection requirements of an ultra-high voltage transmission line iron tower.

Owner:CHINA ELECTRIC POWER RES INST +2

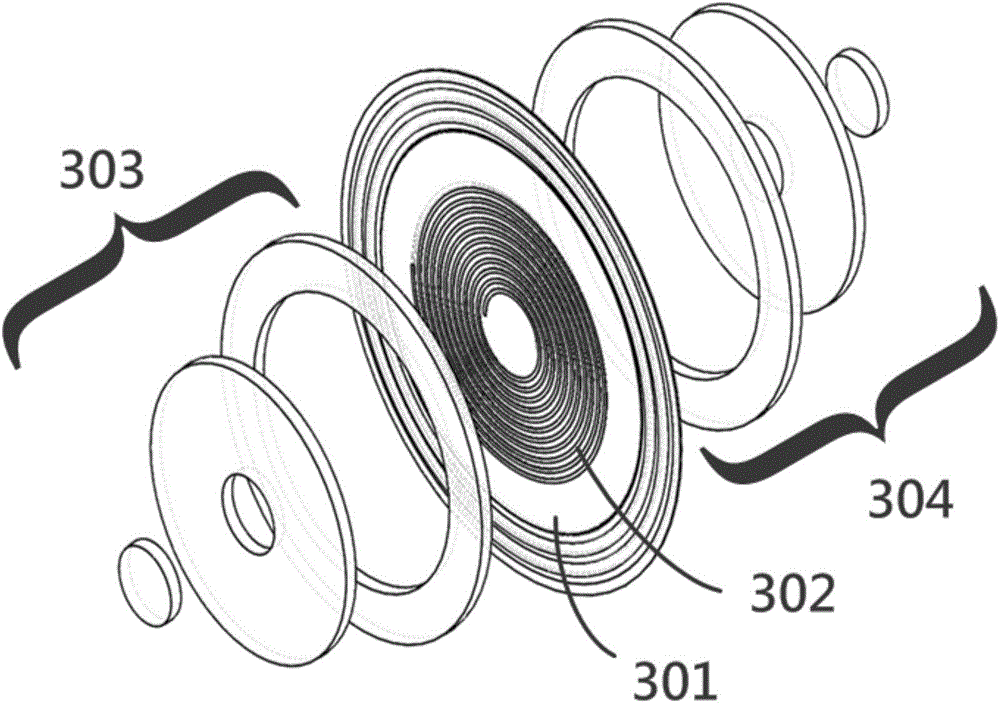

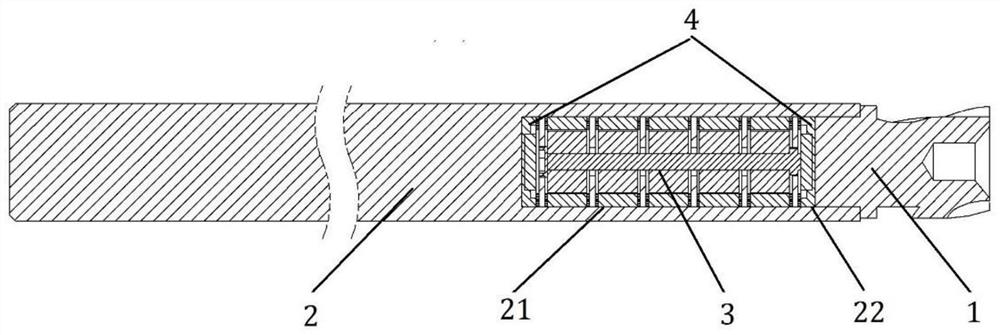

Vibration reduction milling cutter based on layered superposition type permanent magnet dynamic vibration absorber

The invention discloses a vibration reduction milling cutter based on a layered superposition type permanent magnet dynamic vibration absorber. The dynamic vibration reduction milling cutter comprisesa cutter head, a cutter bar, a permanent magnet type dynamic vibration absorber and an axial thrust end cover, and the permanent magnet type dynamic vibration absorber and the axial thrust end coverare installed in a cylindrical cavity of the cutter bar; and the permanent magnet type dynamic vibration absorber is composed of a connecting rod, a rubber gasket, a metal sheet, an inner magnetic ring and an outer magnetic ring. The permanent magnet type dynamic vibration absorber in the dynamic vibration reduction milling cutter is integrally of a layered superposition type structure, it can beguaranteed that the dynamic vibration absorber provides large magnetic rigidity and eddy current damping under the condition of the small size, and therefore rubber and damping materials in a traditional dynamic vibration reduction cutter bar are replaced with the magnetic rigidity and the eddy current damping; the problems of damping liquid leakage, rubber fatigue aging and the like in a traditional dynamic vibration reduction cutter bar are solved, the rigidity and damping of the dynamic vibration absorber are independently designed, the service life of a cutter can be effectively prolonged,and the vibration reduction effect can be effectively improved.

Owner:BEIJING UNIV OF TECH

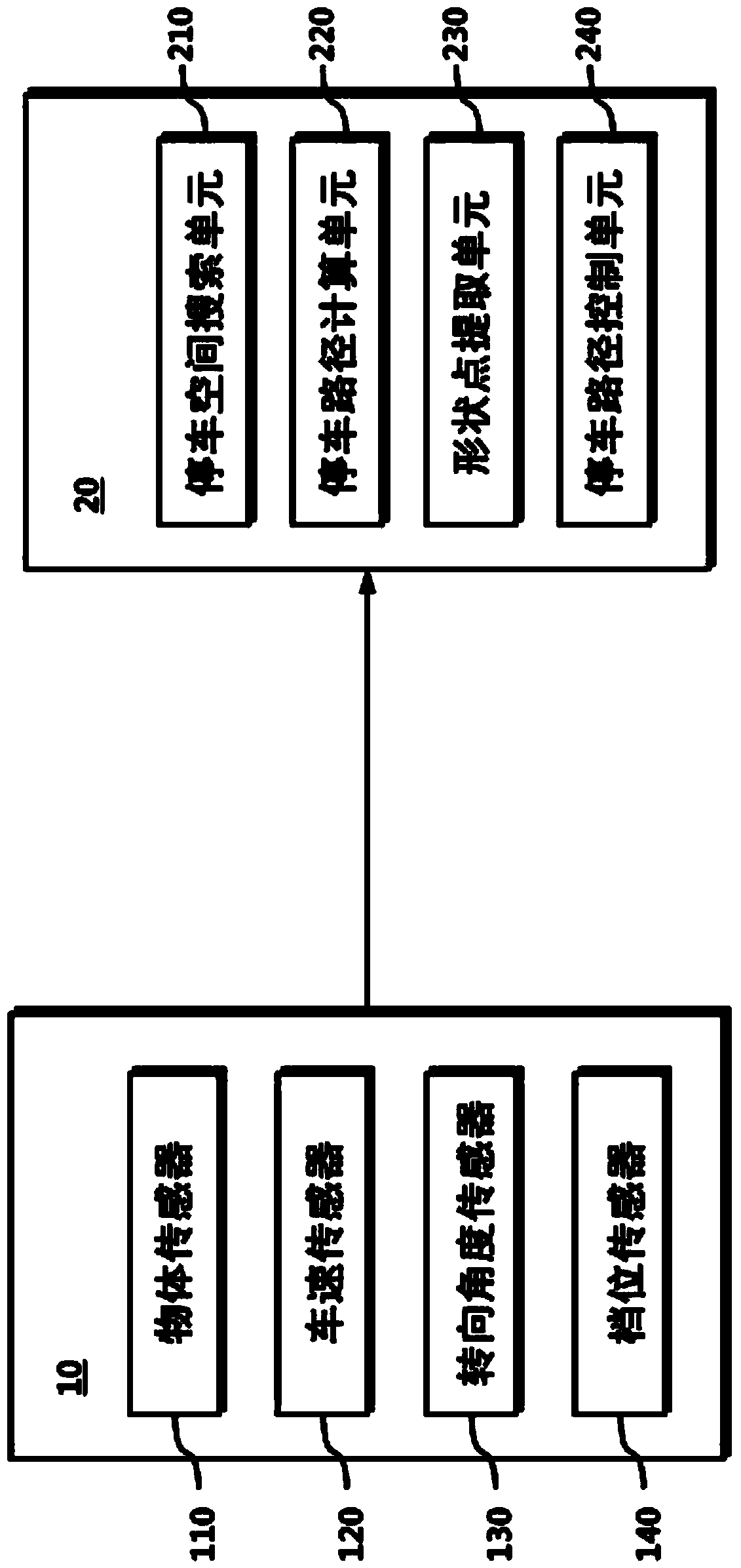

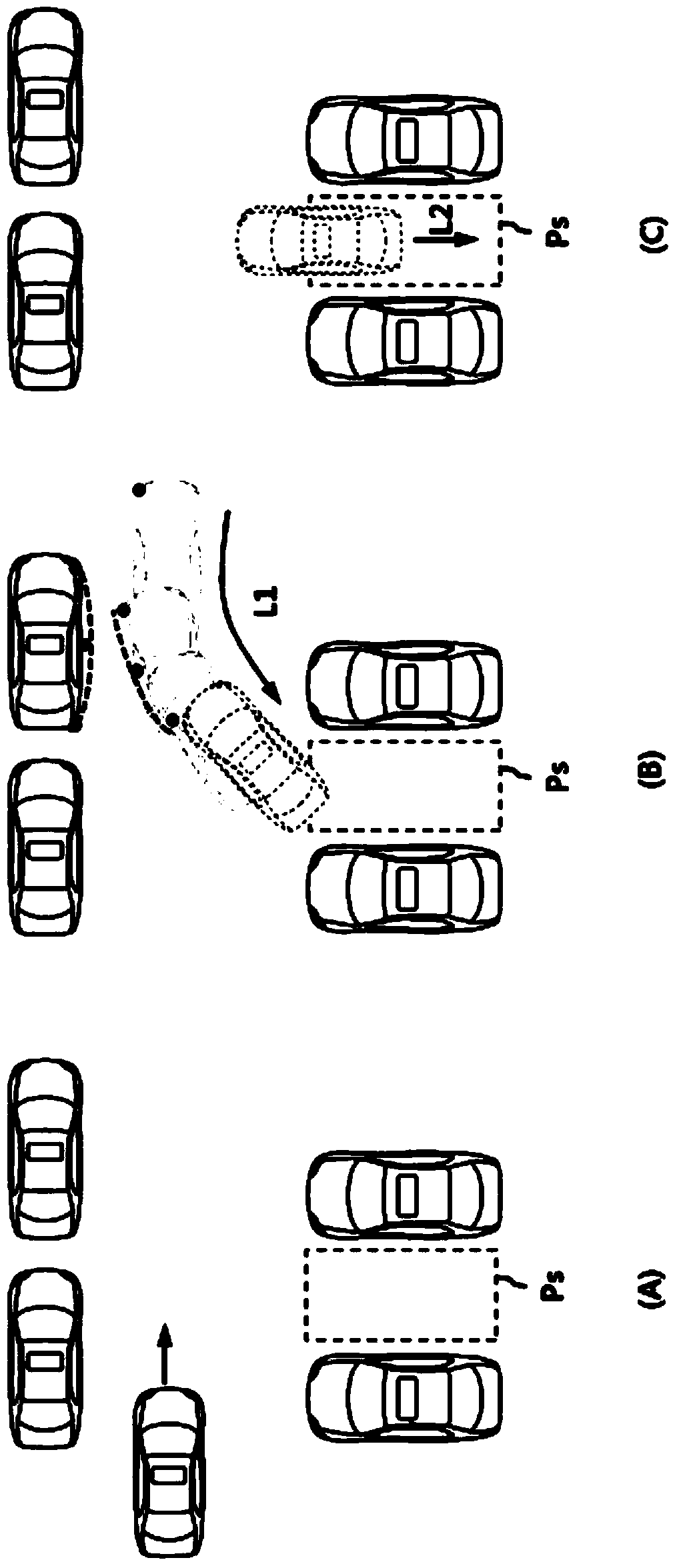

Parking control method, device and system

ActiveCN104228829AStability Parking ControlWon't collideExternal condition input parametersSteering controlsParking spaceReal-time computing

