Automatic turnover device of magnetic steel product and turnover method thereof

A product, the technology of magnetic steel, applied in the field of automatic turning device of magnetic steel products, can solve the problems of low efficiency of surface treatment process, low operation efficiency, harsh environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

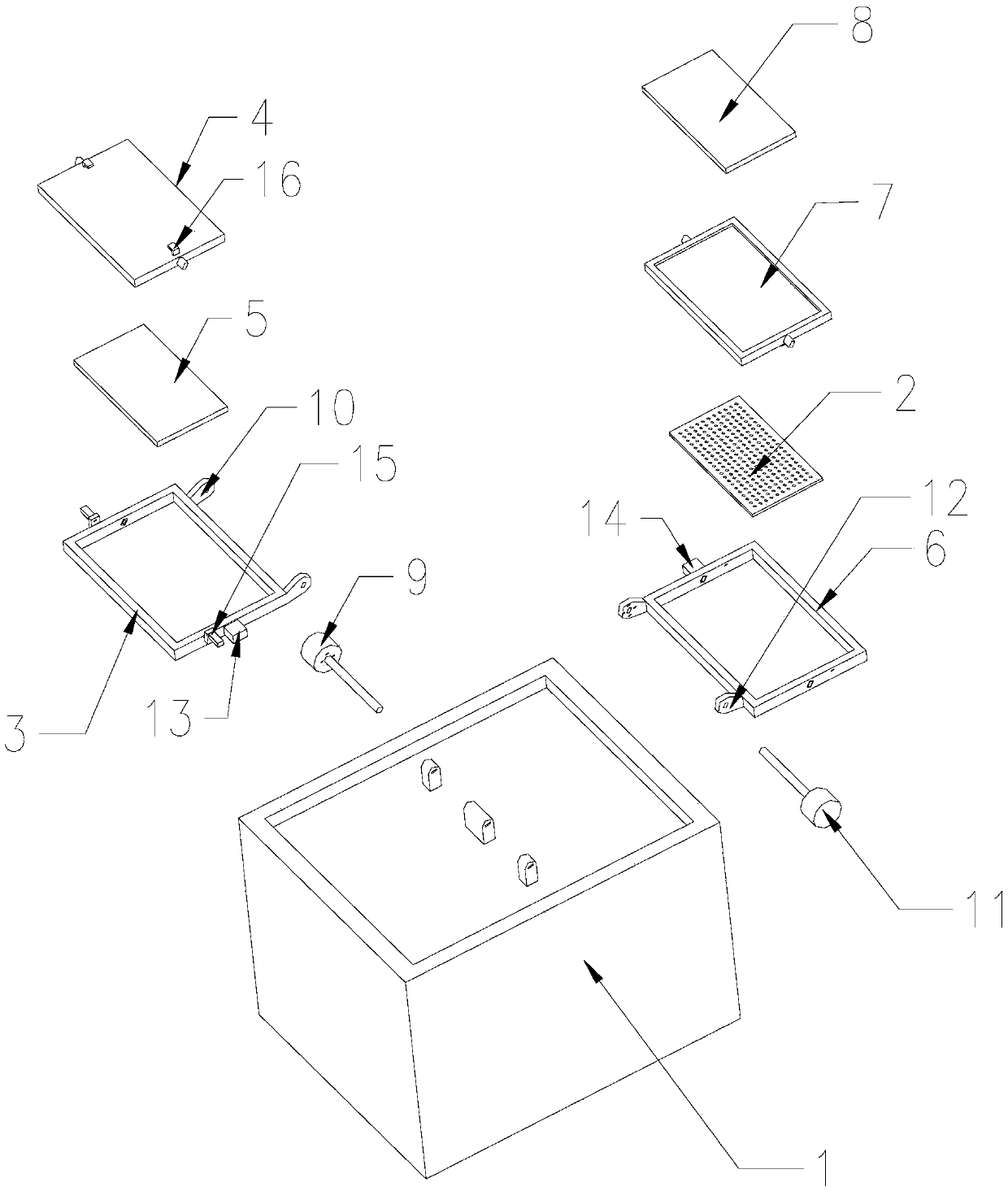

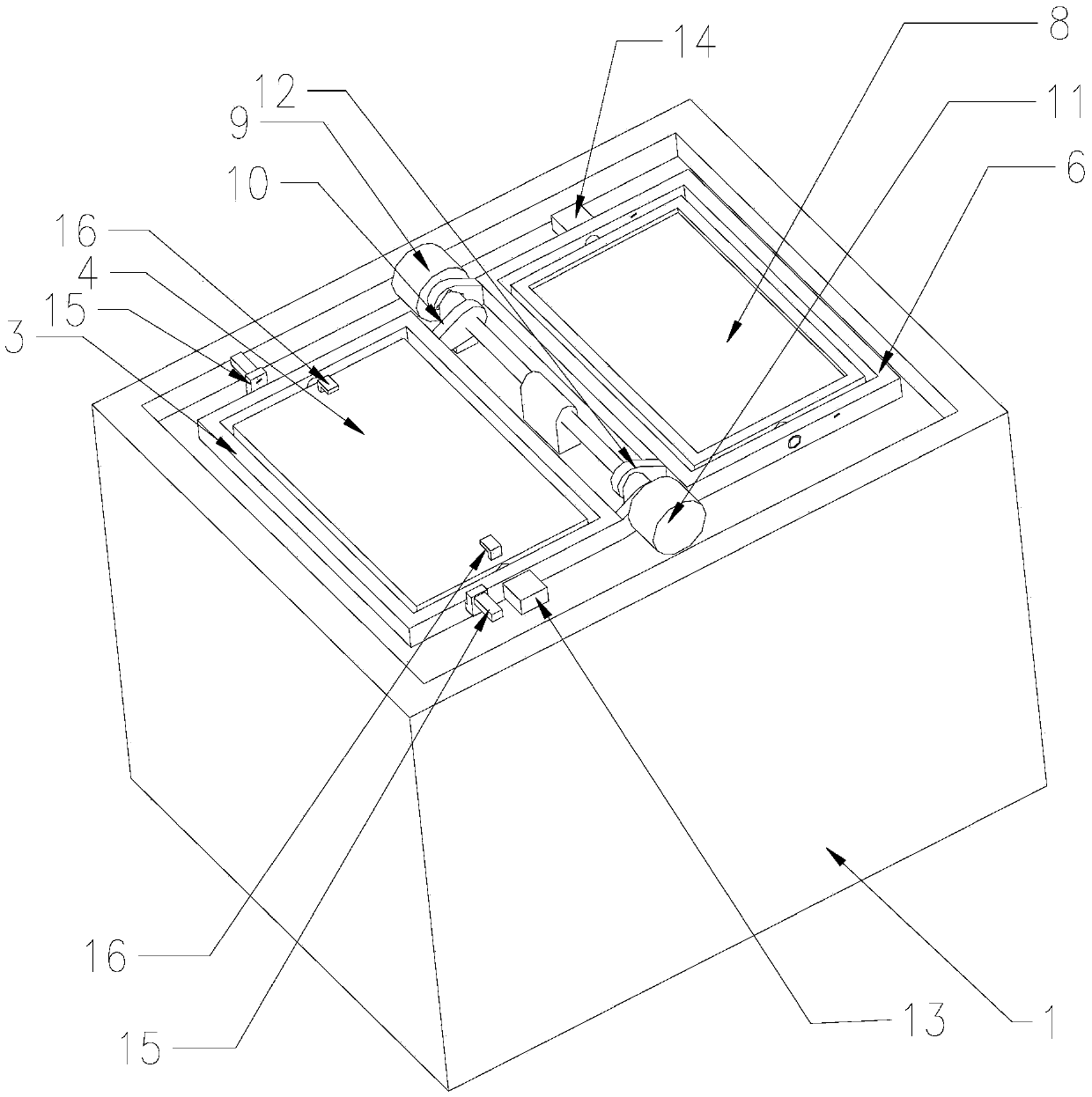

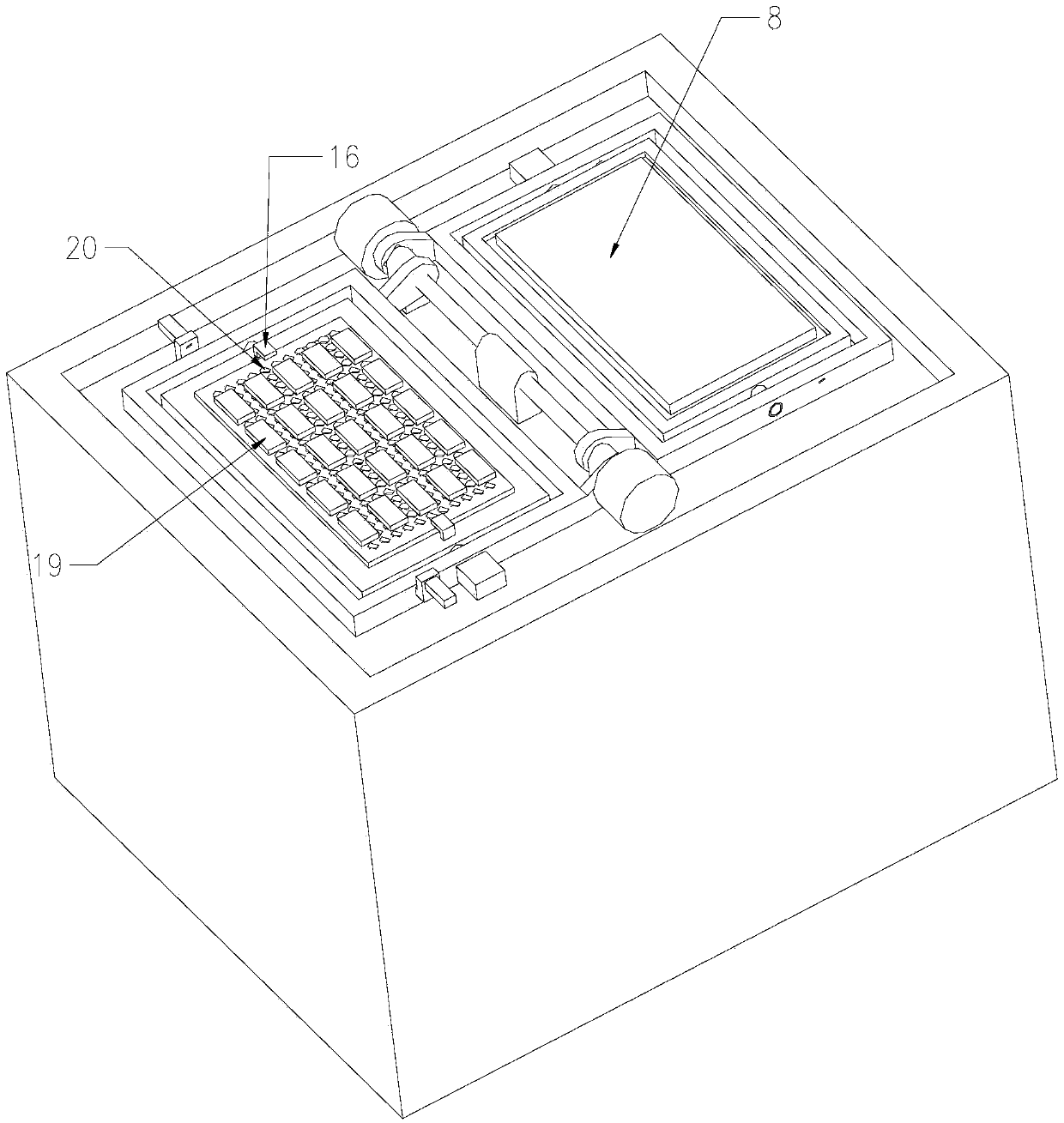

[0045] Example: such as figure 1 and figure 2 Shown, a kind of magnetic steel product automatic flipping device, comprises frame 1, the first turning mechanism, the second turning mechanism, the first rotating mechanism that is used to drive the first turning mechanism to turn over, is used to drive the second turning mechanism. The second rotating mechanism, the third rotating mechanism, the fourth rotating mechanism, the flipping screen 2 and the flipping locking mechanism turned over by the flipping mechanism;

[0046] The first turnover mechanism comprises a first frame 3, a first base plate 4 and a first sponge plate 5; the first base plate 4 is located in the first frame 3, the first sponge plate 5 is attached to the lower surface of the first base plate 4, and the third The rotation mechanism is installed on the first frame 3 and is connected with the first substrate 4, and the third rotation mechanism is used to drive the first substrate 4 to rotate in the first fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com