Owner:HL KLEMOVE CORP

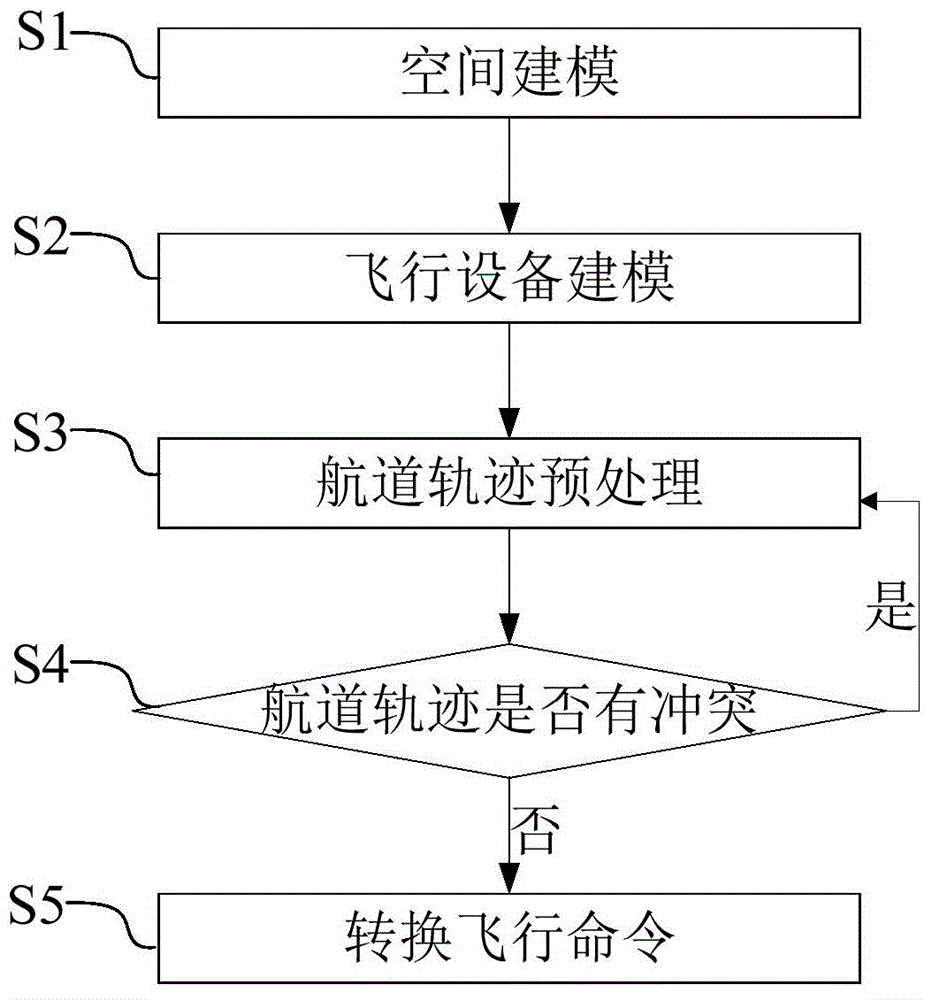

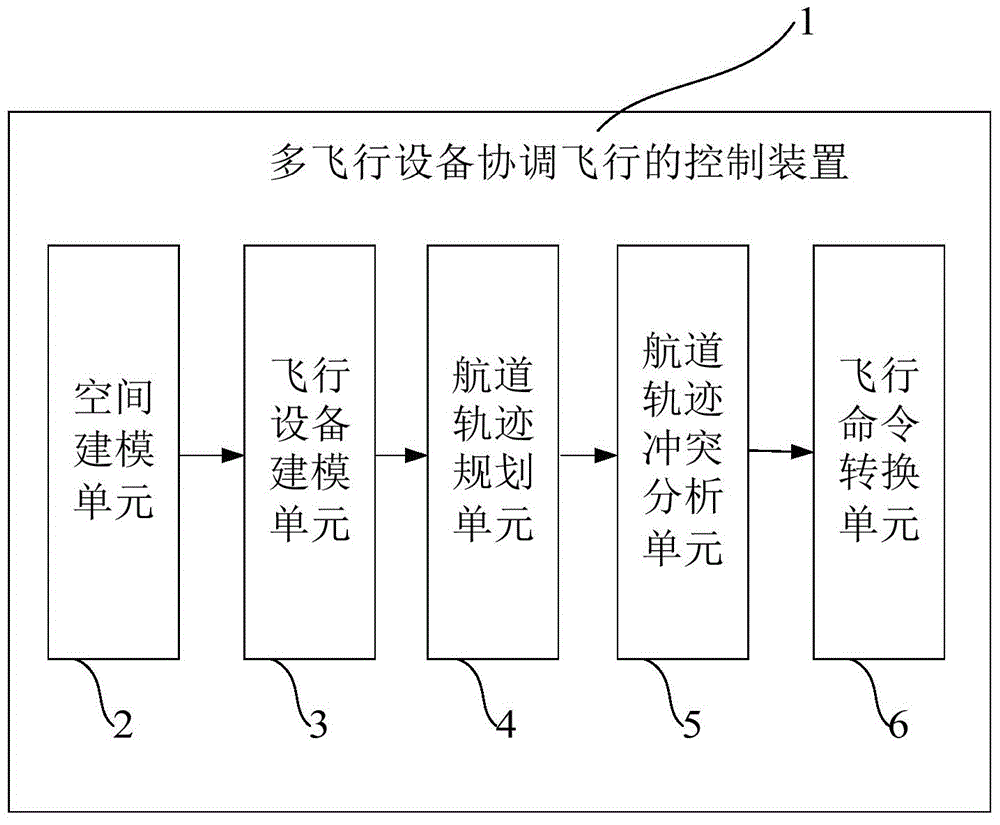

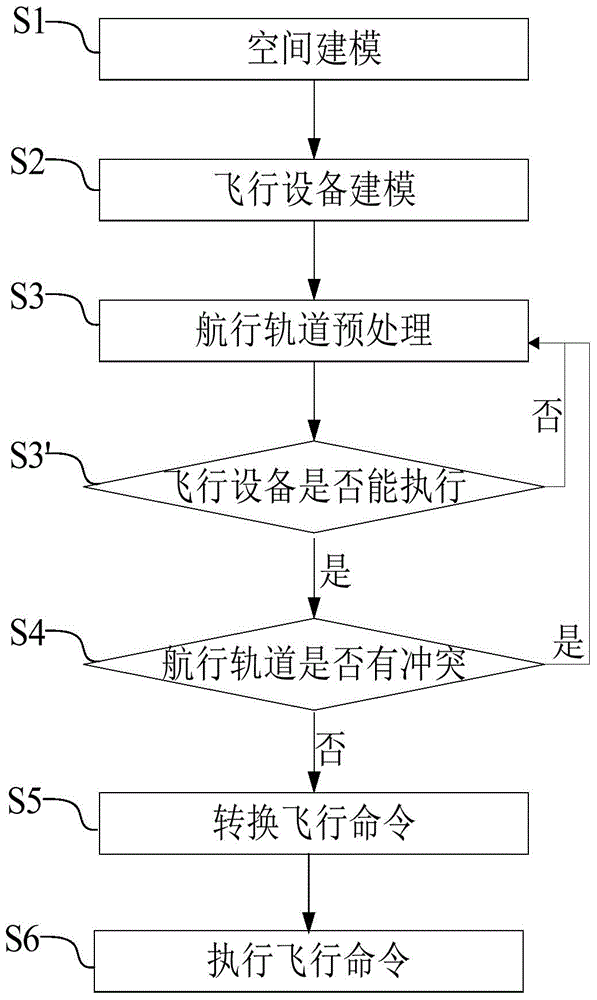

Control method and control device for controlling coordinated flight of multiple pieces of flight equipment

InactiveCN104914875AAvoid Uncertainty and IncongruityWon't collidePosition/course control in three dimensionsTime parameterAerospace engineering

The invention provides a control method and a control device for controlling coordinated flight of multiple pieces of flight equipment. The control method comprises the following steps: (1) spatially modeling an airspace where flight equipment is located; (2) modeling the size and flight parameters of the flight equipment; (3) preprocessing the course trajectories of the flight equipment, wherein preprocessed information includes the position parameters of the flight equipment in a space coordinate system and the time parameters of the flight equipment at different points of the space coordinate system in the flying process; (4) analyzing whether there is conflict in each course trajectory and between different course trajectories, re-preprocessing the course trajectories of the flight equipment if there is conflict, and executing next step if there is no conflict; and (5) converting the preprocessed course trajectories into flight commands which can be performed by the flight equipment. Therefore, the course trajectory of each piece of flight equipment can be defined in advance, and uncertainty and incompatibility caused by manual operation are avoided.

Owner:高域(北京)智能科技研究院有限公司

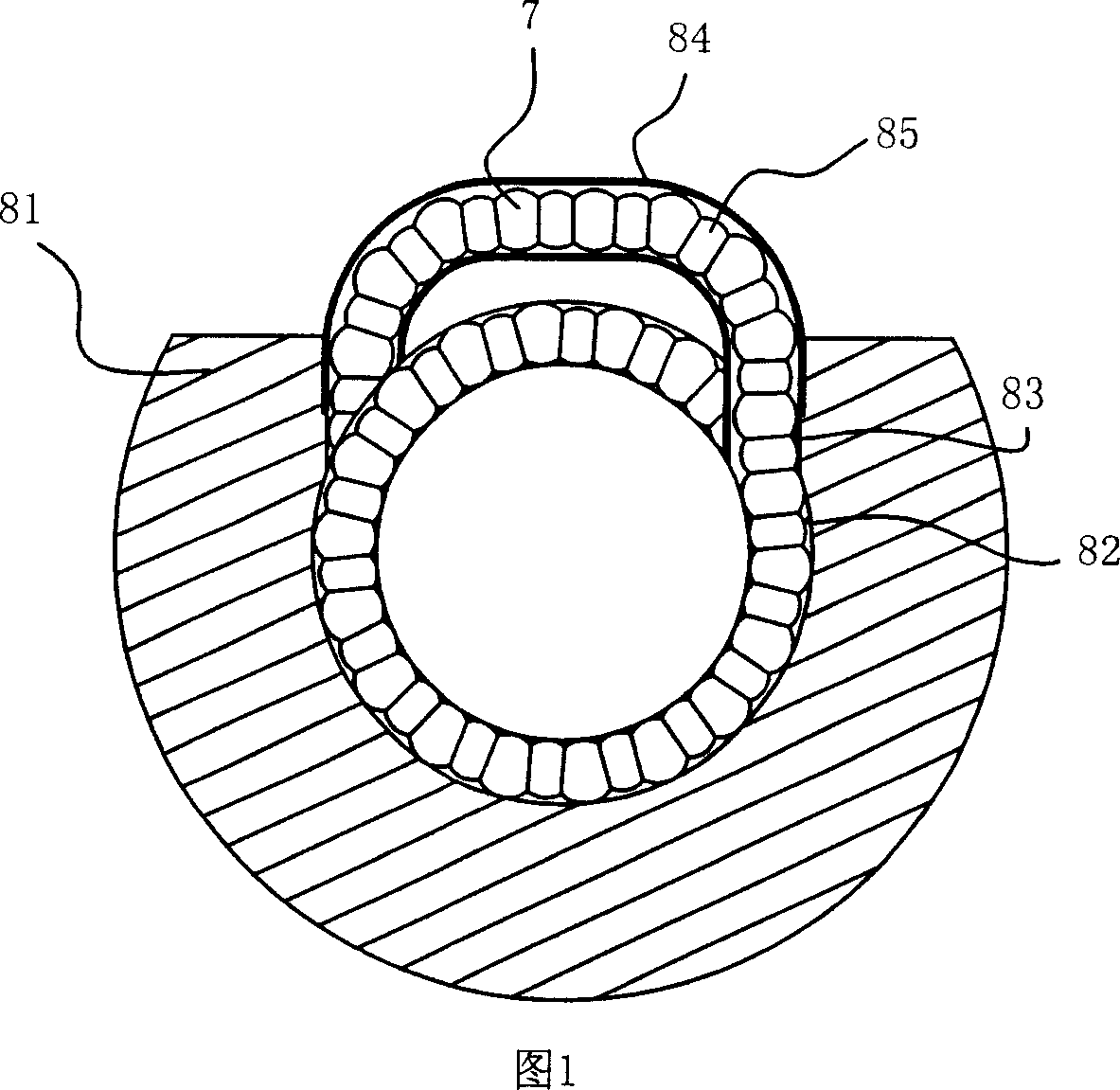

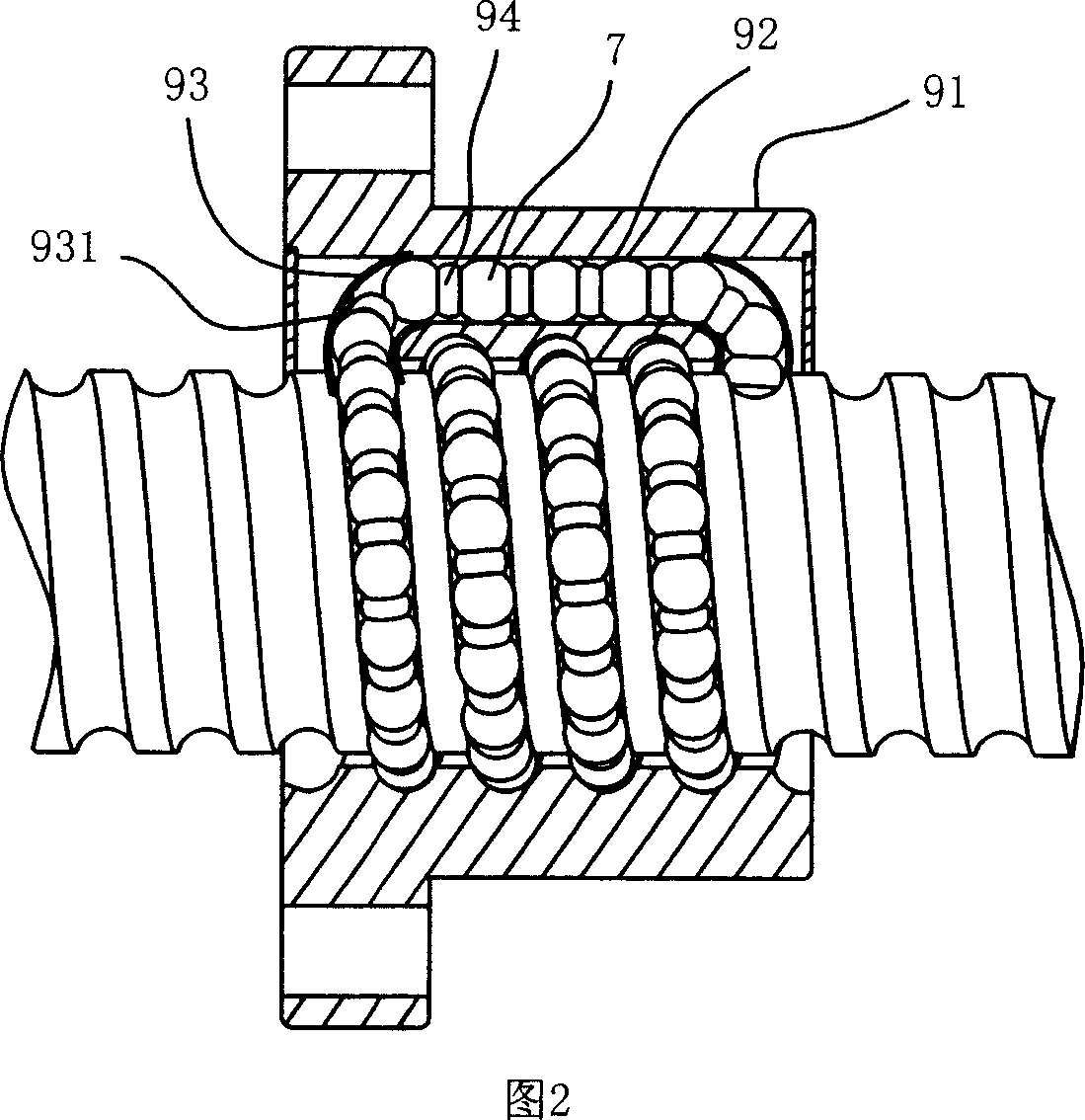

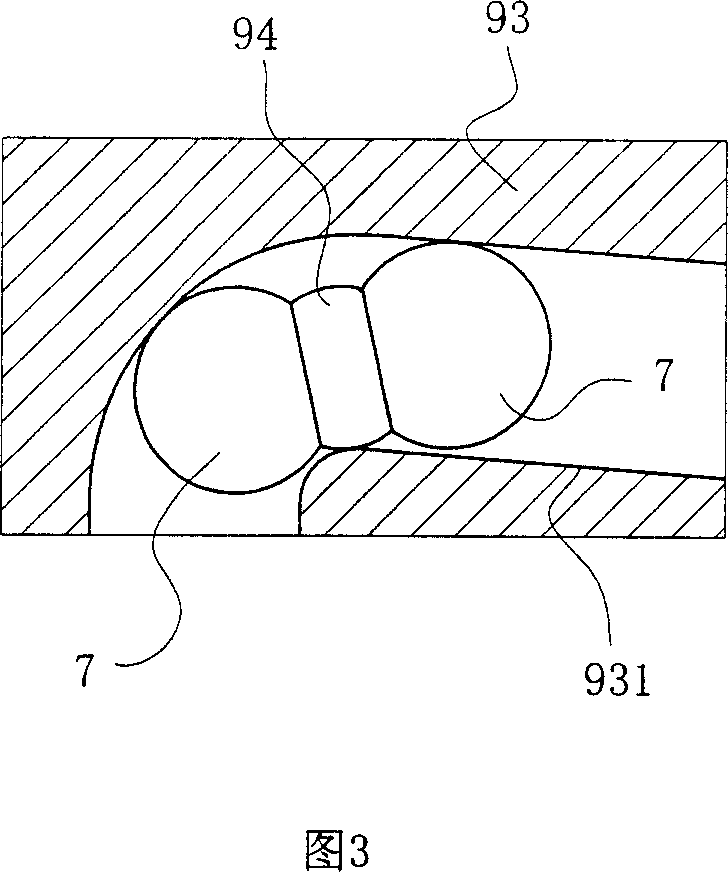

Return way structure of ball screw

The return way structure of ball screw is used for connecting the screw groove of screw nut and return flow hole so as to constitute one path for balls and distance pieces to circulate. Each of the distance pieces in shifting is held by two balls, so that the distance piece in the curved return flow path will be extruded inwards. The present invention shifts the circle center of the inner ace line in the curved return flow path outwards and increases its curvature radius to reduce curving degree, so that the distance piece extruded inwards will not collide with the inner guide surface in the curved return flow path for fluently passing through.

Owner:HIWIN TECH

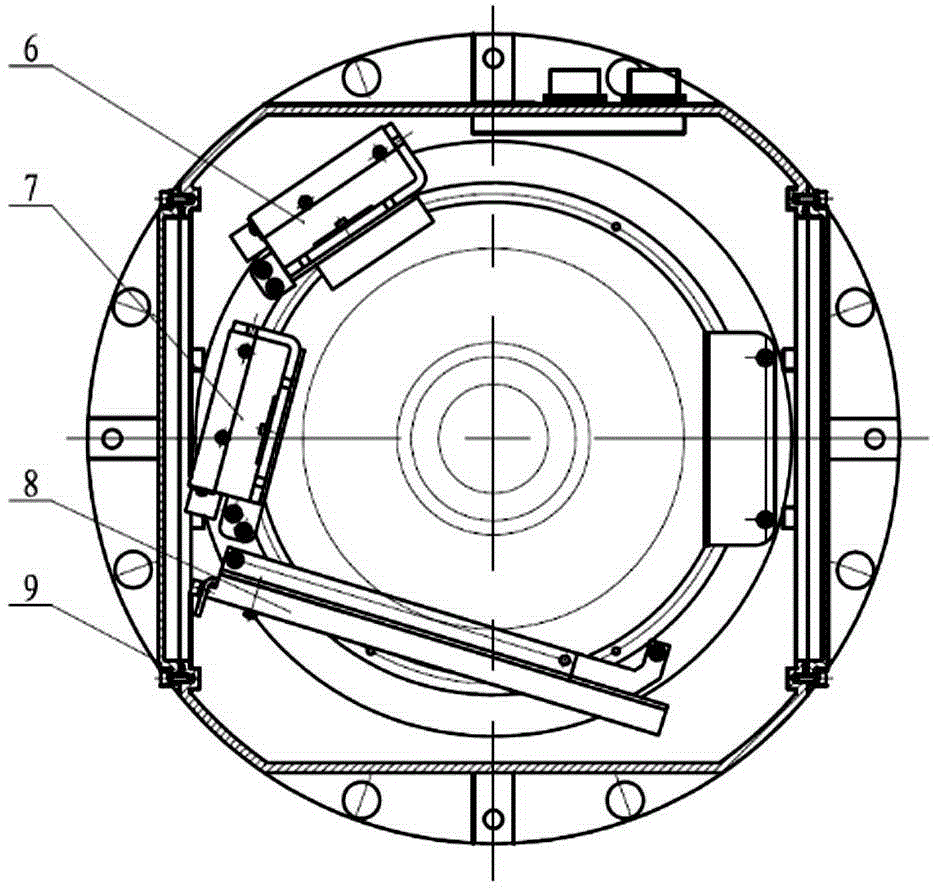

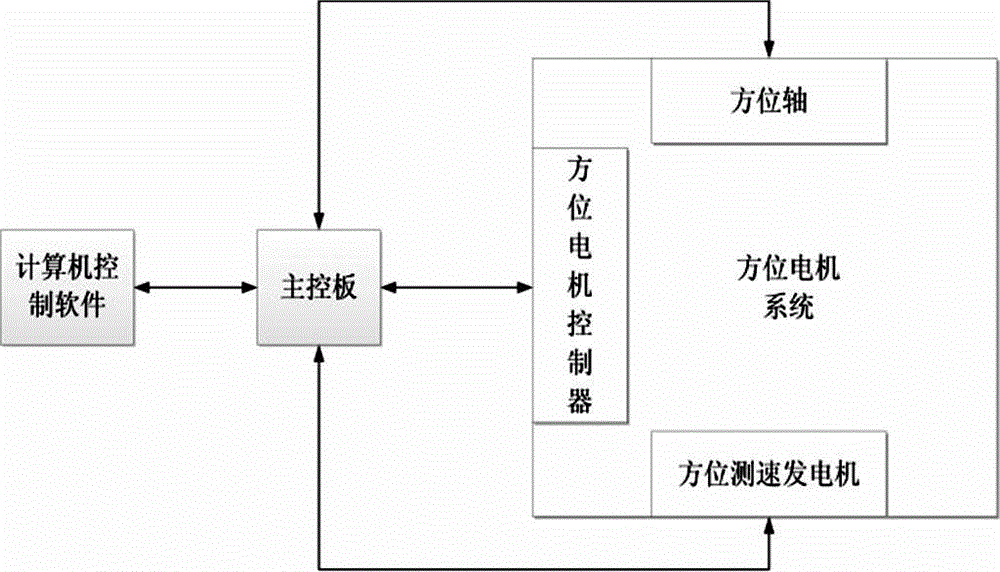

Large and medium monitoring rotary-table rotating system and operation control method thereof

ActiveCN105302163APrevent system runaway or crashConsider comprehensivelyControl using feedbackEmbedded systemSelf repair

The invention discloses a large and medium monitoring rotary-table rotating system and an operation control method thereof. The rotating system comprises a rotating device which continues to rotate for 360 DEG in horizontal direction, and a pitching device which stops in a limit device in a pitching direction. The rotating device and the pitching device are respectively connected with a first main control plate and a second main control plate. A computer control software sends related instructions. The first and second main control plates receive all instructions and control rotation speed, direction and angle. The real-time state information of the rotation speed, direction and angle of the rotary table will be fed back to the first and second main control plates. The feedback information can be calculated and monitored. Real-time rotation states can be recorded and state information can be fed back to the computer control software. In this way, after the large and medium monitoring rotary-table horizontal-direction system and the pitching system break down or operated by mistake, thereby effectively preventing the systems from being out of control or collided and avoiding other damages; and the overall method is comprehensive and simply and effectively designed, and have the certain self-repairing ability.

Owner:HENAN COSTAR GRP CO LTD

Adjustable symmetric swing plate type wave energy generation device

InactiveCN104863786AAdjustable spacingImprove environmental adaptabilityMachines/enginesEngine componentsAuto regulationHydraulic cylinder

The invention provides an adjustable symmetric swing plate type wave energy generation device which comprises anchor chains, a floating body, a sliding table, a first swing plate, a first hydraulic cylinder, a second hydraulic cylinder, a second swing plate, a third swing plate, a third hydraulic cylinder, a fourth hydraulic cylinder, a first rectifying valve group, a first electromagnetic valve, a second rectifying valve group, a second electromagnetic valve, a third electromagnetic valve, a hydraulic motor, a generator and a rectifying filter circuit. The adjustable symmetric swing plate type wave energy generation device has the advantages that through hydraulic pressure, the interval between the front and rear swing plates can be automatically adjusted to be half a wavelength, so that the stability and power generation efficiency of the adjustable symmetric swing plate type wave energy generation device can be greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

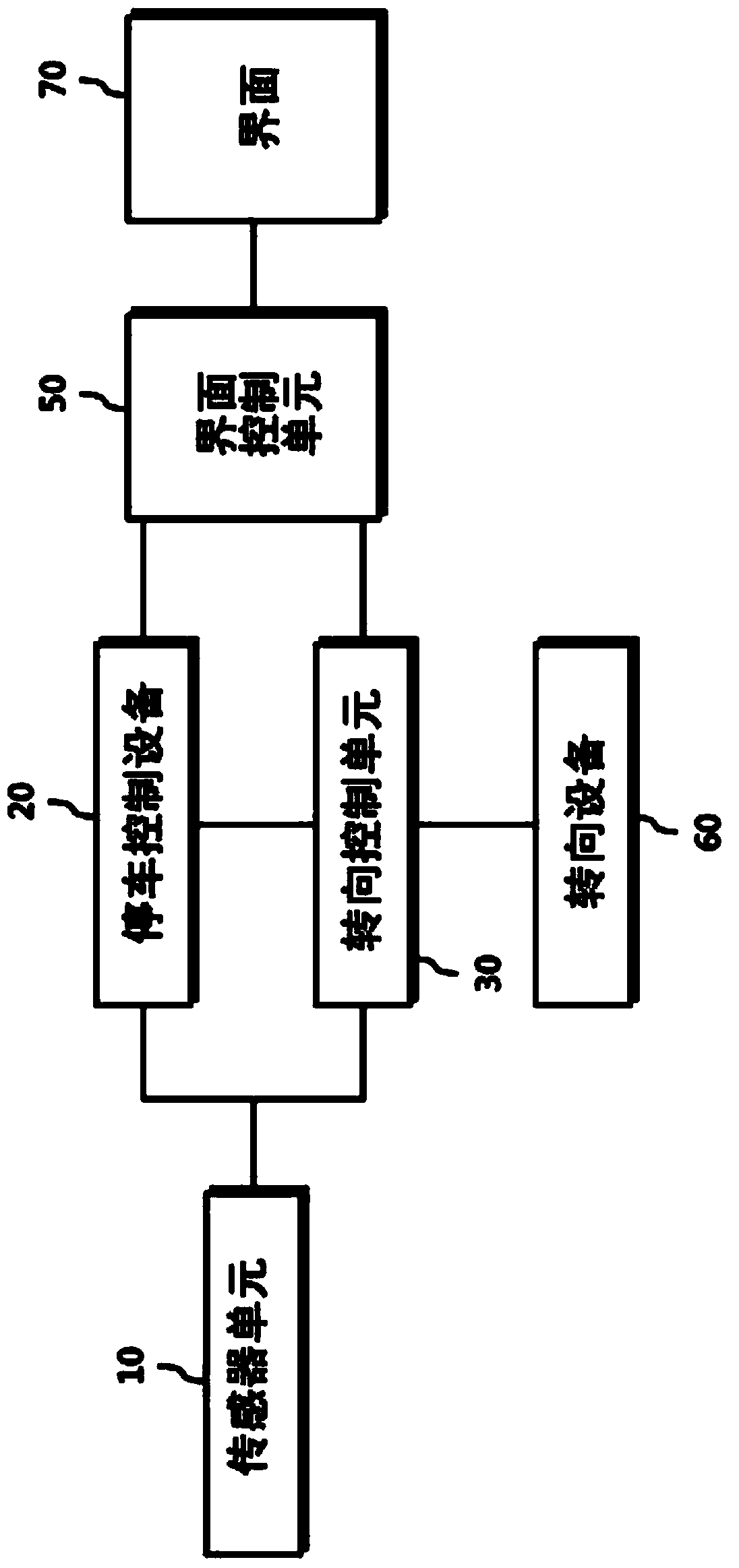

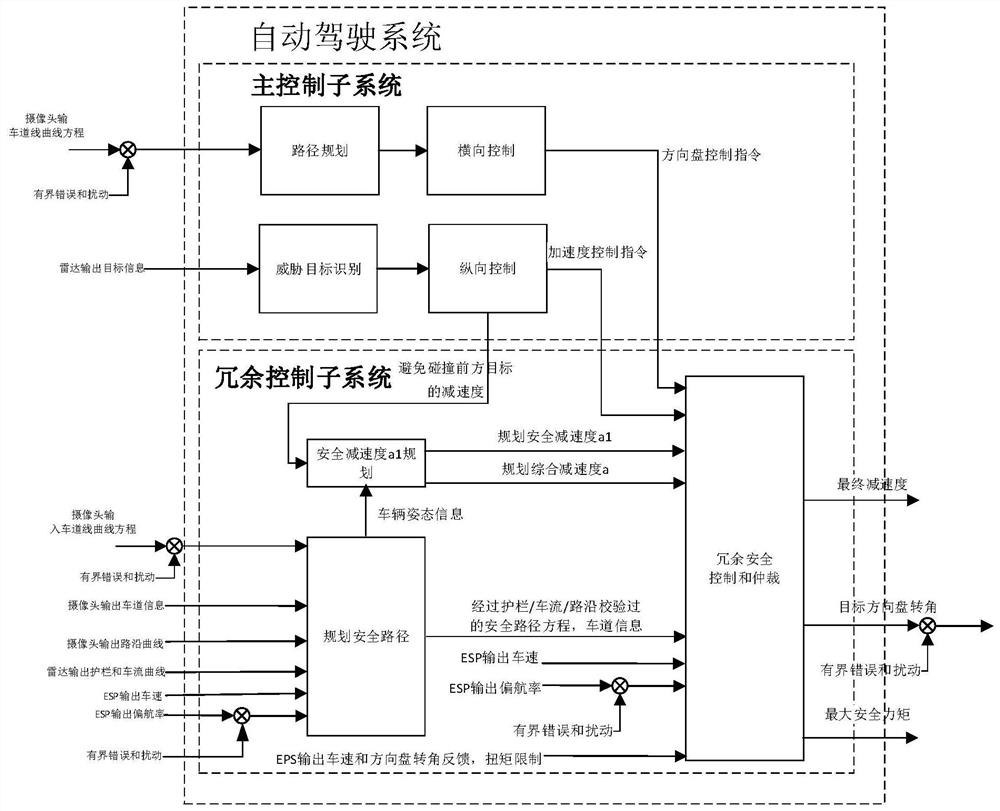

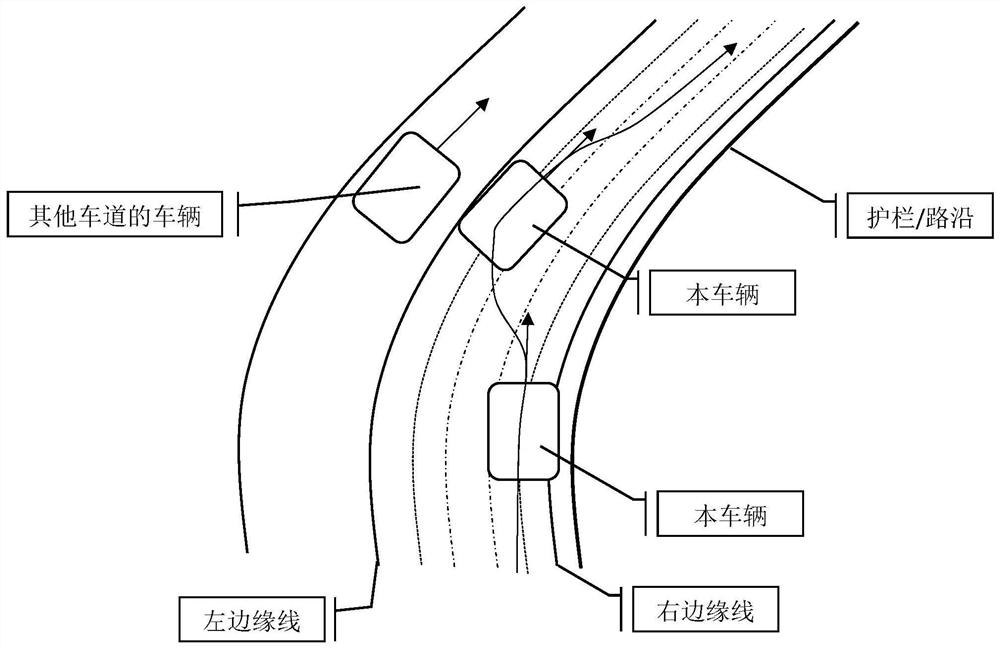

Redundancy control method of automatic driving system, automatic driving system, automobile, controller and computer readable storage medium

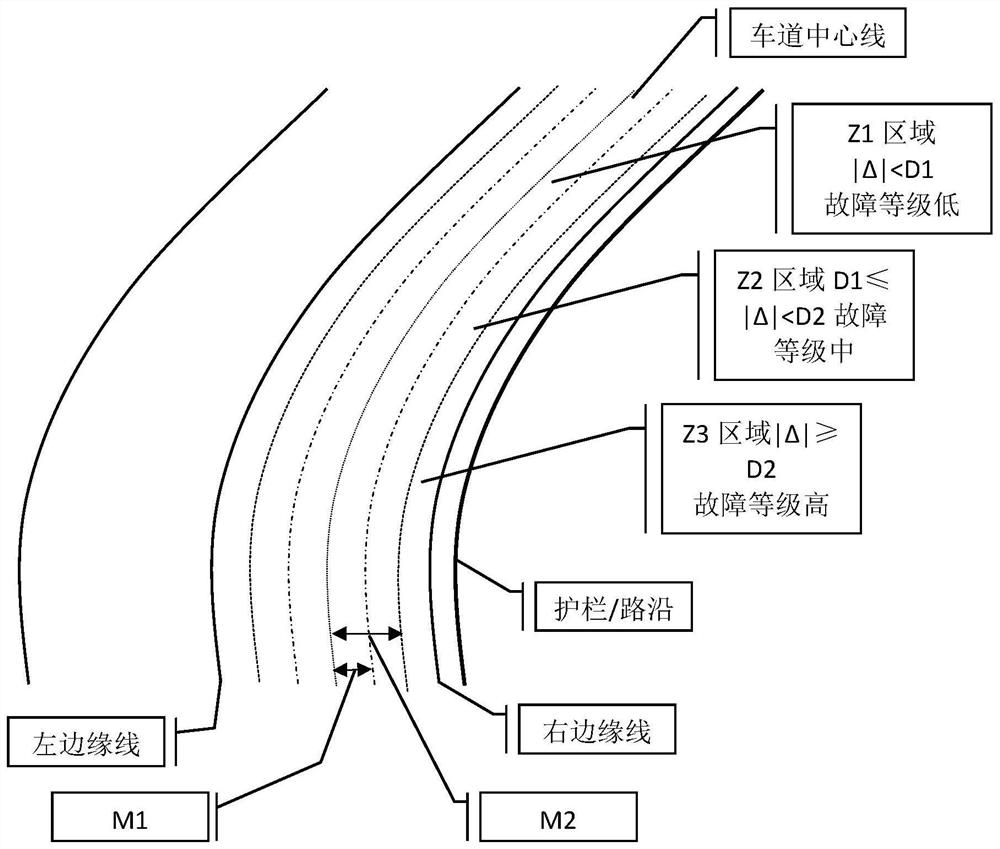

The invention relates to a redundancy control method of an automatic driving system, the automatic driving system, an automobile, a controller and a computer readable storage medium, which are used for keeping running along the center line of a lane when the automatic driving system has a fault and the fault does not exceed tolerance. The method comprises the steps of: when an automatic driving function is activated, fitting a safe path equation enabling a vehicle to run along the center line of a lane according to information collected by a forward-looking camera and a radar, and determiningthe lane width of the lane where the vehicle is located currently; according to the coefficient of the safe path equation and the determined lane width, determining a current specific offset area of the vehicle; determining the current fault level of a main control subsystem according to the offset area where the vehicle is located and whether the vehicle activates the function of a first redundant safety control module in the previous control period or not; and activating the redundancy control function of the corresponding level according to the current fault level of the main control subsystem, and controlling the vehicle according to the redundancy control function of the corresponding level.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

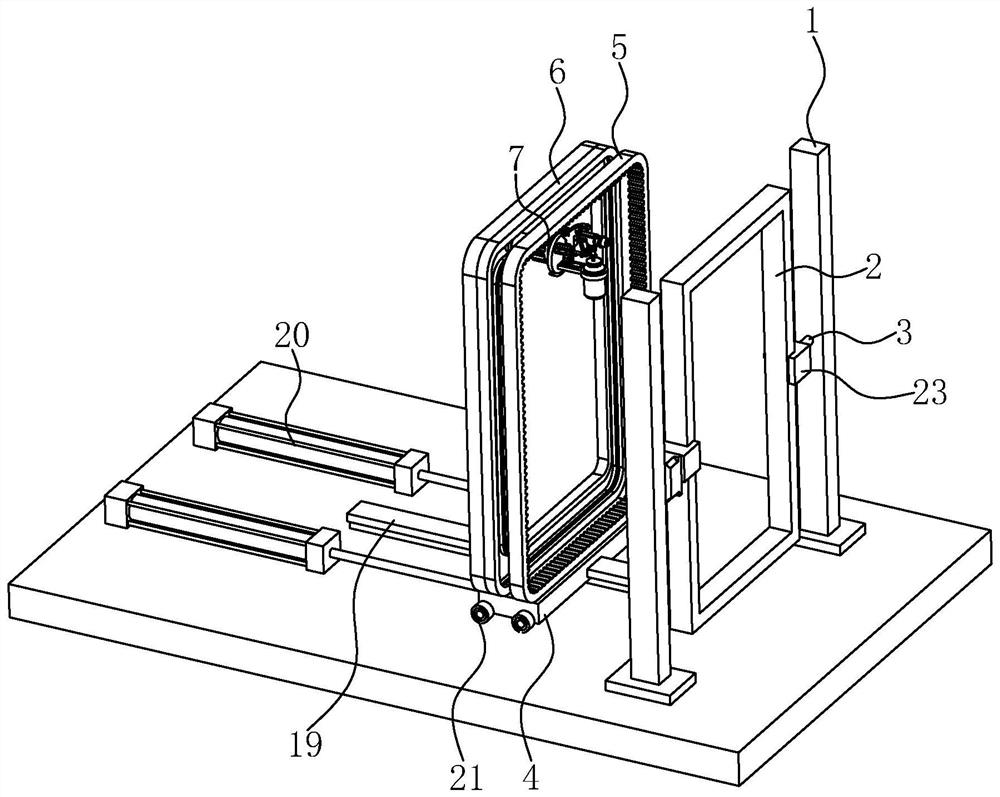

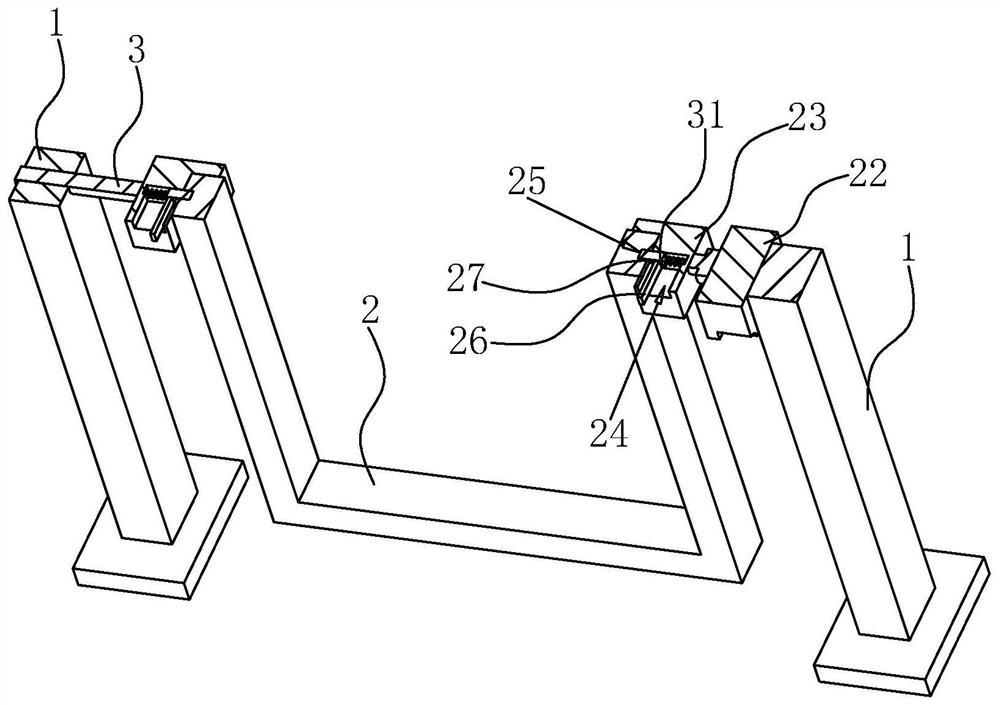

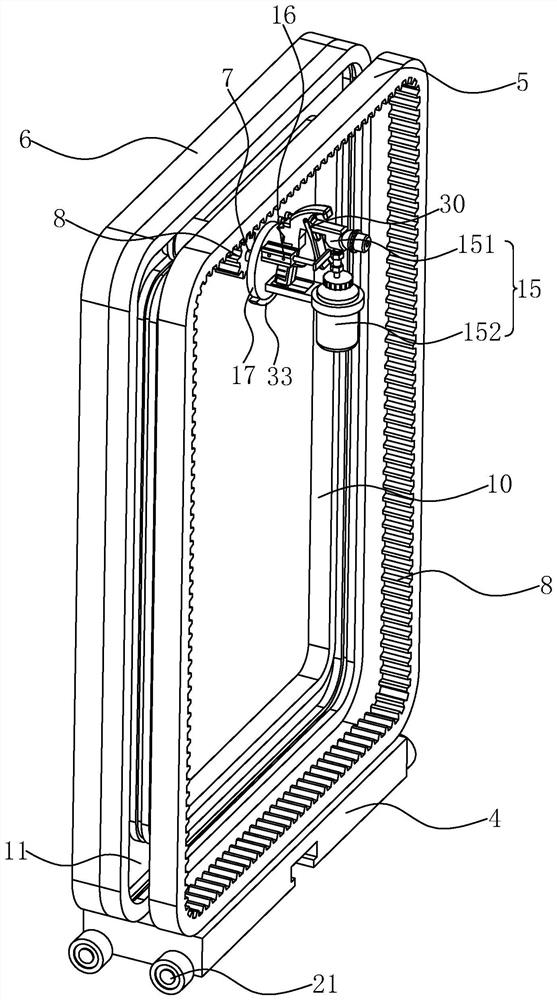

Aluminum alloy door and window machining equipment and machining method

ActiveCN112657715AImprove painting efficiencyWon't collideSpraying apparatusStructural engineeringMachining

The invention relates to the technical field of door and window machining and production, in particular to aluminum alloy door and window machining equipment. The equipment comprises two vertical plates and a window body between the two vertical plates, rotating shafts are rotationally connected to the opposite side faces of the vertical plates, fixing pieces used for fixedly clamping the window body are arranged on the two rotating shafts, and rotating pieces used for driving the rotating shafts to rotate are arranged on the vertical plates. The equipment further comprises a base located on the side face of the window body, a first paint spraying frame and a second paint spraying frame are arranged on the base, the first paint spraying frame and the second paint spraying frame are arranged in a chamfered mode, the first paint spraying frame and the second paint spraying frame are vertically arranged and are parallel to each other, a moving rod is arranged in an inner frame of the first paint spraying frame, a paint spraying device for spraying paint to the window body is arranged on the moving rod, and a driving assembly for driving the moving rod to circumferentially move in the inner frame of the first paint spraying frame is arranged in the inner frame of the first paint spraying frame. The aluminum alloy door and window machining equipment has the effects that automatic paint spraying can be conducted on doors and windows conveniently, manpower consumption is reduced, and therefore production efficiency is improved.

Owner:成都金斯特节能门窗有限公司

Coating robot and control method thereof

ActiveCN110714598AScratch controlWon't collideBuilding constructionsManipulatorControl systemDistance detection

The invention provides a coating robot and a control method thereof, and relates to the technical field of building auxiliary instruments. The coating robot is used for coating a first target body, and comprises a travelling device, a scraping coating part, an executing mechanism, a first distance detecting part and a control system; the scraping coating part is provided with a scraping coating surface, and the scraping coating part is connected with the travelling device through the executing mechanism; the first distance detecting part is used for acquiring a first distance signal which characterizes the distance between the first target body and the scraping coating surface; and the control system is used for controlling the executing mechanism to act according to the first distance signal so as to adjust the distance between the scraping coating surface and the first target body to a first preset value. The coating robot can keep the distance between the first target body and the scraping coating surface always to be the first preset value, so that the coating thickness of the first target body is always the first preset value, then the coating thickness is conveniently controlled, therefore the coating thickness at each parts of the first target body is kept consistent, and the situation that a coating is too thin or too thick due to the fluctuation of the ground height isavoided.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

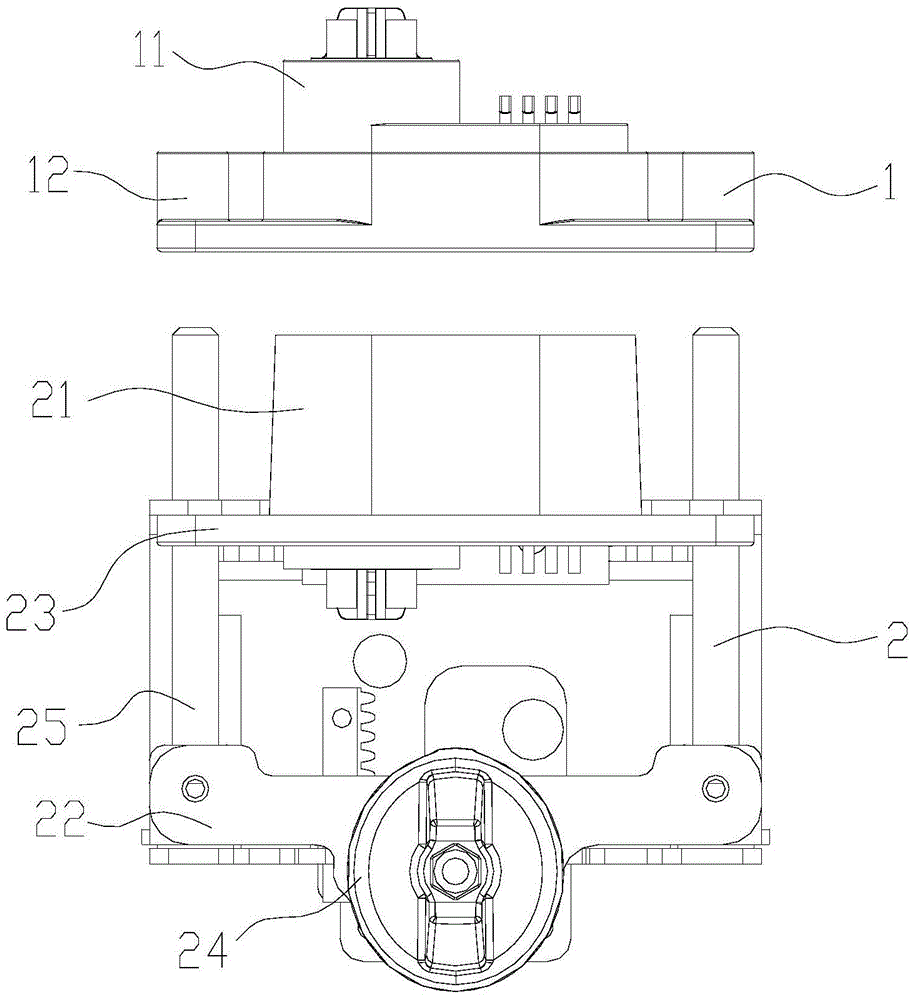

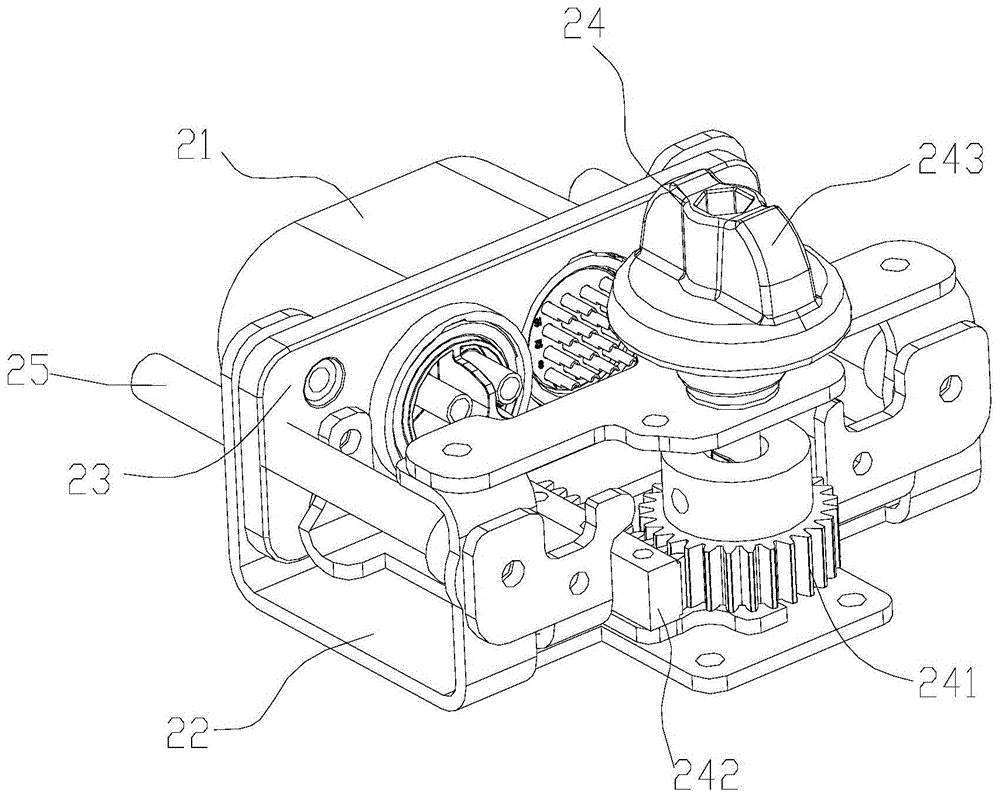

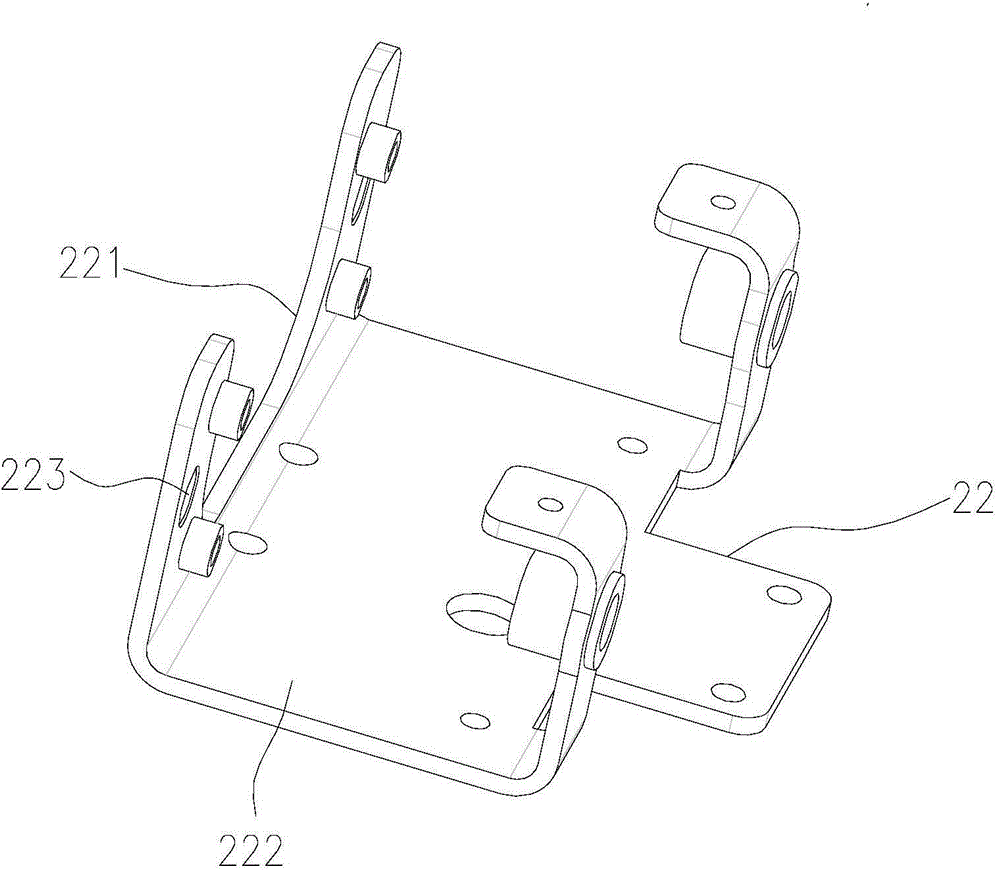

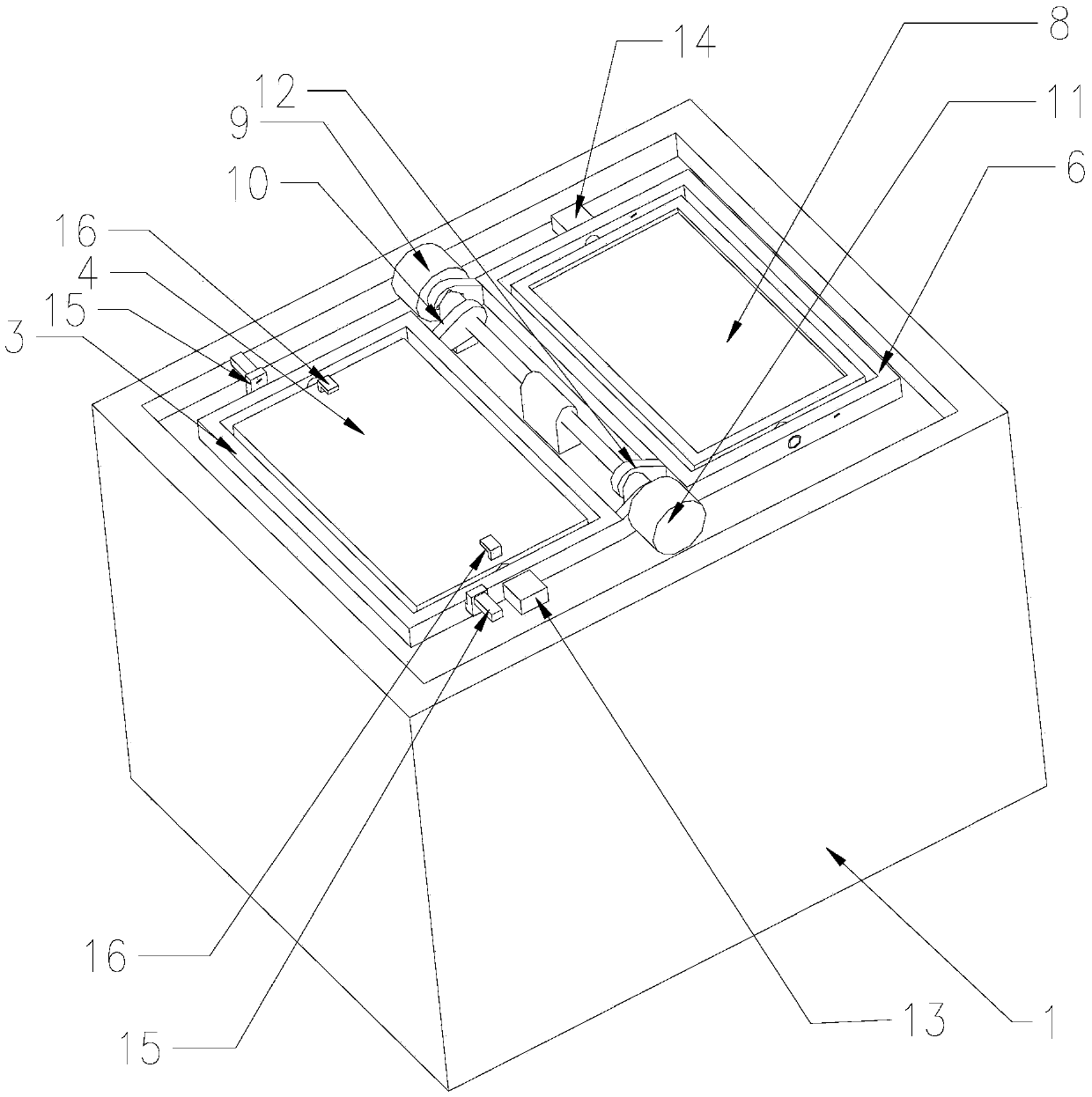

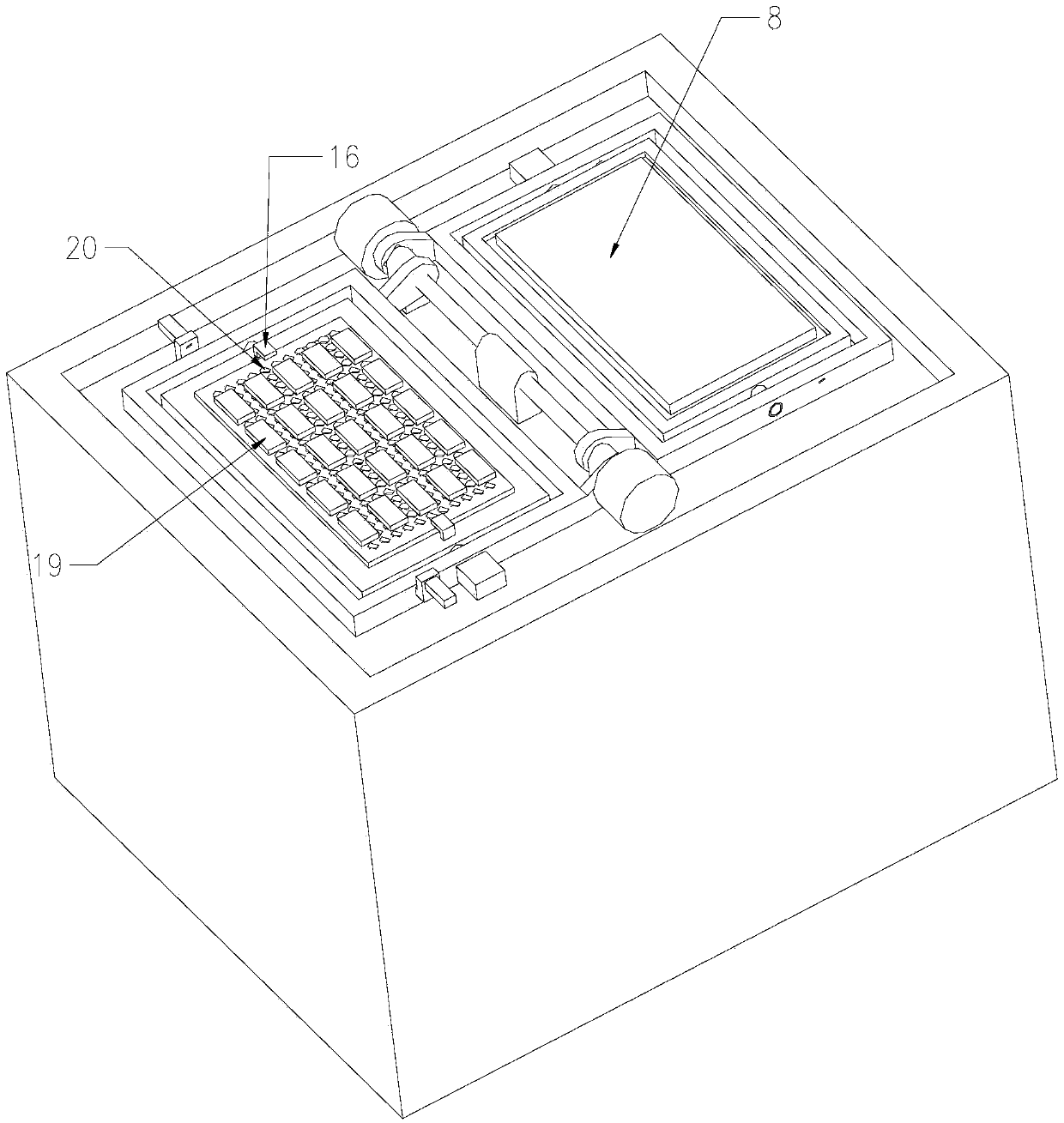

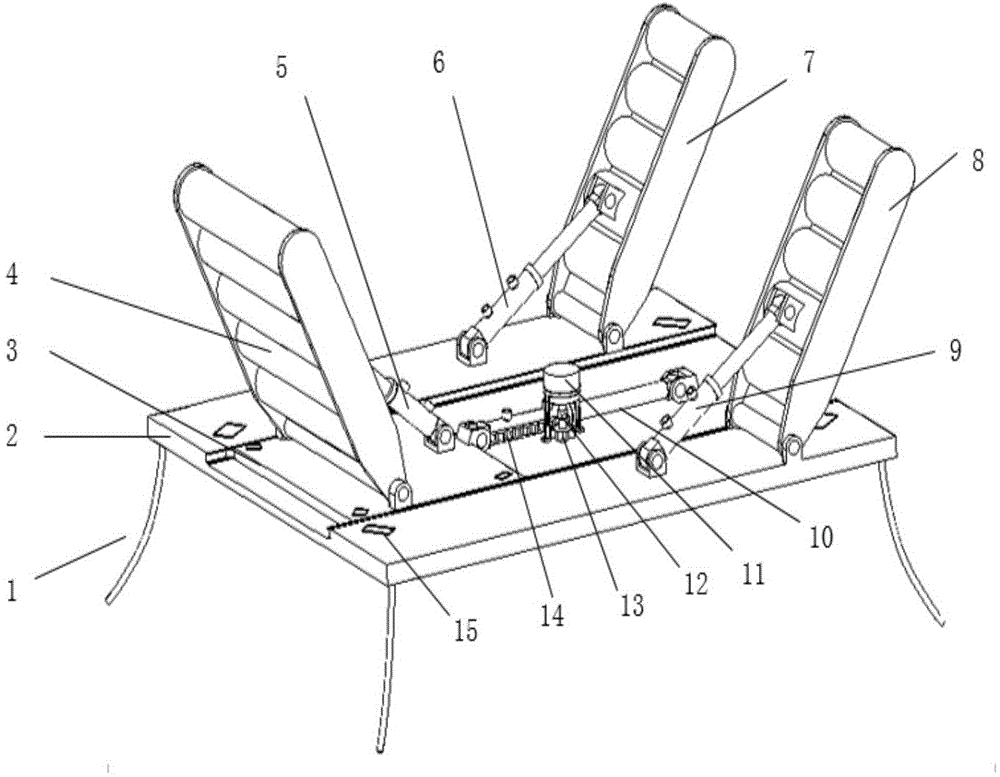

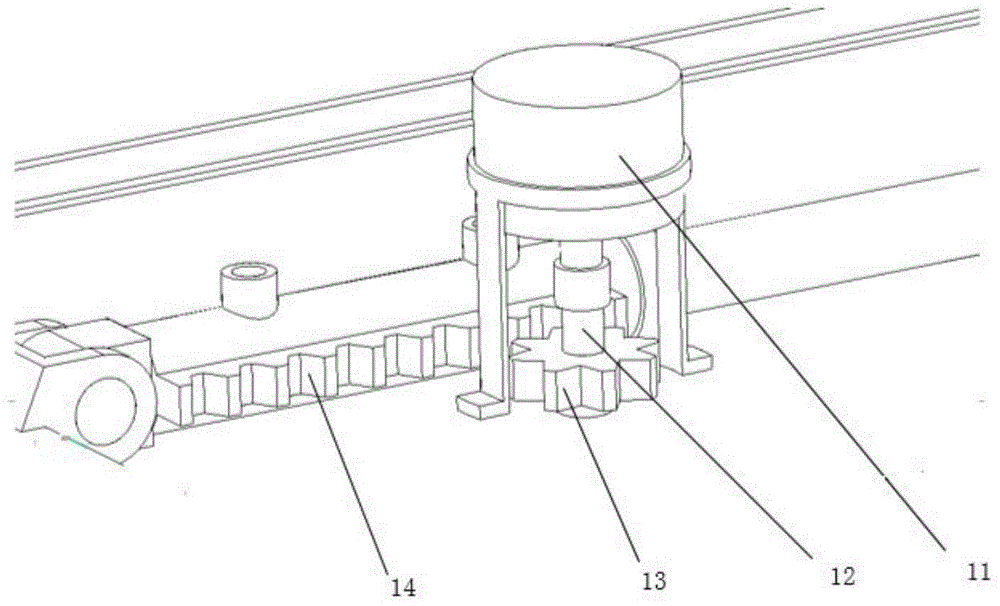

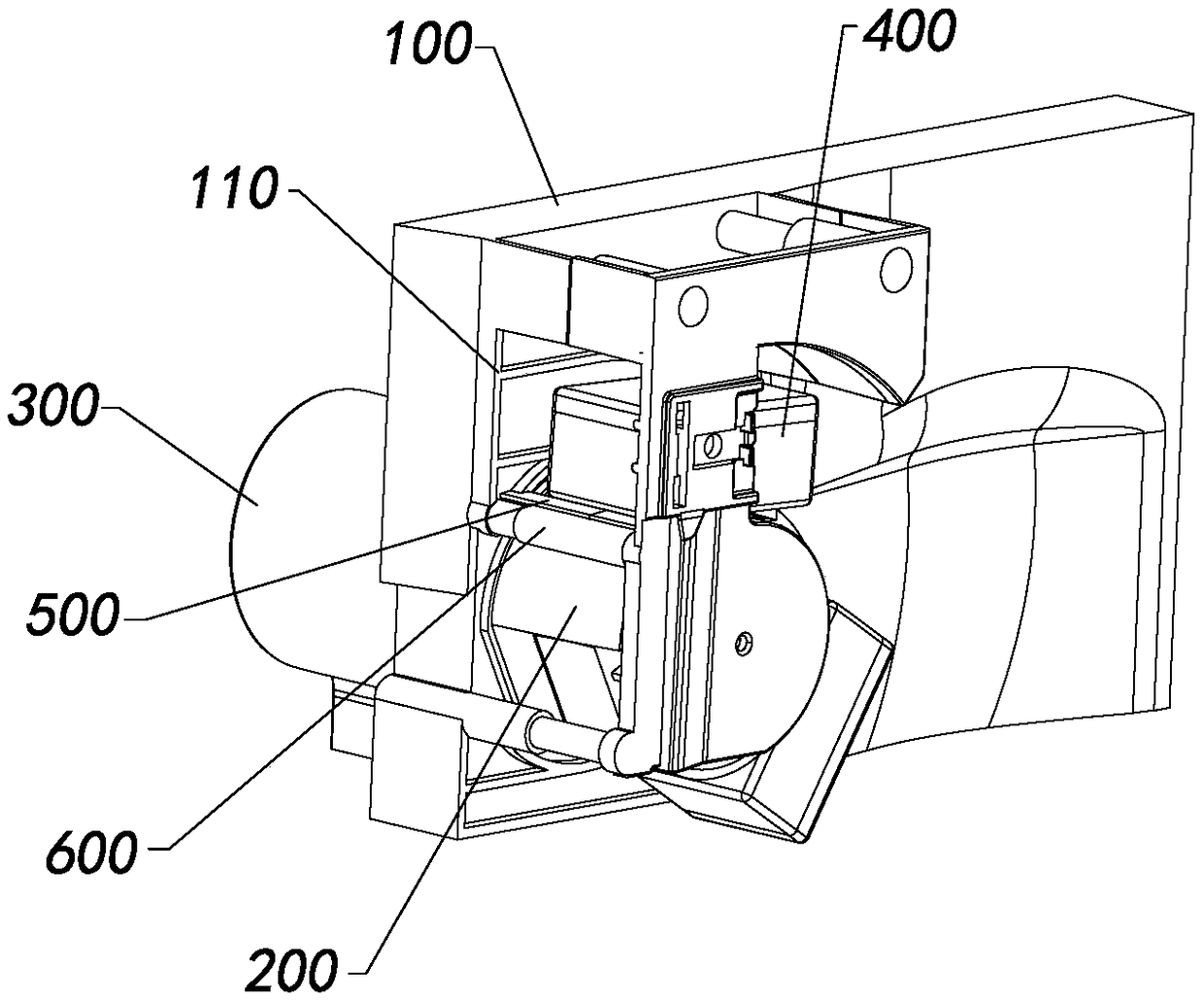

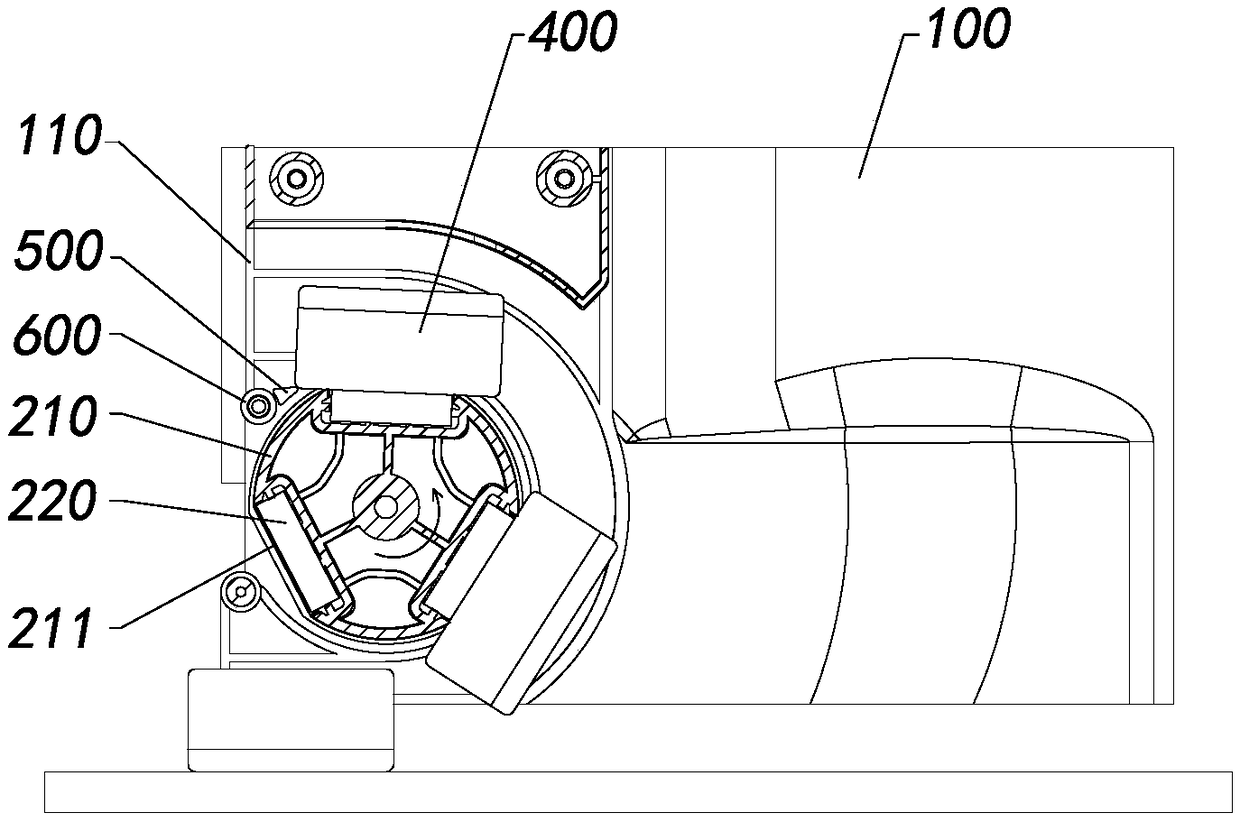

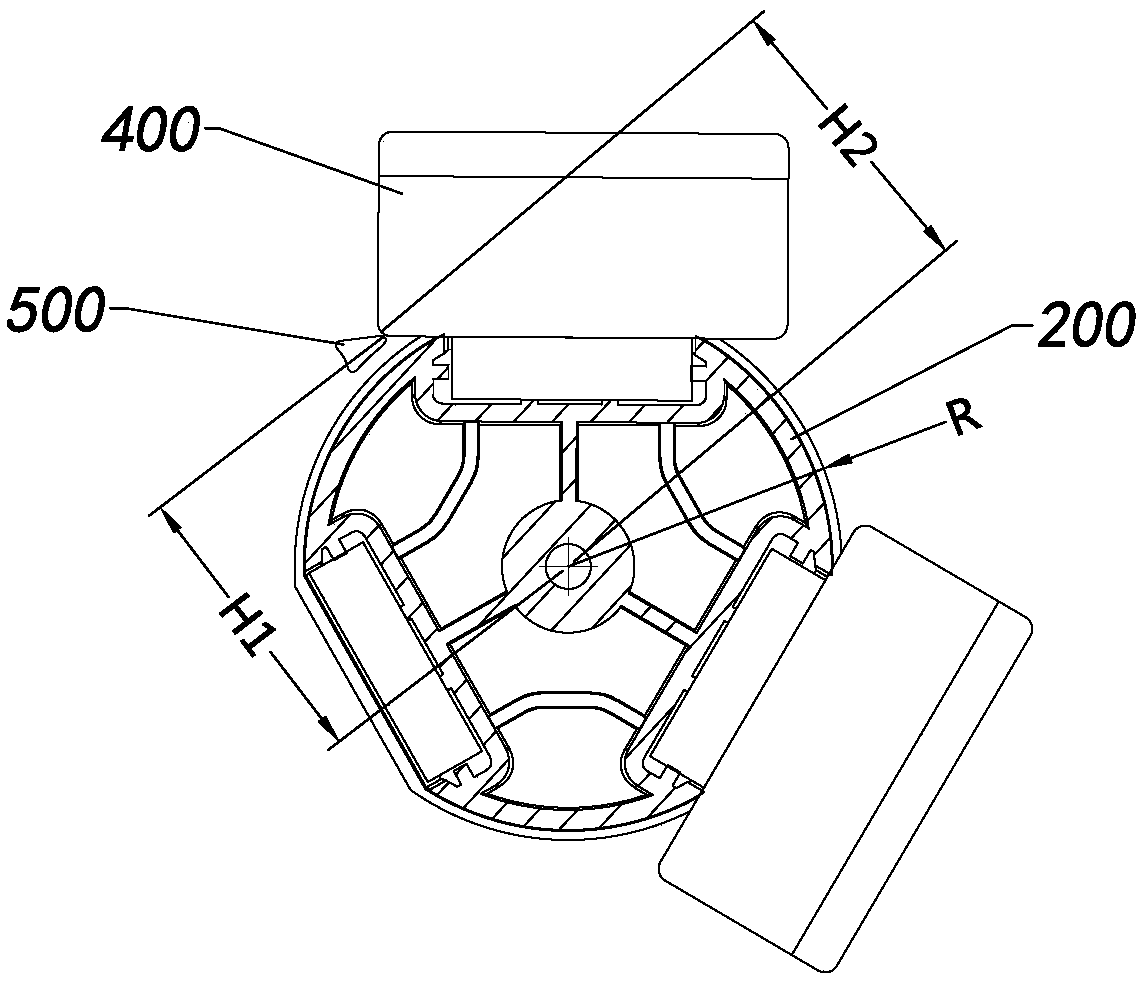

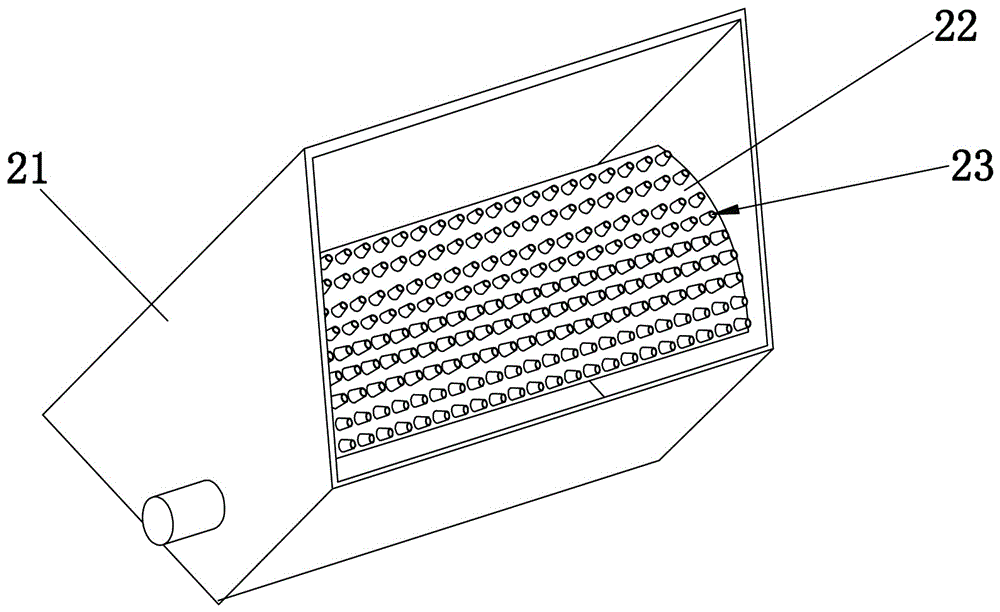

Tile conveying device for automatic mahjong machine and automatic mahjong machine

PendingCN108786098ASimple structureShorten the lengthIndoor gamesMechanical engineeringElectric machine

The invention discloses a tile conveying device for an automatic mahjong machine and the automatic mahjong machine, and belongs to the field of chess and card entertainment equipment. The defects thatexisting tile conveying devices are complicated in tile conveying mode and structure, high in cost and the like are overcome. The tile conveying device for the automatic mahjong machine comprises a tile conveying bracket, a tile sucking wheel and a tile blocking piece; the tile sucking wheel is installed on the tile conveying bracket and driven by a tile conveying motor to rotate, mahjong tiles are sucked to the tile sucking wheel and rotate along with the tile sucking wheel, the tile blocking piece is located on a rotation track of the mahjong tiles and used for blocking the mahjong tiles moving to the tile blocking piece so that the mahjong tiles moving to the tile blocking piece can be separated from the tile sucking wheel and conveyed out of the tile conveying bracket. By means of thetile conveying device, the existing tile conveying mode relying on a conveying belt is changed, the conveying belt and a tile discharging wheel are omitted, a tensioning mechanism of the conveying belt is also omitted, the length of the tile conveying bracket is shortened, the structure of the tile conveying device is greatly simplified, and the space occupied by the tile conveying device is reduced.

Owner:MATSUOTA MECHANICAL & ELECTRICAL CHINA CO LTD

Dispatching truck for bicycles

ActiveCN104827951AWon't collideWon't wear outVehicle with loading rampVehicle carriersTruckElectrical and Electronics engineering

Owner:王文明

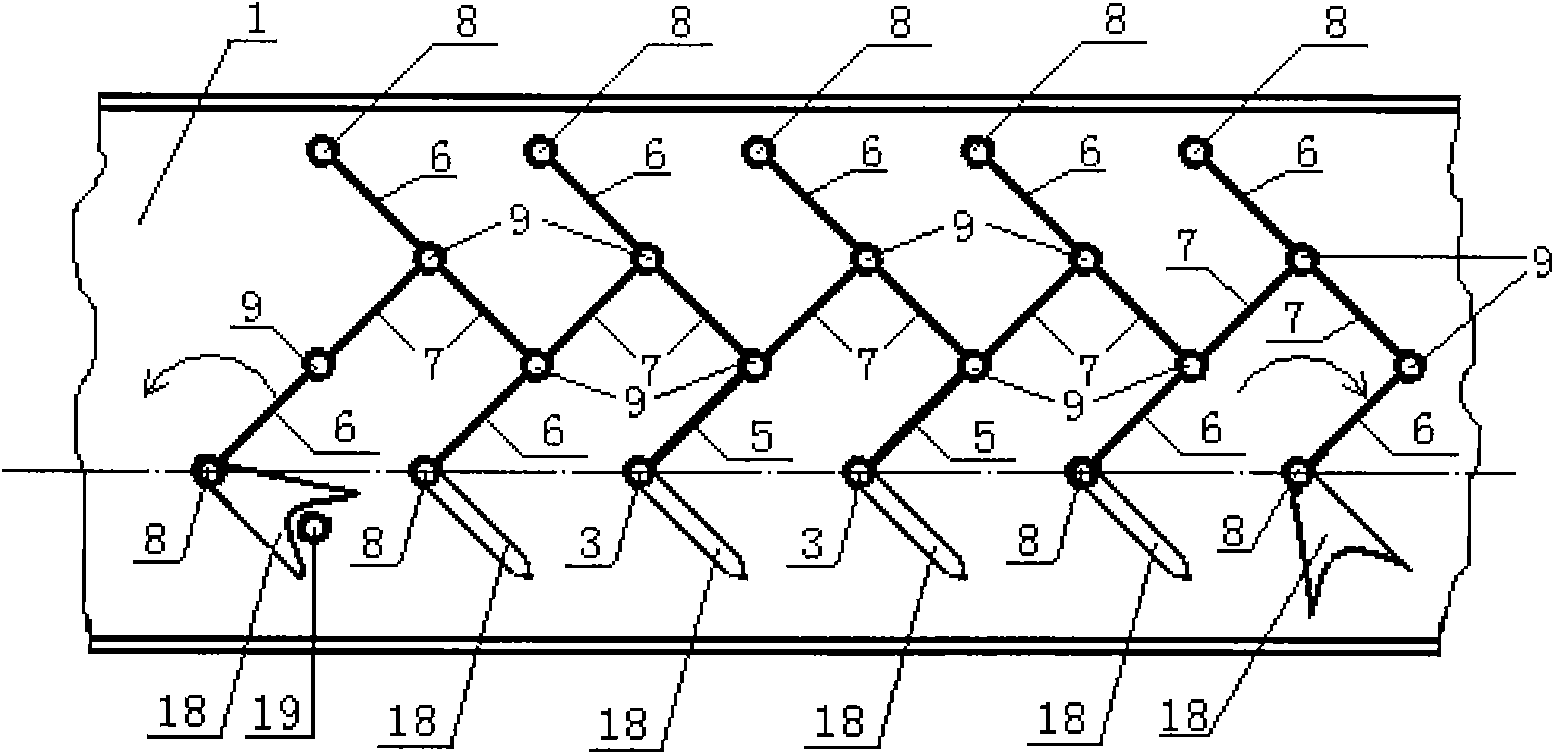

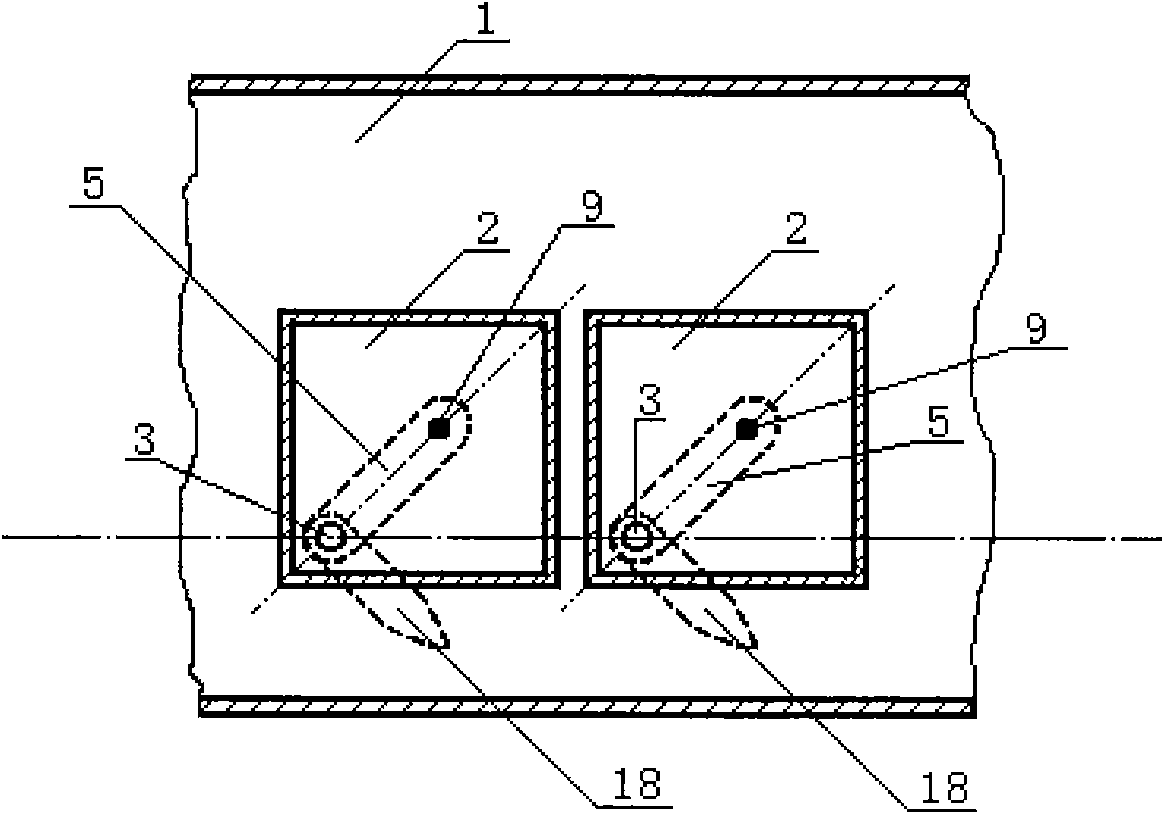

Successive movable type multi-flip billboard

The invention discloses a successive movable type multi-flip billboard, comprising a plurality of side-by-side regular square prisms (2), a frame (1) and an operation control driving device; wherein the regular square prisms moves in succession every time to overturn a picture. The device comprises a hinge link mechanism which is provided with a plurality of rockers (6) along the regular square prisms (2) and connecting rods (7) connecting the regular square prisms (2) with the rockers (6) in series by a hinge (9), the other end of each rocker (6) is connected with the frame (1) by a hinge (8), the rockers (6) and the connecting rods (7) at least comprises one rocker (6) connected with at least two connecting rods (7) in series between each two adjacent regular square prisms (2) connected in series, and the position of the regular square prism (2) moving into position previously can be locked by the regular square prism (2) which moves into position subsequently and the rocker (6). Thus, the regular square prisms (2) can not collide owning to out of control of positional accuracy.

Owner:刘小连

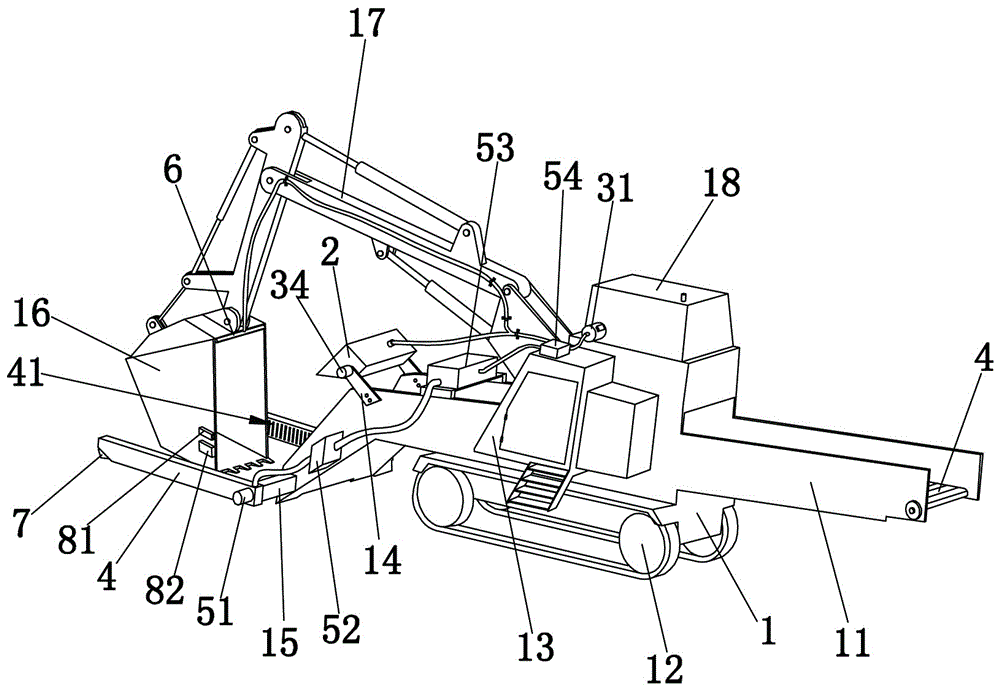

Garbage excavation all-in-one machine

ActiveCN106013306AQuick and effective removalAvoid harmSoil-shifting machines/dredgersTherapeutic effectEngineering

The invention discloses a garbage excavation all-in-one machine, and relates to the field of garbage treatment. The garbage excavation all-in-one machine comprises a machine body. The machine body is provided with a bucket, a conveying trough, a driving cabin and a traveling mechanism, and the conveying trough is provided with a conveying belt. The garbage excavation all-in-one machine further comprises a dust precipitating system and an air purification system. The dust precipitating system comprises a water tank, an atomizer and a sprayer which communicate in sequence through pipes. The air purification system comprises air intake pipelines, an exhaust fan and an air purification box which communicate in sequence through hoses. The garbage excavation all-in-one machine has the beneficial effects that the air purification system and the dust precipitating system can rapidly and effectively remove dust generated during excavation of garbage and purify the air, thereby avoiding injury to workers and pollution to the environment; the sprayer is arranged above the feeding end of the conveying trough; two air intake pipelines are located on the left side and the right side of the bucket correspondingly; and the sprayer and the air intake pipelines are both very close to the excavation point, so that dust and harmful gas are removed immediately when not dispersing yet. The garbage excavation all-in-one machine has the advantage of good treatment effect.

Owner:DATIAN WEST ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com